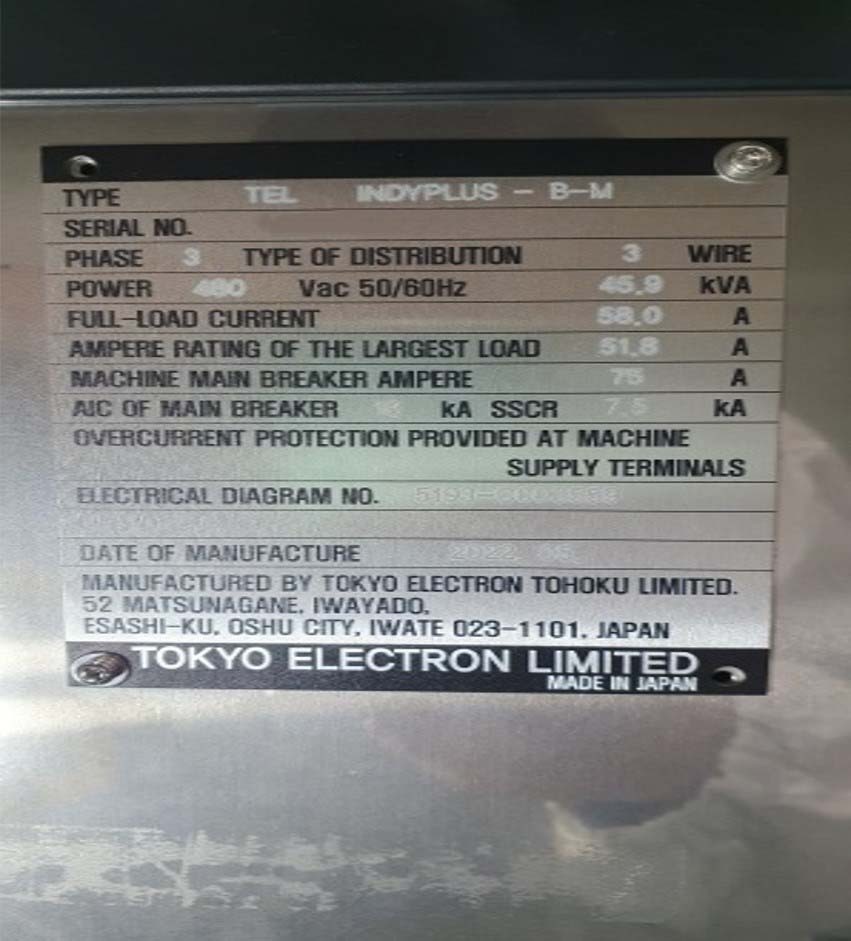

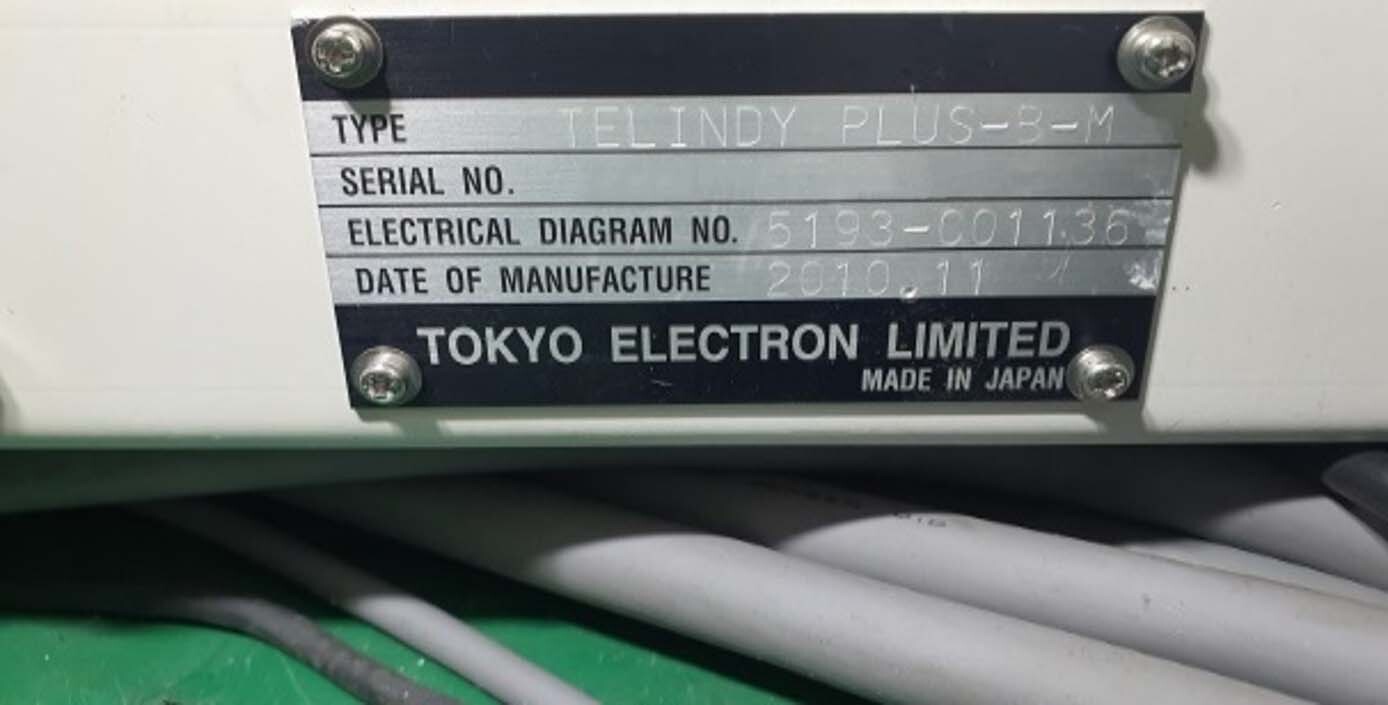

Used TEL / TOKYO ELECTRON INDY PLUS B M #293656658 for sale

URL successfully copied!

Tap to zoom

ID: 293656658

Vintage: 2010

Furnace

Process: LPCVD, Poly

Hard Disk Drive (HDD)

Load port

Carrier transfer

FIMS

Boat elevator / Seal cap rotation

