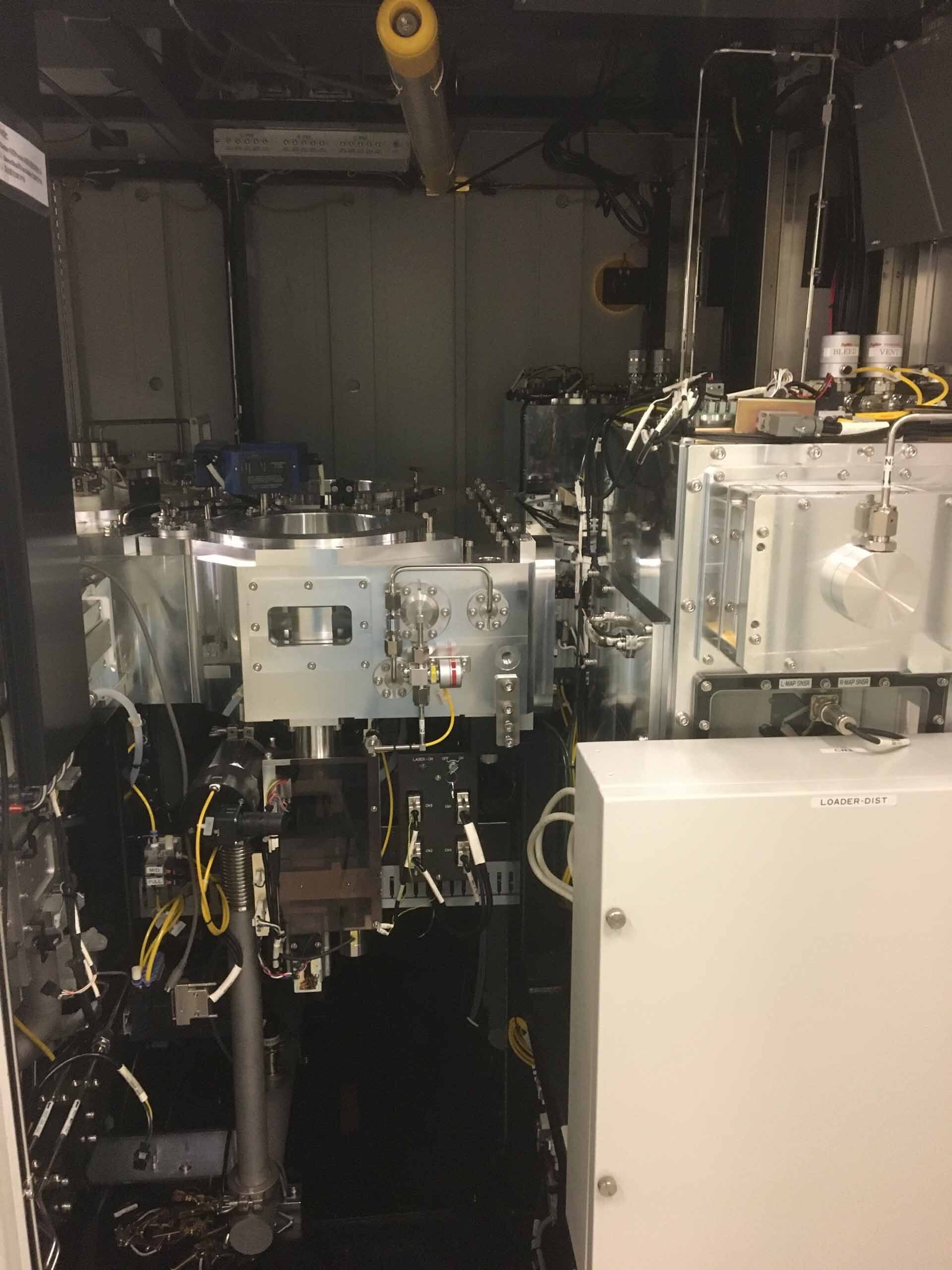

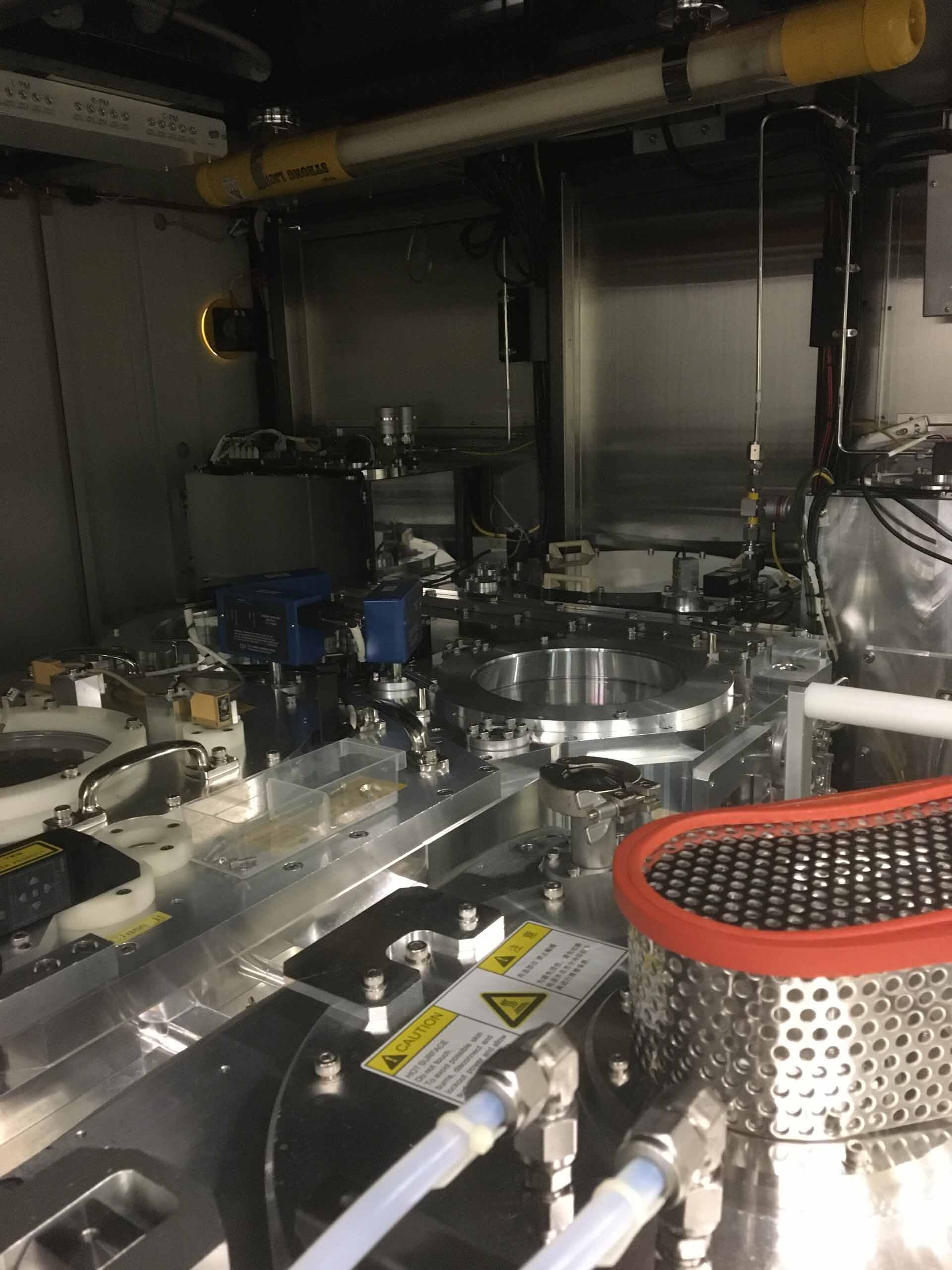

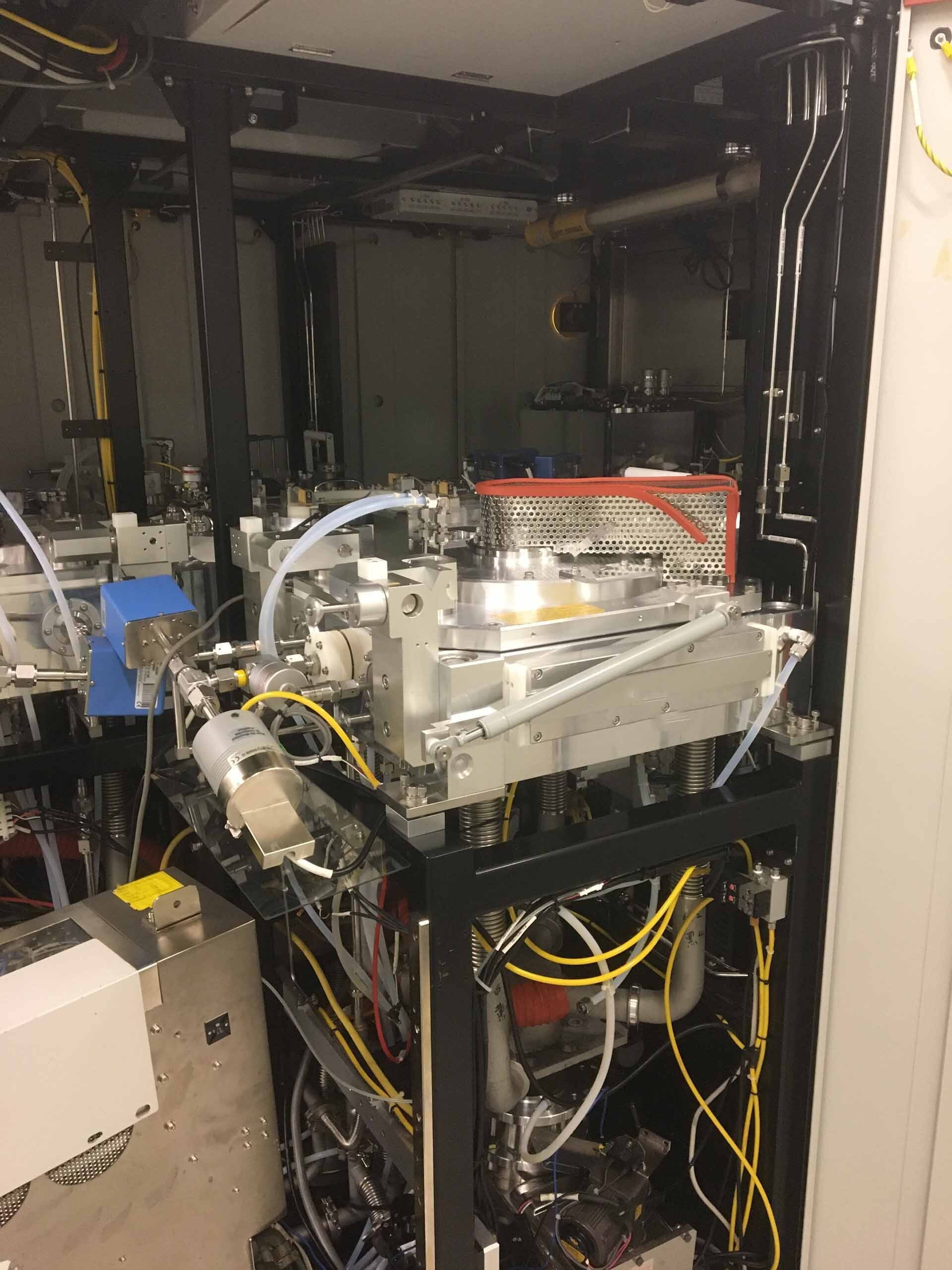

