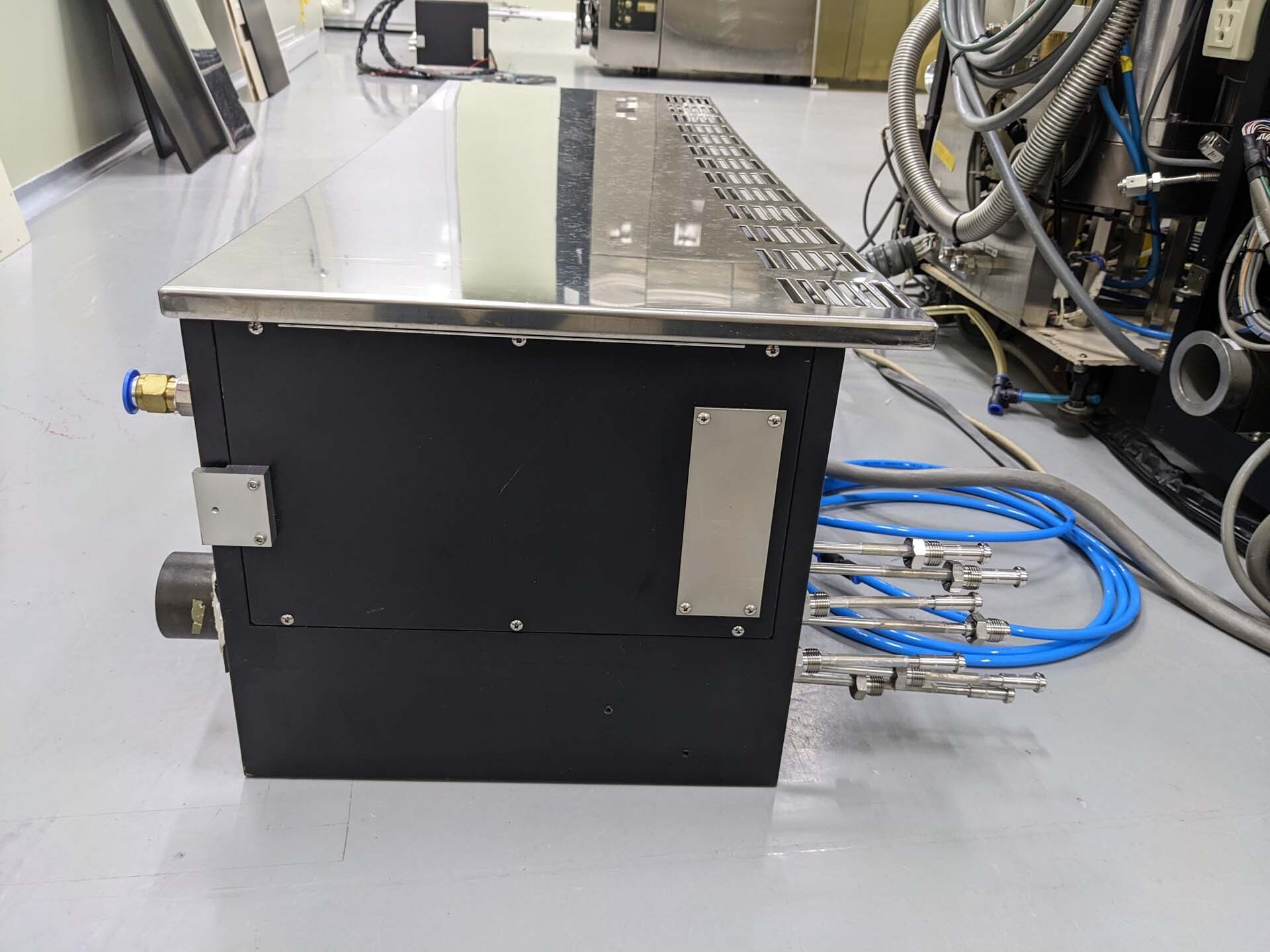

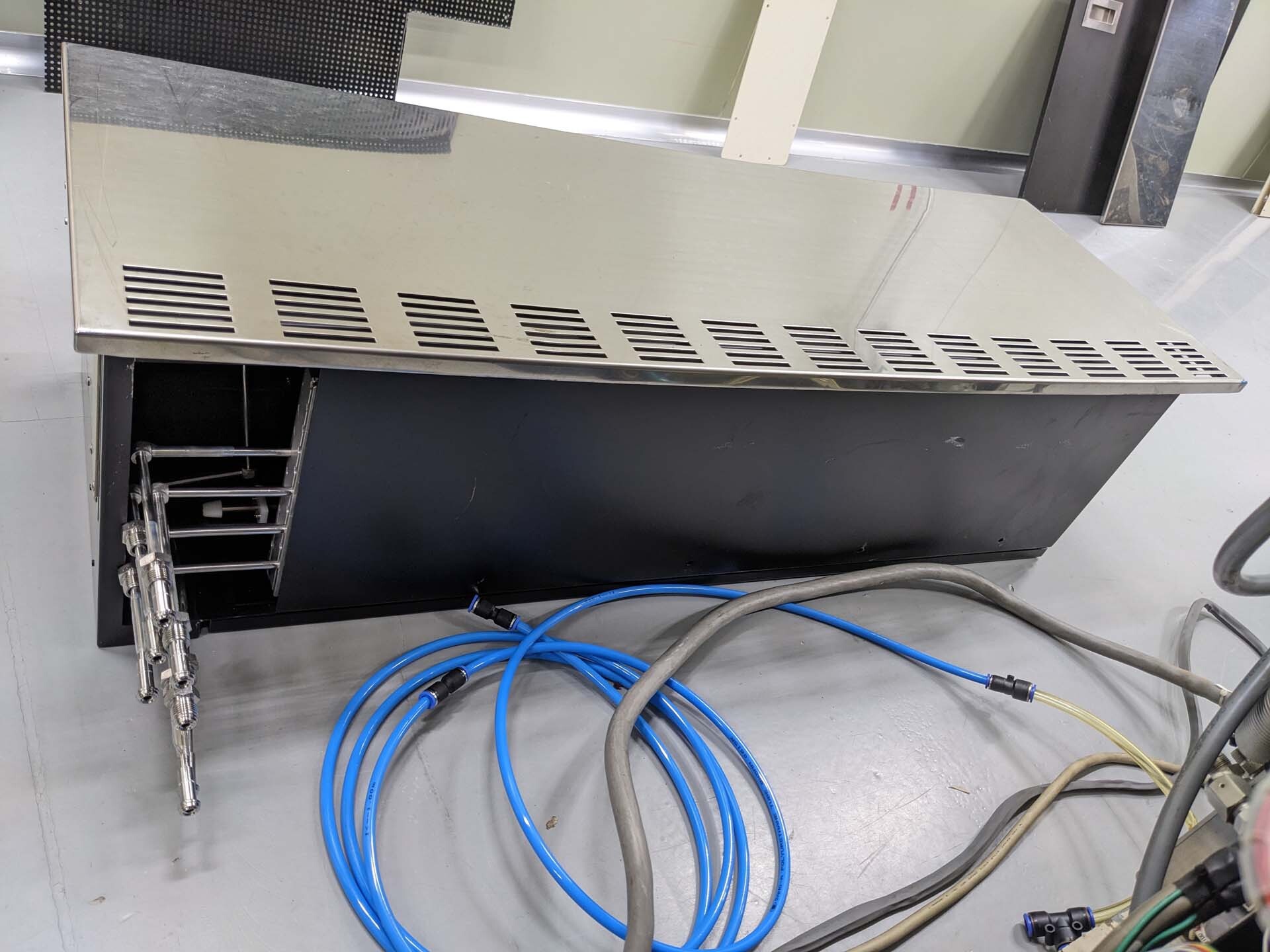

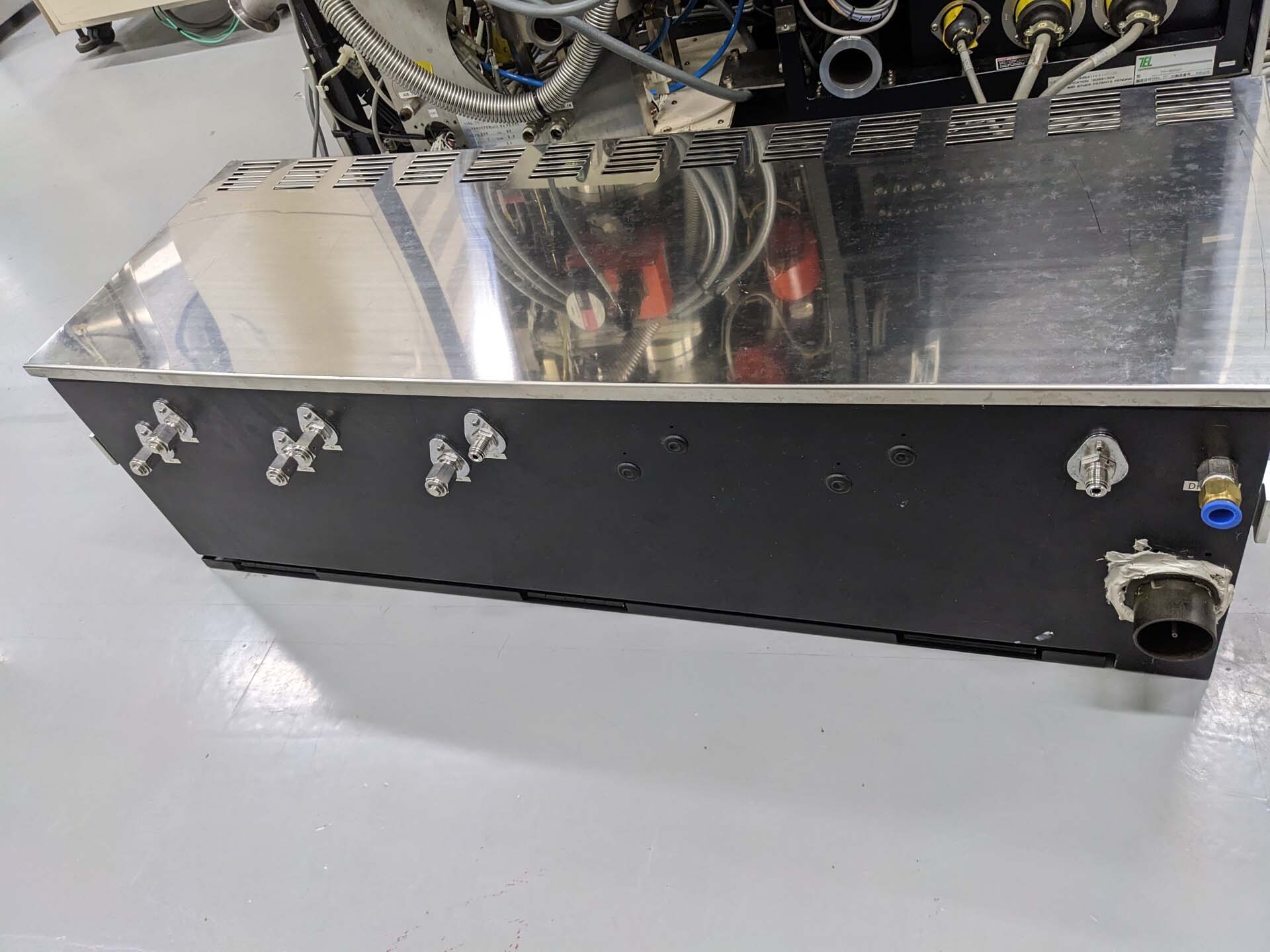

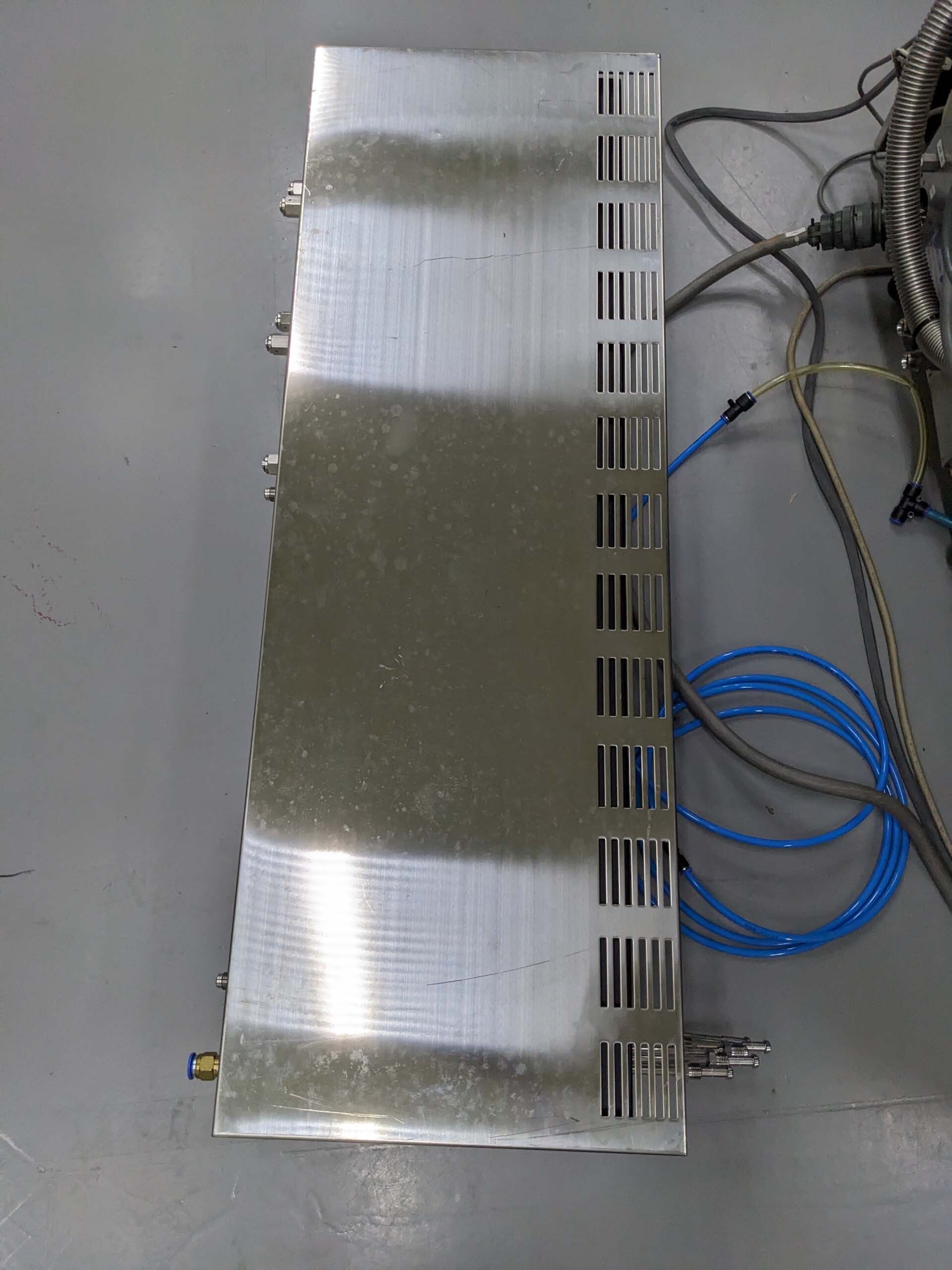

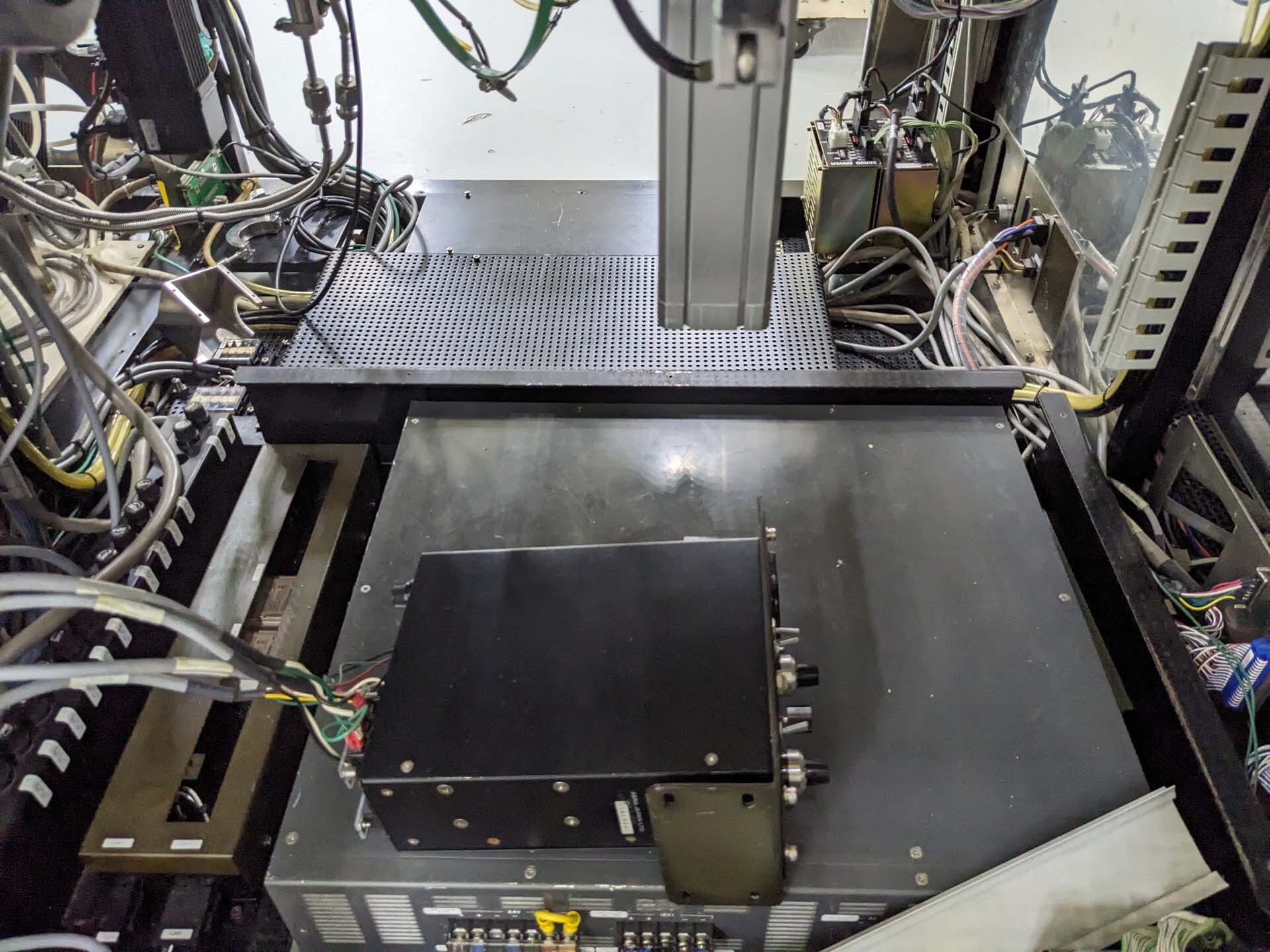

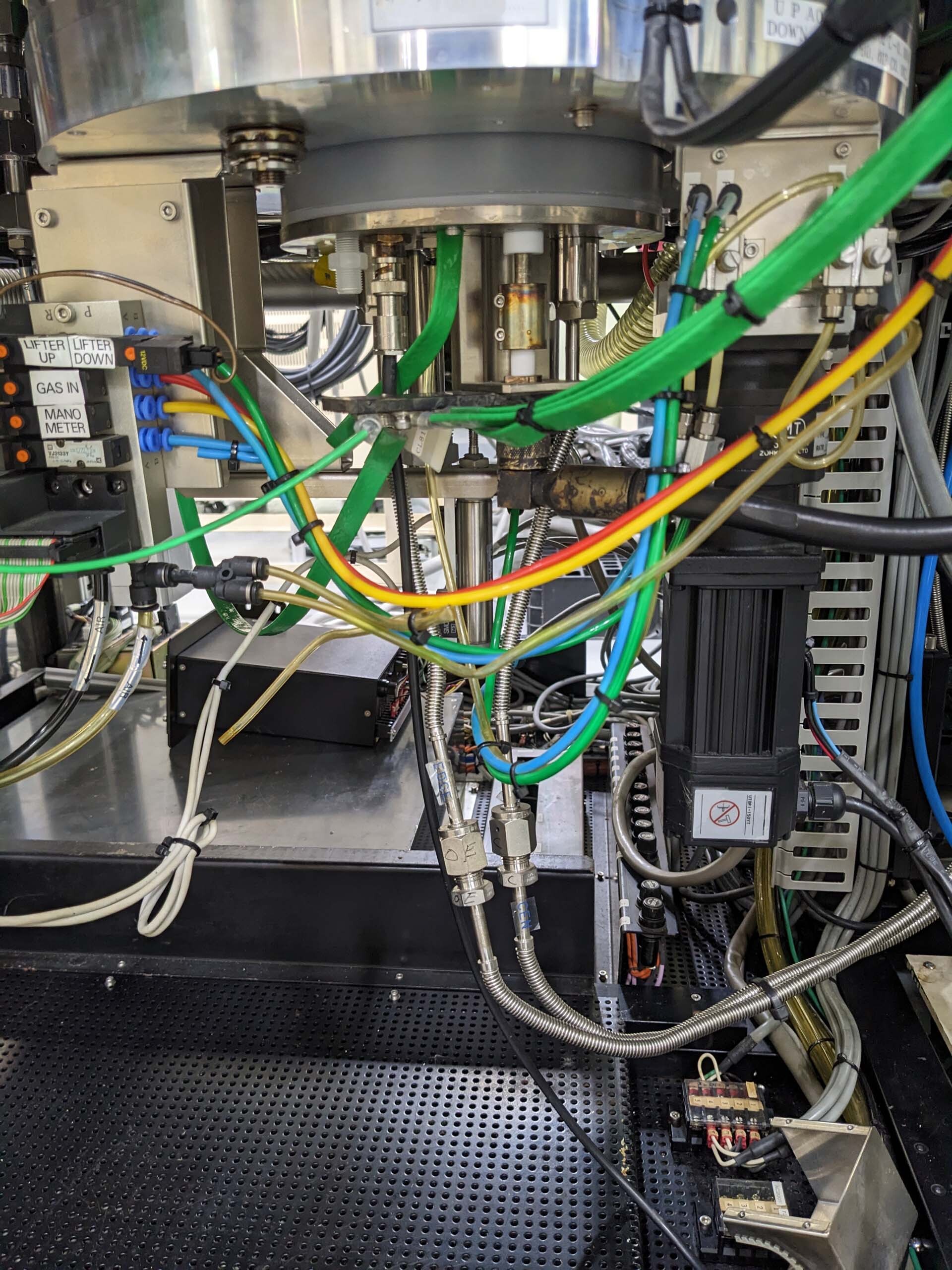

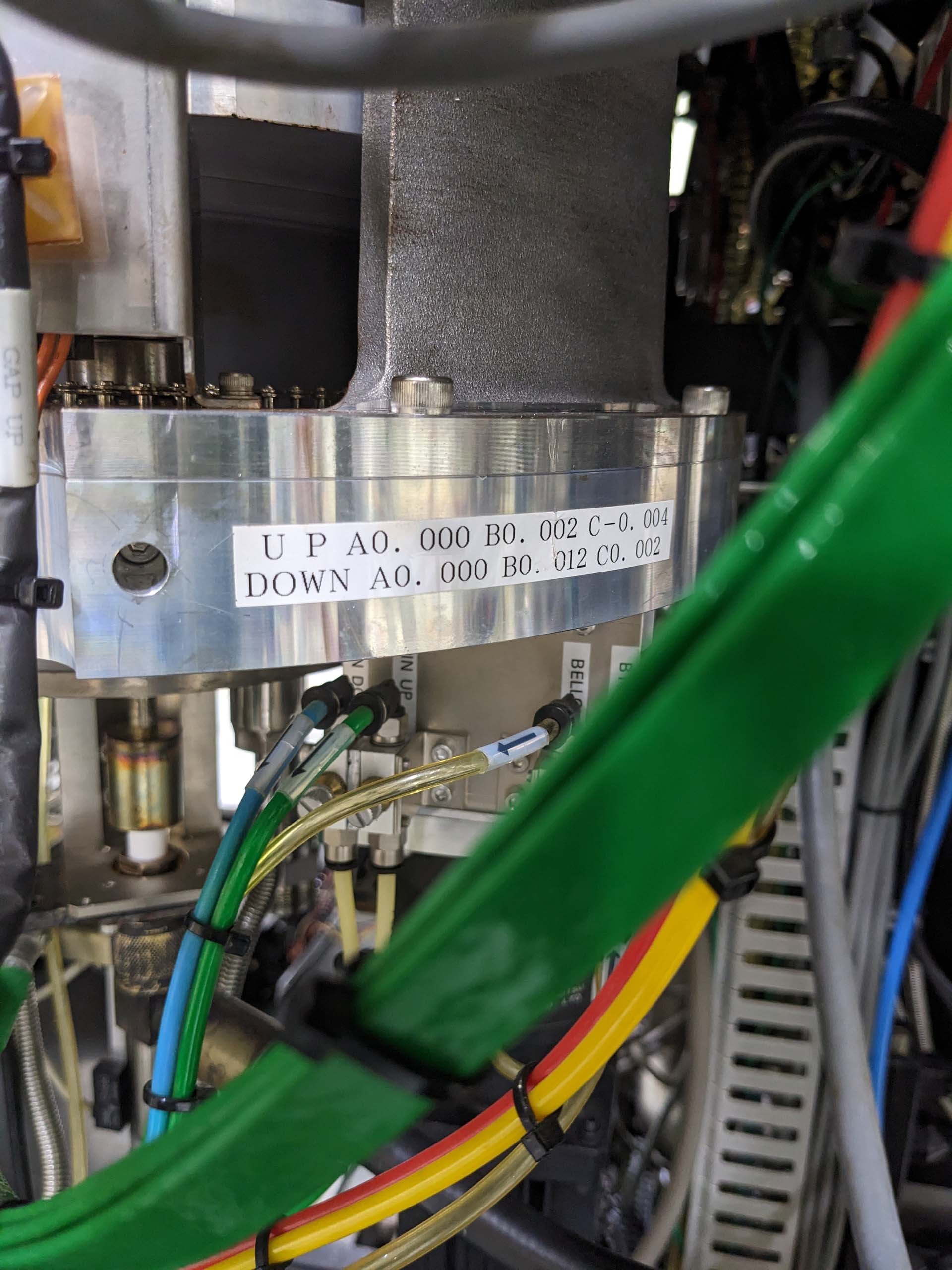

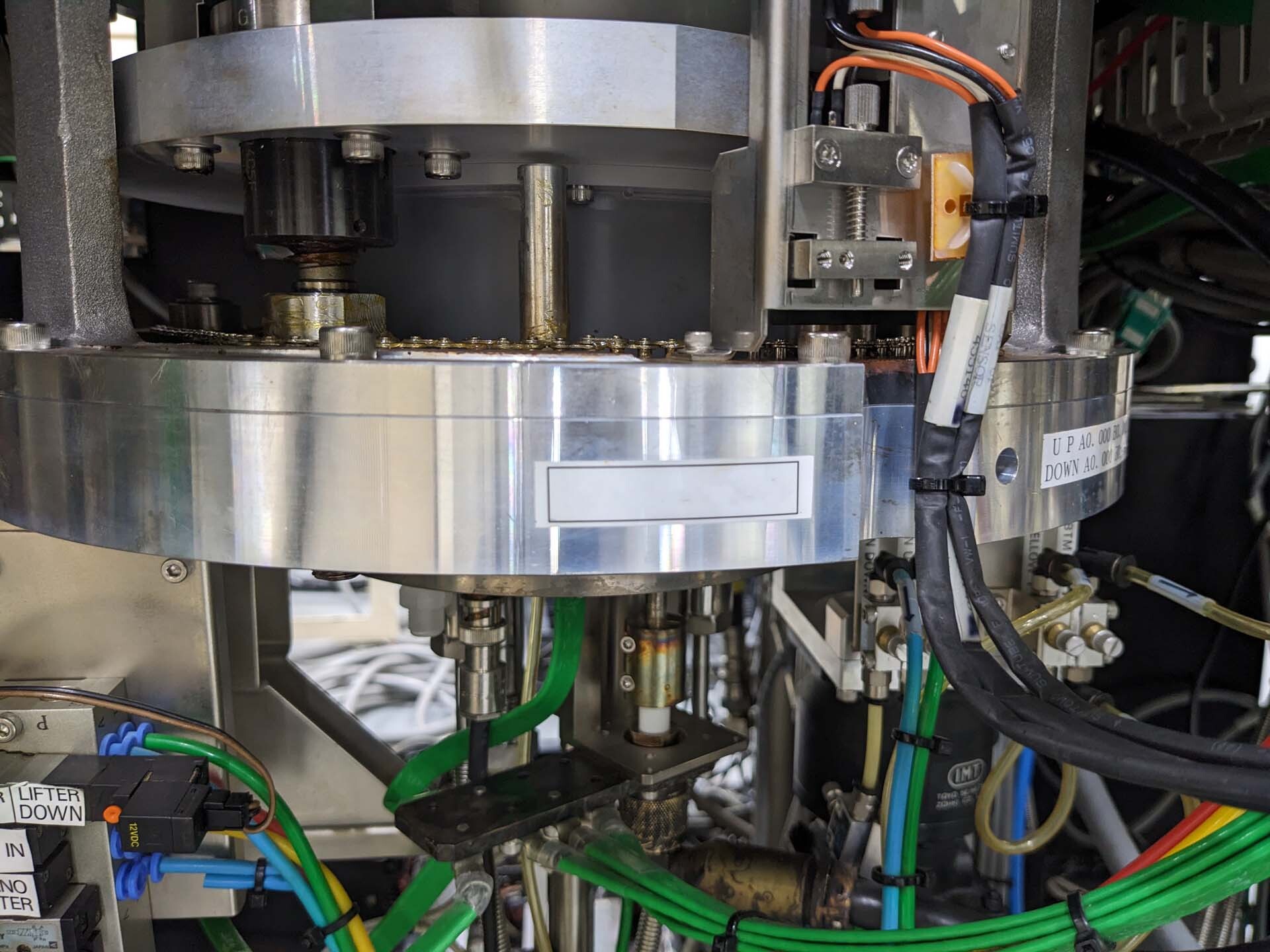

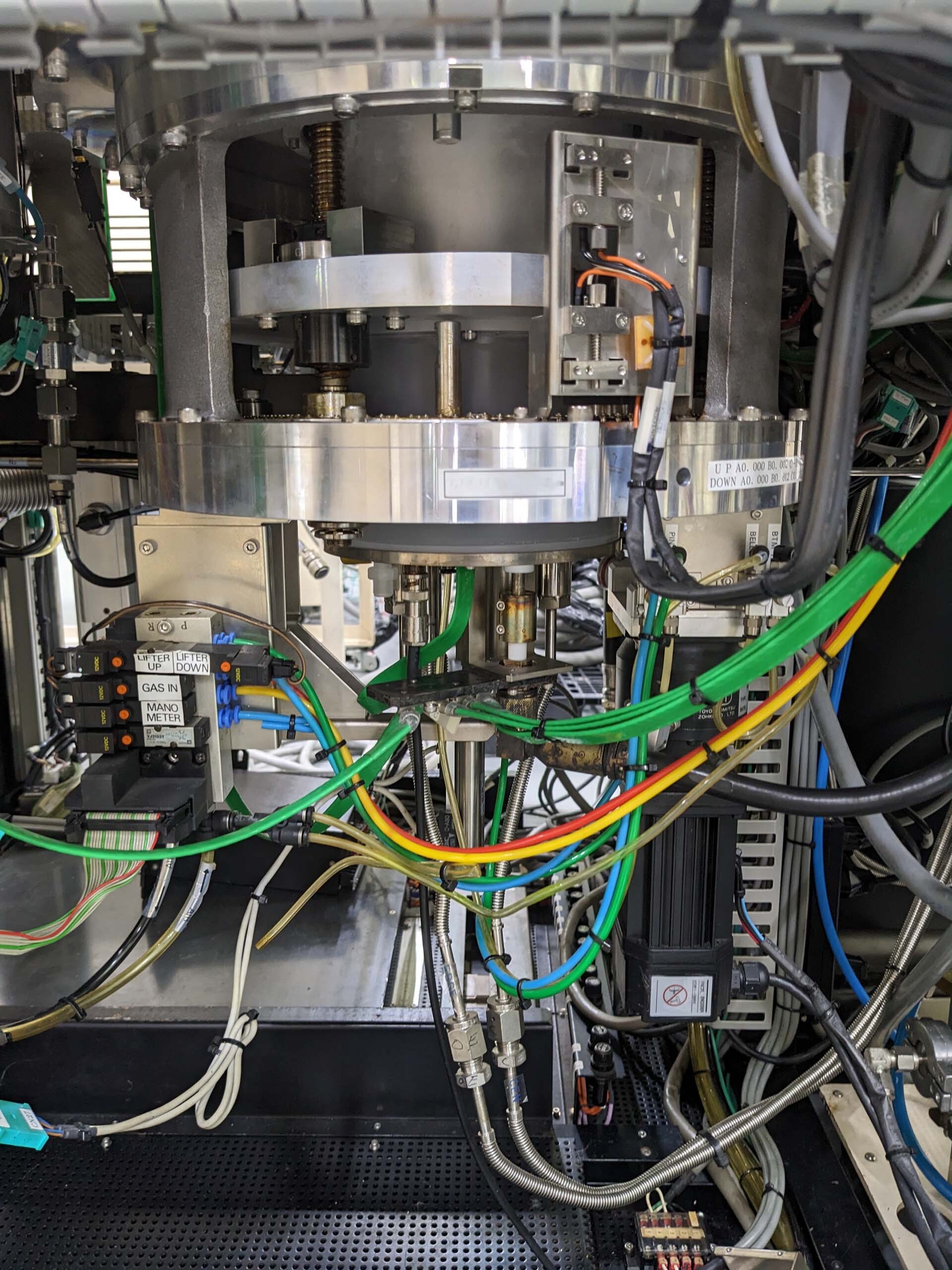

