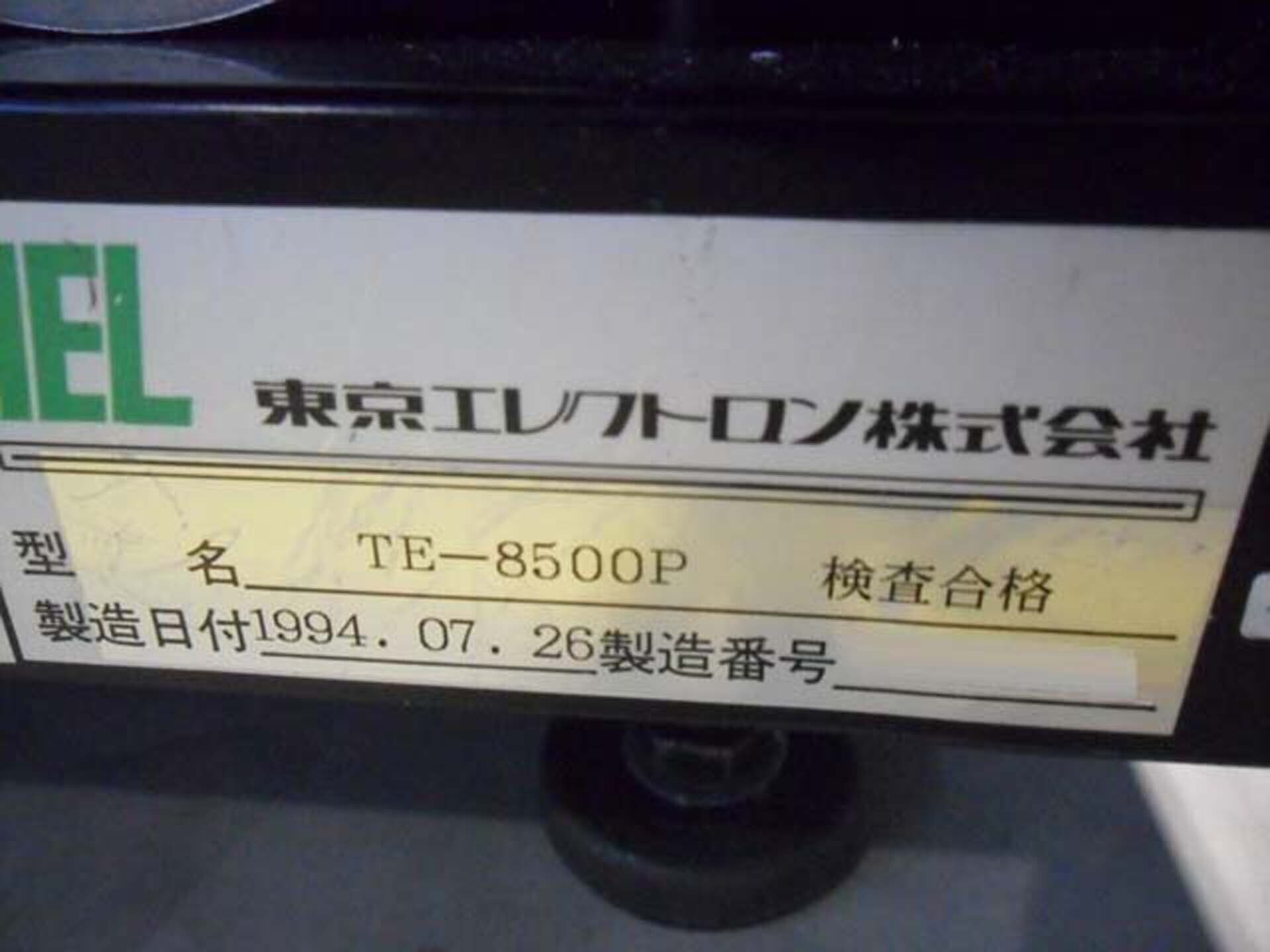

Used TEL / TOKYO ELECTRON TE 8500 #9350658 for sale

URL successfully copied!