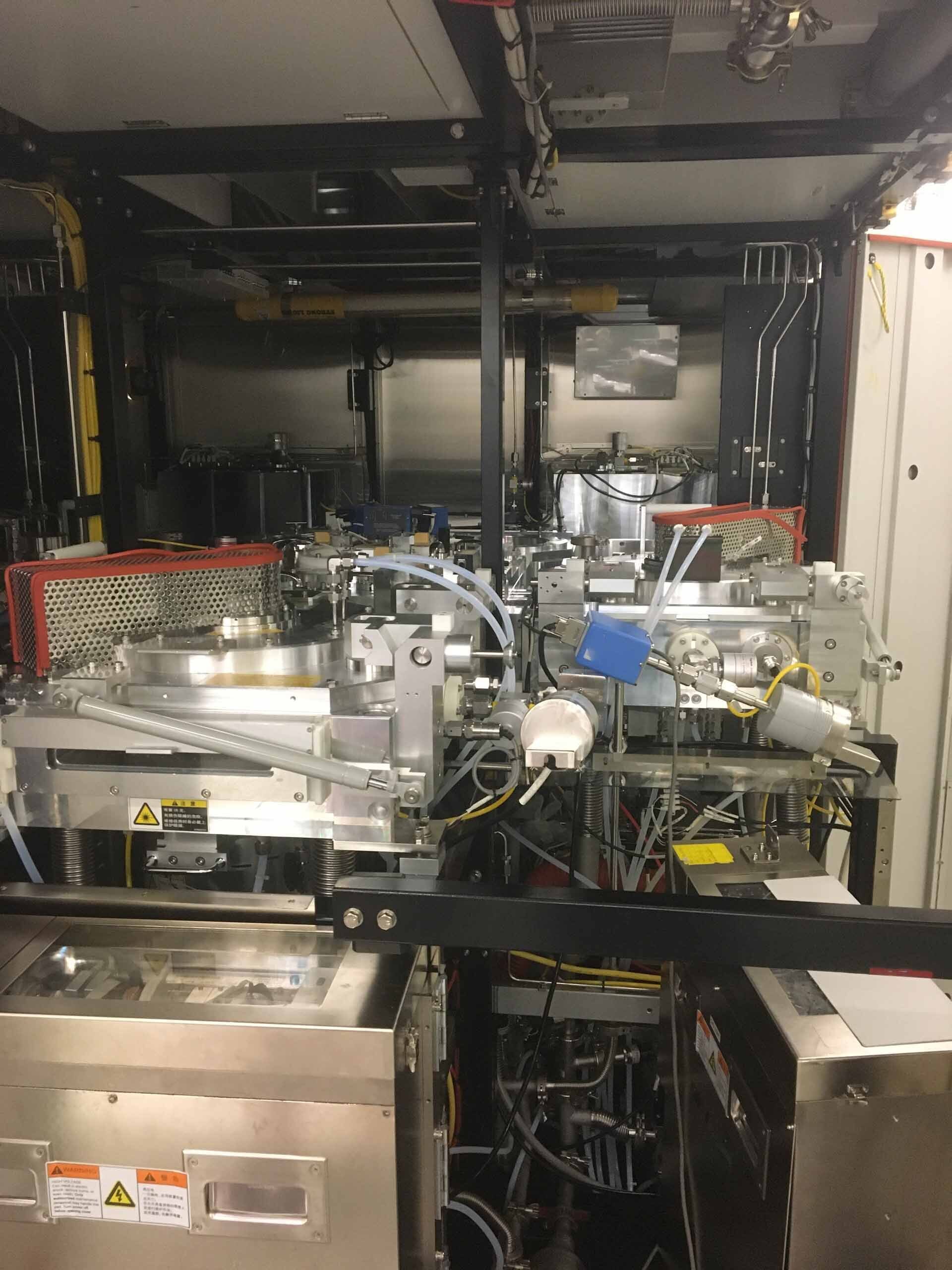

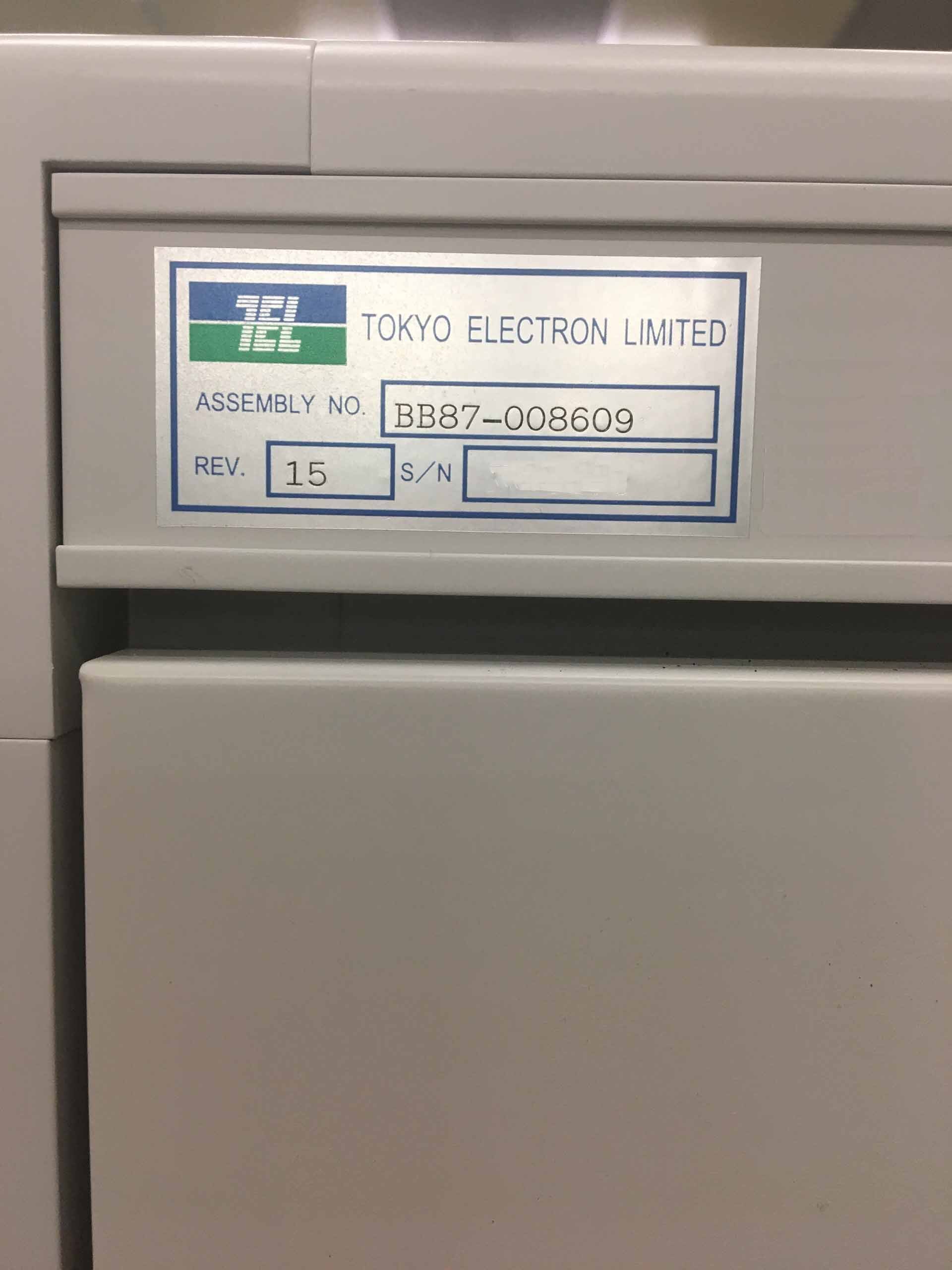

Used TEL / TOKYO ELECTRON MB2-730 #9395107 for sale

URL successfully copied!