Auto shutter

VMM-56-201 Heater

Process: LPCVD, Poly

N2 Load lock

Load port

HTR

Exhaust box

Power box

Front and reer upper cover

Final valve box

Wafer transfer

Carrier transfer

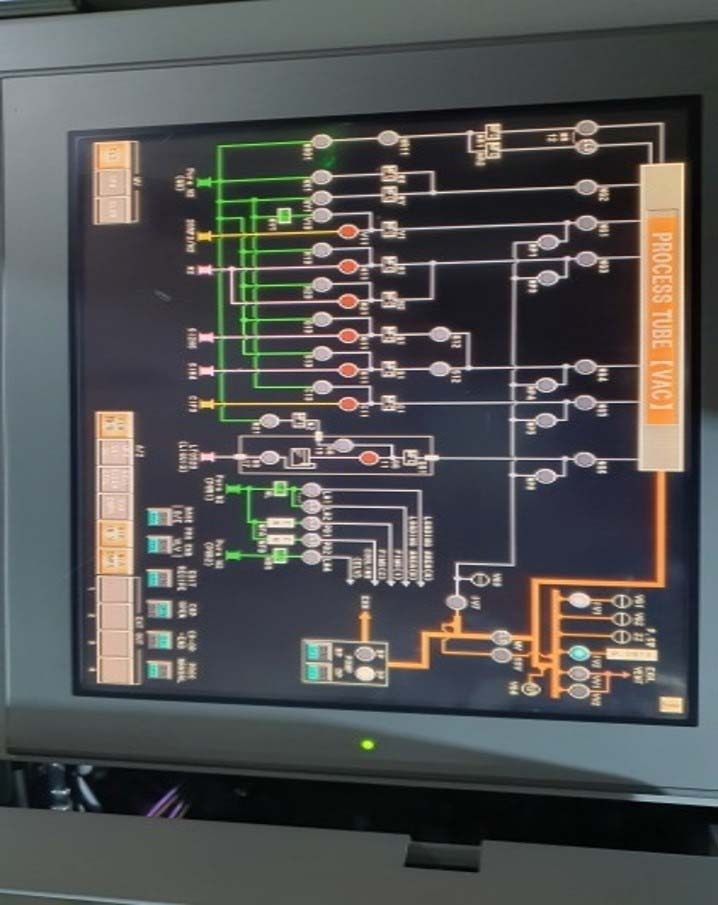

Gas flow chart

O2 Analyzer

Does not include HCT

Si SEMI STD-Notch, 12"

