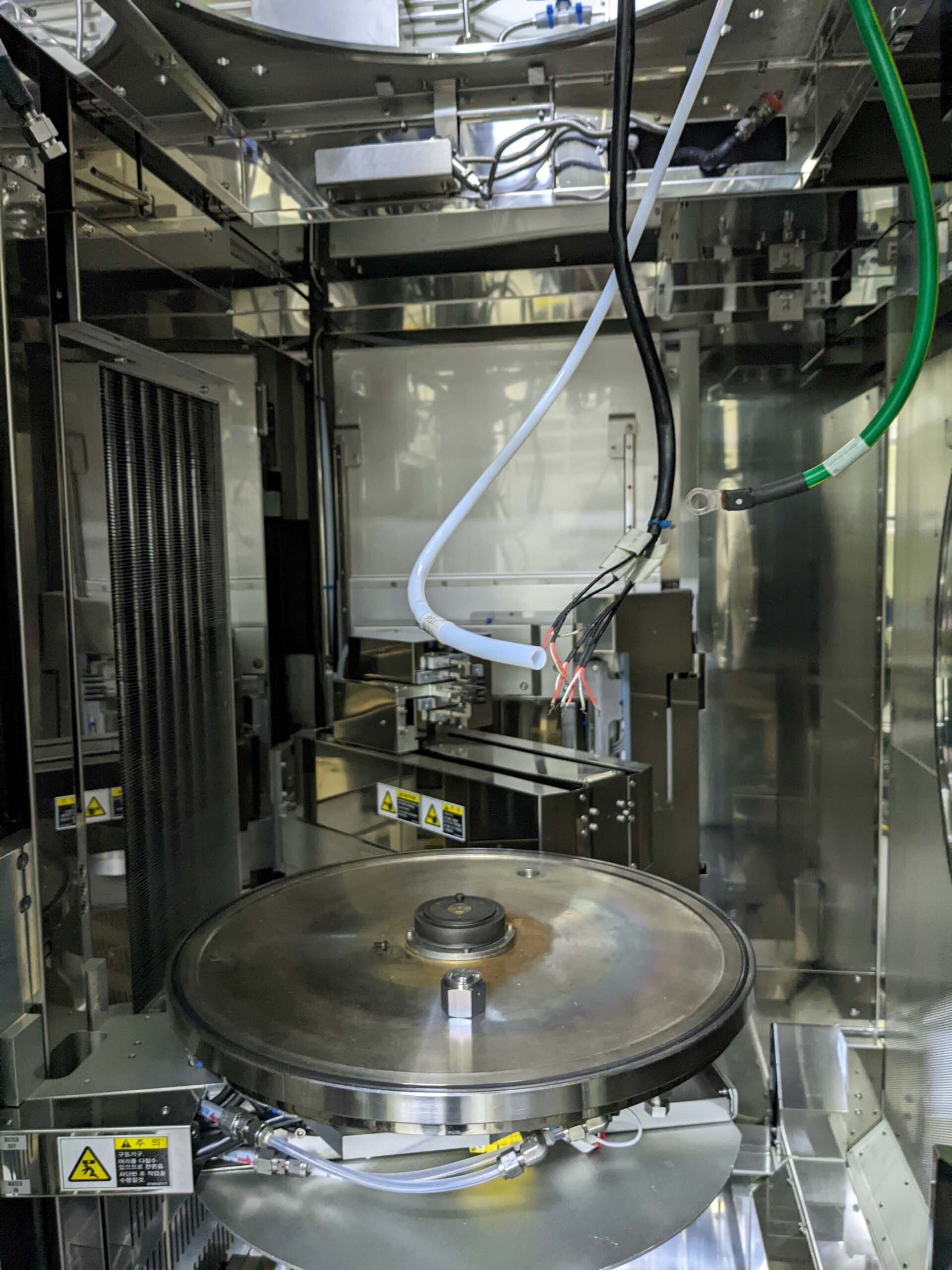

Used TEL / TOKYO ELECTRON Indy-B-L #293637436 for sale

URL successfully copied!

Tap to zoom

ID: 293637436

Wafer Size: 12"

Vintage: 2009

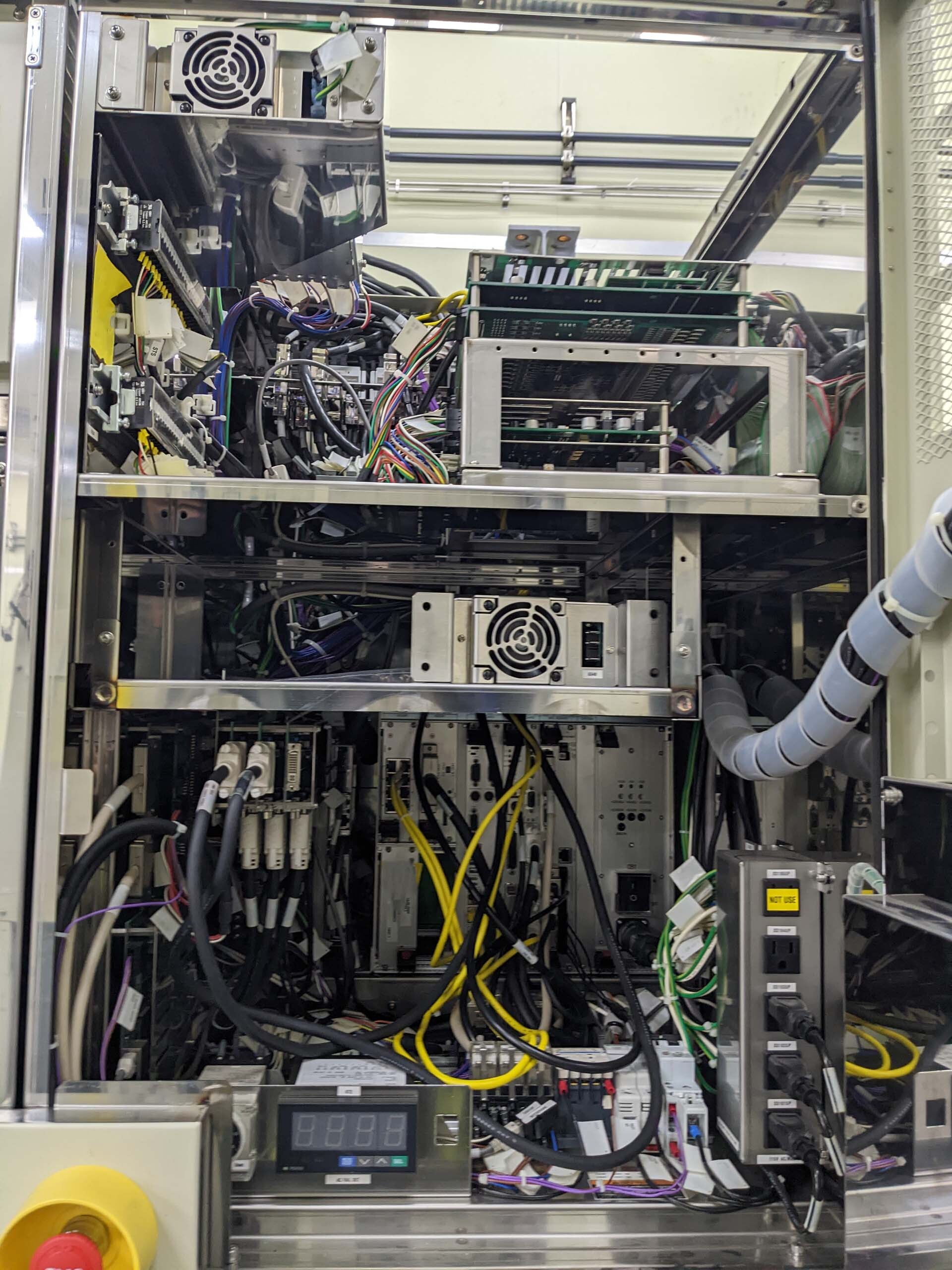

LPCVD Furnace, 12"

Wafer type: Si semi STD Notch

(100) Production wafers

Maximum operating temperature: 500-1000

N2 Load lock

Boat type handling position

O2 Density control for N2 Load lock

N2 Boat shower wafer cooling

560A Furnace temperature controller

VMM-56-002 Heater

Wafer / Carrier handling:

(25) Carrier type: FOUP

ENTEGRIS A300

Carrier stage capacity: 16

Pin pad A, B

Fork material: Al203 and peek

W/T Type: 1+4 Edge grip

W/T Auto teaching

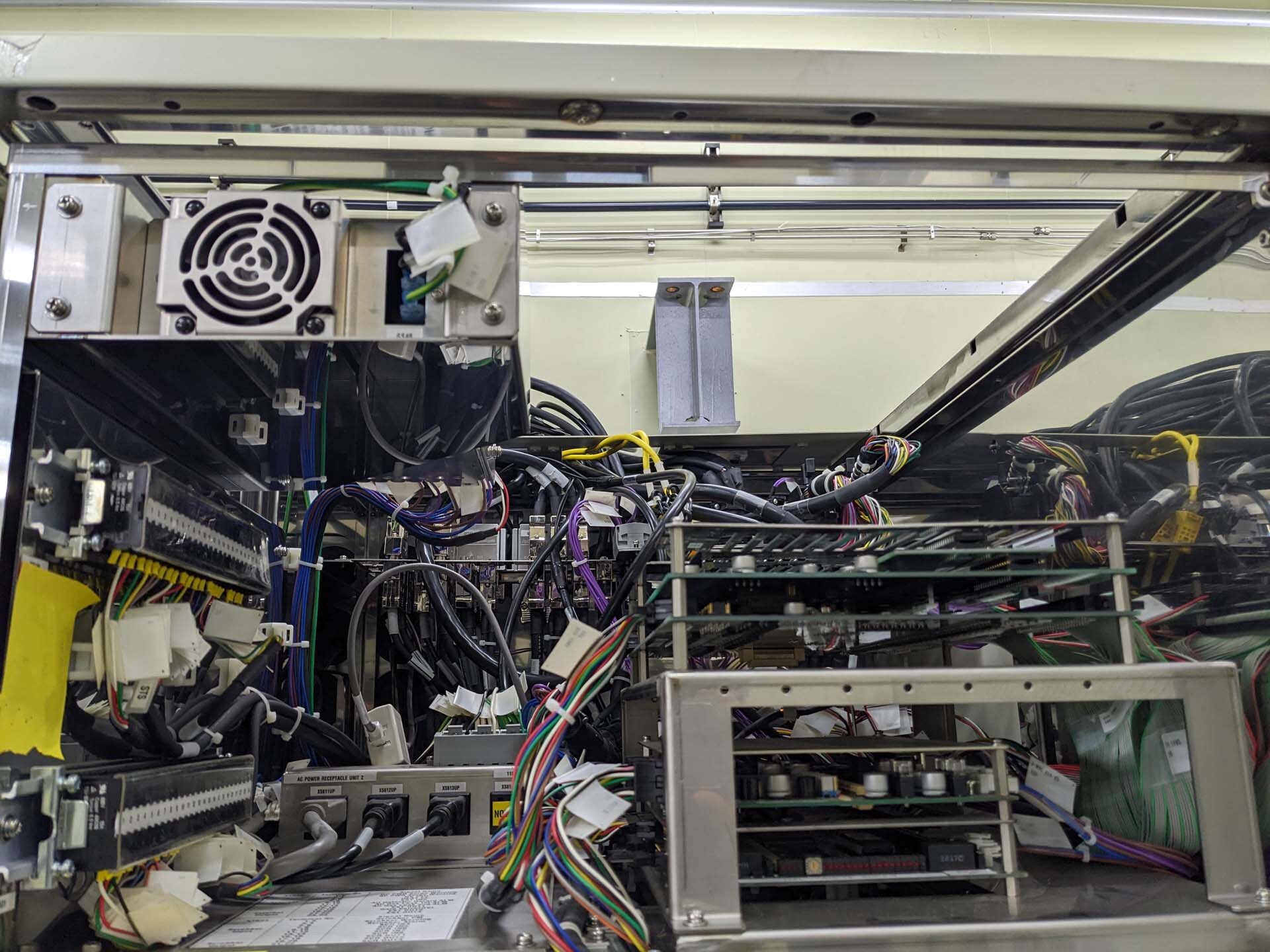

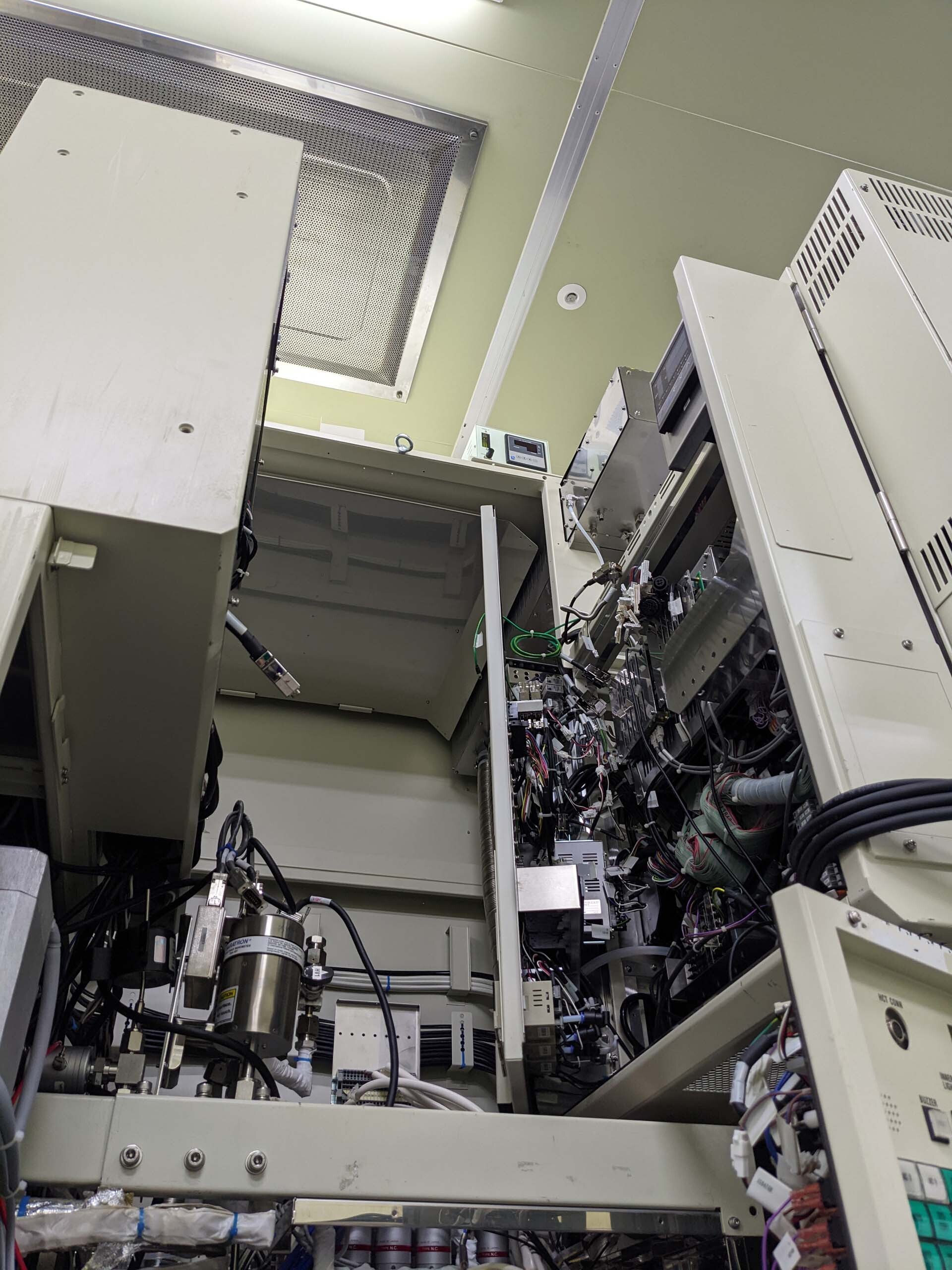

Furnace facilities:

Furnace exhaust connection point: Top connection

Cooling water connection point: Bottom connection

Gas specification:

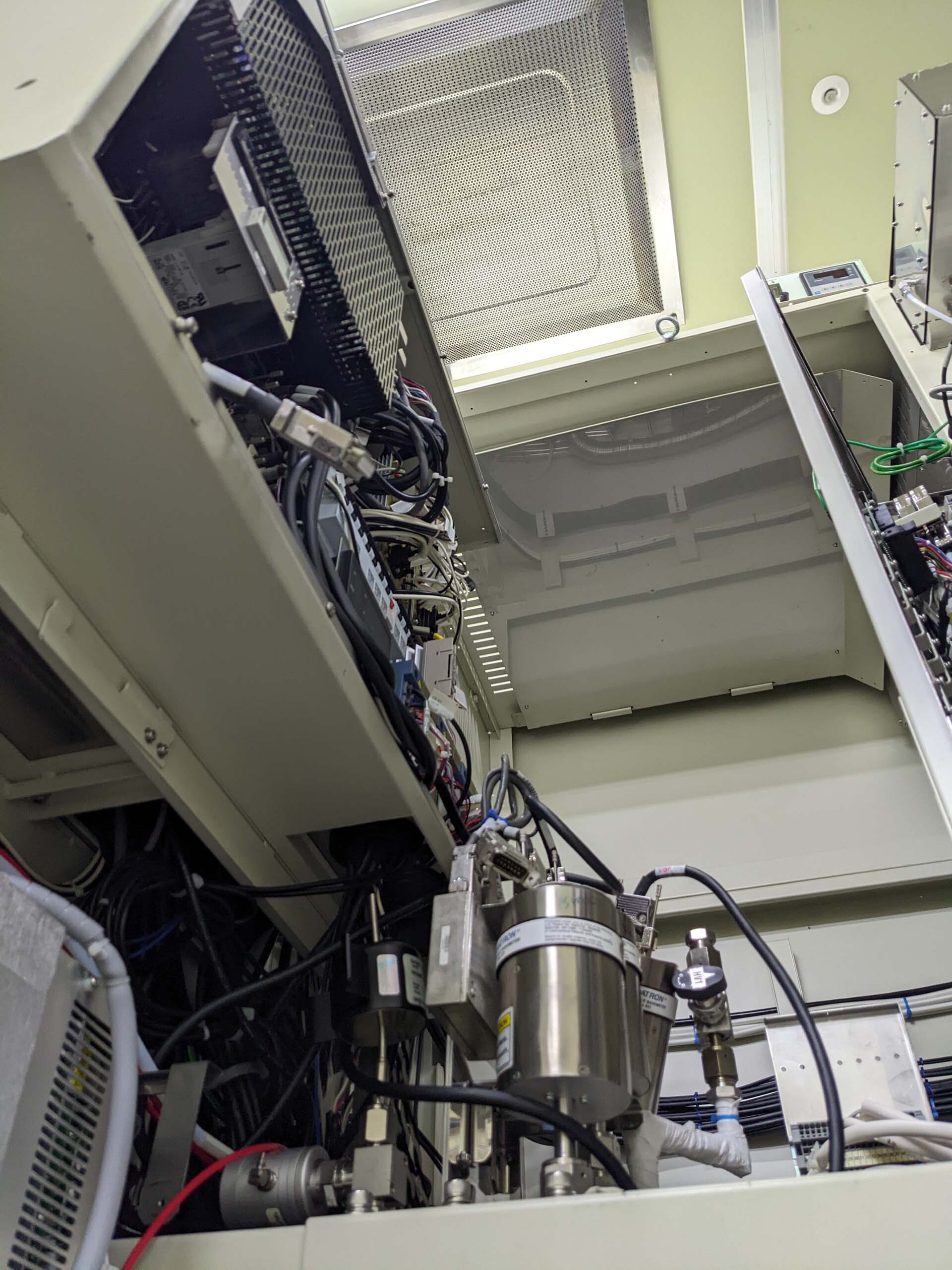

IGS 1.5" W-seal rail-mount

FUJIKIN IGS

Tubing bend bend (Less than 90°)

HORIBA STEC

Incoming gas connection point: Bottom connection

Gas vent connection point: Bottom connection

Gas unit exhaust connection point: Bottom connection

Process gas exhaust connection point: Bottom connection

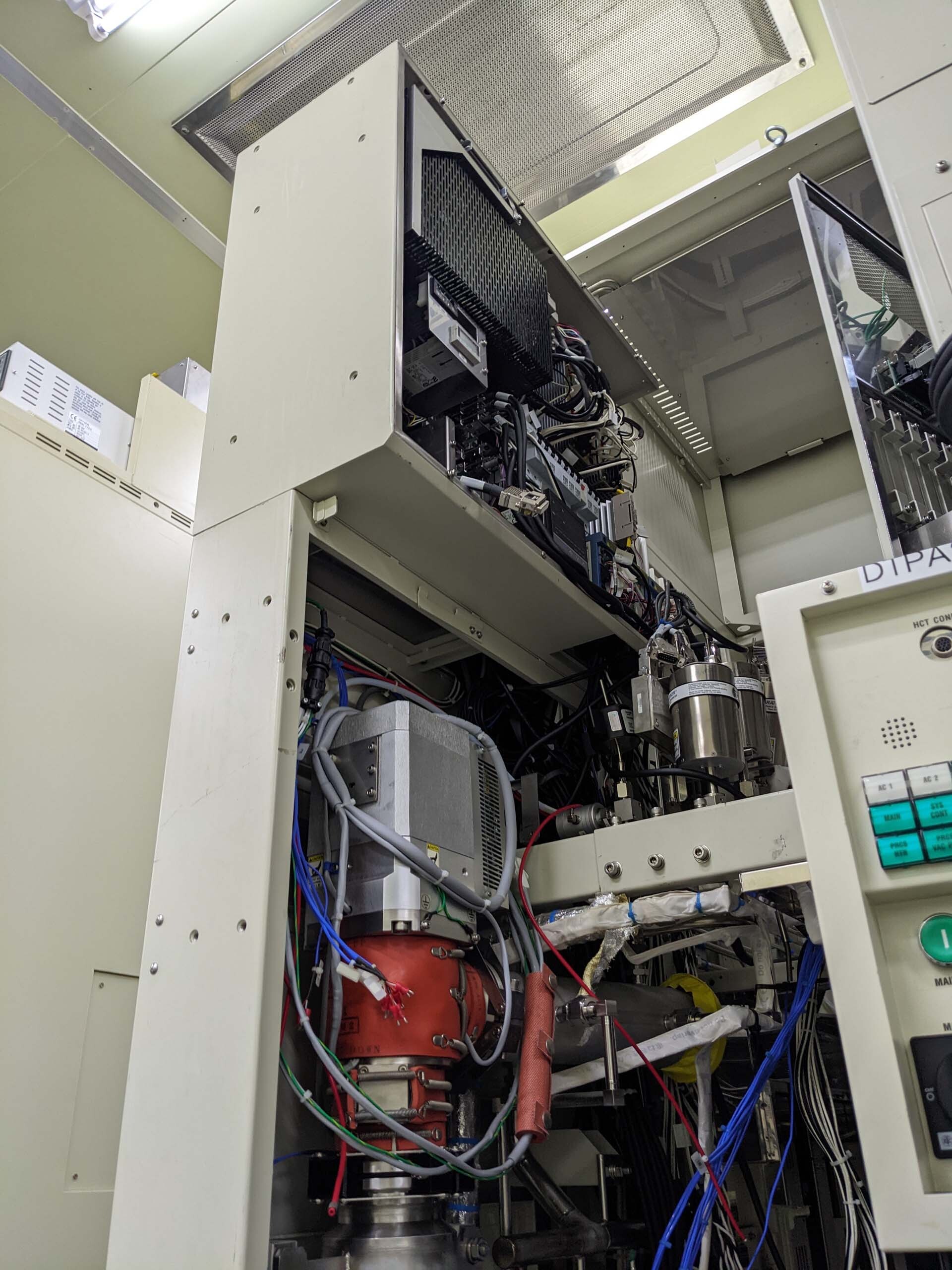

Exhaust specification:

MKS Vacuum gauge-press controller

MKS Vacuum gauge-press monitor

MKS Vacuum gauge-pump monitor

CKD-VEC Main valve

Condenser

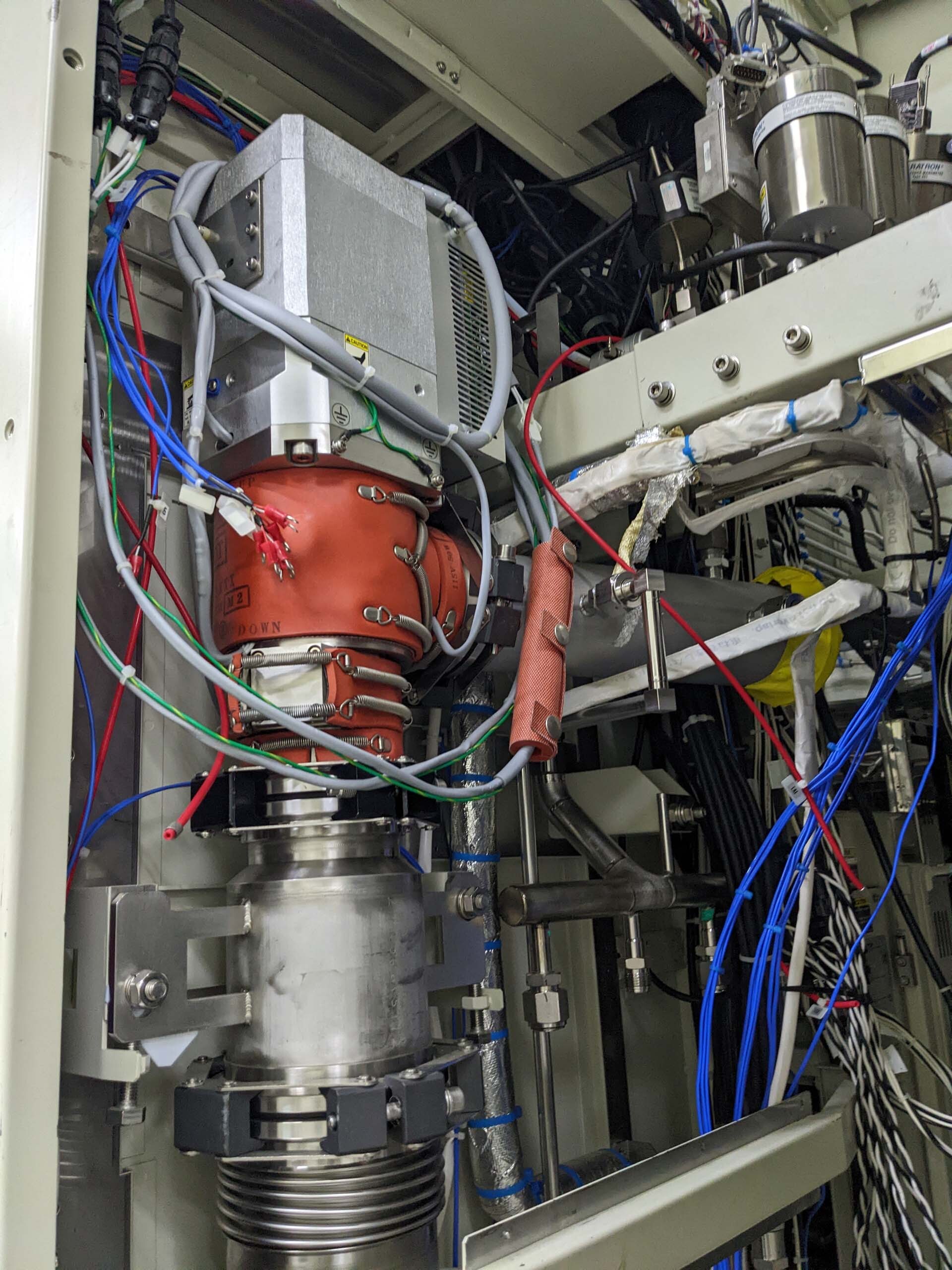

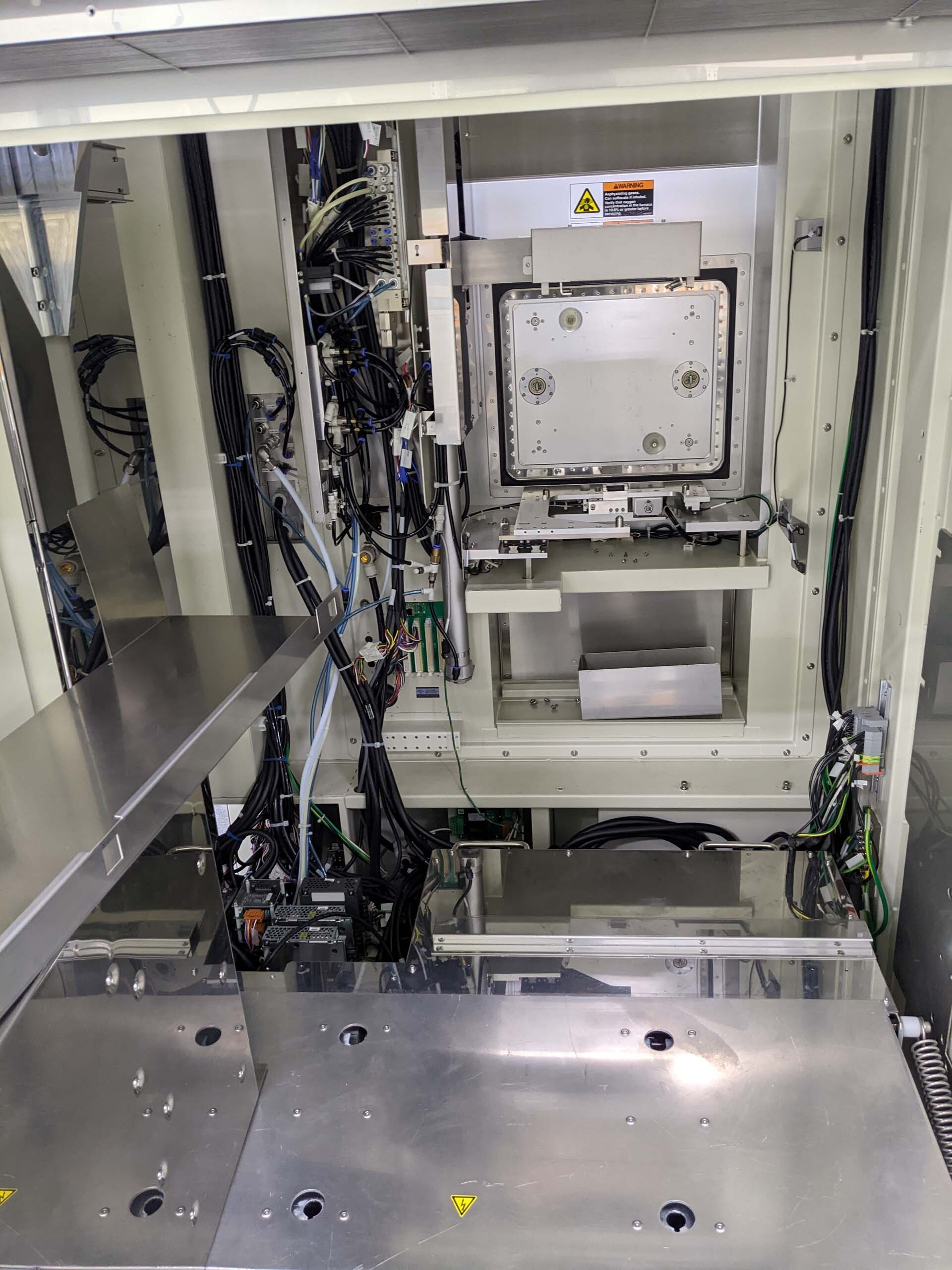

Reactor specification:

Tube material: Quartz (outter), quartz (inner)

Inner tube Type (LP): Straight

Inner T/C: Outer tube inferior (wall type)