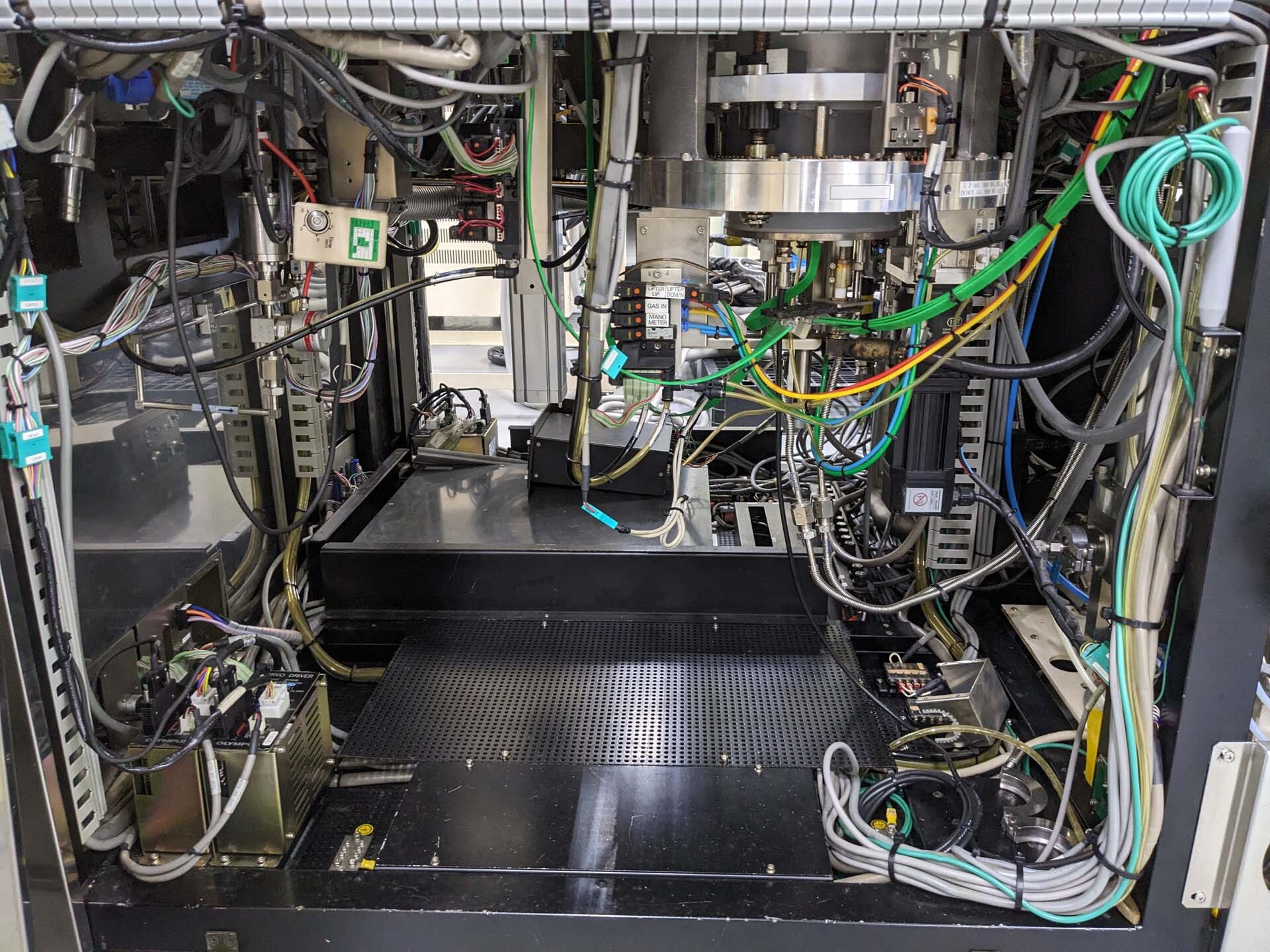

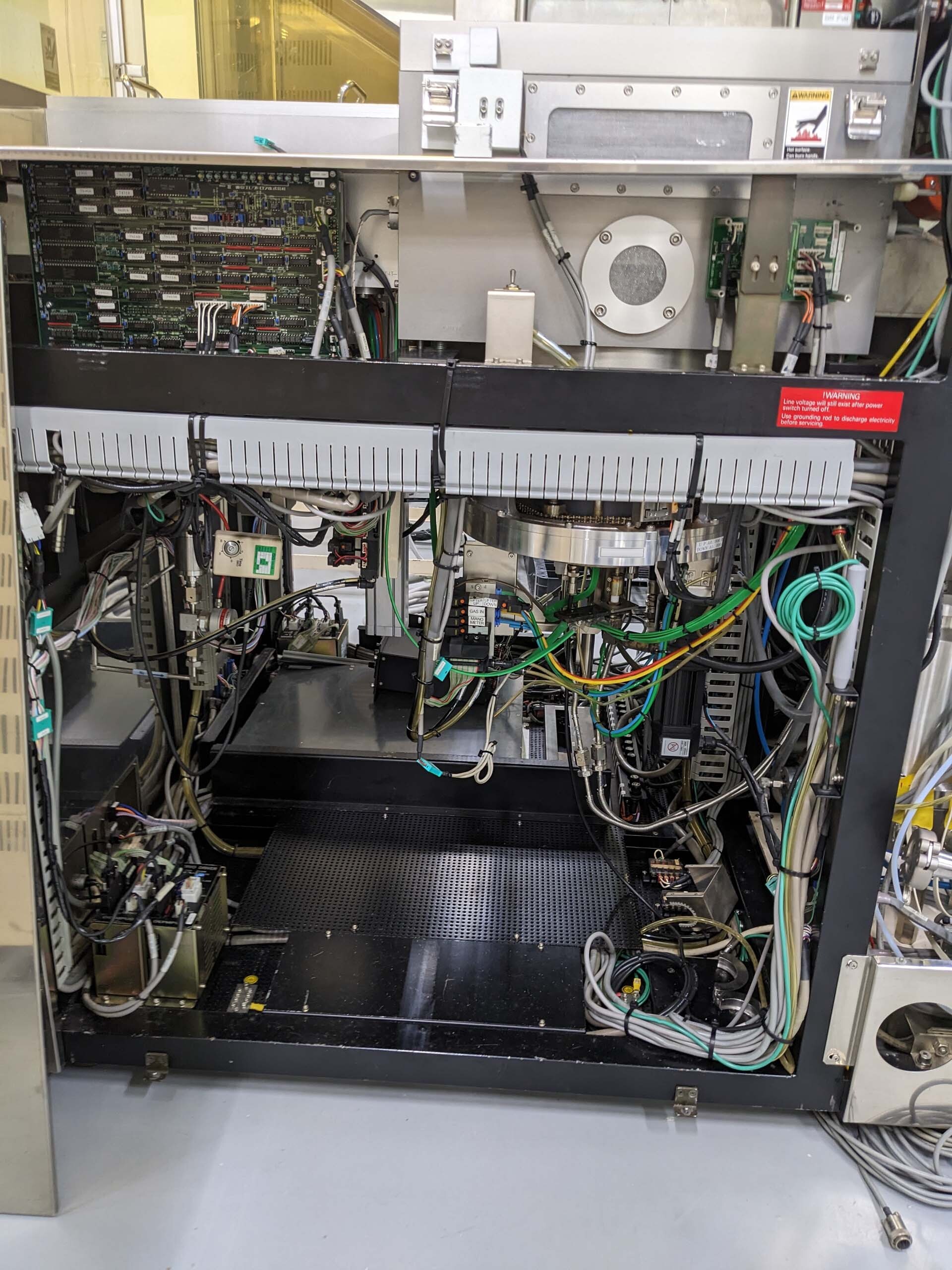

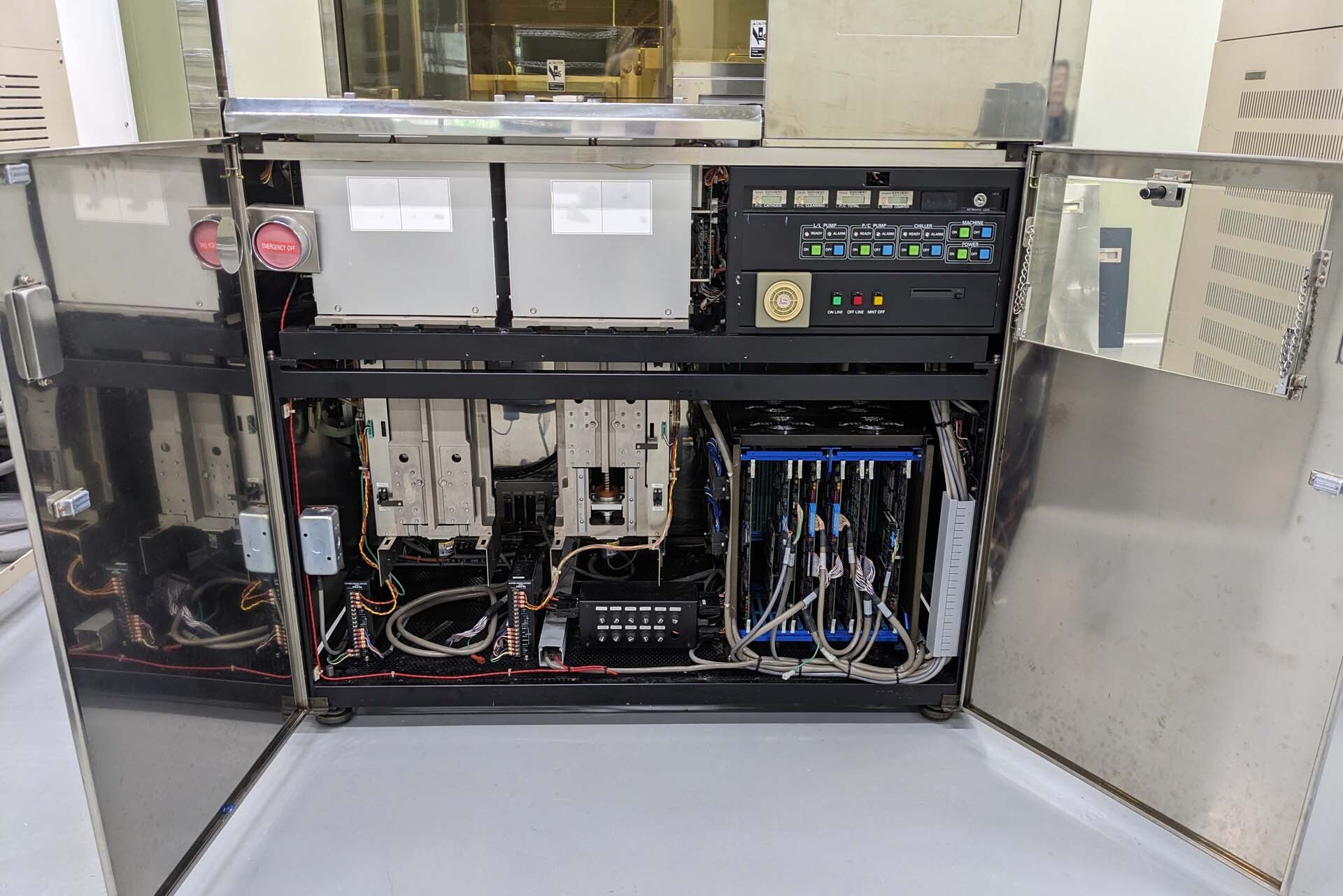

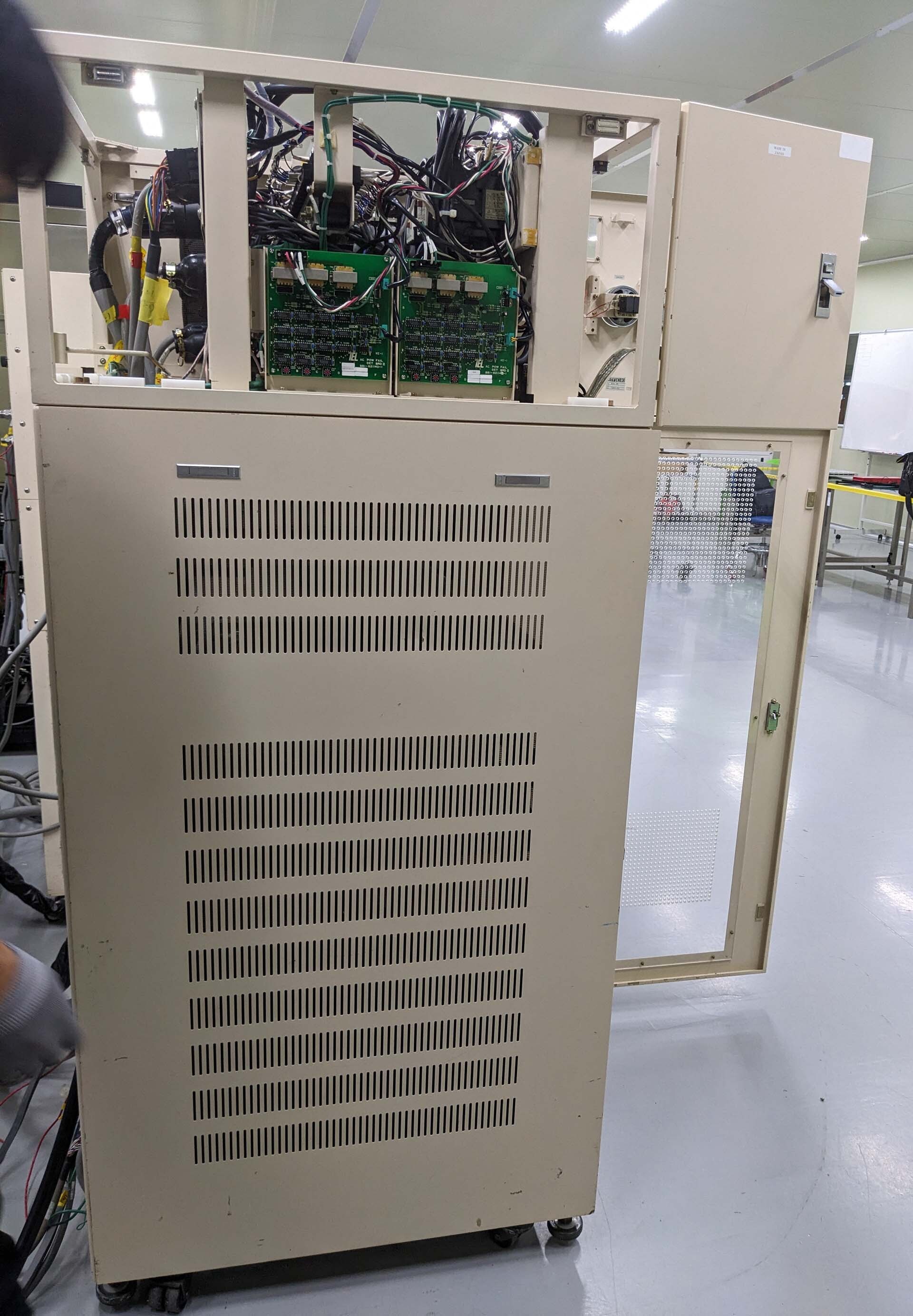

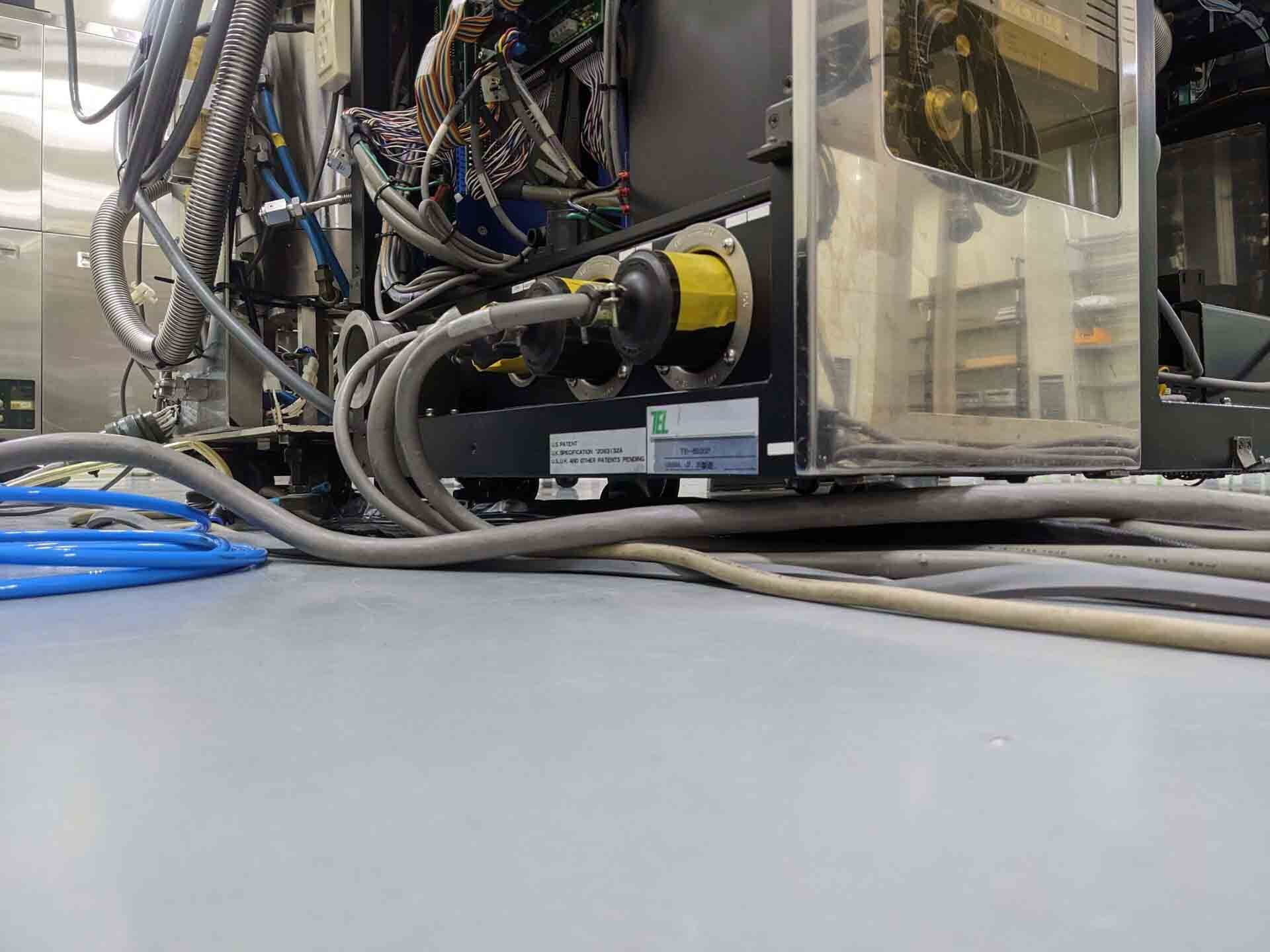

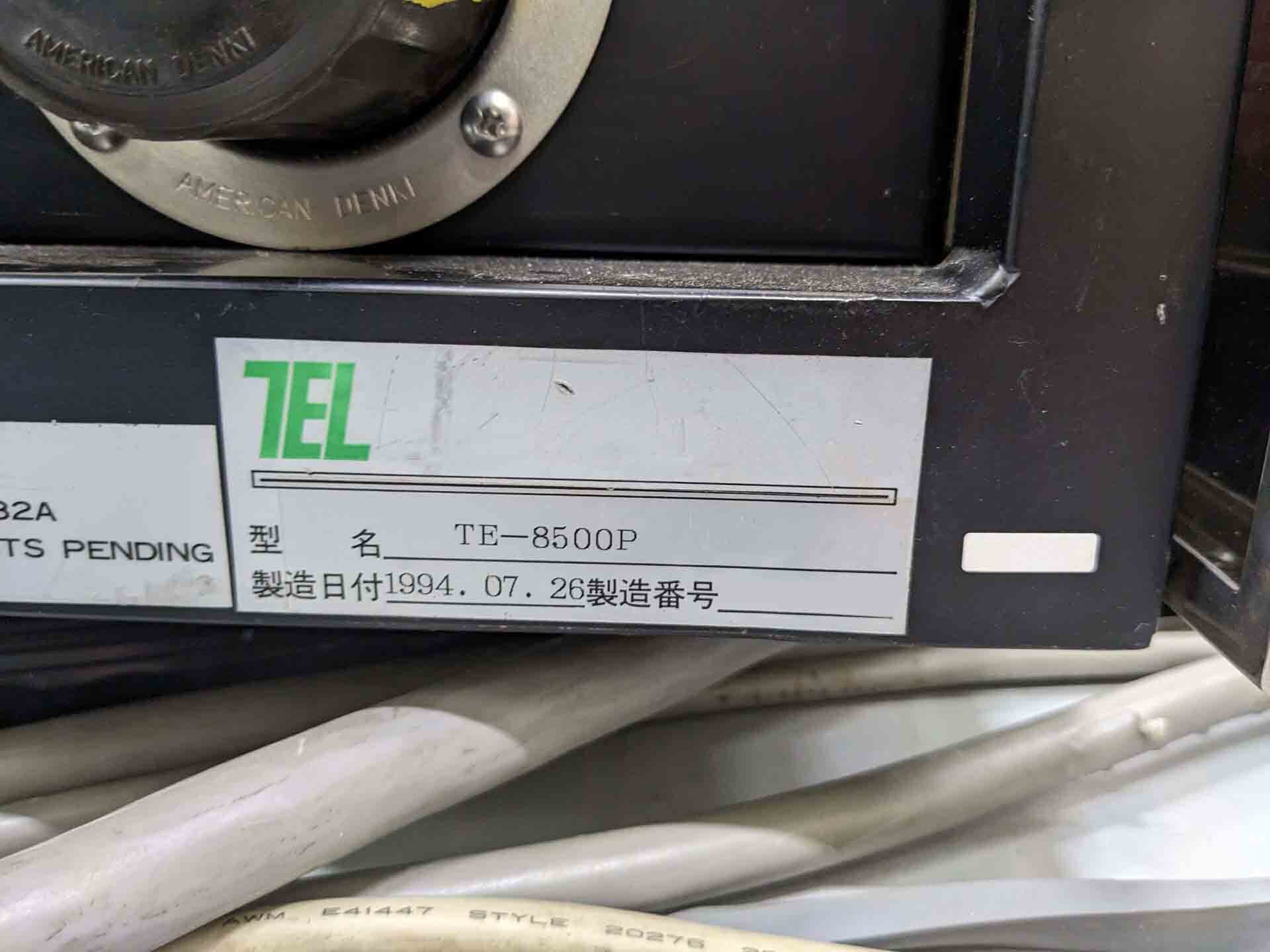

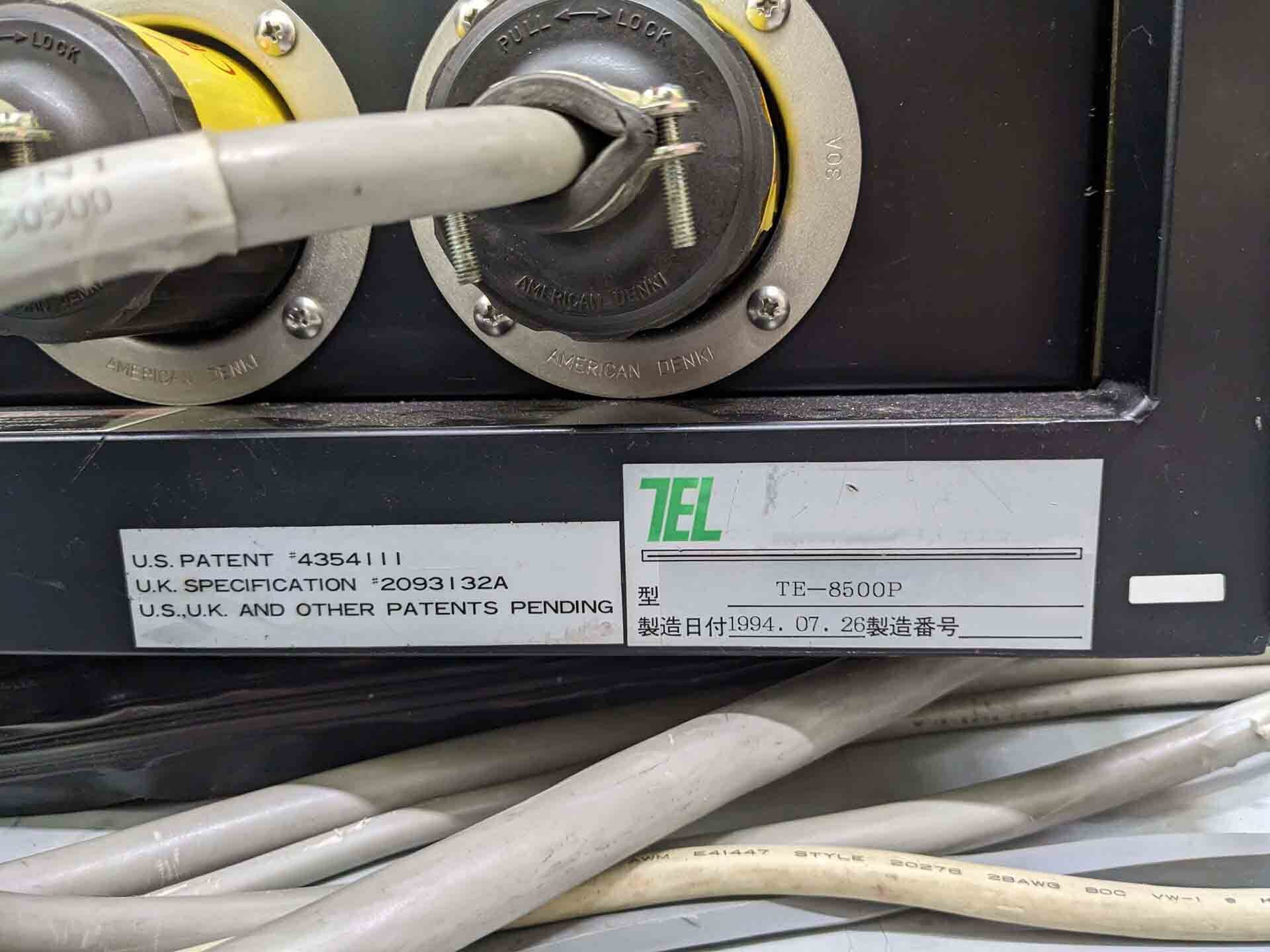

Used TEL / TOKYO ELECTRON TE 8500 #9394809 for sale

URL successfully copied!

