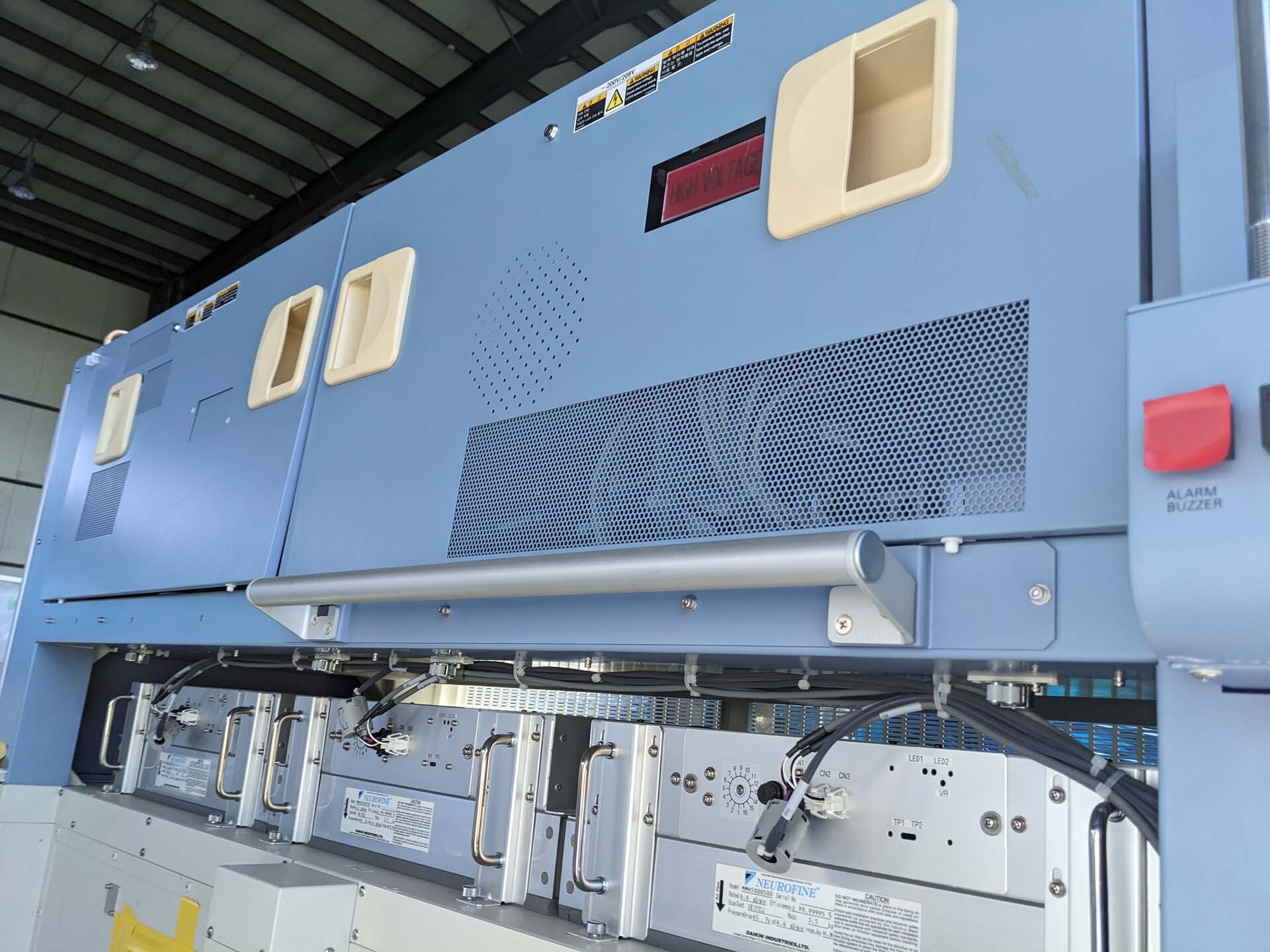

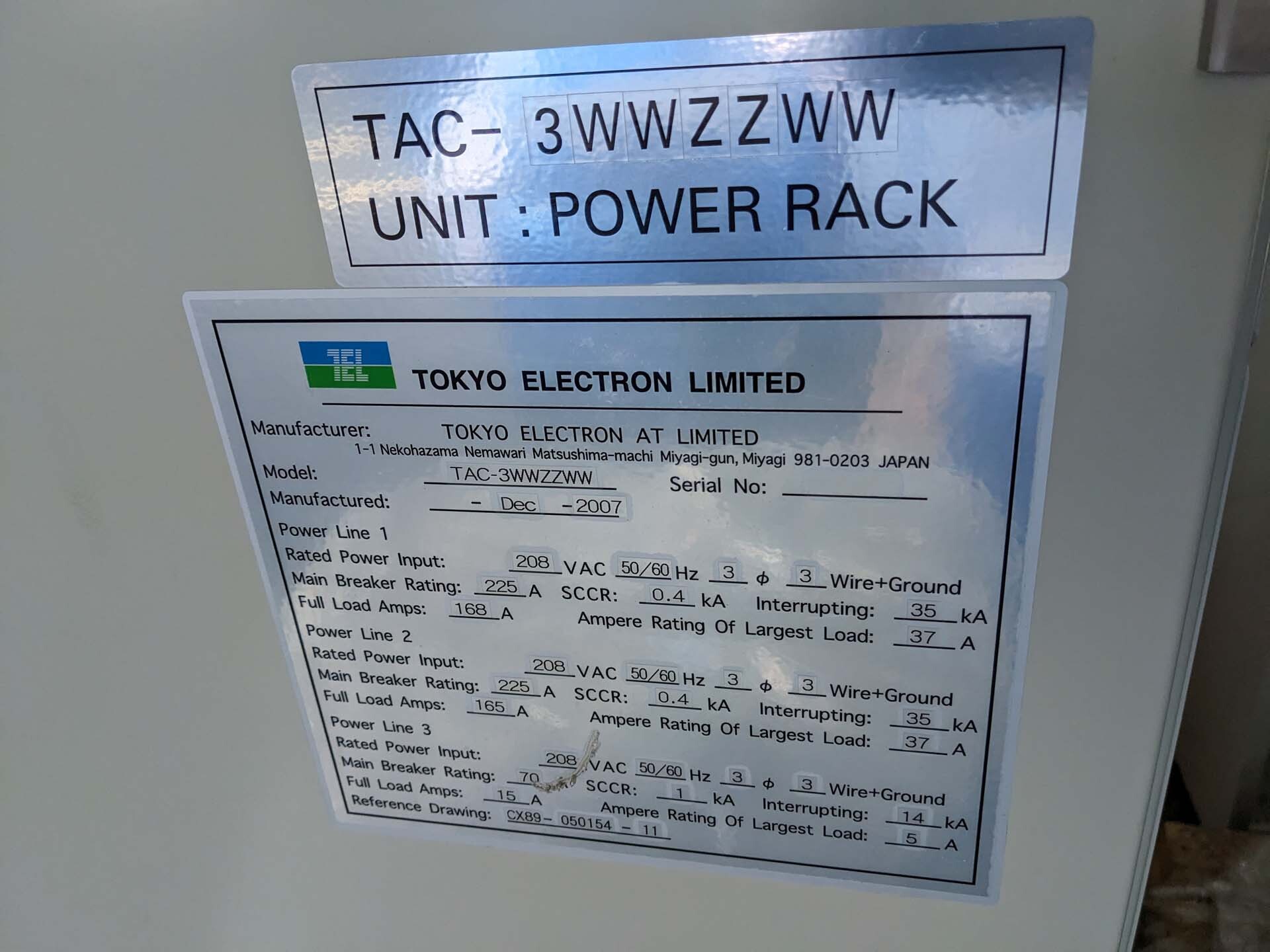

Used TEL / TOKYO ELECTRON TAC-3WWZZWW #293587739 for sale

URL successfully copied!

