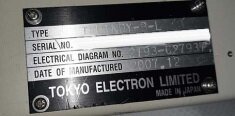

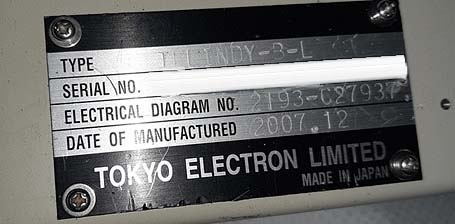

Used TEL / TOKYO ELECTRON Indy-B-L #9244878 for sale

URL successfully copied!

Tap to zoom

ID: 9244878

Wafer Size: 12"

Vintage: 2007

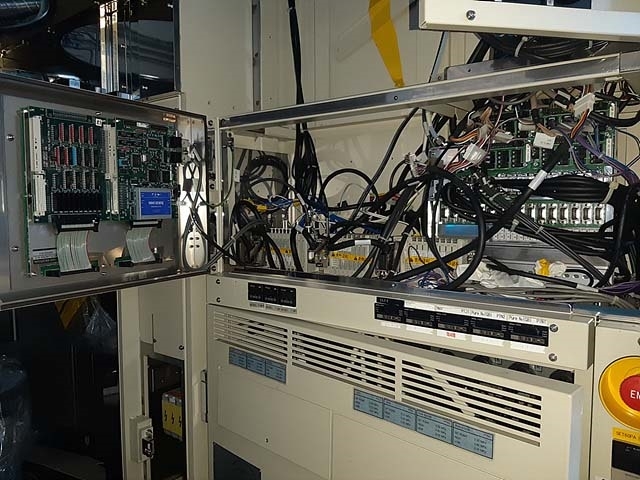

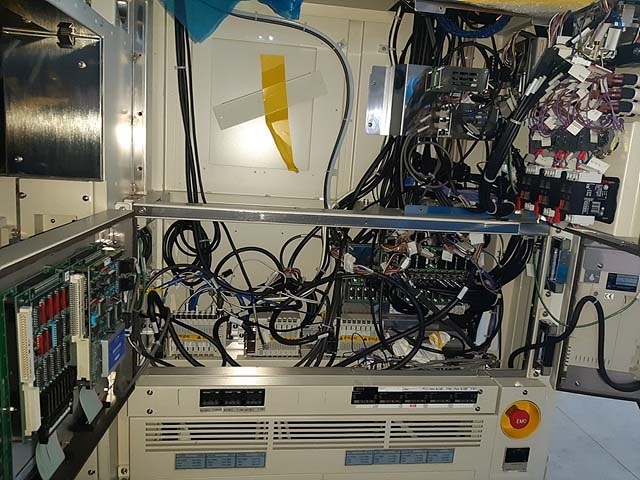

Diffusion furnace, 12"

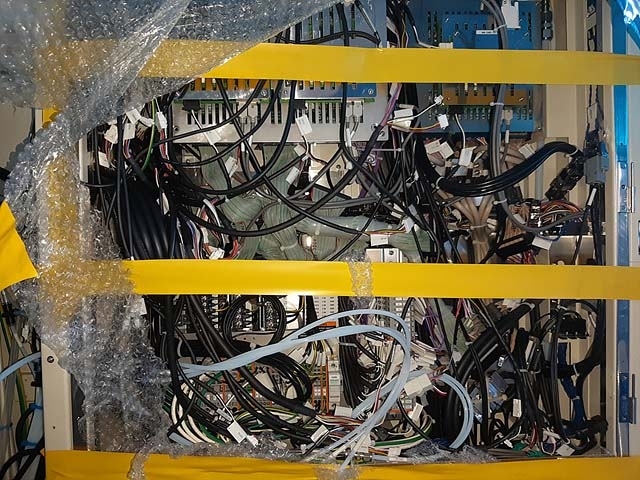

Hard Disk Drive (HDD) Missing

2007 vintage.

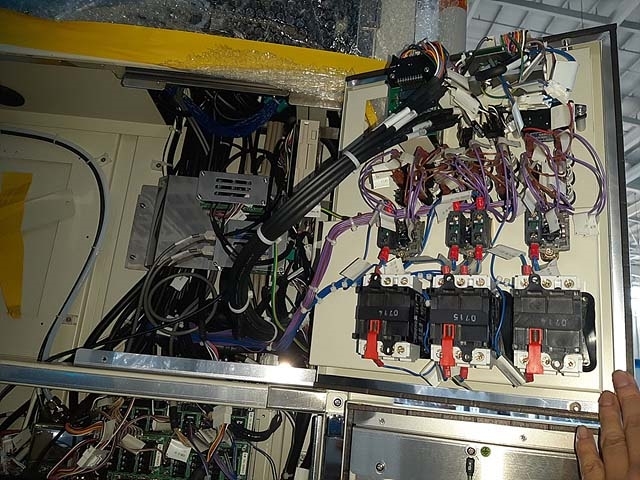

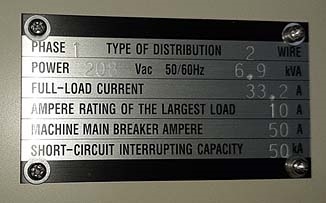

TEL / TOKYO ELECTRON Indy-B-L is a high-performance etcher/asher for semi-conductor industry. It is mainly used for back grinding, taper etching, topographical processing, back spacer etching and other critical applications. It can be utilized for various thinning processes of a semiconductor wafer such as TEM/FIB sample preparation, sample grinding, back side spacer etching, surface patterning, back end of line processing, and others. The machine features high precision, large double working area, and fast etch time. TEL INDY B L etcher/asher is equipped with a Cascading Charts of Dry Etching, which is a fully automated process developed by TEL. This process offers superior process control, improved flexibility and cost savings. It is also equipped with an integrated process monitoring system that ensures that all processes are running at the optimal conditions. This system monitor the pressure, temperature, etch rate and timing to maintain an optimal state. TOKYO ELECTRON INDY B-L is designed with a spacious work area which provides ample room for easy manipulation of wafers during the etching process. The large work area has been designed to ensure that operators can easily move or adjust the wafers during the etch process. Furthermore, the machine is capable of processing large substrates with a maximum in-plane dimension of 500 mm x 500 mm. TEL INDY B-L's high speed etching capabilities makes it suitable for processing a variety of substrates and applications. For example, it is capable of processing multiple samples at the same time for high throughput applications. It also features a laser assisted etching function, which is capable of processing sub-30 nm feature depths, as well as outputting detailed wafer maps that can be used for locating defects and tracking process performance. TOKYO ELECTRON Indy-B-L is designed with a variety of safety features such as a fully enclosed stainless steel work space and a dust collection system. This helps ensure a clean and safe work environment for etching processes. Furthermore, the machine is designed with a wide variety of etching gas control features such as a flow rate monitor, a static pressure monitor and a temperature monitor. All in all, INDY B L has been designed to provide superior etching performance for a wide range of applications in the semiconductor industry. It is capable of providing high speed, high precision and reliable etching processes with all the necessary safety precautions. Furthermore, the automated process control makes it suitable for high throughput applications.

There are no reviews yet