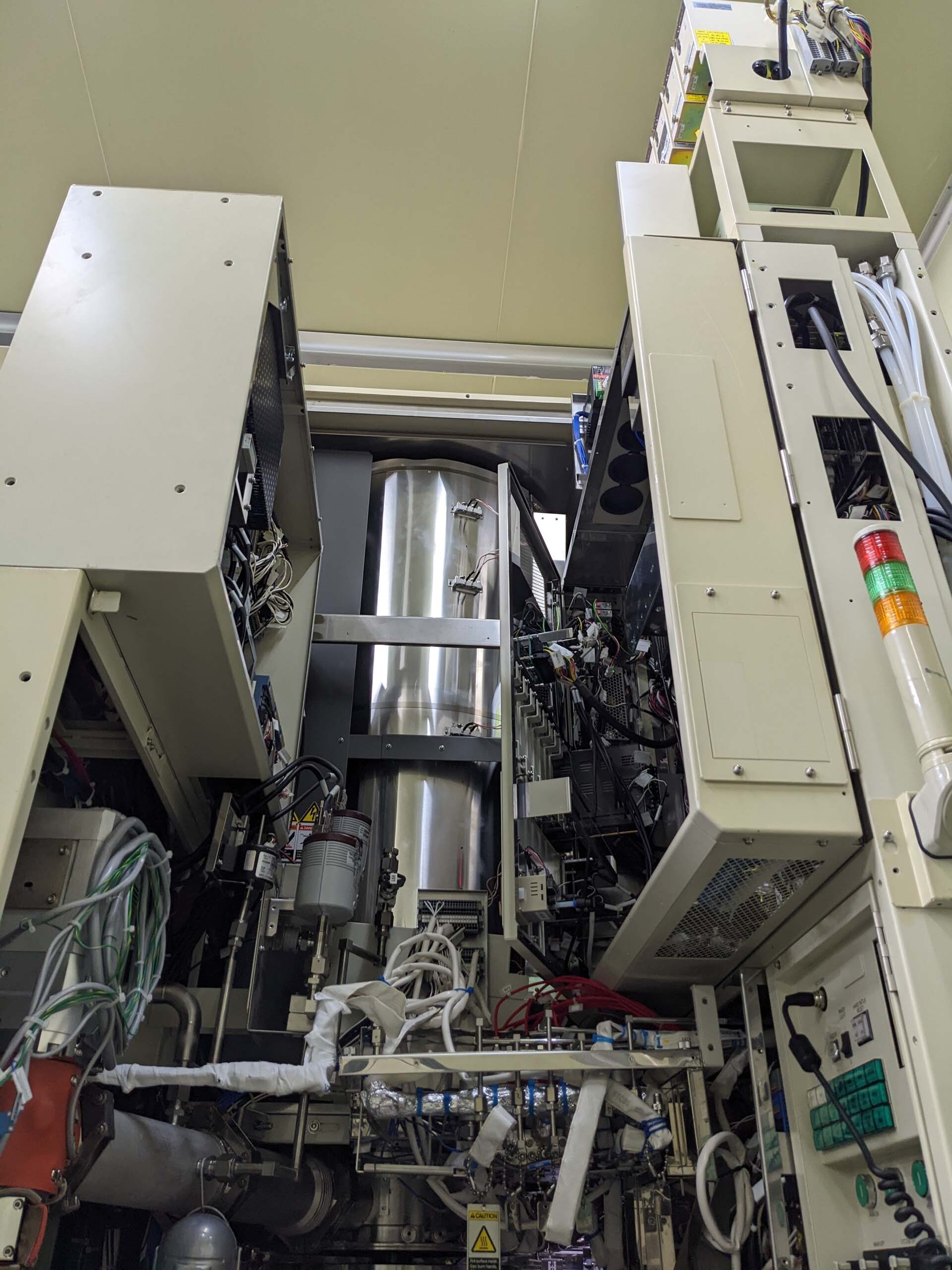

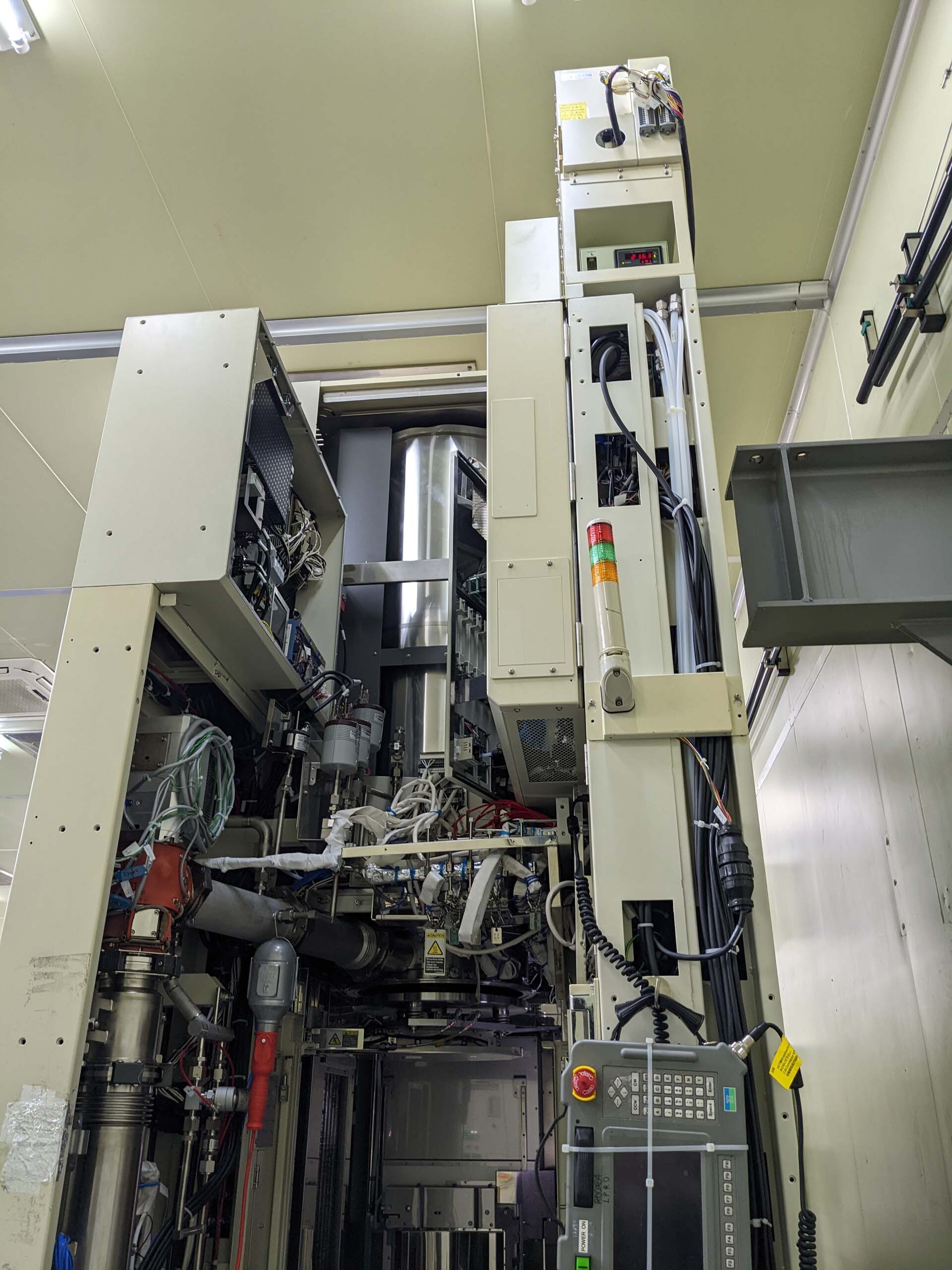

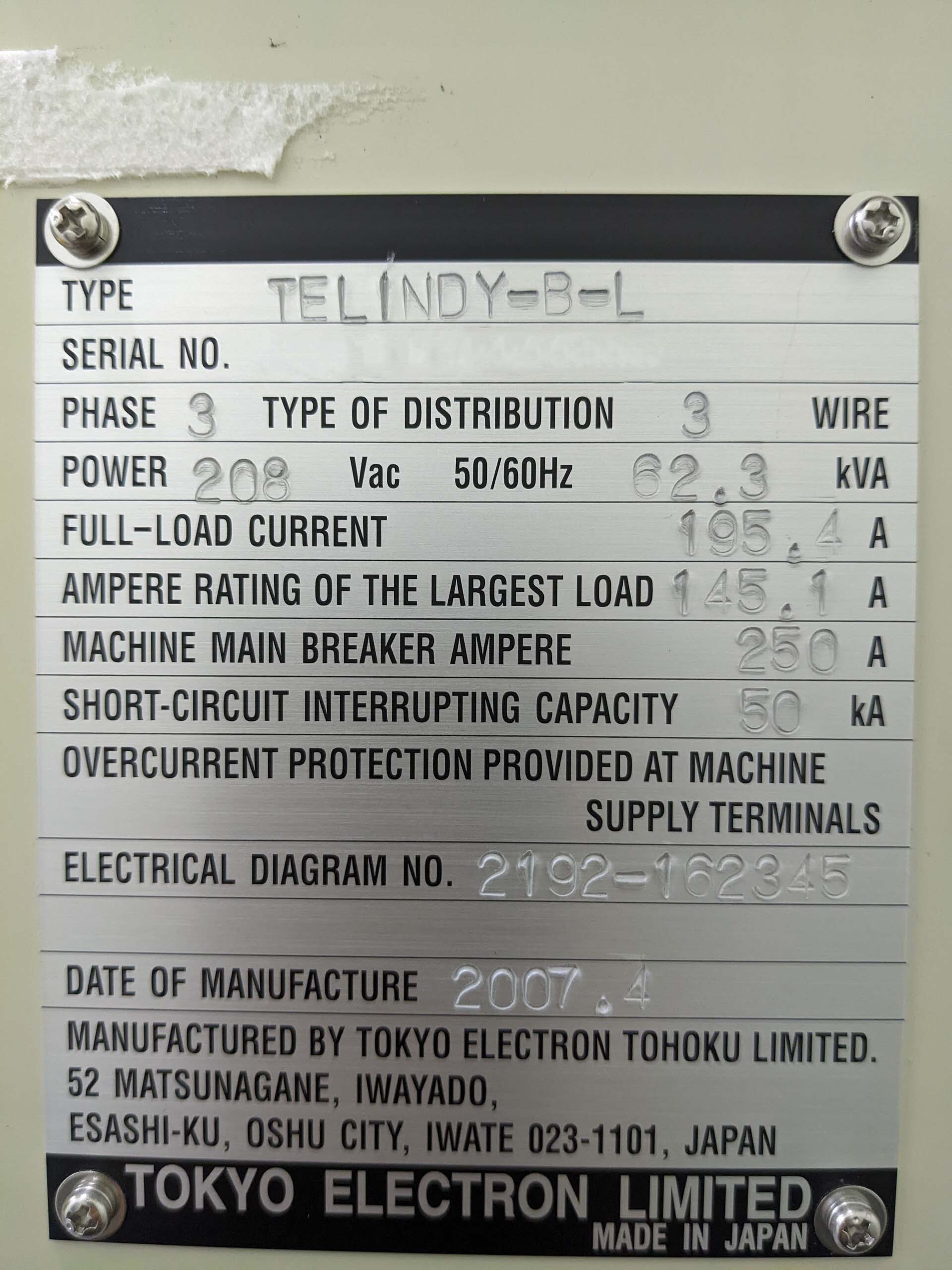

Used TEL / TOKYO ELECTRON Indy-B-L #293637434 for sale