Tap to zoom

ID: 9395107

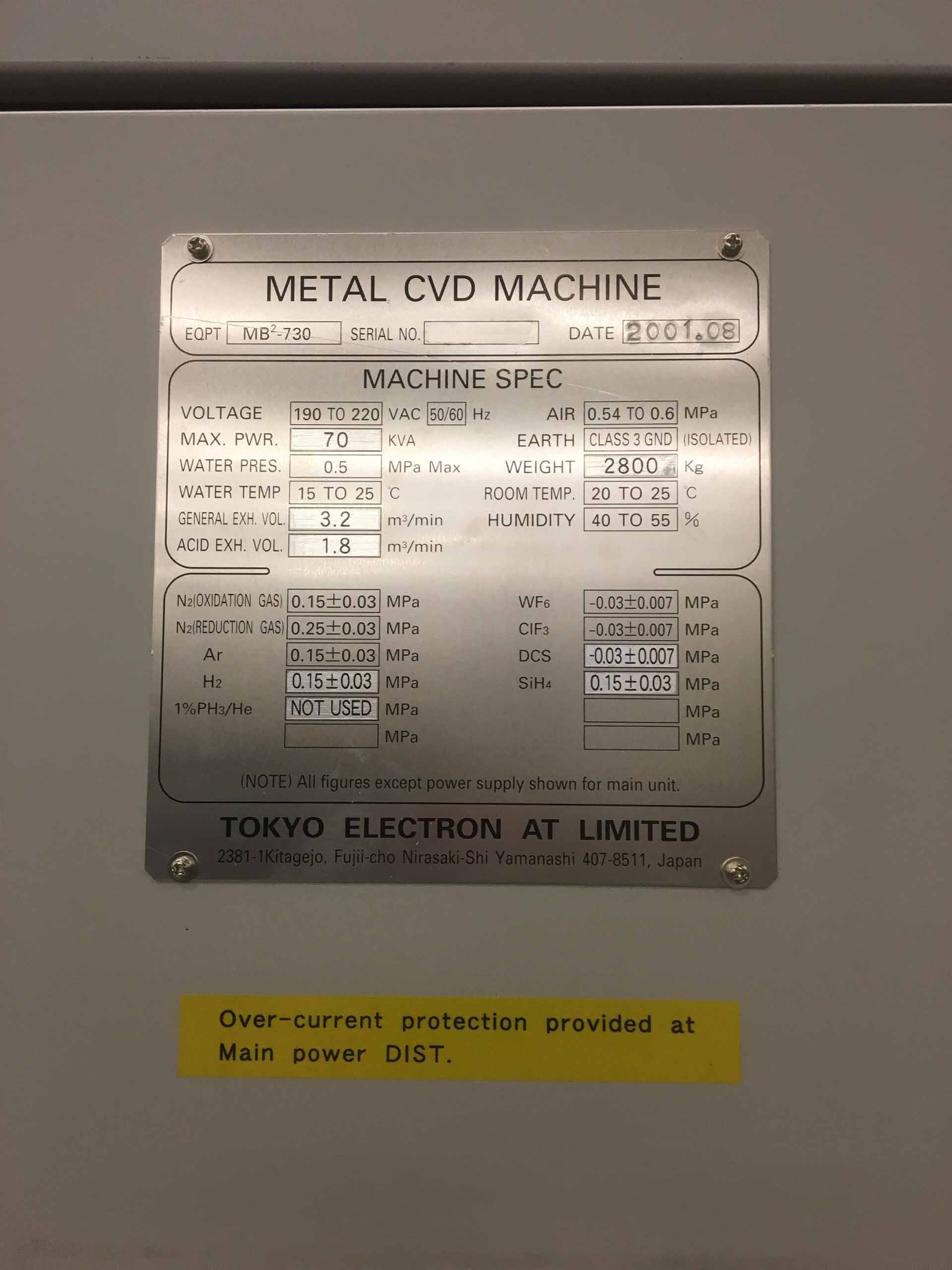

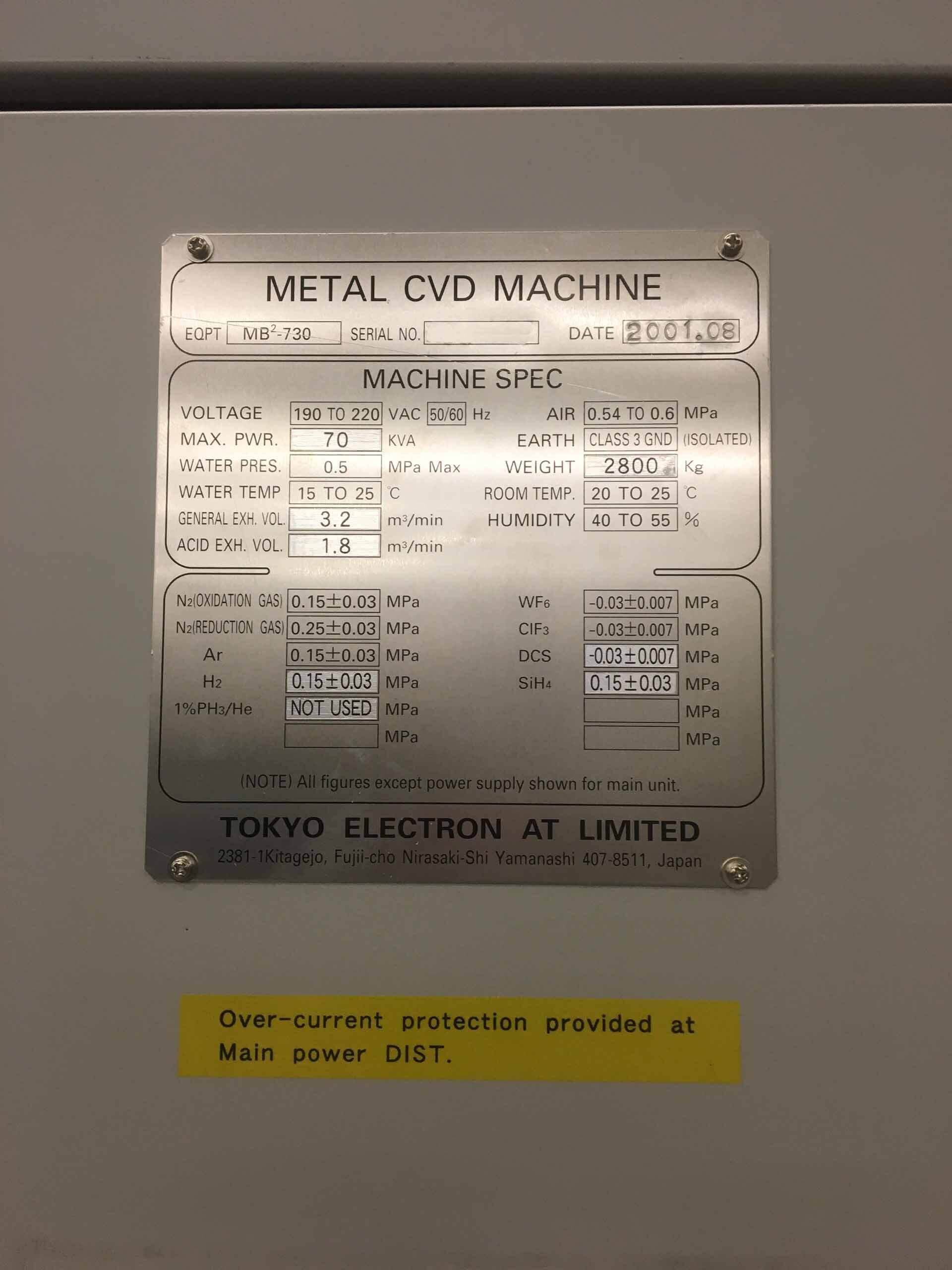

Vintage: 2001

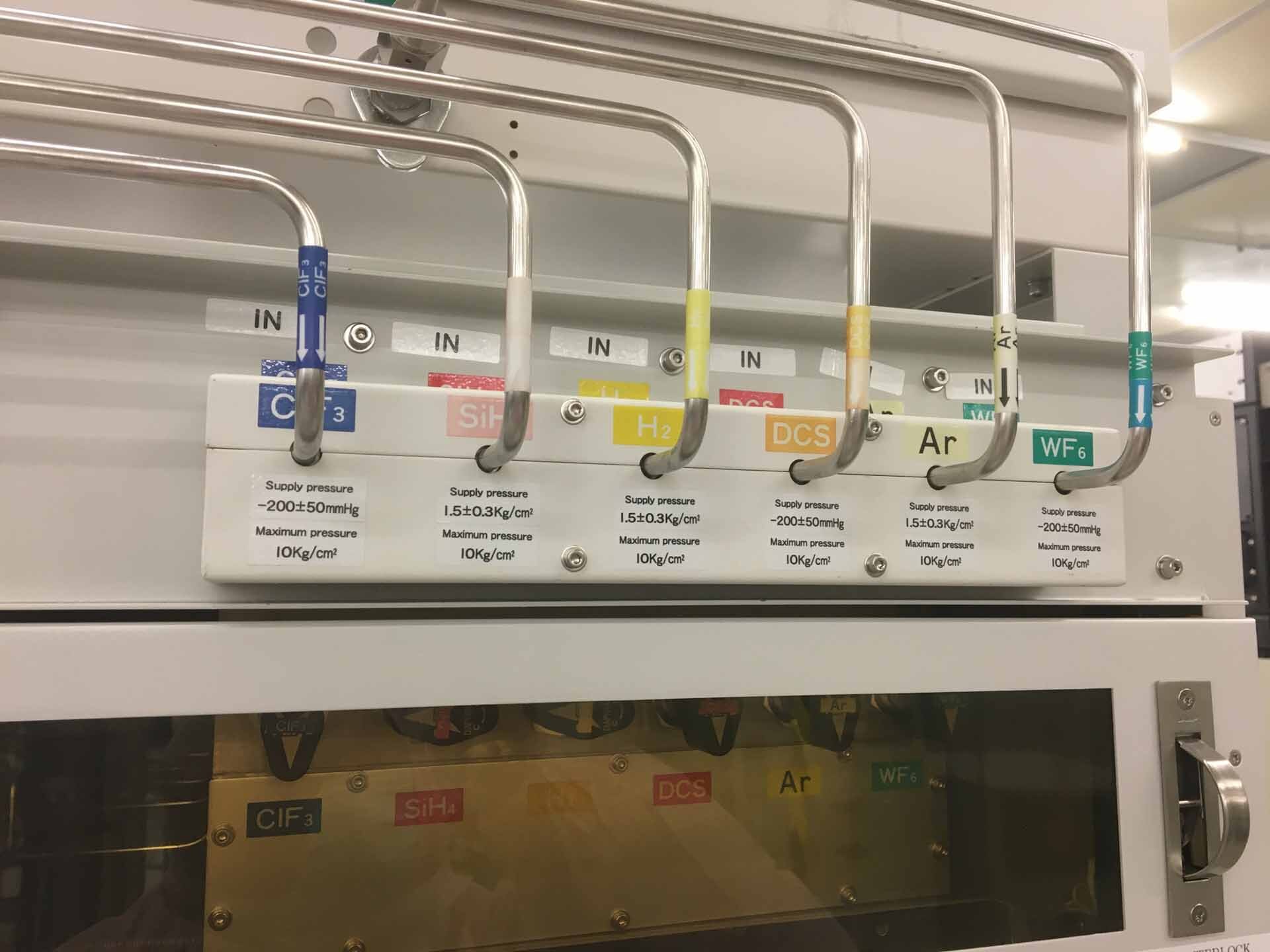

