Used TEL / TOKYO ELECTRON Indy-A-L #293622226 for sale

URL successfully copied!

Tap to zoom

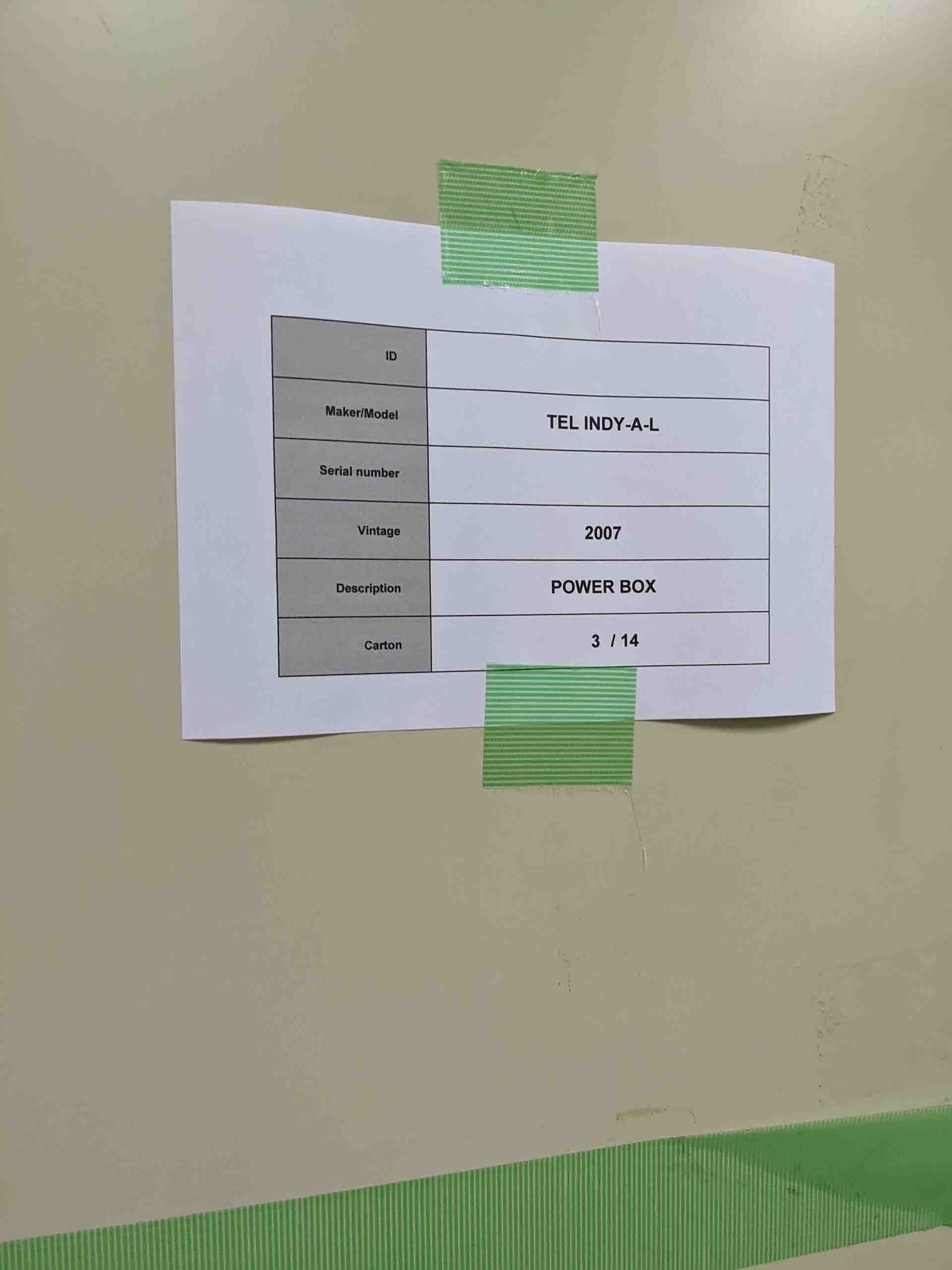

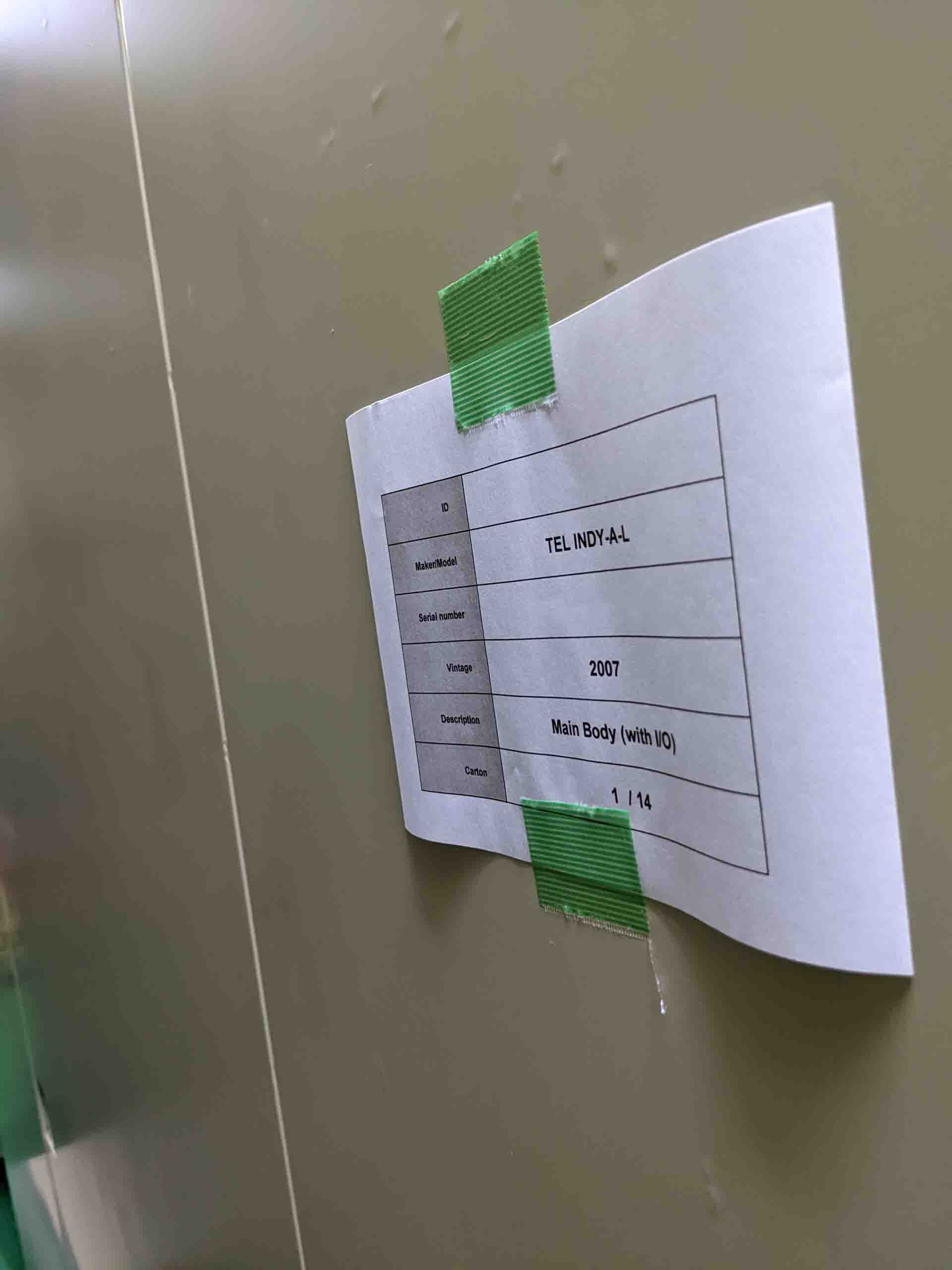

ID: 293622226

Vintage: 2007

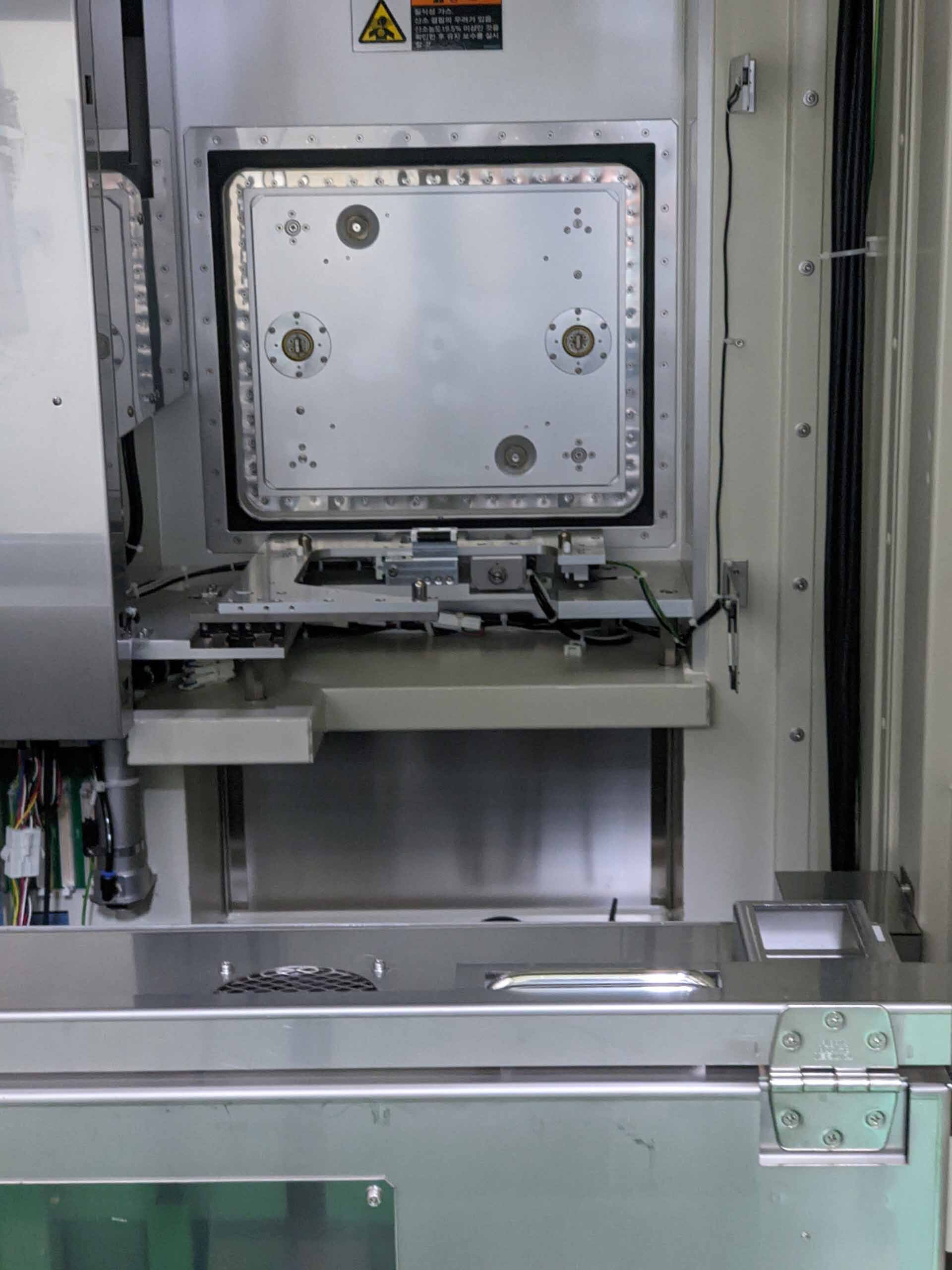

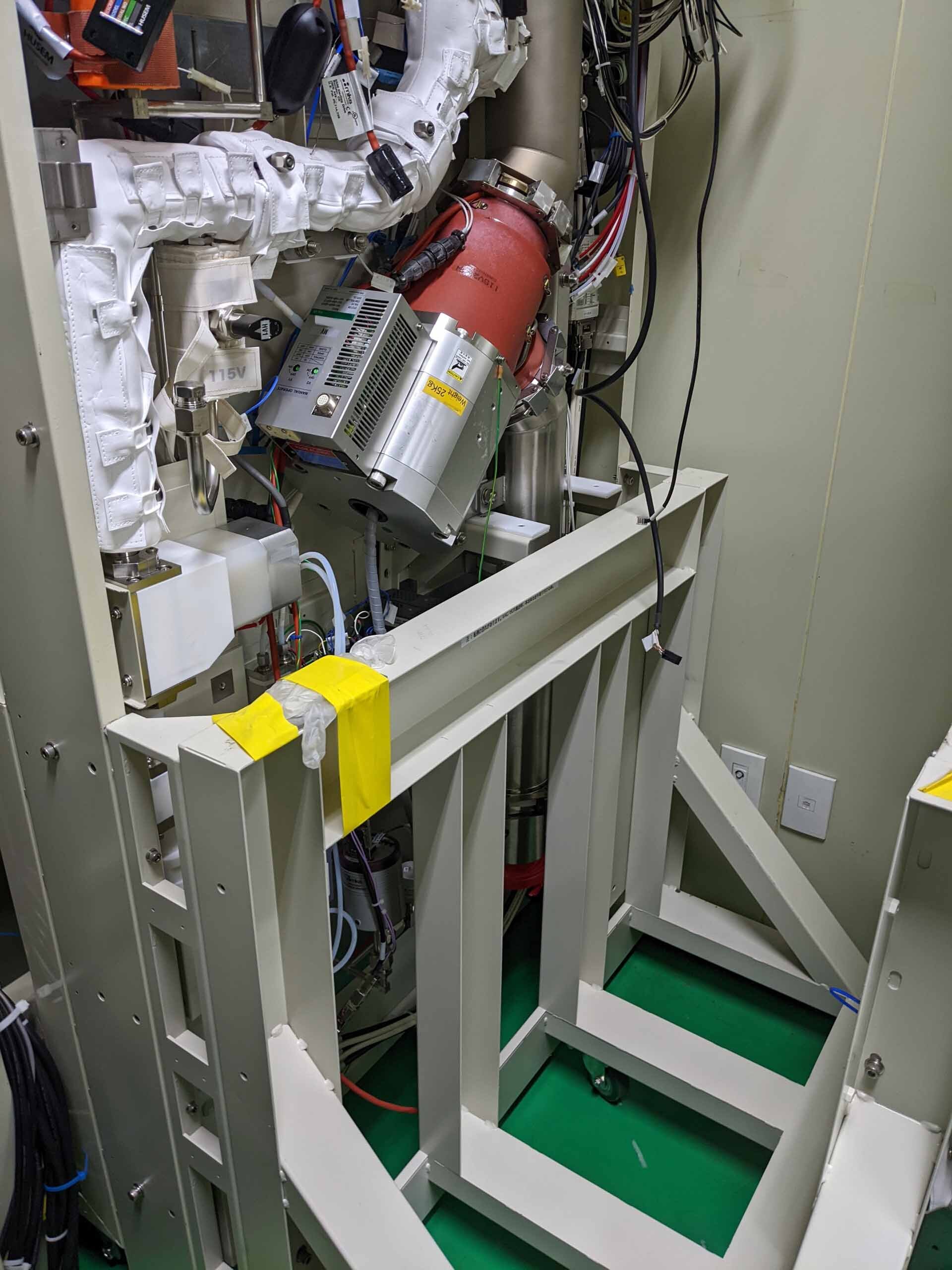

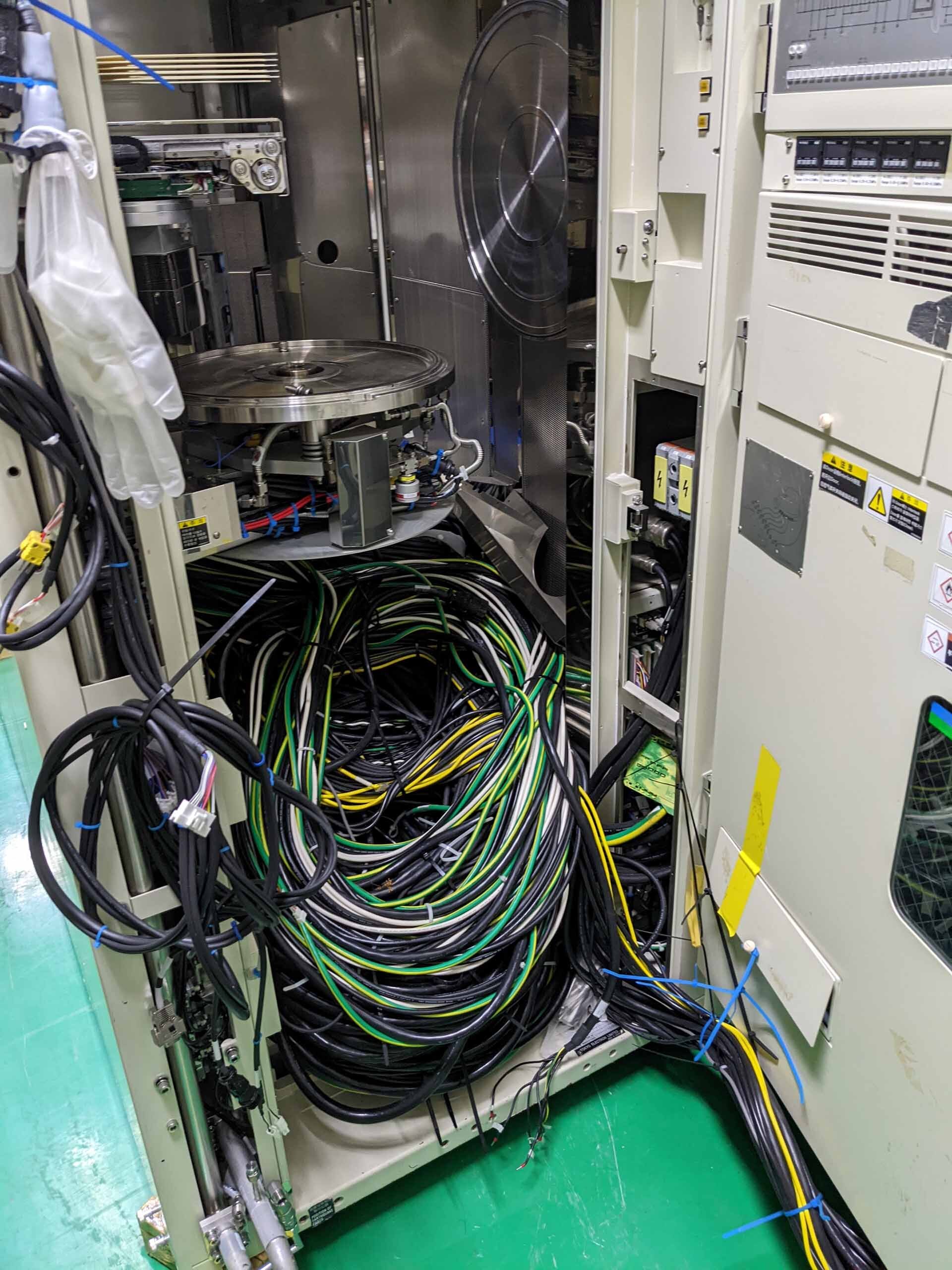

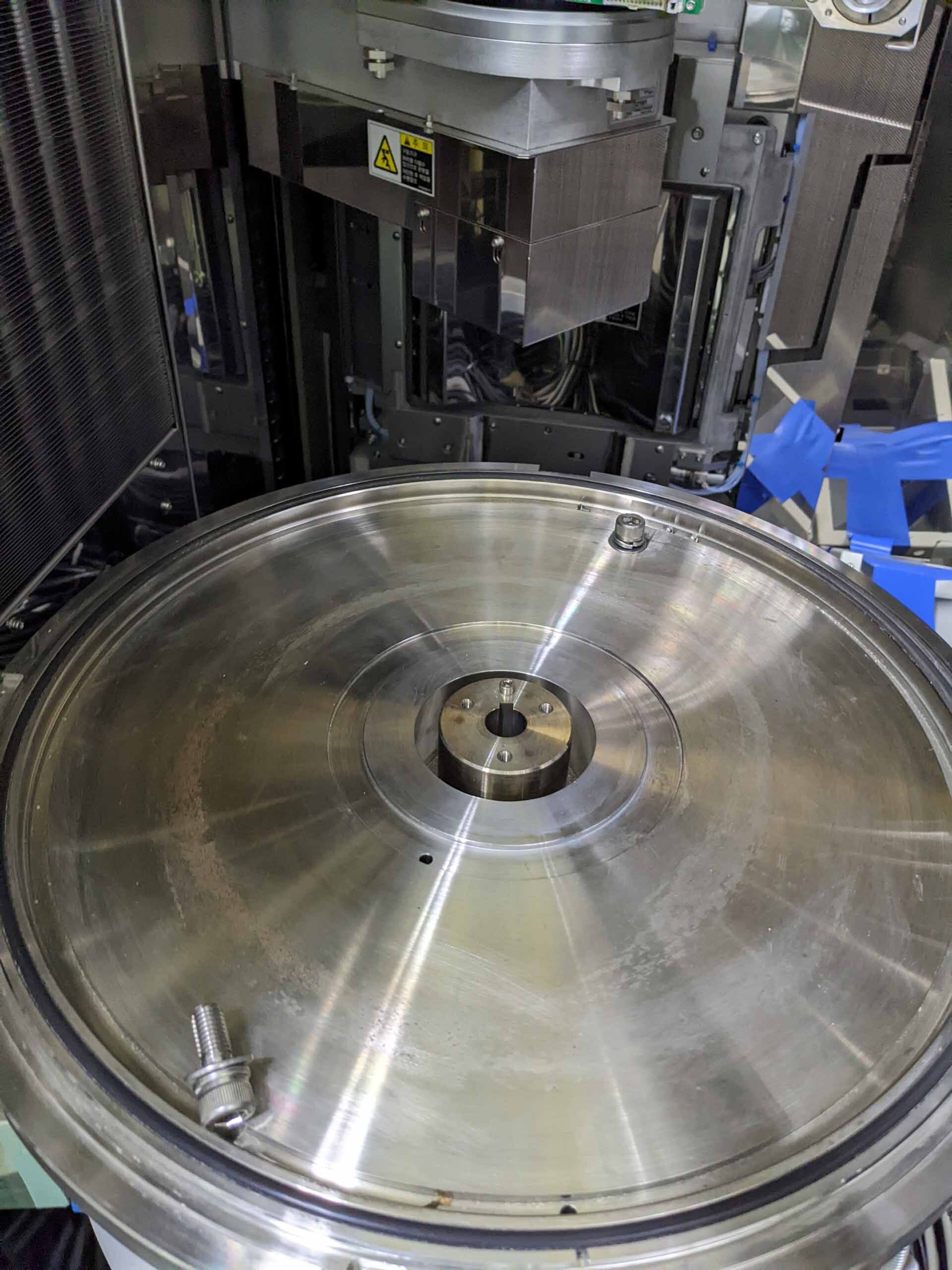

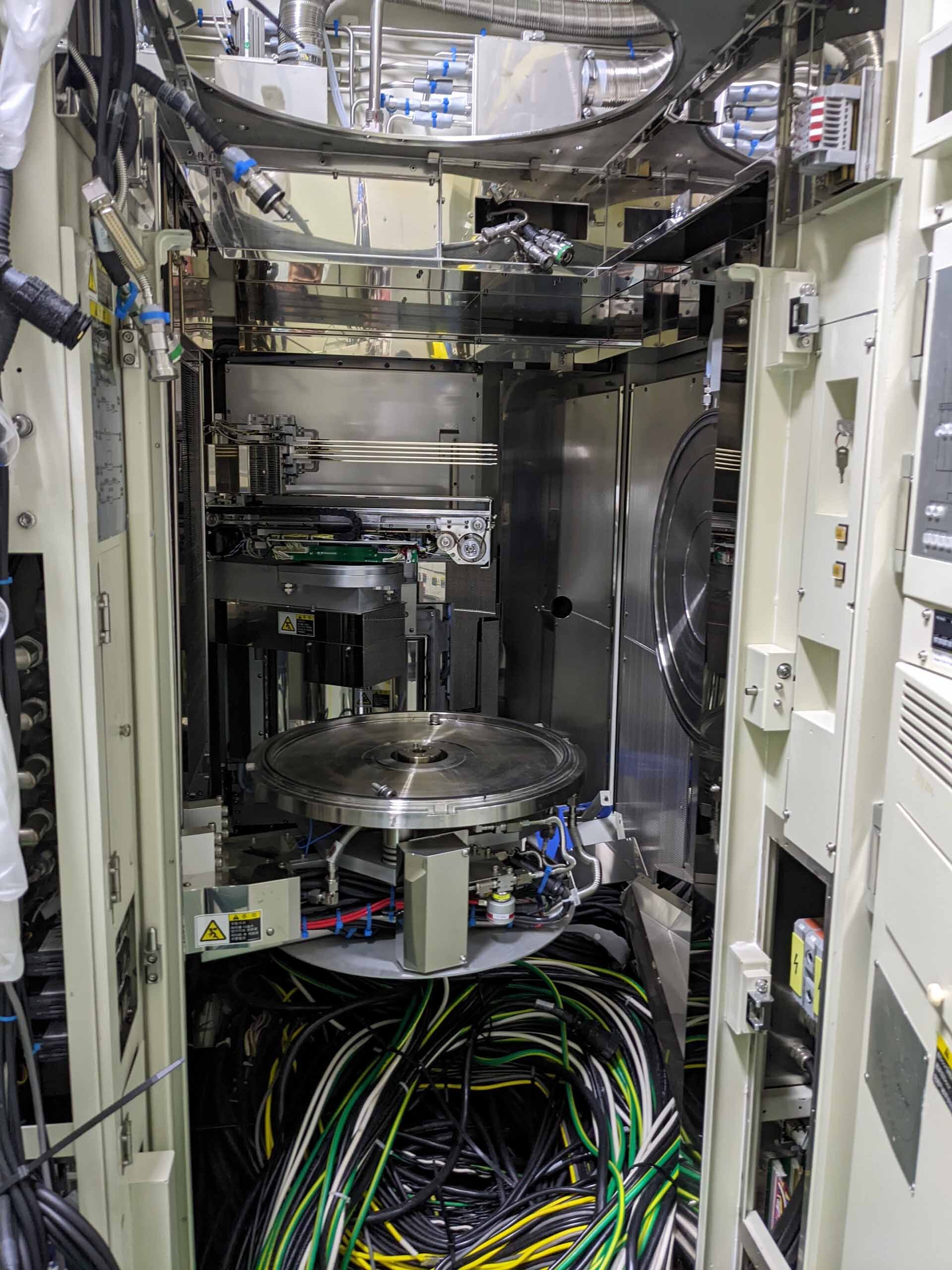