Tube sealing: O Ring

Soft backfill injector

Boat type: (117) Slots, pitch, 8 mm

Boat rotation

Pedestal type: Quartz

No shutter purge type

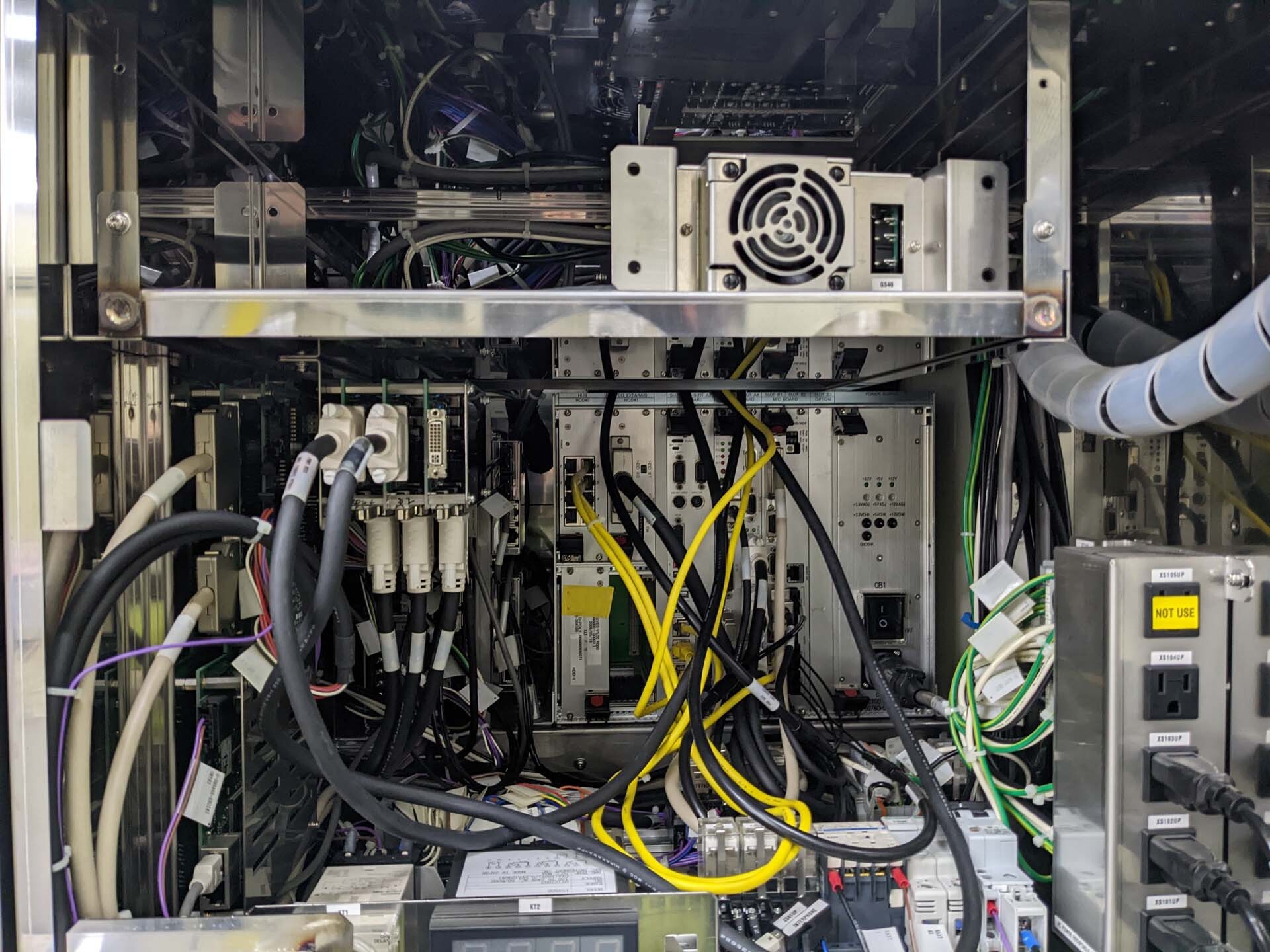

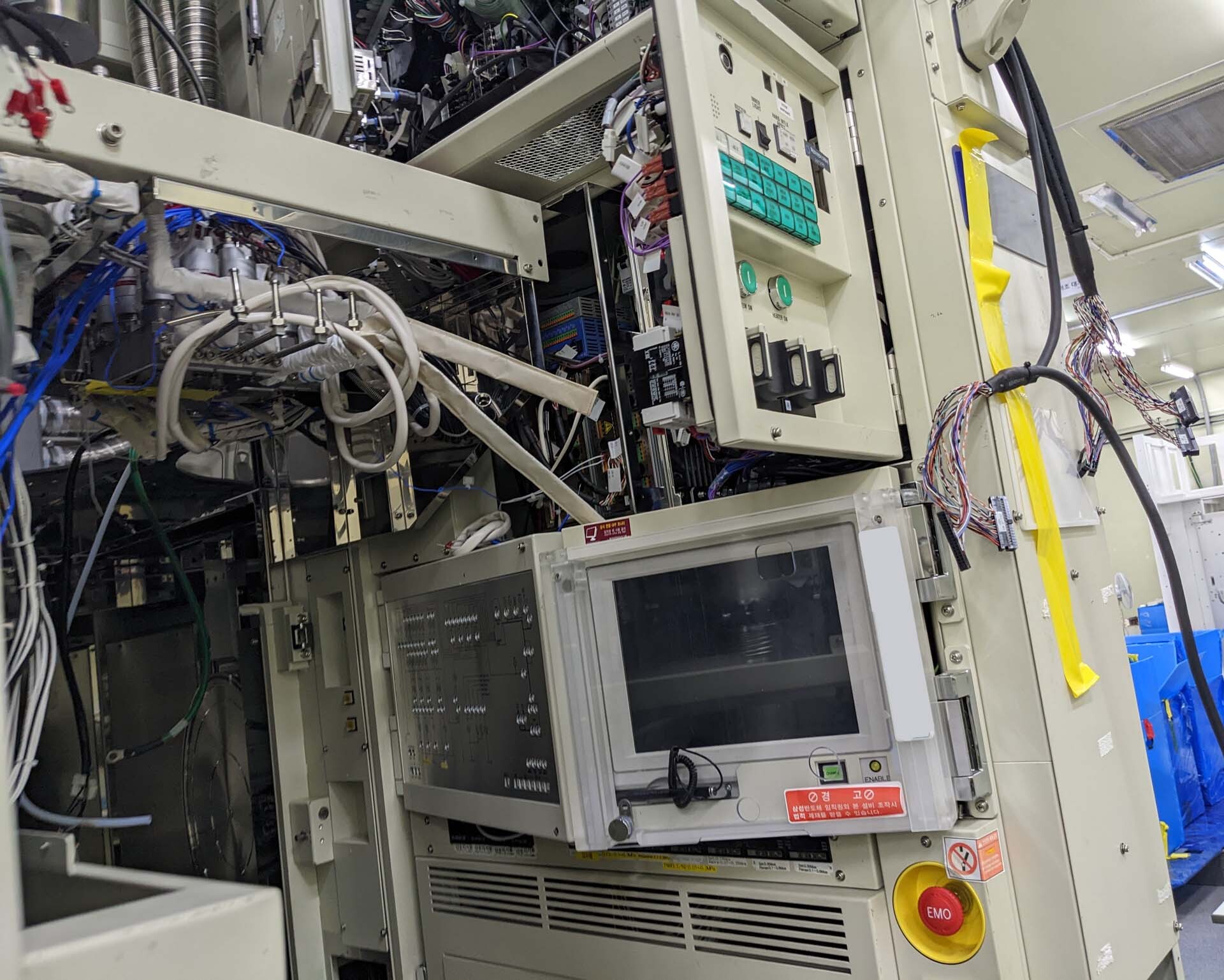

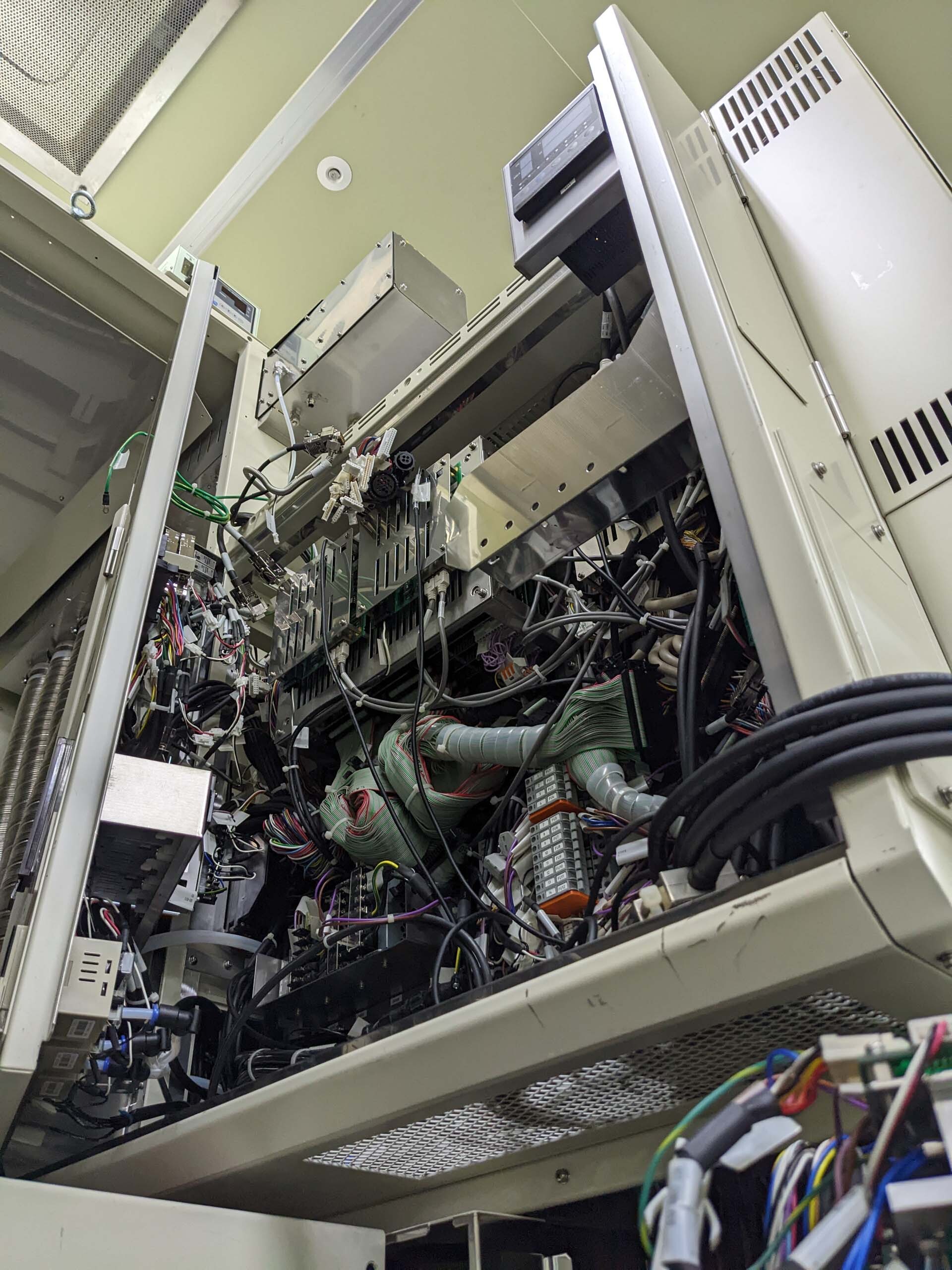

Interface specification:

Host communication: Comply with GJG

Equipment host I/F connection: Gas box top HSMS

Ingenio

OHT Capability

Load port operation: Upper

PIO I/F Location: FNC Top

HOKUYO DMS-HB1-Z PIO

RF Carrier ID reader writer type

CIDRW L/P: Read and write

ASYST ATR 9100 CIDRW

TEL CIDRW

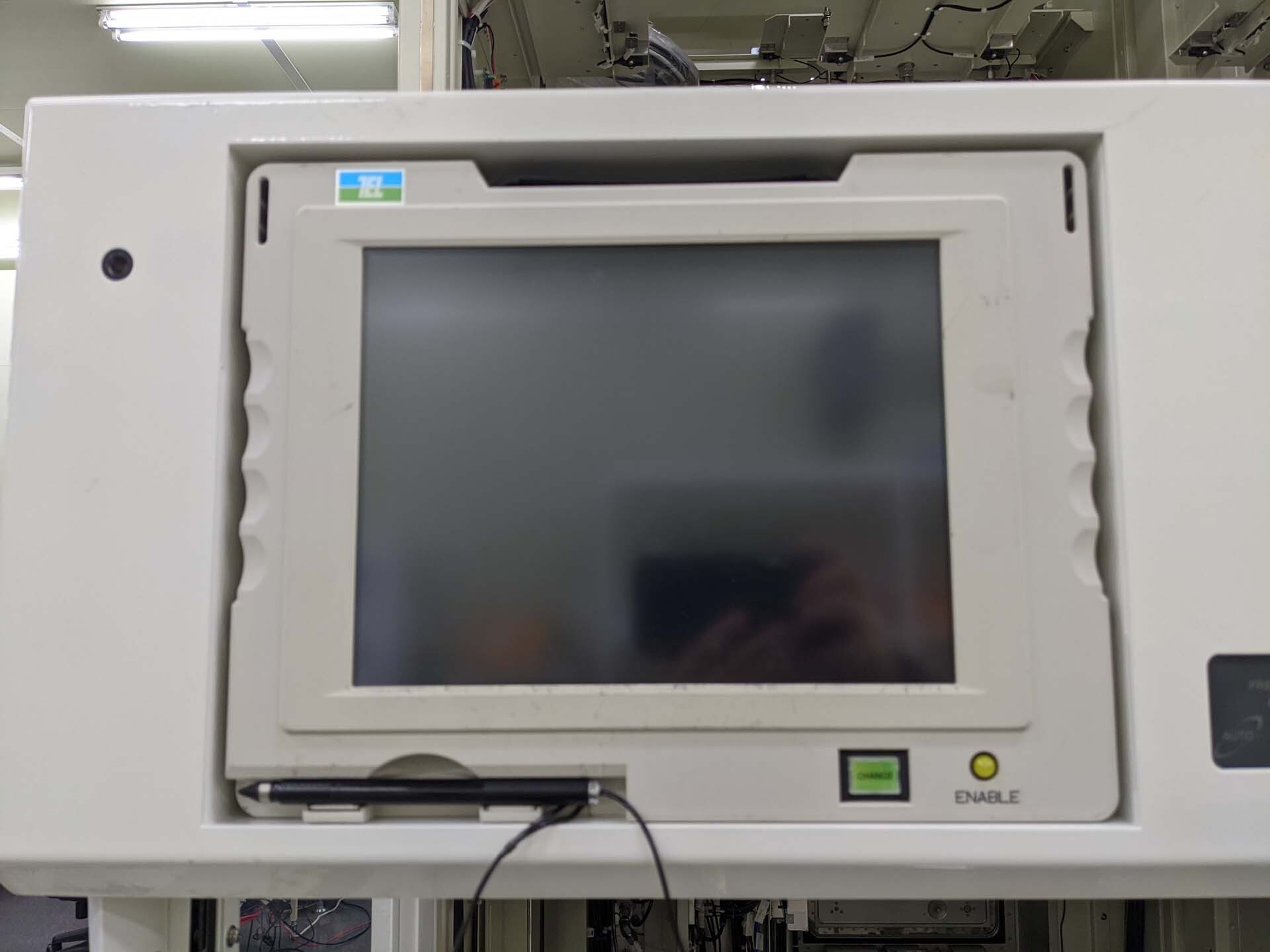

User interface

Signal tower model: Customized

Signal tower colors (From the Top): Red / Green / Yellow

Signal tower location: Front

Front operation panel

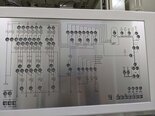

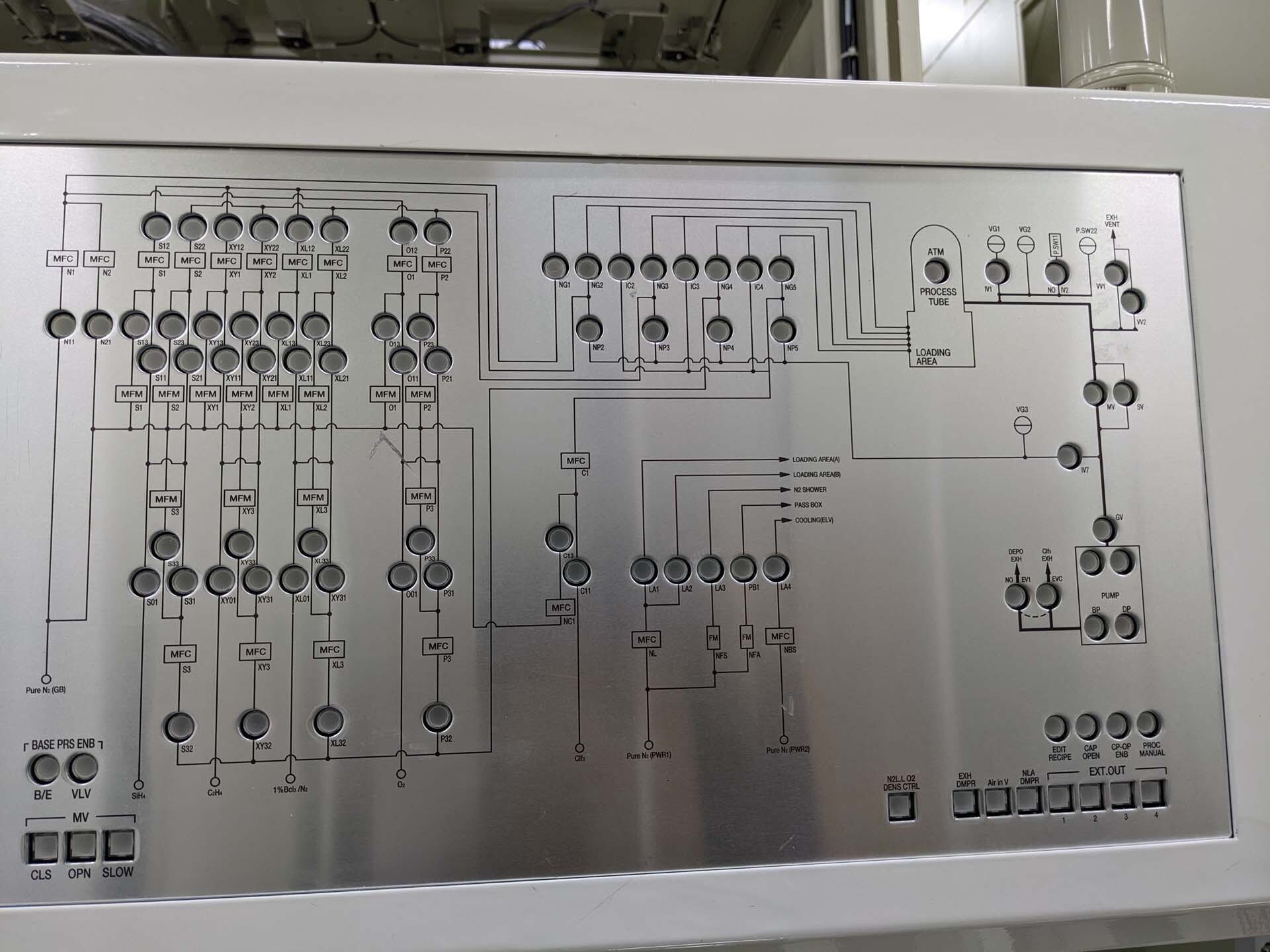

MMI and gas flow chart: Gas box and front operation panel installed

Indicator type: Superset

Operator switch: Operator access / orange

Pressure display unit (gas inlet / vacuum): Mpa / Pa

Cabinet exhaust pressure display unit: Pa

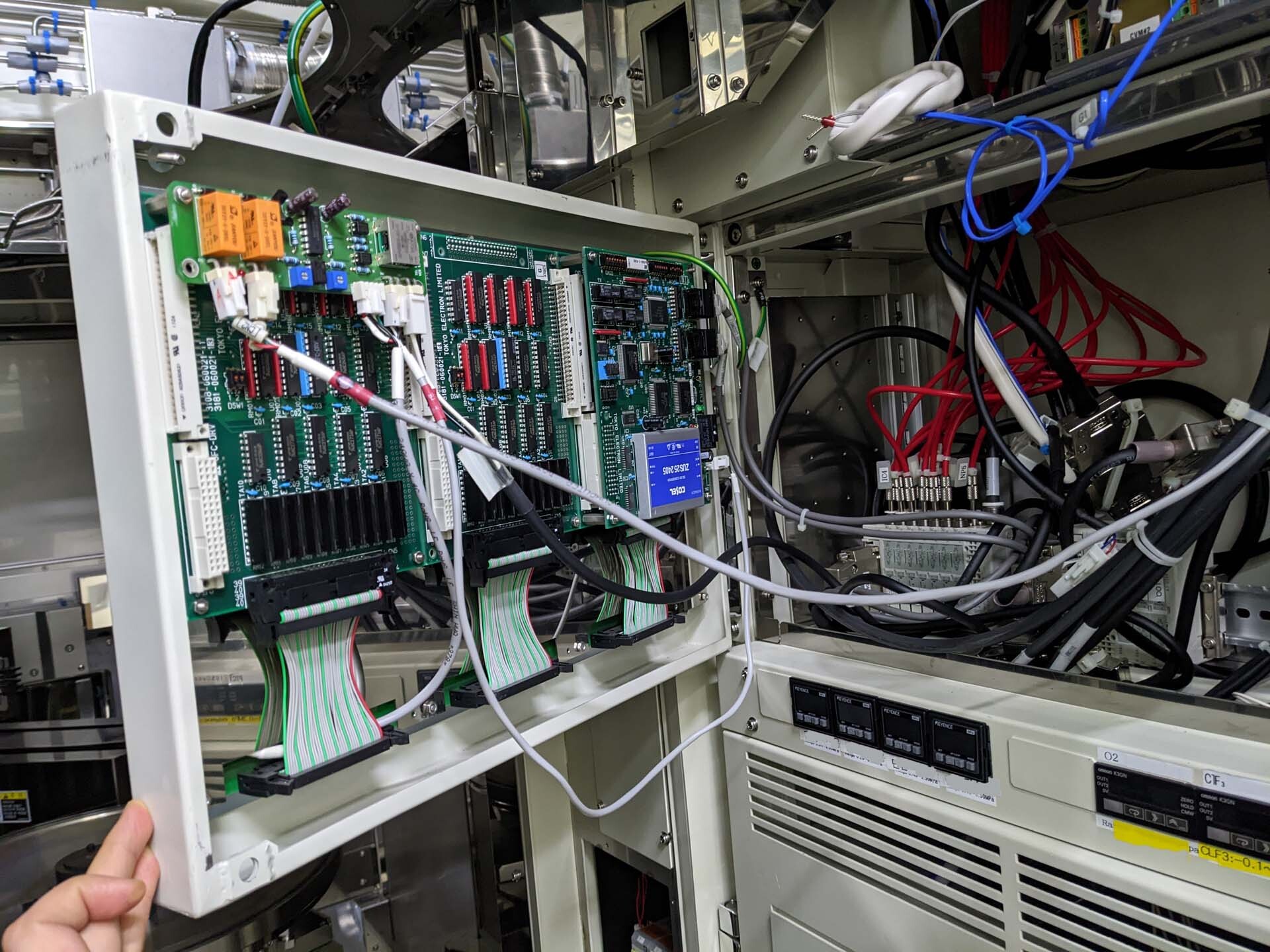

Gas leak detector:

Gas1 / SiH4

Gas2 / PH3

Gas3 / ClF3

Cable length:

FNC-Power box: 20 meter

Power box -refill system: 30 meter

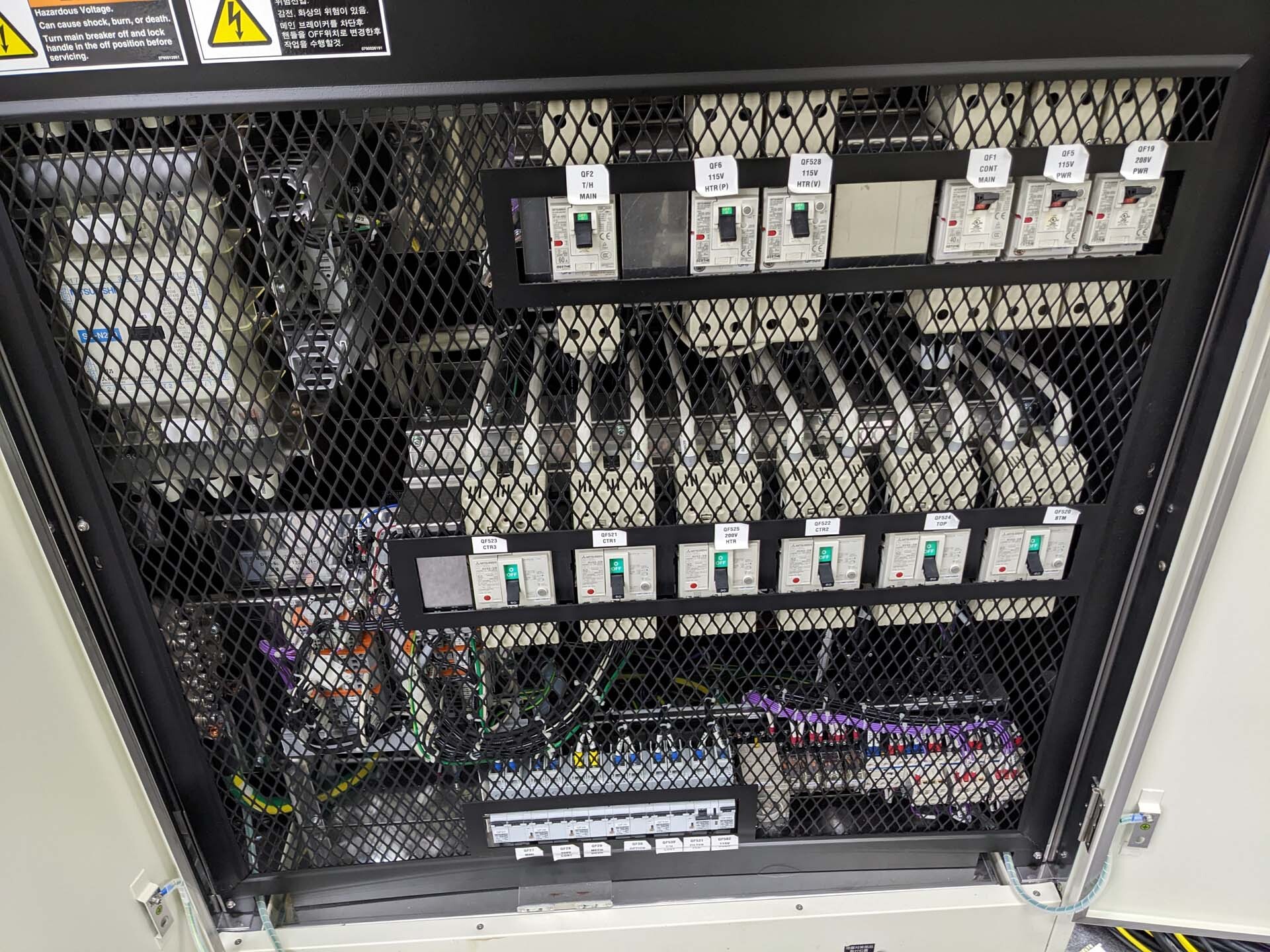

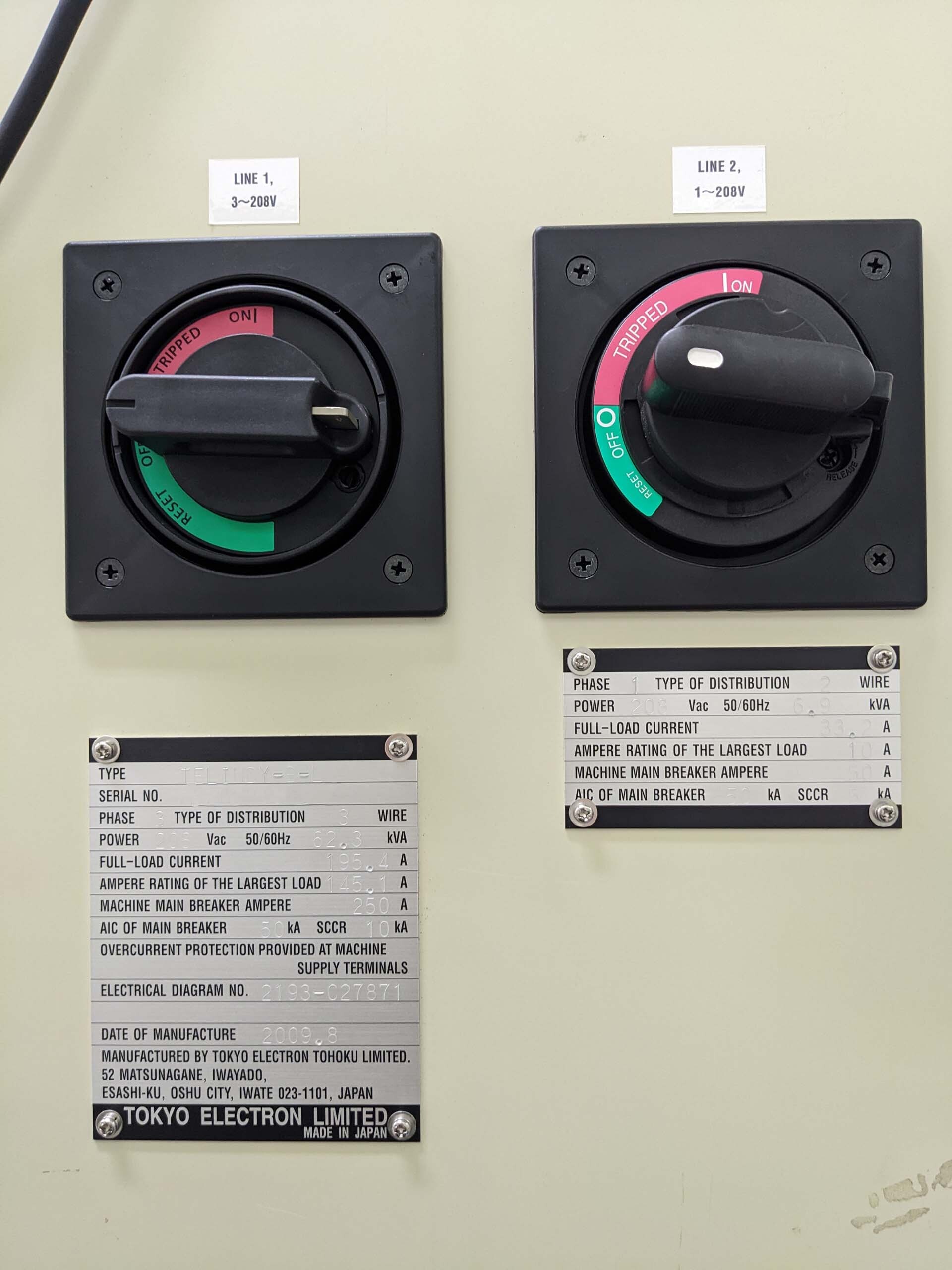

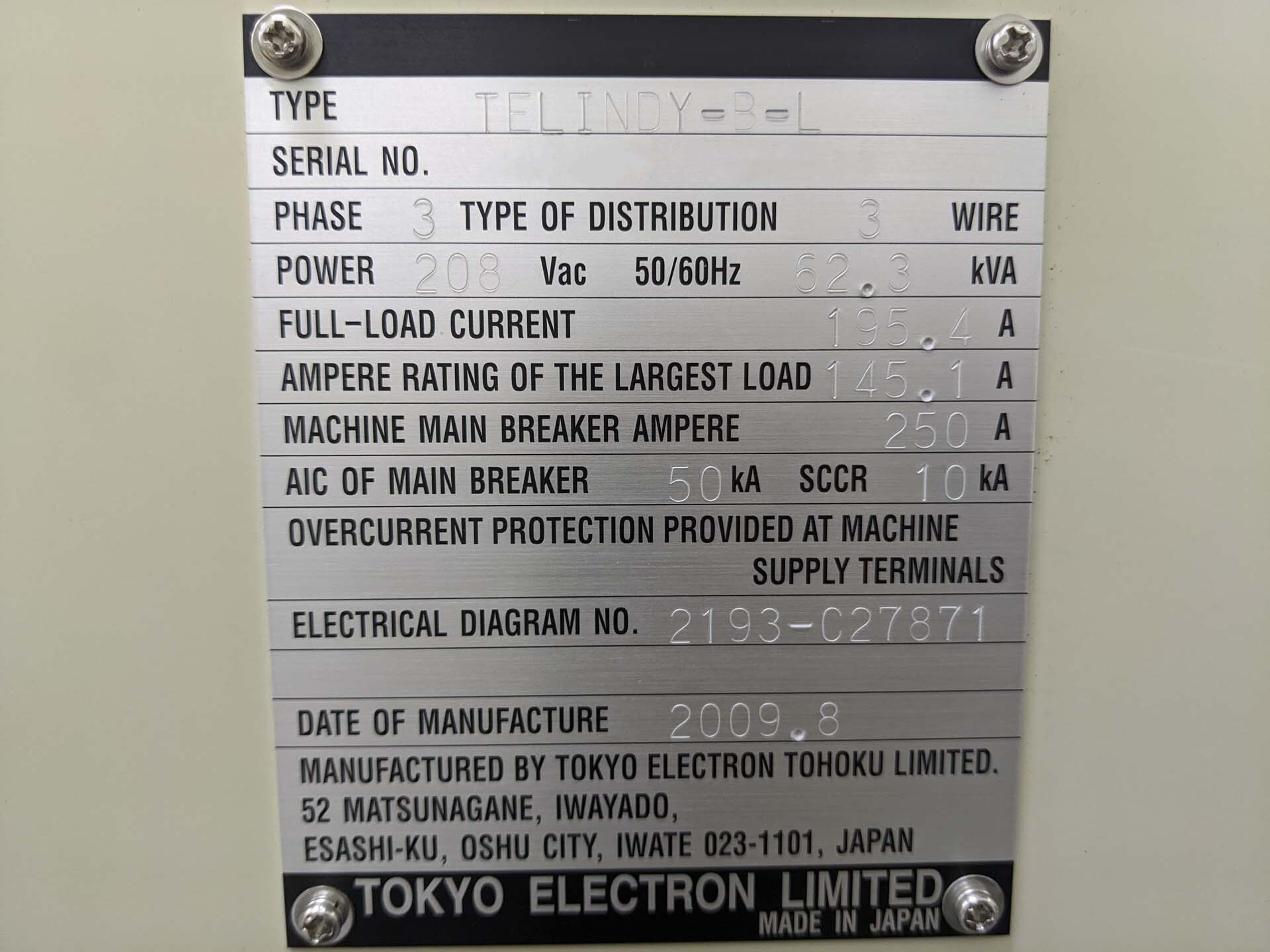

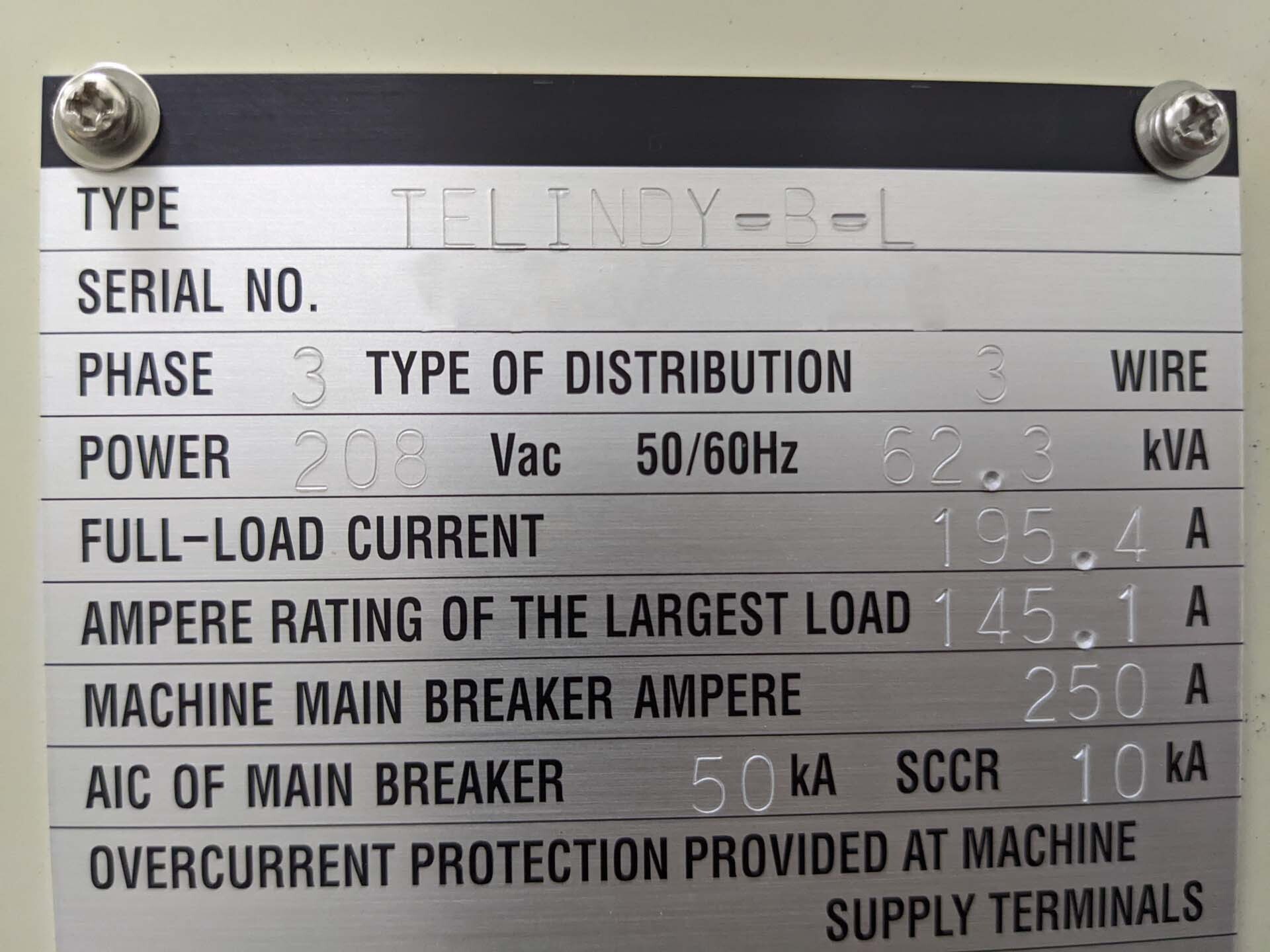

Power specification:

Voltage: 208 VAC, 3 Phase

Phase connection type: Star connection

Voltage single-phase: 120 VAC

Single-phase connection type: Grounded

Frequency: 60 Hz

Power cable input entrance location: Power box top

2009 vintage.