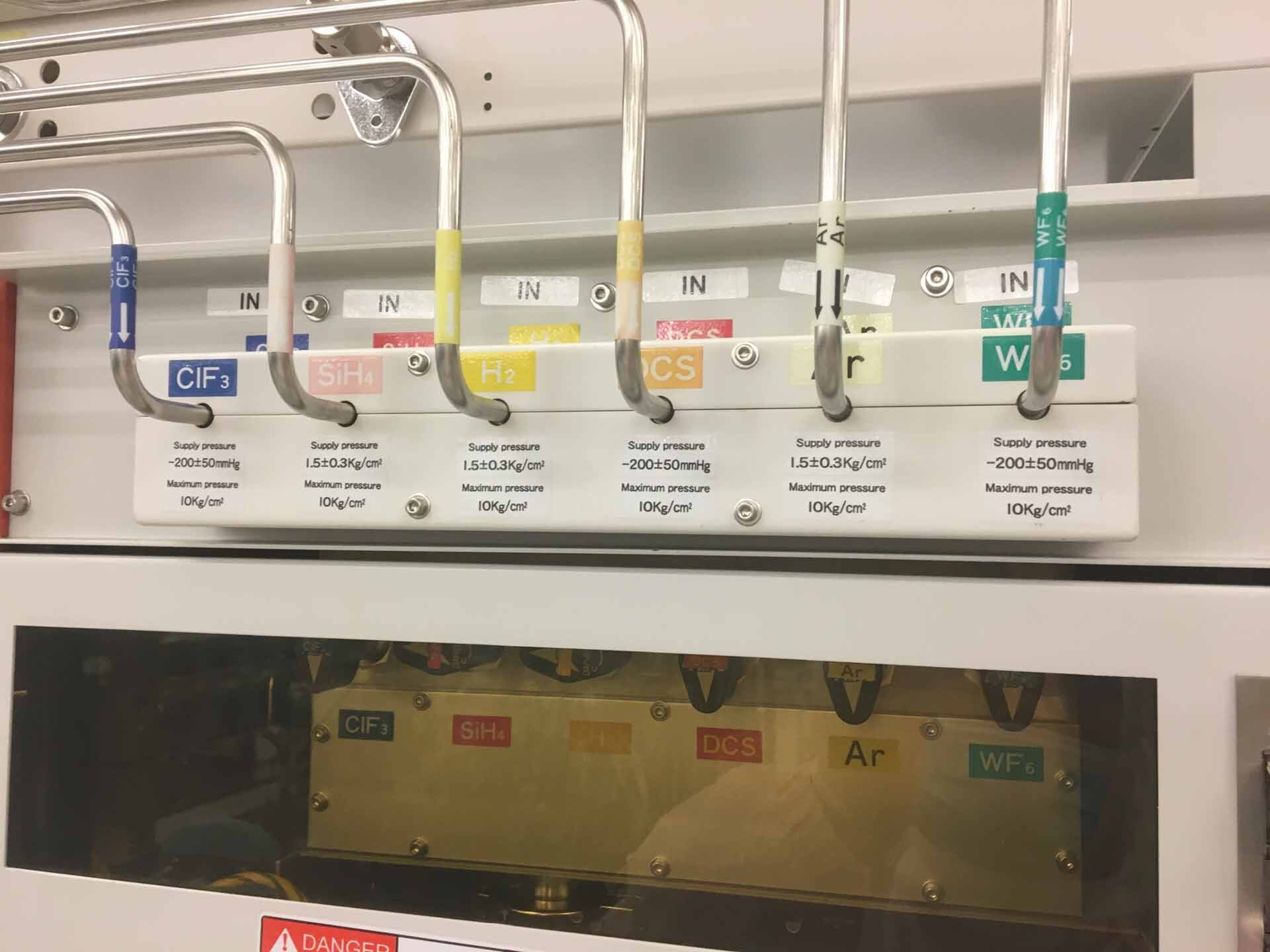

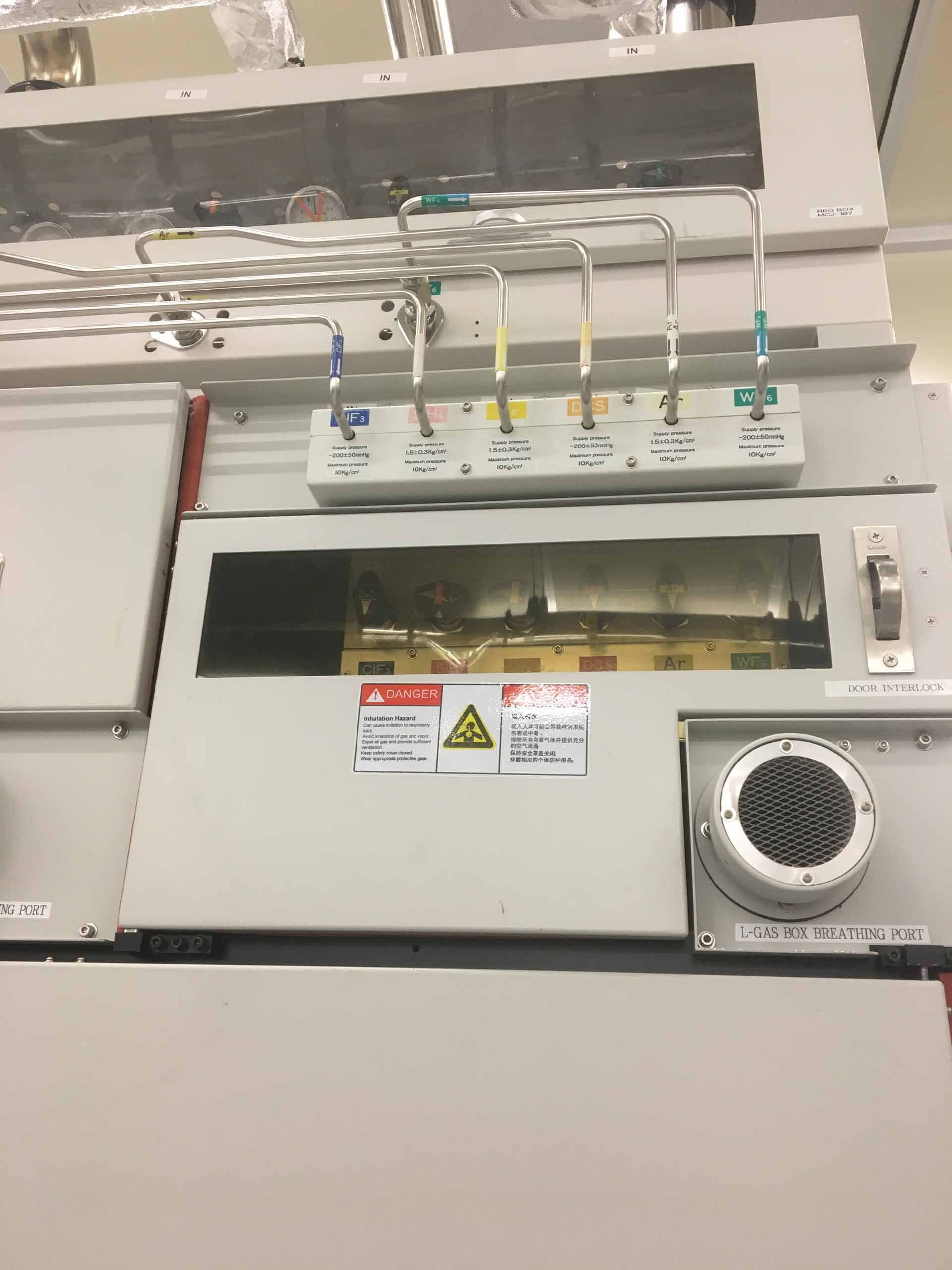

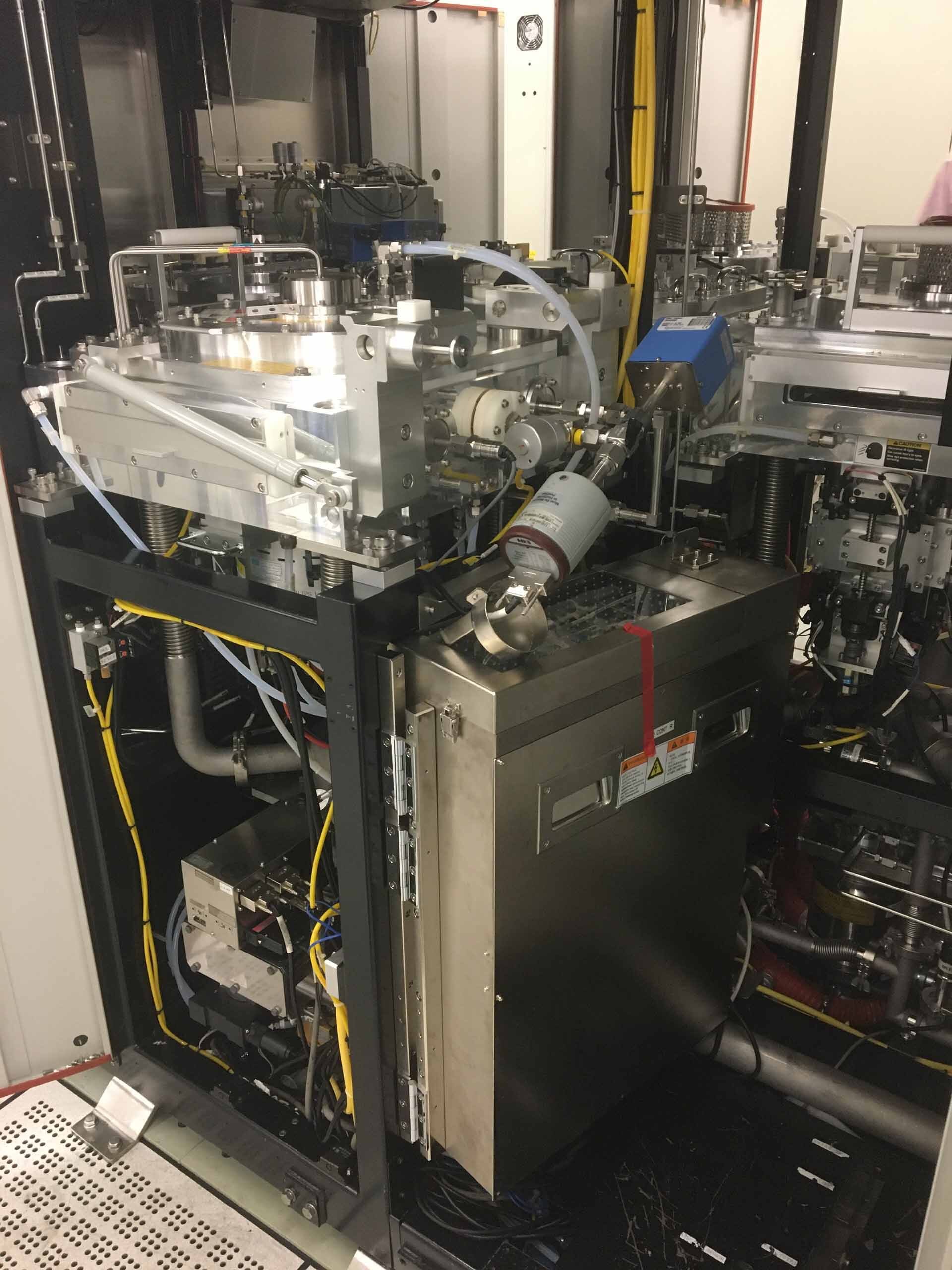

