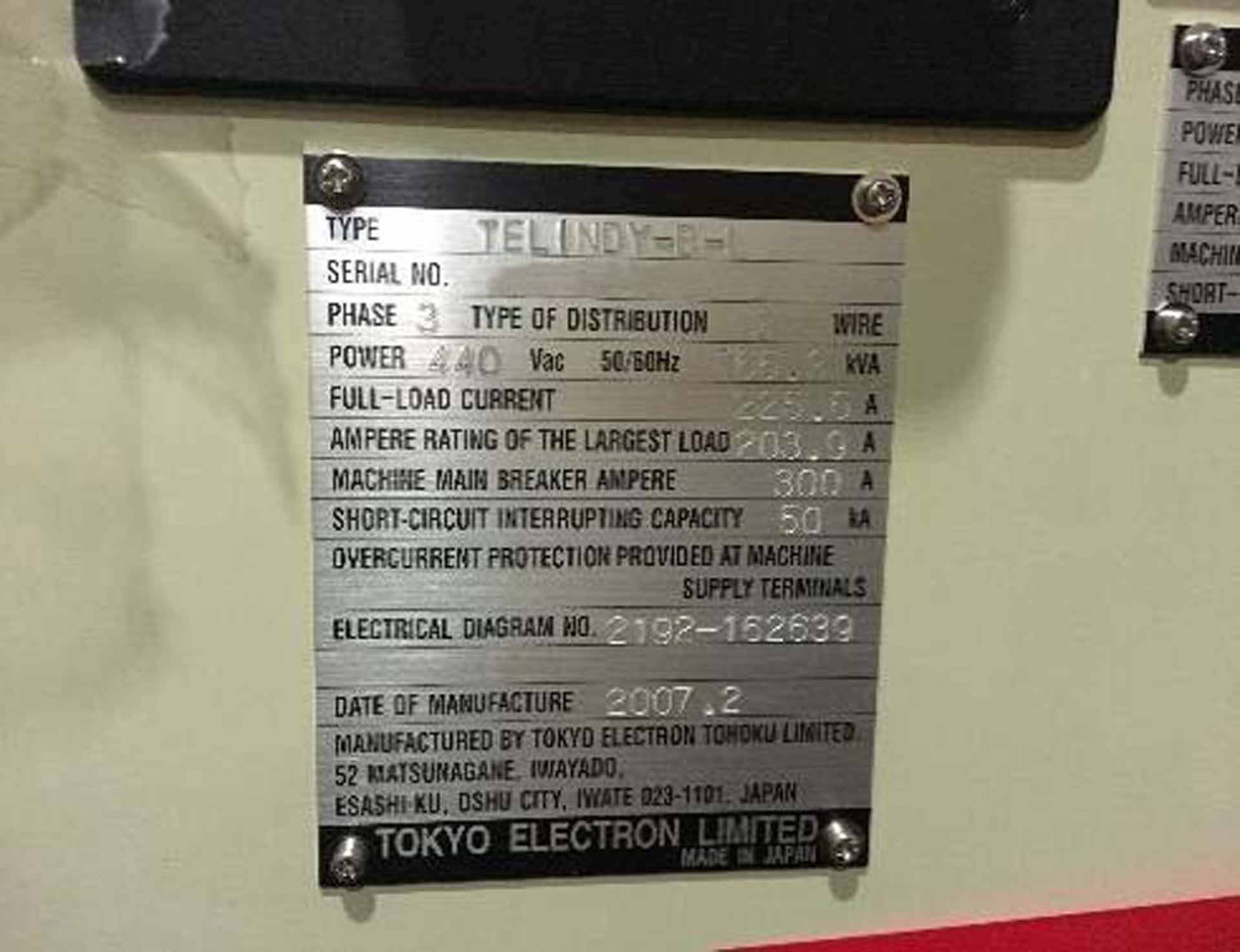

Used TEL / TOKYO ELECTRON Indy #9381806 for sale

URL successfully copied!

