Used TEL / TOKYO ELECTRON Indy Plus-A-M #293656320 for sale

URL successfully copied!

Tap to zoom

ID: 293656320

Wafer Size: 12"

Vintage: 2016

Furnace, 12"

Process: Low-temperature nitride

Maximum operating temperature: 850°C

N2 Load lock

Wafer type: 300 Si semi STD-Notch

(100) Production wafers

(2) Boat type / (2) boat operation (B/S)

Loading area light: White (LED)

O2 Density control N2 LL

N2 Boat shower wafer cooling

ENTEGRIS F300-2005- 17UT1502

Carrier type: FOUP 25 slots

Edge grip W/T type

VMM-56-306C Mid temperature

Top furnace exhaust connection point

Bottom cooling water connection point

FUJIKIN IGS

Tubing bends: Bend (Less than 90°)

IGS Final filter

CKD IGS Regulator

HITACHI Digital

IGS Press transducer: Nagano

HITACHI AS102S-A HCD SCCM

MKS Capacitance manometer

Press monitor

Pump monitor

Main valve: CKD-VEC

Power box top

Vacuum exhaust system, 4"

Piping trap

CKD-VEC Vacuum pressure control

Quartz material: Electric fused

Quartz inner/outer tube material

Internal T/C: Process tube interior wall type

Tube sealing: N2 Purge and O-Ring seal

Manifold heater

Switch valve for manifold cool

QUARTZ Boat material

117-Slots Ladder (8mm pitch)

Two quartz fins are welded at the bottom

Cap heater

QUARTZ Pedestal type

Shutter purge type

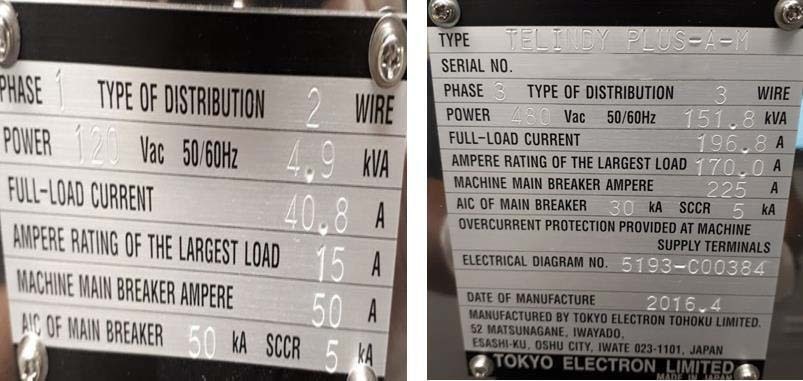

Power supply:

3-Phase connection type: Star connection

Single phase connection: Grounded

Single phase voltage: 120 VAC

3-Phase voltage: 480 VAC

2016 vintage.

TEL / TOKYO ELECTRON Indy Plus-A-M is a state-of-the-art 3D Etching/Ashing tool. It features robust design, superior etching and ashing precision and accuracy and has been developed to meet the needs of today's Semiconductor Equipment manufacturers. With TEL Indy Plus-A-M, users can etch and ashing wafers with less process variation and shorter cycle times. TOKYO ELECTRON Indy Plus-A-M is apt for various etching and ashing applications, as well as for advanced doping, layer transfer, annealing processes and thick film etching. The tool is equipped with an LOBOTRON™ (Laser Optical Beam Optical Tron)plus Mechanized Reflector (MR). Using an LOBOTRON™, Indy Plus-A-M is able to perform etching/ashing with decreased laser-focusing errors due to its robust design. Furthermore, thanks to the MR technology, direct processing (e.g. high aspect ratio etching/ashing) is achievable with a low process variability. TEL / TOKYO ELECTRON Indy Plus-A-M offers a wide range of process capabilities, including the ability to process wafers down to 5-µm for ultra high-aspect-ratio processes and up to 9-mm for high-throughput applications. It can also provide users with repeatable and robust etching/ashing on various types of metals, plastic and oxide materials, as well as crystalline/non-amorphous materials. TEL Indy Plus-A-M is designed to reduce manufacturing costs and improve productivity. Its Closed-Loop Control (CLC) feature provides accurate etching/ashing performance for long-term repeatability. It also ensures consistent product quality by providing real-time feedback of the process parameters. In addition, its automated preconditioning functions help to shorten the etch times while maintaining the desired process endpoints. Overall, TOKYO ELECTRON Indy Plus-A-M is an ideal solution for users who require advanced etching and ashing processes with low cost of ownership. The tool's easy-to-use user interface, affordability, and built-in safety features make it the perfect tool for today's semiconductor industry. It is ideal for manufacturers looking to boost their production yield, reduce waste and improve product quality.

There are no reviews yet