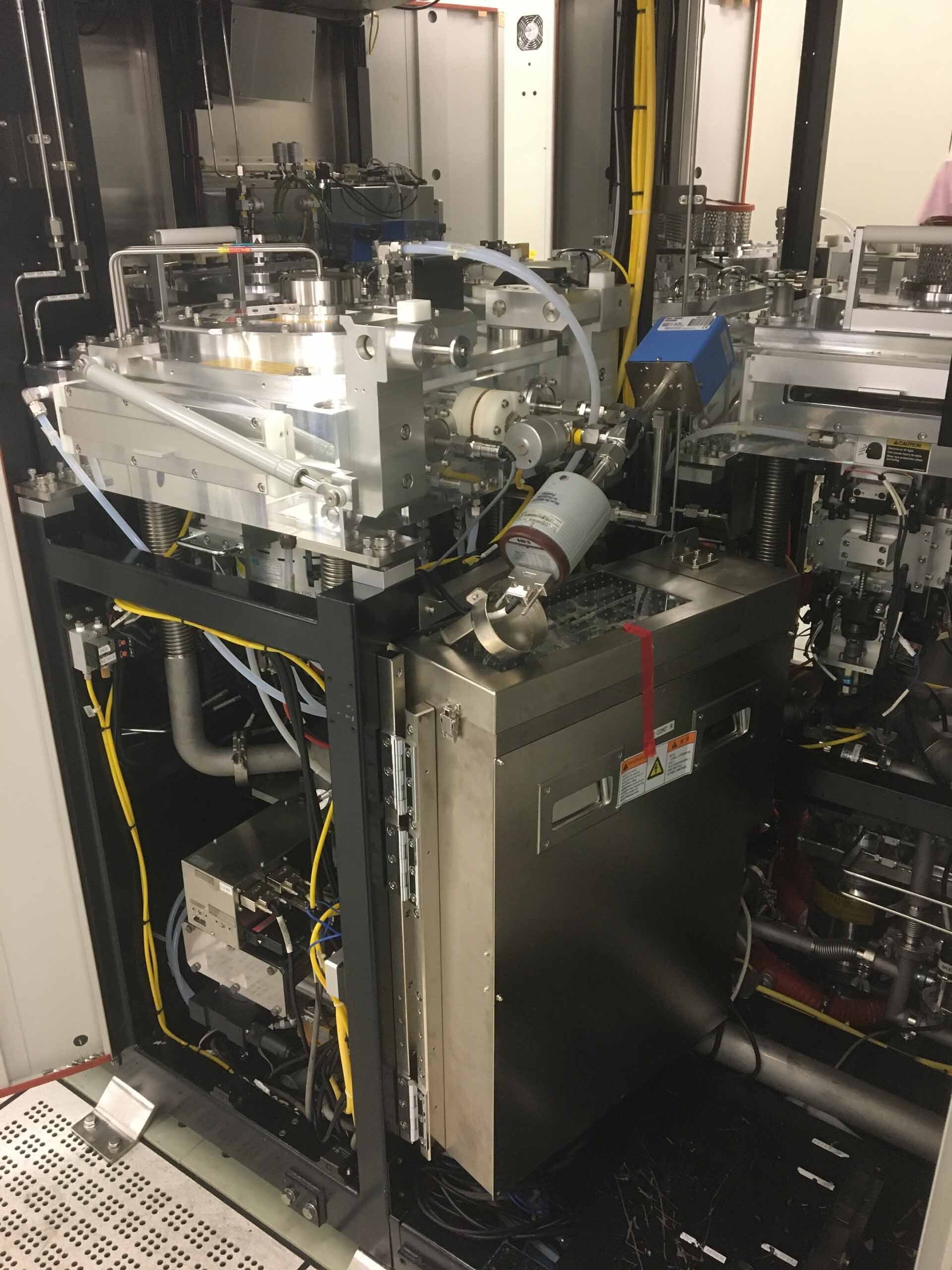

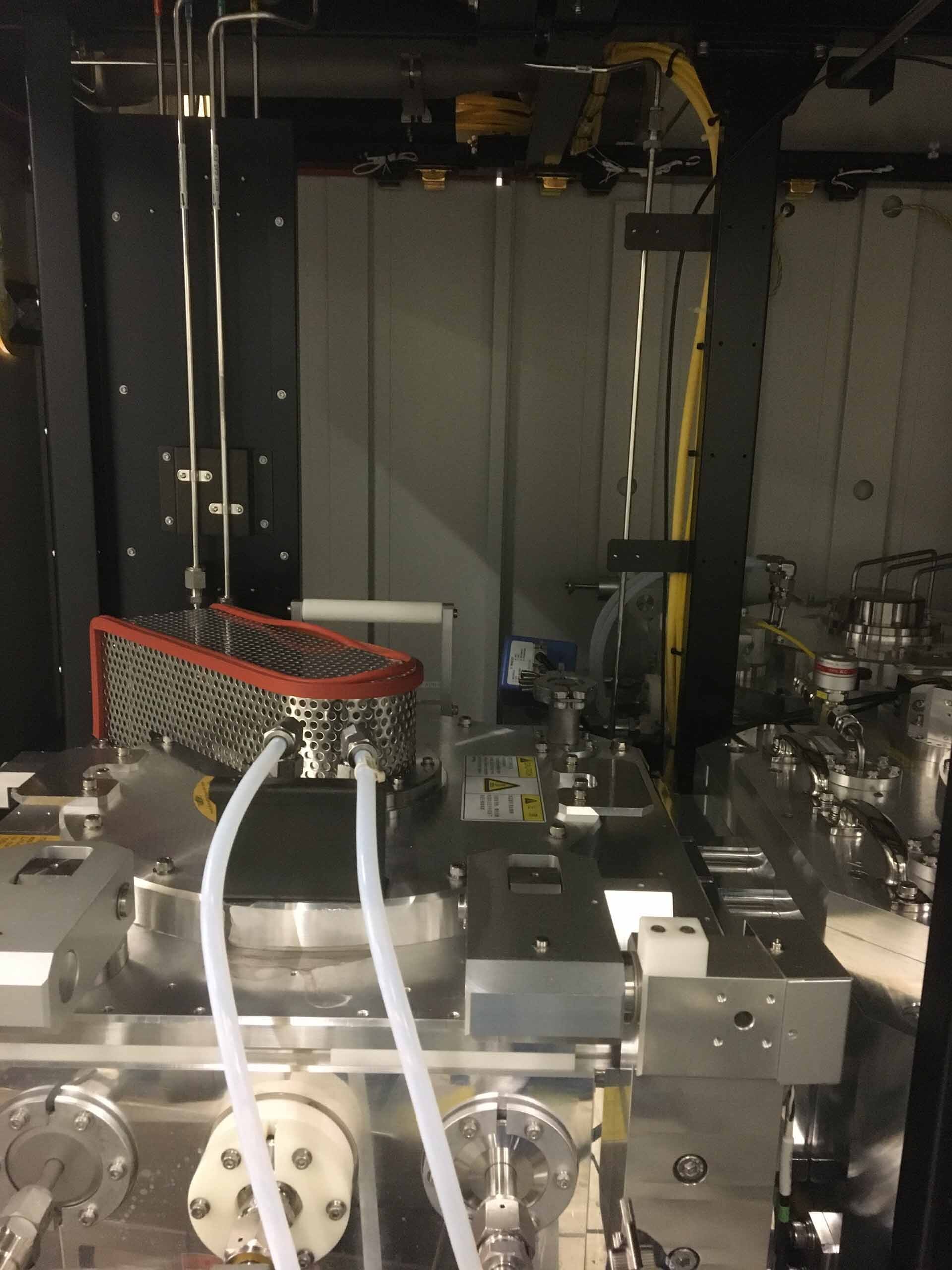

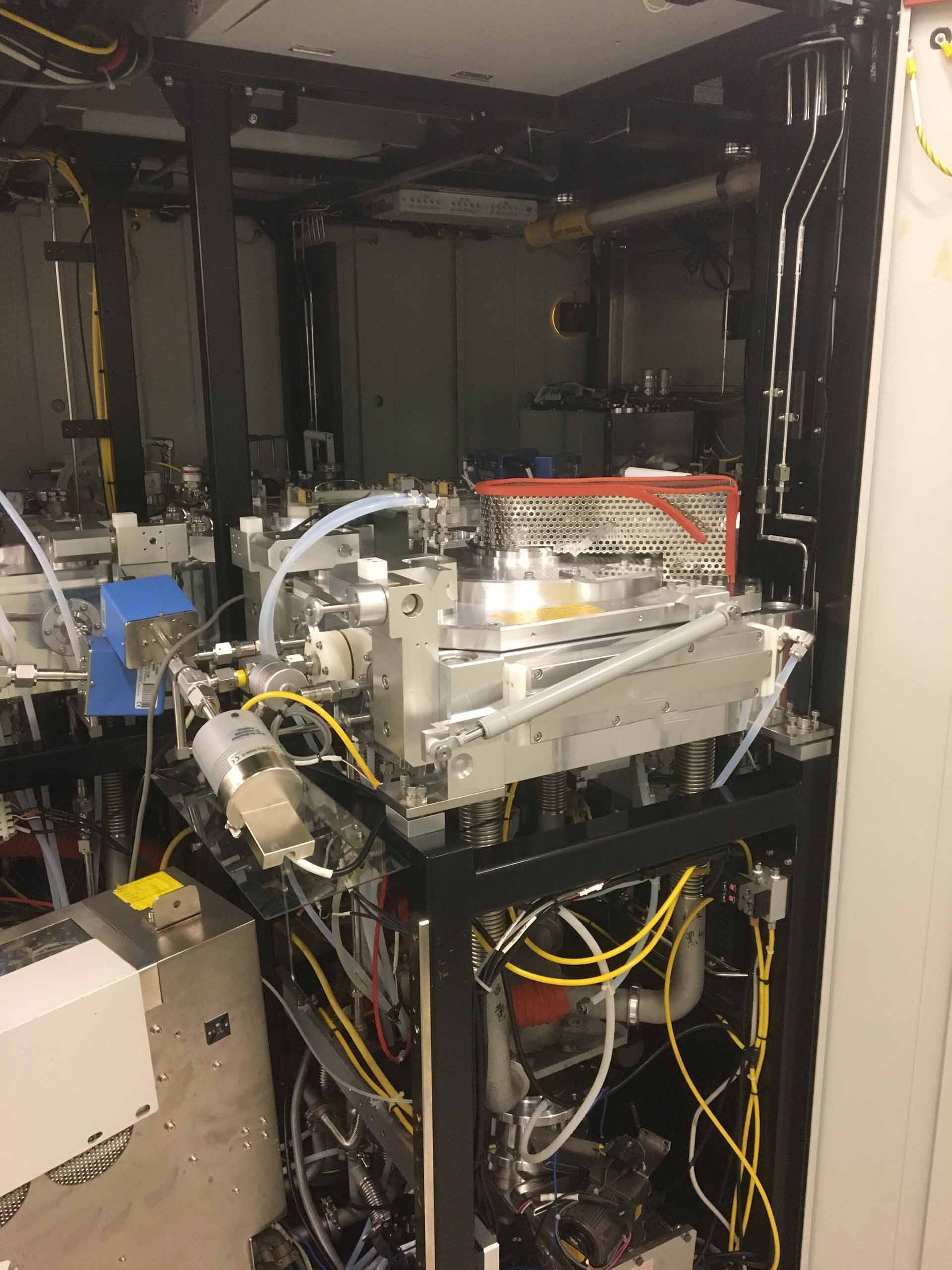

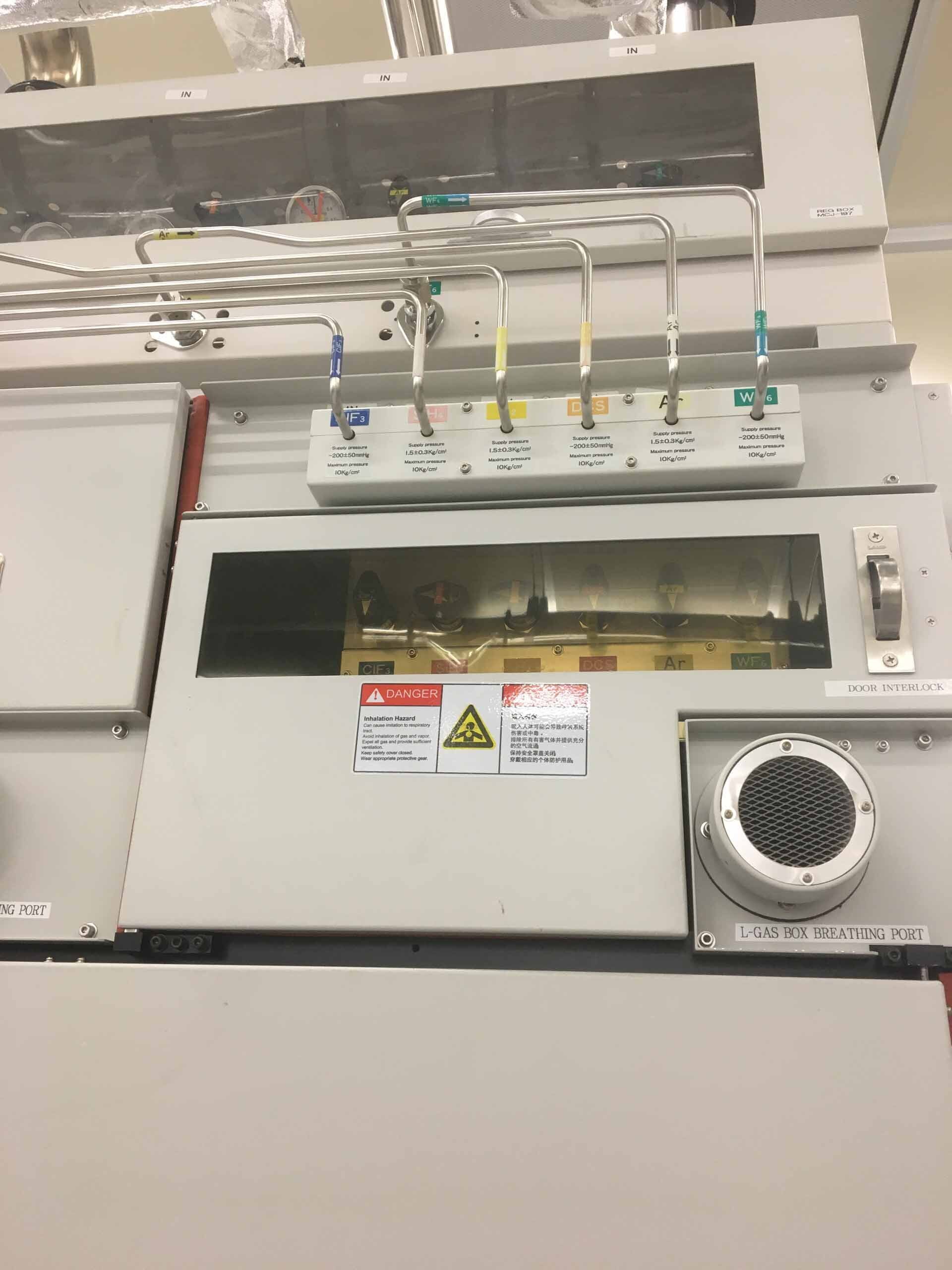