Tap to zoom

ID: 9381806

Wafer Size: 12"

Vintage: 2007

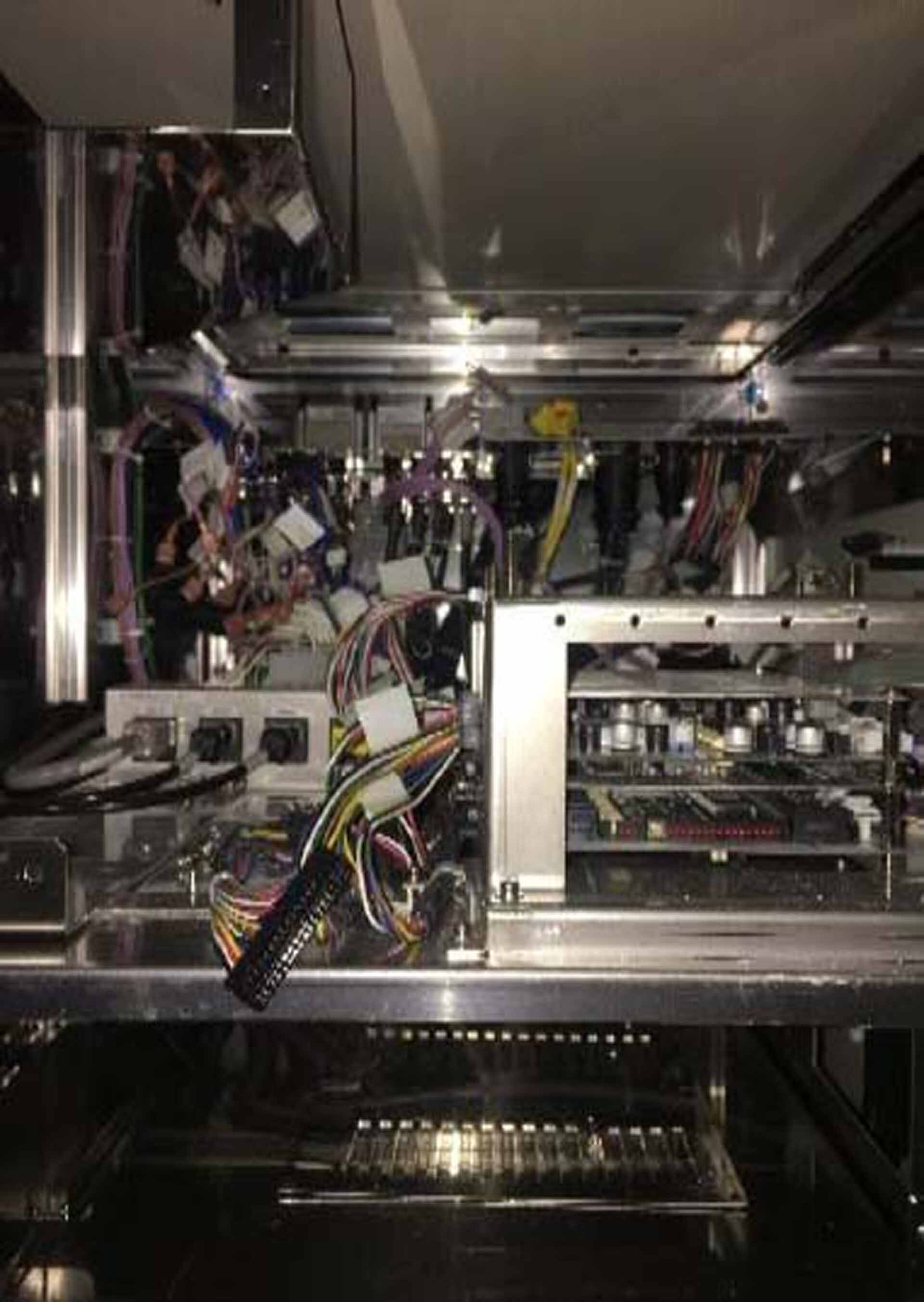

LPCVD Furnace, 12"