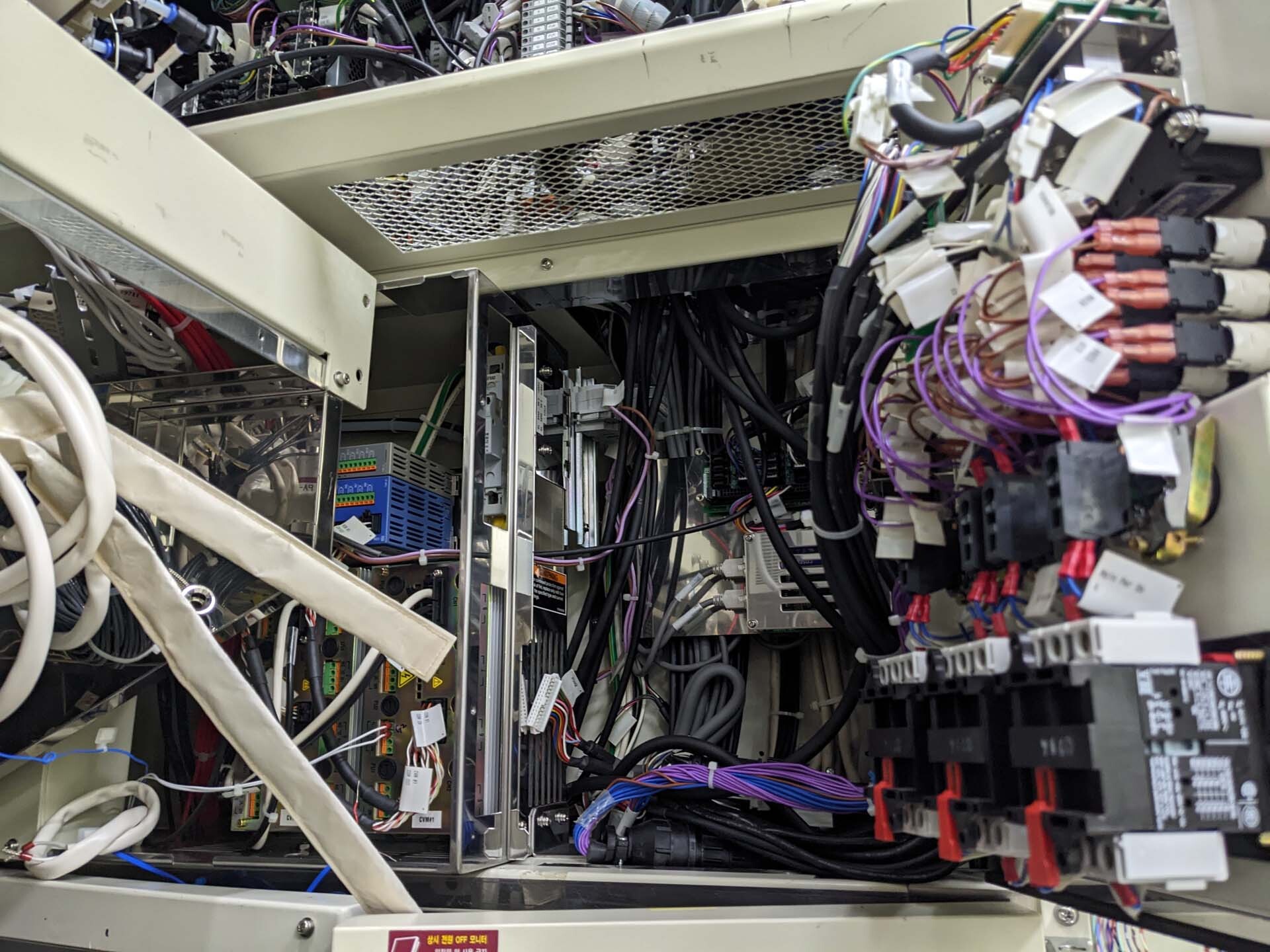

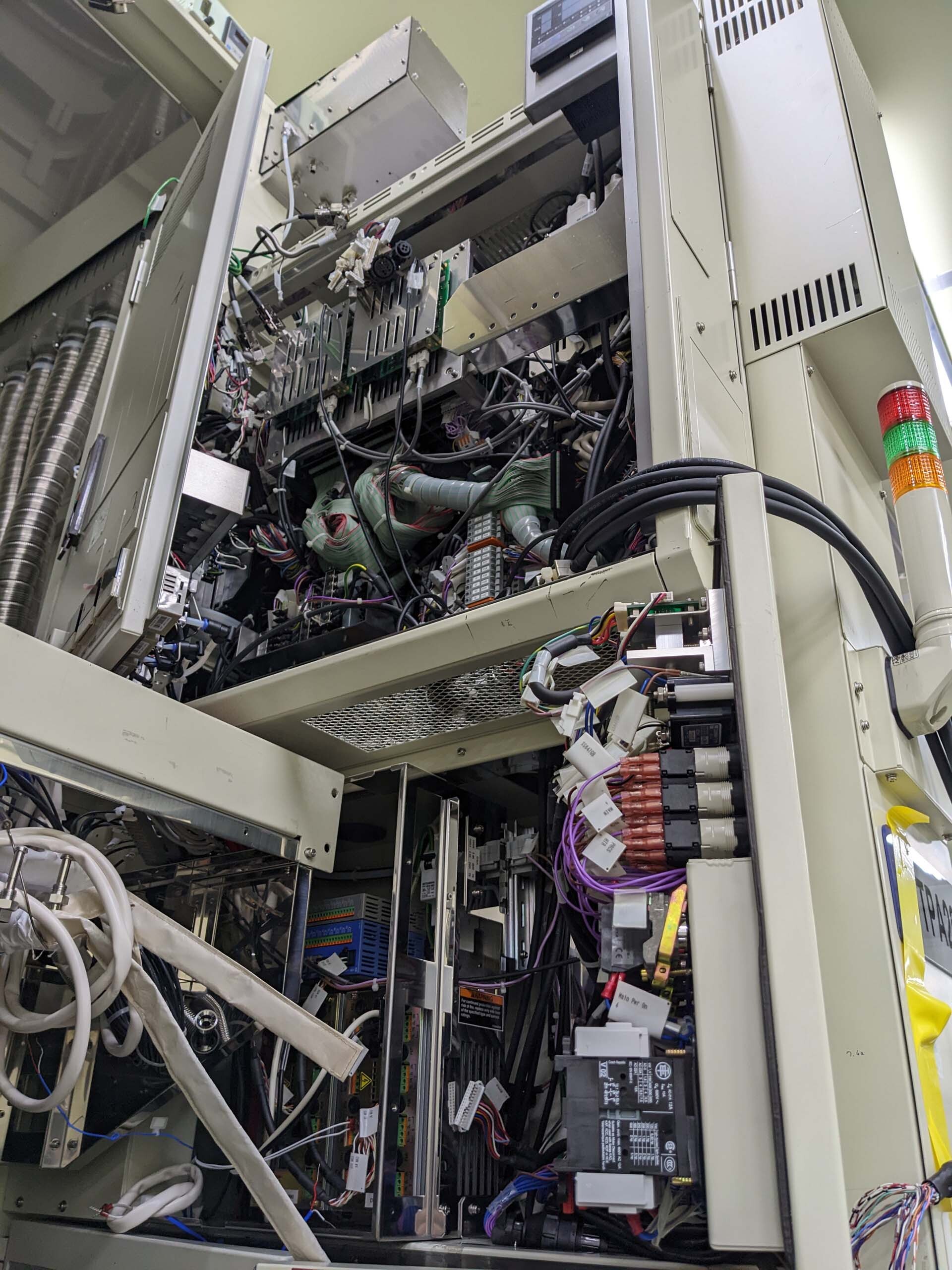

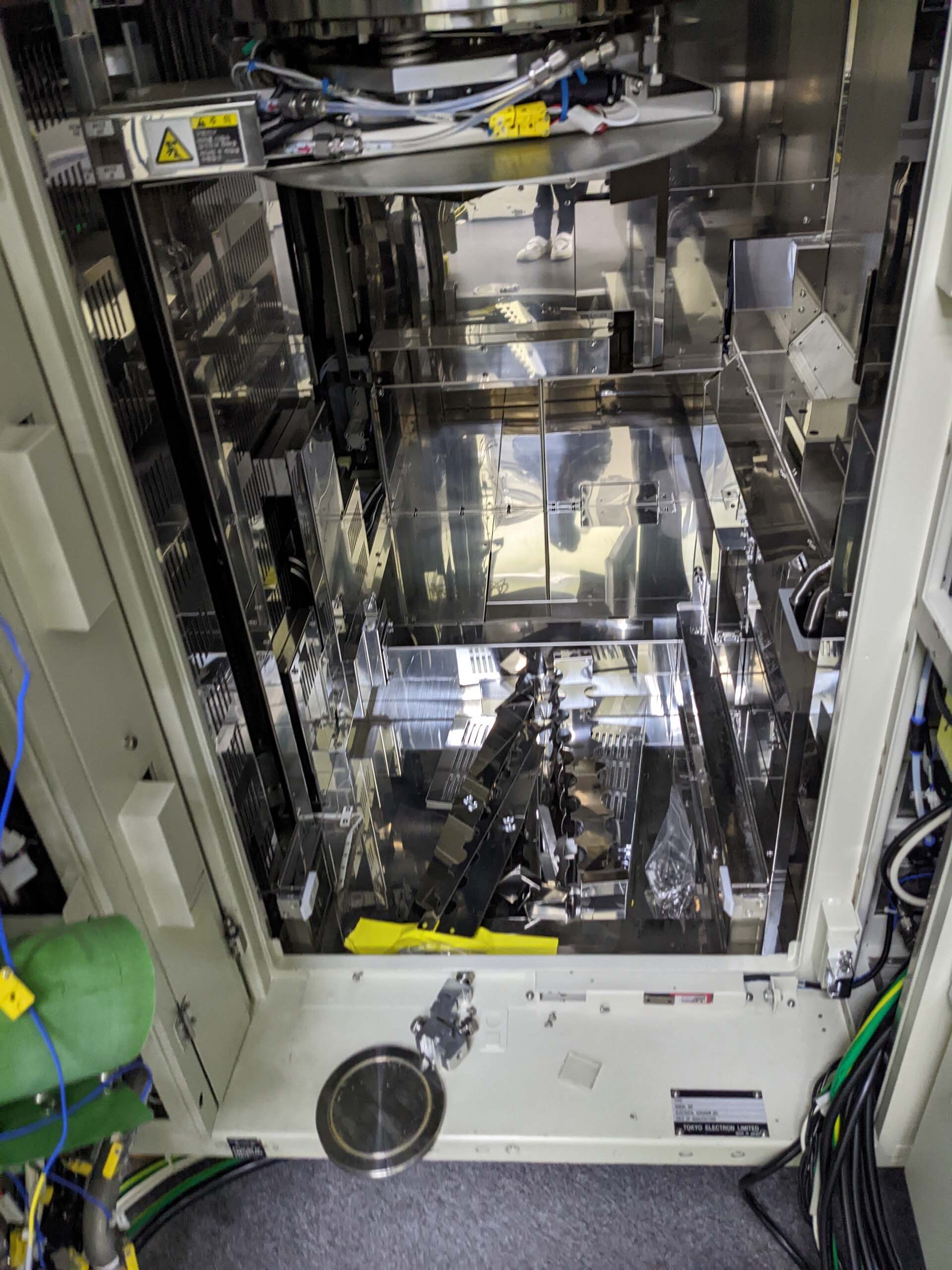

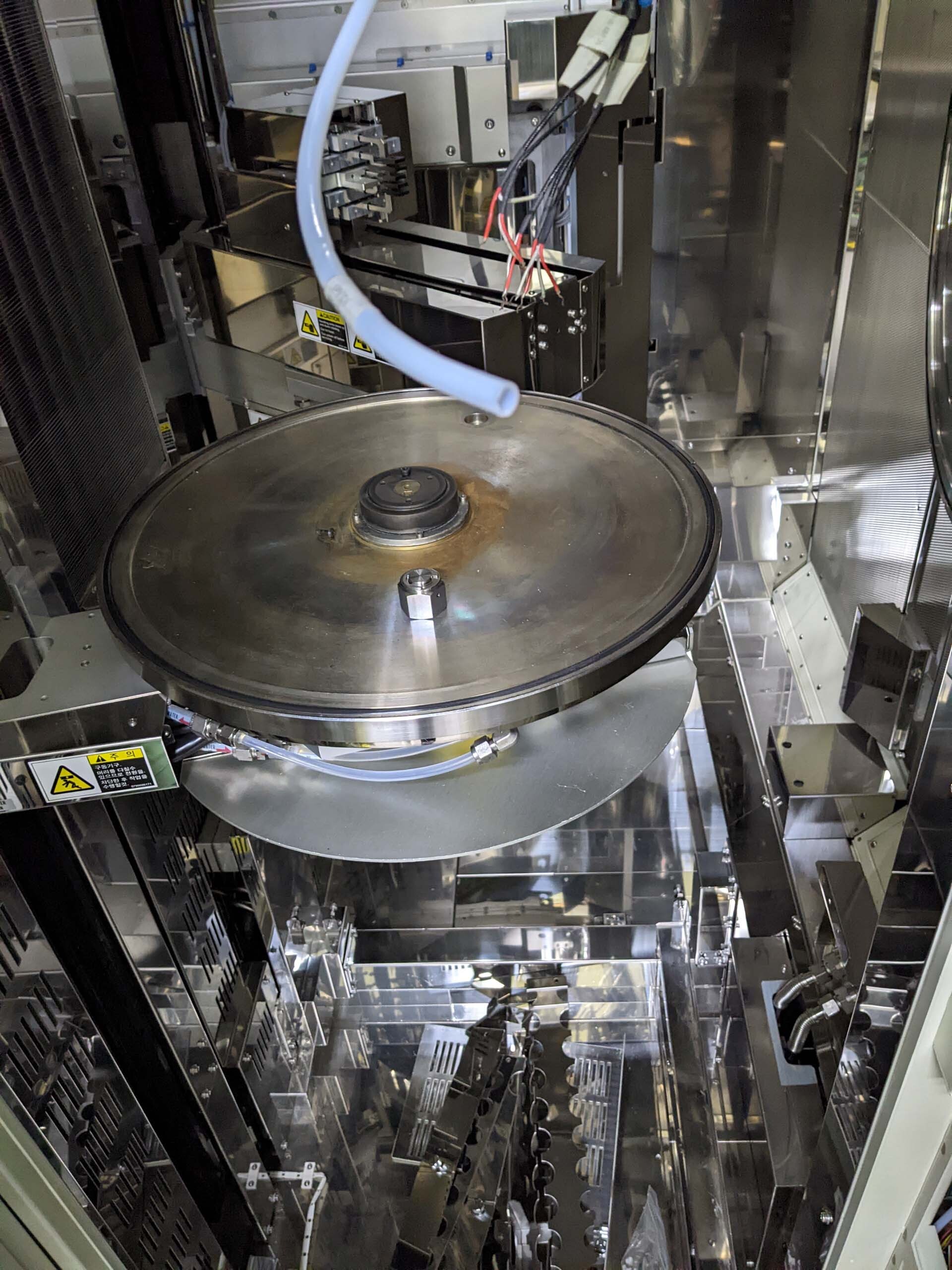

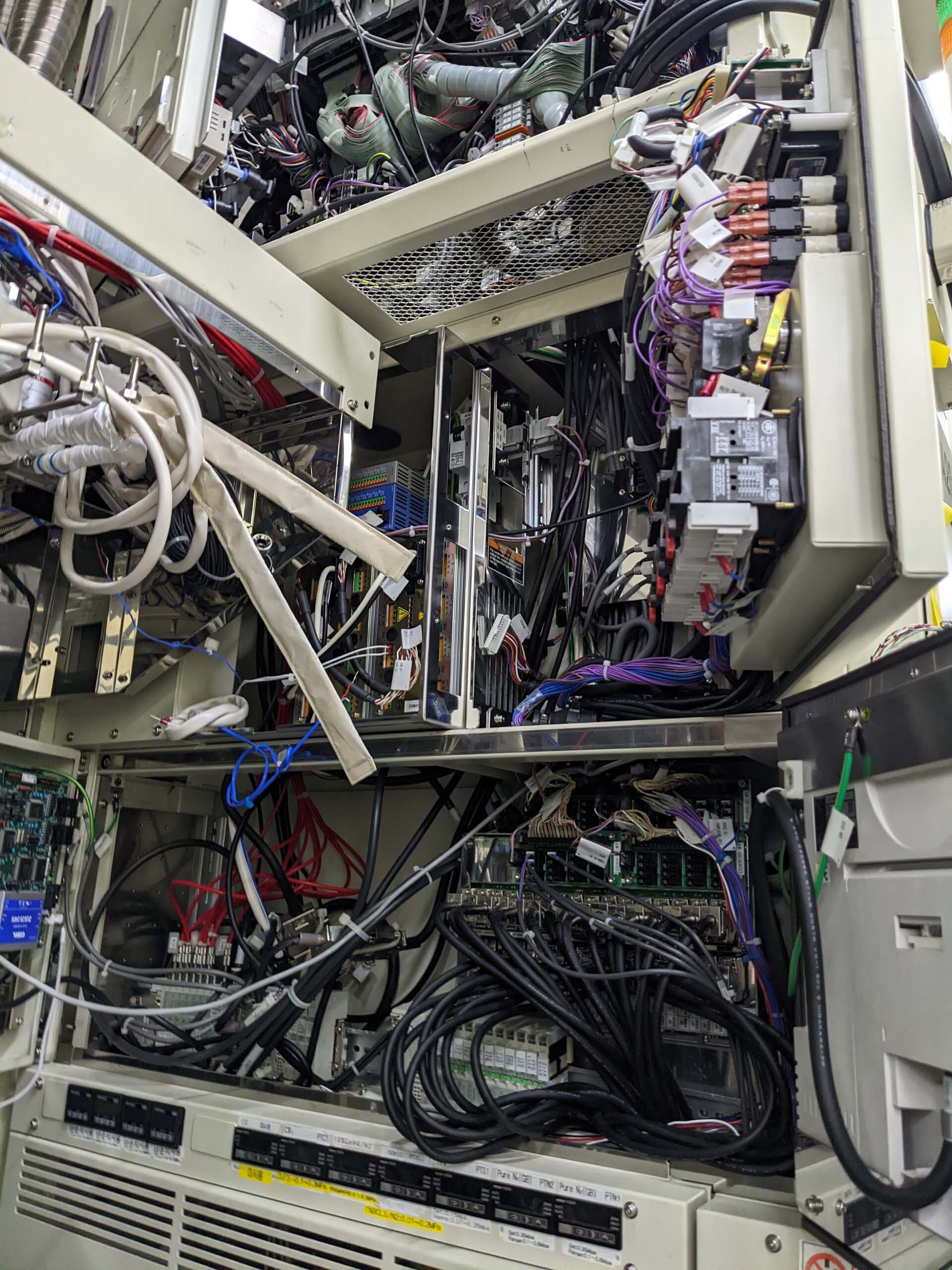

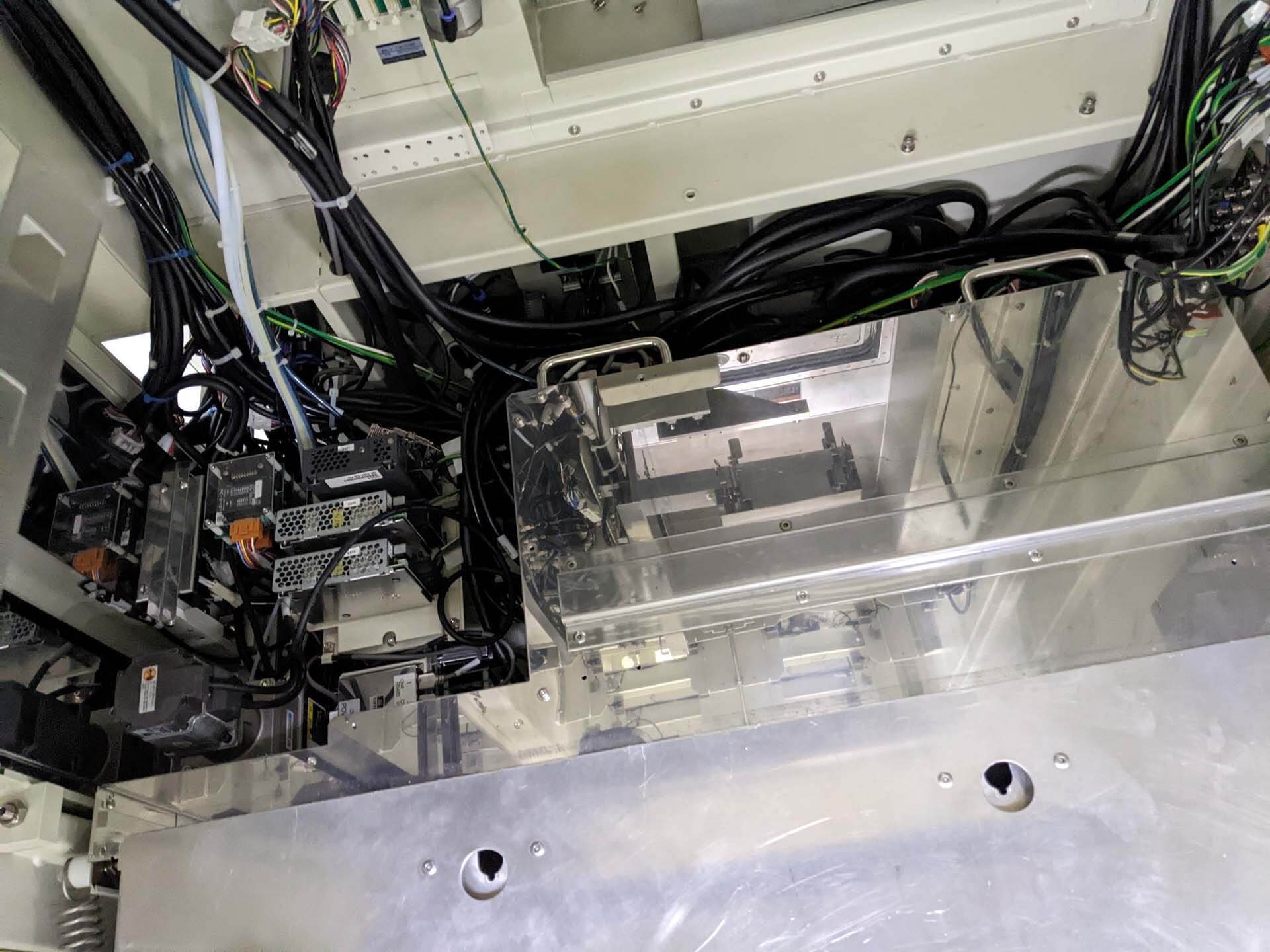

TEL / TOKYO ELECTRON Indy-B-L is an indoor wafer etcher/asher creating thin oxide films on semiconductor wafers. It is a high performance, medium-throughput, single-chamber dry etching equipment. The system is fully automated with an operator's interface providing users with a user-friendly process control and optimization. TEL INDY B L unit is capable of performing both etching and ashing processes for a large variety of applications such as CoO, AlOx, ITO, and others. Inside TOKYO ELECTRON INDY B-L there is a 5 layer Quartz chamber, adjustable pressure pipes, and 4 independently controlled jet N2 purge outlets. The pressure is monitored and controlled by the components inside the control rack; a sensor sends readings both outside and inside the chamber. The N2 purge outlets and parameter setup in the etcher/asher enable precise and complete exhaust of the reaction gas for residue free wafers. TEL Indy-B-L has a chamber maximum size ranging from 200 mm to 8 inches with the highest temperature processing of up to 400°C. High-density, ECR plasma is generated by the magnecreons which can be individually adjusted in order to achieve high quality results with a low load level and excellent matching characteristics across the rotation axis. The ECR source plasma offers improved uniformity in active layer etching at higher etching rate and better selectivity than traditional arc sources. INDY B-L is also equipped with an absorbent filter that automatically changes color in order to indicate the degree of contamination. This feature is useful for maintaining a consistent quality in both batch and single wafer processes. The absorbent will absorb and collect dust particles from the etching or ashing process, preventing it from entering the machine and contaminating the wafers. The programmable wafer-handling robot and transfer arm included with TEL / TOKYO ELECTRON INDY B L allows for batch and single wafer processing. It also provides an easy, safe wafer handling for a single operator. Additionally, there is a wafer detecting laser tool that makes sure the robot stays calibrated and reaches the optimal position when transferring and etching the wafers. TEL INDY B-L with its ECR plasma source and precise oven setting provides repeatable etching/ wiring with low uniformity errors, excellent process control and a low maintenance cost. It is a highly reliable asset with simple and intuitive user interface controls and alert functions, ideal for batch and single wafer processing applications.

There are no reviews yet