Used TEL / TOKYO ELECTRON TE 5000 #9192931 for sale

URL successfully copied!

Tap to zoom

ID: 9192931

Wafer Size: 6"

Vintage: 1991

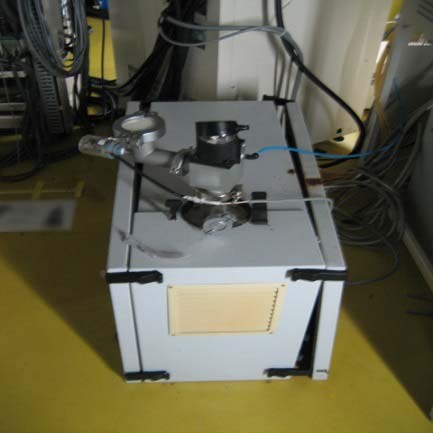

Plasma etcher, 6"

Process: Oxide

Vacuum type

Gauge:

MKS 622A02RAE Pressure gauge

VACUUM GEMERAI CMLA-21 Pressure gauge

(2) GRANVILLE PHILLIPS 275071 Convection gauges

Sub module:

EDWARDS CDP80 Dry pump

EDWARDS DP80 Dry pump

SEIKO SEIKI MG-STPH600C-T21/60 TMP

SMC INR-341-60A-X15 Chiller

TEL / TOKYO ELECTRON Chiller Trans OEM

Valve:

VEXTA PH265-02 APC

(3) KURODA C-2-50-60-R3 Gates

Gas flow control:

STEC SEC-4400RC 100 SCCM MFC (CHF4)

STEC SEC-4400MC-302 100 SCCM MFC (CF4)

STEC SEC-4400MC-302 1 SLM MFC (Ar)

STEC SEC-4400MC-302 1 SLM MFC (He)

STEC SEC-4400M 50 SCCM MFC (N2)

RF Unit:

DAIHEN MFG-20SA3A Generator

DAIHEN MFG-20SA3 RF Controller

ASTECH ATL-100 Matcher

JOBIN YVON H-10 VIS EPD

TEL GAP

Power supply: 208-230 VAC, 50/60 Hz, 40 A, 3 Phase

1991 vintage.

TEL / TOKYO ELECTRON TE 5000 is an etcher, or asher, used in the semiconductor manufacturing process. It is an automated machine designed to alleviate production time and organize etching processes on a silicon substrate. The equipment is manifolded for precise process accuracy, fiber-optic communications and rapid data transfer. TEL TE5000 is designed for flexibility. It is equipped with a highly rigid frame that allows for easy, safe and precise loading and unloading of substrates. It has a corrosion-resistant and airtight operation chamber, in addition to a built-in vacuum system that ensures the tightness of the process chamber. TOKYO ELECTRON TE-5000 is equipped with an automated wafer/substrate holder which can be programmed to provide precise transfer of the substrate to the proper processing position. This ensures accurate etching during the entire process run. Additionally, TEL / TOKYO ELECTRON TE5000 is also equipped with a fully automated match-up station which allows for automatic setup of the substrate and environment within the chamber. The machine is powered by a high performance motor which is capable of driving the entire etching unit. The motor is equipped with advanced control systems such as a three-level power supply unit which monitors and adjusts the power level automatically according to the required process, ensuring precise etching results. Additionally, high accuracy motion control systems adjust the speed and acceleration of the process so that very precise results can be achieved. The machine also provides fault-checking capabilities with a display machine that allows operators to verify etching conditions prior to the process start. This is essential for ensuring that the machine is operating correctly without discrepancies. To ensure an efficient and reliable process, TEL TE 5000 is equipped with various features. For example, a high-accuracy flip stacker is used to raise and lower substrate up to 400mm without distortions. Additionally, the machine is also equipped with a central transfer, which mimics the movement of substrate and vacuum systems during processing. In conclusion, TEL TE-5000 provides users with a powerful and reliable etch solution for a variety of semiconductor applications. The built-in automation and monitoring capabilities drives process accuracy to give consistent results every time.

There are no reviews yet