Process: DCS-MTO

Rapid cooling unit

Pump box

Power box

VOS-56-101P Heater

FUJIKIN Air valve

MFC, MFM: STEC

MAIN / APC: CKD

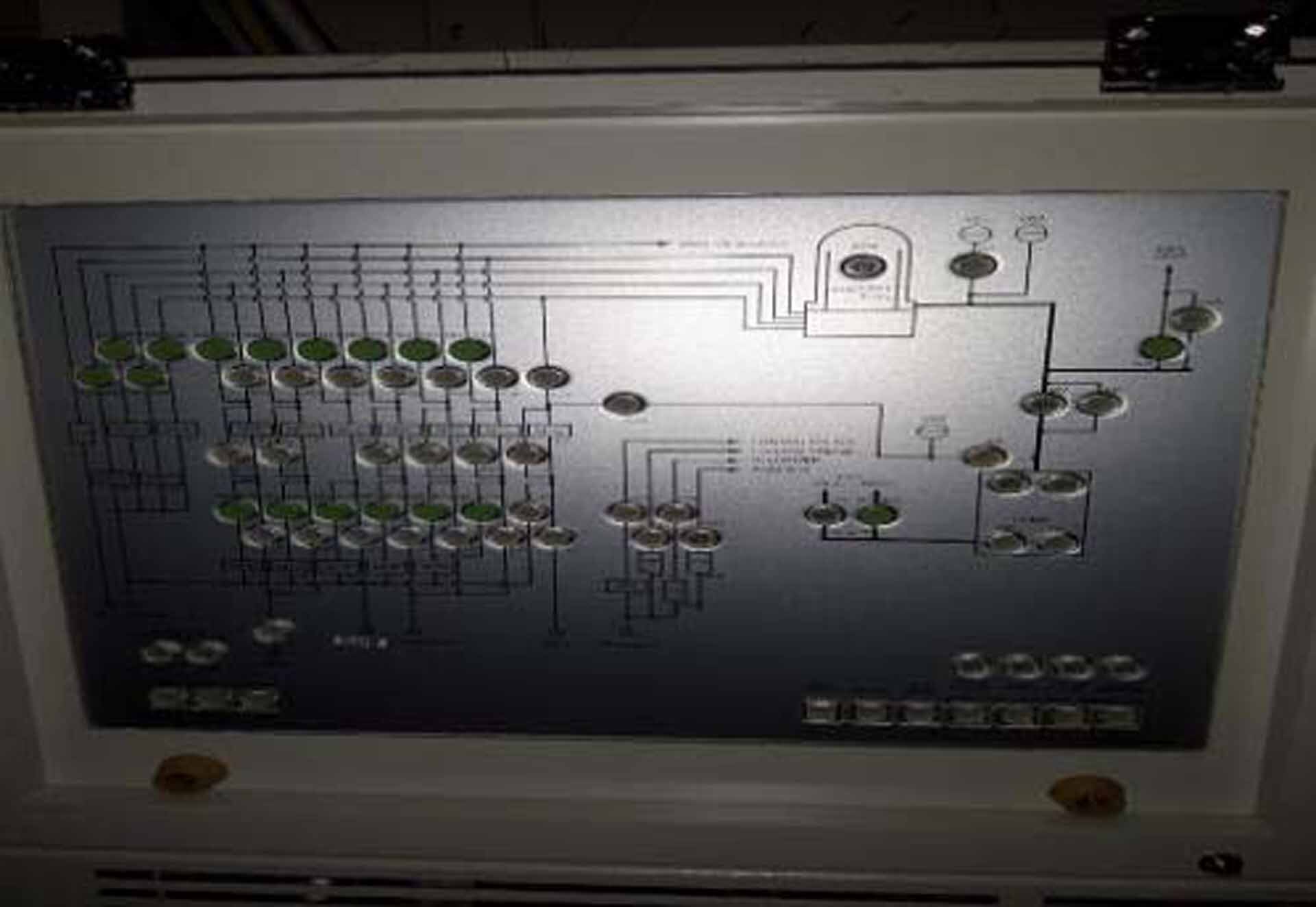

Load lock system

Storage

Front panel signal tower

Carrier transfer

FIMS Port

Wafer transfer

Boat elevator