Tap to zoom

ID: 9394809

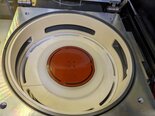

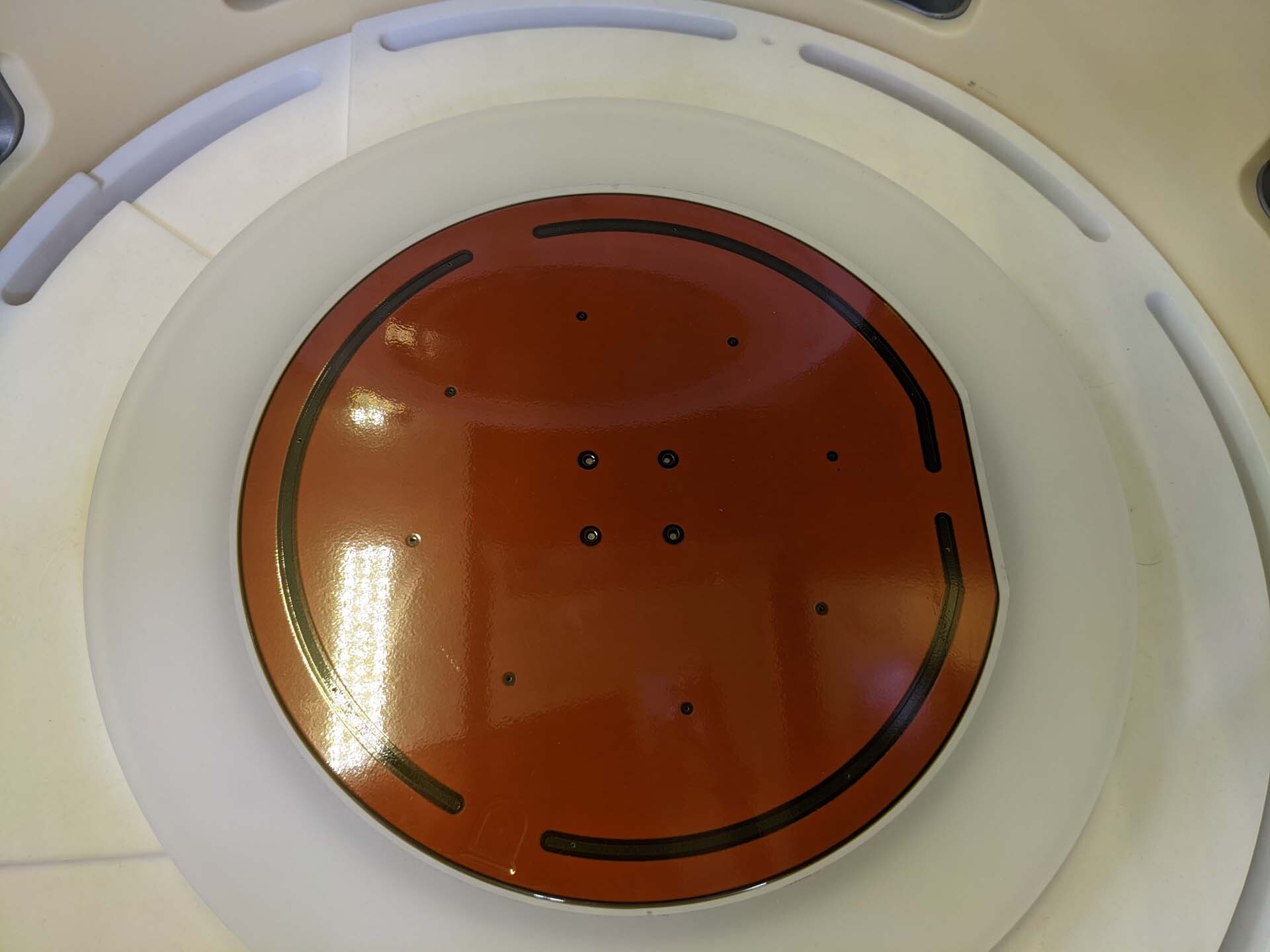

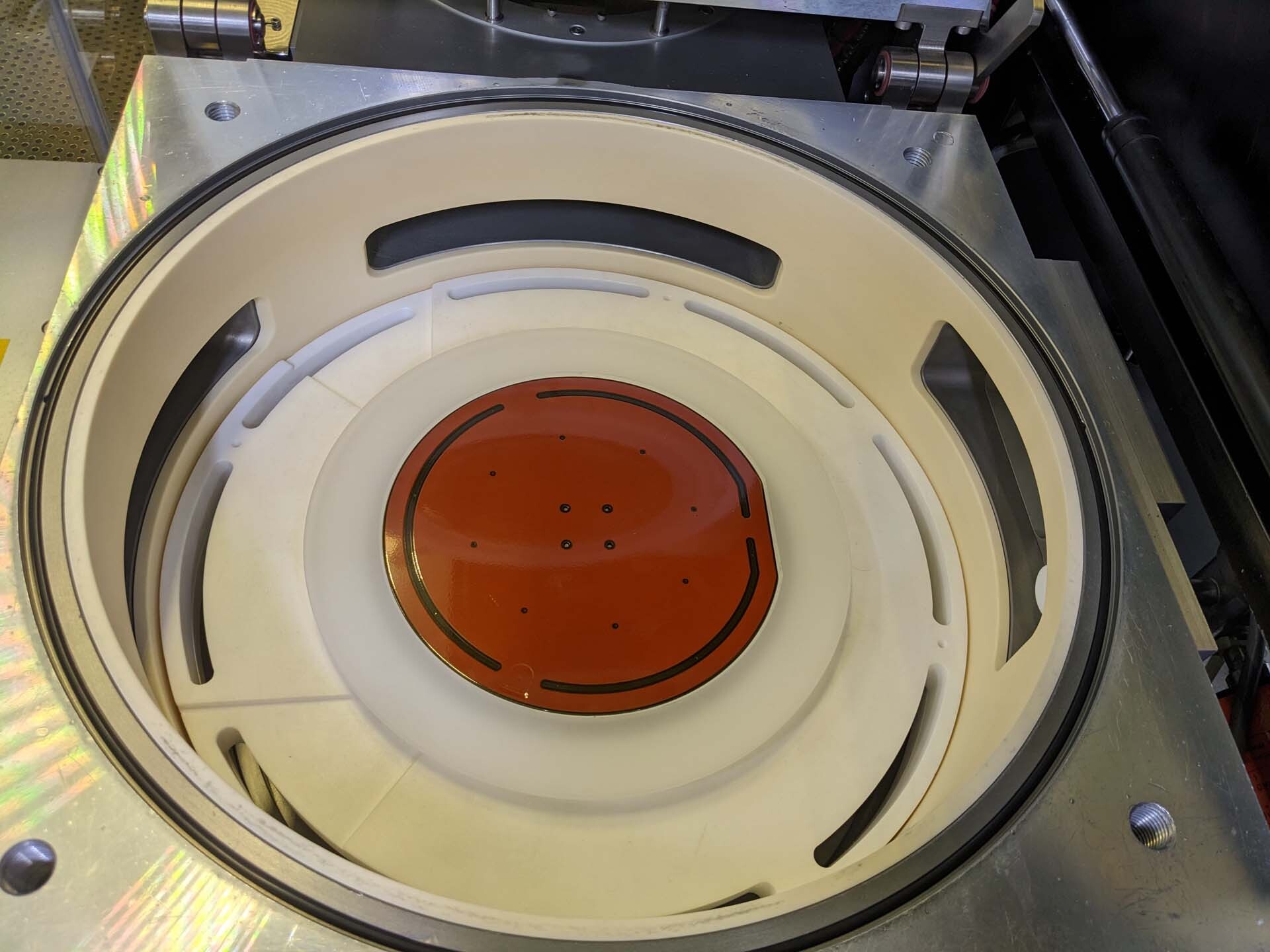

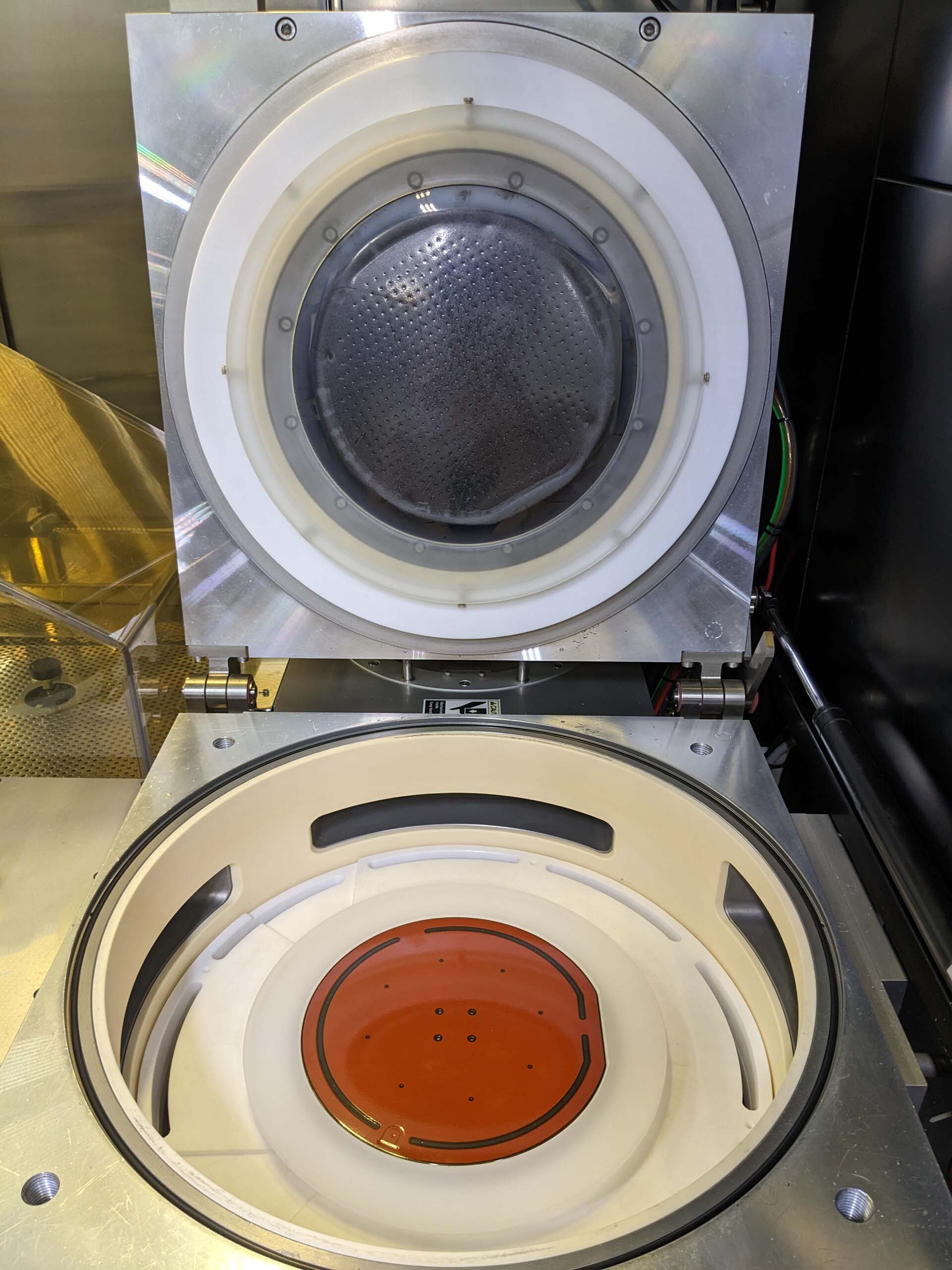

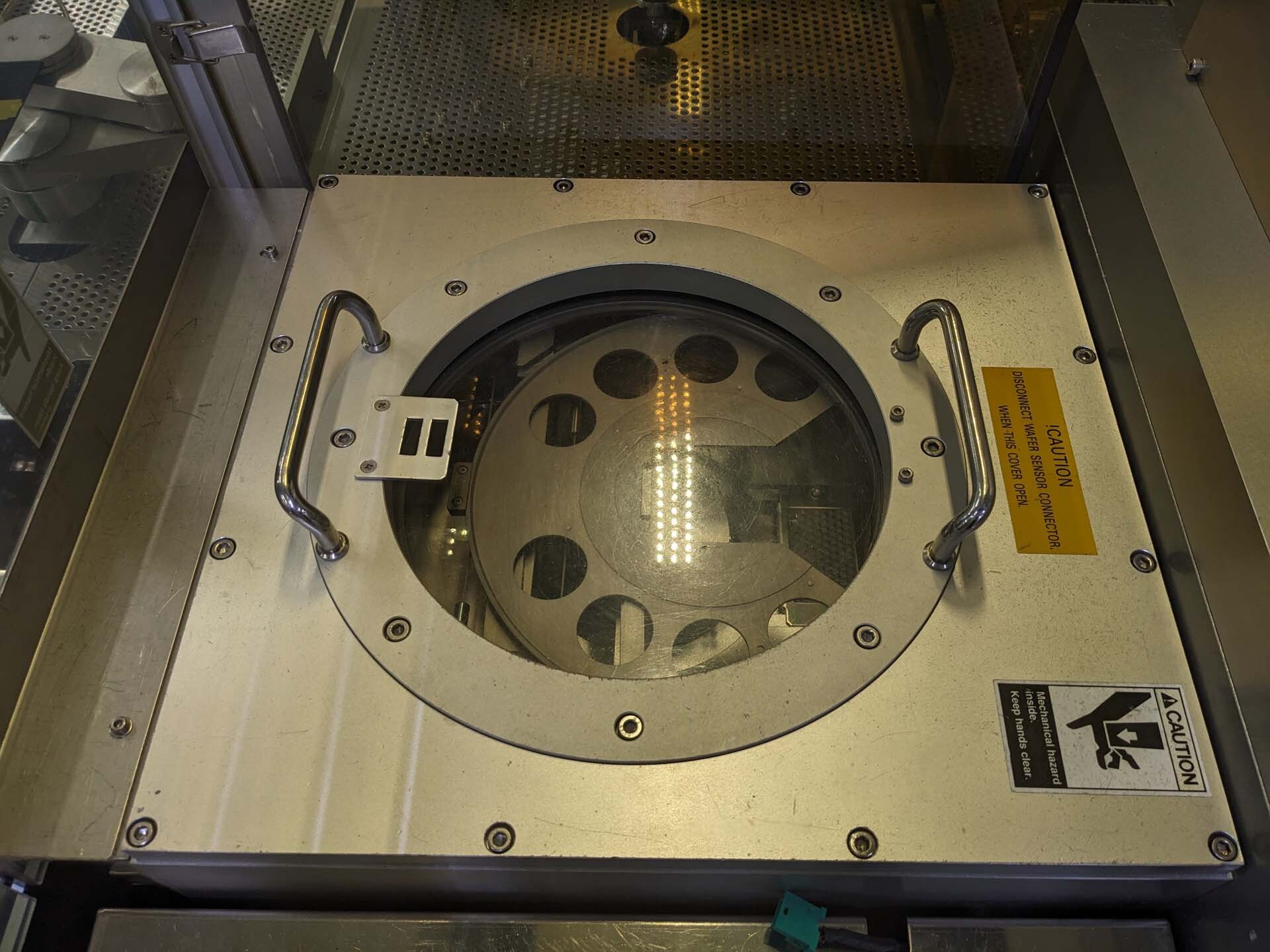

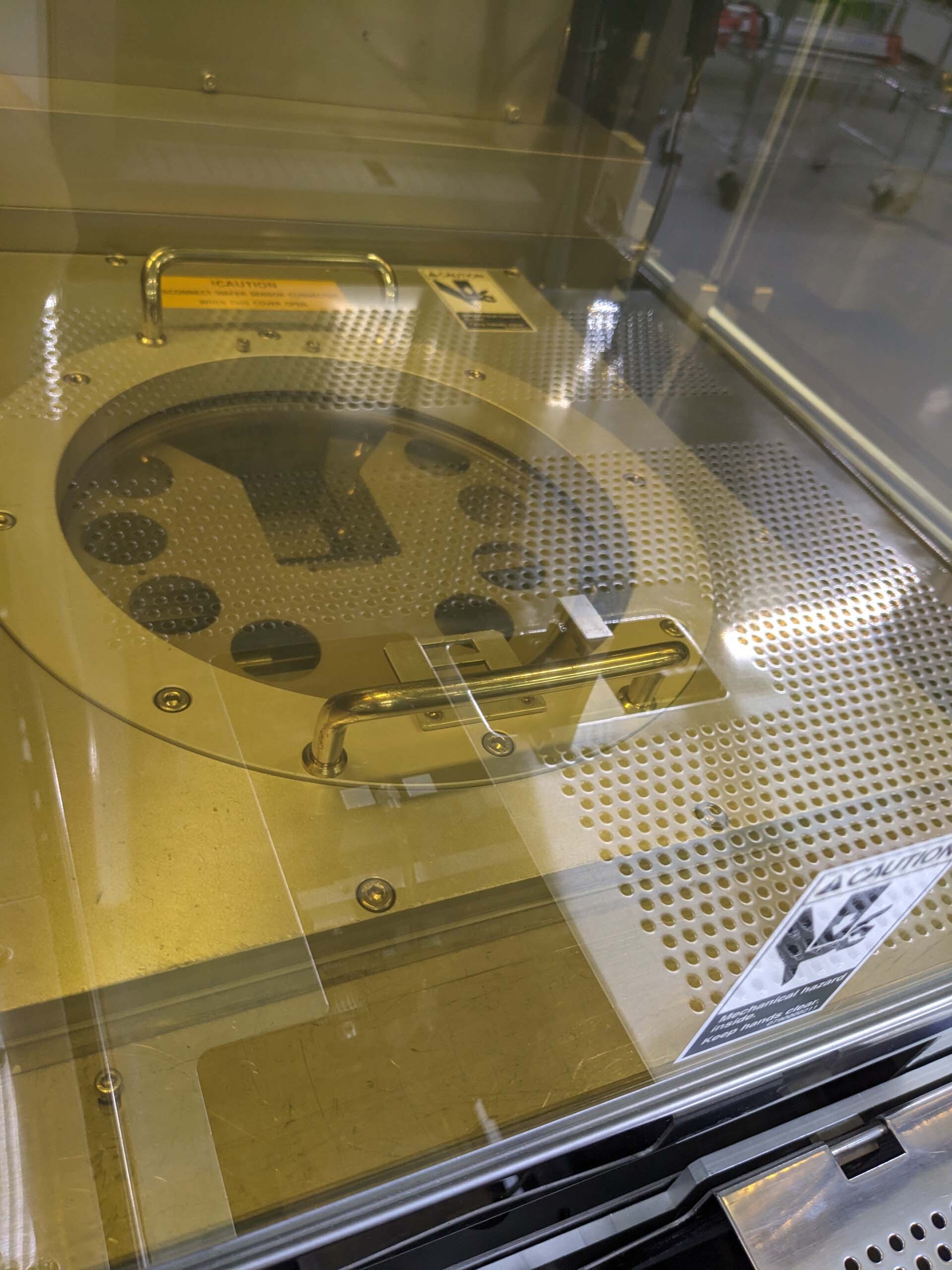

Wafer Size: 8"

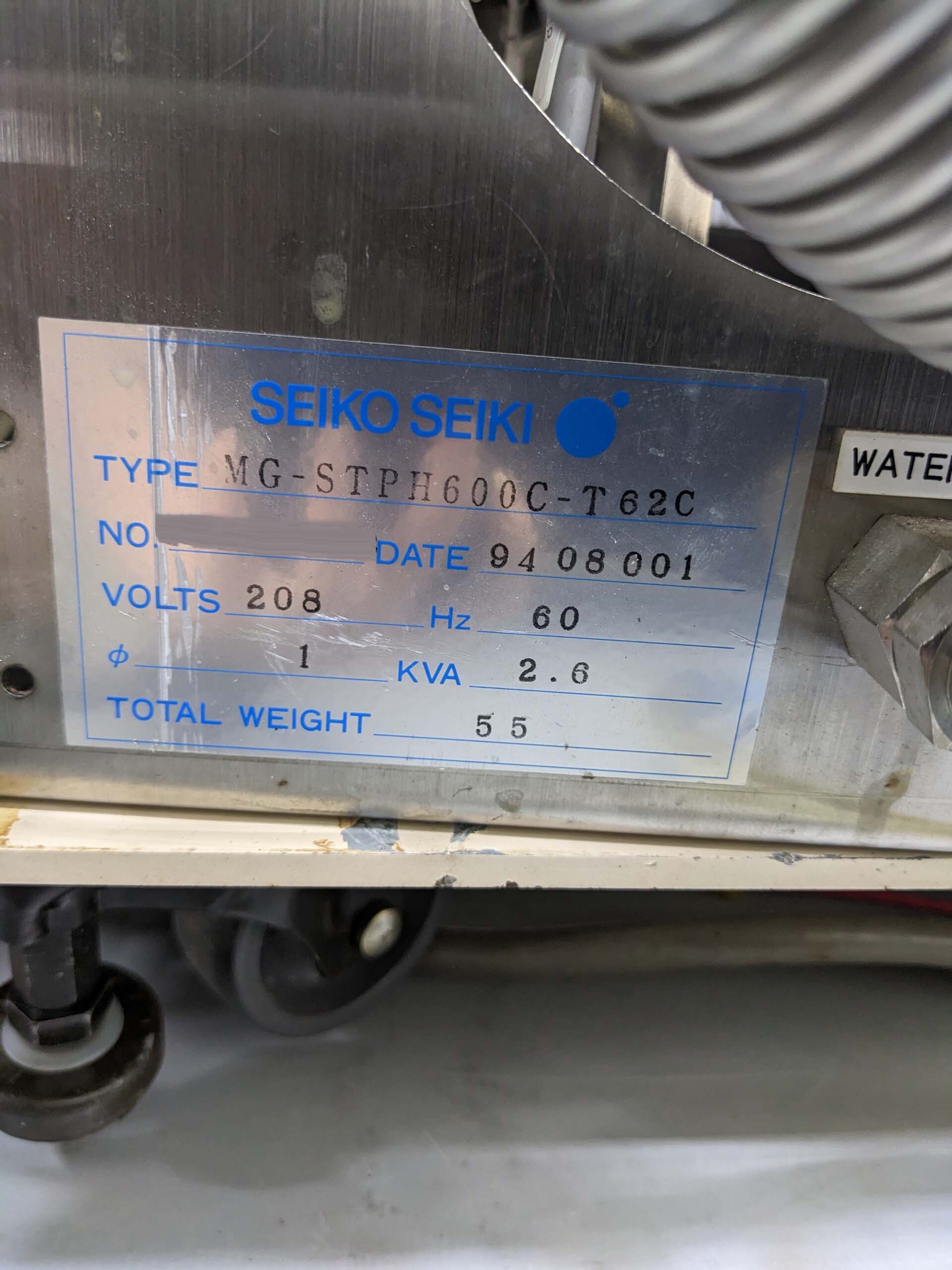

Vintage: 1994

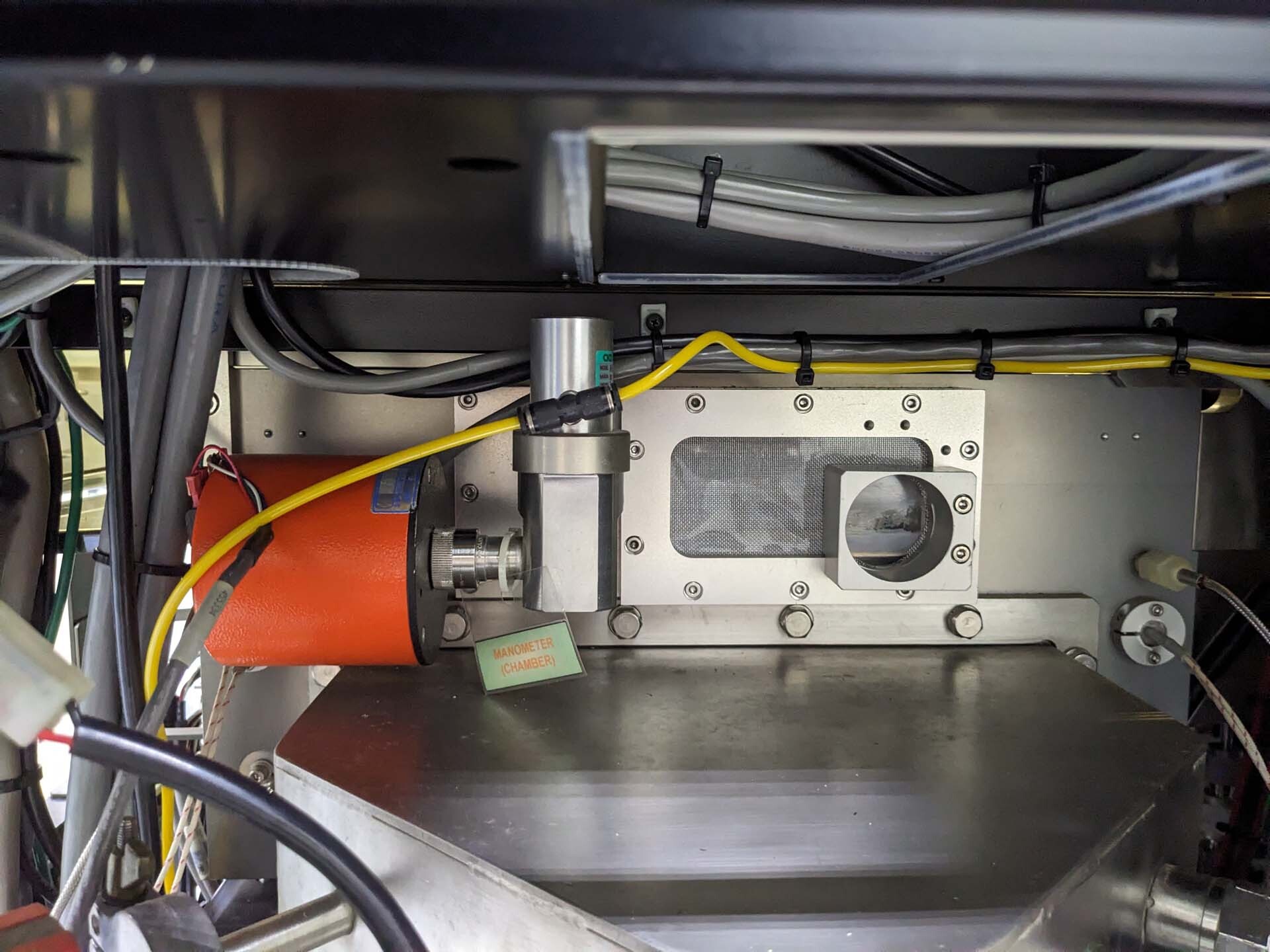

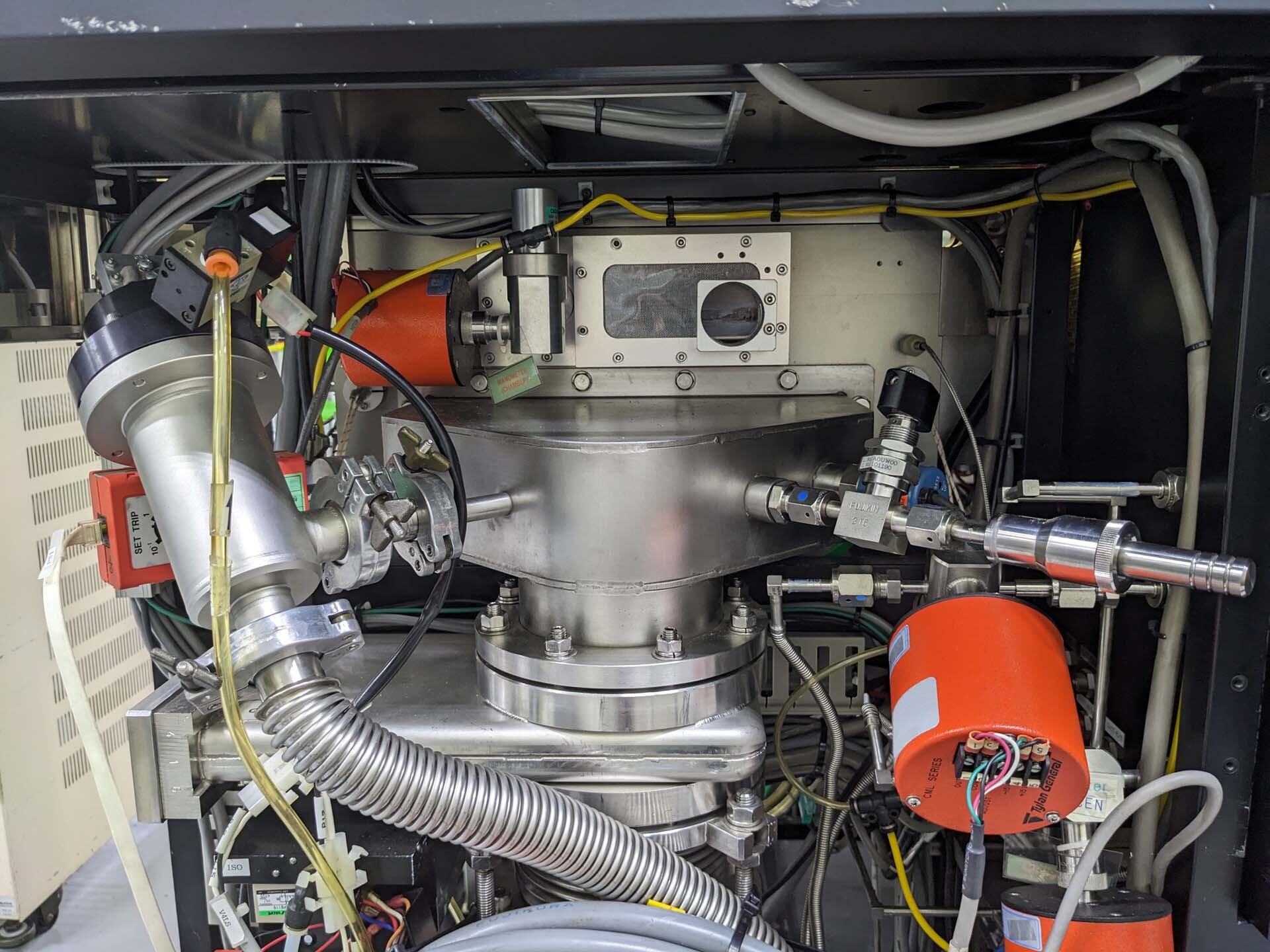

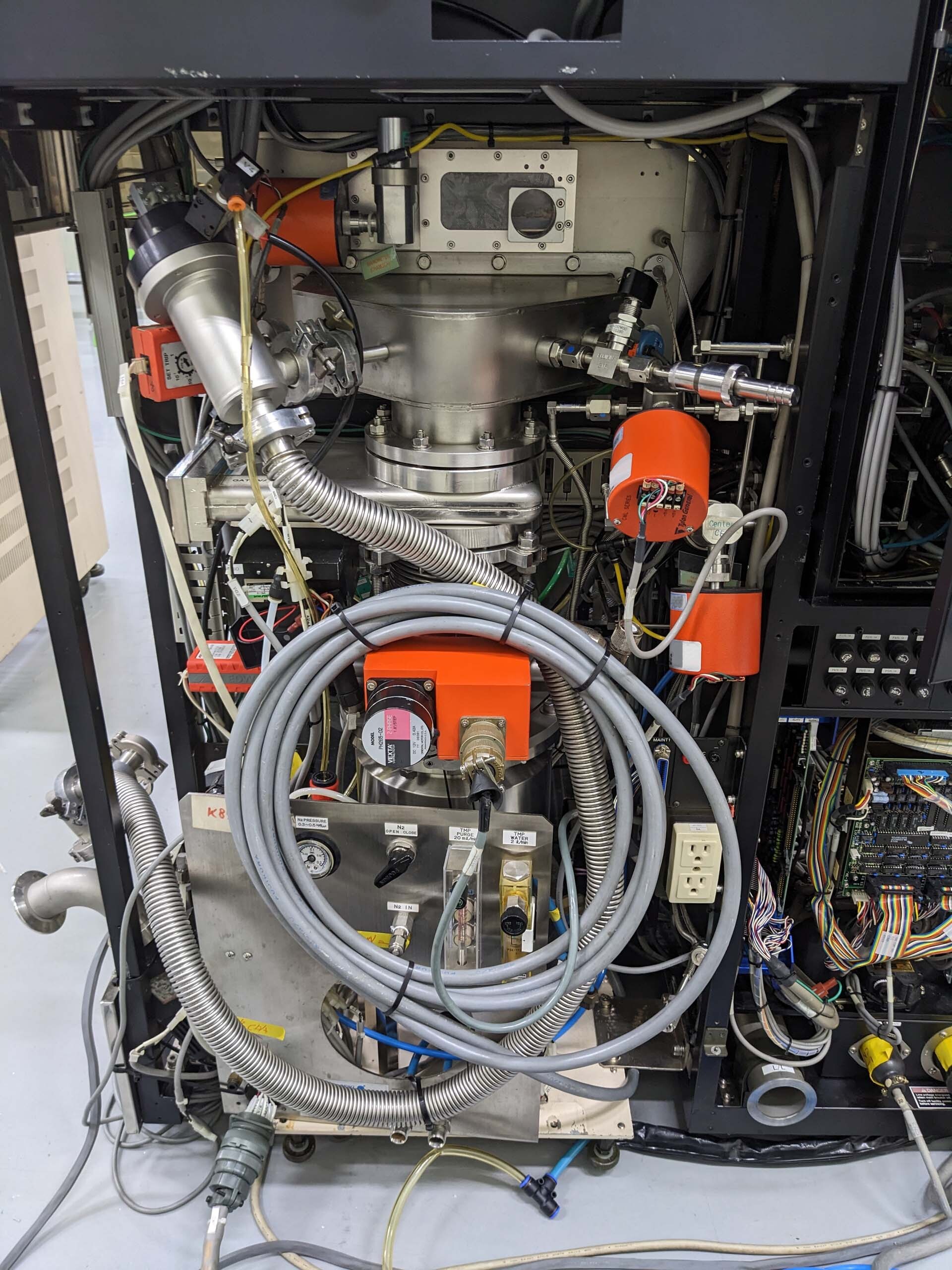

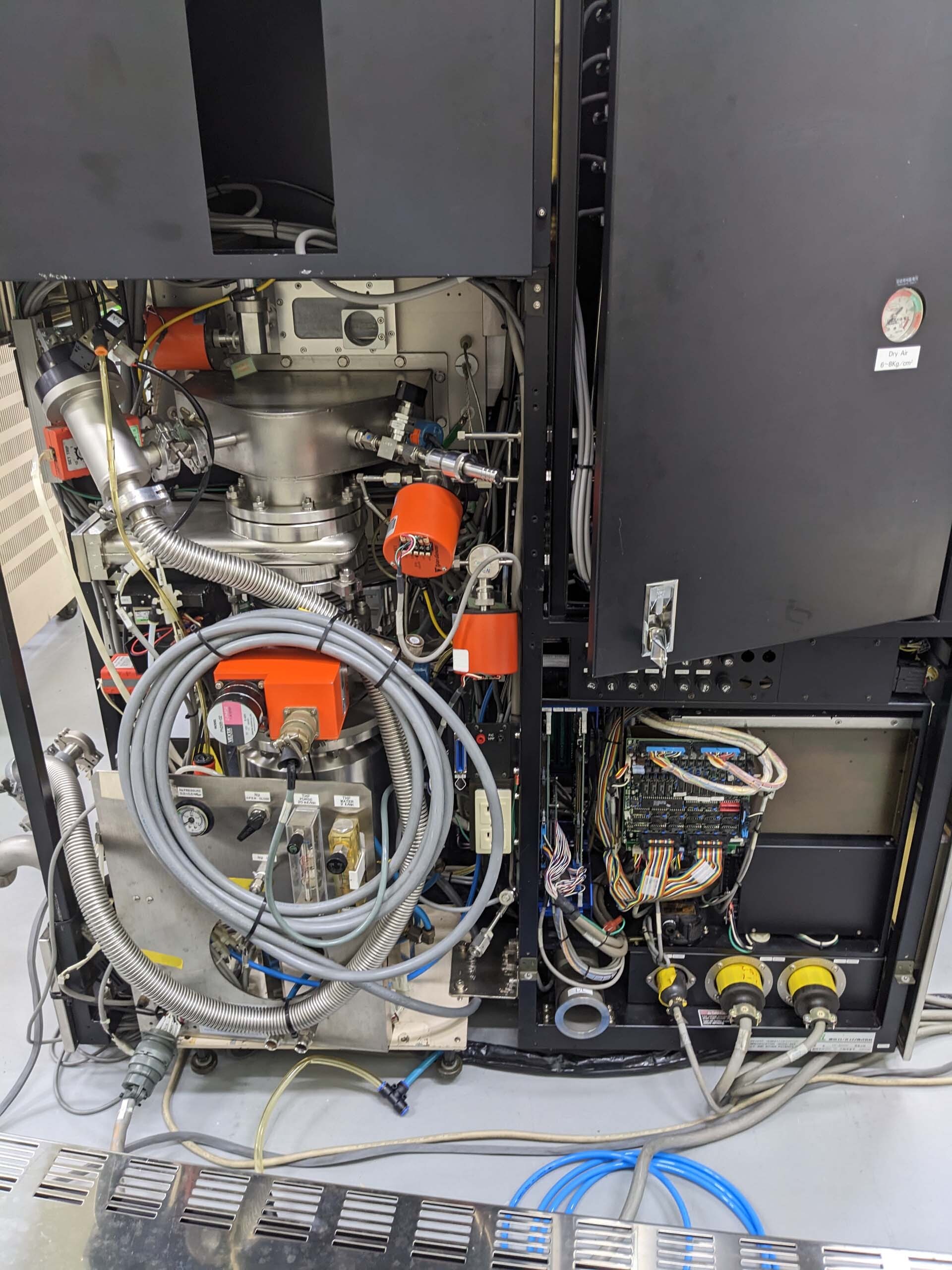

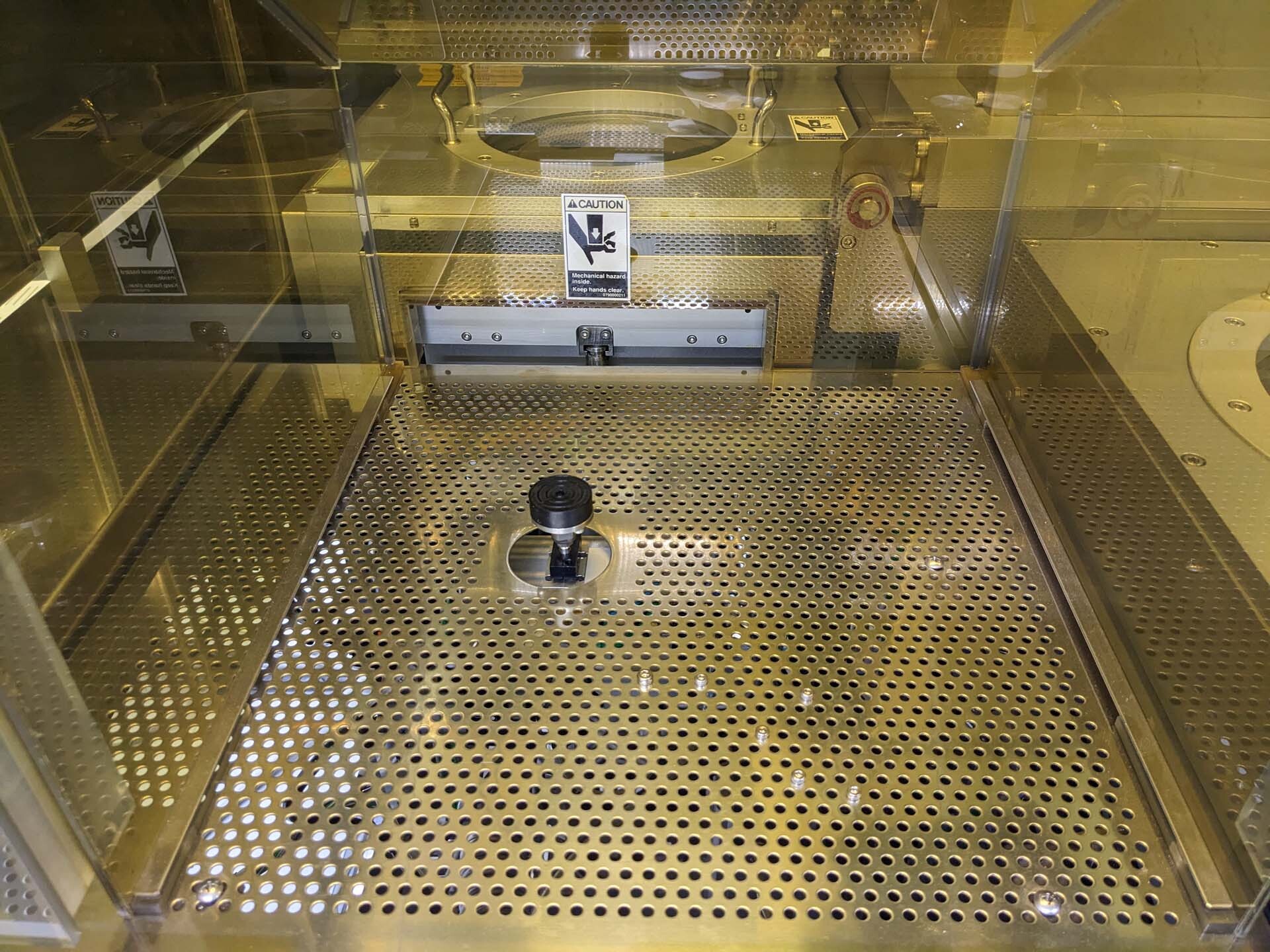

Oxide etcher, 8"