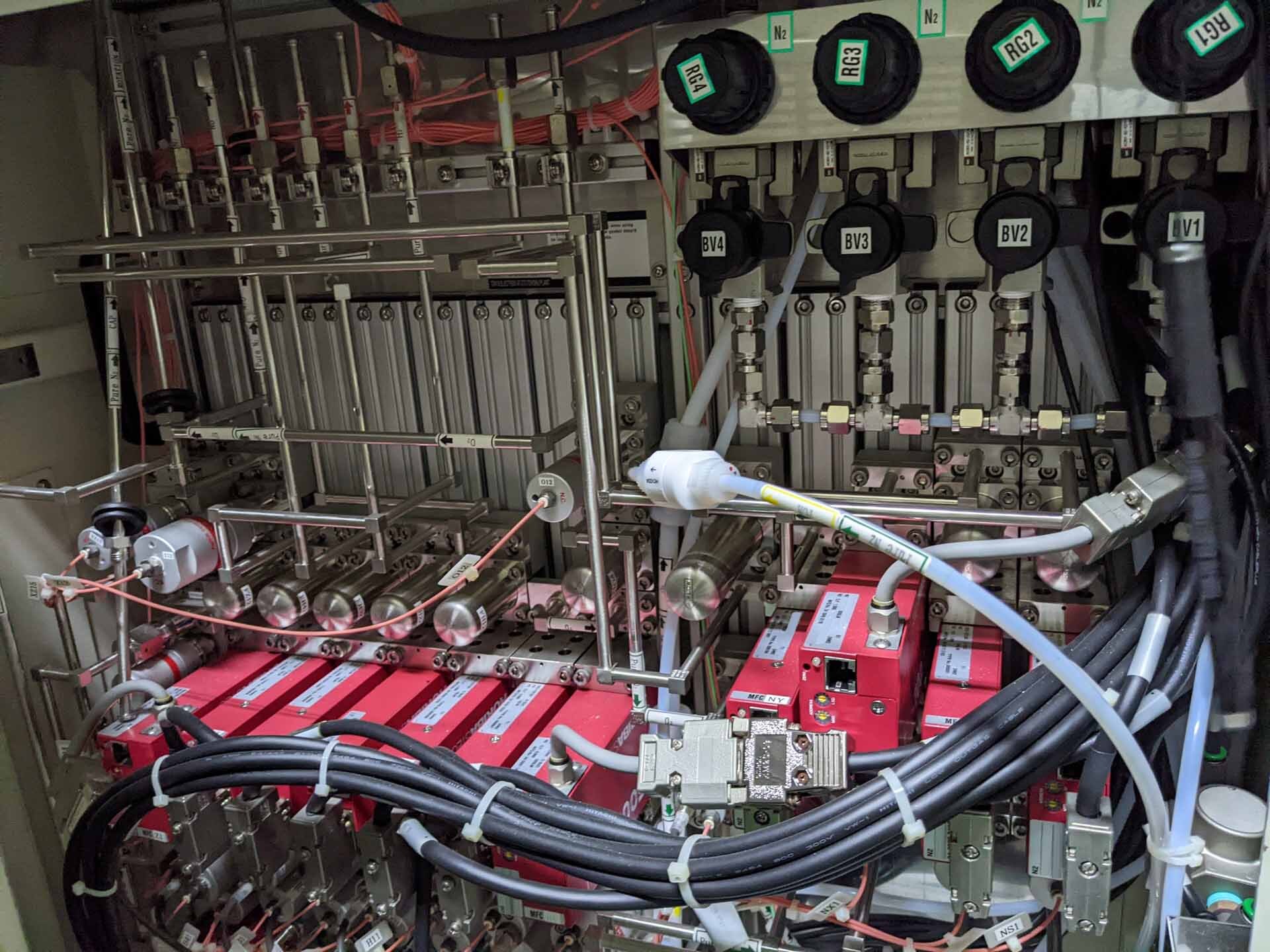

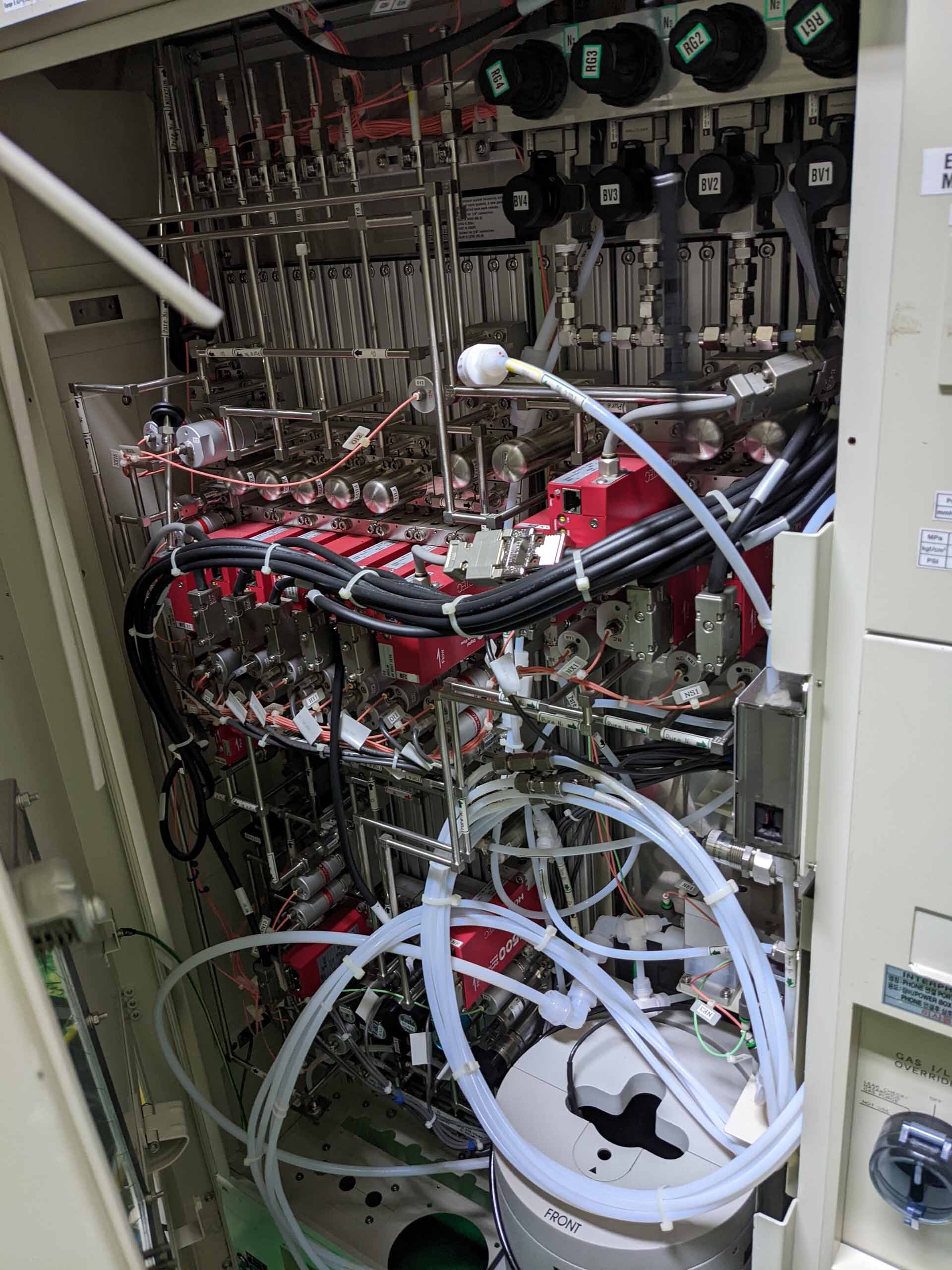

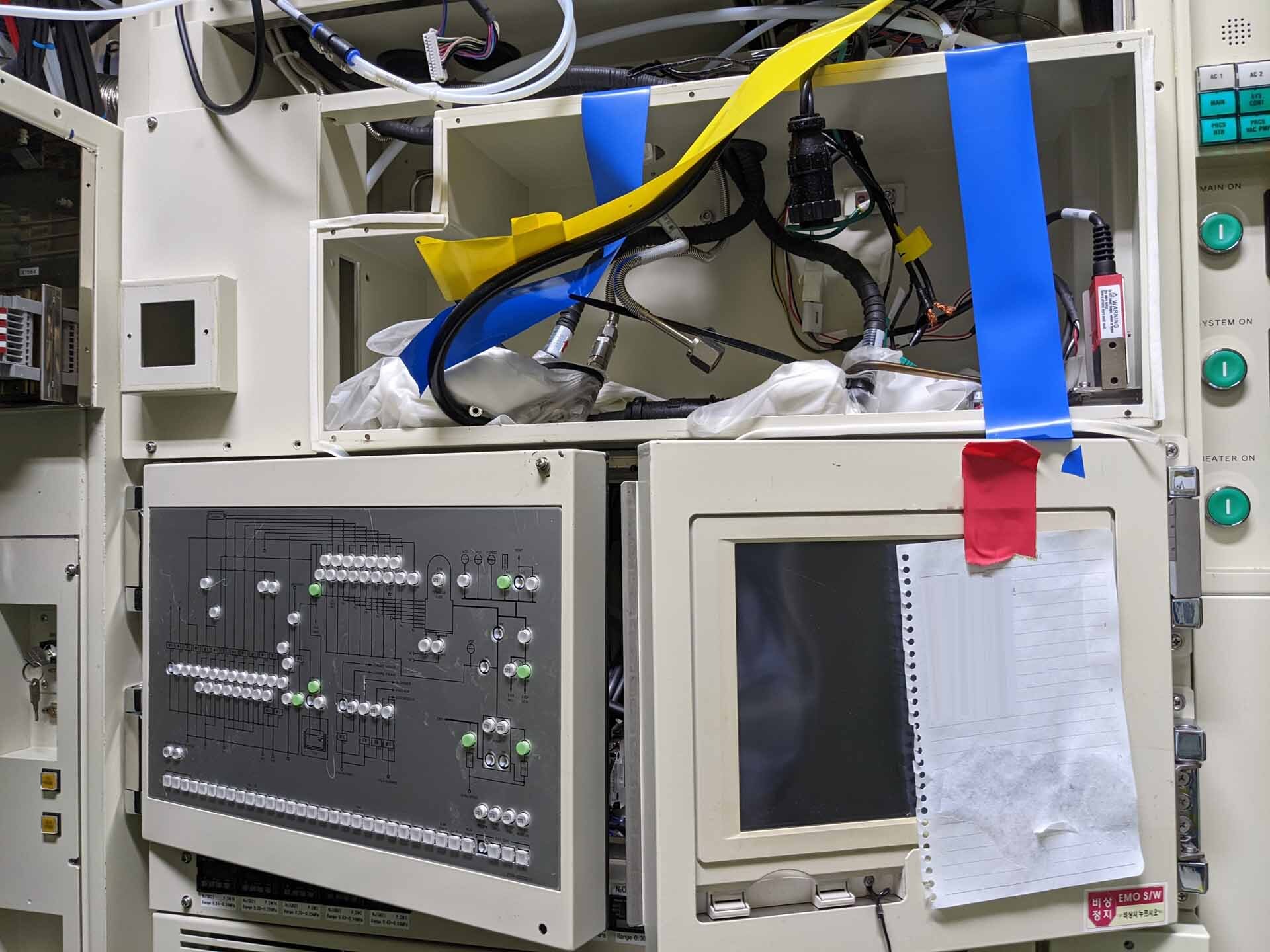

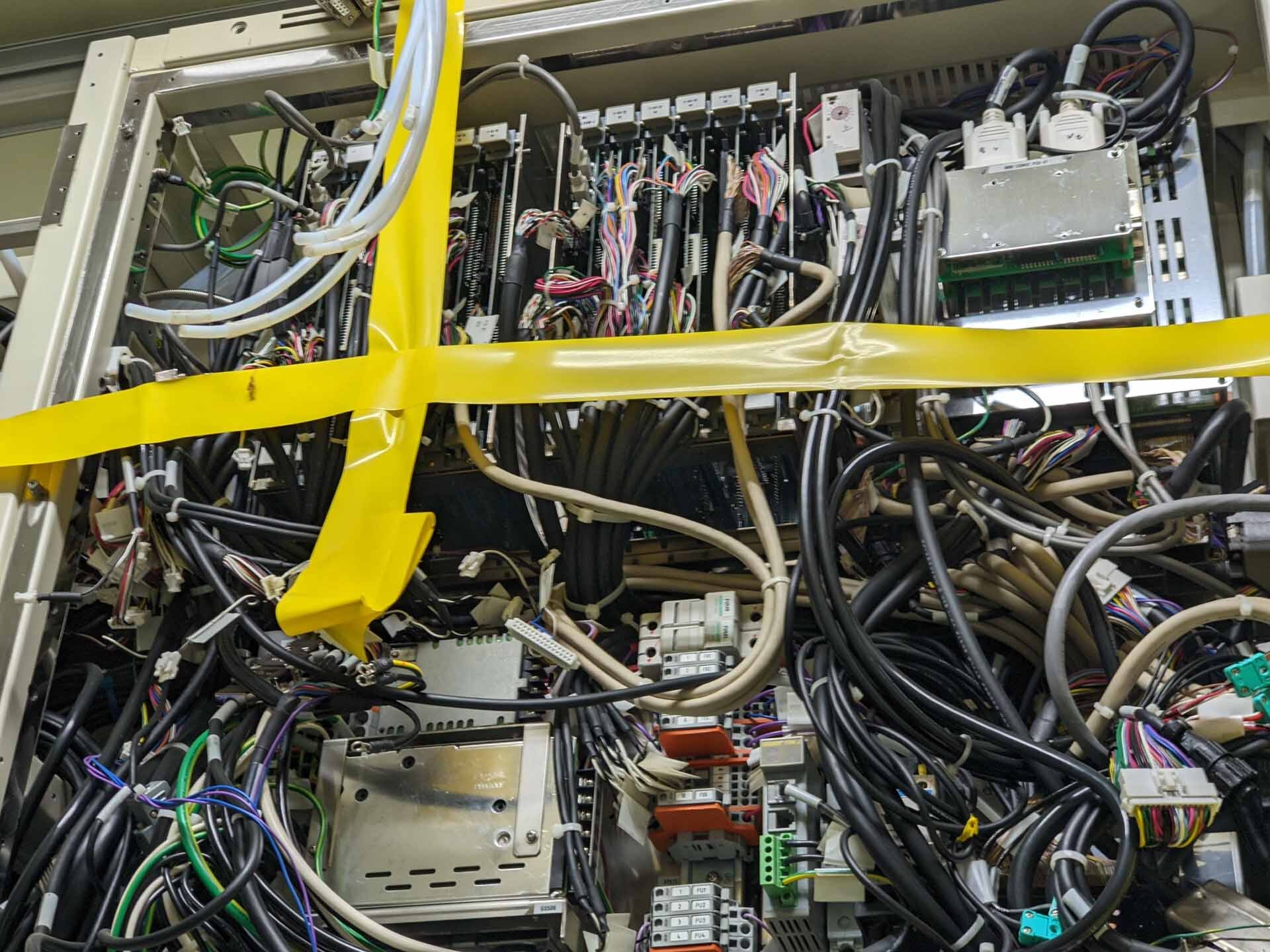

Vertical furnace

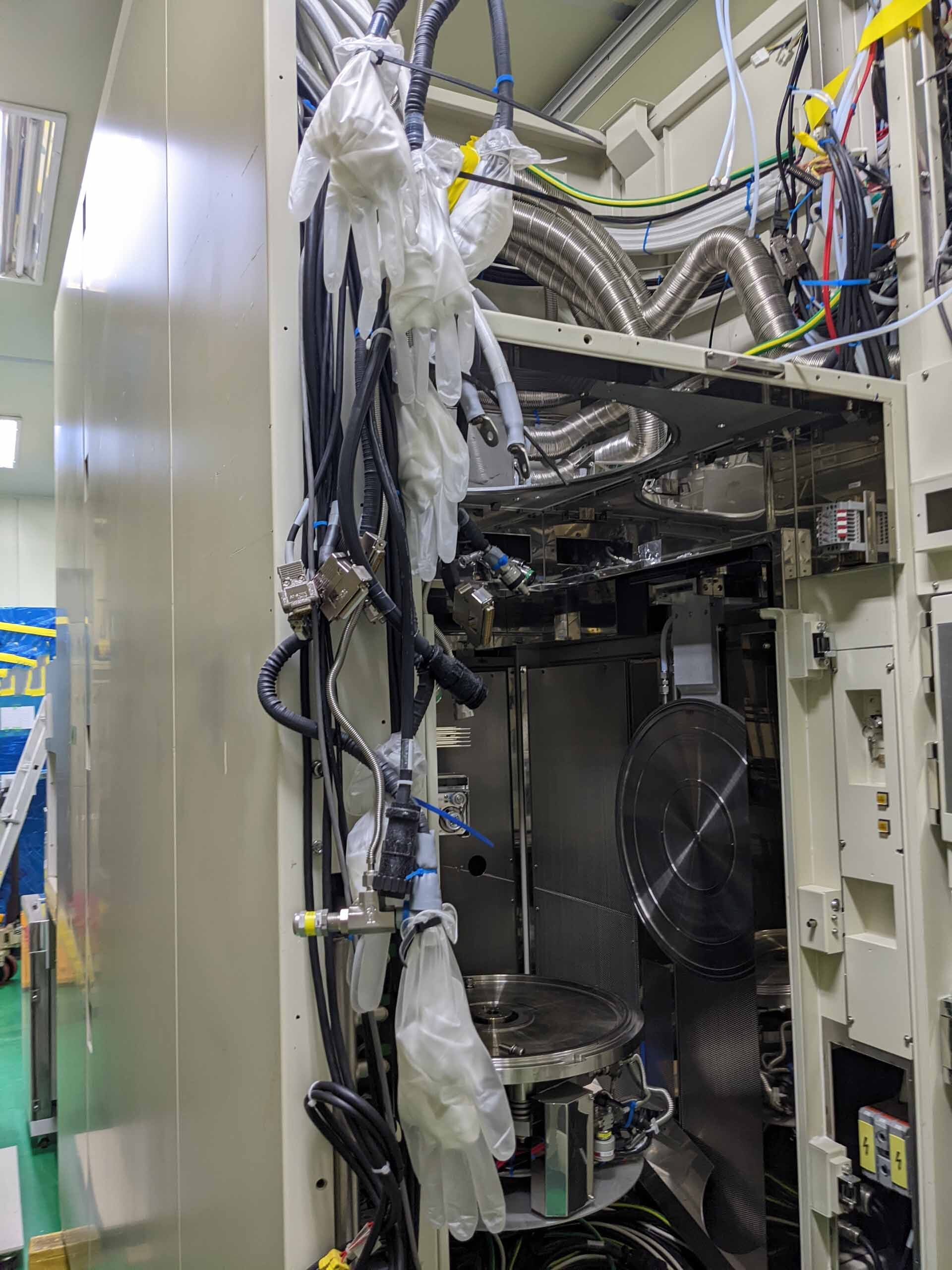

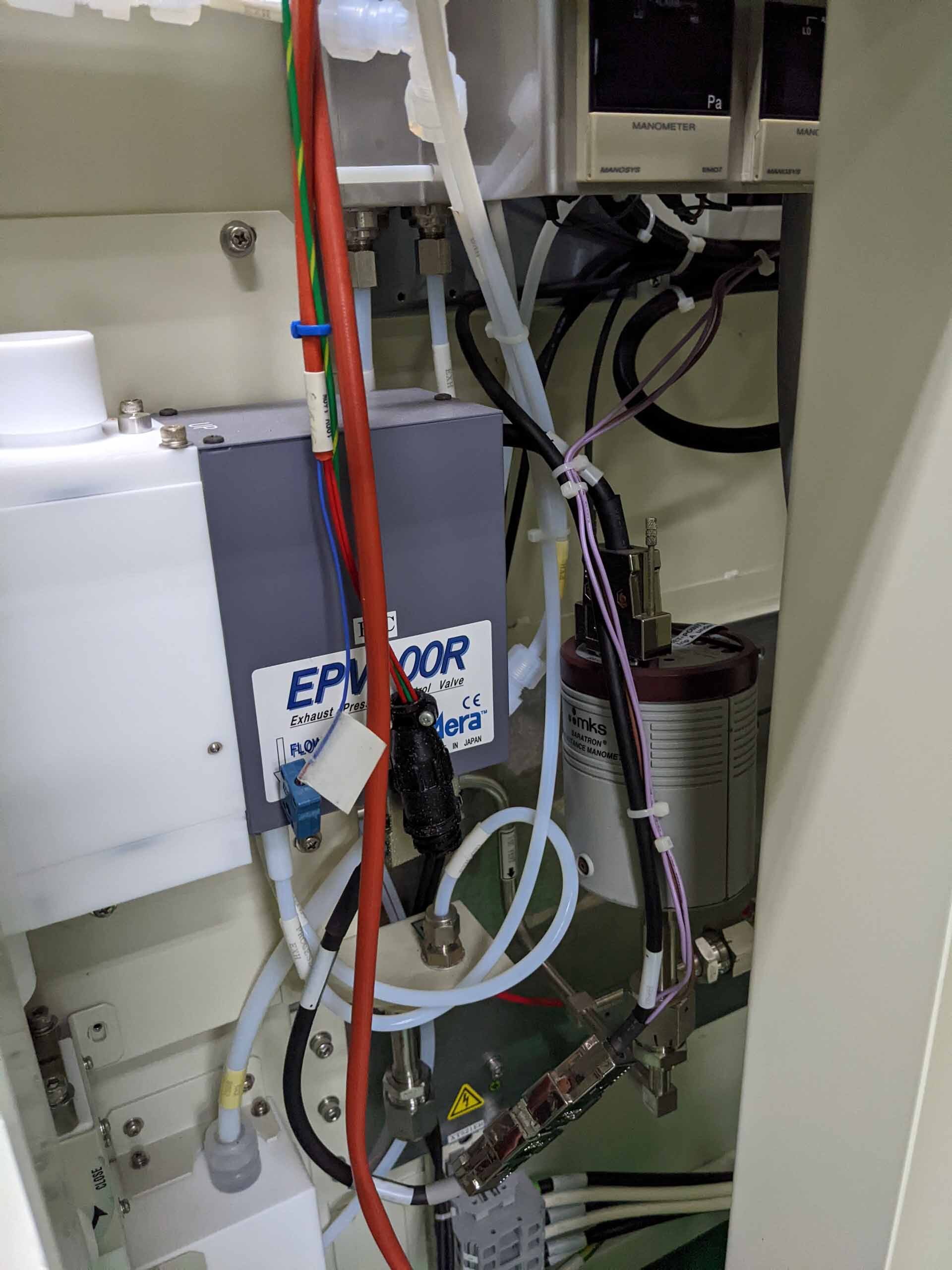

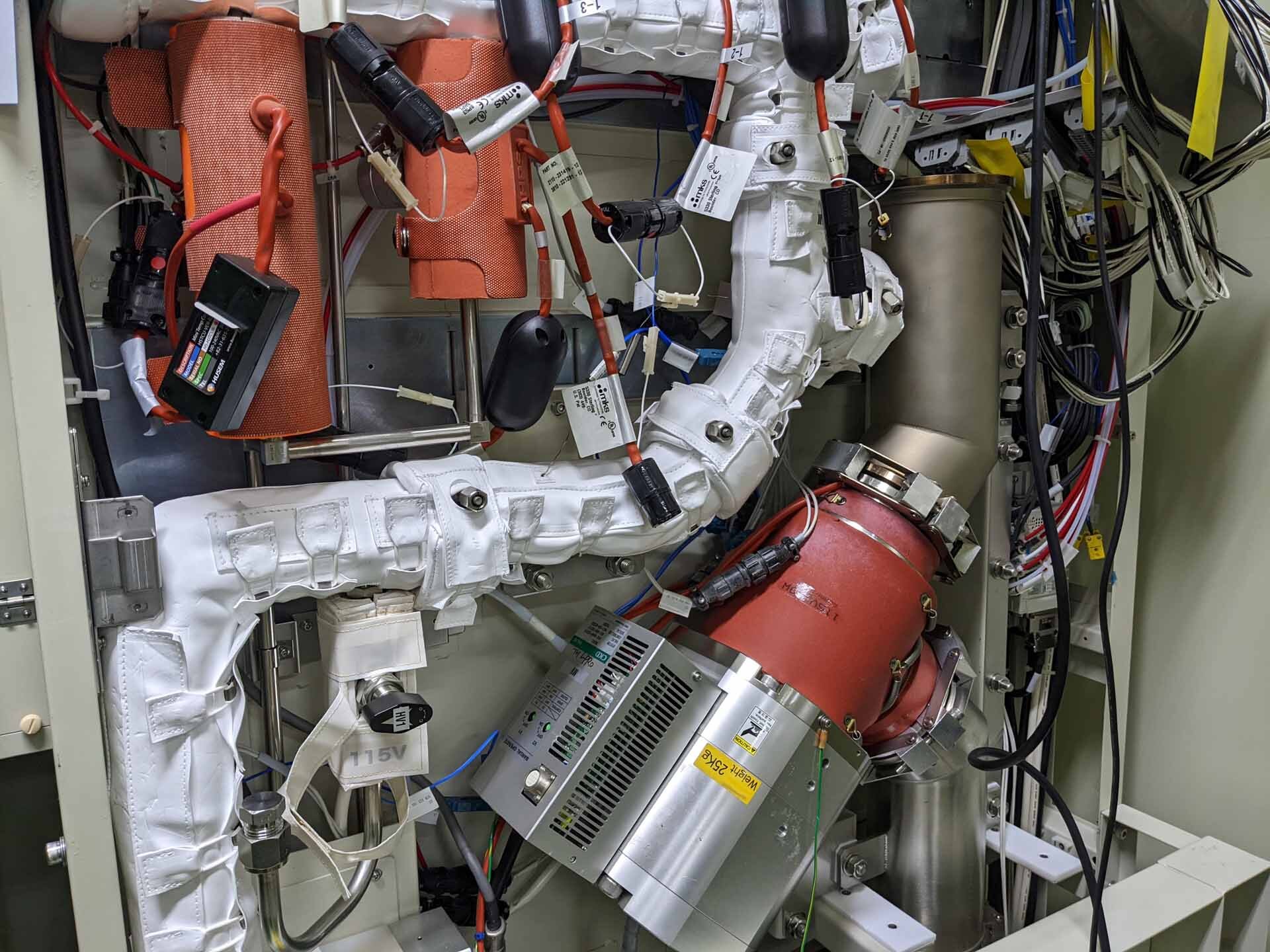

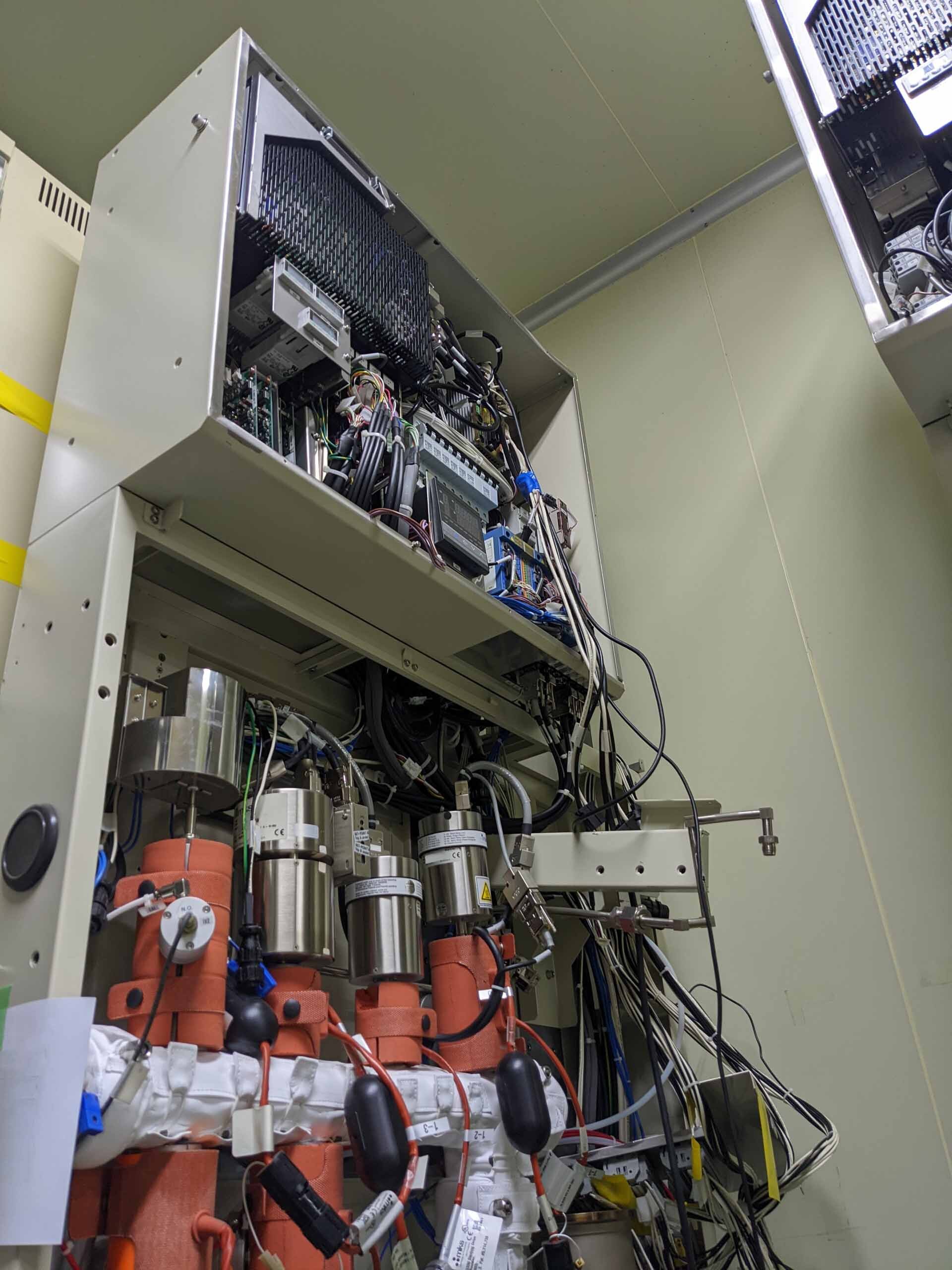

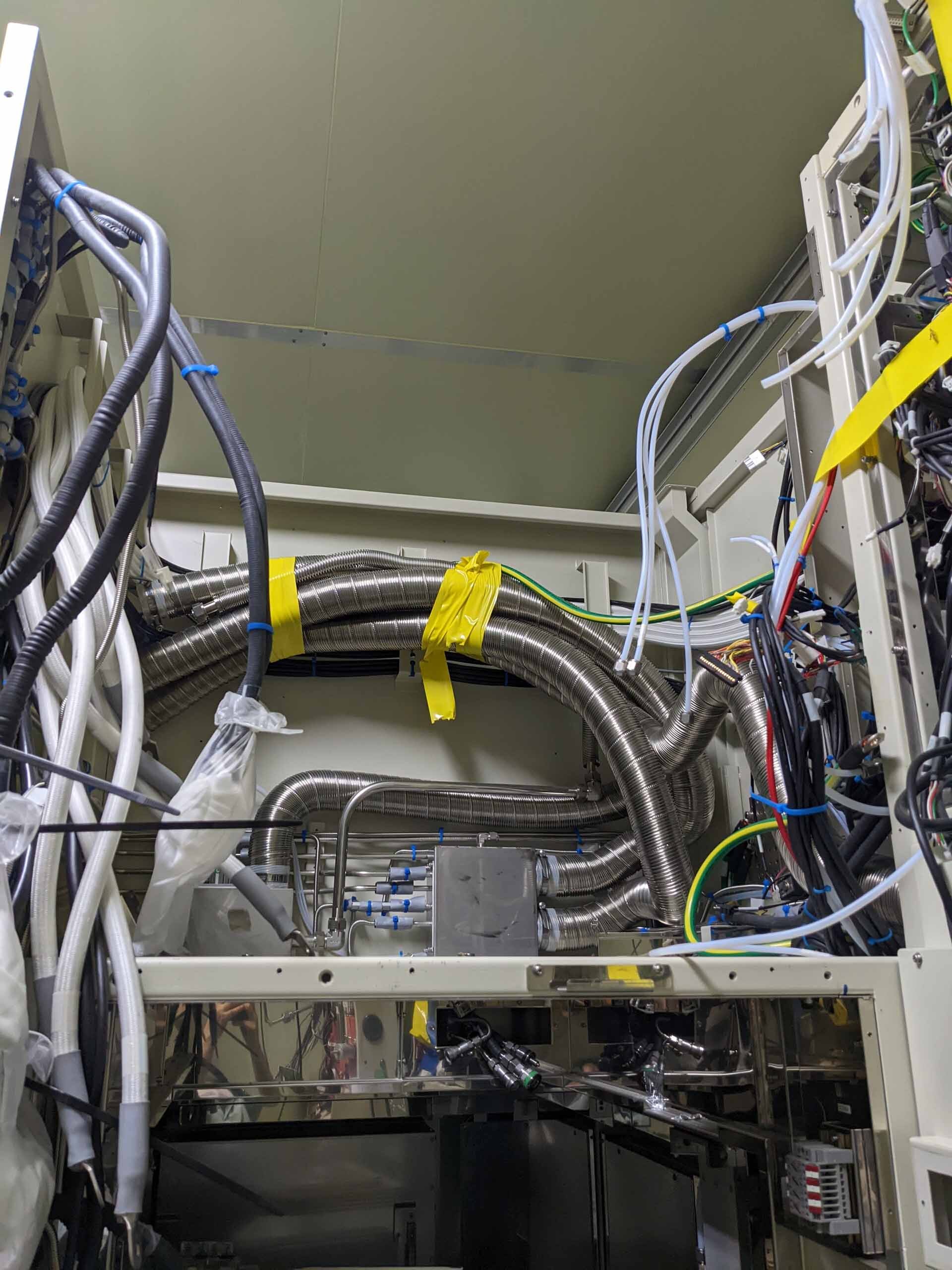