Tap to zoom

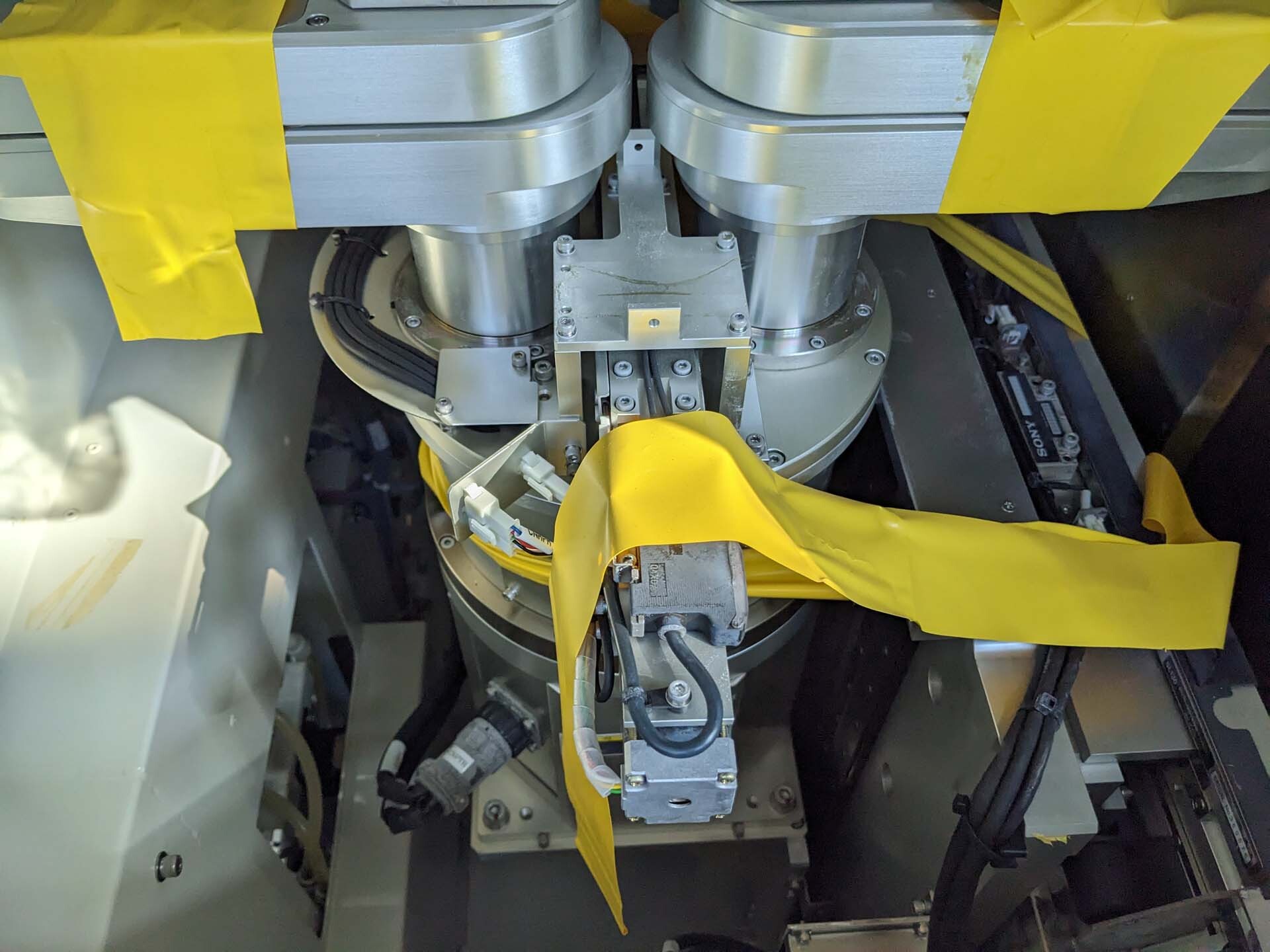

TEL / TOKYO ELECTRON TAC-3WWZZWW is a semi-automatic wafer etcher / asher developed by TEL Limited. The equipment is designed to enable high-throughput and repeatable etching and ashing of all types of electronic components on up to four 8-inch (200 mm) diameter wafers at a time. The system is capable of processing a wide range of materials, such as noble metals, silicon, quartz, and other high-k dielectrics. Features of TEL TAC-3WWZZWW include automatically controlled temperature, a low gas consumption rate, and a unique optical-fiber illumination that ensures uniformity of etch and ash processes throughout the chamber. TOKYO ELECTRON TAC-3WWZZWW's etcher / asher chamber is constructed of stainless steel and has a cylindrical shape with a bottomless crucible. It also features a mass flow controller and a thermocouple for controlling the temperature in the chamber. Furthermore, it is equipped with two automated valves, one for loading and unloading wafers and one for gas introduction. The chamber also features pressure control, allowing operators to precisely adjust the process pressure. In addition, the unit is designed to be able to work in any orientation, allowing precise etch and ash processes to be carried out with a minimum of process variations. TAC-3WWZZWW also includes a safety interlock machine for preventing accidental gas leakage. The tool consists of a metal box, pressure switch, and leak detector. It is designed to shut down the asset immediately in the event of a pressure drop. It also includes a built-in exhaust model to filter out any hazardous gases in the event of a leak. TEL / TOKYO ELECTRON TAC-3WWZZWW boasts several advanced technologies that enable efficient and repeatable wafer etched and ashed processes. It includes Digital Microcontroller Interface (DMIF), an advanced sensor technology that enables operators to accurately monitor the temperature and process conditions within the chamber. The equipment also features a set of powerful features, such as automated tight-sealing wafer holders, real-time chamber temperature monitoring, recipe-based programming, and up to four programmable pre-heat temperatures. TEL TAC-3WWZZWW is an ideal tool for etching and ashing of a wide range of electronic components. It is designed to provide repeatable and reliable processes with ease of use. Its automatic control features allow operators to quickly and accurately carry out the fabrication process without the need for intensive manual input. The system is also perfect for semiconductor processing labs that require high-throughput and maximum accuracy in etching and ashing processes.

There are no reviews yet