URL successfully copied!

Tap to zoom

ID: 293637434

Wafer Size: 12"

Vintage: 2007

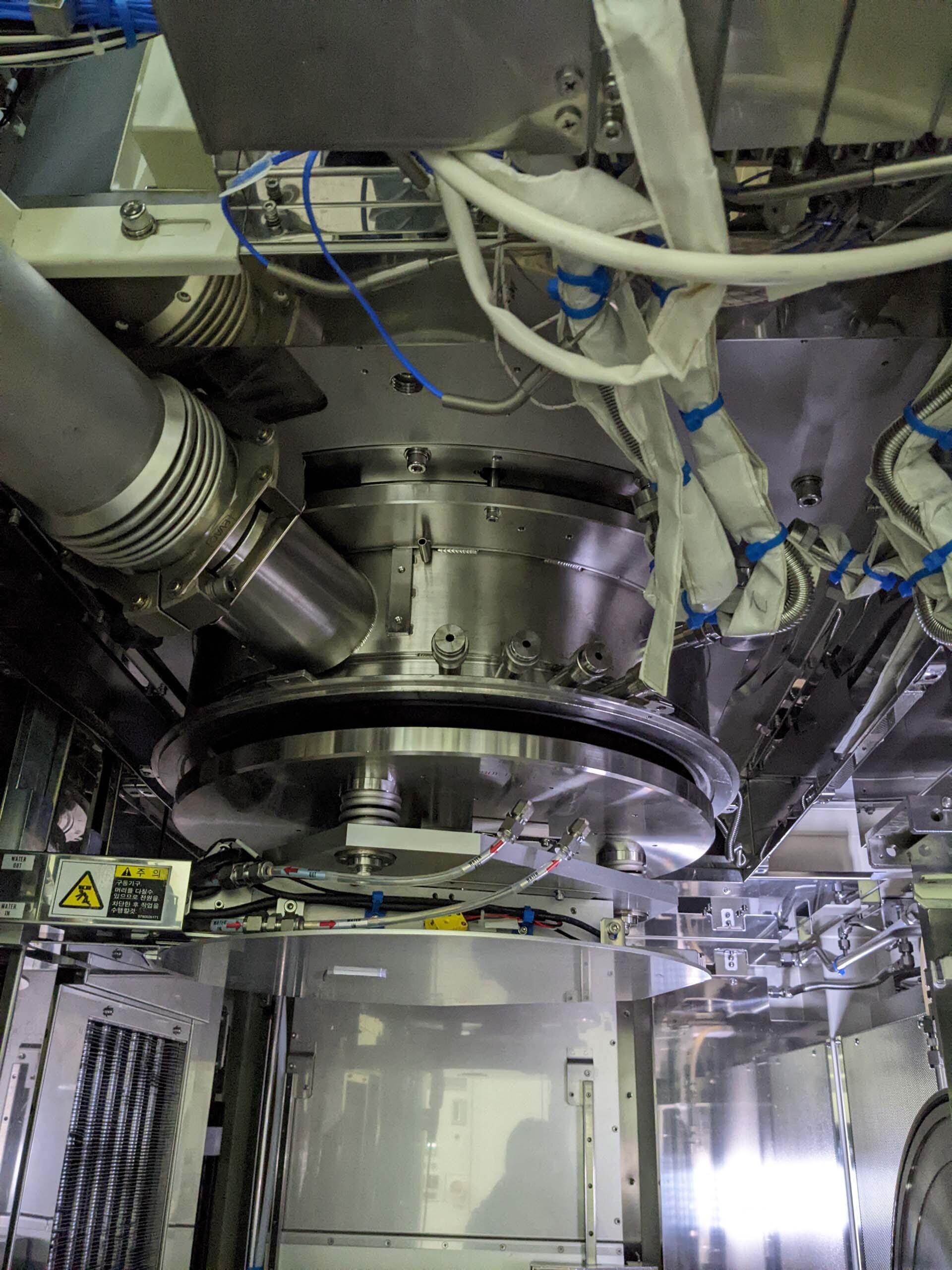

LPCVD Furnace, 12"