Chuck type: ESC

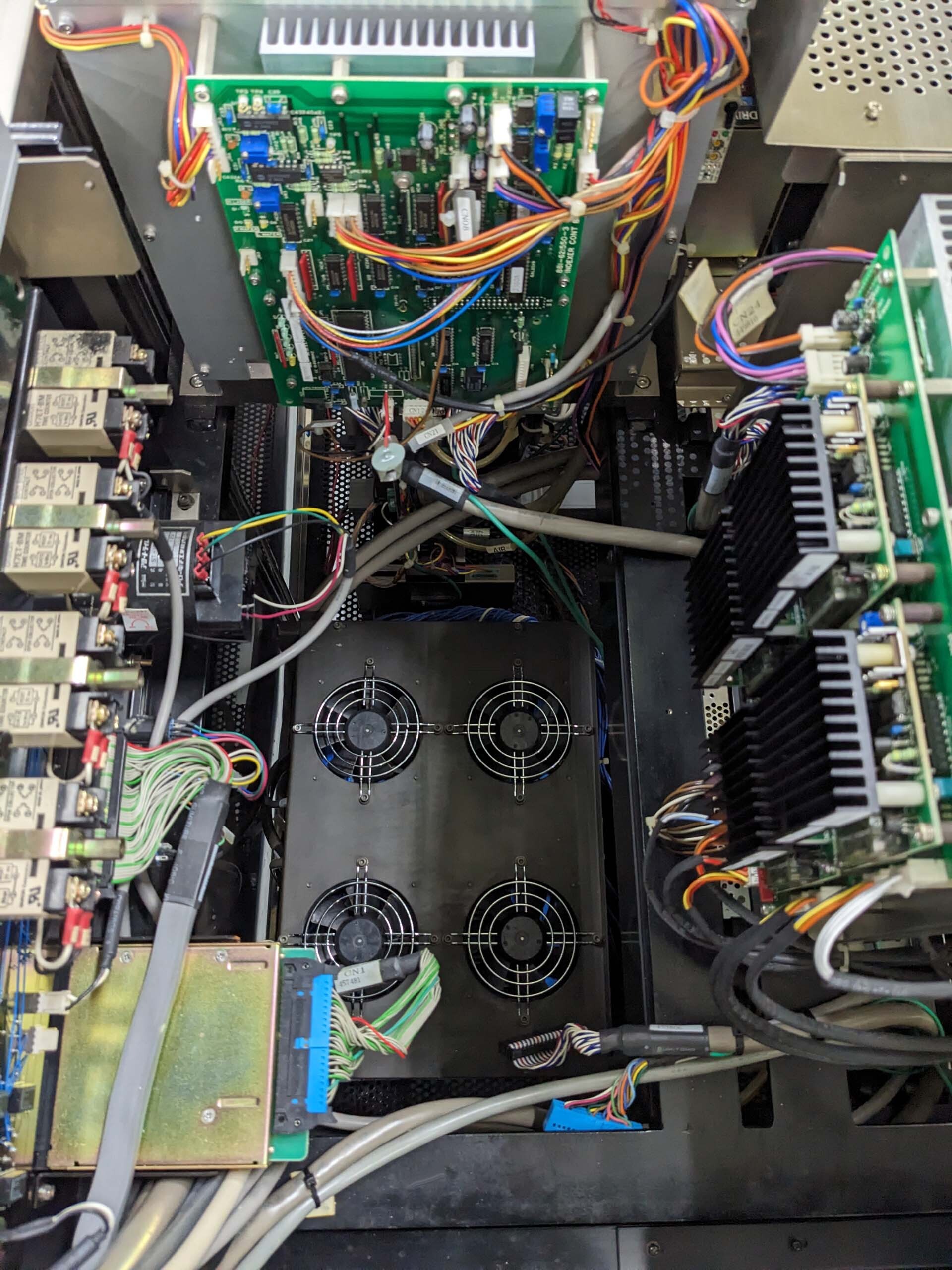

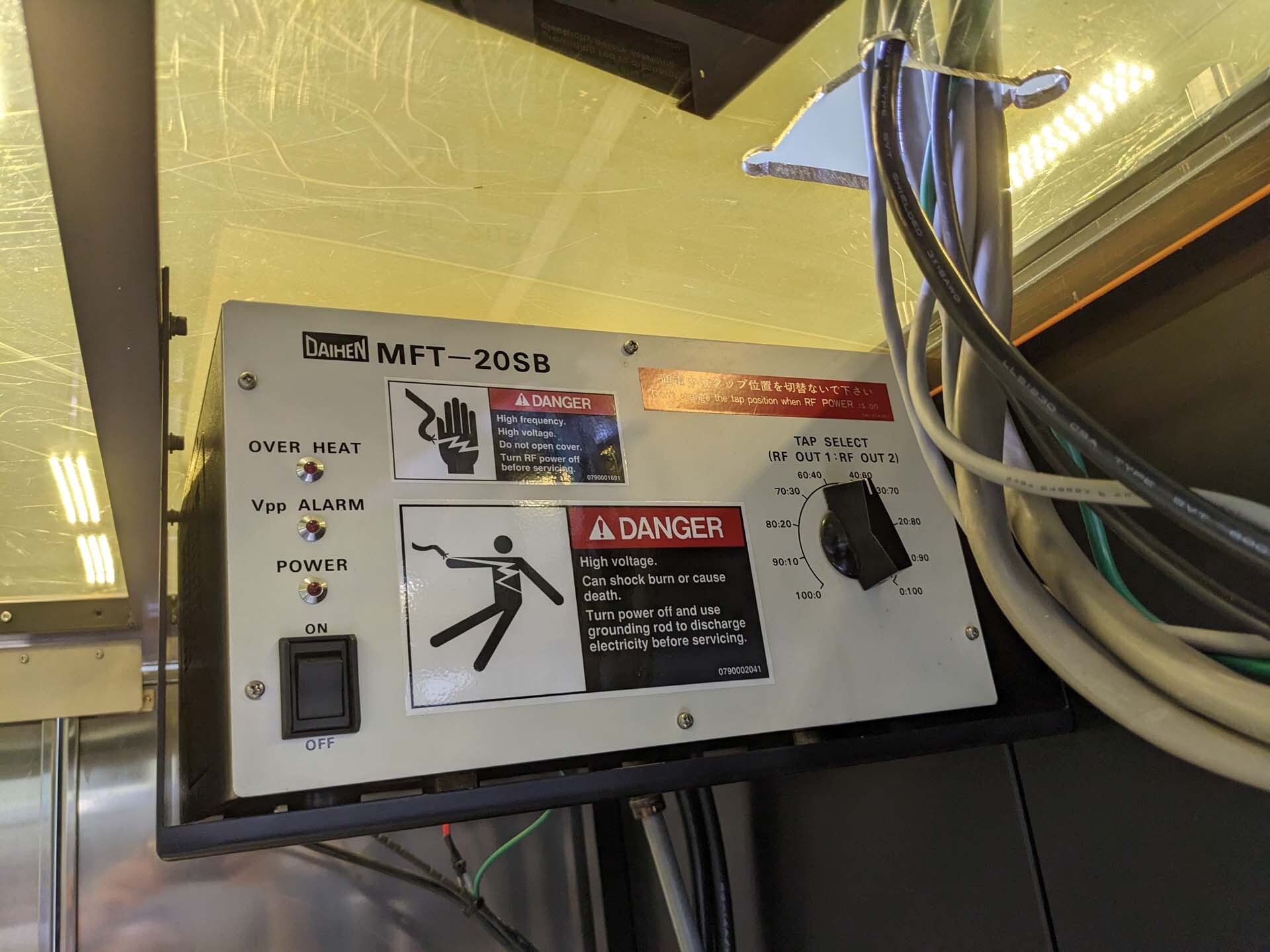

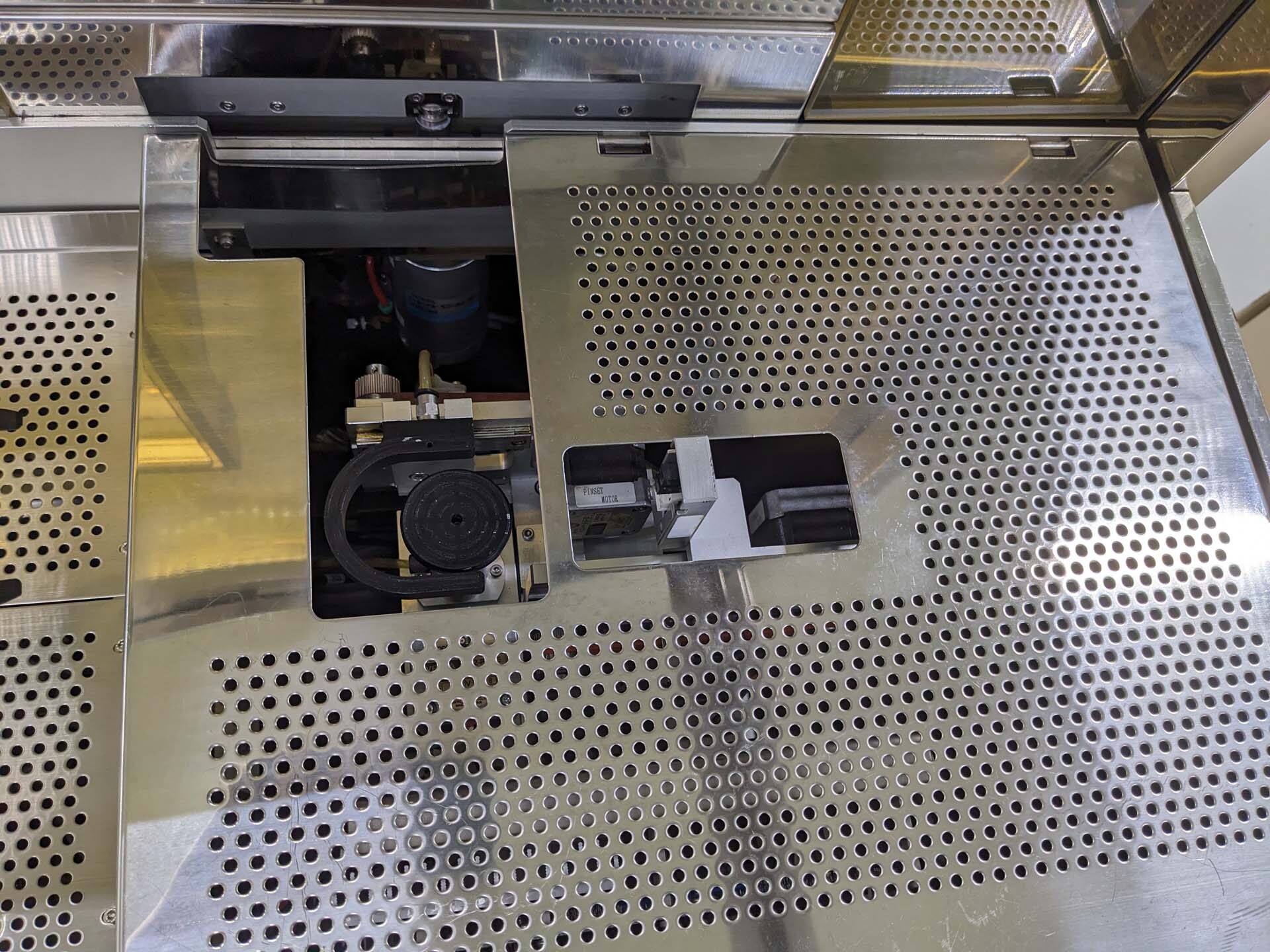

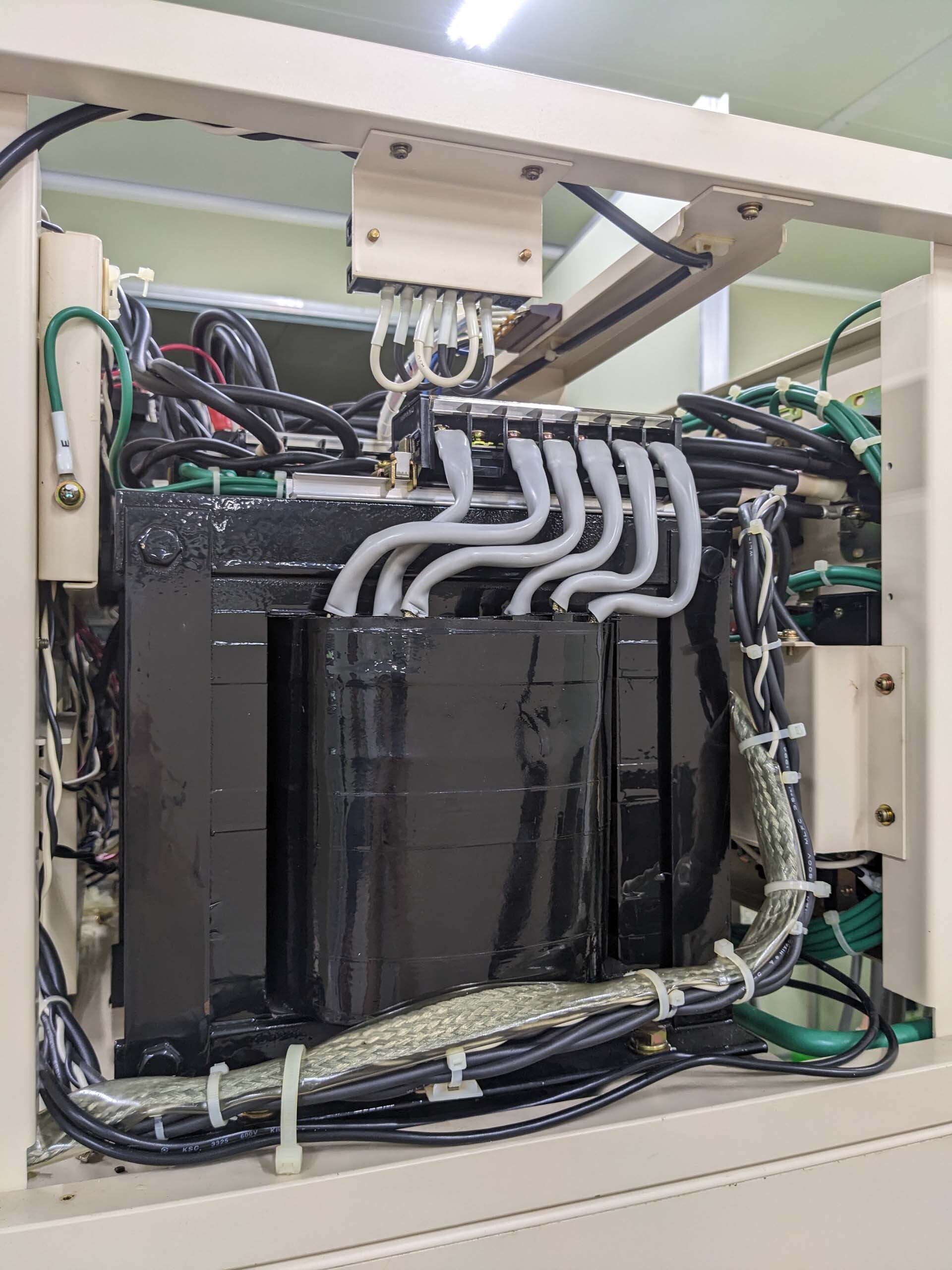

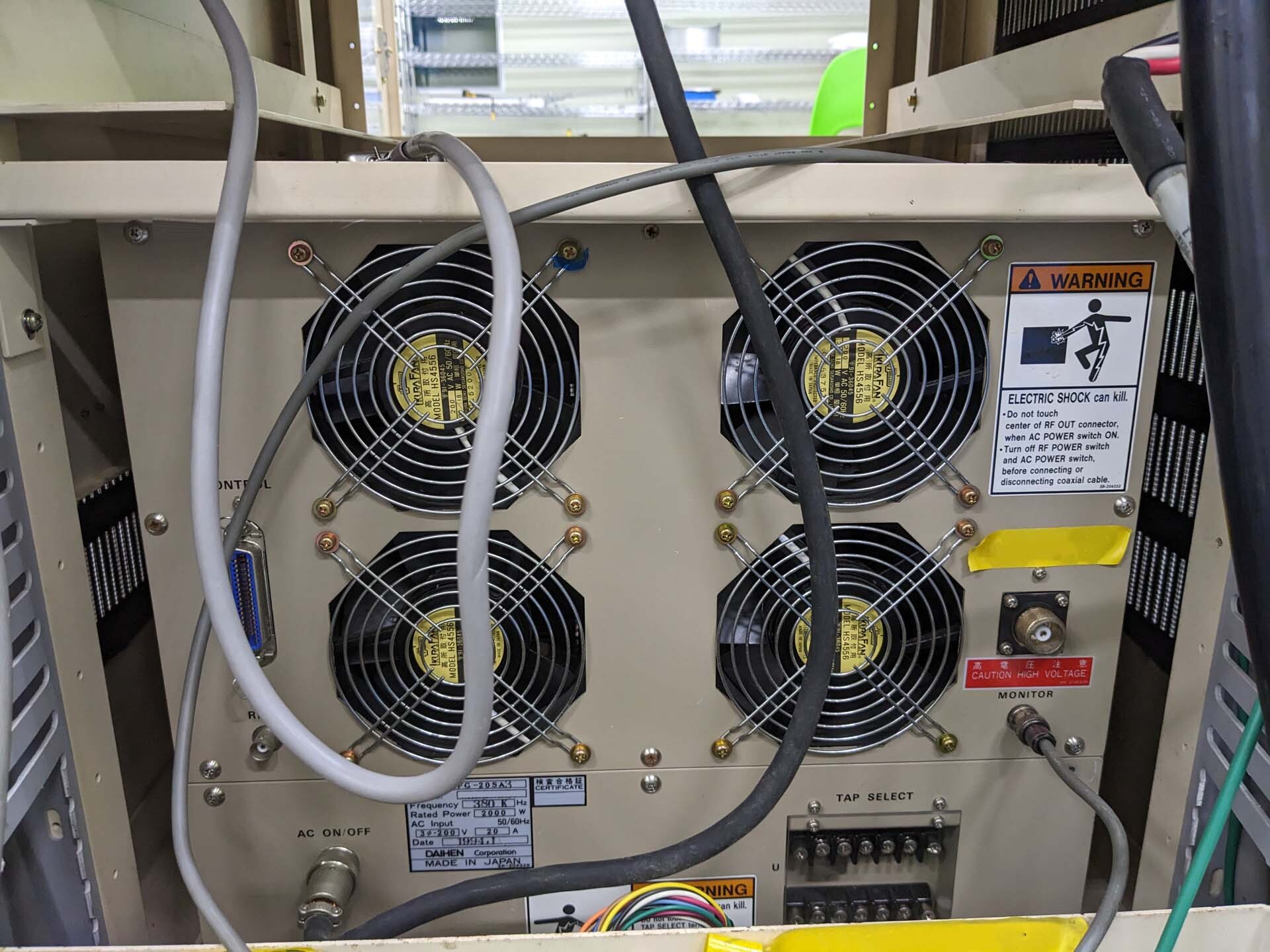

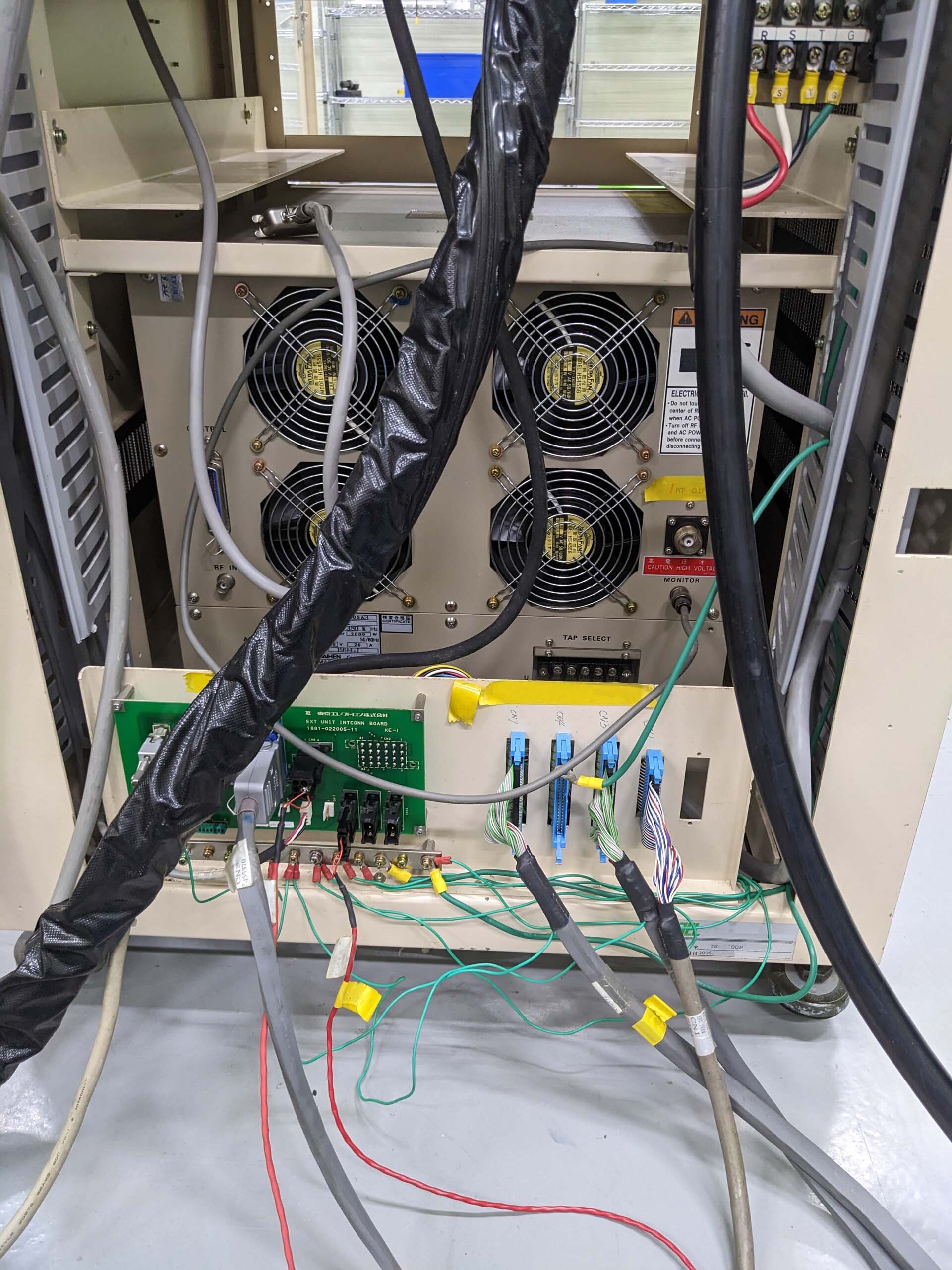

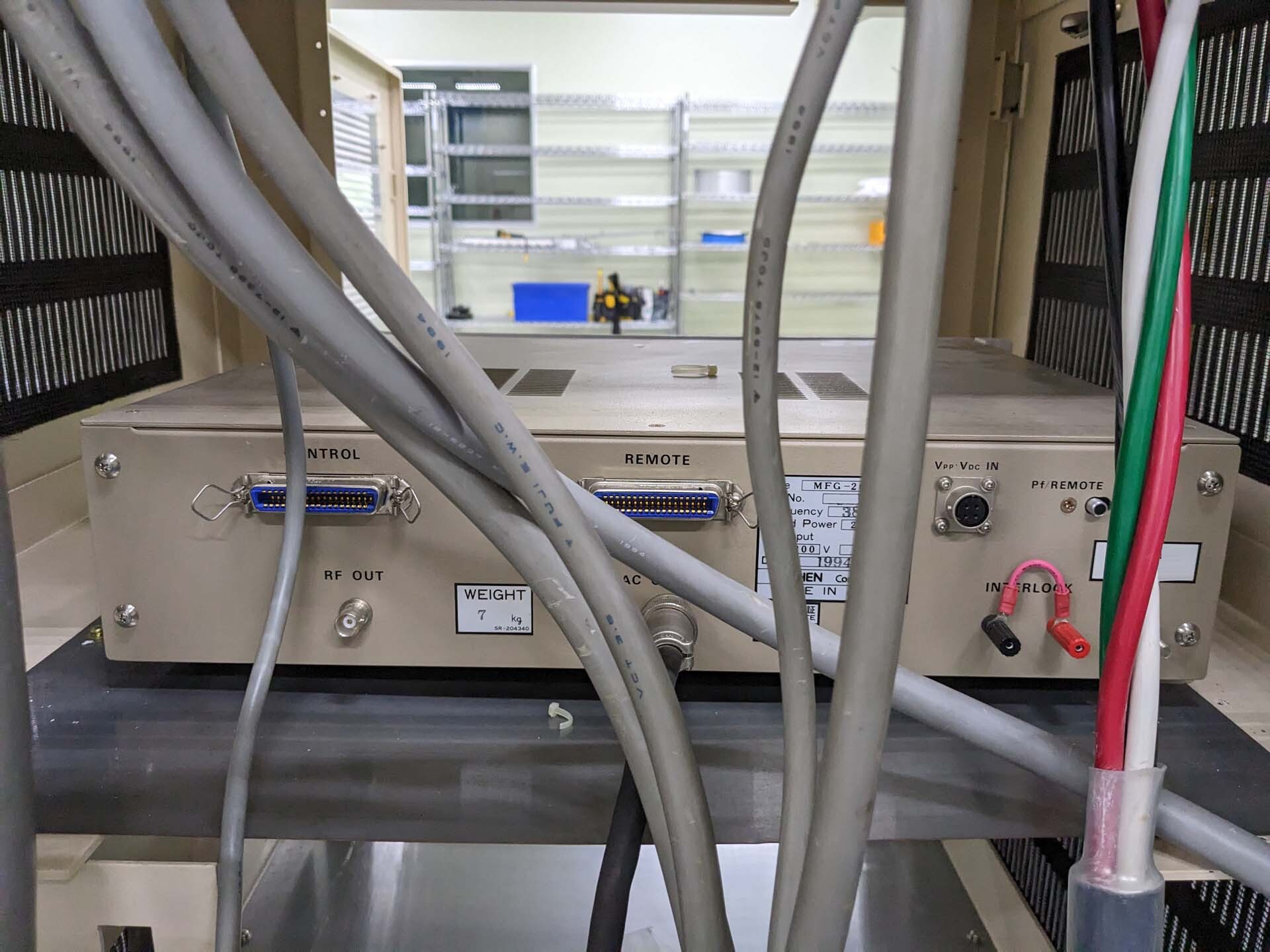

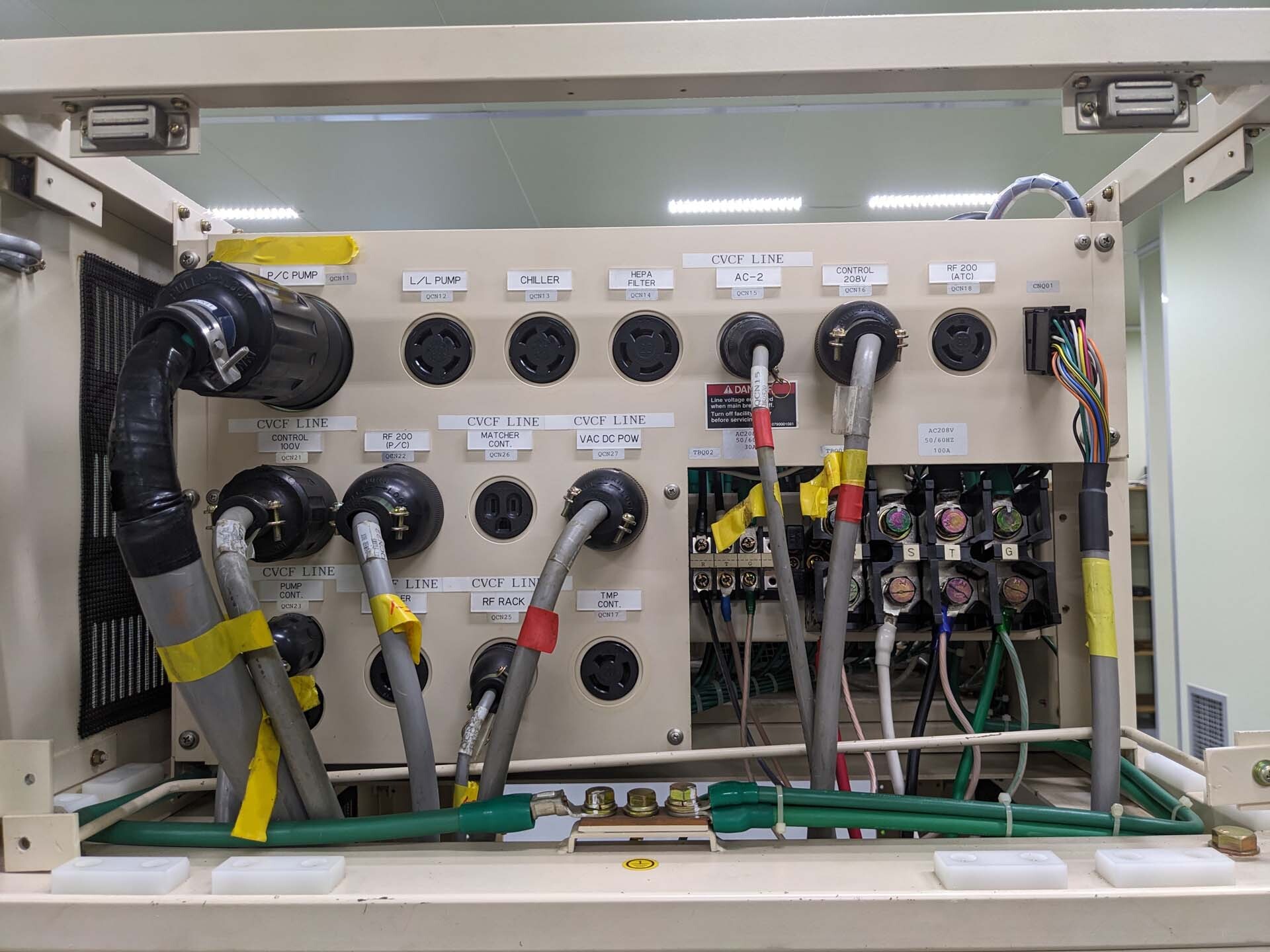

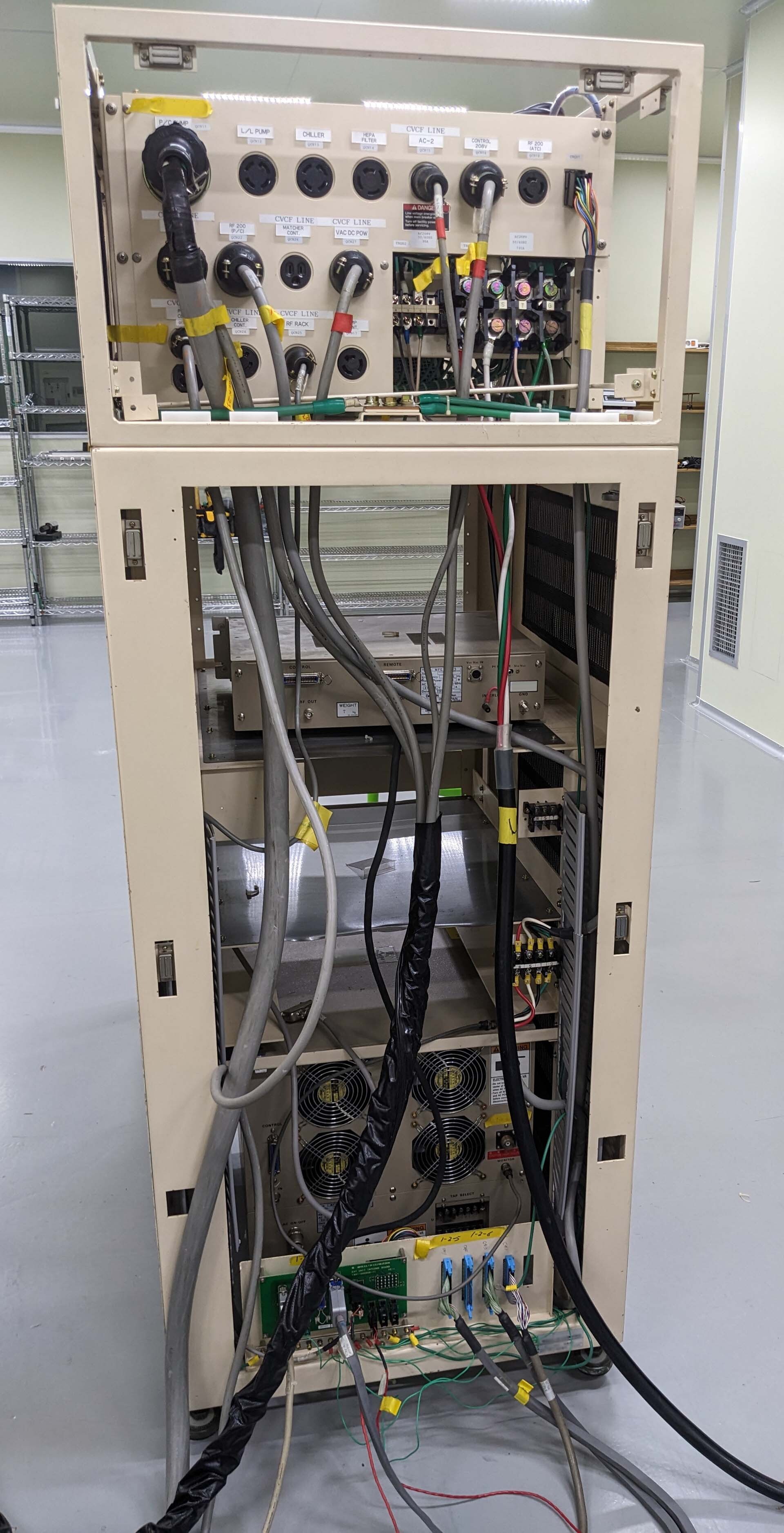

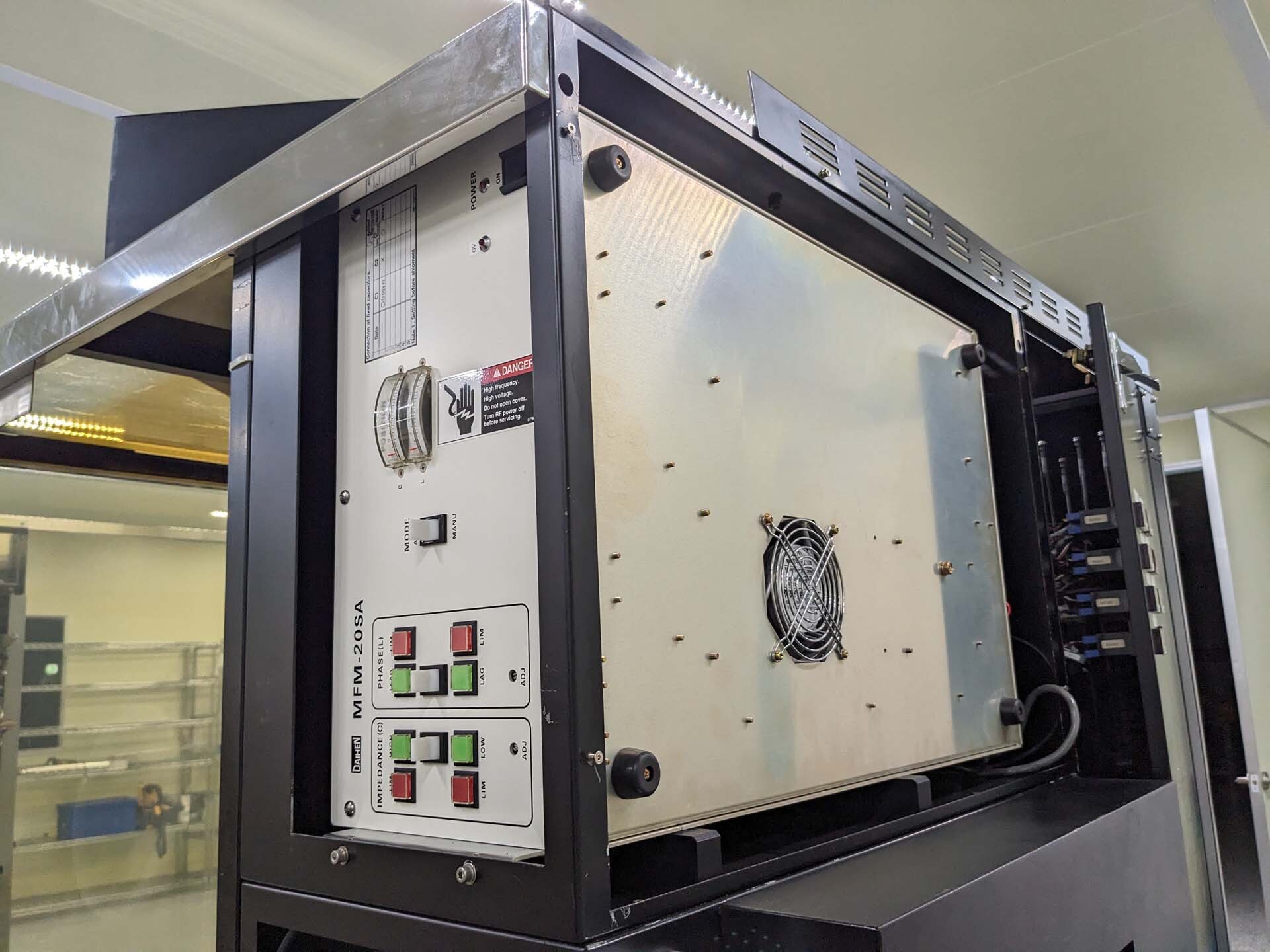

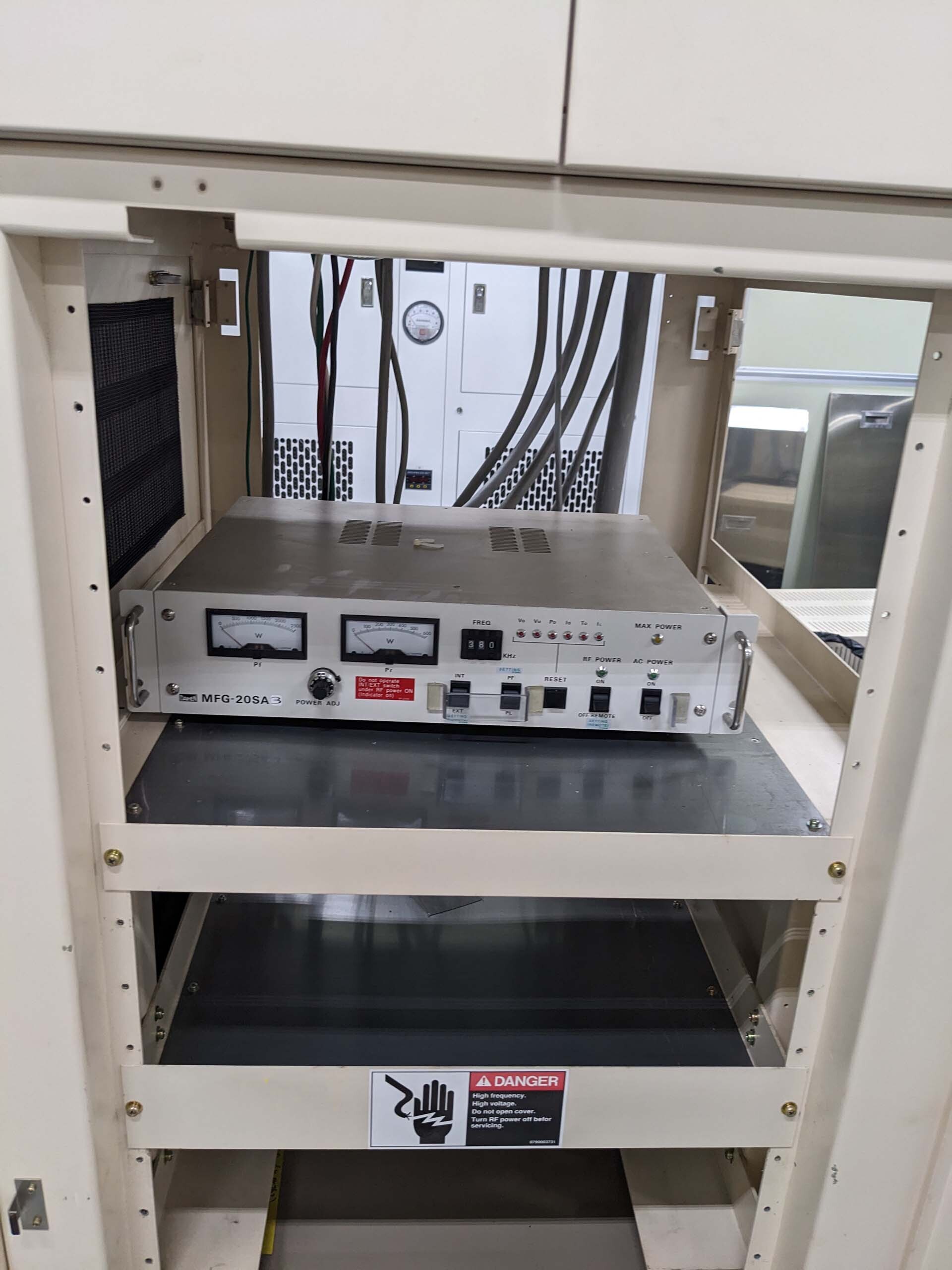