Auto shutter

Operating system: Linux V2.13

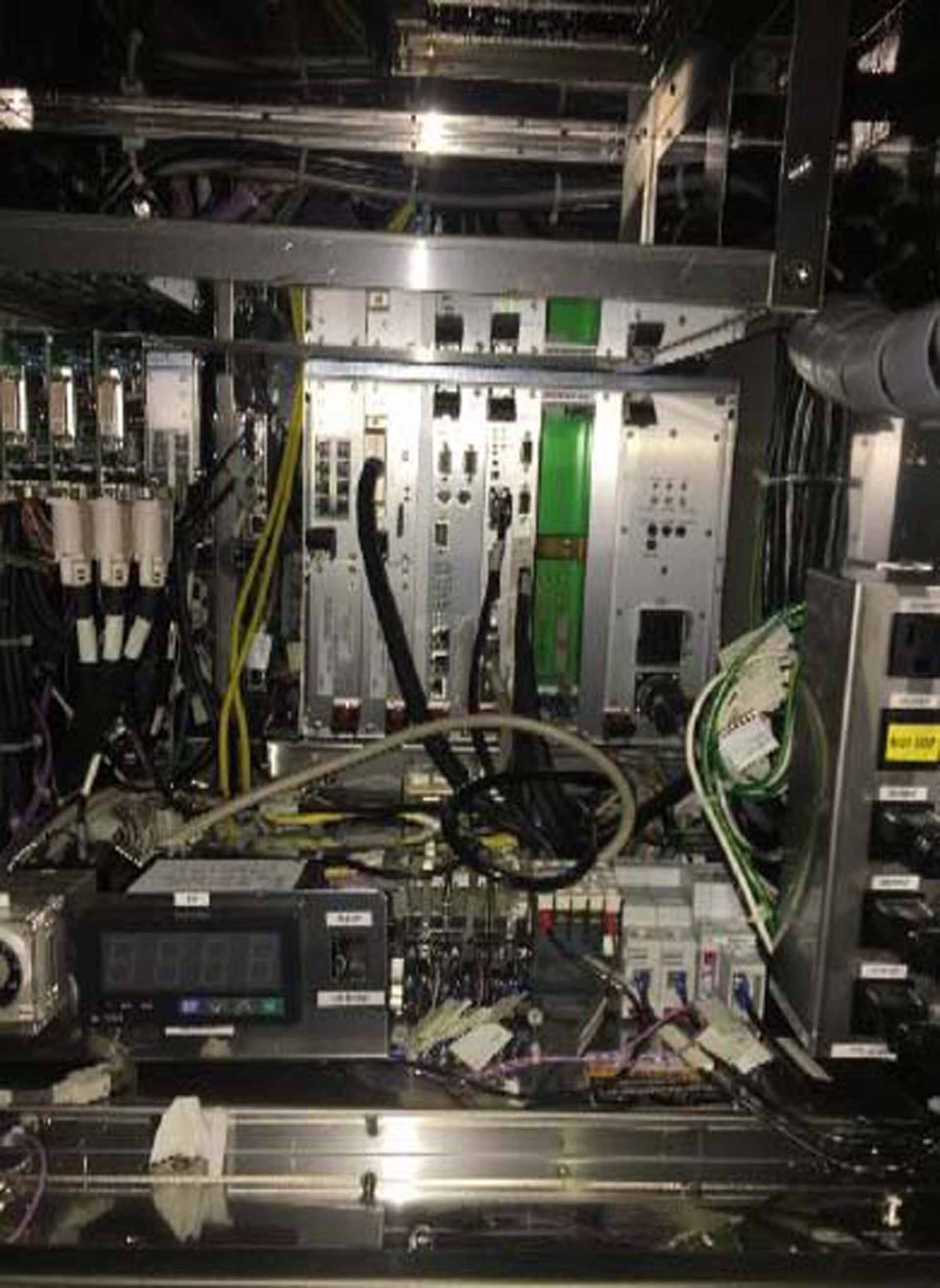

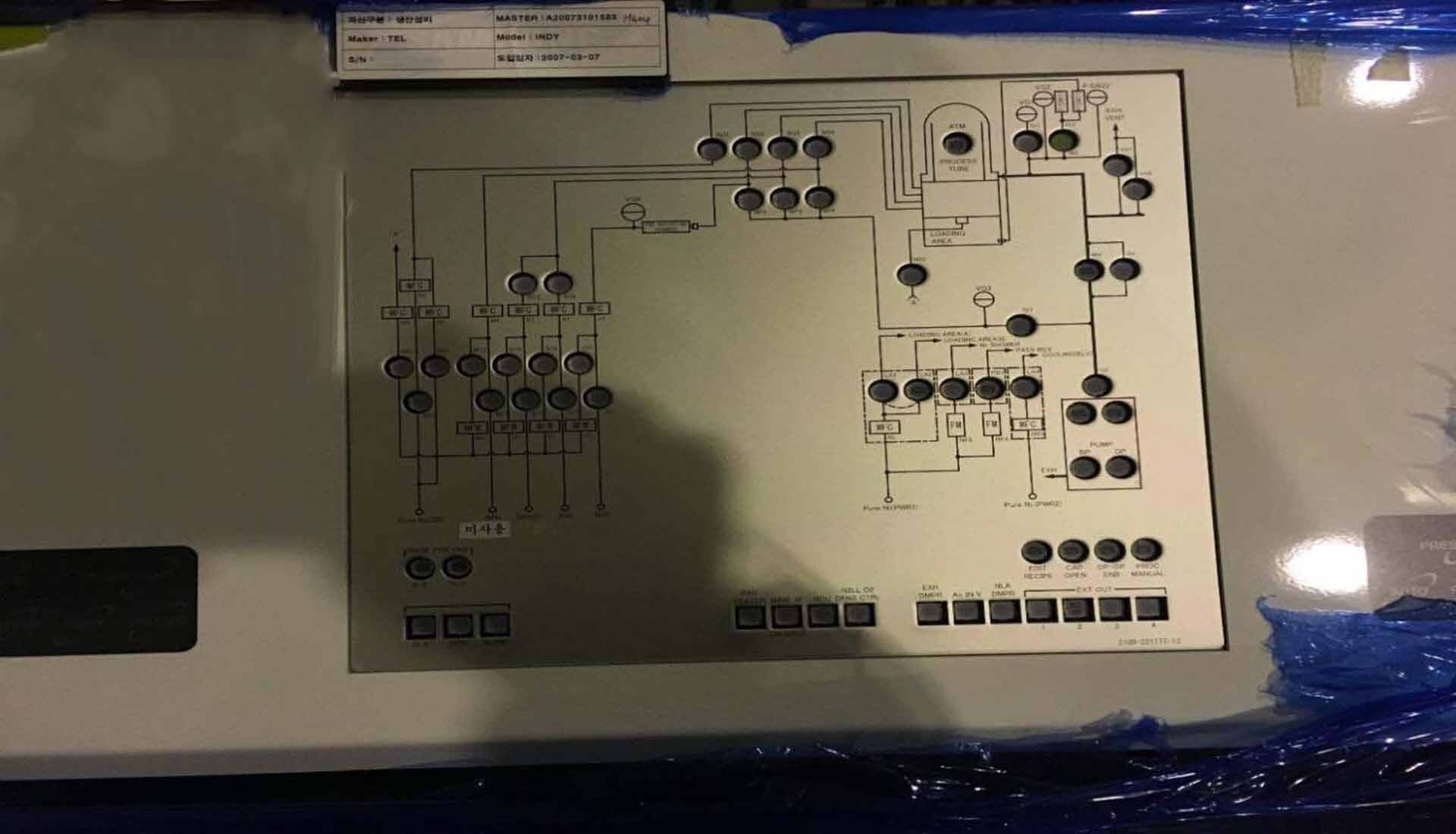

Utility box:

WAVES Controller

GFC Panel

Operation panel

Data I/O

Gas unit

Cooling unit

APC Controller

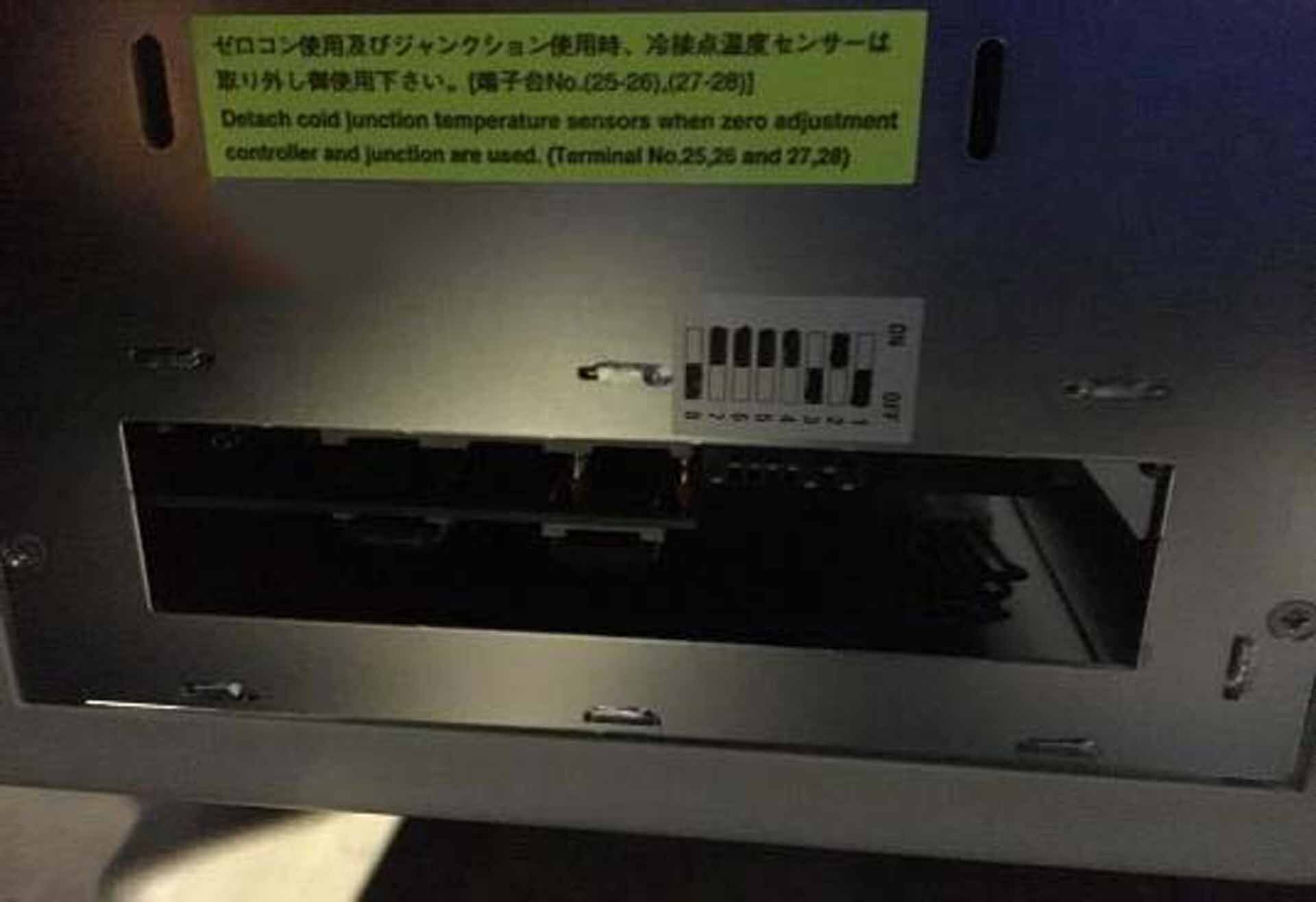

Temperature controller

Vacuum line

Load port:

I/O FFU

Side FFU

Furnace subsystem:

Automation system

Heater

Process chamber

Temperature controller

Cooling water unit

Gas subsystem:

Gas supply unit

Exhaust

Vacuum line

Power box:

EMO Unit

Control board

Hardware switch

Transformer

SCR Unit

N2 Purge unit

RCU Unit

Gases:

SiH4

SiH4Cl2

N2O

NH3

Missing parts:

QUARTZ Wares

Scavenger

Manifold

(2) Hard Disk Drives (HDD)