Wafer type: Si semi STD Notch

(100) Production wafers

Maximum operating temperature: 500-1000

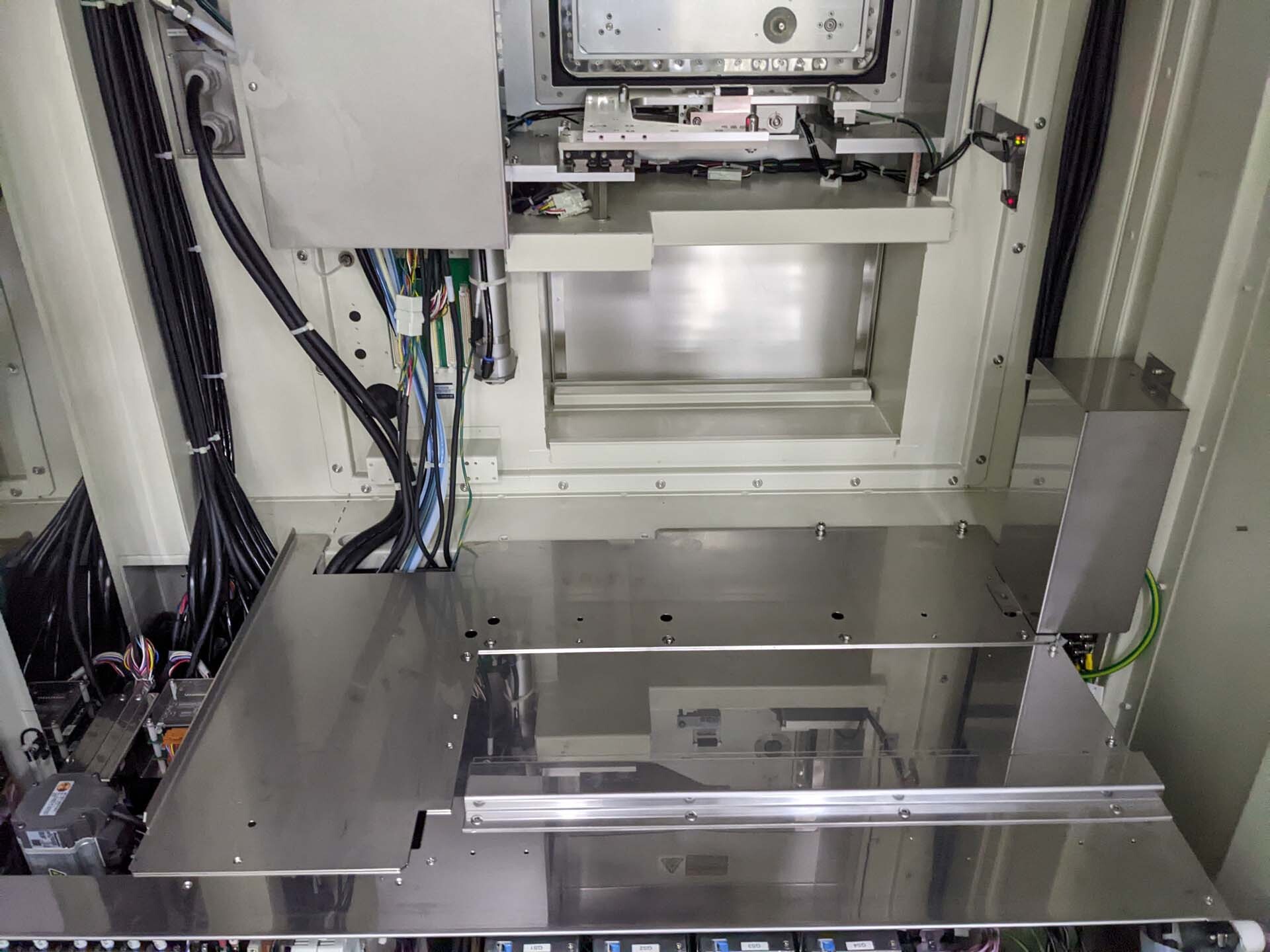

N2 Load lock

Boat type handling position

O2 Density control for N2 Load lock

N2 Boat shower wafer cooling

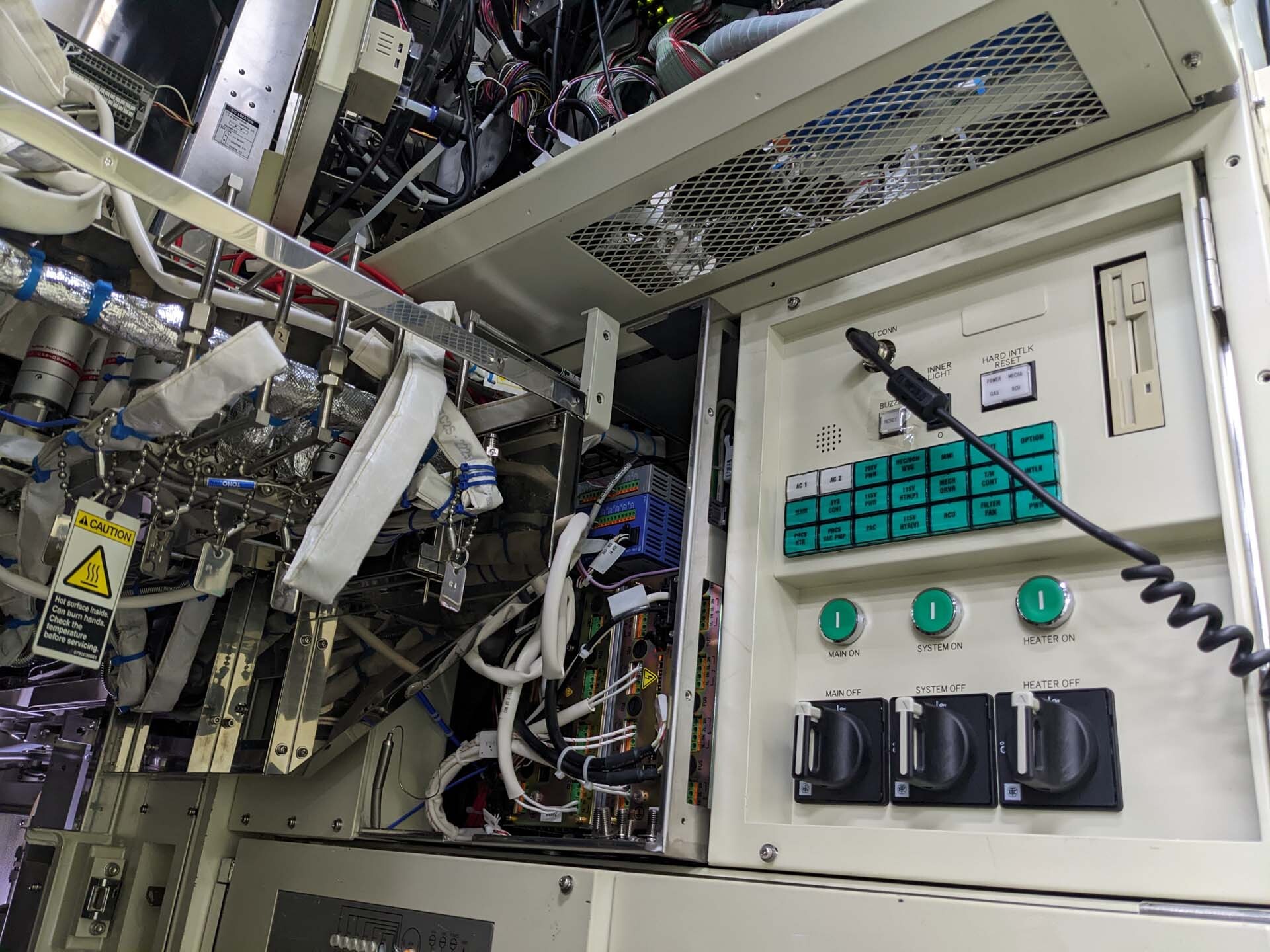

560A Furnace temperature controller

VMM-56-002 Heater

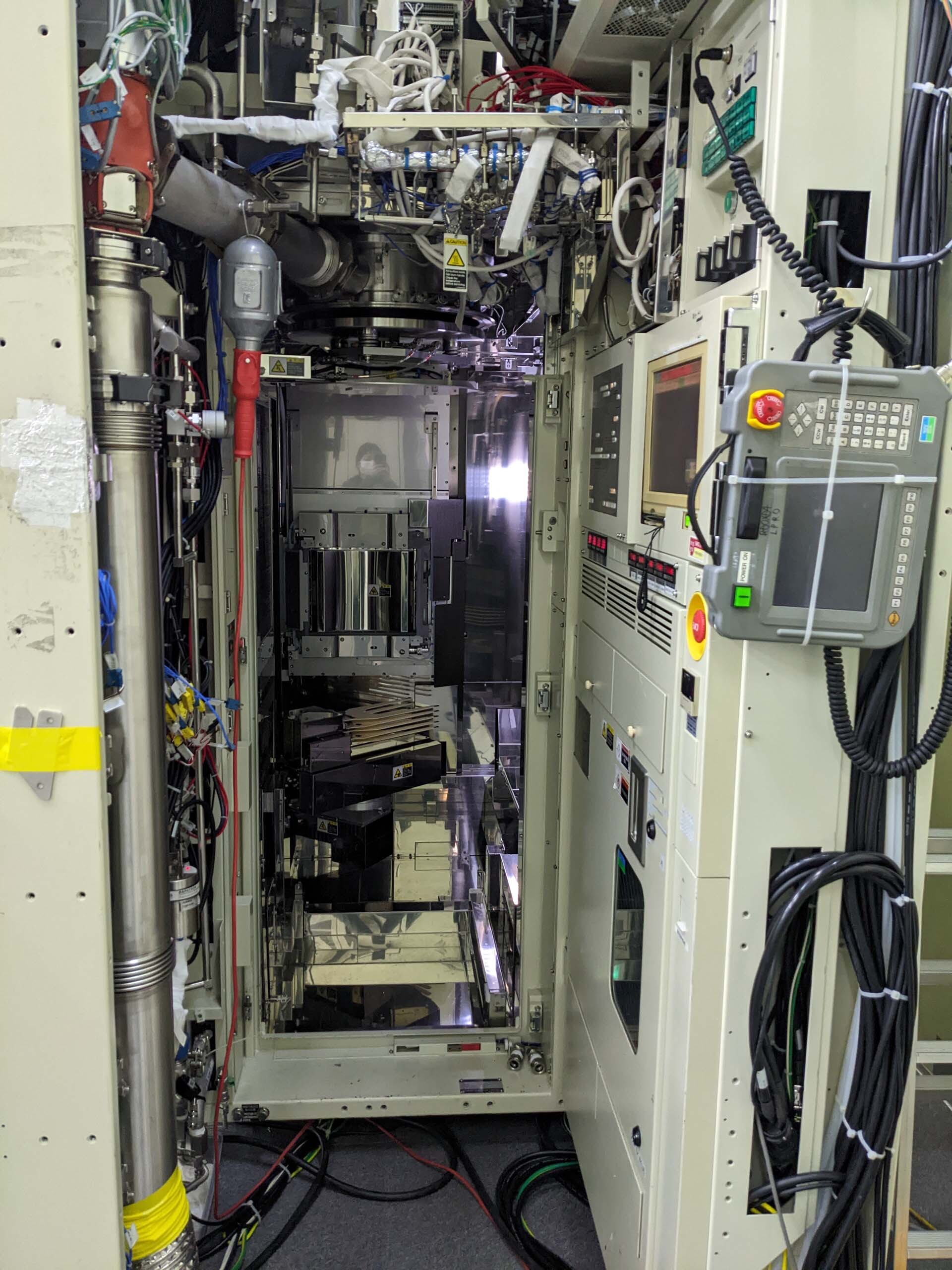

Wafer / Carrier handling:

(25) Carrier type: FOUP

ENTEGRIS A300

Carrier stage capacity: 16

Pin pad A, B

Fork material: Al203 and peek

With type: 1+4 Edge grip

With auto teaching

Furnace facilities:

Furnace exhaust connection point: Top connection

Cooling water connection point: Bottom connection

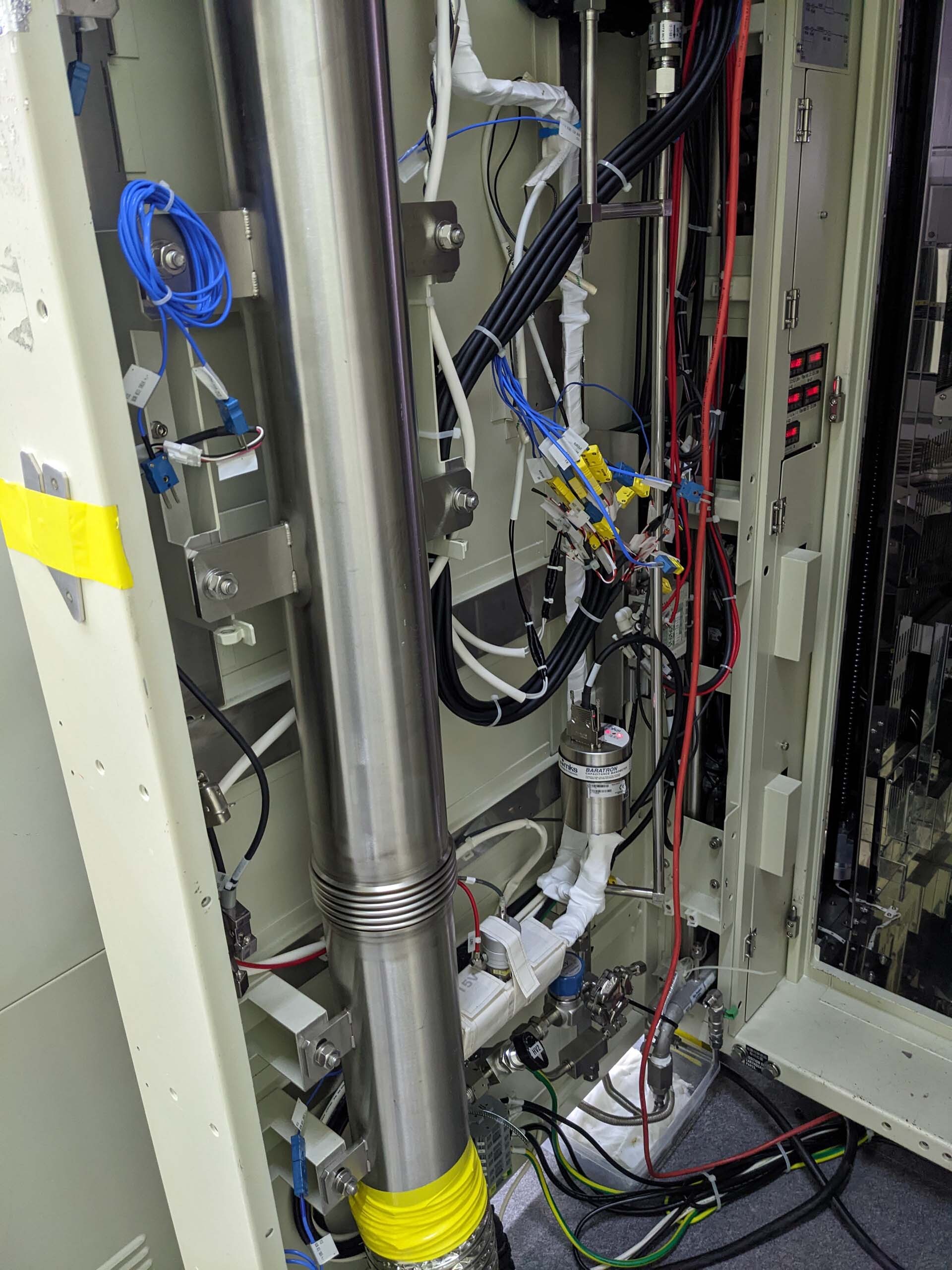

Gas specification:

IGS 1.5" W-seal rail-mount

FUJIKIN IGS

Tubing bend bend (Less than 90°)

HORIBA STEC

Incoming gas connection point: Bottom connection

Gas vent connection point: Bottom connection

Gas unit exhaust connection point: Bottom connection

Process gas exhaust connection point: Bottom connection

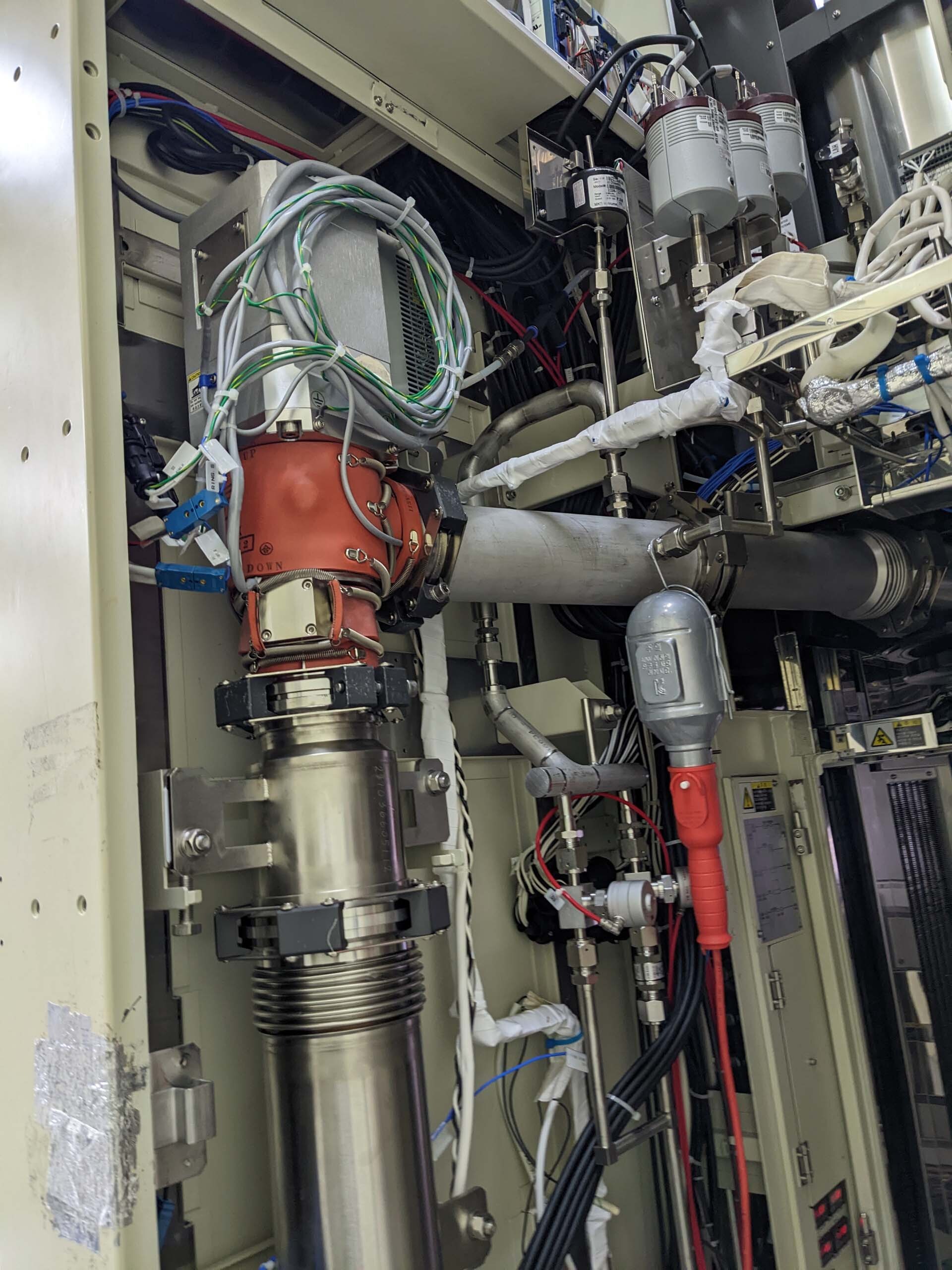

Exhaust specification:

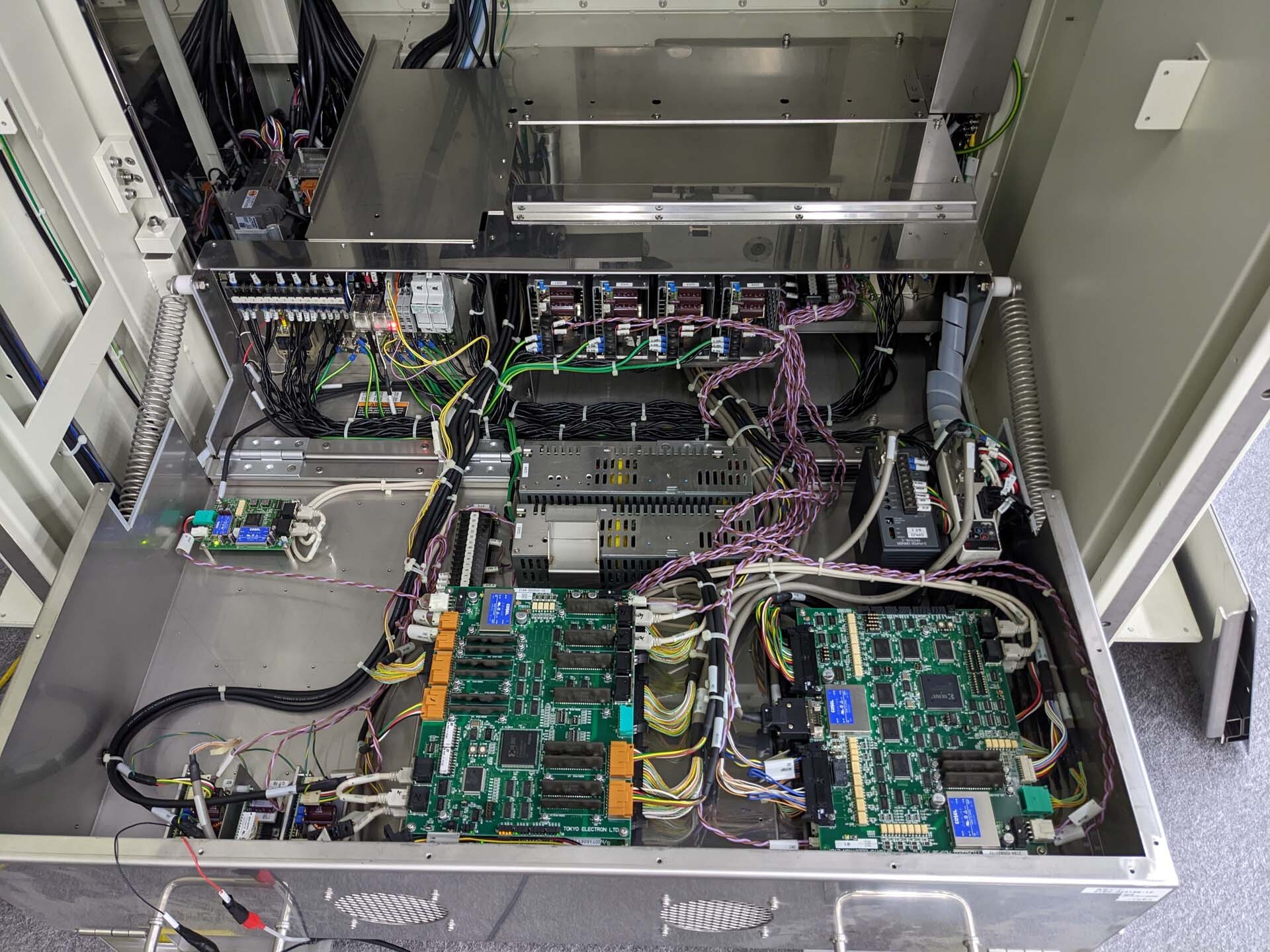

MKS Vacuum gauge-press controller

MKS Vacuum gauge-press monitor

MKS Vacuum gauge-pump monitor

CKD-VEC Main valve

Condenser

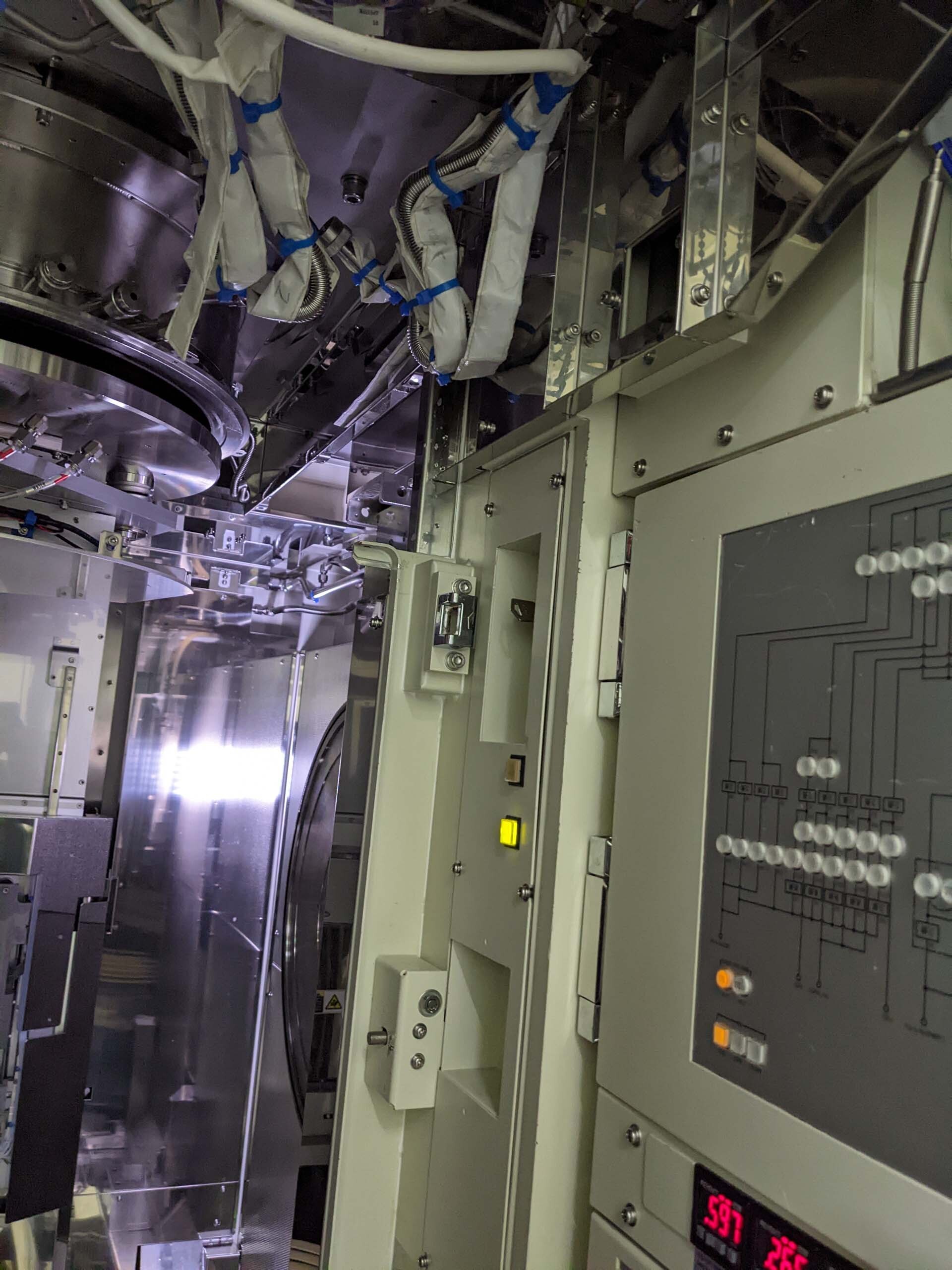

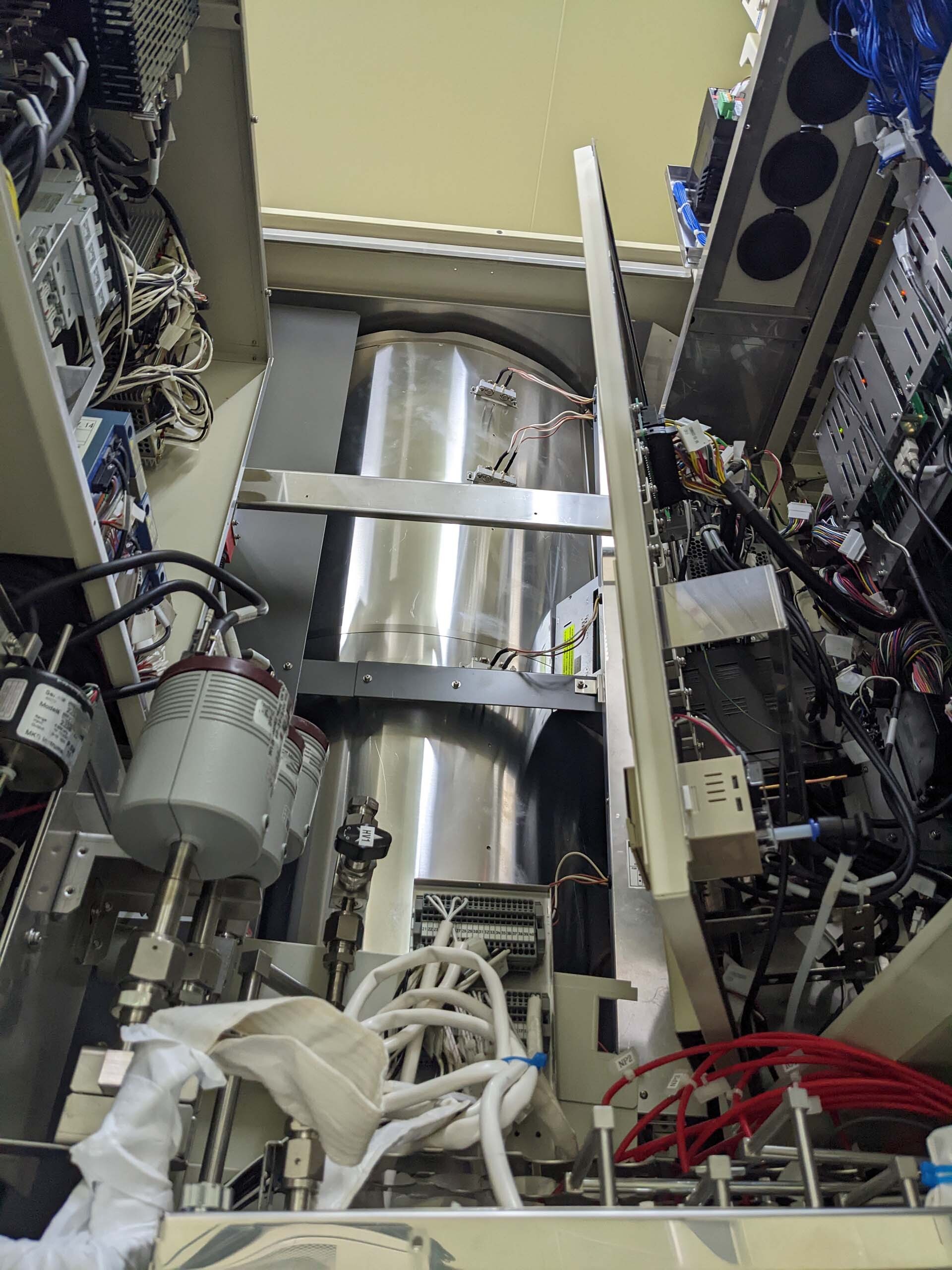

Reactor specification:

Tube material: Quartz (outter), quartz (inner)

Inner tube type (LP): Straight

Inner T/C: Outer tube inferior (wall type)