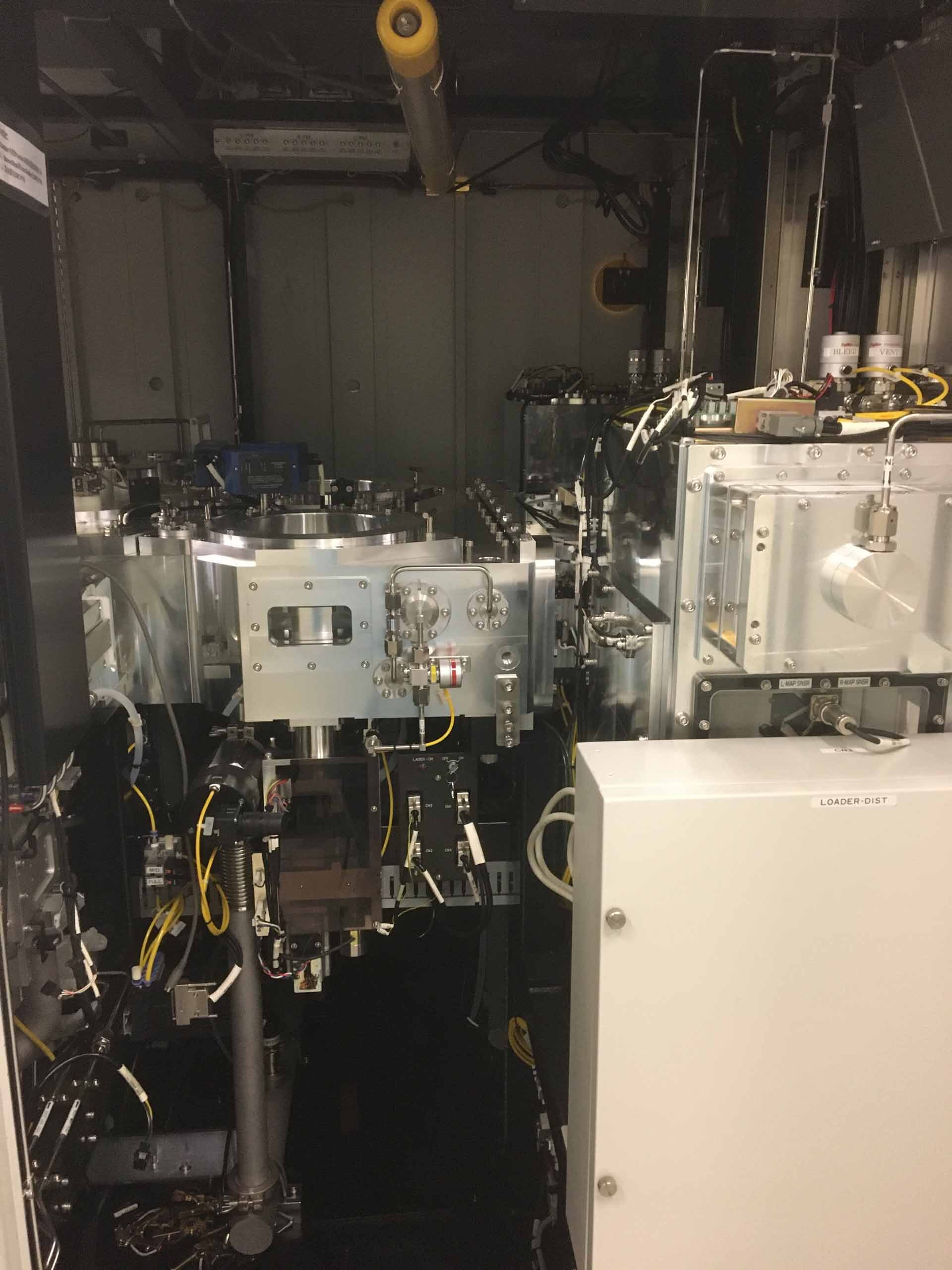

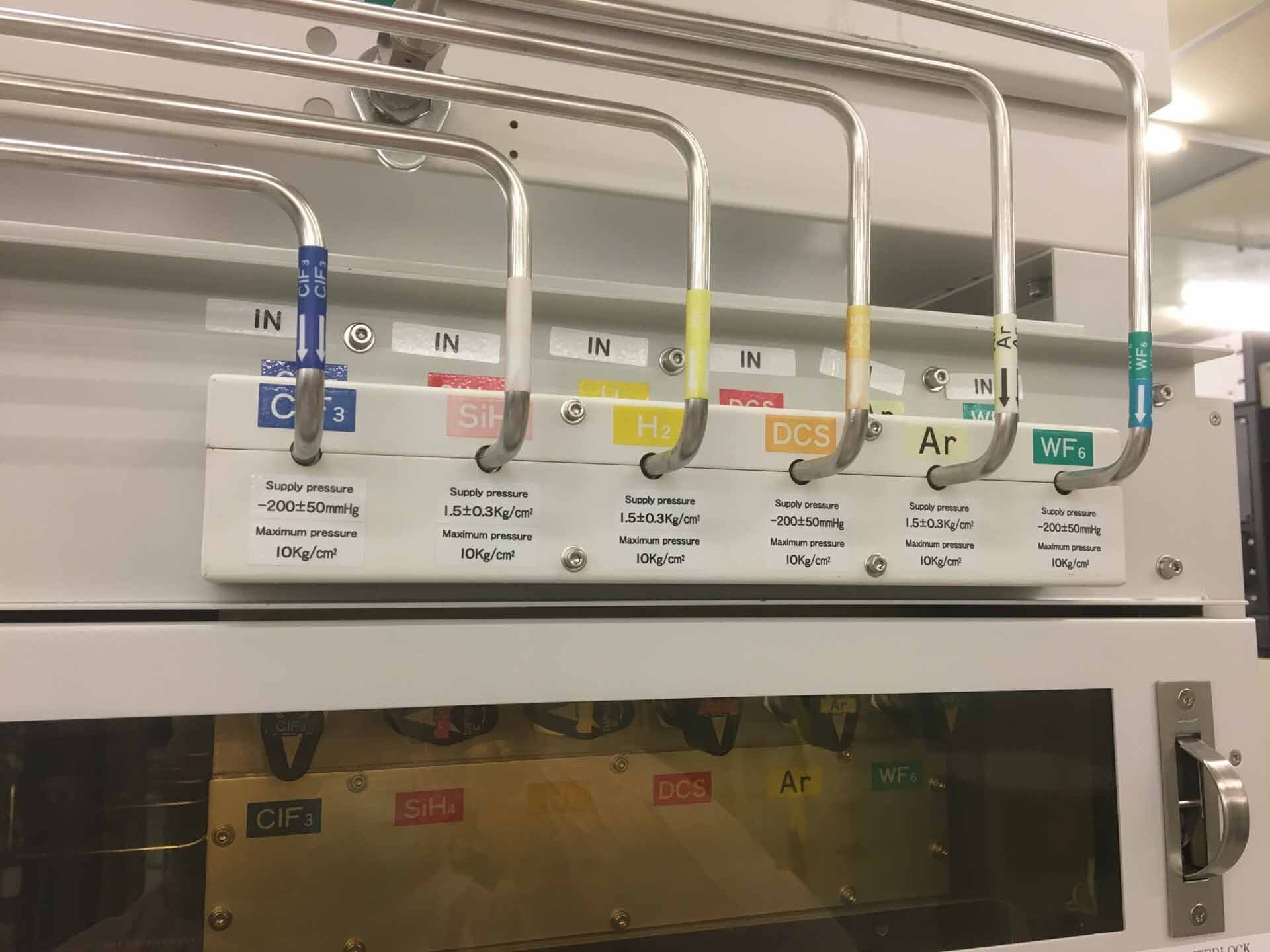

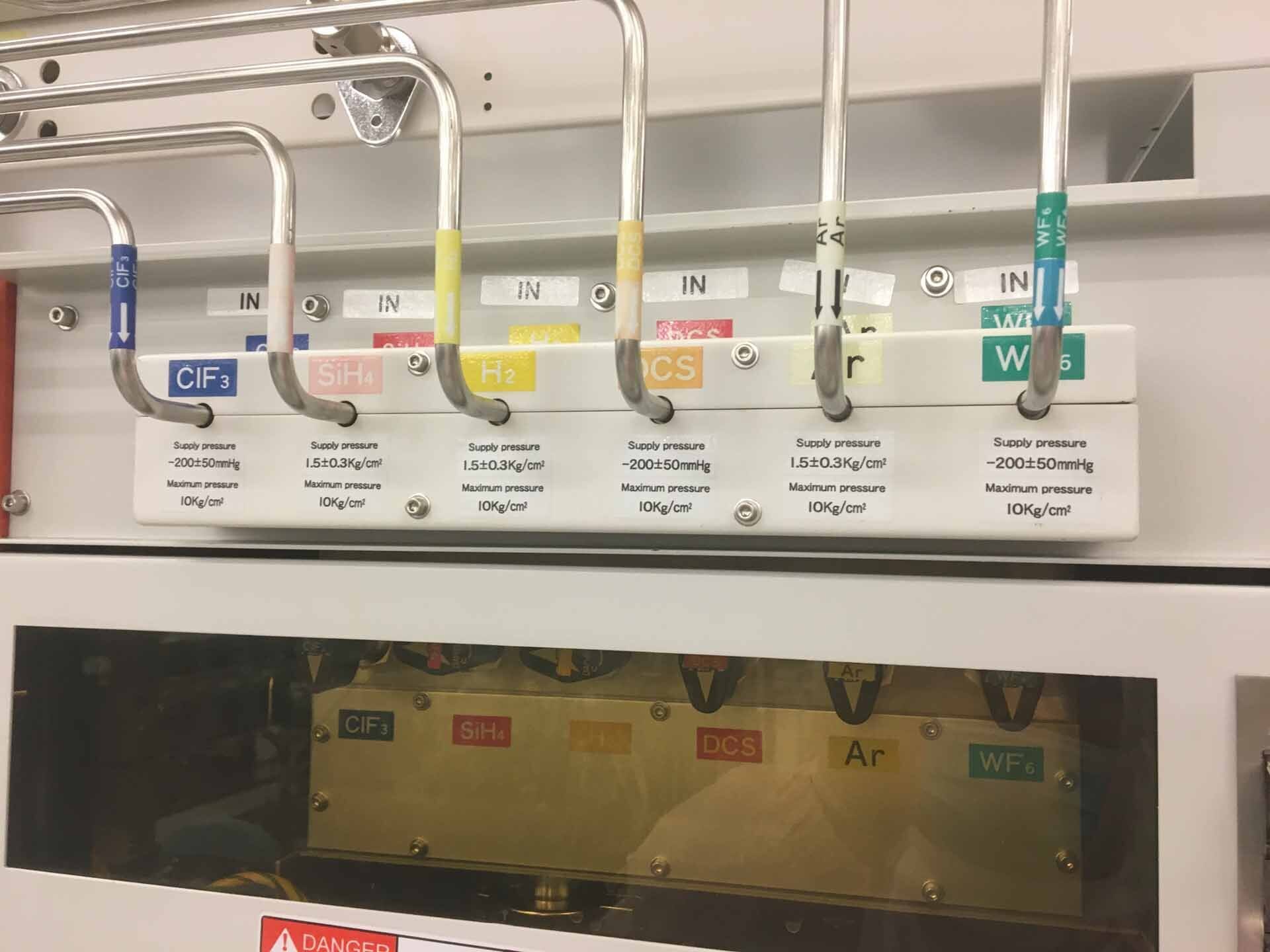