Tap to zoom

ID: 9350658

Wafer Size: 8"

Vintage: 1994

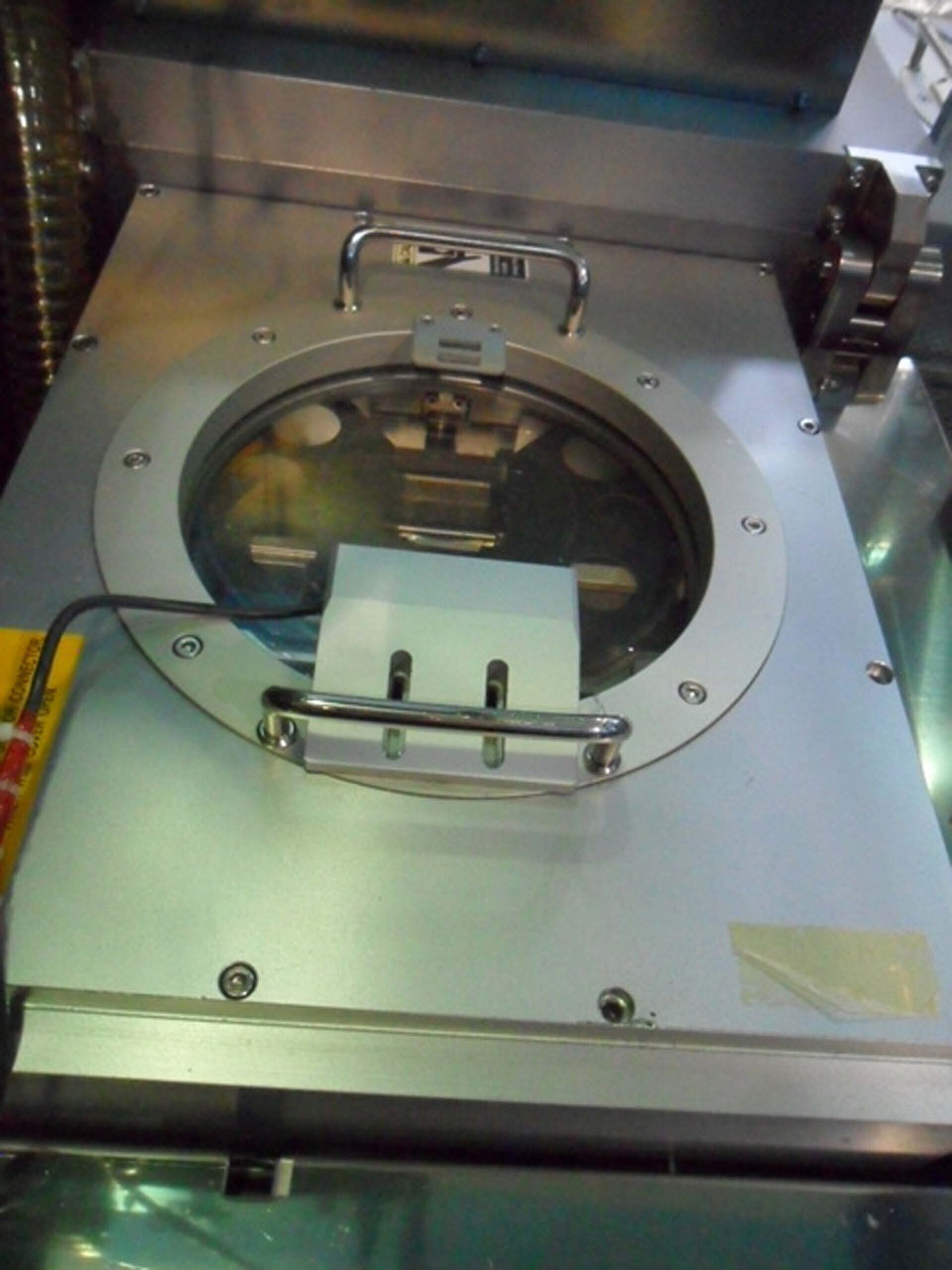

Etcher, 8"

