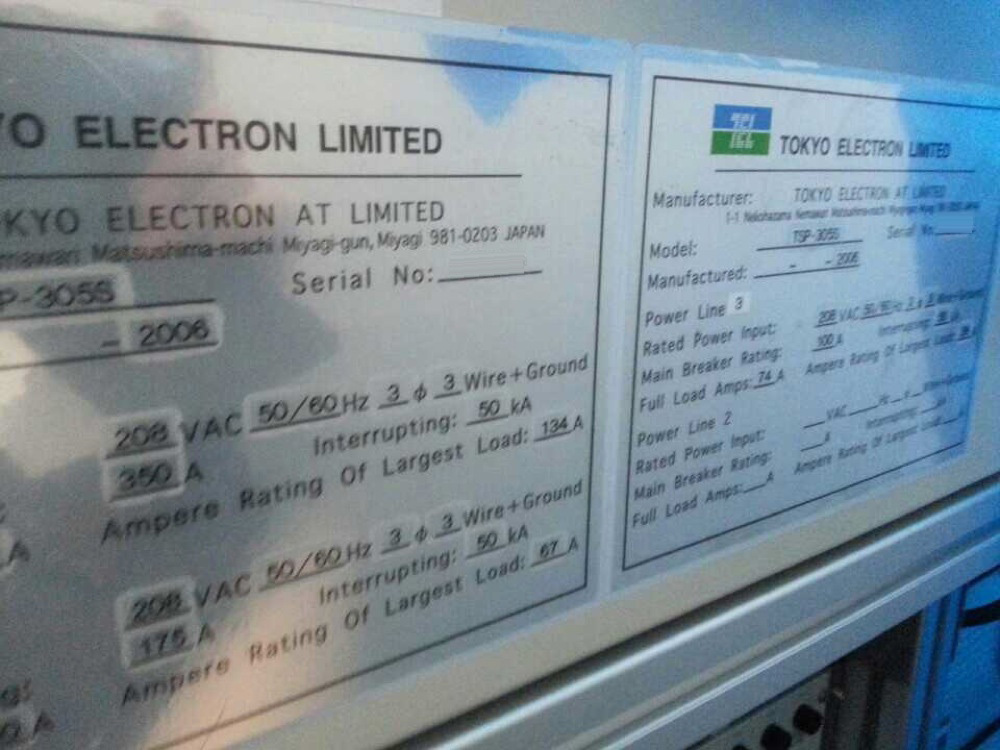

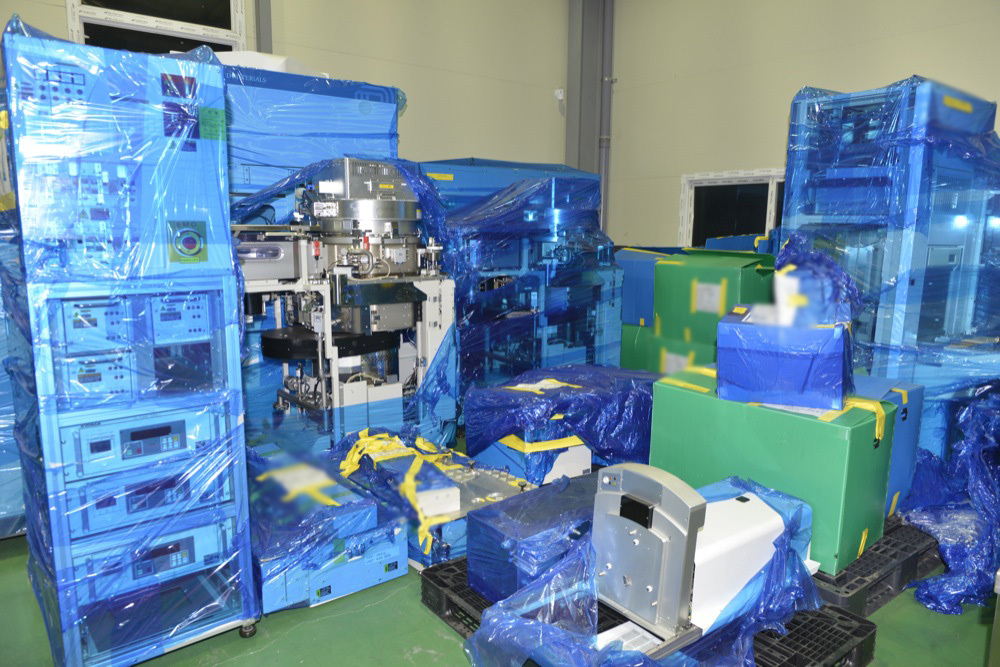

Used TEL / TOKYO ELECTRON SCCM JIN #9038421 for sale

URL successfully copied!