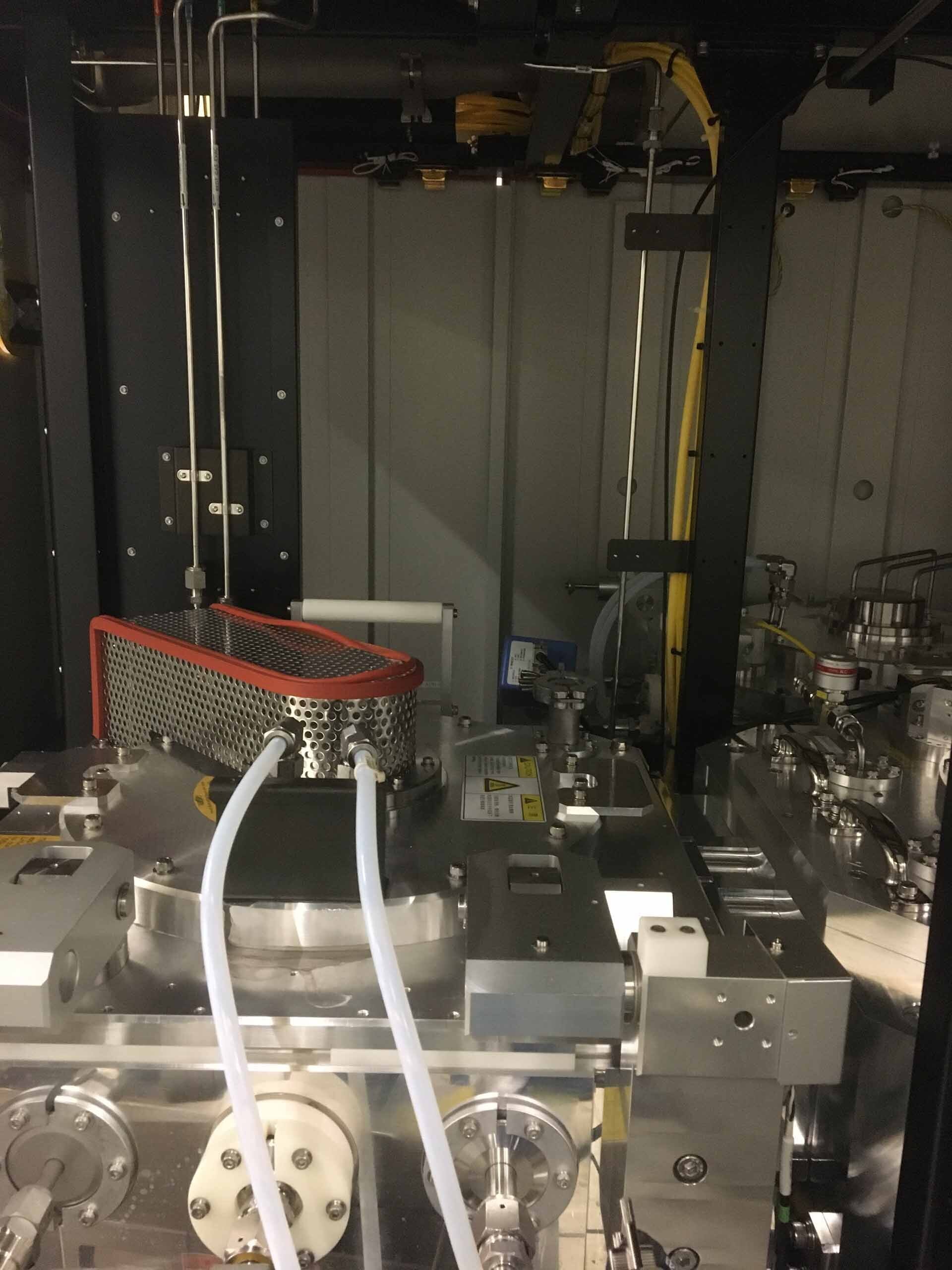

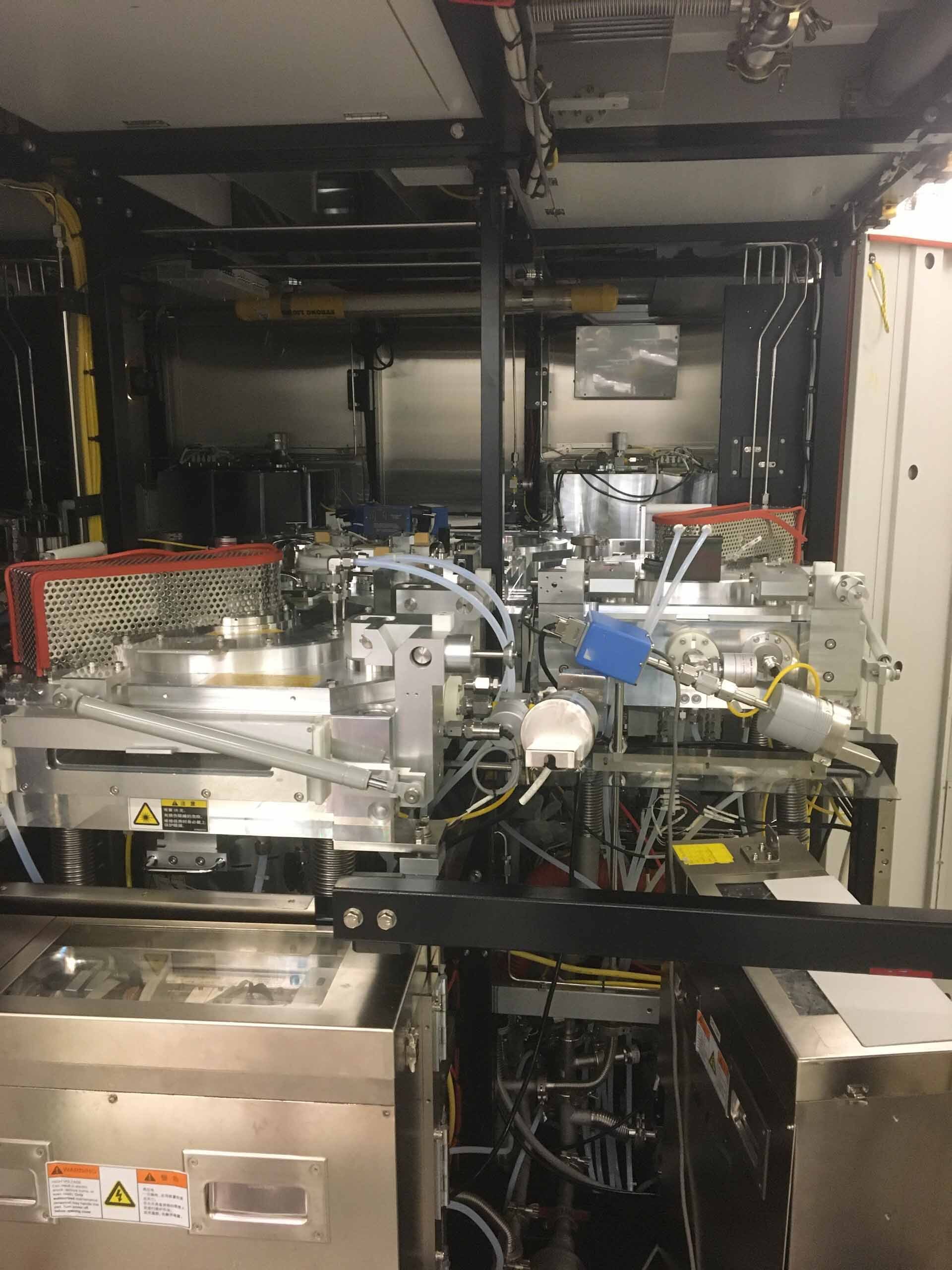

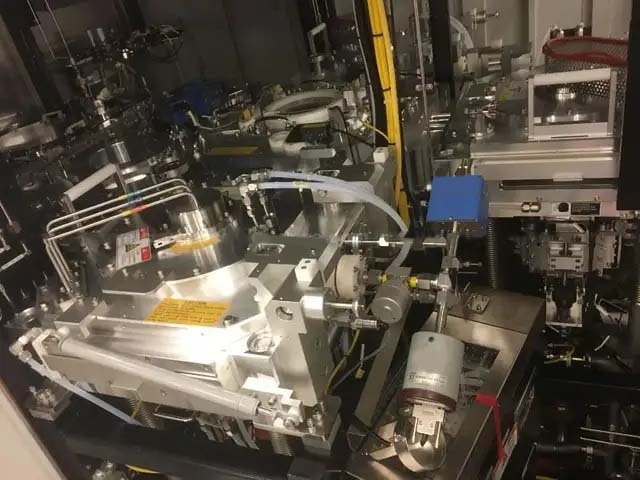

Metal CVD system, 8"