Main

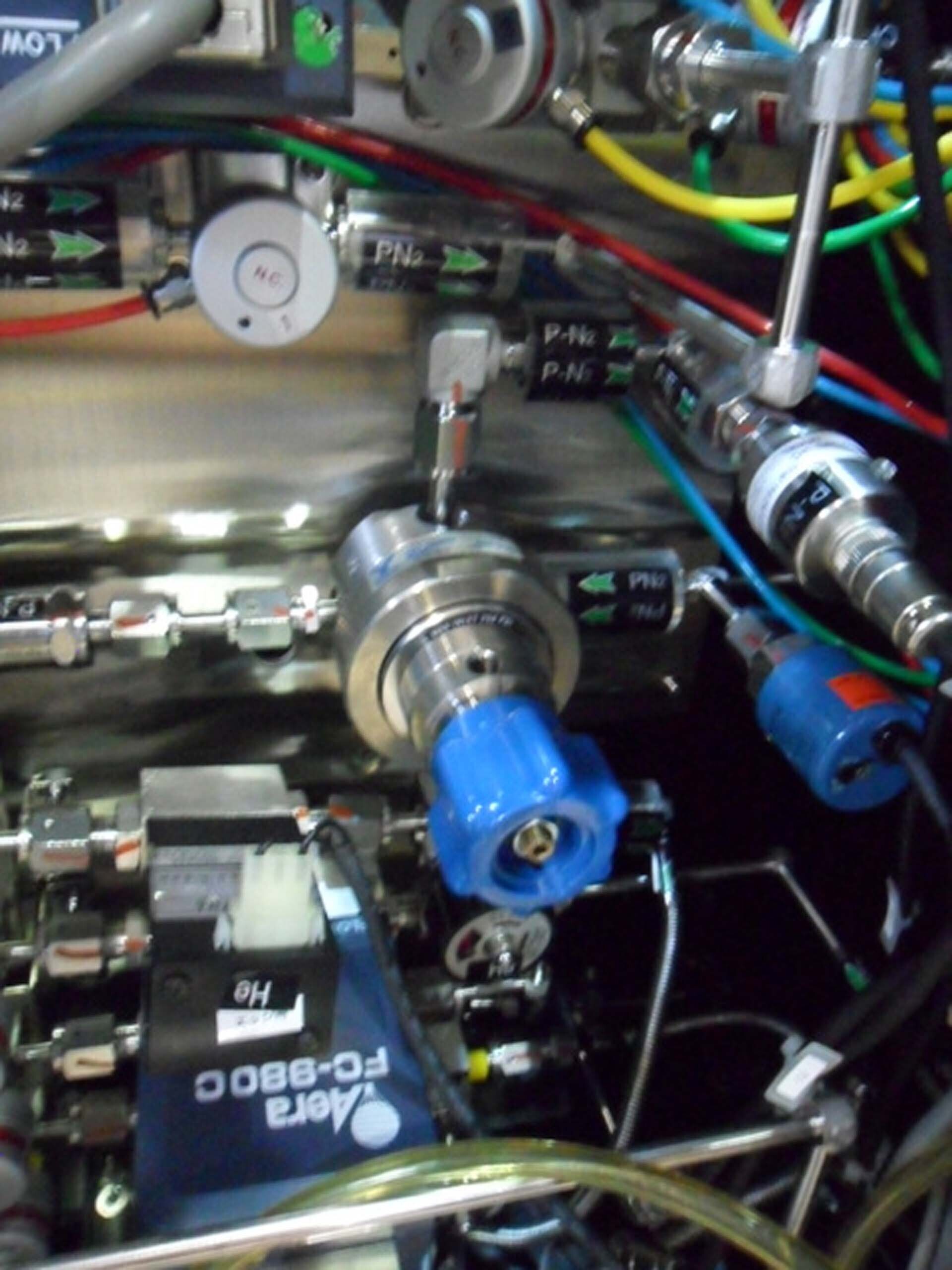

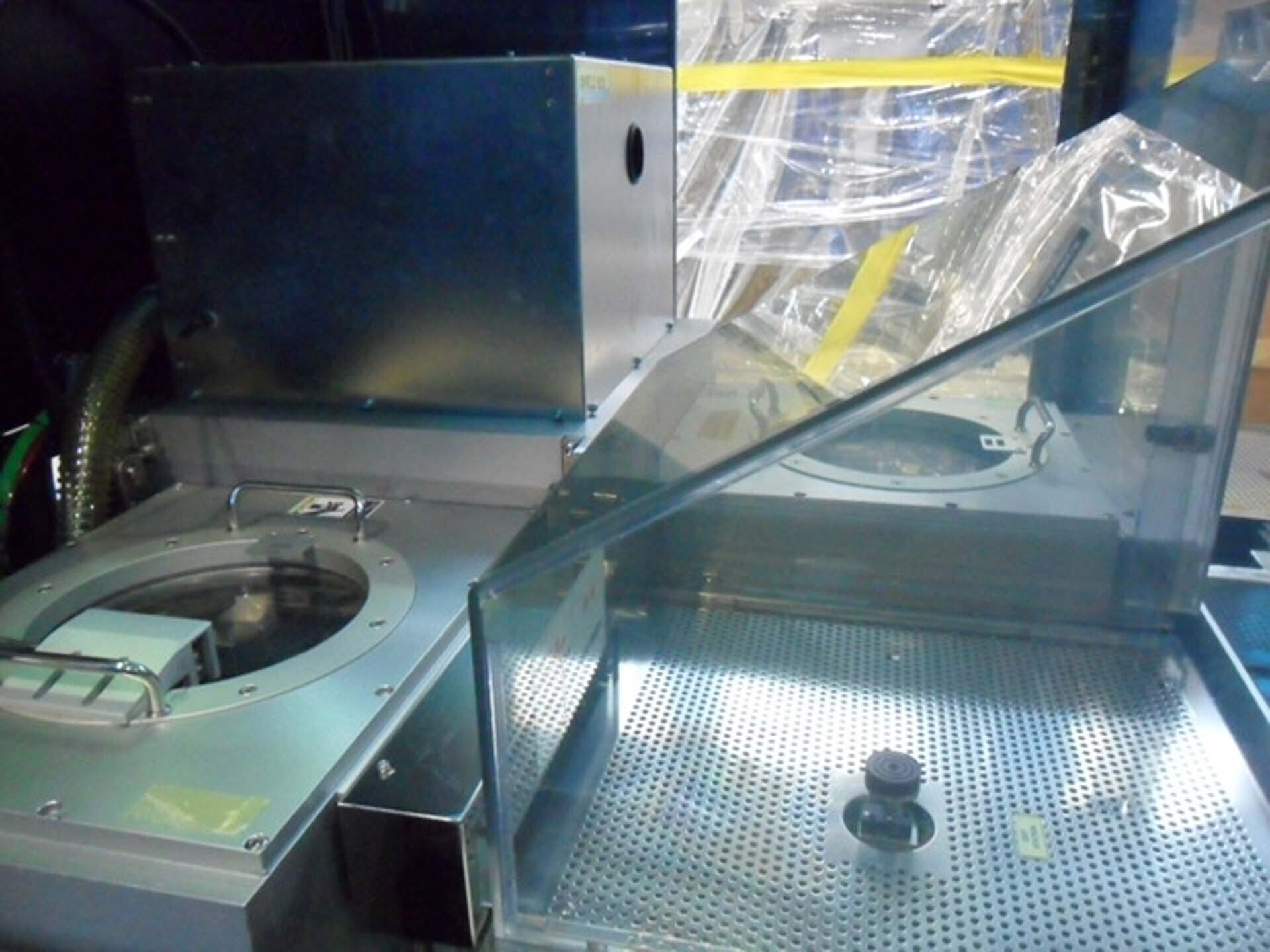