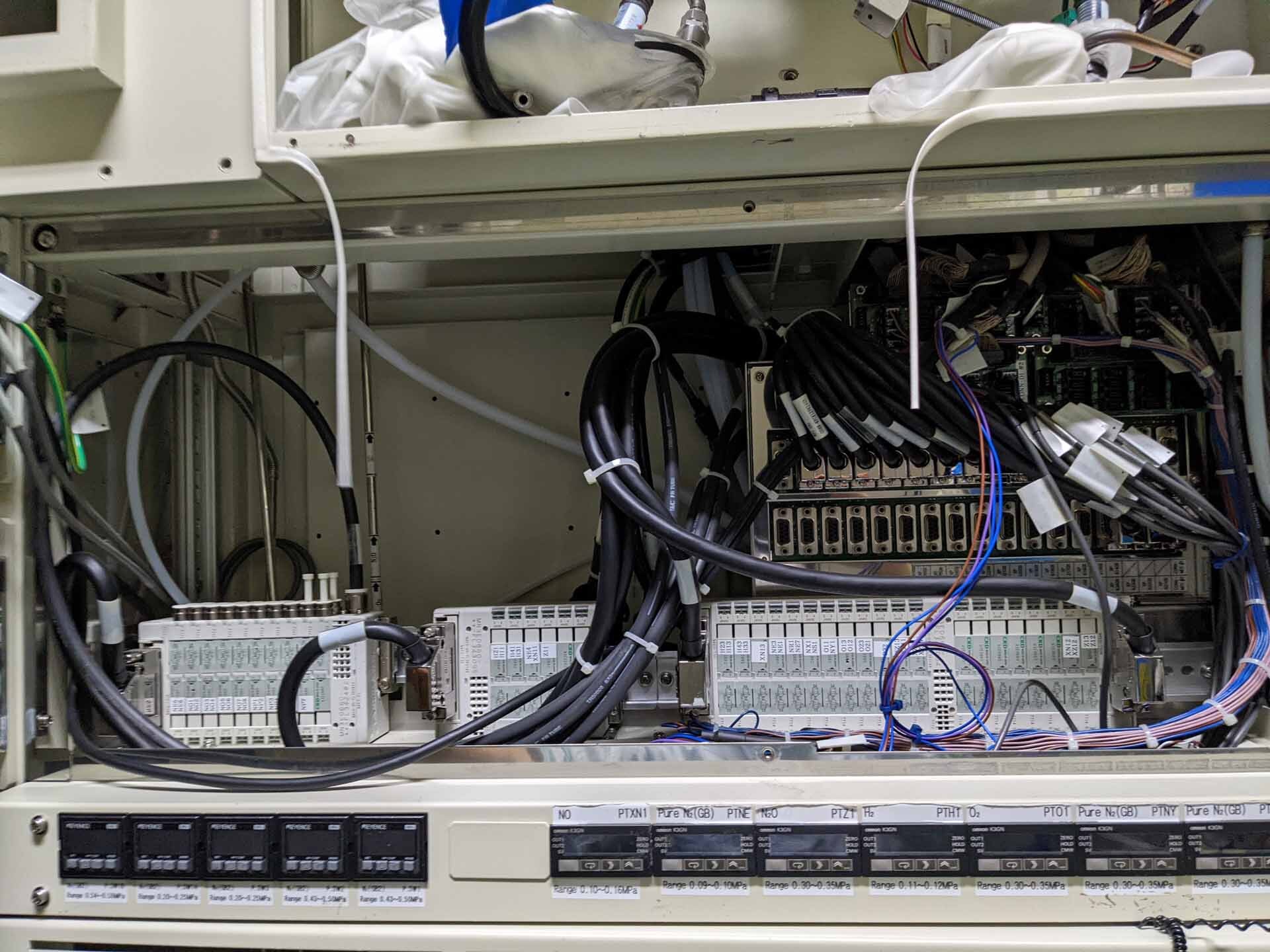

Exhaust box

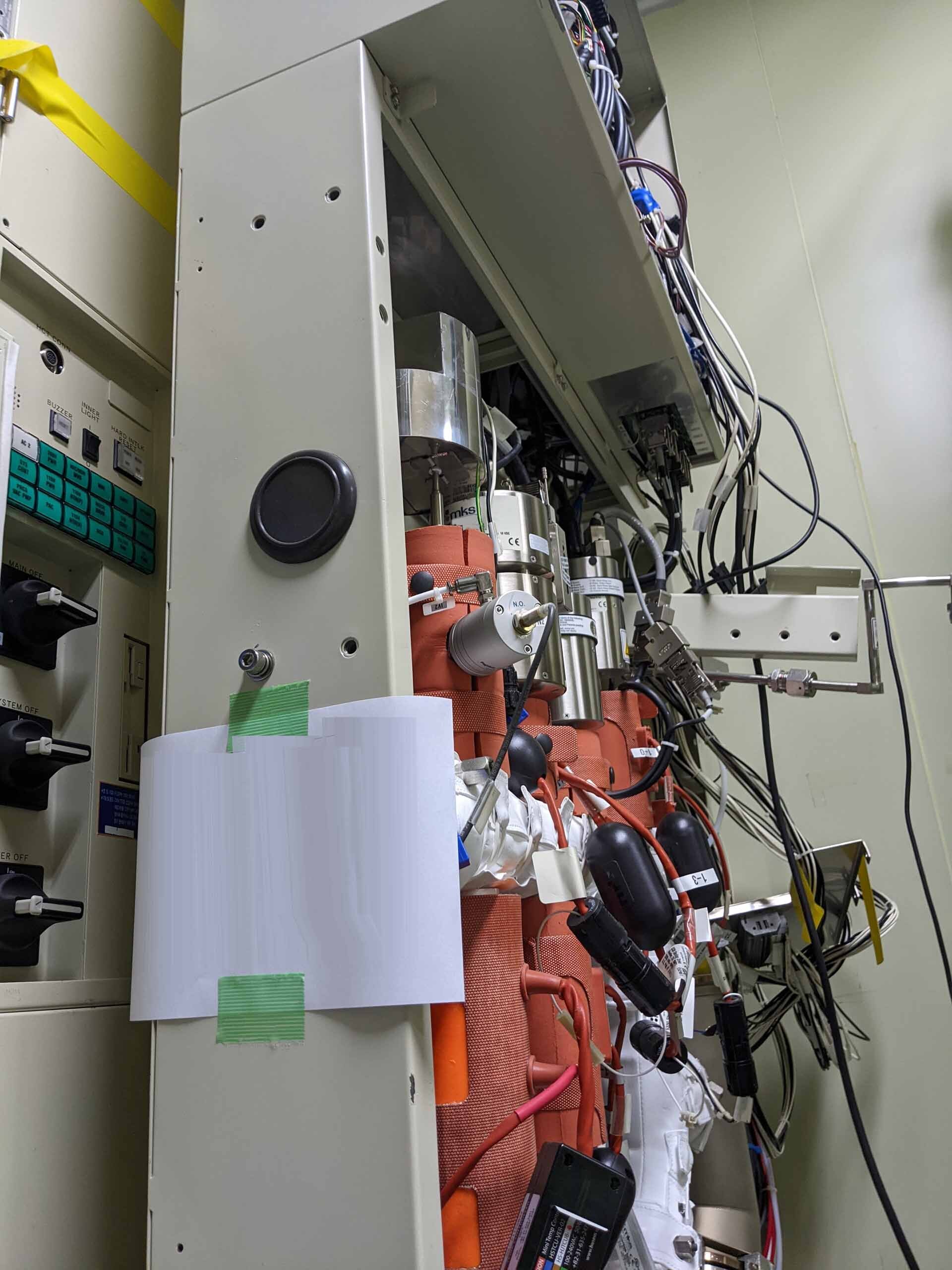

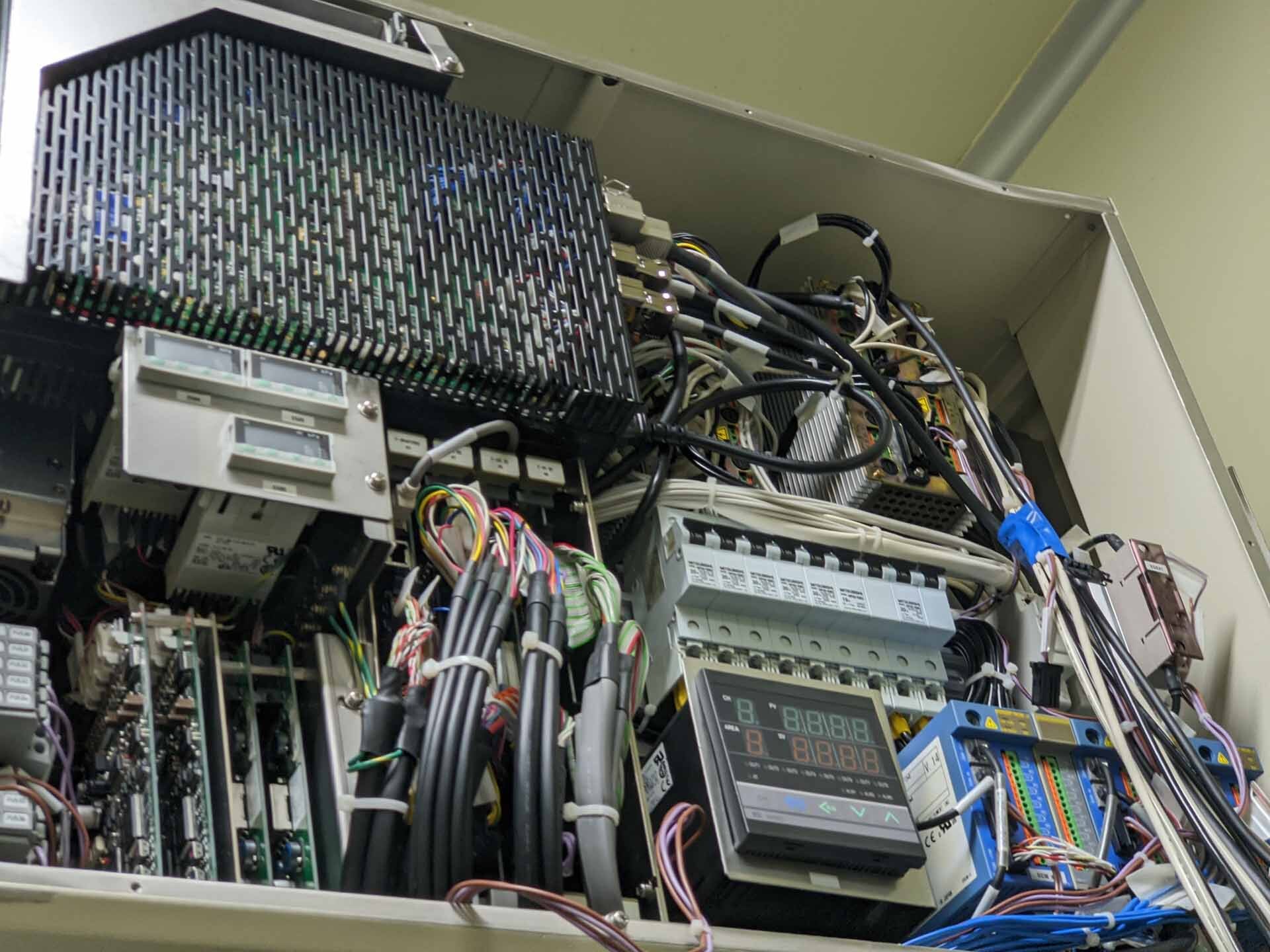

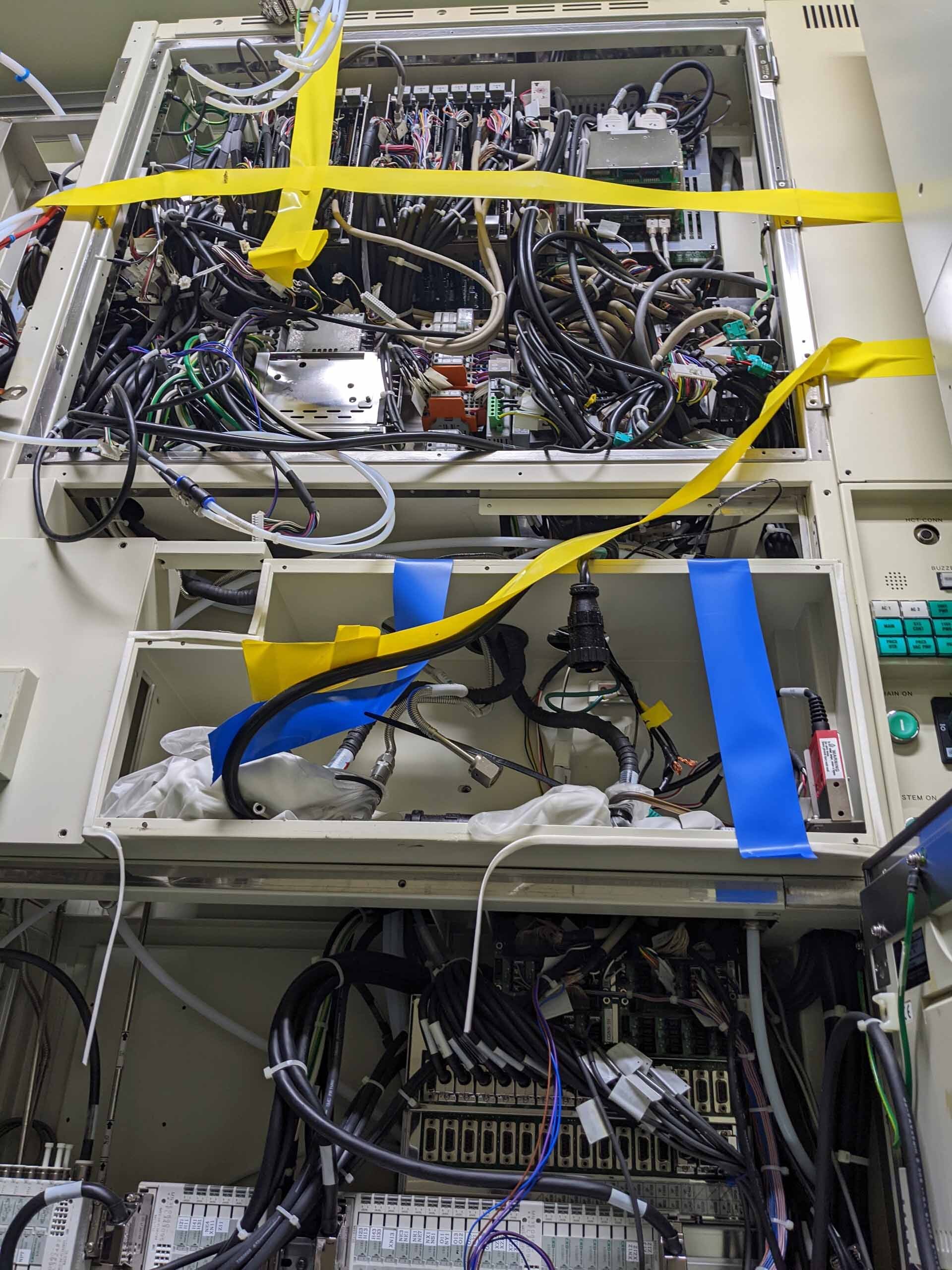

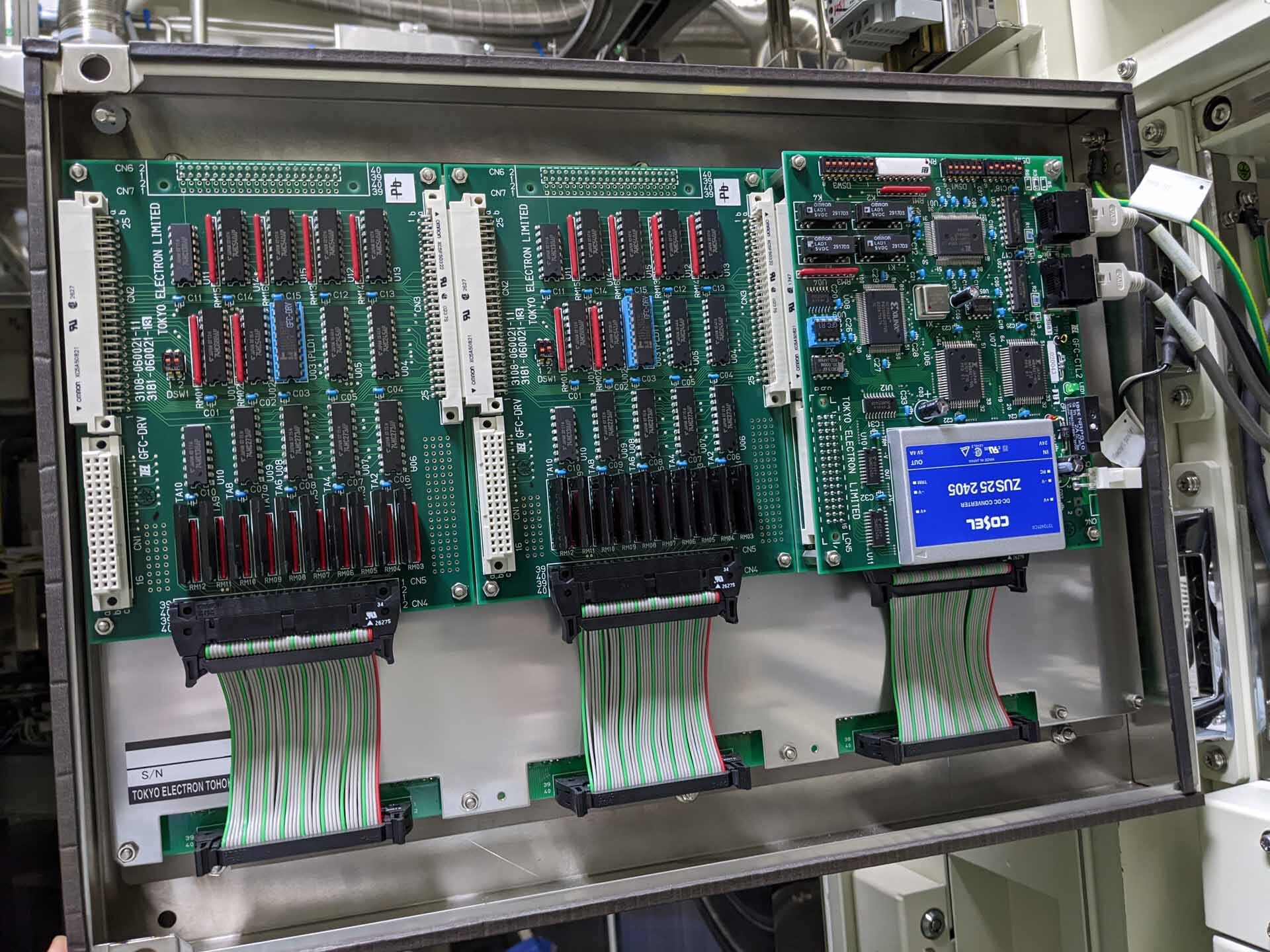

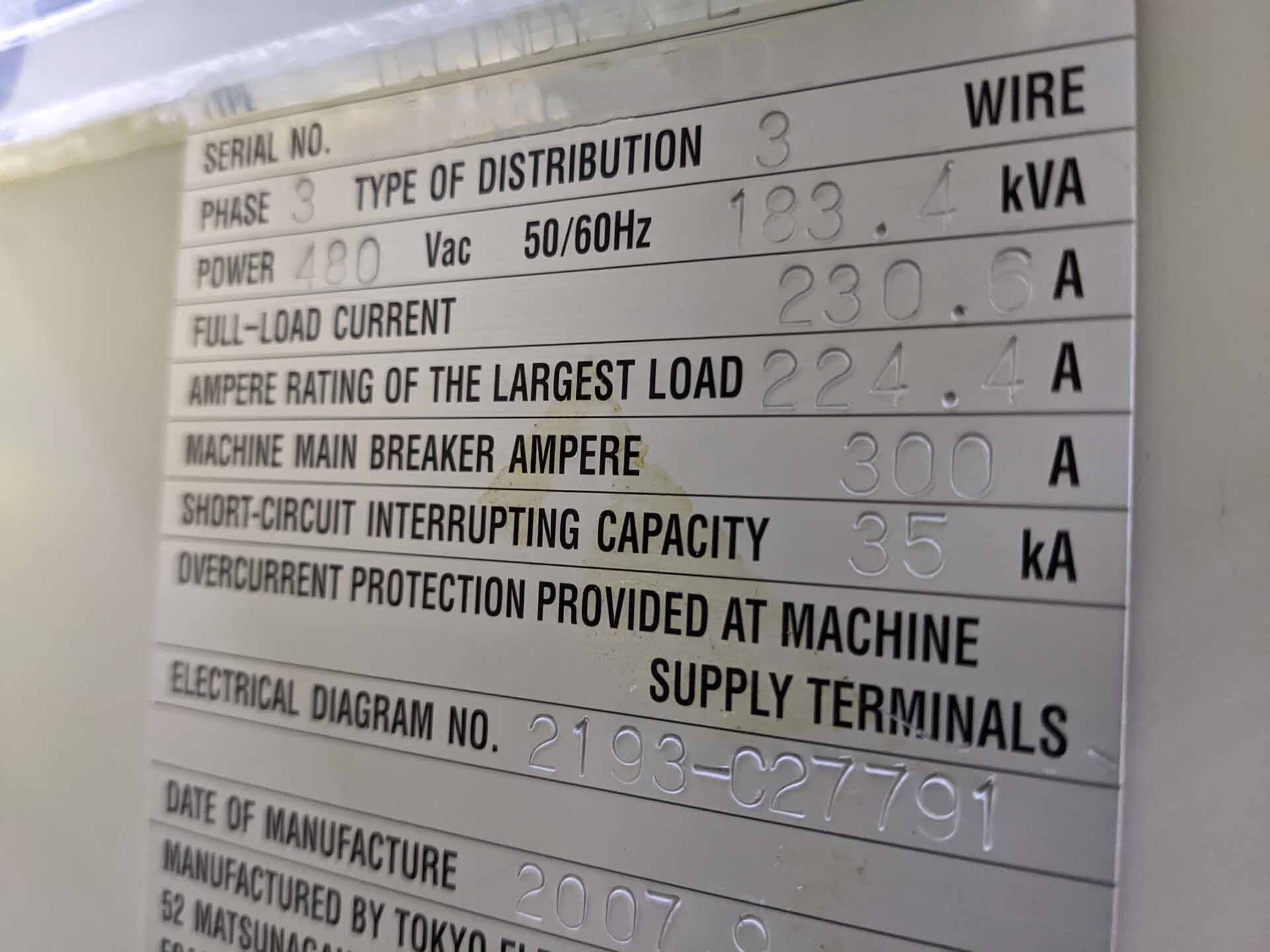

Power box

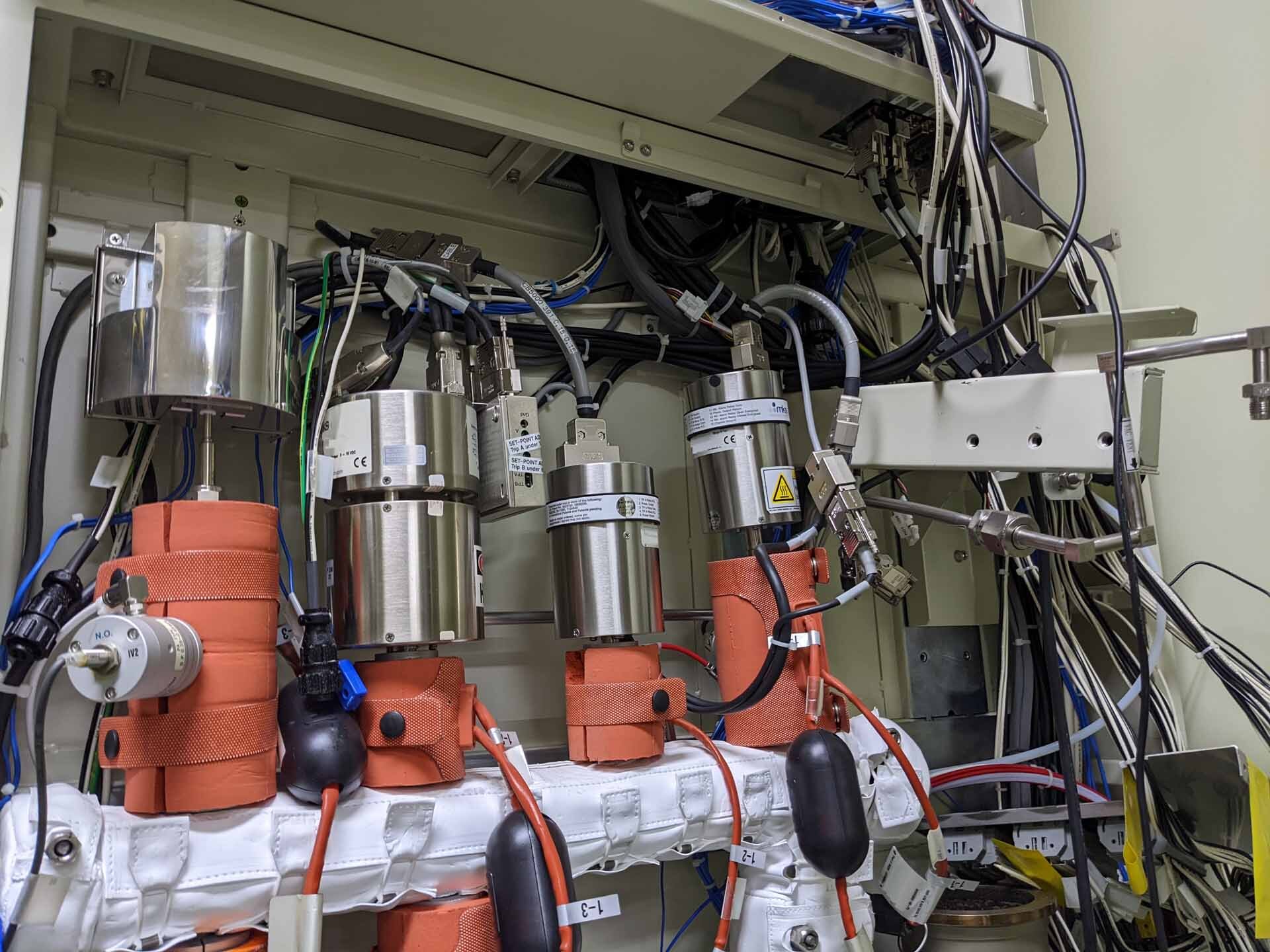

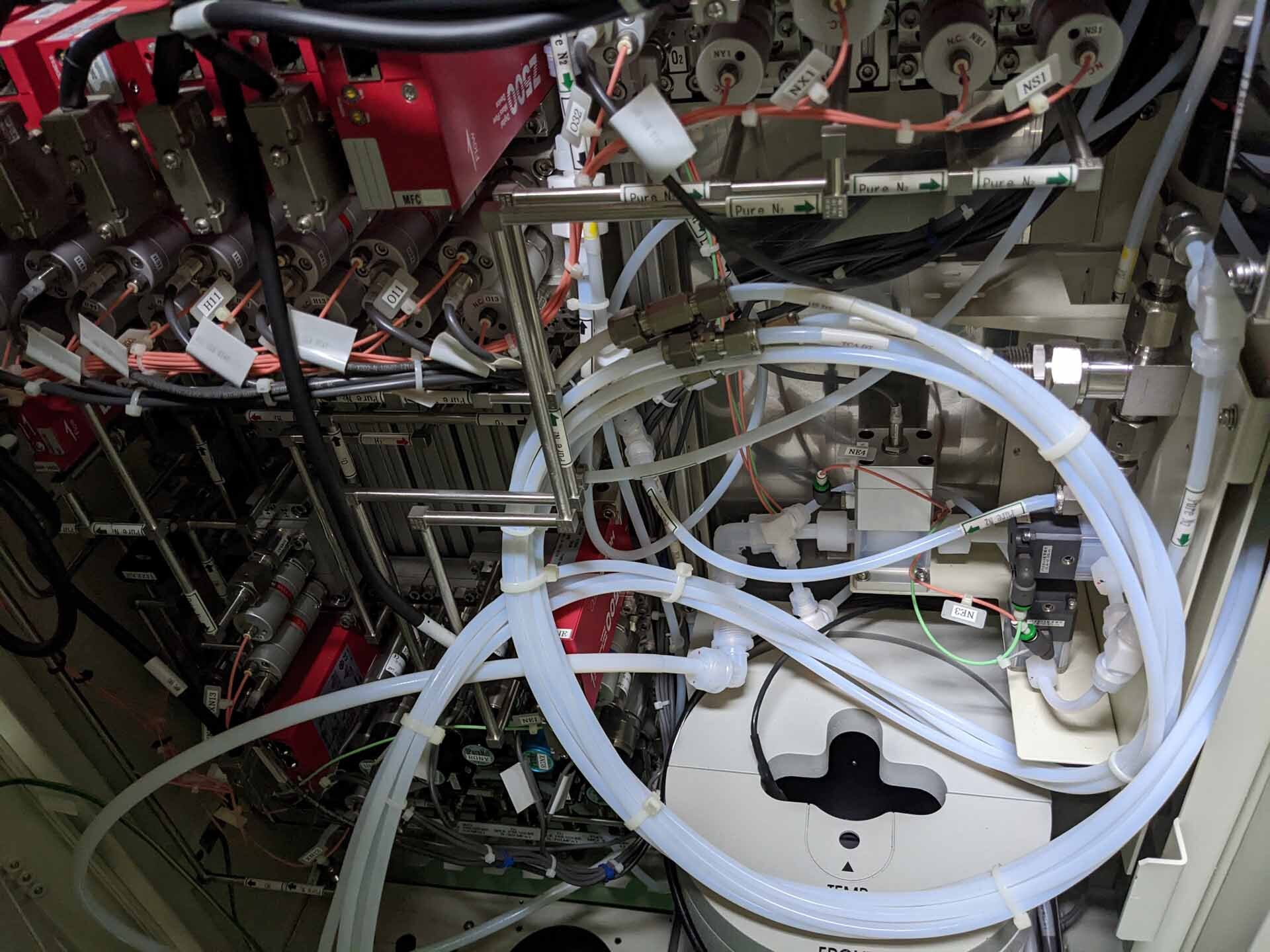

Heater

2007 vintage.