Tap to zoom

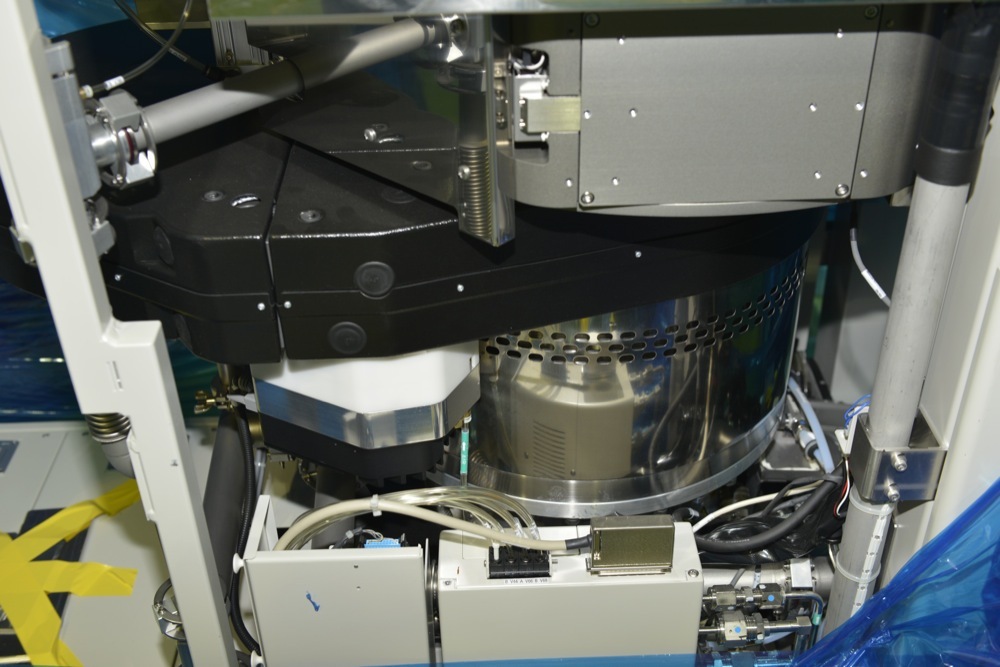

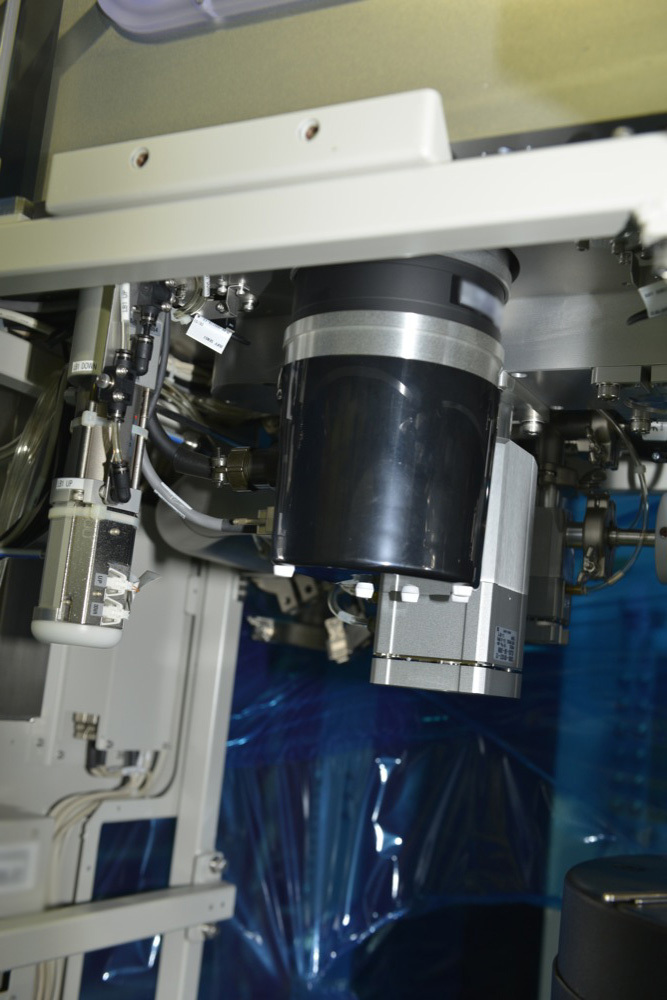

TEL / TOKYO ELECTRON SCCM JIN is an etcher/asher that utilizes plasma-enhanced chemical vapor deposition technology, offering superior results for the formation of custom-etched materials. TEL SCCM JIN's advanced controller enables the user to adjust the etching rate, temperature, and pattern to produce a desired result. It offers versatile and precise etching/hashing capabilities, enabling the user to produce custom etchings within tight tolerances. TOKYO ELECTRON SCCM JIN utilizes a process chamber that can hold up to 300cc of etching/hashing material and employs etching/hashing gases such as CF4, O2, Ar or H2. The chamber pressure is adjustable, allowing the user to customize the etching/hashing process. The chamber is equipped with an upstream and downstream bellows to allow for the increased pressure within the chamber during the etching/hashing process. SCCM JIN utilizes a Substrate Heater to effectively and accurately heat the substrate material without risking fracture or nonuniform heating. The process gases and the numerical control transmitter enables the user to adjust the etch rate, temperature, and pattern for customizable etching/hashing. TEL / TOKYO ELECTRON SCCM JIN employs the use of a sequential source-driven technique to accurately cut into the metal substrate material. It incorportates a uniform waveform generator, which accurately controls the etching/hashing process. TEL SCCM JIN employs an E-Beam Etcher that allows the user to put down smaller feature sizes than the traditional etching/hashing using laser and ion beam methods. It gives excellent pattern repeatability and accuracy, enabling the user to produce intricate etching/hashing patterns for custom applications. The system utilizes a remote monitor that can store and track results from up to 30 experiments at a time. Additionally, TOKYO ELECTRON SCCM JIN provides optional software modules that can monitor the etch rate, temperature, and etch pattern in real-time. In summary, SCCM JIN is an etcher/asher with a superior etching/hashing solution that offers versatile and precise capabilities with excellent repeatability and accuracy. It utilizes multiple process chamber, bellows, and generators, E-Beam etchers, and remote monitors to enable the user to etch/hash custom materials with optimal results.

There are no reviews yet