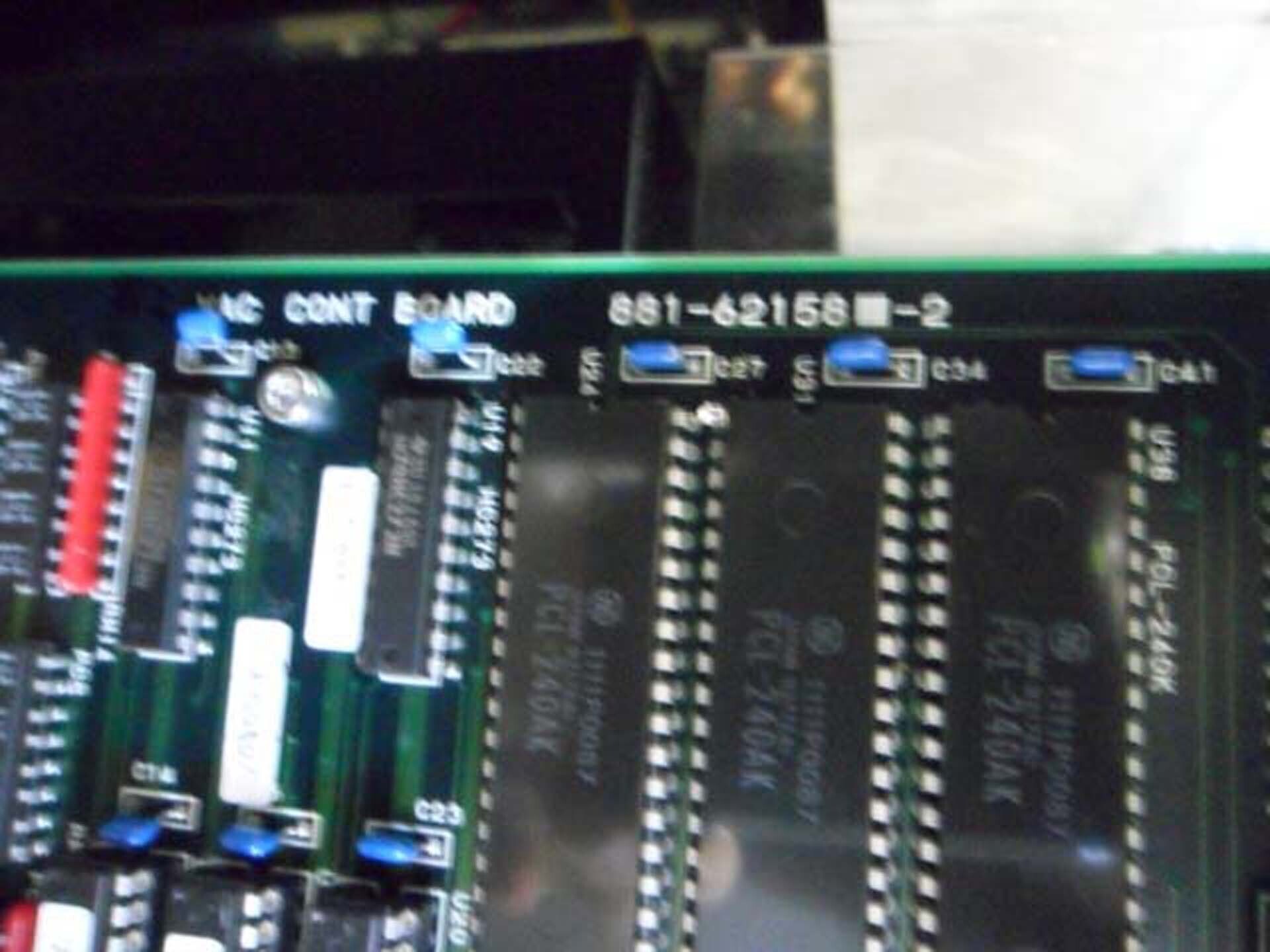