TEL / TOKYO ELECTRON Indy-A-L is an advanced etching equipment used in semiconductor device manufacturing. This sophisticated system is designed to etch a variety of materials quickly, effectively, and with minimal contaminants. TEL Indy-A-L features a three-stage etching process, including plasma, reactive ion etching (RIE), and physical vapor deposition (PVD). In the first stage, the material is exposed to a high-energy plasma. This allows ions to penetrate the material, leaving a microscopic pattern etched into its surface. The second stage, RIE, allows different gases to interact with the material, resulting in more intricate etching. In the third stage, the PVD adds material to predetermined areas, allowing for a greater level of control and customization. This versatility makes TOKYO ELECTRON Indy-A-L suitable for a range of Advanced Packaging and MEMS (Micro-Electro-Mechanical Systems) processes. It has a very small footprint - its size is just 75 cm x 105 cm (width x depth) - so it can fit into a designated area in any existing production line. The unit also has a low-thermal-budget design, meaning its temperature is kept low during operation. Indy-A-L also features a specialized Edge Tollerance Control (ETC) machine that enables precise etching on the edges of parts. The tool is also equipped with an upper-arm robot arm guard and an ion beam source, both of which ensure that the process is conducted safely. Finally, TEL / TOKYO ELECTRON Indy-A-L is compatible with a variety of analytical tools, including SEM (Scanning Electron Microscope) and XPS (X-ray Photoelectron Spectroscopy). This allows for easy and accurate measurement of the features etched onto the material. In summary, TEL Indy-A-L is a sophisticated etching asset with a range of features that make it well-suited for use in the semiconductor device manufacturing industry. Its versatile design, small footprint, and advanced analytical tools make it an invaluable tool for companies looking to produce high-quality components with high precision.

There are no reviews yet