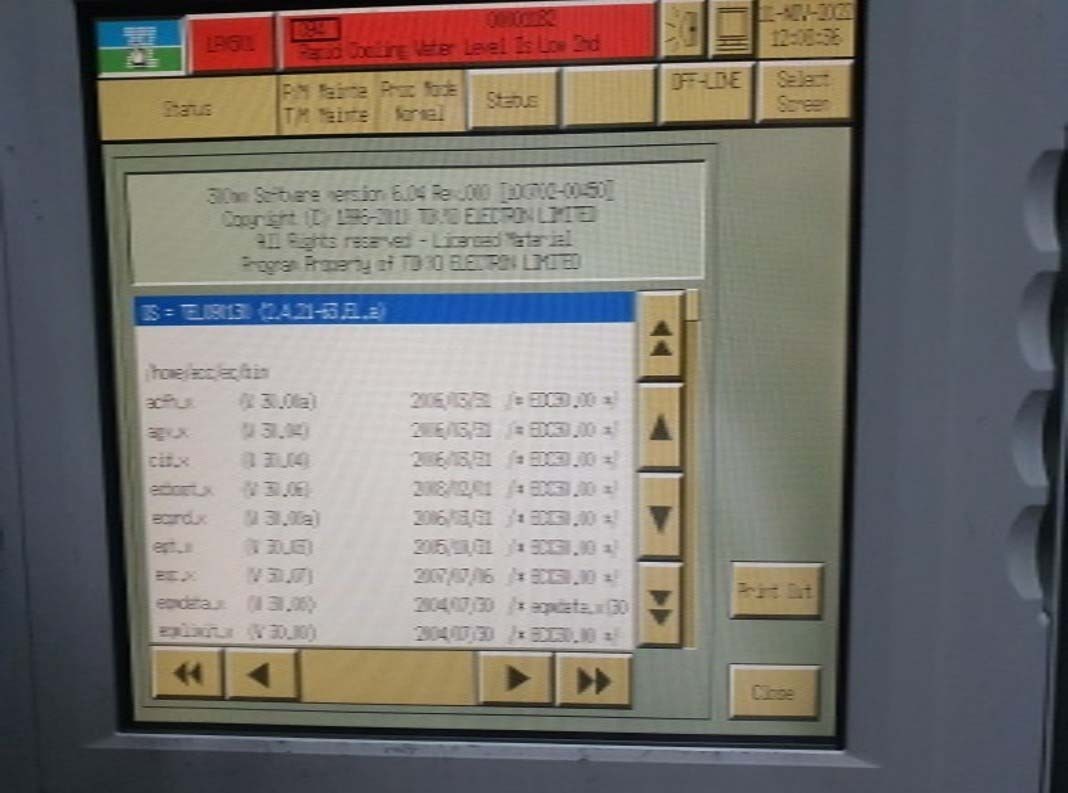

M780 Furnace temperature controller

User interface:

Pressure display Unit: MPa / Torr

Carrier type: FOUP / 25slots SEMI STD

Carrier stage capacity: 16

Fork material: Al203 and PEEK

W/T Type: 1+4 Edge grip

RCU

Power distribution system:

3-Phase connection type: Star connection

Single-Phase connection: Grounded

Gas distribution system:

FUJIKIN Integrated Gas System (IGS)

MFC Z500 IGS Final filter, regulator

Power supply: 400 VAC, 50/60 Hz, Single phase, 3-Phase

2010 vintage.

TEL / TOKYO ELECTRON INDY PLUS B M etcher (also known as asher) is a highly advanced semiconductor processing tool designed for high-throughput applications. This equipment provides superior control and reliable accuracy for various substrates, from thick film photoresist to thin film metal interconnects. The main feature of TEL INDY PLUS B-M etcher is its unique design that combines two processing technologies: KOS (Known Oxidation Strip) and MPT (Multi Patterning Technology). The KOS technology uses a high-speed plasma beam that is capable of removing the organic contaminants on the surface of a wafer. This process is ideal for applications such as oxide removal, oxide desmearing, or oxide stripping. The MPT technology, on the other hand, uses a lower-energy beam and a higher-pressure of evaporative gas to etch high-density patterns onto a substrate. TOKYO ELECTRON INDY PLUS-B-M is designed to cut processing time while maintaining quality. It utilizes a computer-controlled software that allows users to program the etching settings according to their needs. The software also integrates an advanced software routine to help users quickly and accurately select the settings for certain types of applications. Additionally, TEL / TOKYO ELECTRON INDY PLUS-B-M features a range of options that allow users to select settings for specific processes such as pattern density, timing, gas type, and gas flow rate. INDY PLUS B M also comes with a variety of peripheral components and sensors that help users to control and monitor the etching process. The system includes an advanced optical pyrometer which measures the wafer temperature and allows users to precisely adjust the etching parameters accordingly. Additionally, this unit has various safety features such as an anti-collision machine, a sensor that prevents disasters with potential high voltage arcs, and an alarm tool that notifies the operator when a problem arises. TOKYO ELECTRON INDY PLUS B-M etcher is ideal for semiconductor companies and research institutions that are looking for a reliable and accurate etching asset. It offers the capability to process a variety of substrates with high-throughput and accuracy, making it an ideal tool for a wide range of applications.

There are no reviews yet