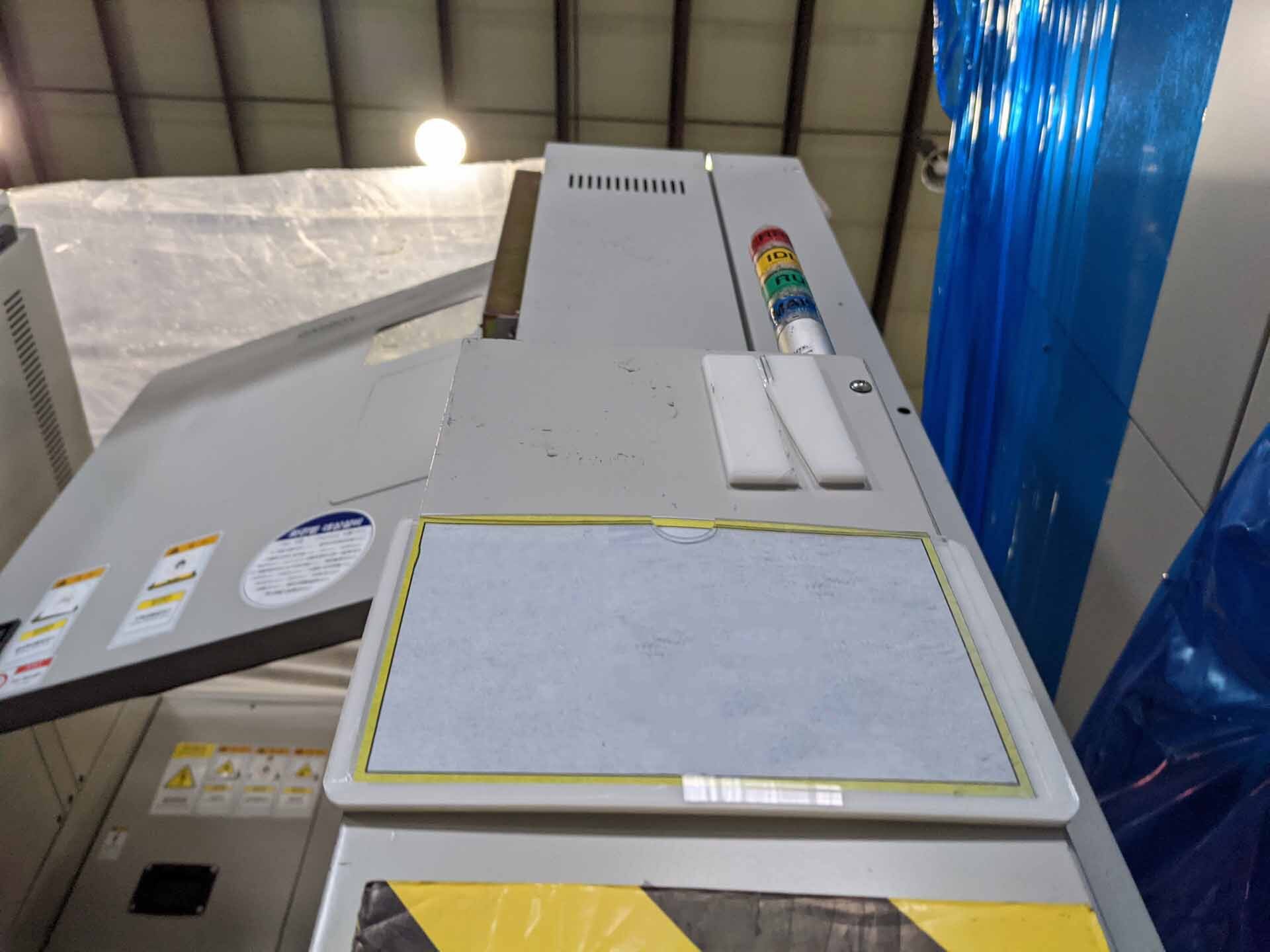

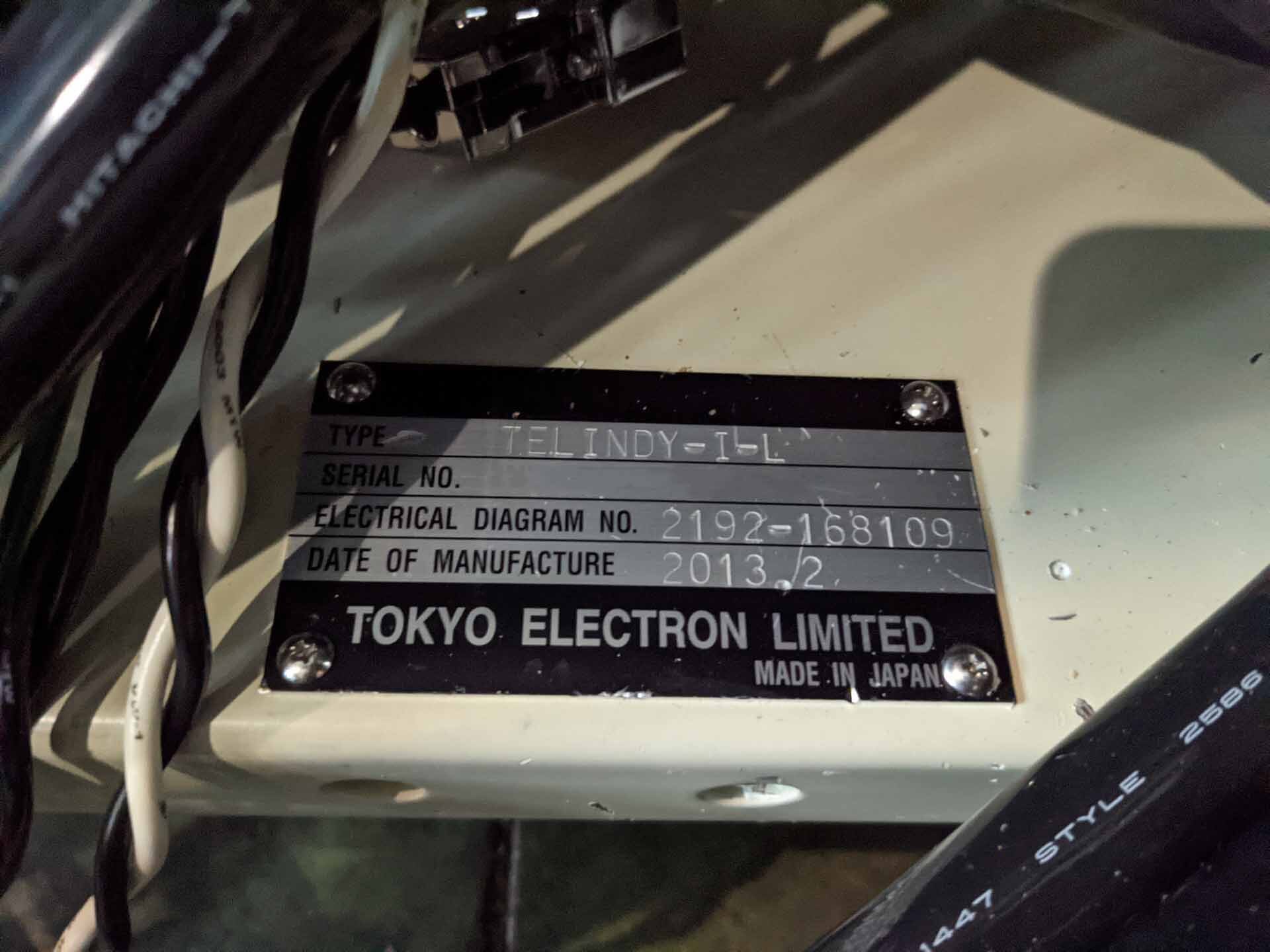

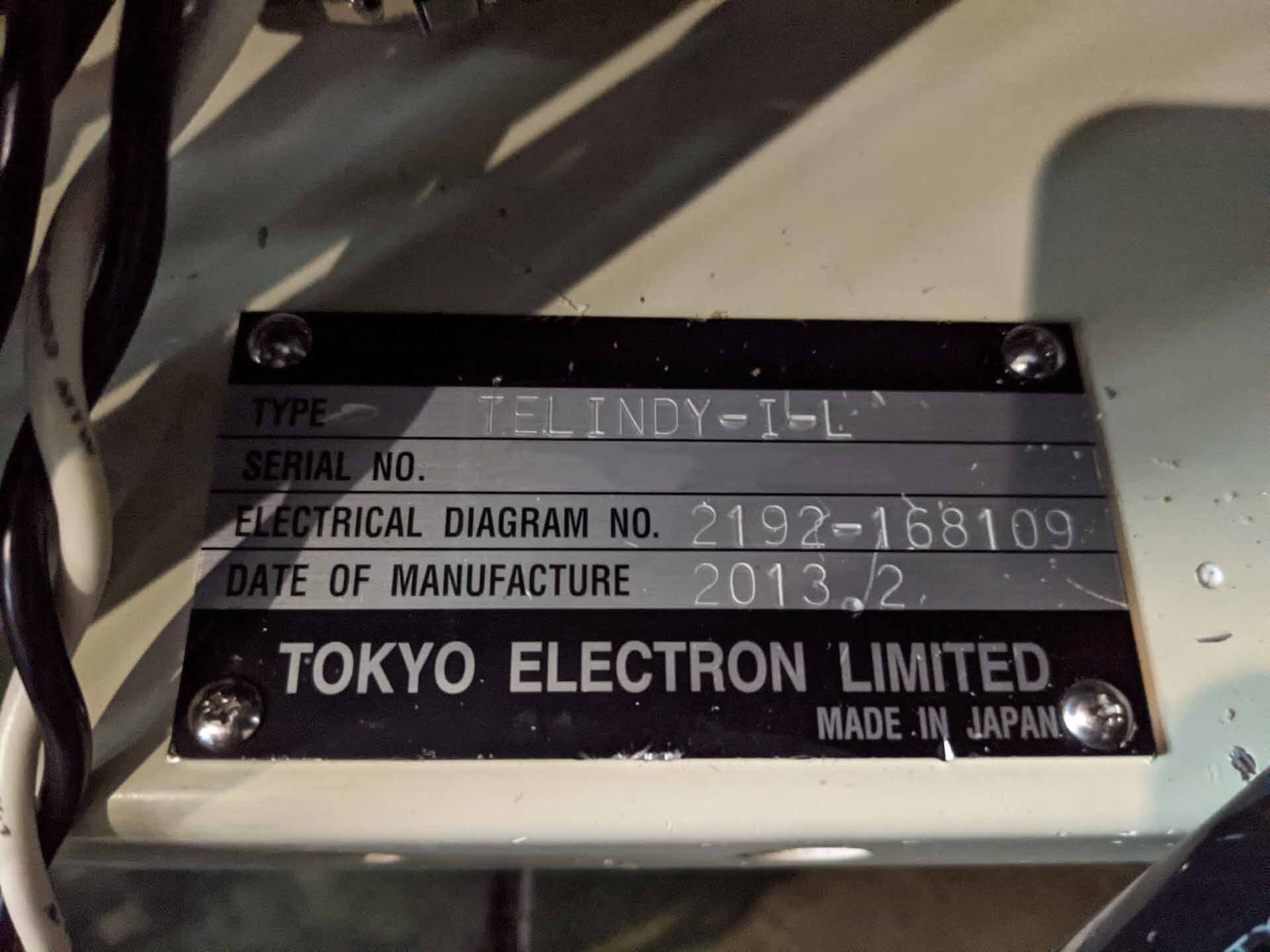

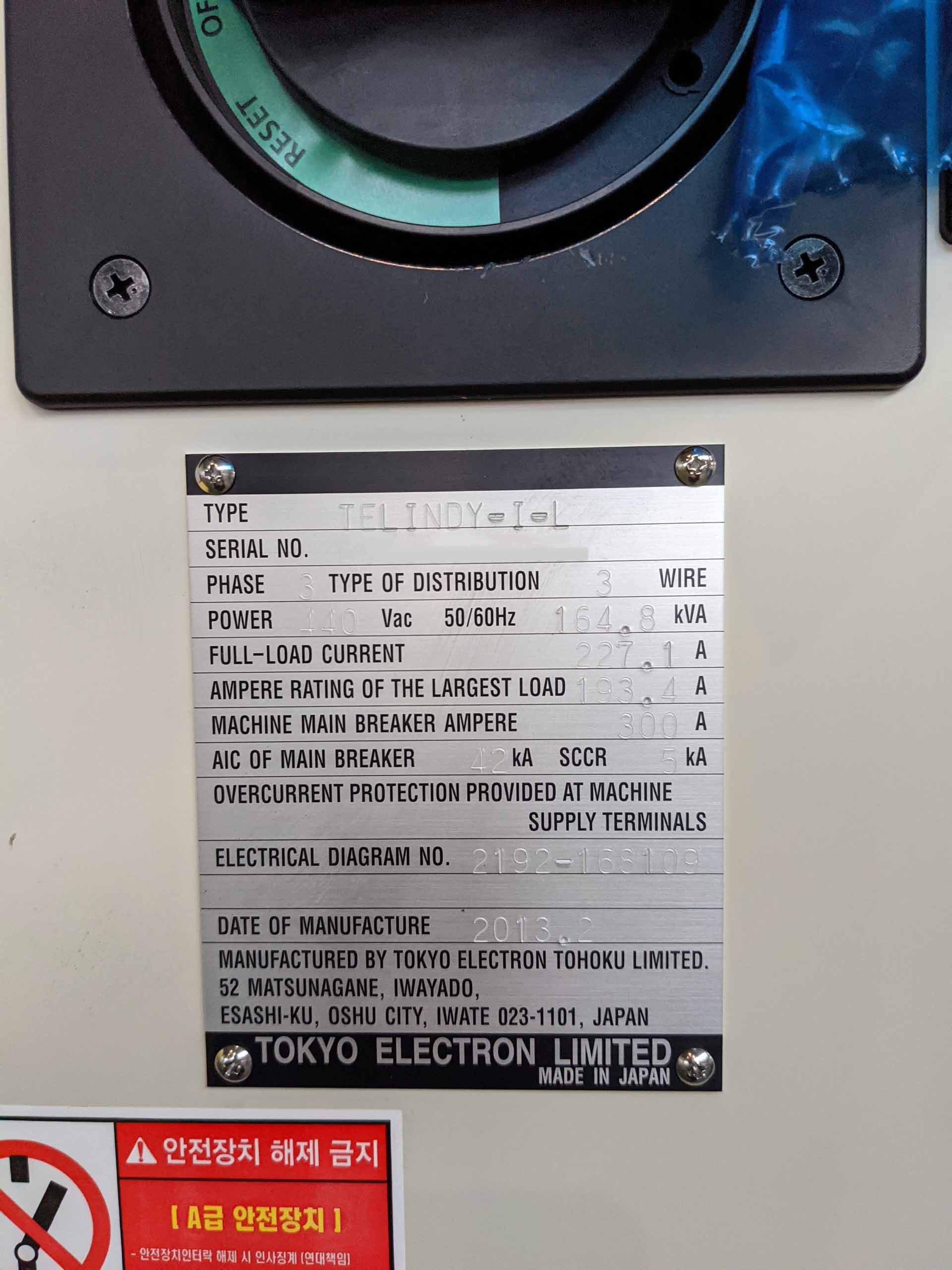

Used TEL / TOKYO ELECTRON Indy-I-L #293587748 for sale

URL successfully copied!

Tap to zoom

TEL / TOKYO ELECTRON Indy-I-L is an etcher/asher designed for both batch and single wafer processing. It comes with a large processing chamber, a combination of an automatic wafer centering mechanism and a built-in sensor for wafer thickness measurements, a wafer cooling unit, alignment plates and air adjustment units. TEL Indy-I-L is an all-in-one equipment