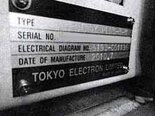

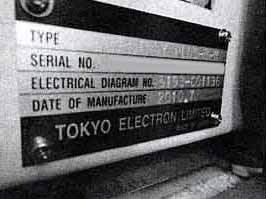

Used TEL / TOKYO ELECTRON INDY PLUS B M #293637534 for sale

URL successfully copied!

Tap to zoom

ID: 293637534

Wafer Size: 12"

Vintage: 2010

Diffusion furnace, 12"

Carrier stage body

Main body

Vacuum box

X-Precursor bubbler box

Option box

Heater

PWR Box:

XP41VP

(2) XP42VP

XS7VP

XP2

XS5

Pump interphone

MM1 INTFC 2XP1

XP56VP

XS73VP

(2) XT902 TMA SAFTY Unit

XS103VP

XP776VP

XT 514-8

XT516

XT739

(2) XT901 TMA SAFTY Unit

Interphone XP92VP

XT530

XP40VP

GRSO PCB CN1

GRSO CN2

(5) XT513

(11) XT514

(5) XT510

XT513-1

XT513-2

XT513-3

XT510-7

(2) XP 1028 EXC

XP 1023 EXC

XP 1024 EXC

XP 1025 EXC

T/C Unit

T/C Cable

T/C Box

Control box top cover

Gas piping duct

RCU Piping box

Piping

Gas detector

Smoke detector

T/C Junction box

G/Box exhaust connection

FNC TOP Exhaust connection

O2 Analyzer

Vacuum box cover-1

Control box fox jig

Cooling water piping

Facility connection cover

Scavenger cover

Heater panel

Vacuum box cover-2

Heater frame support

Option box cover

Shutter corer

Carrier stage TOP Cover front panel

Fixed tripod

Positioning iron piece

Screws

Manifold

Main valve

Vacuum piping P1

Vacuum piping P2

Vacuum piping P3

Vacuum piping P4

Vacuum piping P5 (Bellow)

Inner tube support ring

Pedestal plate

Center ring

Outer tube lock ring

Boat rotate support

Inner tube lock ring

Outer tube seal ring

Manifold heater

Vacuum piping tape heater

Manifold ceiling water piping

Leak check port handle valve

Vacuum piping clamp

Heater insulator

Power box

2010 vintage.

TEL / TOKYO ELECTRON INDY PLUS B M is a powerful etching equipment designed to meet the demanding requirements of today's semiconductor manufacturing processes. This etcher is capable of processing various substrates ranging from silicon to organic materials such as plastics and organic light emitting diodes (OLEDs). The system's advanced etching process, called physical vapor deposition (PVD), allows for precise control of the shape, size, and composition of each layer. It features a highly uniform deposition pattern and a high process yield. The etcher is equipped with a high-performance chemical vapor deposition (CVD) facility for performing rapid and uniform plasma etching of layers. TEL INDY PLUS B-M offers a range of temperature control options to allow for optimal etching conditions. It includes both a hot plate and induction heater, enabling precise temperature control up to 2000°C. An electromagnet in the etch chamber helps maintain uniform deposition across the sample. The unit also includes an innovative automated chamber height control mechanism which ensures level substrate height and uniform plasma dispersion over the substrate. What really sets TOKYO ELECTRON INDY PLUS-B-M apart is its user-friendly, high-precision plasma etching software. The machine features a robust user adjustable power control for controlling etch time, power and duty cycle. Through its powerful automation modes, the etcher enables easy process development and optimization. It also features a 3D graphical display of the etch chamber which enables users to monitor and control the etch process. In addition, TOKYO ELECTRON INDY PLUS B-M features a powerful optical emission spectrometer for precise end point detection. A quartz tube oven is also included for strain free processing of thermally unstable substrates. The etcher's automatic layer-by-layer deposition capabilities make it easy to tailor the layer thickness of targeted structures. INDY PLUS B-M is an advanced etcher offering superior performance in a compact and user-friendly package. With its powerful etching process and intuitive control systems, it makes fabricating high-precision structures easier than ever. This etcher is a great choice for today's demanding semiconductor manufacturing operations.

There are no reviews yet