Tube sealing: O Ring

Soft backfill injector

Boat type: (117) Slots, pitch, 8 mm

Boat rotation

Pedestal type: Quartz

No shutter purge type

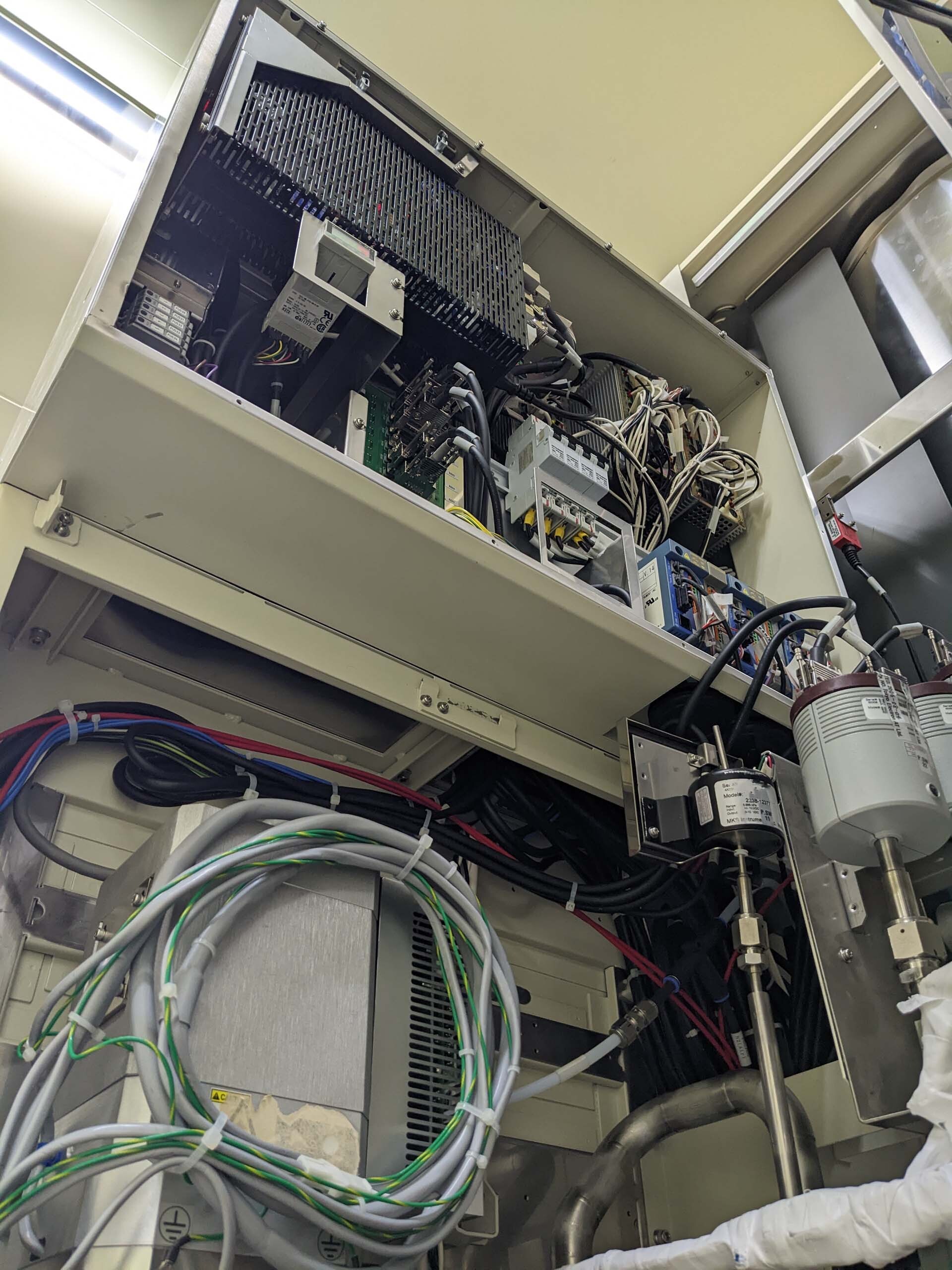

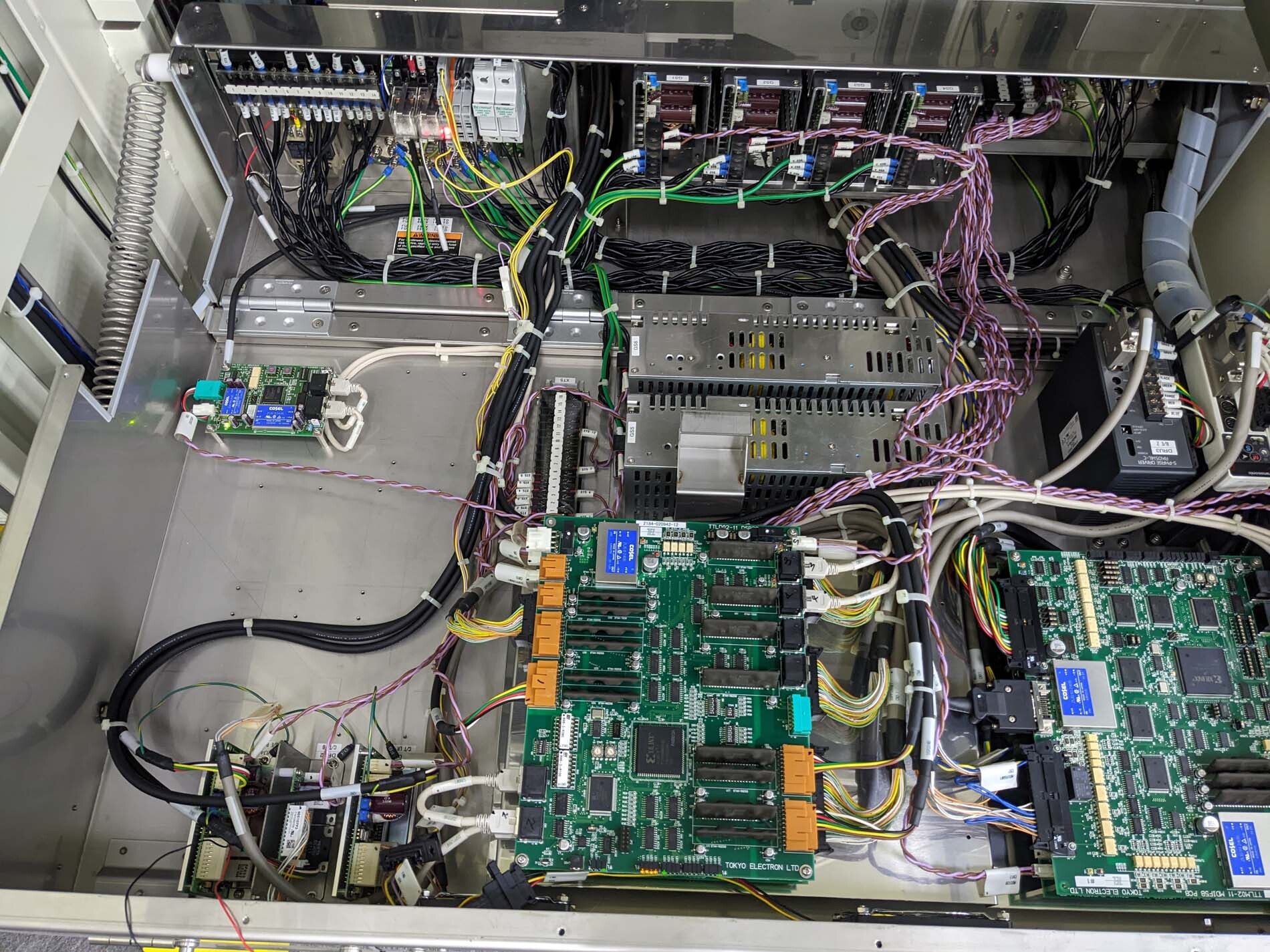

Interface specification:

Host communication: Comply with GJG

Equipment host I/F Connection: Gas box top HSMS

Ingenio

OHT Capability

Load port operation: Upper

PIO I/F Location: FNC Top

HOKUYO DMS-HB1-Z PIO

RF Carrier ID Reader writer type

CIDRW L/P: Read and write

ASYST ATR 9100 CIDRW

TEL CIDRW

User interface

Signal tower model: Customized

Signal tower colors (From the top): Red / Green / Yellow

Signal tower location: Front

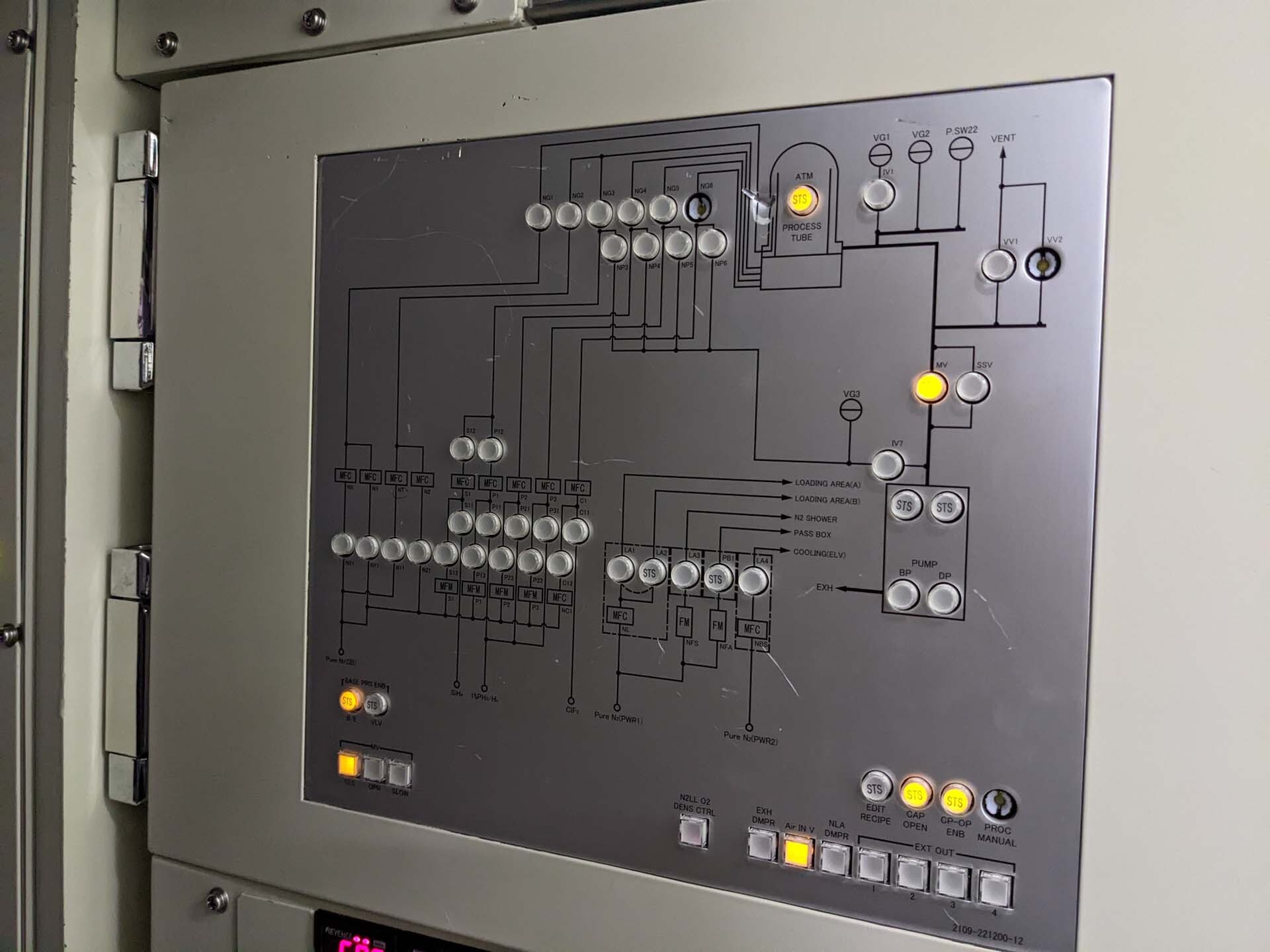

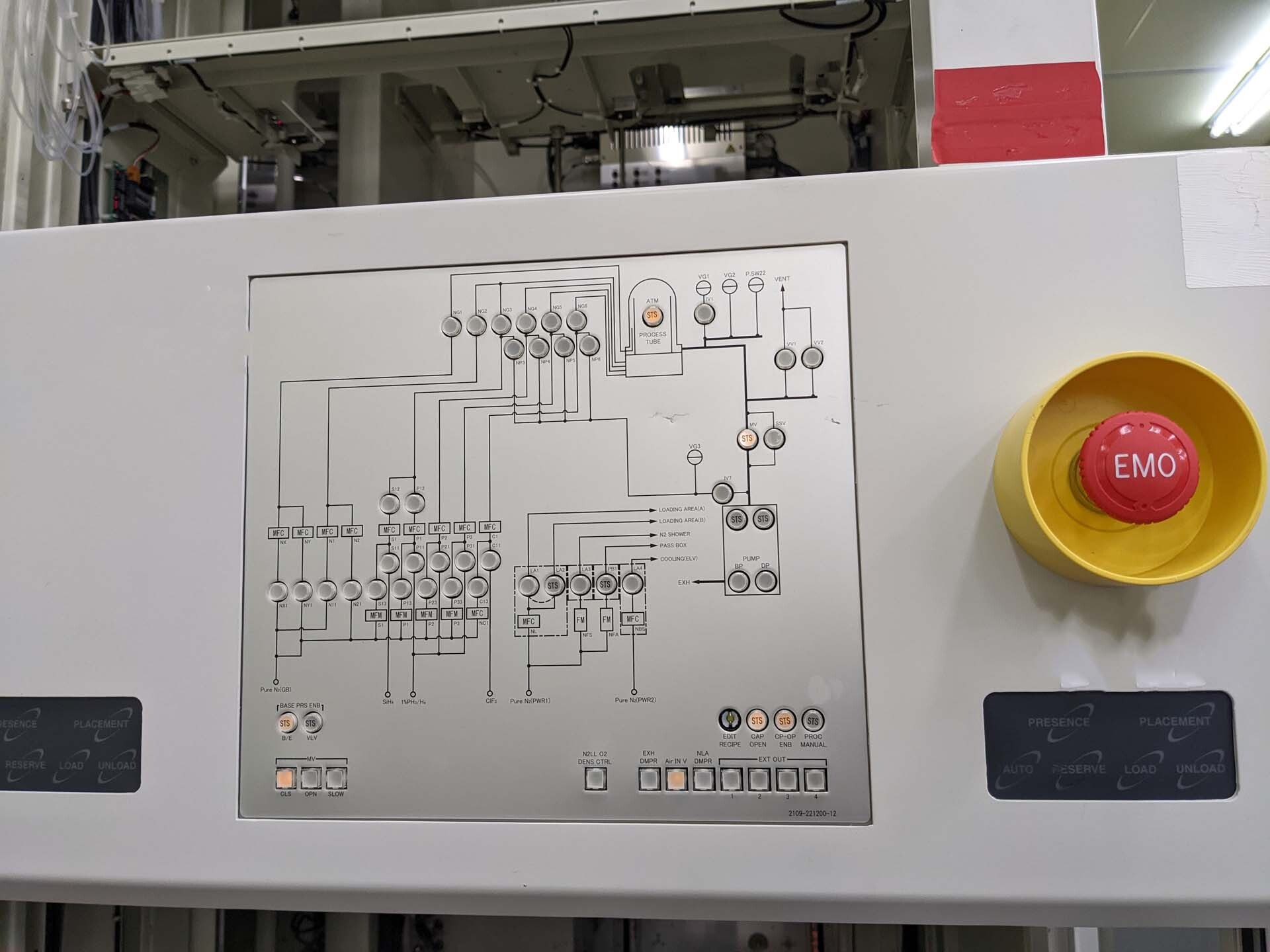

Front operation panel

MMI and gas flow chart: Gas box and front operation panel installed

Indicator type: Superset

Operator switch: Operator access / orange

Pressure display unit (Gas inlet / vacuum): Mpa / Pa

Cabinet exhaust pressure display unit: Pa

Gas leak detector:

Gas1 / SiH4

Gas2 / PH3

Gas3 / ClF3

Cable length:

FNC-Power box: 20 meter

Power box -refill system: 30 meter

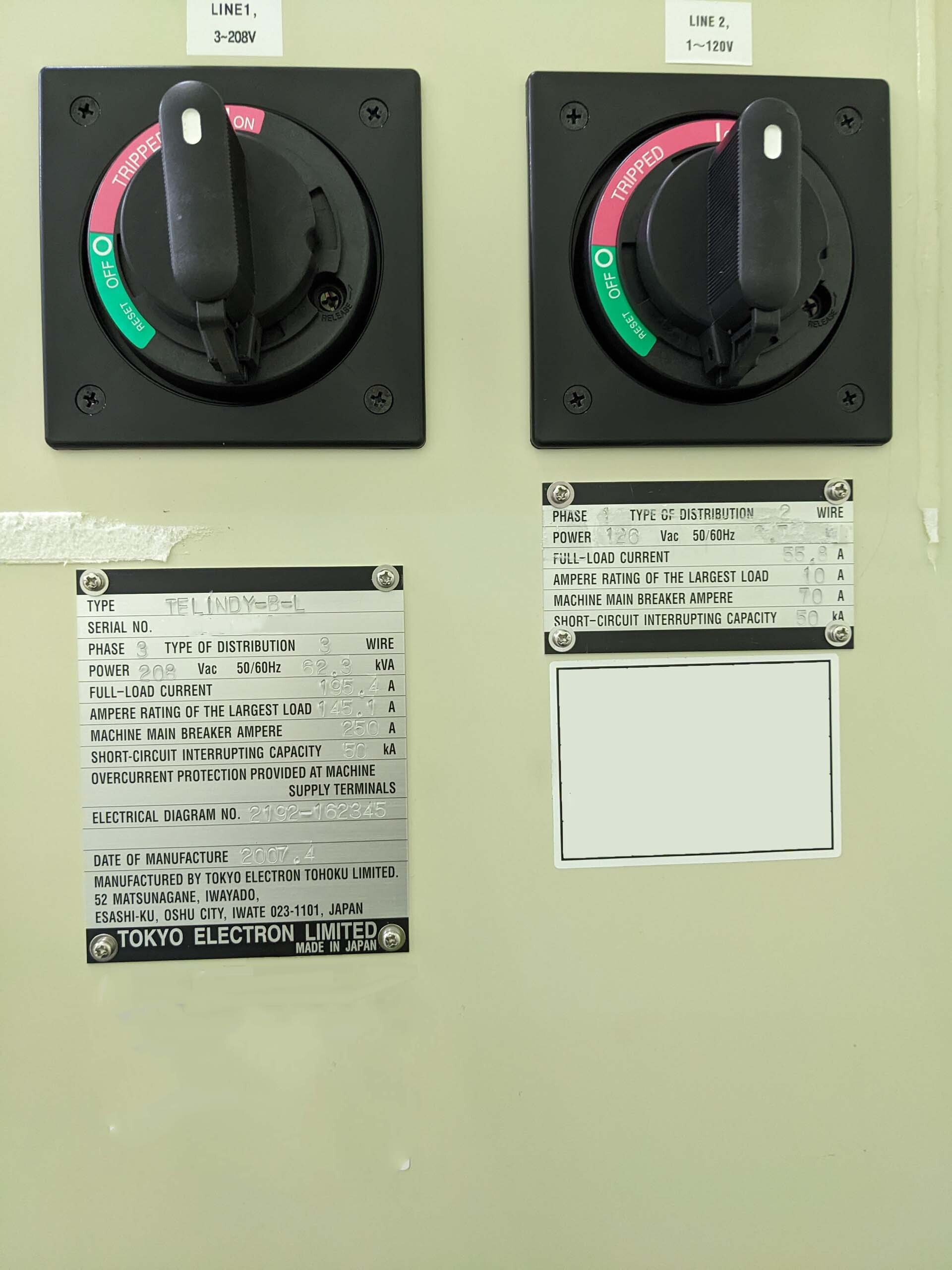

Power specification:

Voltage: 208 VAC, 3 Phase

Phase connection type: Star connection

Voltage single-phase: 120 VAC

Single-phase connection type: Grounded

Frequency: 60 Hz

Power cable input entrance location: Power box top

2007 vintage.

TEL / TOKYO ELECTRON Indy-B-L is an etcher / asher designed for the semiconductor and compound materials industries. It is an advanced, reliable, and highly precise etch / ashing equipment used to manufacture the finest of materials. TEL INDY B L etcher features a programmable stages system that can perform various functions such as pre-cleaning, degassing, ashing, etching and etch/healing. The pre-cleaning stage is used to remove contaminants from the substrate while the degassing stage removes unwanted gas