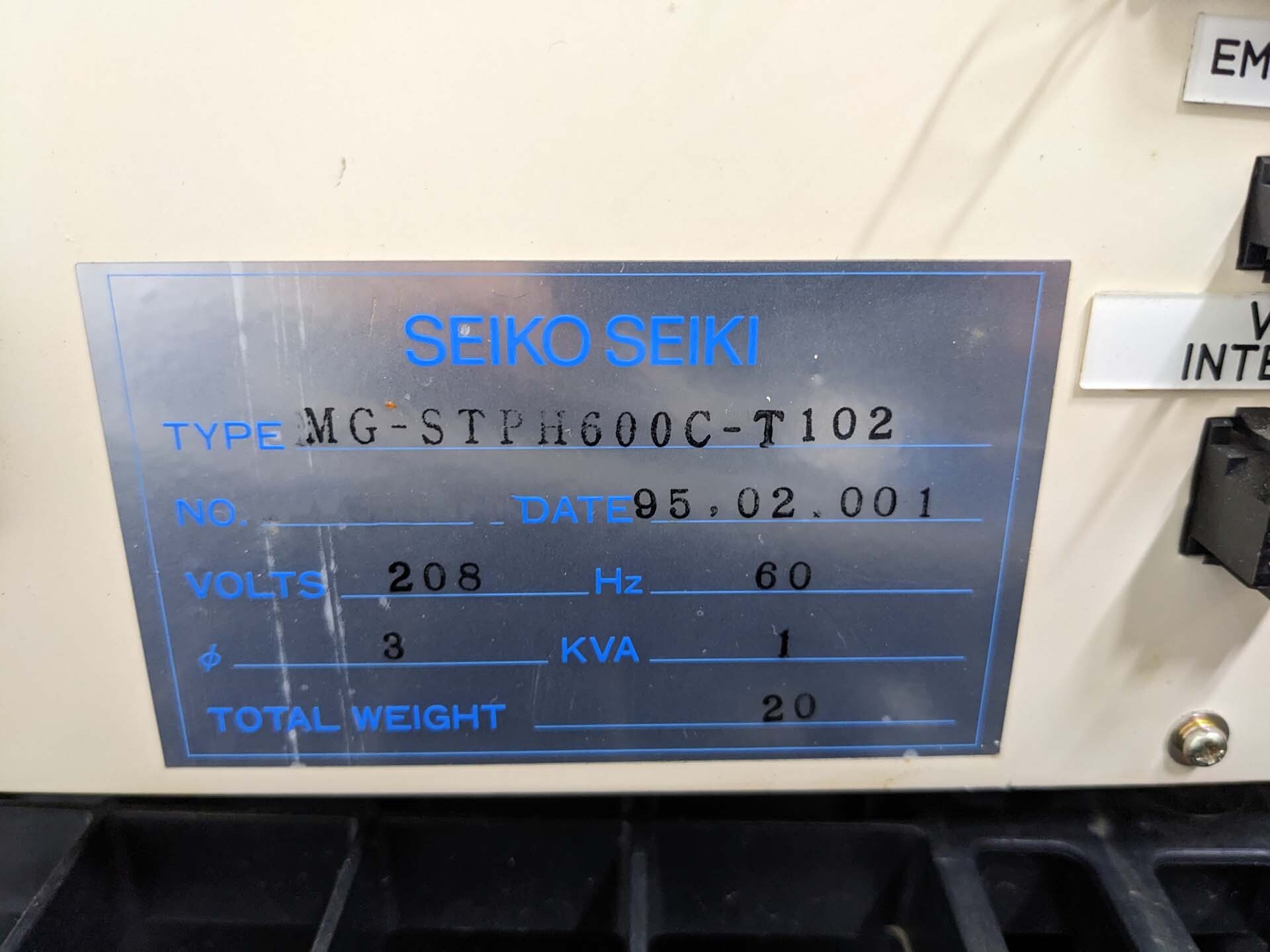

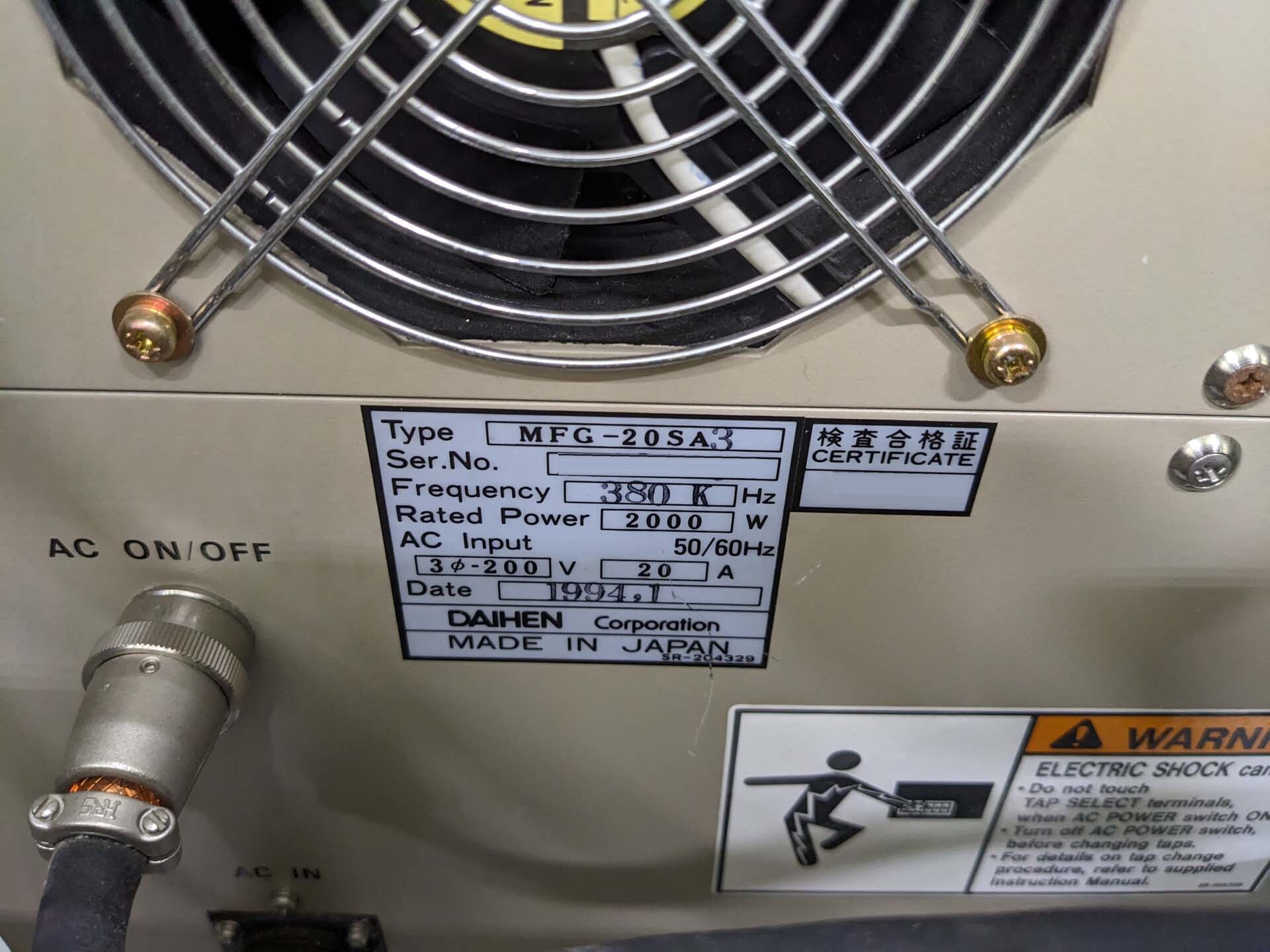

RF Generator

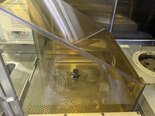

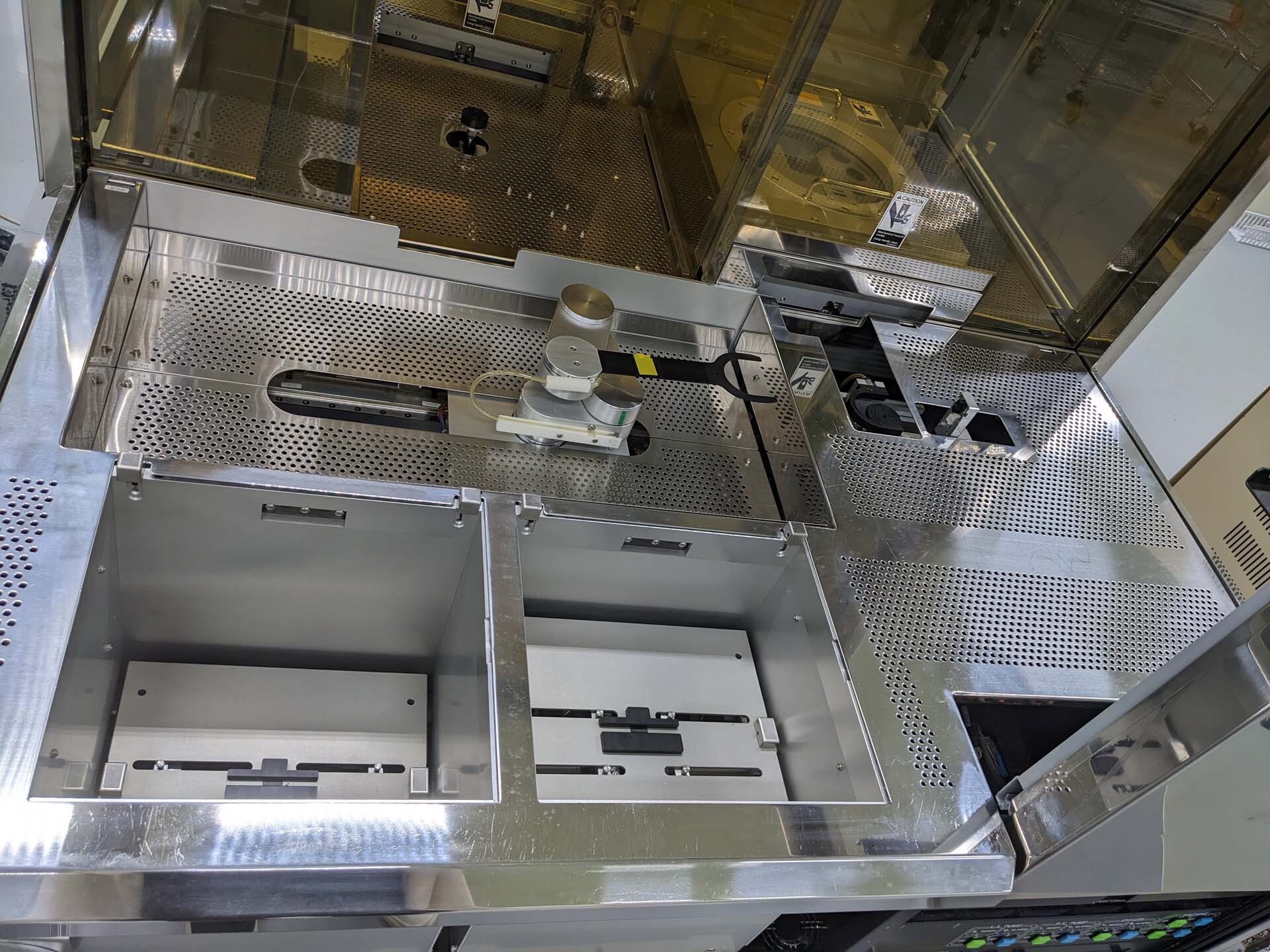

ENT Shuttle

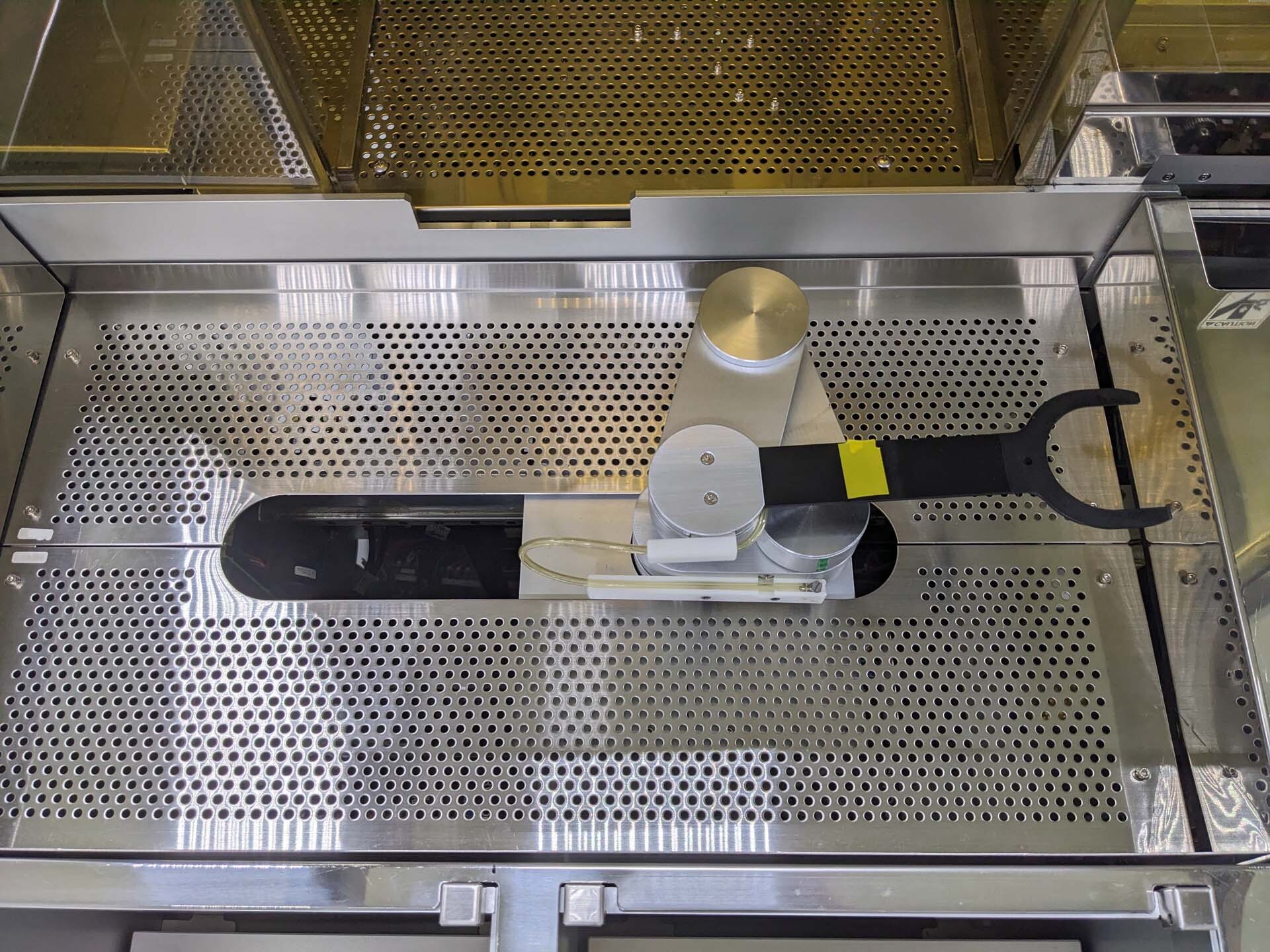

Aligner

ISO Module

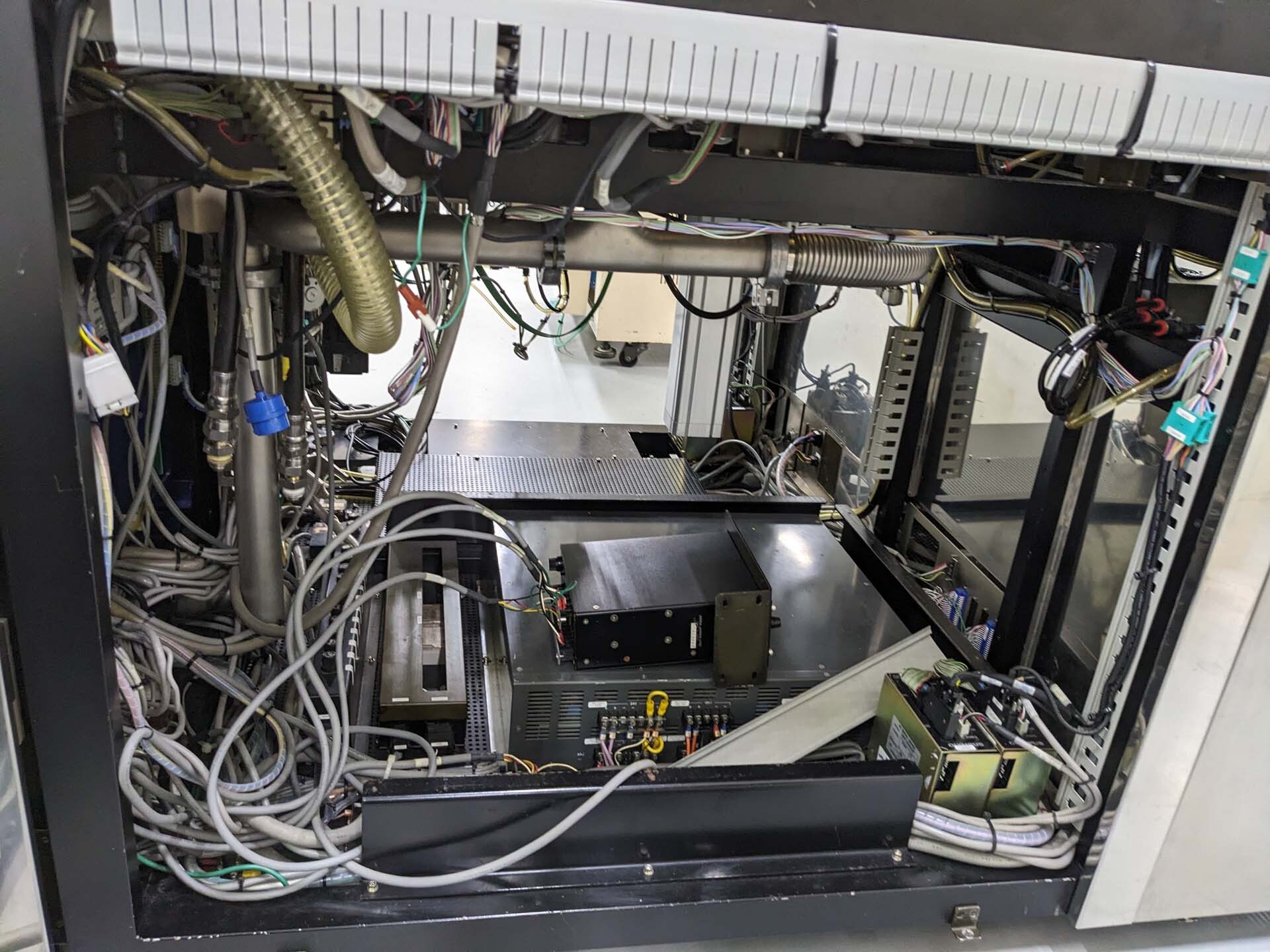

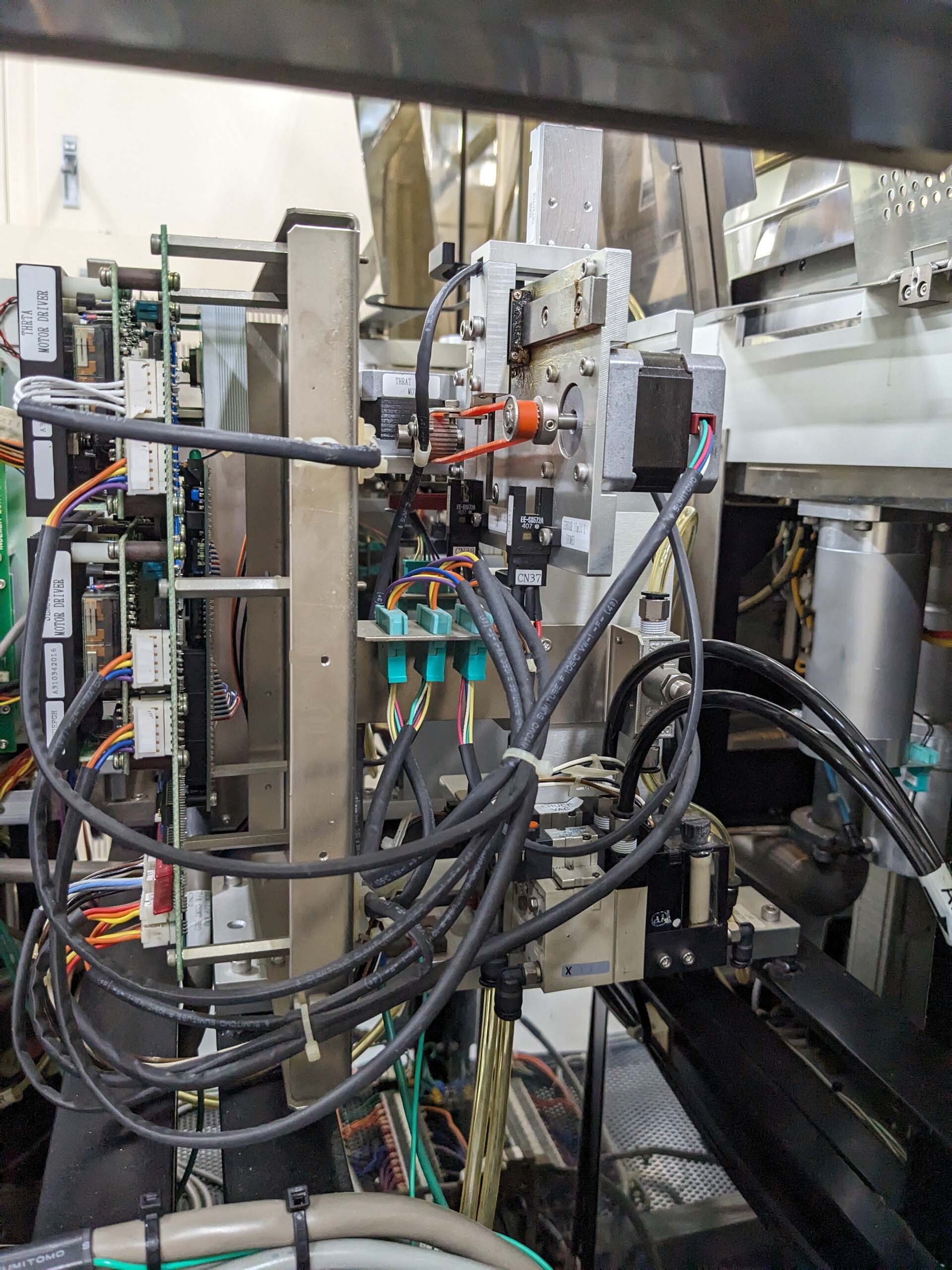

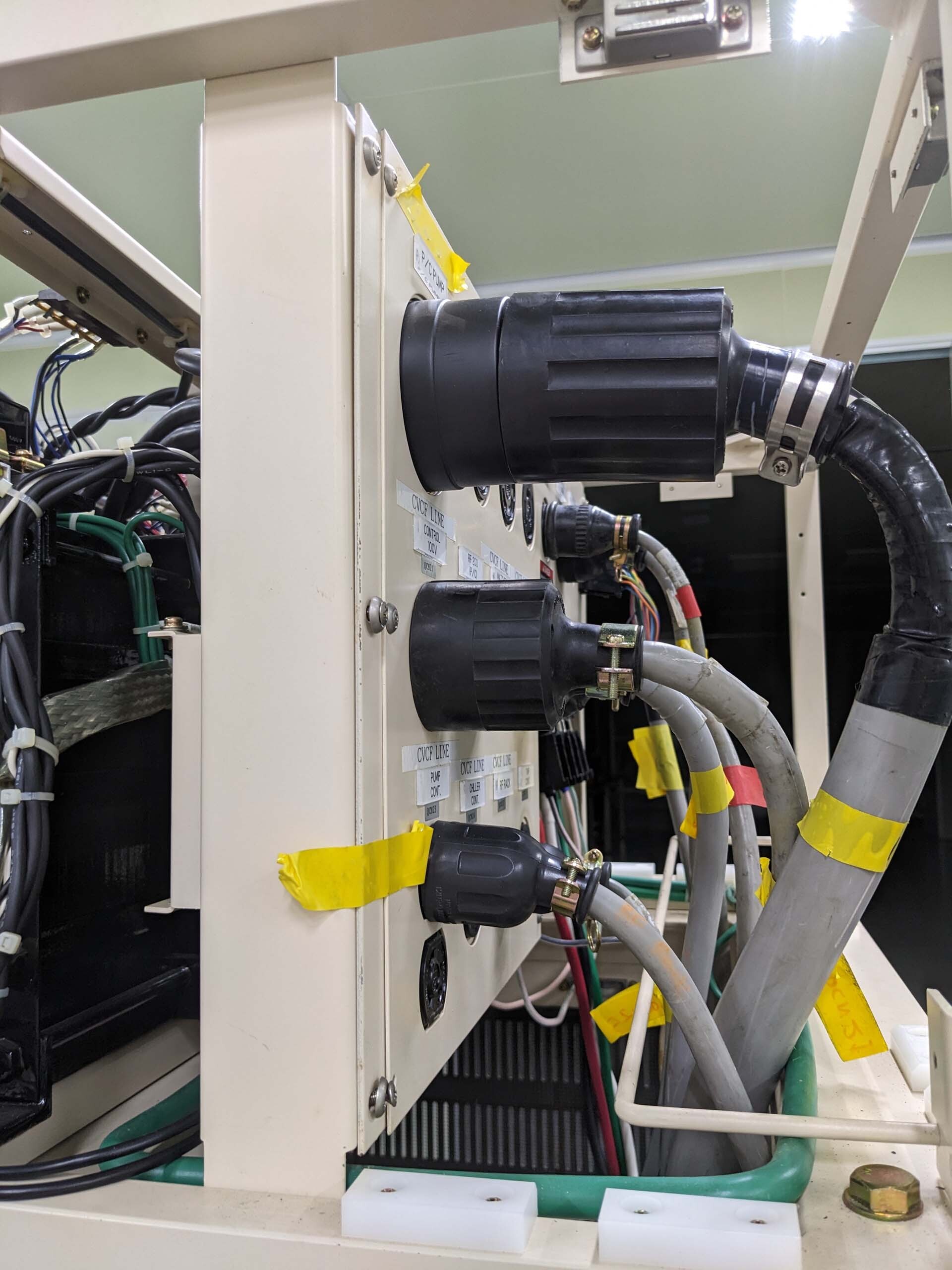

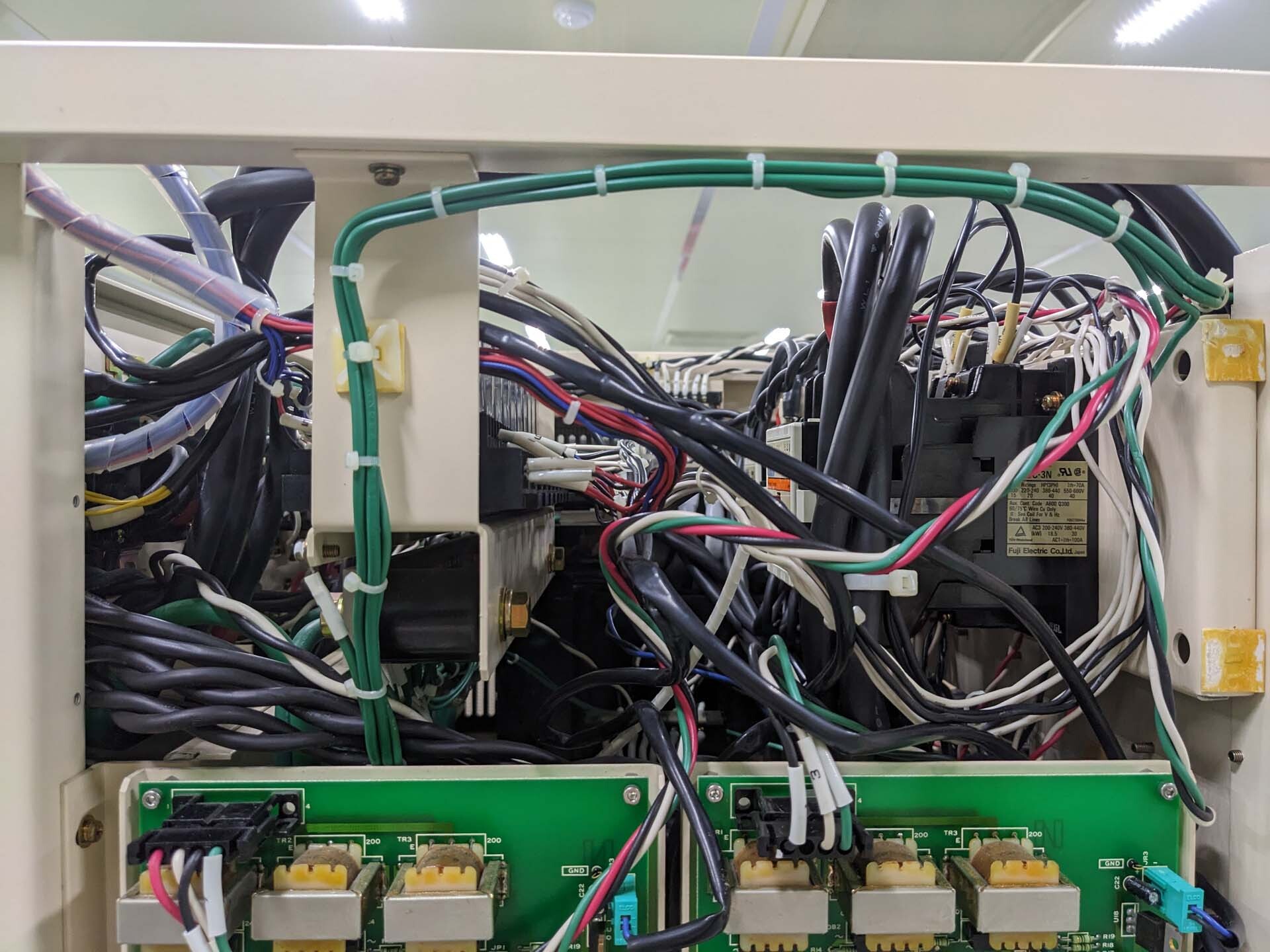

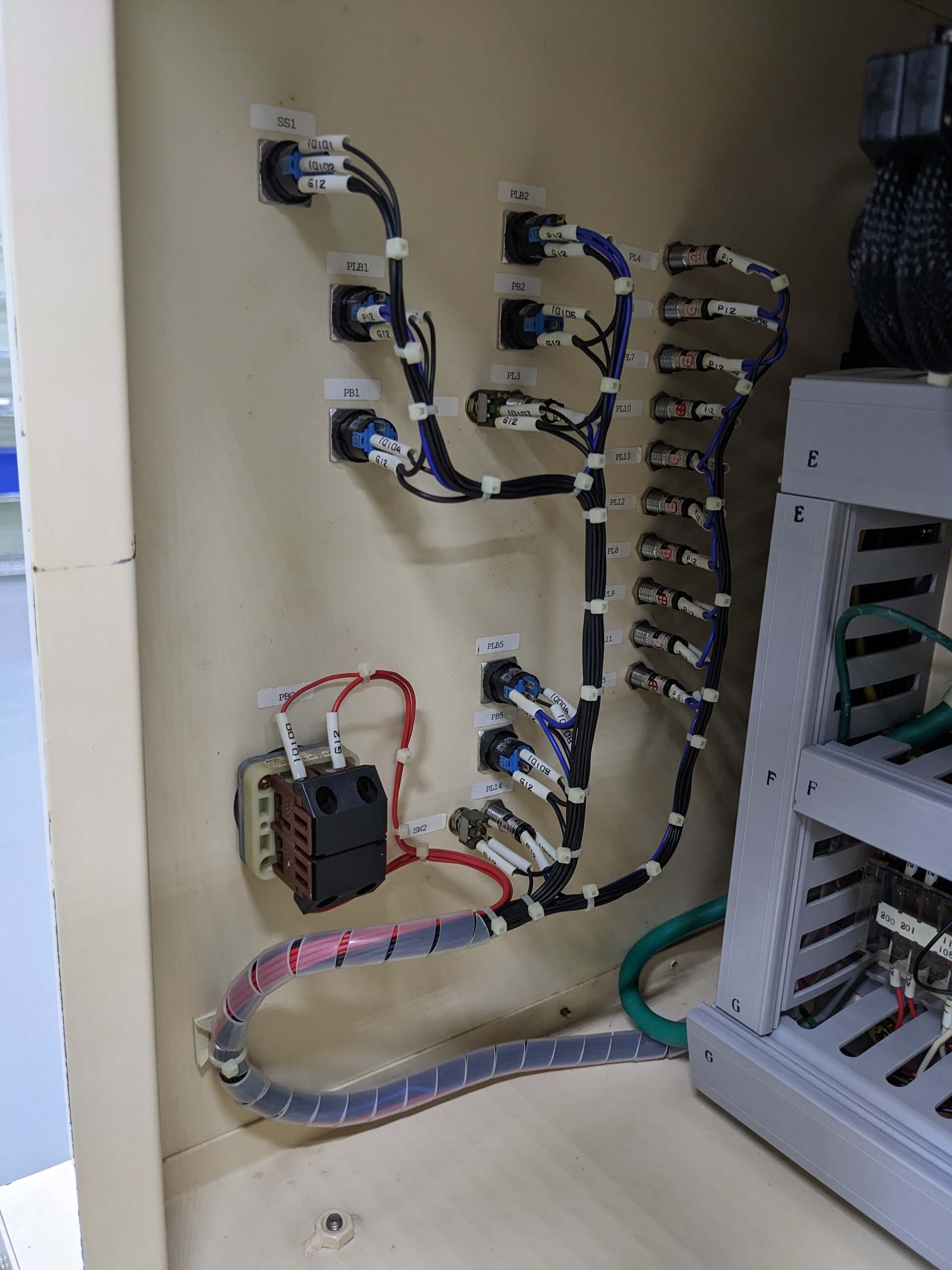

Cable harness