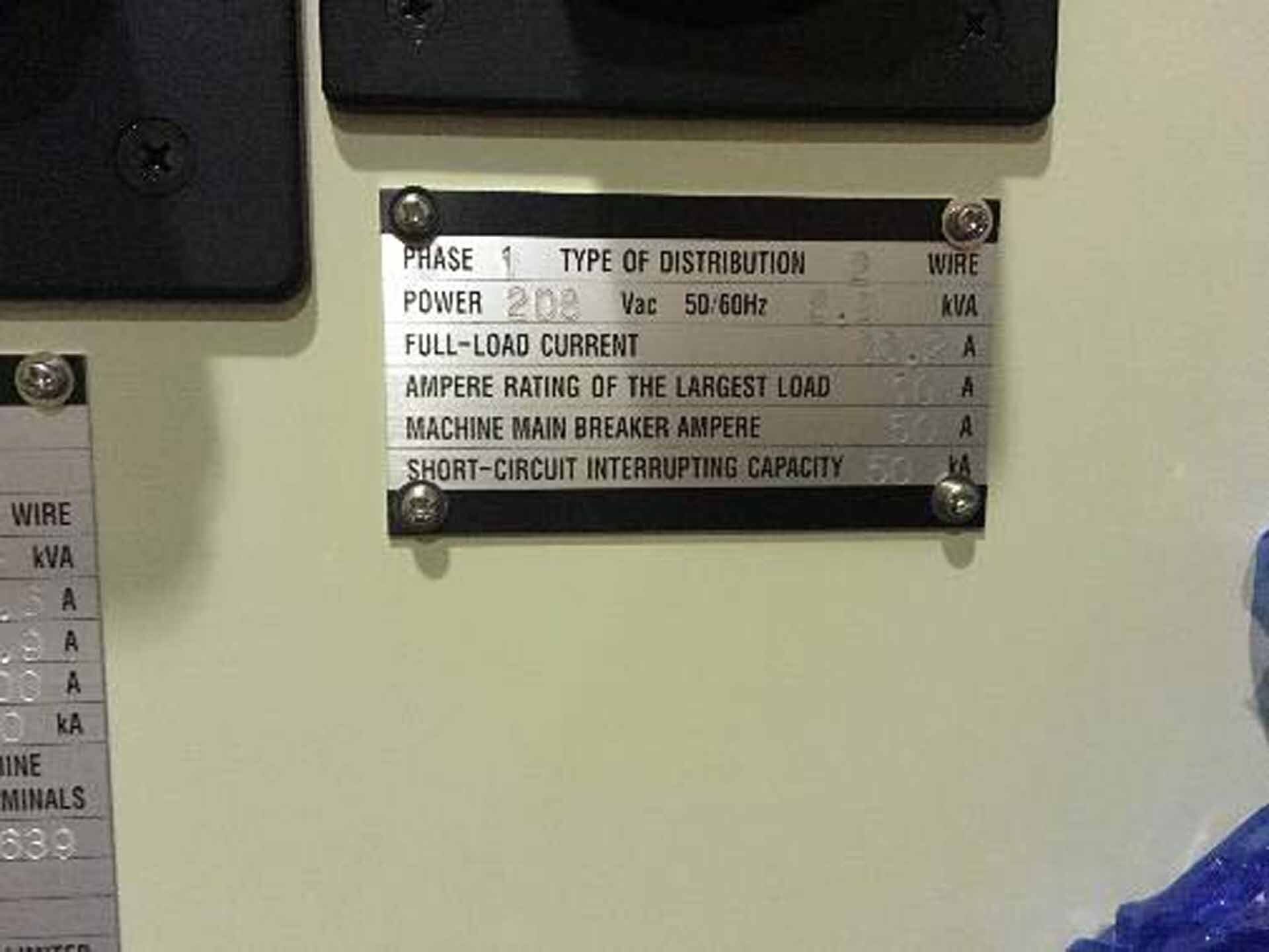

Power supply: 440/208 V

2007 vintage.

TEL / TOKYO ELECTRON Indy is a reliable asher/etcher equipment designed for precise large scale etching of wide range of materials. The system has an integrated source of advanced process technology and technology platforms to provide excellent etching performance. This allows for etching a wide range of material types such as semiconductors, semiconductor chips, organic substrates, thin films, and many others at a high level of accuracy. The unit comes with a programmable robot controller for precise movement and control, enabling the accurate etching of even intricate patterns. The machine is capable of supporting a variety of process recipes, such as single layer etch, multiple layer etch, AutoClick, and multi-mask etch. These features combine to give the user a complete etching solution with multiple combinations of process capabilities. The tool also has an integrated auto-cleaning feature for quick and efficient cleaning of the etch chamber, ensuring consistent performance. Additionally, the asset is also capable of using argon, nitrogen and oxygen-based gases for etching applications. The model also provides efficient protection against process contamination, with a high purity environment, an efficient gas delivery equipment, and advanced control algorithms. This allows for the maximum extraction of process chemicals, while minimizing the contamination rate. In addition to safe etching performance, the system also comes with a variety of additional features, such as a comprehensive user interface, up to twice the speed of media speed of other equipment, and compatibility with various materials. The unit also has a real-time monitoring capability that allows users to monitor in-situ the etch rate of different materials, as well as an array of alarms to detect any unexpected changes in etching conditions. Overall, TEL Indy etcher/asher is an ideal machine for those who need a reliable, efficient, and comprehensive etching solution. With its user-friendly interface, ability to support a wide range of etching recipes, and advanced features, TOKYO ELECTRON Indy is an ideal choice for a wide variety of etching applications.

There are no reviews yet