Used TEL / TOKYO ELECTRON Formula-1S-H #293654963 for sale

URL successfully copied!

Tap to zoom

ID: 293654963

Vintage: 2005

Diffusion furnace

Control system

Heater temperature: 600°C-900°C

Load port

FIMS

Wafer transfer

Boat elevator / Seal cap rotation

Auto shutter

Heater model

N2 Load lock

Boat operation

Process: LPCVD

Si SEMI STD-Notch, 12"

Furnace temperature controller: M780

HTR

Power box

Carrier transfer

Mechanical driver

Exhaust box

Front and rear upper cover

Final valve box

Gas flow chart

O2 Analyzer

Hard Disk Drive (HDD)

Does not include HCT

User interface:

MMI and gas flowchart: Gas box and front operation panel installed

Pressure display Unit: Mpa / Torr

Carrier type: FOUP / 25slots SEMI STD

Fork meterial: Al203 and PEEK

W/T Type: 1+4 Edge grip

16-Carrier stage capacity

Wafer notch aligner

RCU

UPS

Power distribution system:

3-Phase connection type: Star connection

Single-Phase connection: Grounded

Single-Phase voltage

Gas distribution system:

FUJIKIN Integrated Gas System (IGS)

IGS Final filter, regulator: MFC Z500 Type

MKS Capacitance manometer vacuum gage - press monitor (133 Kpa)

Power supply: 400 VAC, 3 Phase, 50/60 Hz

2005 vintage.

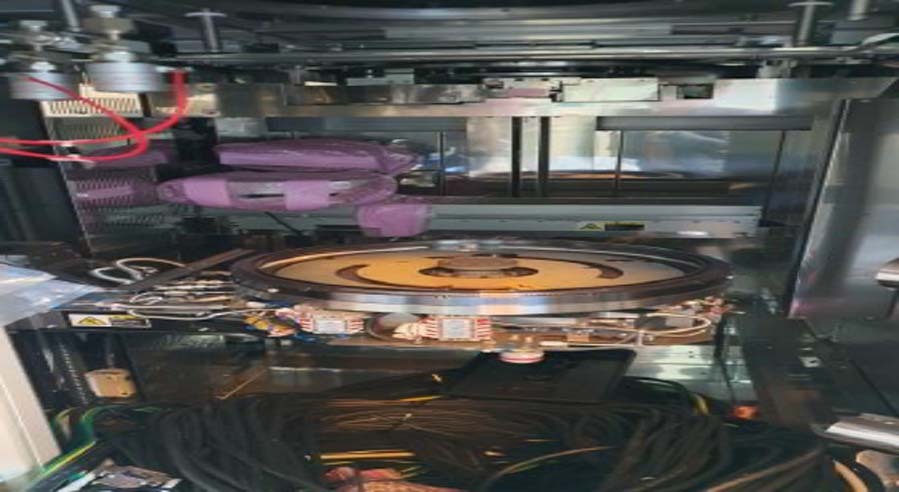

TEL / TOKYO ELECTRON Formula-1S-H is an etcher/asher designed for applications where a quick, precise and fine etching process is required. The equipment uses a combination of a plasma source, etching gas, controlled power and high frequency (RF) electric power to create a perfect etch profile. The etching process starts by ensuring a clean and exactly planar substrate. This is done to ensure that the etching process yields uniform etching results in the substrate. Next, the etching gas is injected into the system chamber, which is separated from the substrate by an independent RF antenna section. The unit then applies RF energy to the chamber, creating a plasma consisting of charged particles and reactive species that interact with the substrate. The rate of etching is then controlled by a combination of parameters such as the etching area, the flow rate of the etching gas and the power intensity. TEL Formula-1S-H is equipped with a precision etch chamber that is suitable for etching high aspect ratio (HAR) structures while also guaranteeing a low vertical erosion profile. This makes it possible to define even the most complicated three-dimensional structures with a high level of accuracy. In addition, the machine has a variety of user-friendly features, such as automatic wafer recognition, an on-board chemical management tool, condensed chemistry maintenance and an assisted procedure guide. TOKYO ELECTRON Formula-1S-H has a high throughput rate, allowing it to produce high-quality etch results in a relatively short process time. The asset is also designed to be reliable since it has been designed to withstand high-power RF fields and extreme temperatures. All of these features make it an ideal choice for etching applications that require quick and precision etchings.

There are no reviews yet