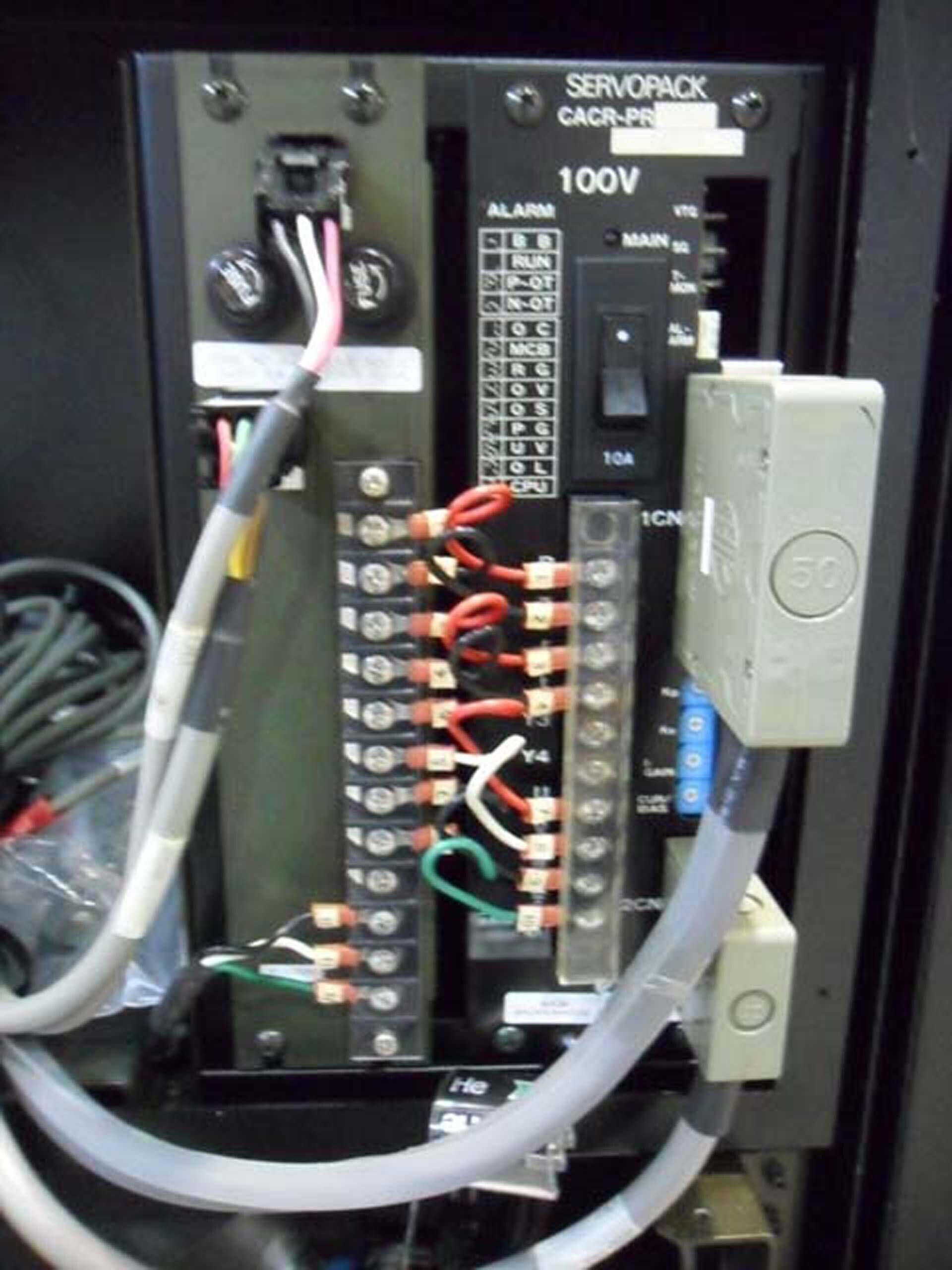

AC Rack

Parts box

1994 vintage.