that can handle a variety of materials and processes, allowing for fine tuning and easy process optimization. Its easy-to-use interface and touchscreen controls make TOKYO ELECTRON Indy-I-L suitable for all users, no matter their level of experience. Indy-I-L also features a unique cassette-based recipe system that allows multiple recipes to be saved in the same file, allowing for quick and efficient parameter changes. TEL / TOKYO ELECTRON Indy-I-L is equipped with an optimized unit of multi-process channels, allowing for independent process operation and concurrent processes. This machine reduces cycle time and increases flexibility and throughput. TEL Indy-I-L's many etching processes include dry etching, sputter etching, RIE etching and chemical vapor deposition. It is also capable of sputtering simultaneously on both the front and backside of the wafer. Various gases, including CF4 and Helium, can be used for etching. TOKYO ELECTRON Indy-I-L provides a wide the range of recipes, including atomic layer etching, nano-imprint lithography and dielectric etching. Indy-I-L is designed with a state-of-the-art cooling tool to maintain high process quality and stability. Its high-pressure gas asset allows for precise gas flow control, while its advanced vacuum control model ensures high-quality etching processes. Its powerful vacuum source ensures reduced particle counts, while its floating beam source provides precise energy distribution. TEL / TOKYO ELECTRON Indy-I-L is a great etcher/asher for advanced semiconductor processing. Its multi-process capability and quick changeover between different recipes make it a great choice for production of cutting-edge devices. Its intuitive touchscreen interface, advanced cooling equipment and high-precision processes make it well-suited for today's demanding semiconductor requirements.

There are no reviews yet