(3) Chambers

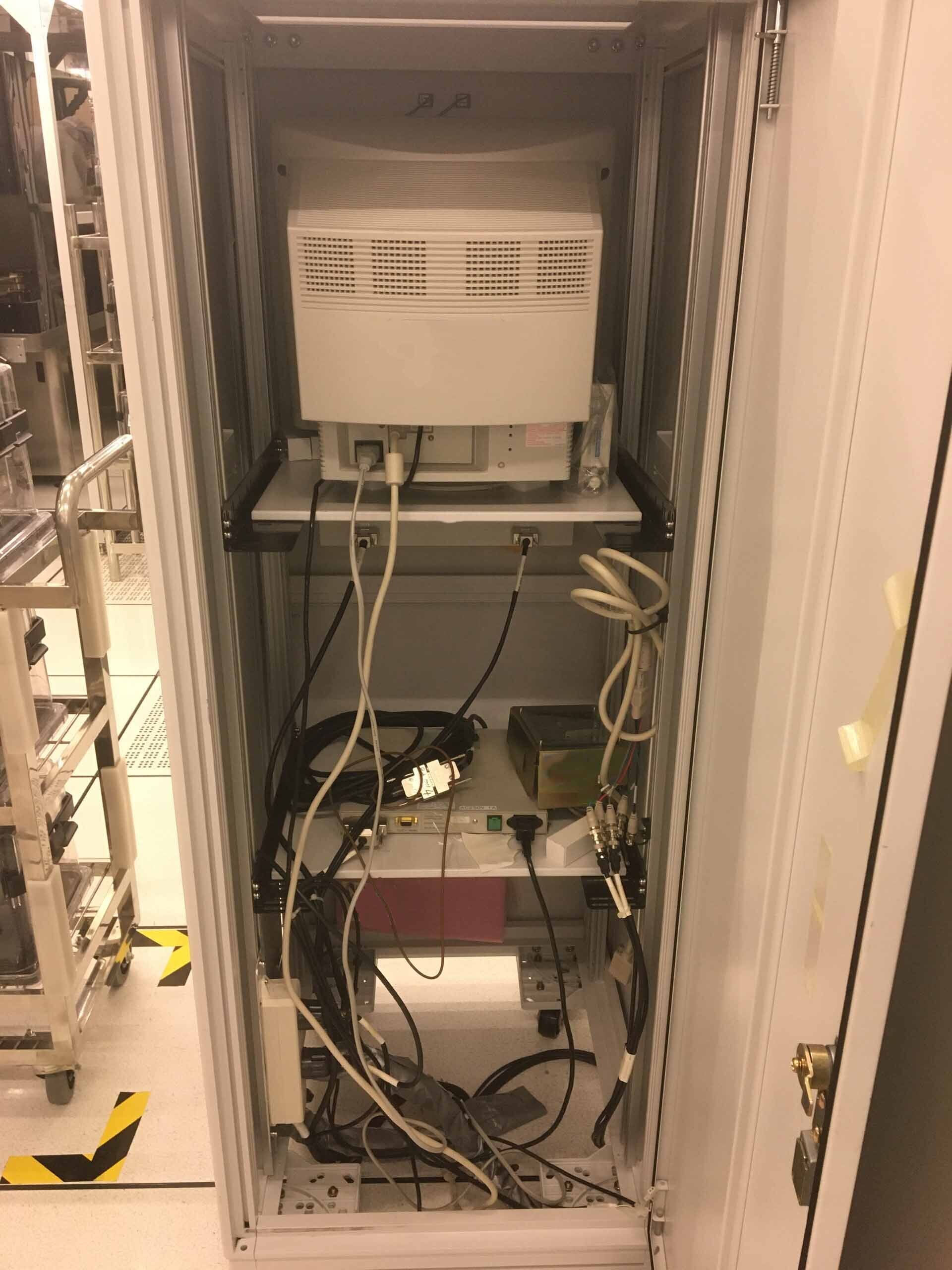

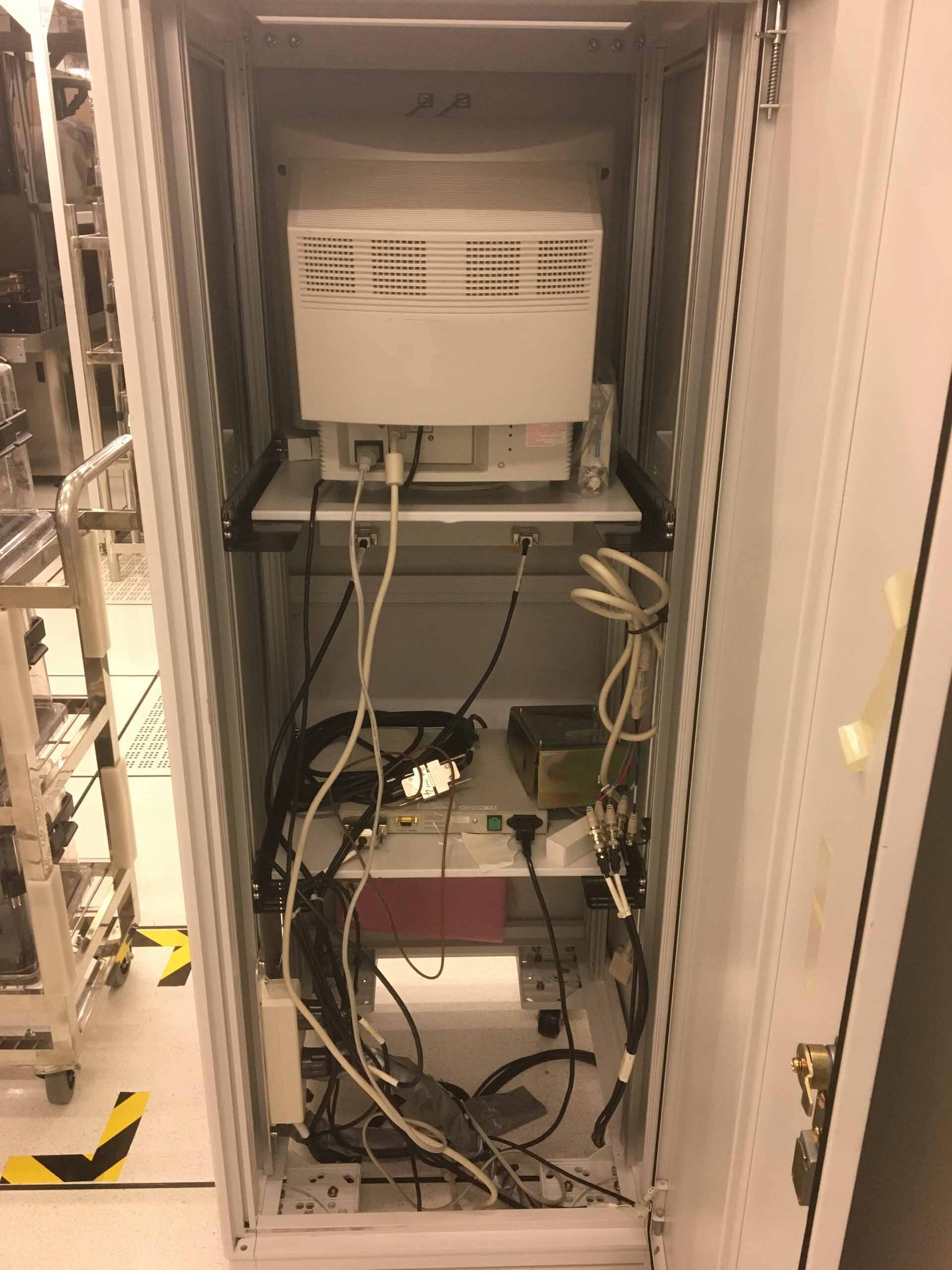

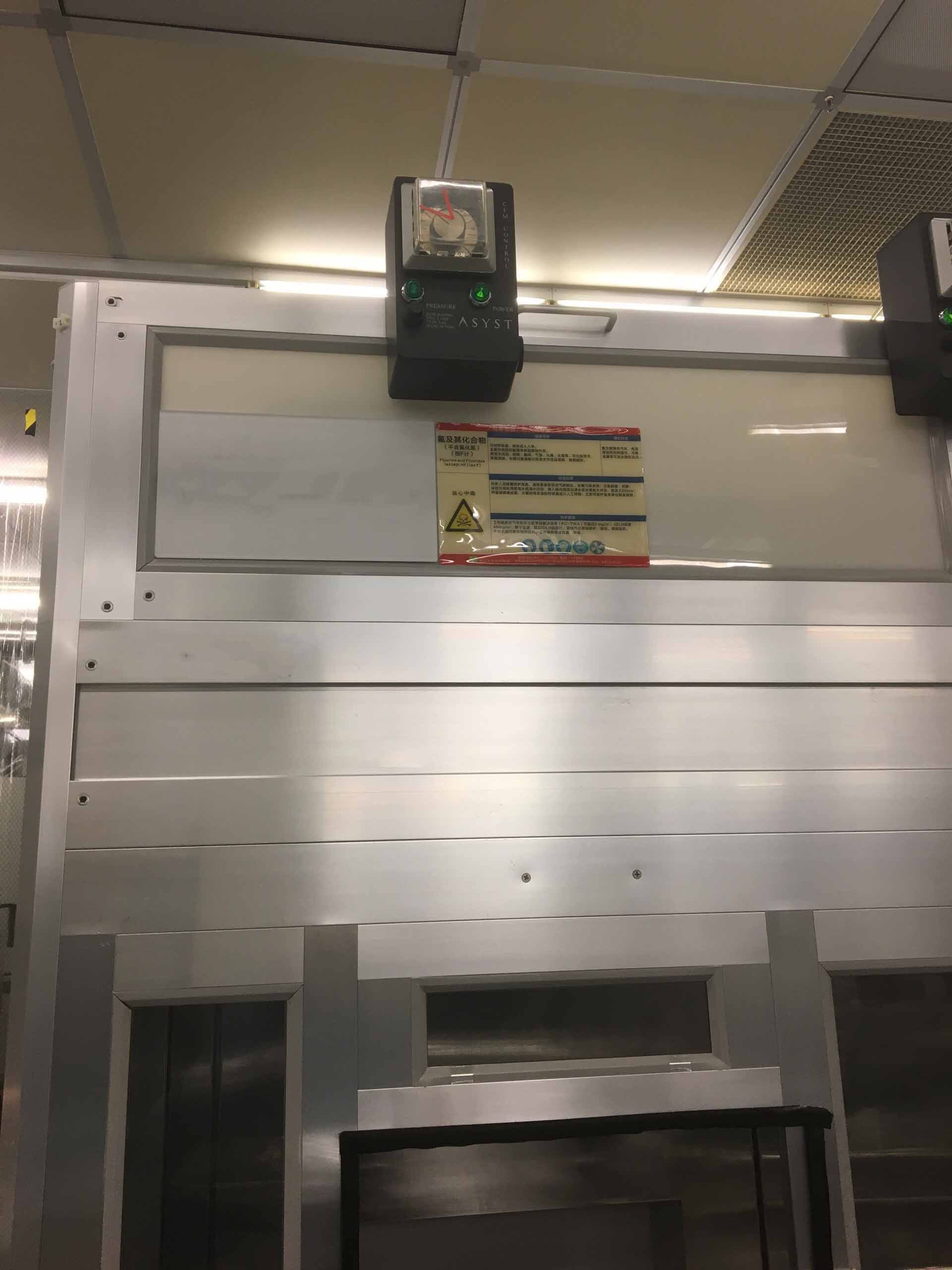

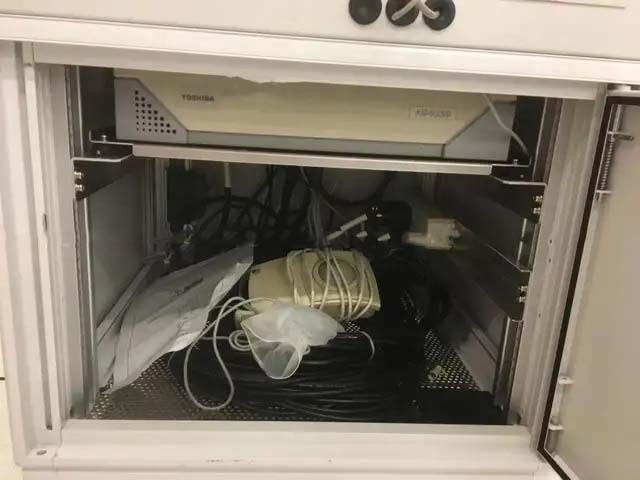

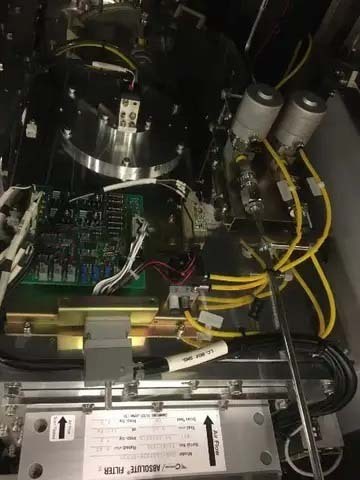

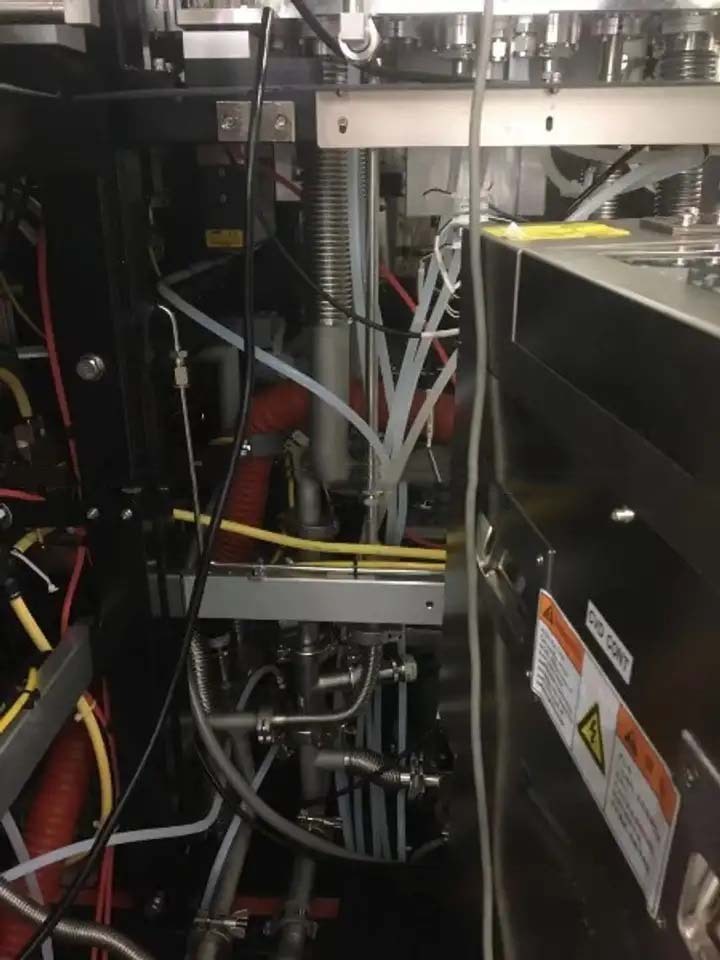

Control cabinet

No SMIF

Monitor

Monitor rack

2001 vintage.

TEL / TOKYO ELECTRON MB2-730 is a high-precision industrial etcher/asher designed to produce a high-precision etched or ashed surface on a rangeof materials. The etcher/asher has a maximum throughput of 730 wafers per hour, with each wafer receiving a uniform etch or ash operation. The machine is equipped with a precision plasma source, capable of offering etching depth as low as 0.6µm or lower. The equipment utilizes an advanced pressure controller to provide precise control over the etching process, allowing for high accuracy in etching results. The system utilizes a high contrast etching process, so that the etched or ashed surface is highly visible and easily identifiable. The etcher/asher also features a sophisticated pulse modulated oscillator unit, allowing for pulsed plasma mode for controlling the etching process. TEL MB2-730 also features an advanced closed-loop control machine, ensuring that the etch or ash meets the strict requirements for a specific application. The systems support a variety of substrates including silicon, quartz, glass, and metals. The tool also supports deposition of polymer, tracks, and metallization. The asset is highly compatible with a range of tool and material designs, helping to increase production efficiency and reduce process cost. Additionally, the integrated cleaning process allows for efficient cleaning between etching and ashing operations, leading to consistent batch results. The etcher/asher is designed for maximum safety and easy handling. It features a host of safety features to protect personnel and materials. The model is equipped with thermal sensors, ultrasonic sensors, and optical sensors to monitor the process and ensure safe operation. The machine is also designed for automatic remote operation, allowing for easy setup and operation of the machine. TOKYO ELECTRON MB2-730 is the perfect choice for a variety of etching and ashing operations, offering precision etching and ashing down to 0.6 microns. The machine is equipped with a selection of high-precision control features, as well as an integrated cleaning process for consistent results. Its safety features offer multiple levels of safeguard from potential accidents. Finally, its remote operation and automated setup make it an easy option for any etching and ashing needs.

There are no reviews yet