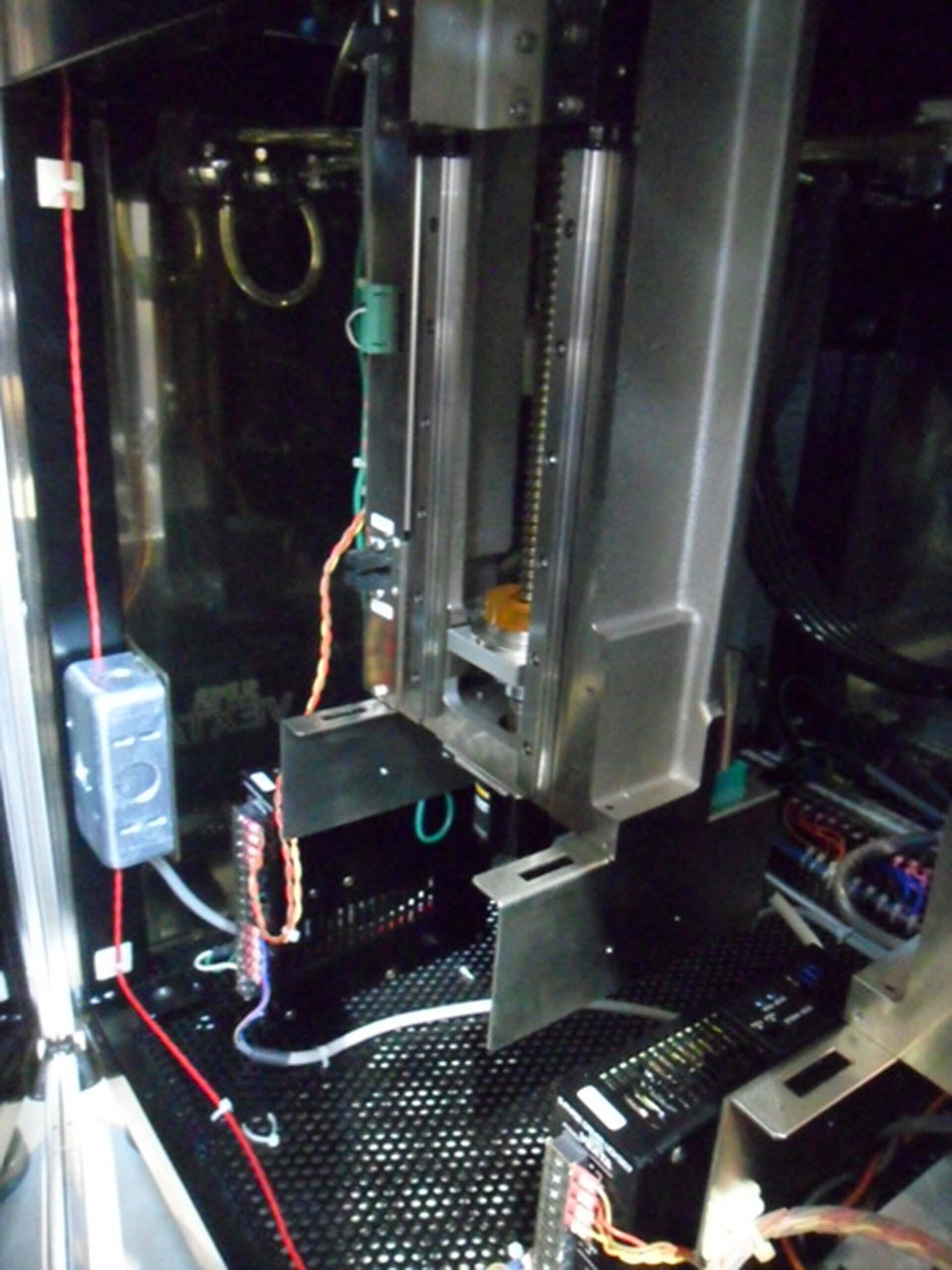

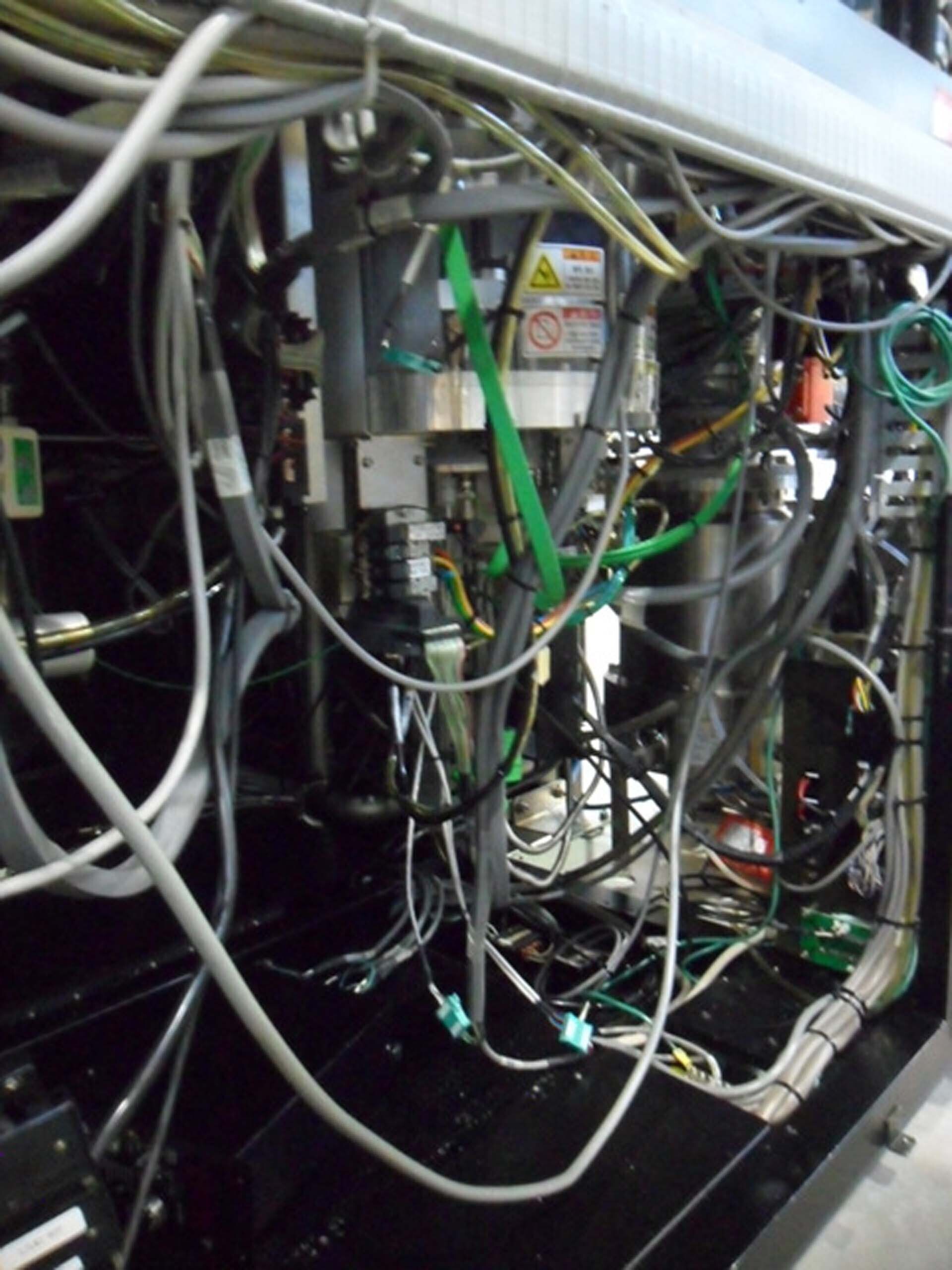

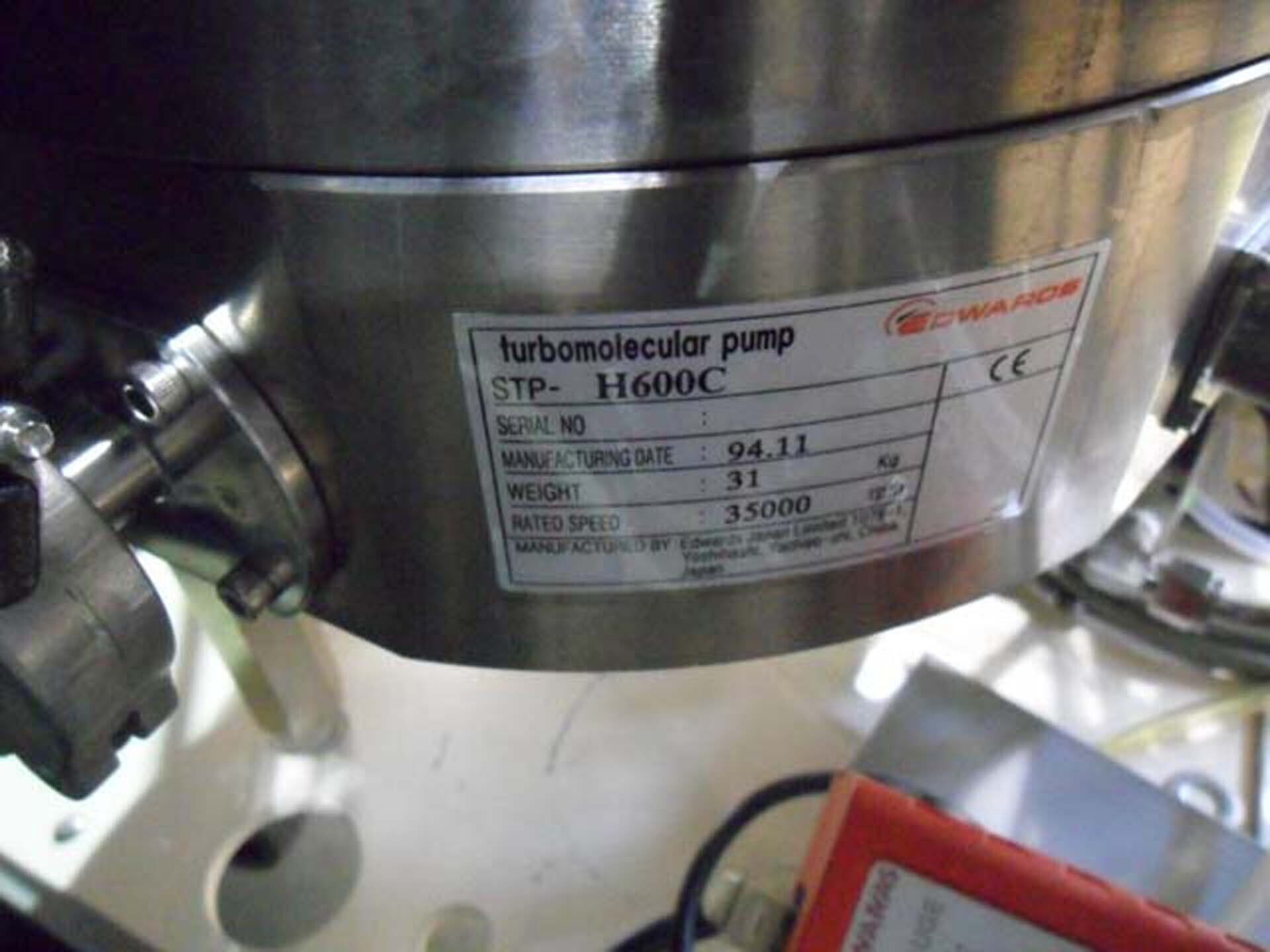

TEL / TOKYO ELECTRON TE 8500 is a high performance etcher/asher equipment offering improved cost and productivity. This semiconductor device-producing system is an essential part of the fabrication process that creates complex microscopic circuitry for all kinds of electronic products. It combines advanced computer simulating and Analytical-Chemical techniques to etch or "ash" layers of material while precisely controlling the temperature, pressure, and gases used. This unit offers a range of features to ensure device uniformity, reduce device degradation, and minimize production downtime. Its advanced reach frequency power supply gives exceptional repeatability when etching and ashing, making it ideal for high volume production runs. In addition, its high-resolution sensors monitor the process atmosphere to maintain the optimal gas