molecules. The ashing process removes surface atoms, while the etching process removes delicate and hard layers from the substrate. The etch/healing stage is used to reduce the residual stresses on the substrate. The etcher utilizes the advanced AI-based Smart Cooling Unit (SCS) to maintain optimal temperatures for precise etching. TOKYO ELECTRON INDY B-L offers a wide range of specialized etching capability, including deep etch, post-etch unification and low temperature etching. The machine also offers precise surface modification of parts as small as 10 nanometers, making it ideal for high-end applications such as MEMs and LSI devices. The etcher is also fully automated and can be operated through its simple touch-panel interface. TOKYO ELECTRON INDY B L also offers comprehensive safety features to ensure the protection of its operators and the surrounding environment. It is equipped with a highly sophisticated built-in Vacuum Leak Detection Tool (VLDS) to identify any potential leaks. It also features a Standardized Gas Supply Asset (SGSS), where gases are only supplied through the model if safety conditions permit. Finally, the Innovative eco-friendly Cooling Equipment (KIECS) conserves energy by automatically reducing gas consumption during pauses in the operation. Overall, Indy-B-L is a sophisticated etcher/asher designed for high-end applications in the semiconductor and compound materials industries. It features advanced features such as the SCS, VLDS, SGSS and KIECS, and offers precision etching down to the nanometer-scale. Its safety features ensure optimal safety conditions and its sophisticated touch-panel interface make it easy to operate.

There are no reviews yet