composition during the etching or ashing process. Its controls also minimize gas flow and dissipate airborne particles for a cleaner processing atmosphere. Its unique computer algorithms further enhance its performance by controlling the material etch/ash time for smoother device layering and realistic etch/ash results. TEL 8500 machine is easily configured for specific customer demands with a range of multi-configurable etcher/asher workcells. Customers can select from 4 to 16 workcells that can be modified to process different wafers. The tool also has a new pre-scan feature that uses laser optics to detect wafer distortion and automatically rejects it. Its patent-pending contactless centering device allows for quick wafer mounting without damaging it. TEL TE 8500 asset also has a modular design with several innovation options and features that make it highly adaptable and flexible. It can be synchronized with other systems to provide a fully integrated manufacturing line for greater throughput and higher production yields. Customers can also use Etcher/Asher Software (EAS) to monitor their process, adjust the feed rate, temperature, and other parameters as needed. The EAS also provides recording of key parameters, wafer mapping, PEEP processing, per zone adjustment, and recipe generation capabilities. TOKYO ELECTRON TE 8500 model also uses the latest technology to safely and accurately process wafers at high speeds. Its automated safety features include several fail-safe alarms, easy-to-read graphical displays, and the ability to diagnose technical issues with an in-depth troubleshooting guide. It also offers a wide range of optional accessories, such as input/output devices, conveyors, and environmental controllers, that further expand its production capabilities. TE 8500 is a reliable, high-performance etcher/asher equipment that offers unparalleled flexibility and performance.

There are no reviews yet