No chillers

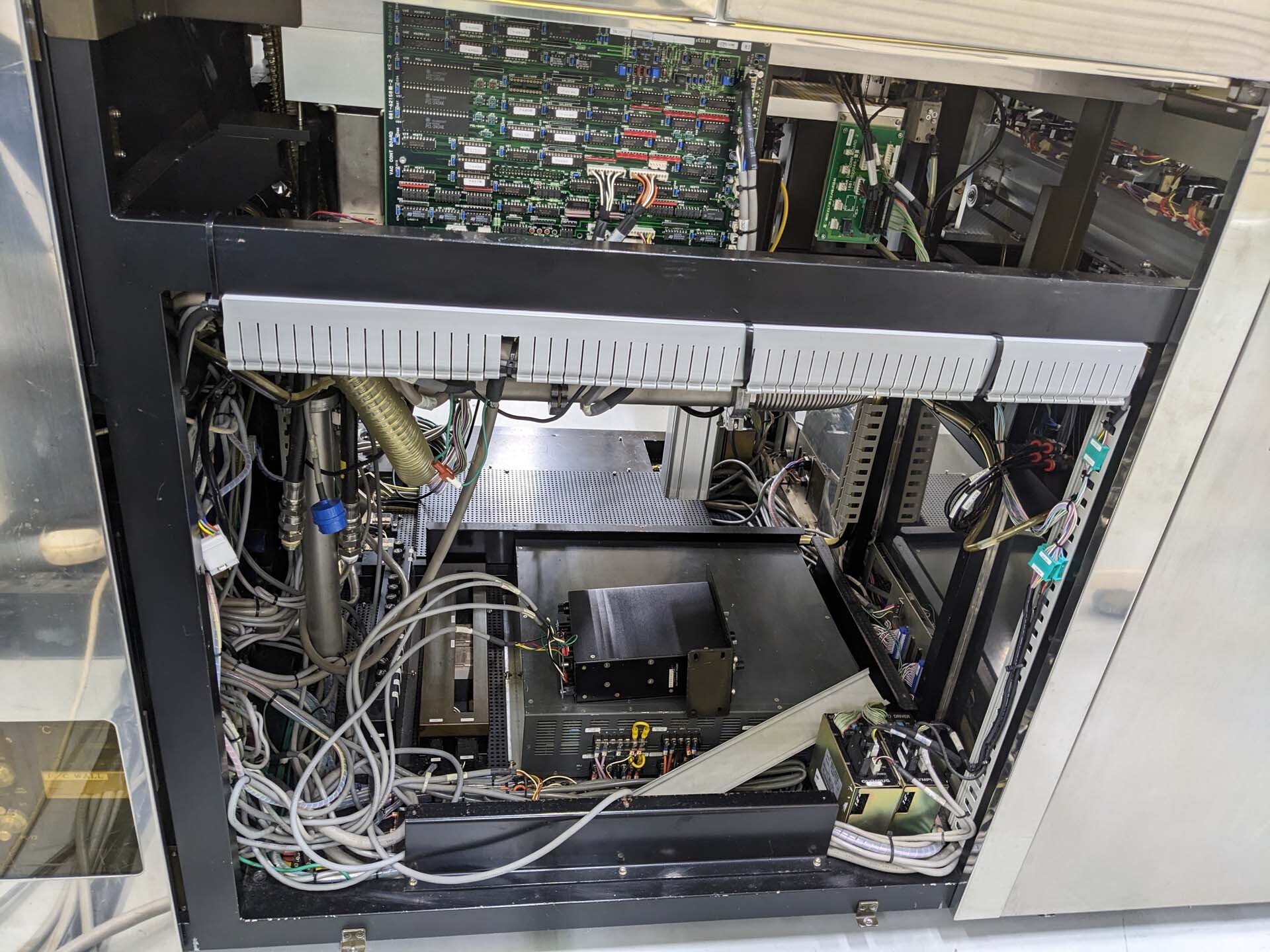

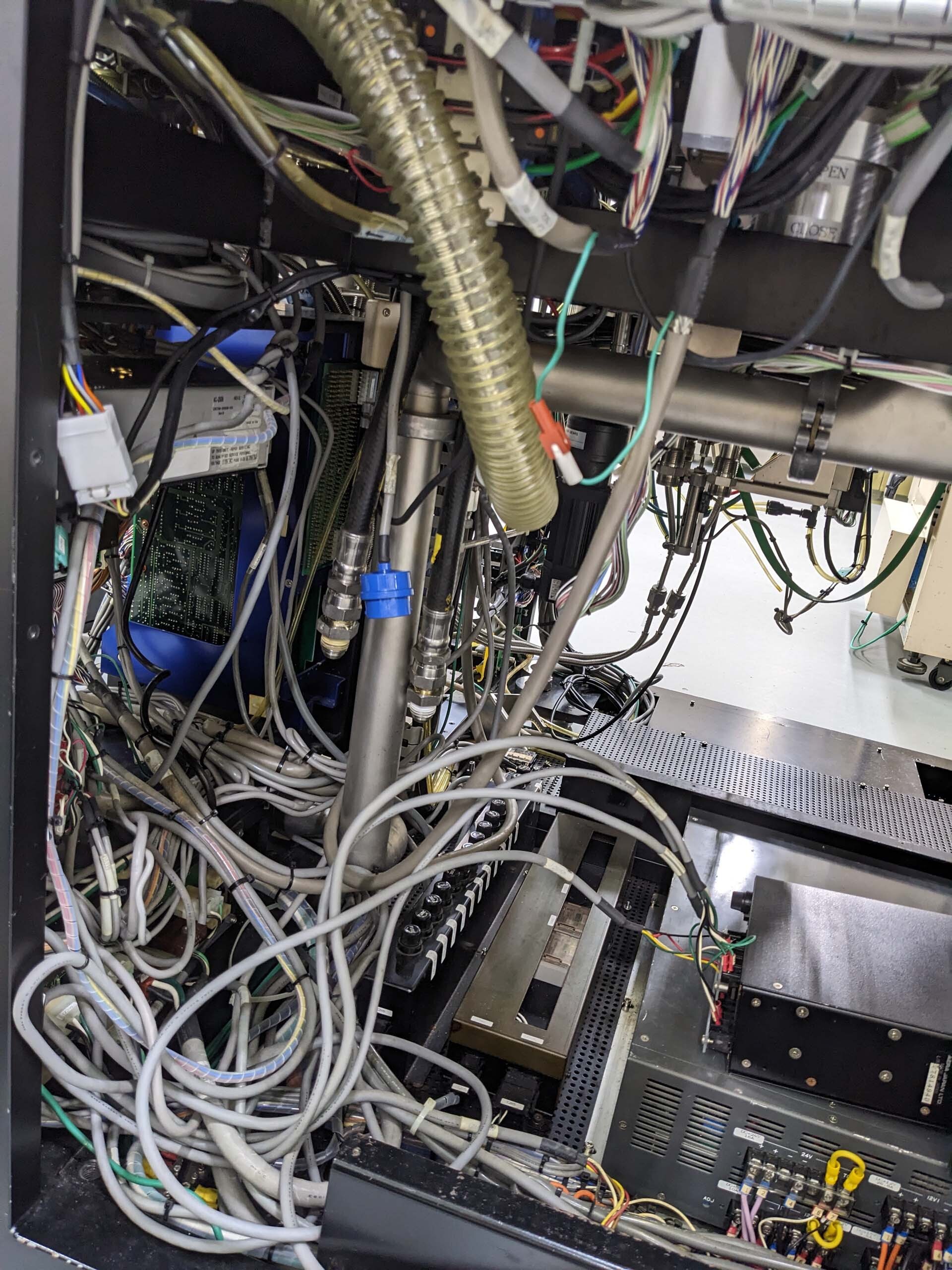

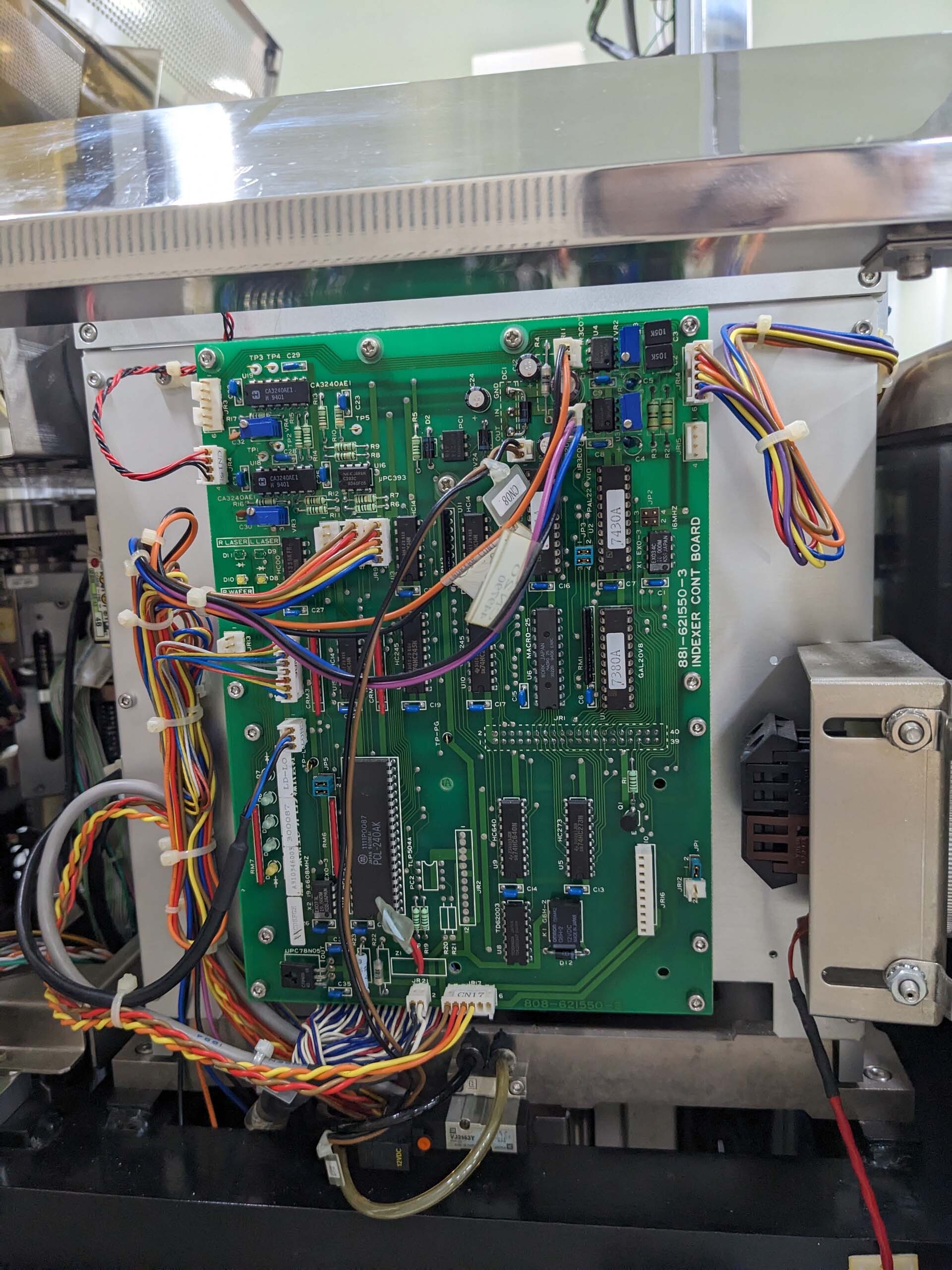

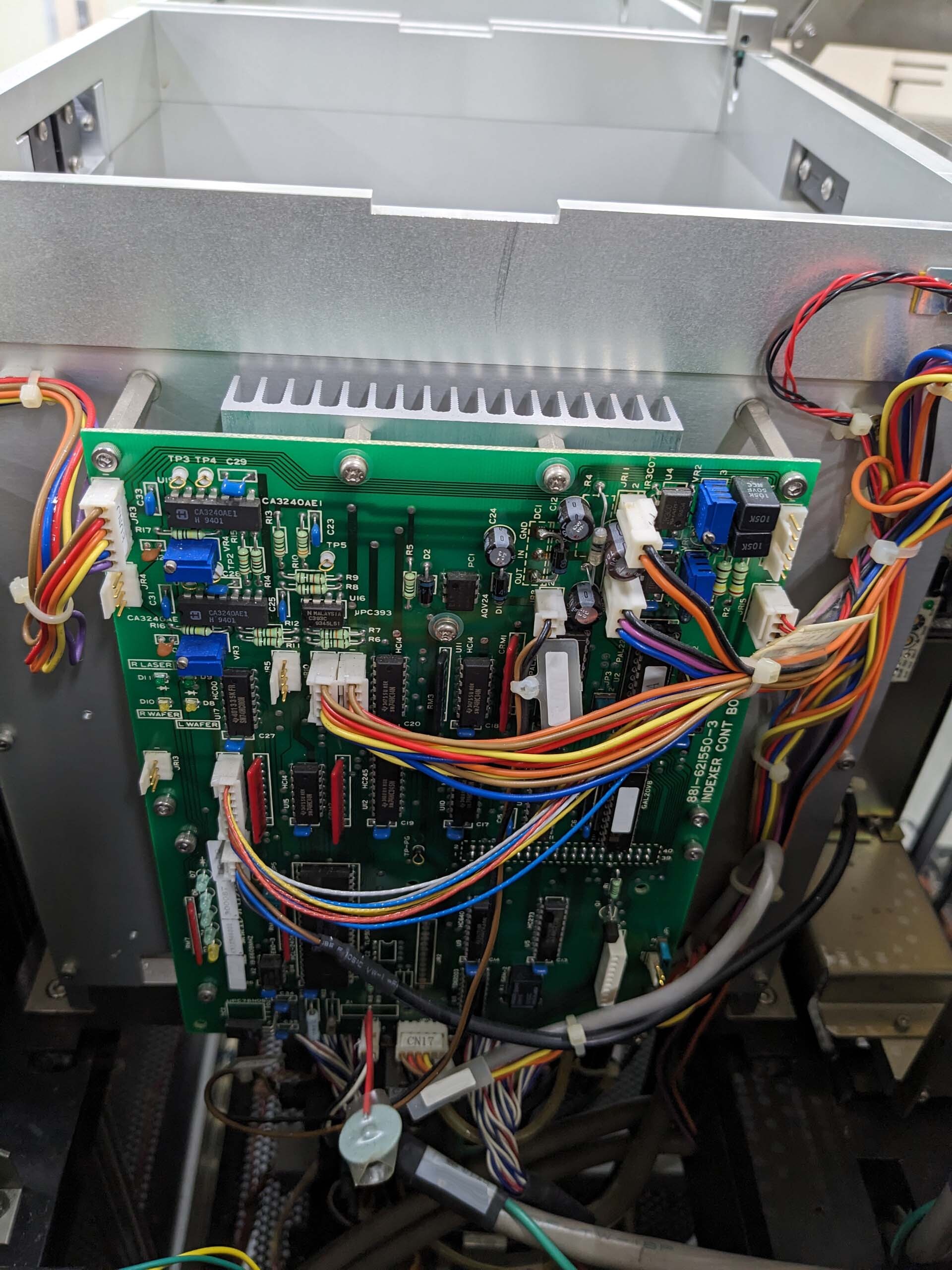

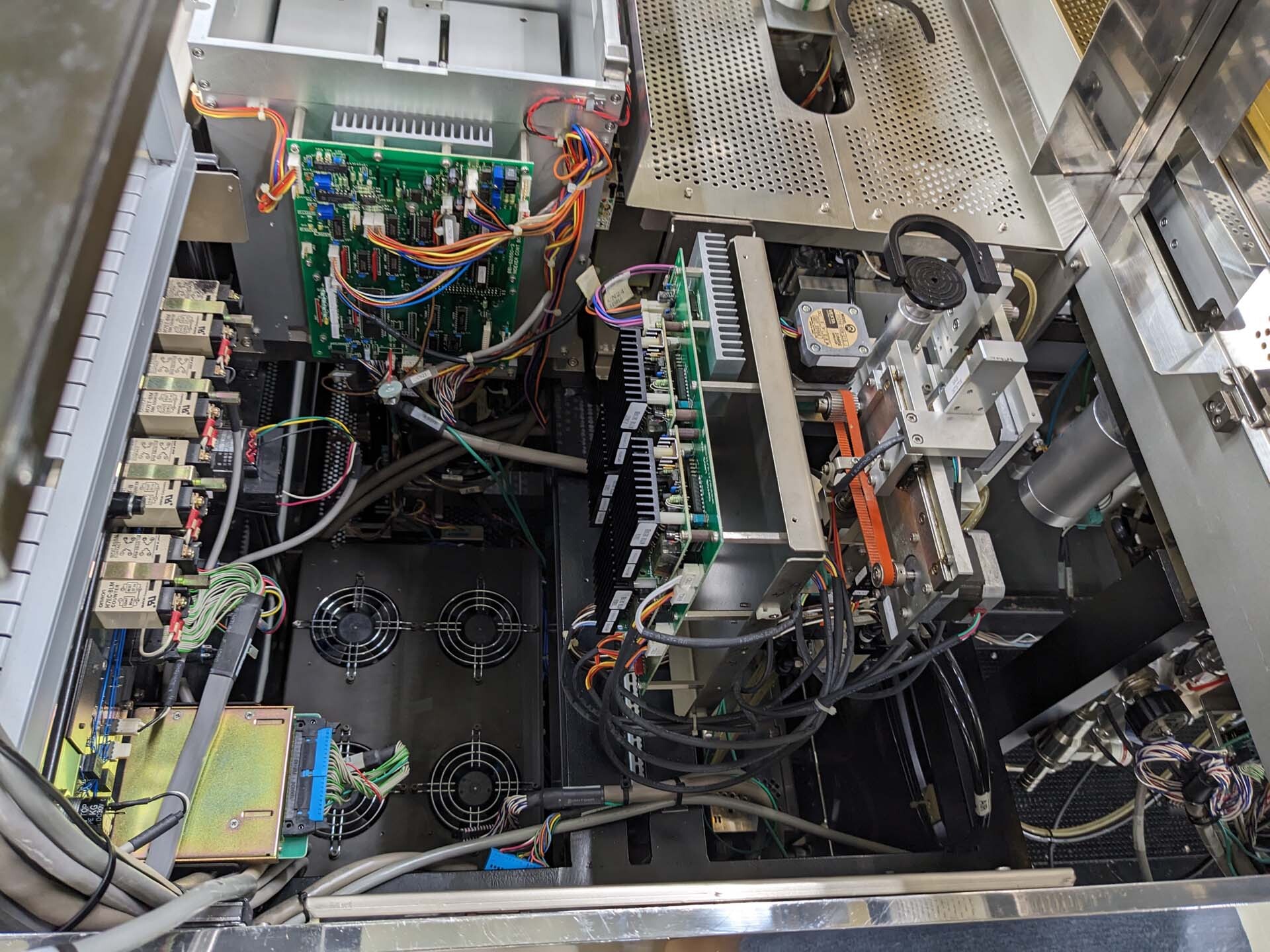

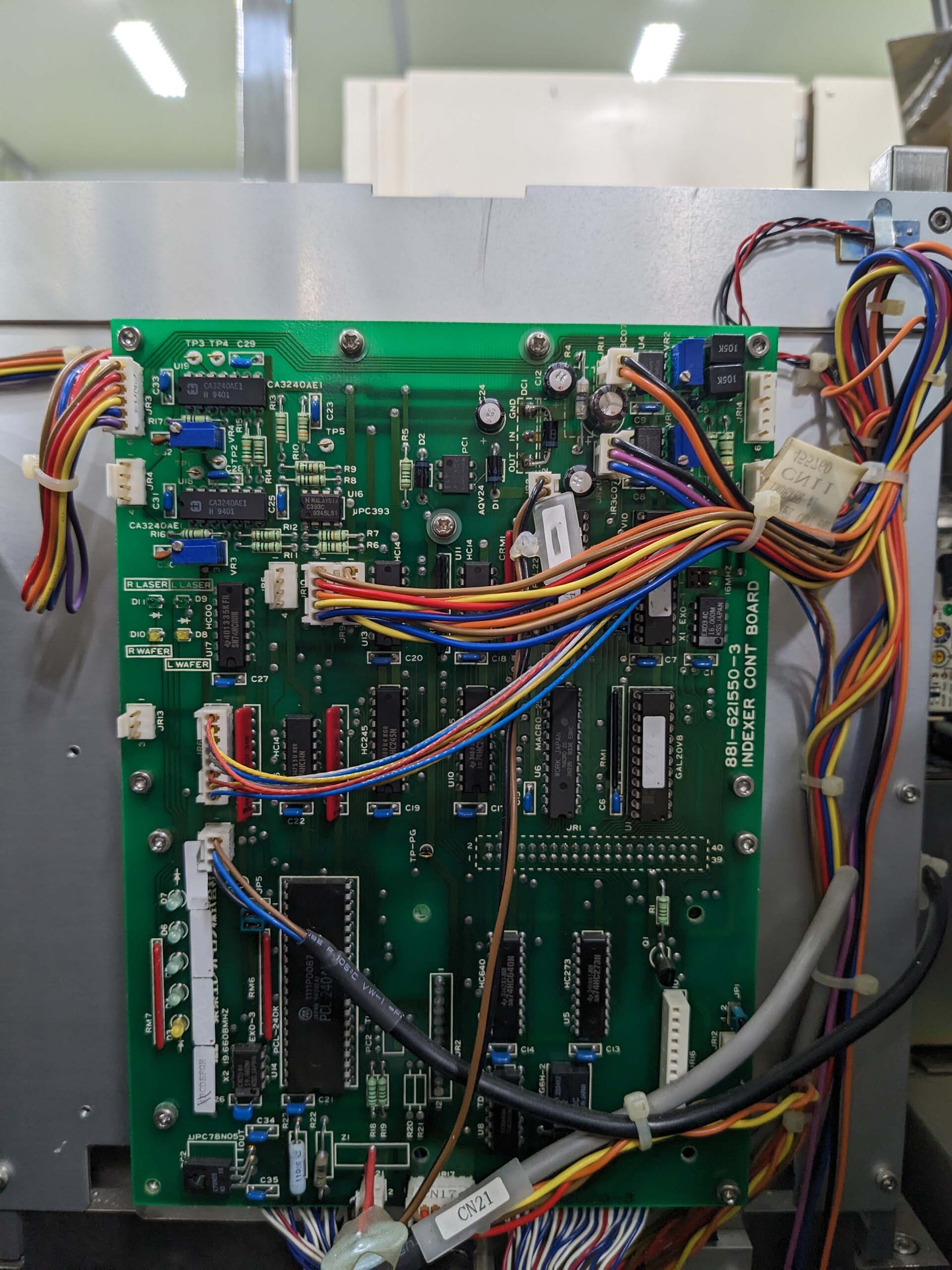

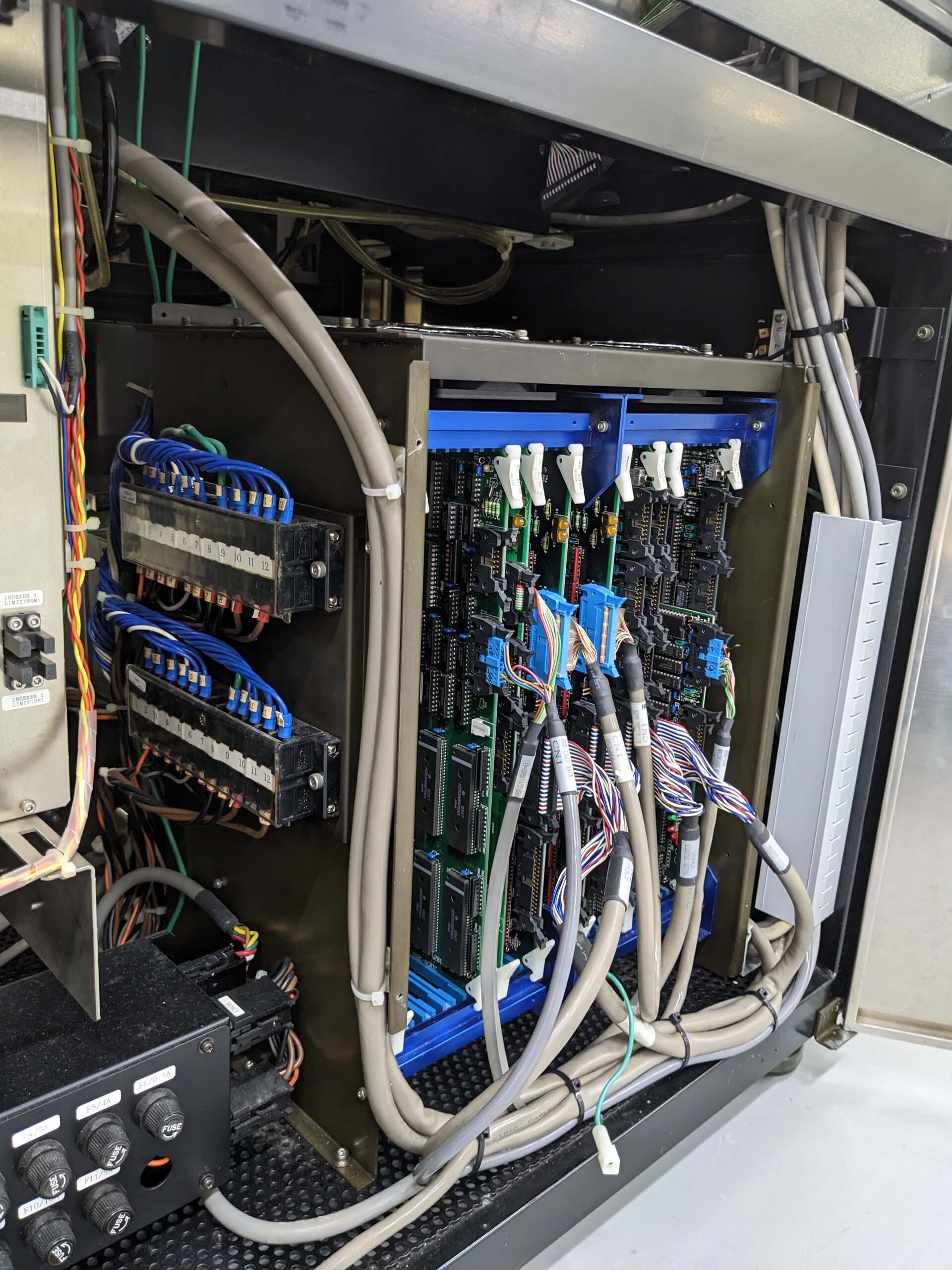

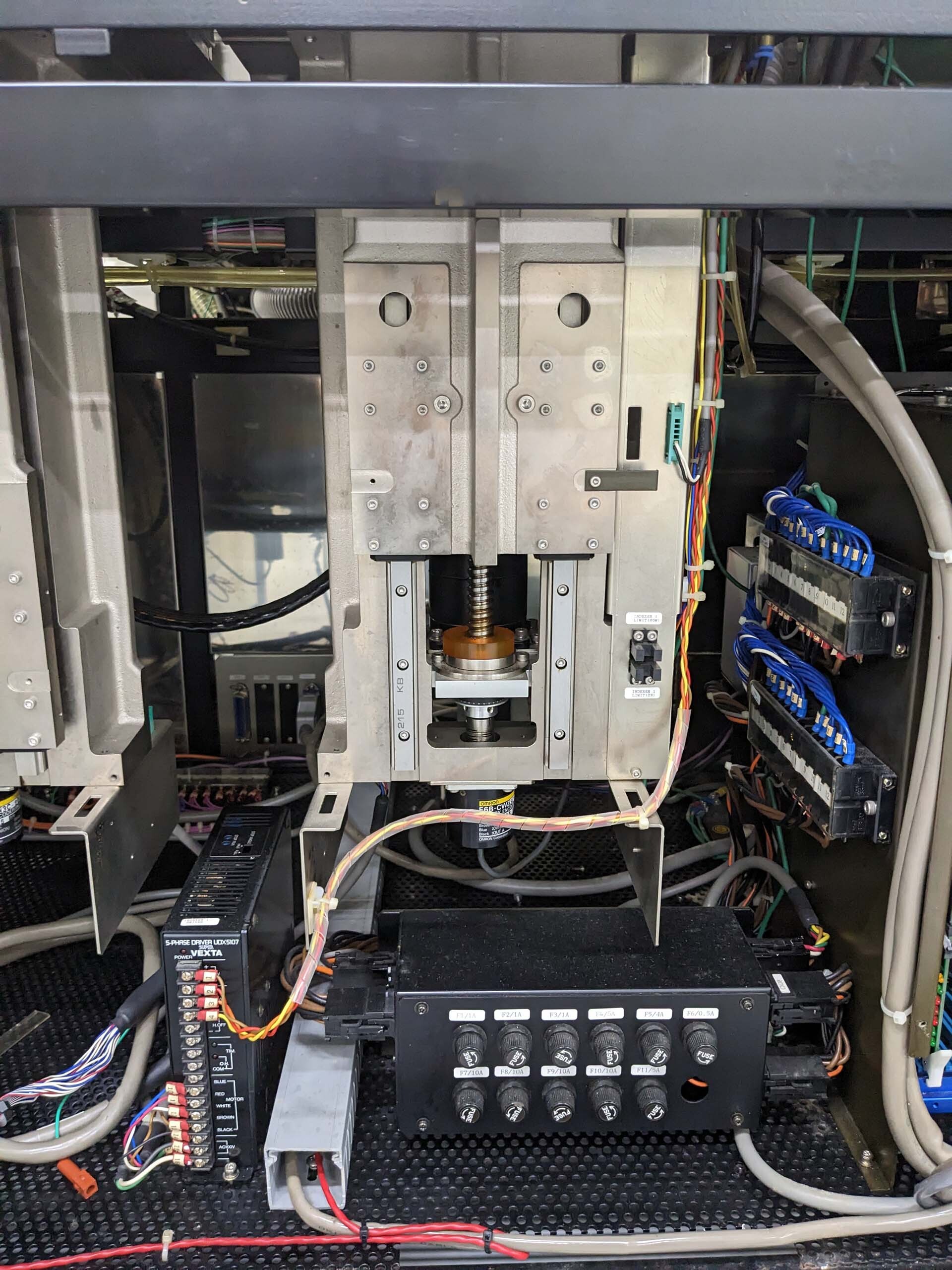

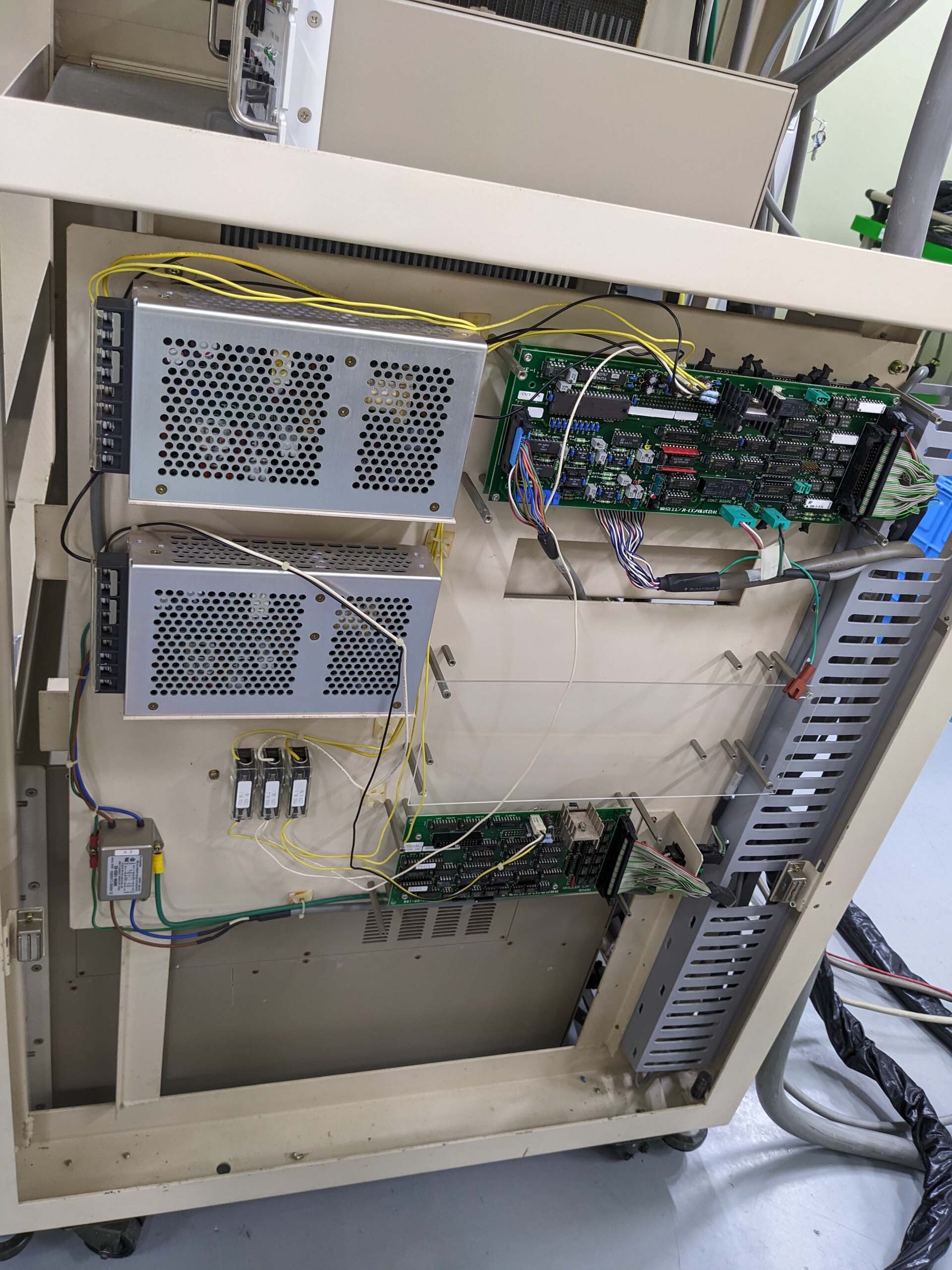

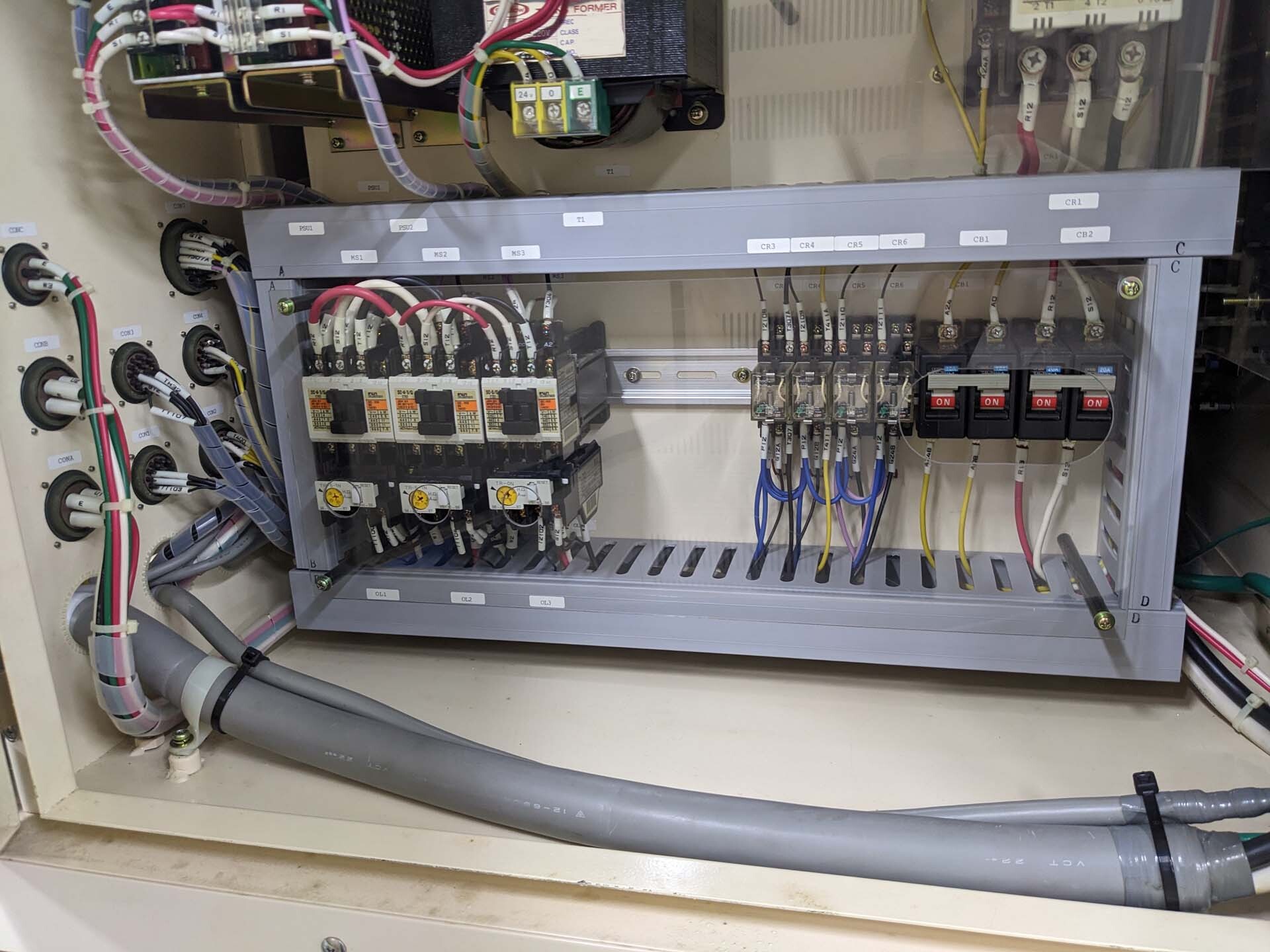

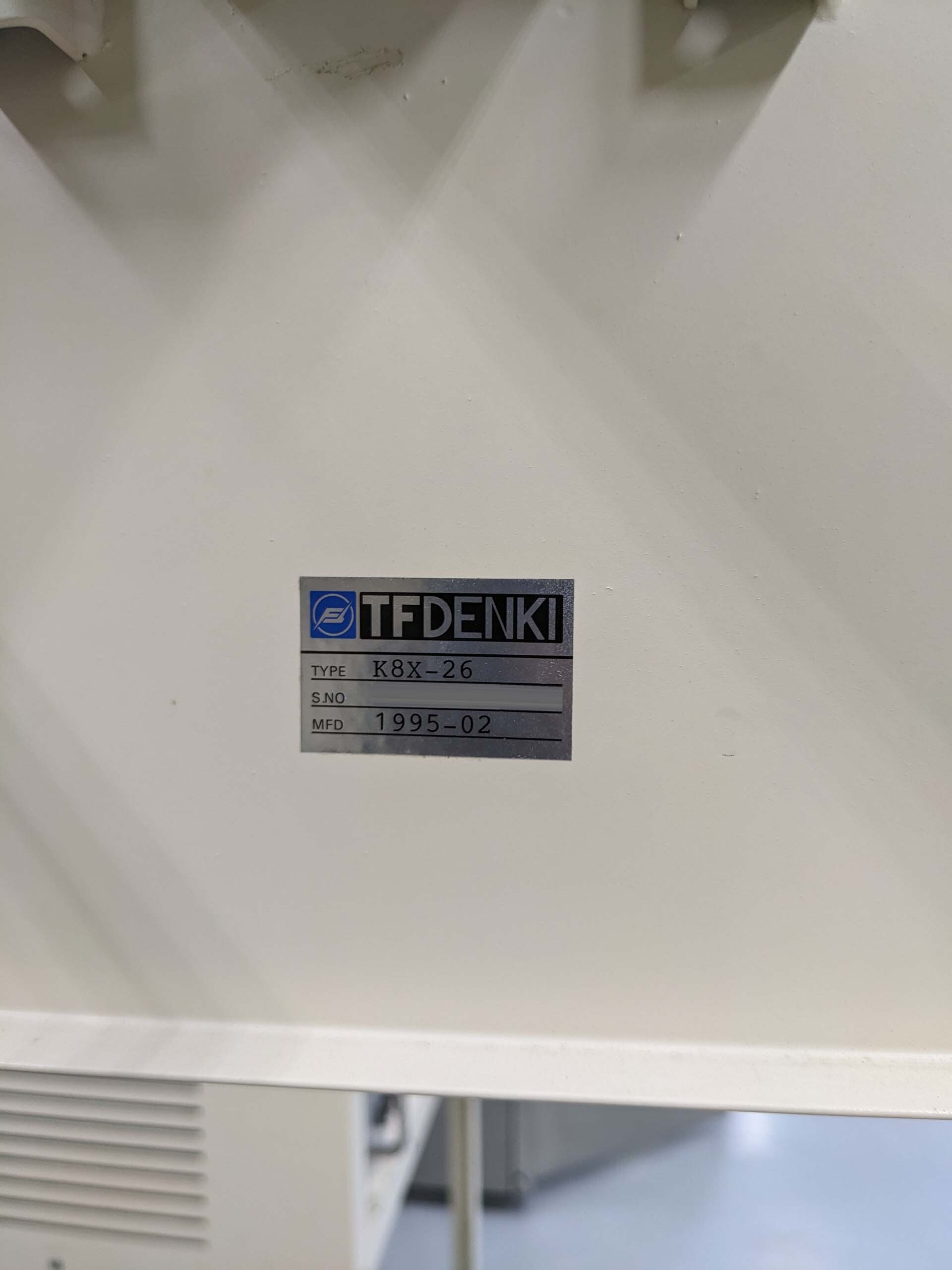

(2) Indexers:

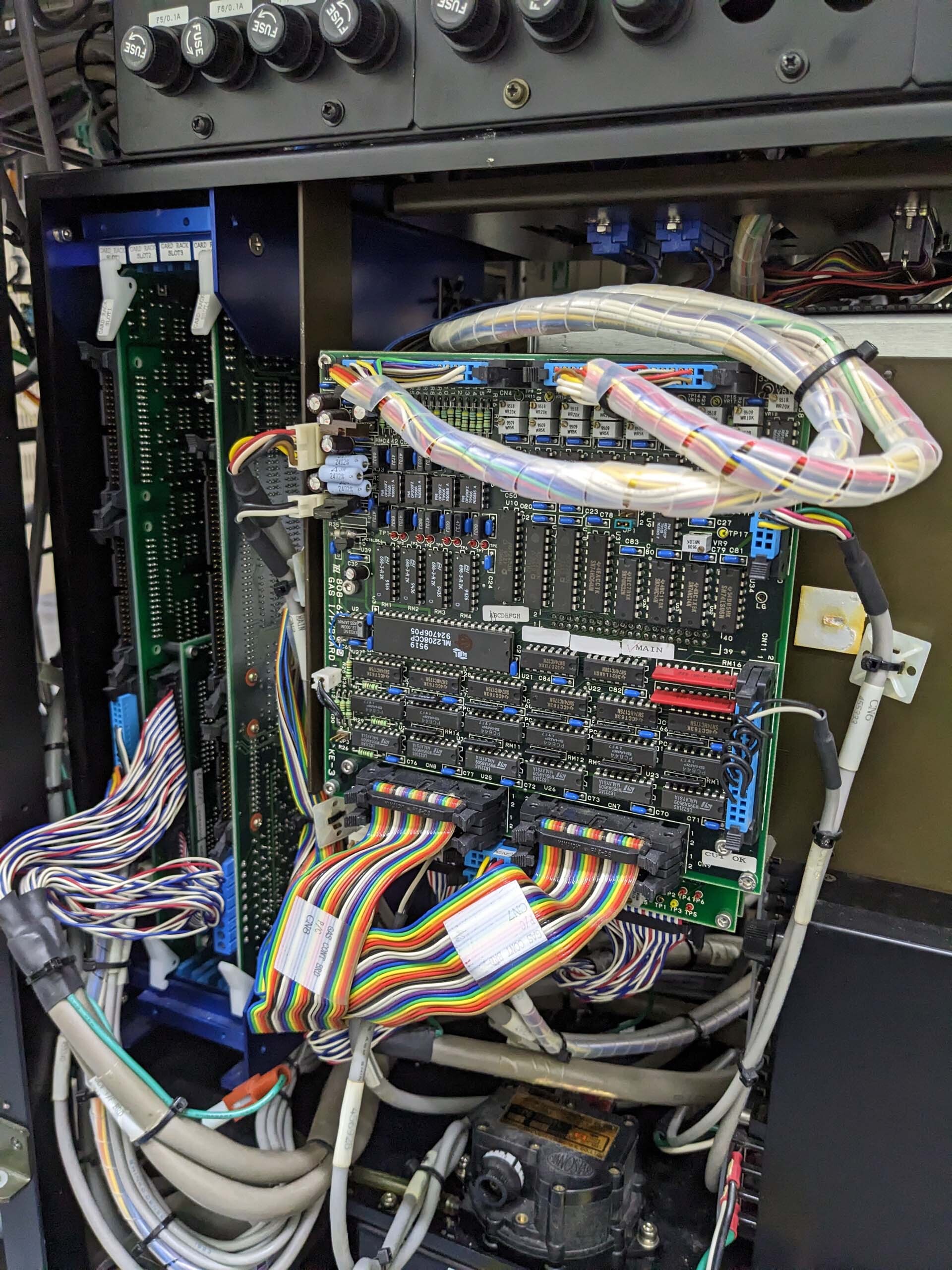

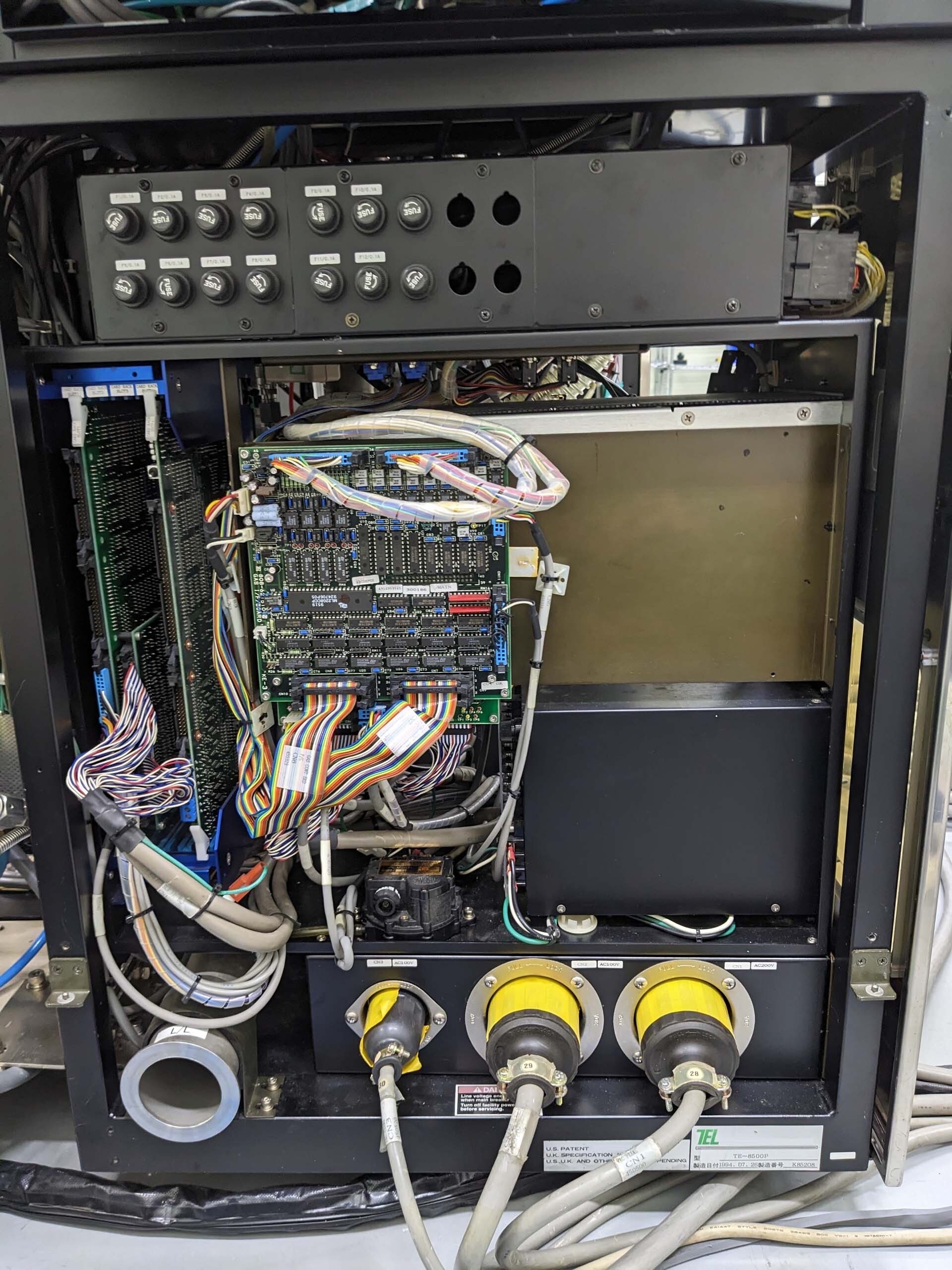

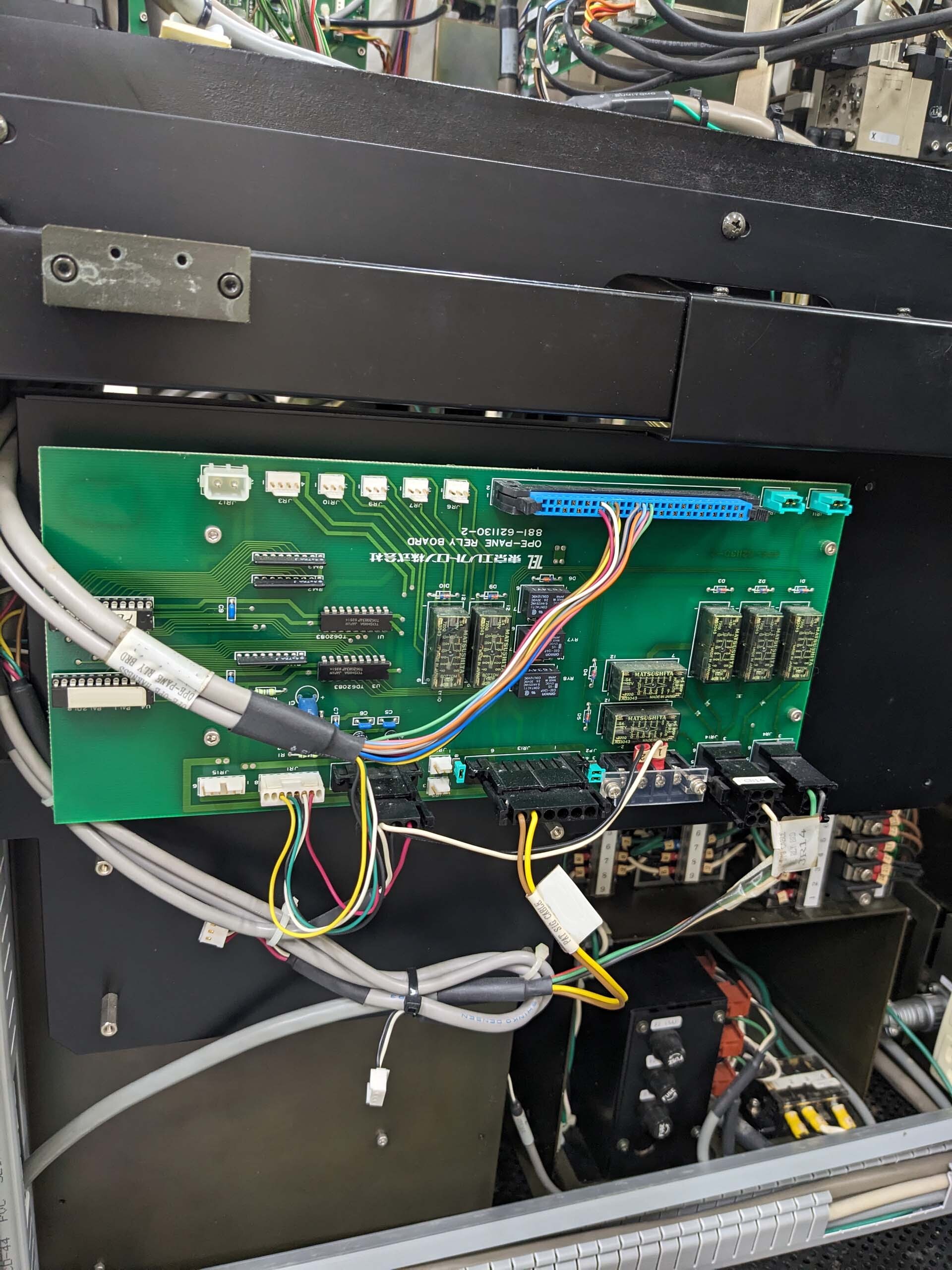

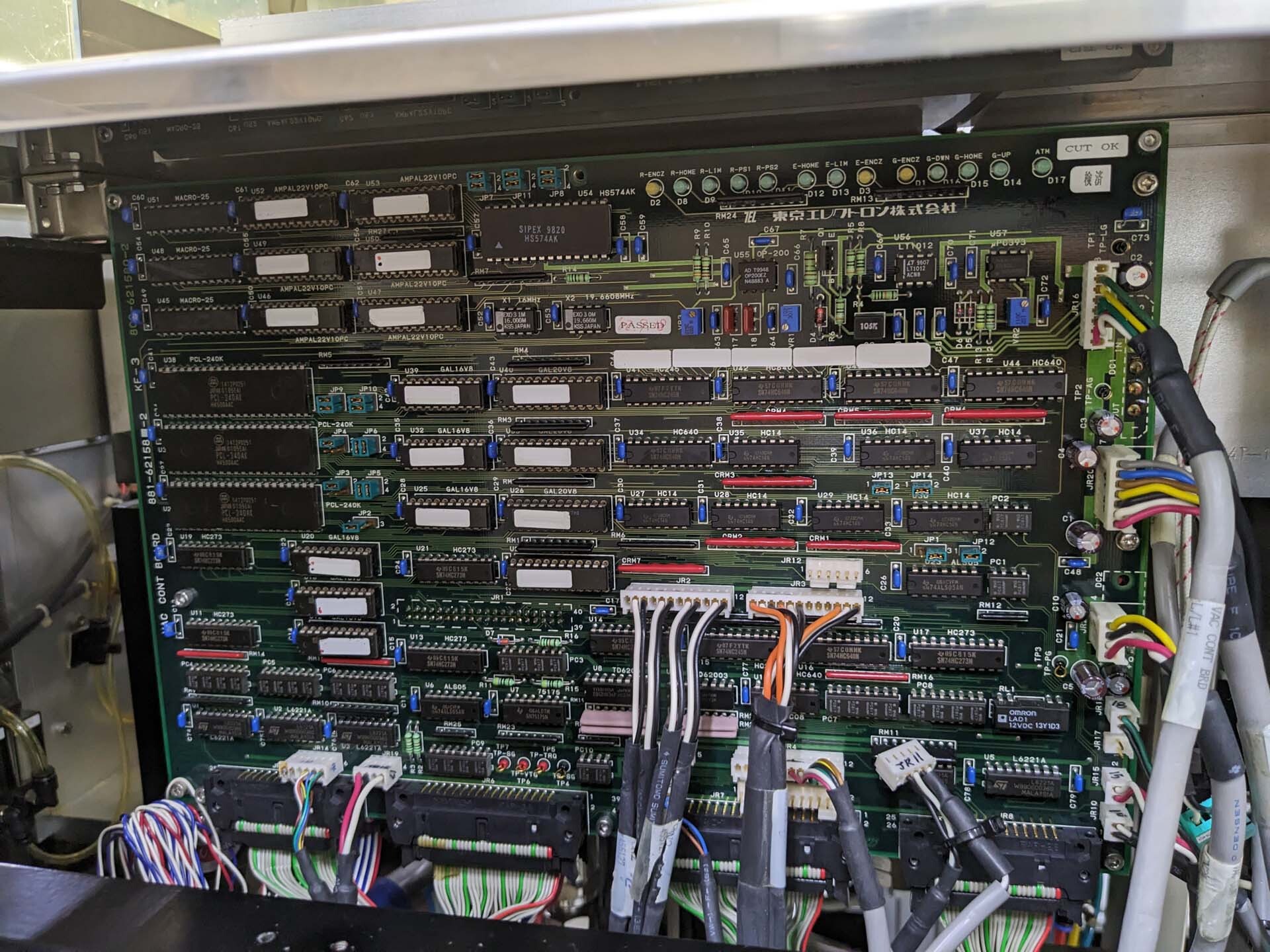

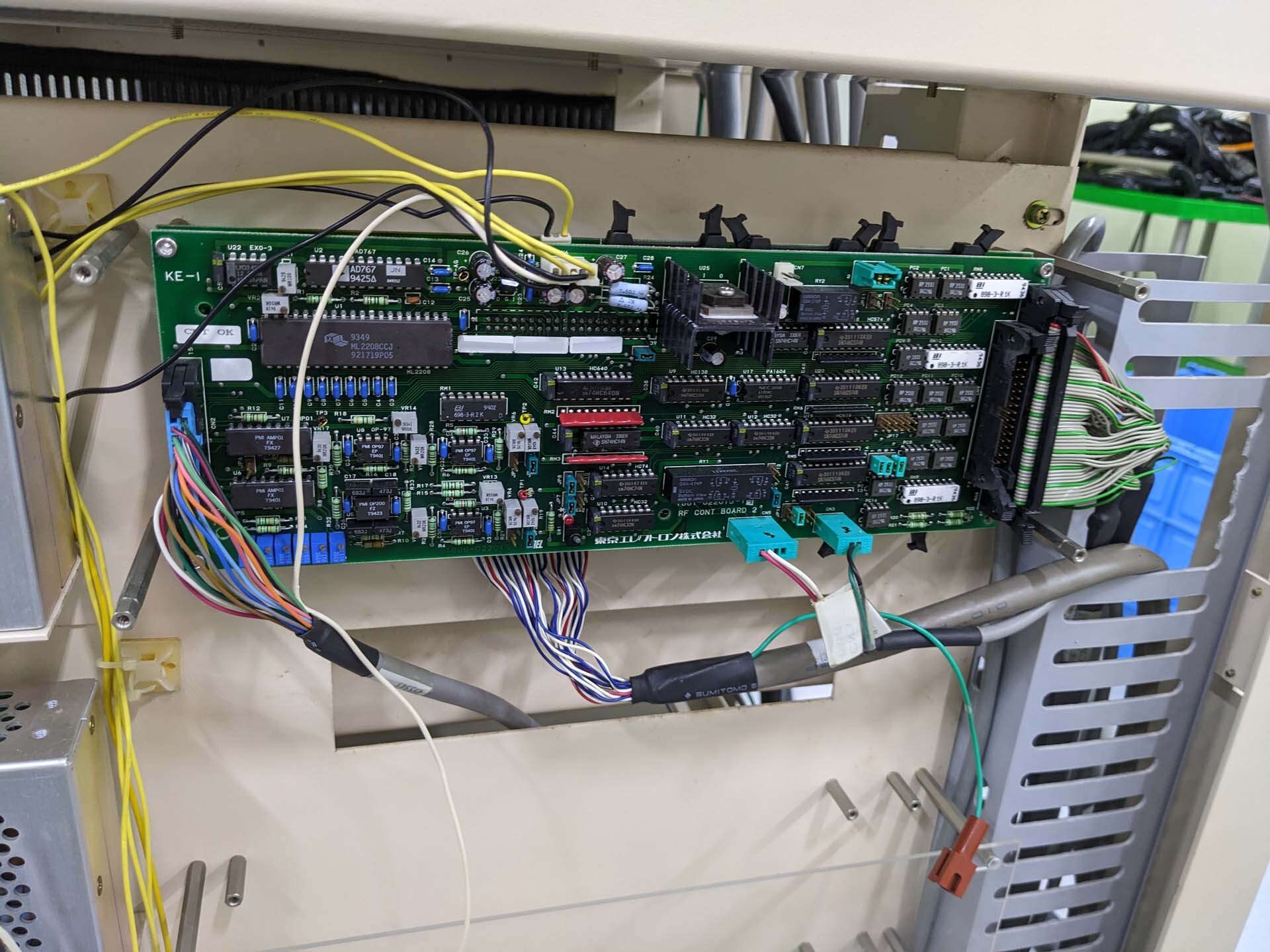

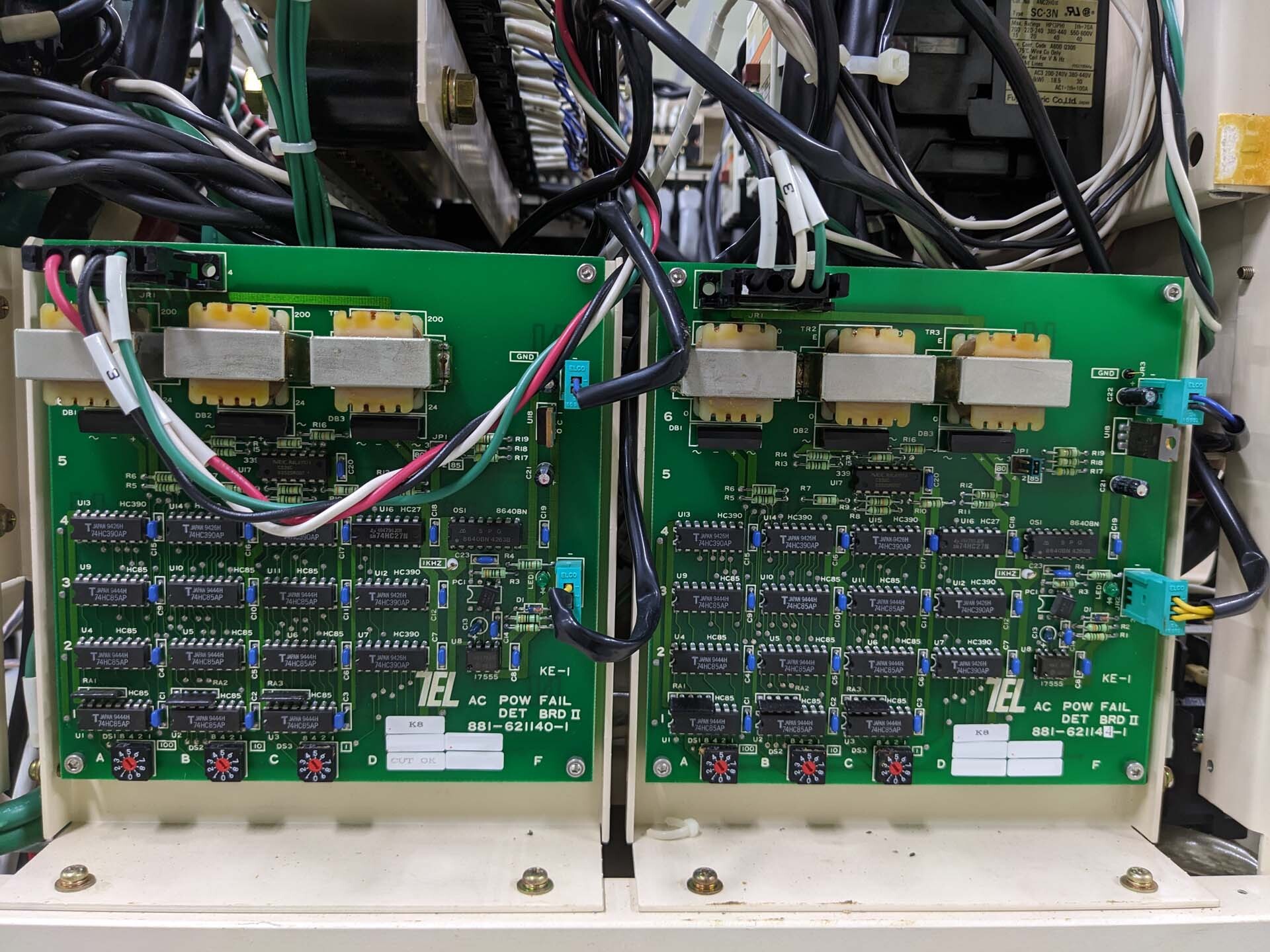

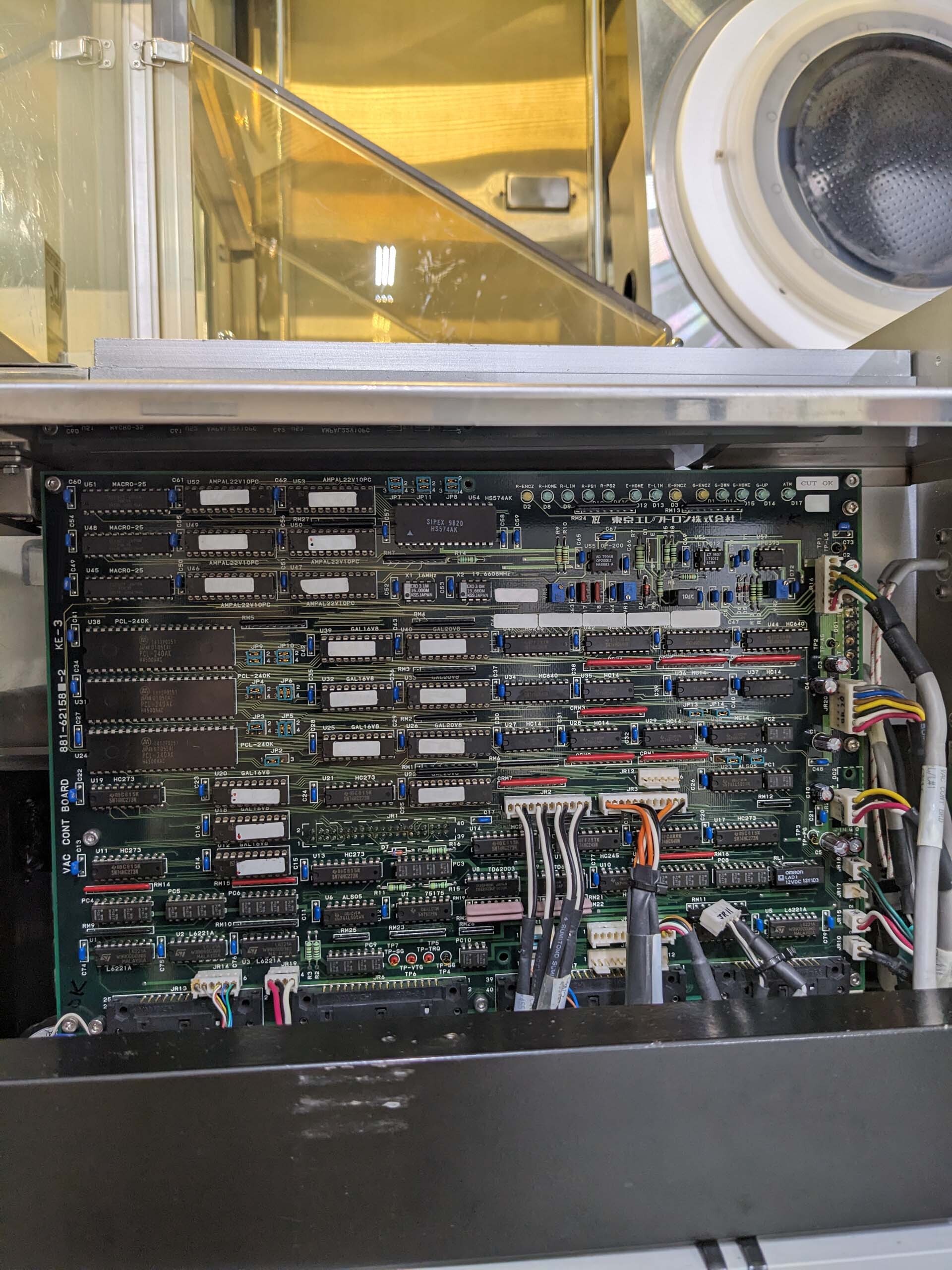

881-621550-3 Control board

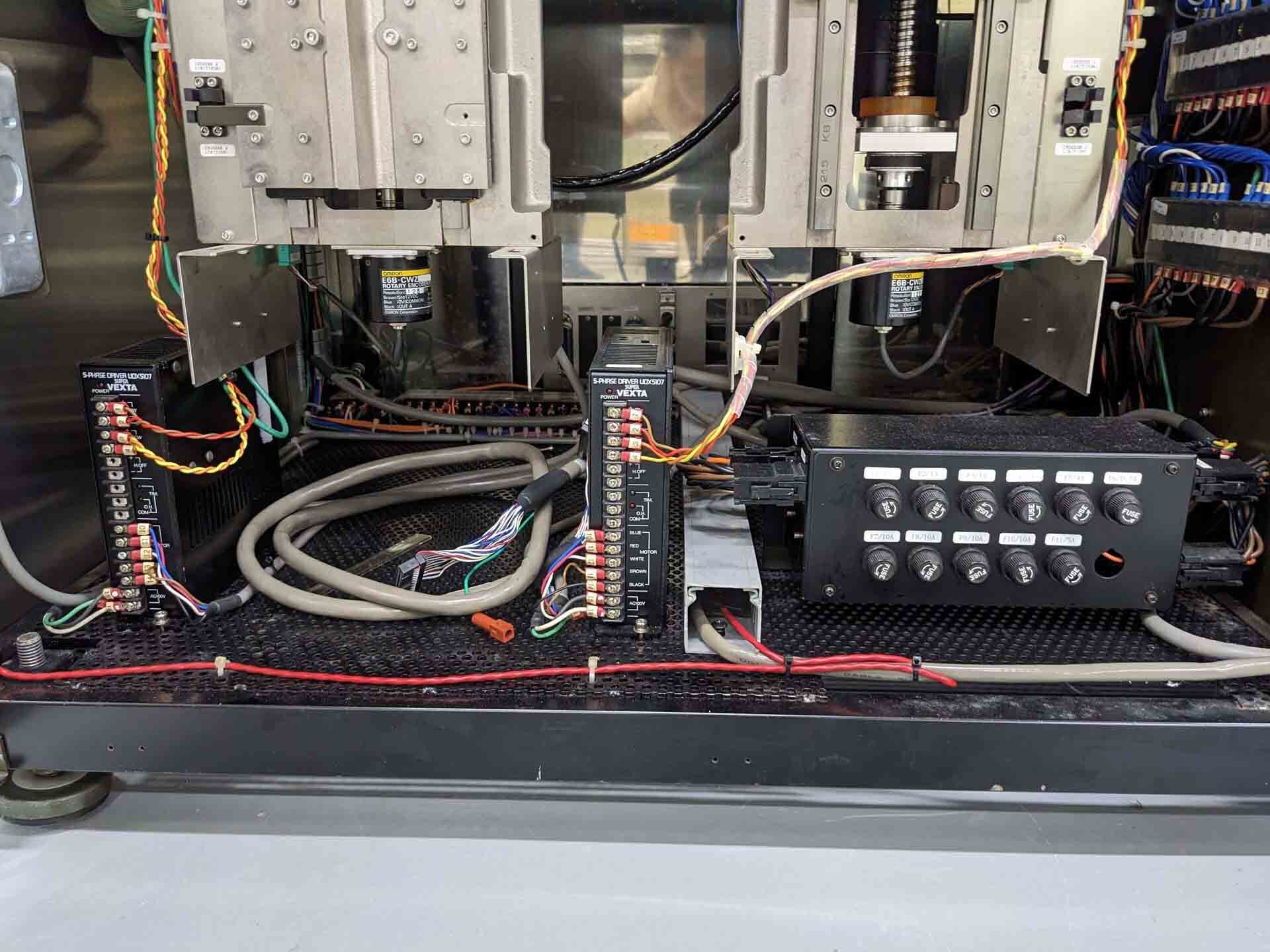

UDX5107 5-Phase driver

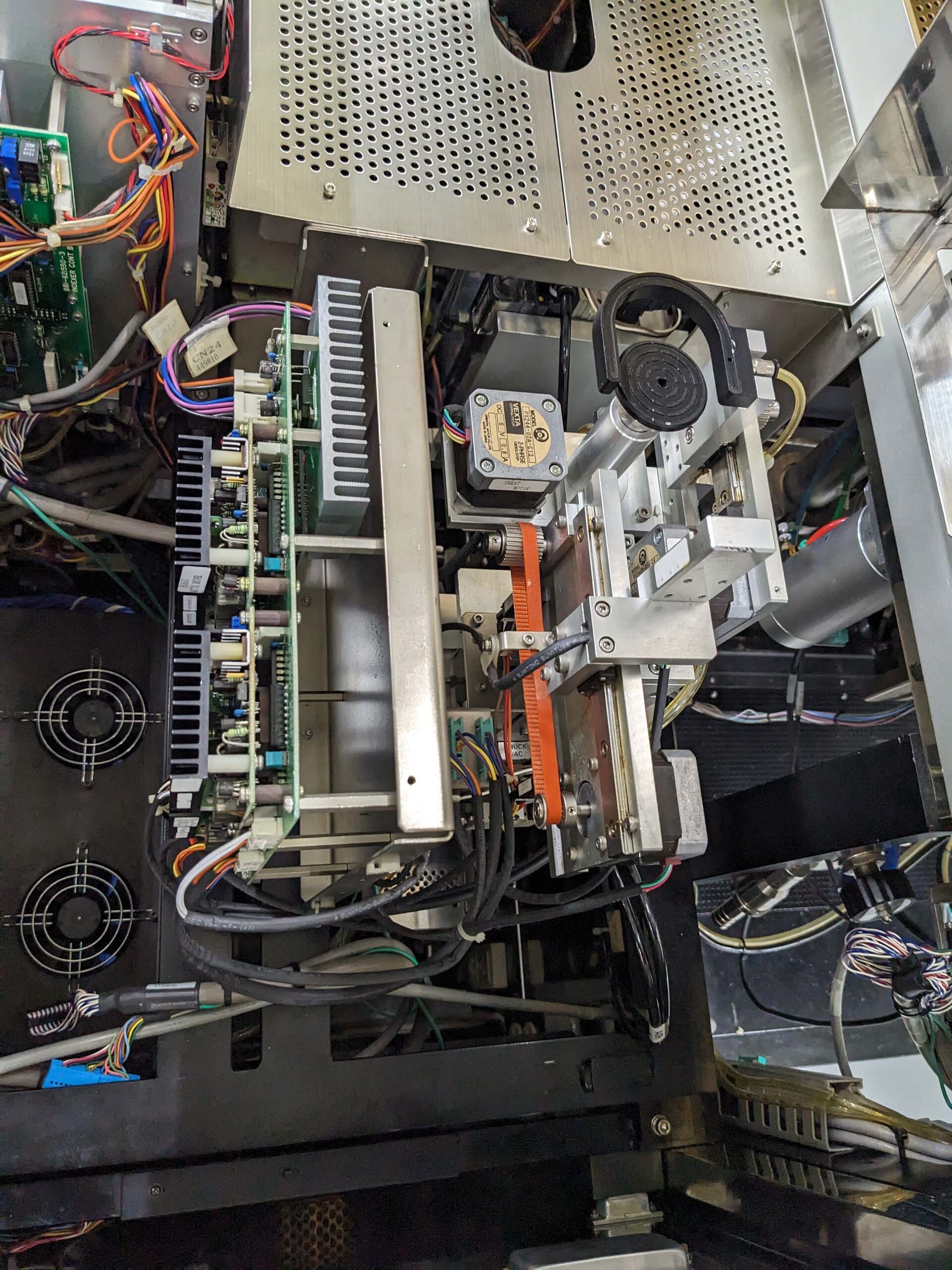

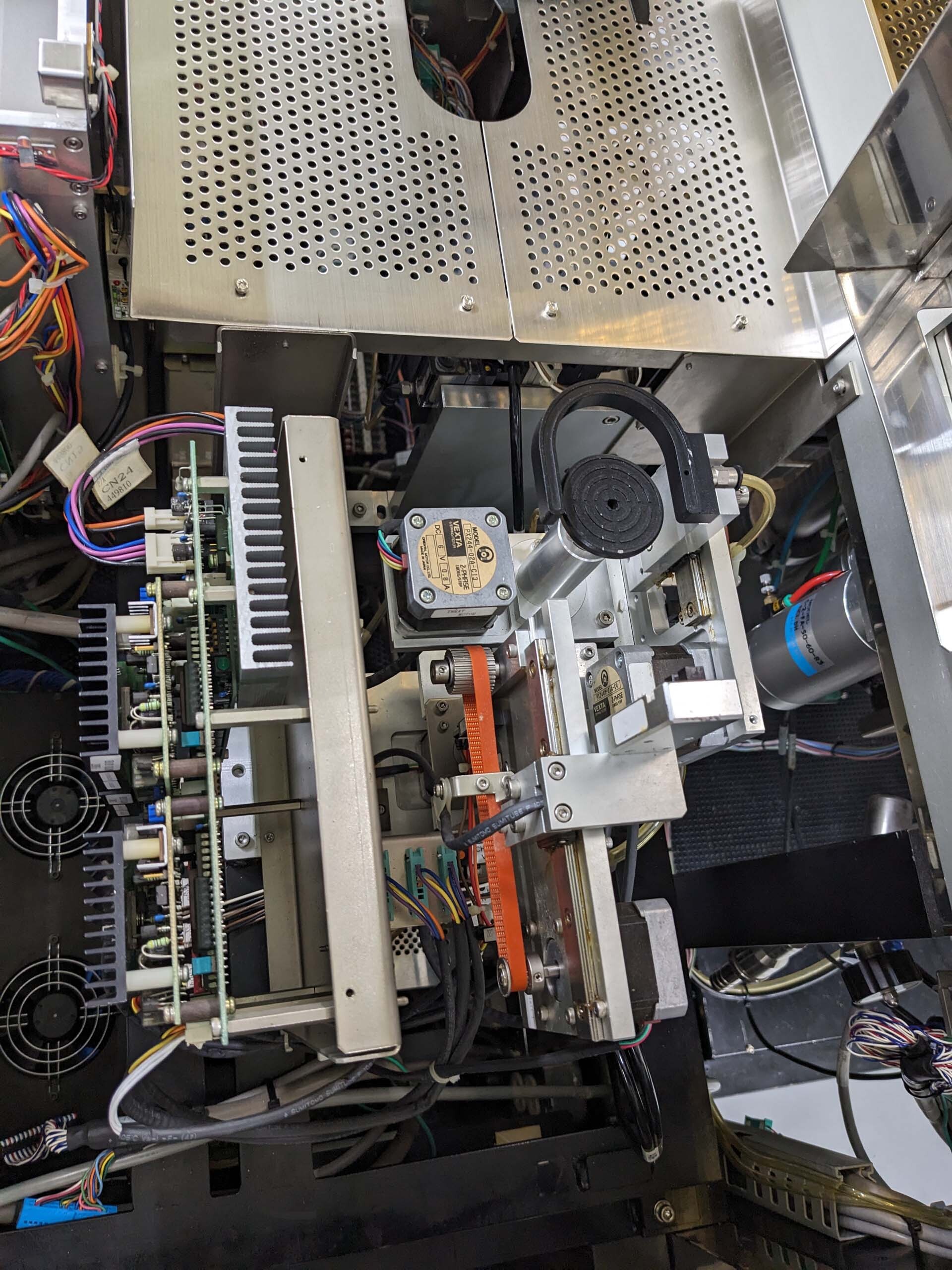

Handler arm:

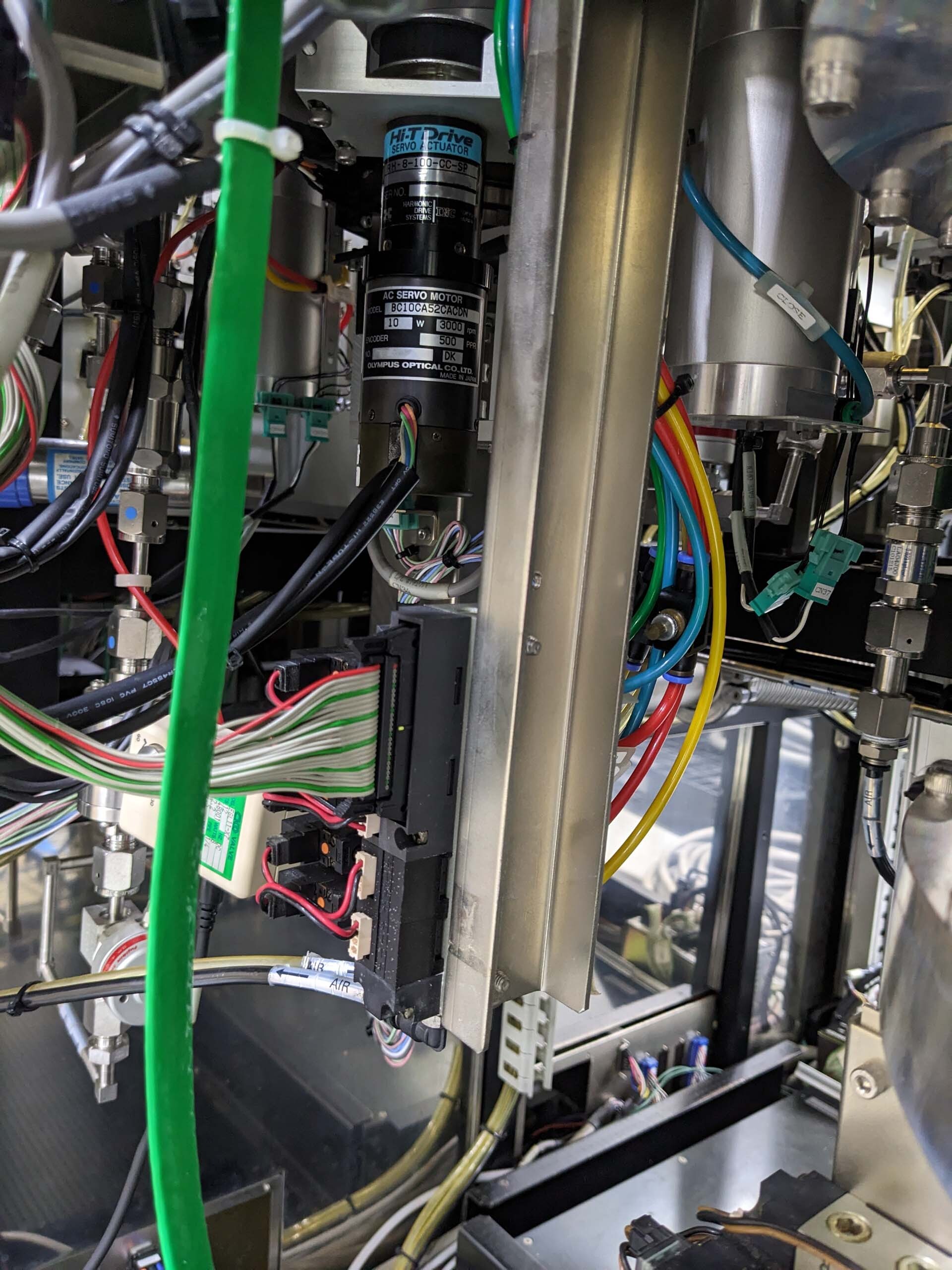

BC10CA52CACDN AC Servo motor: 3000 rpm, 10 W

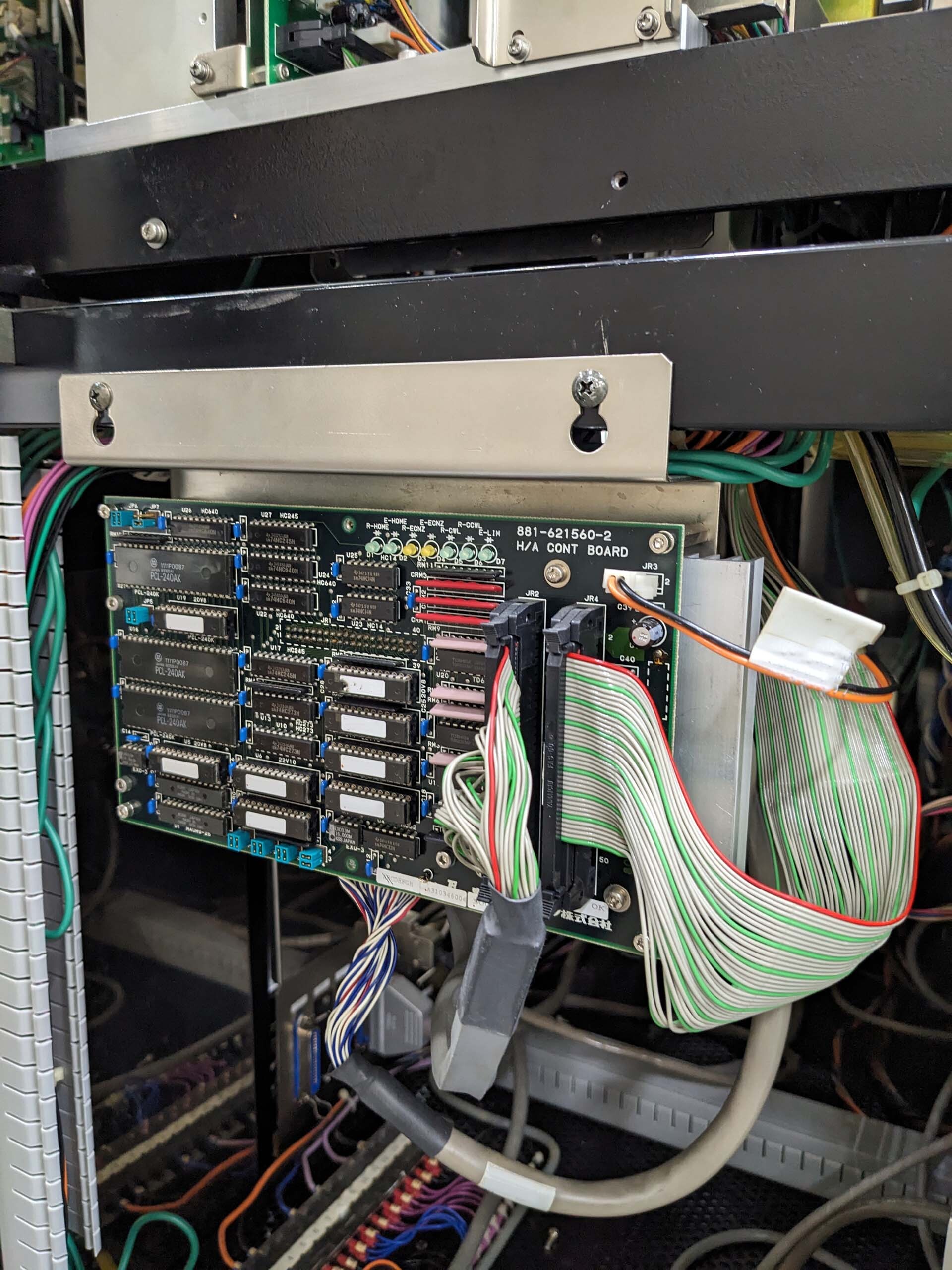

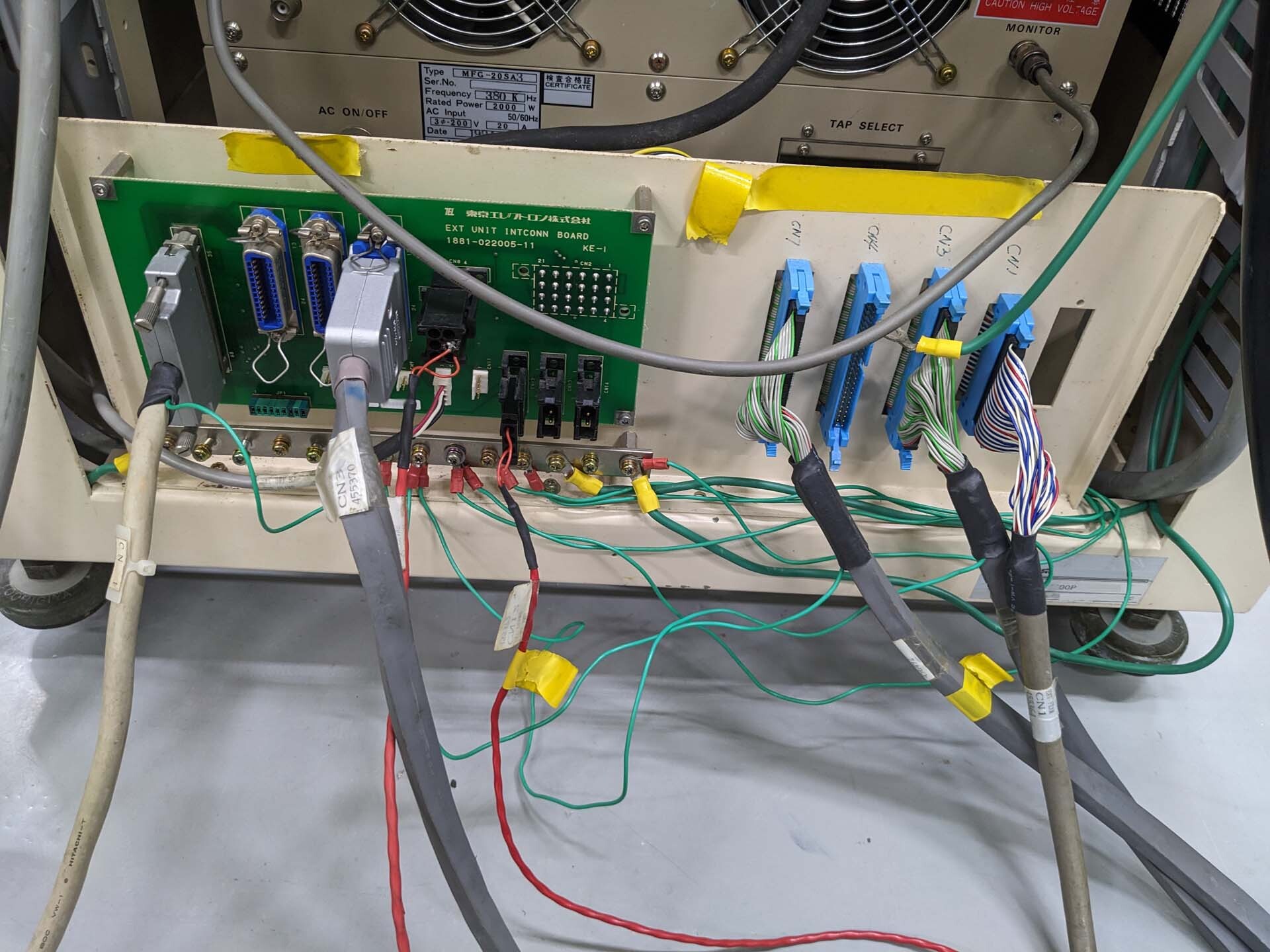

881-621560-2 Int conn board

893-020880-2 Control board

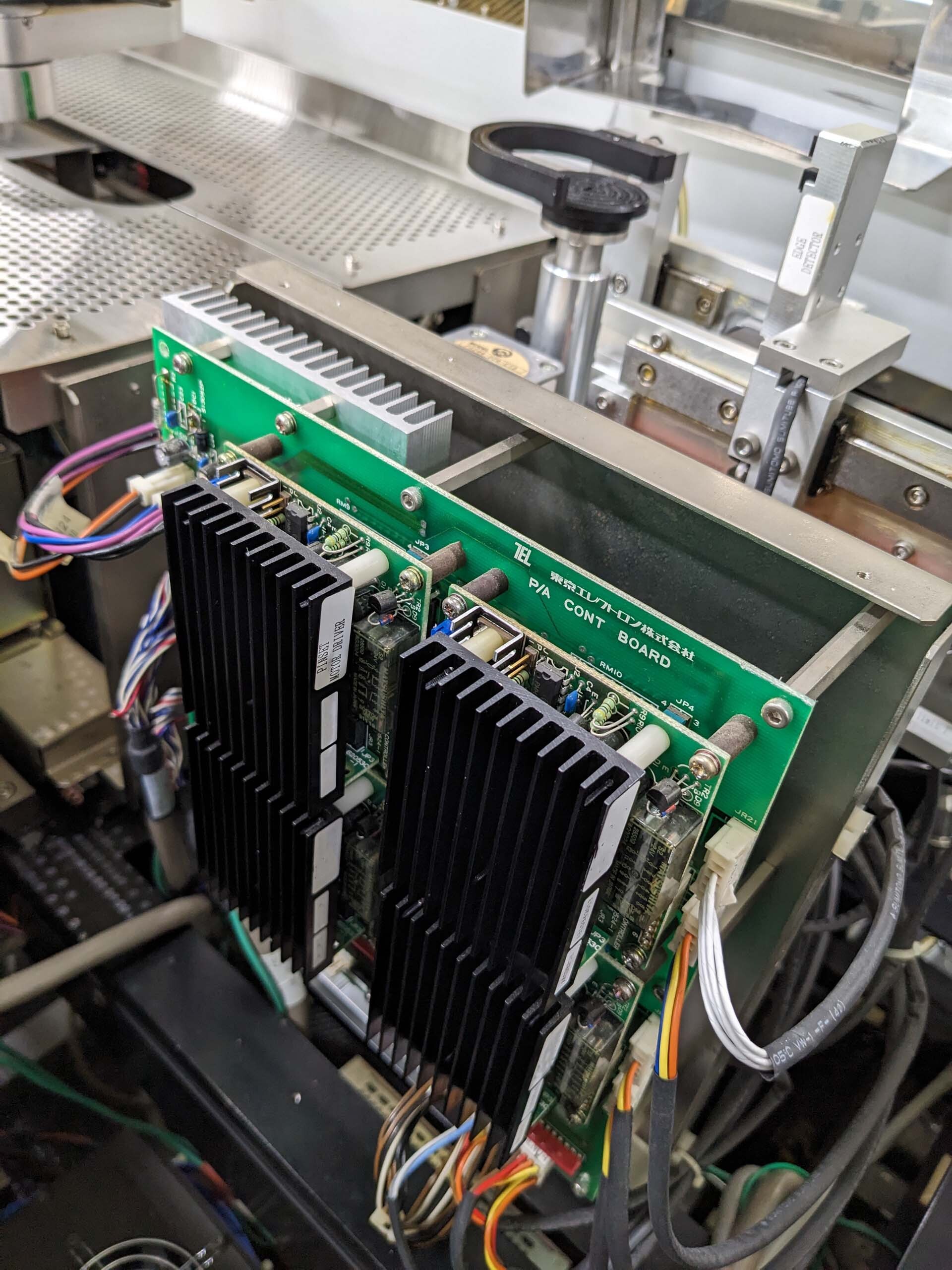

Prealignment:

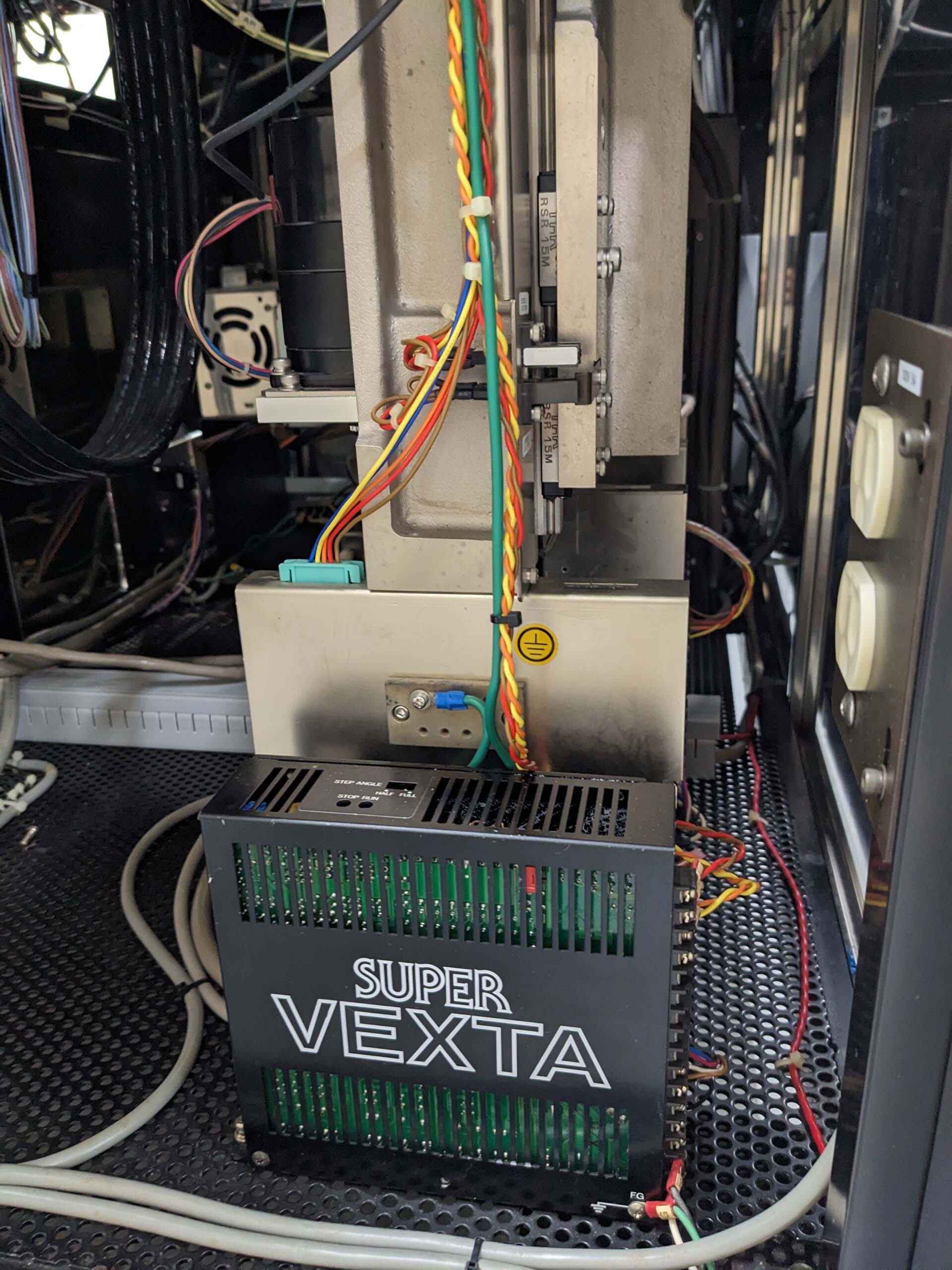

(2) VEXTA PX244M-01A-C4 Stepping motors, 4 V, 1.2 A

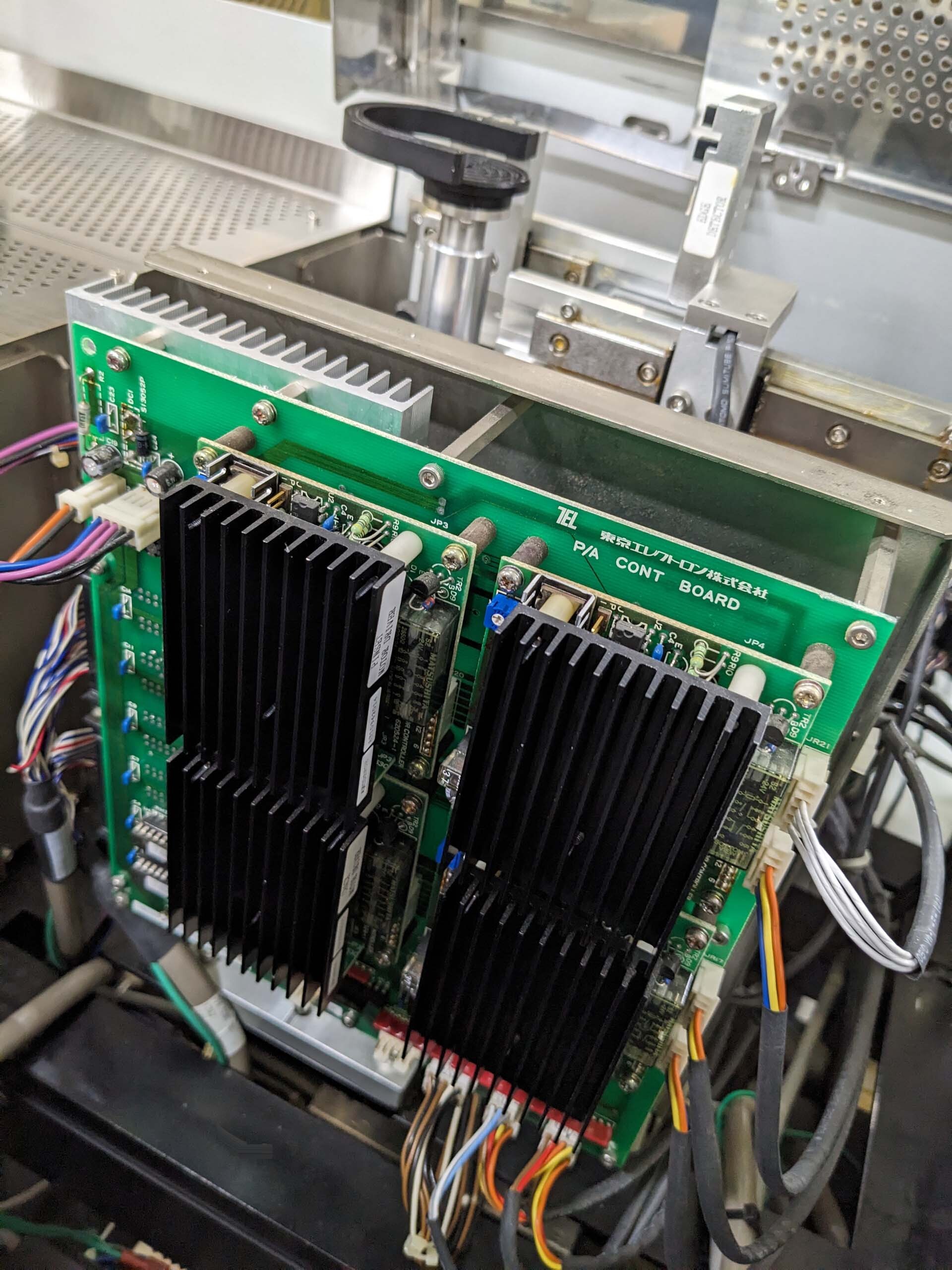

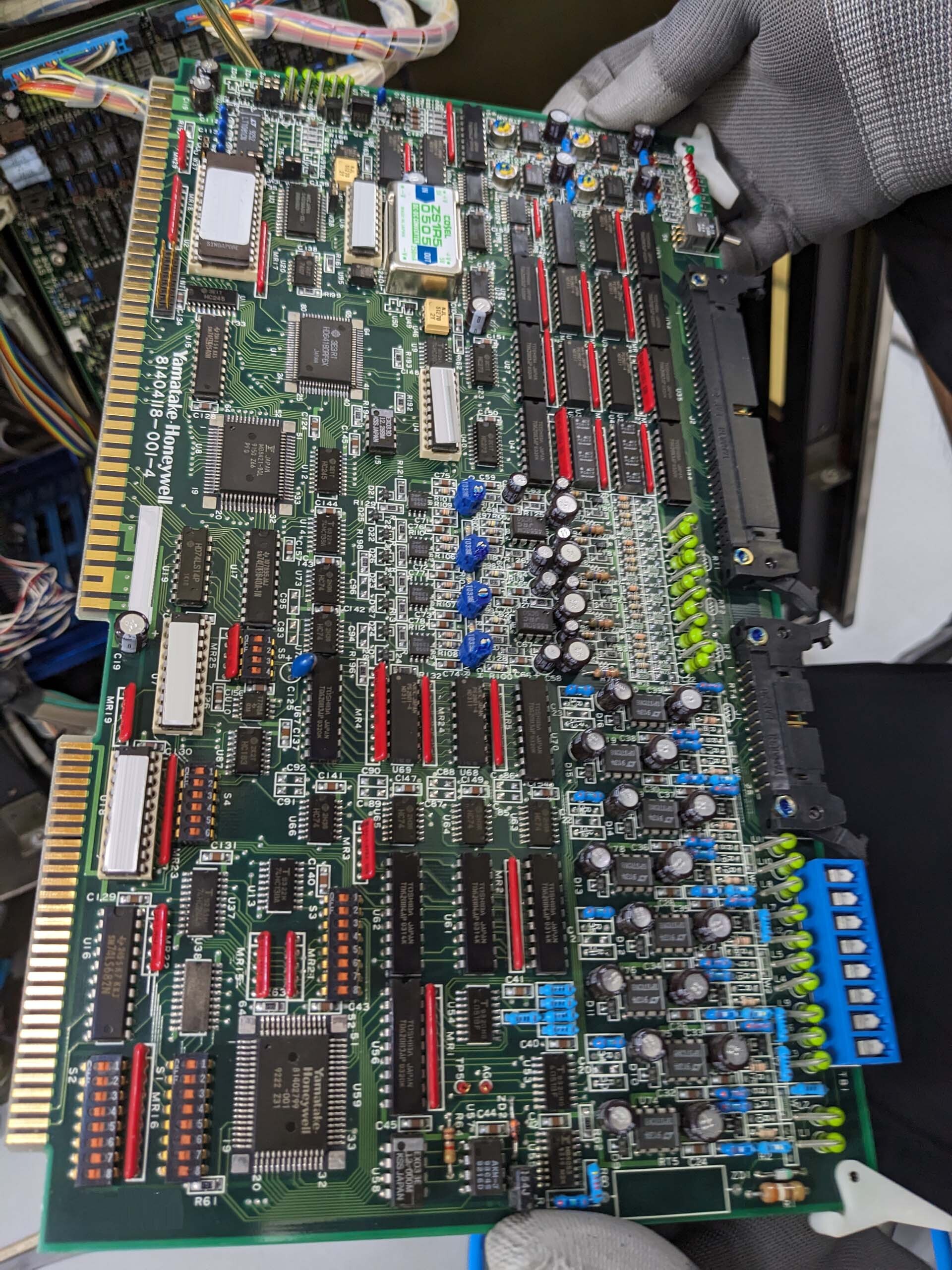

808-621570-2 PA Control board

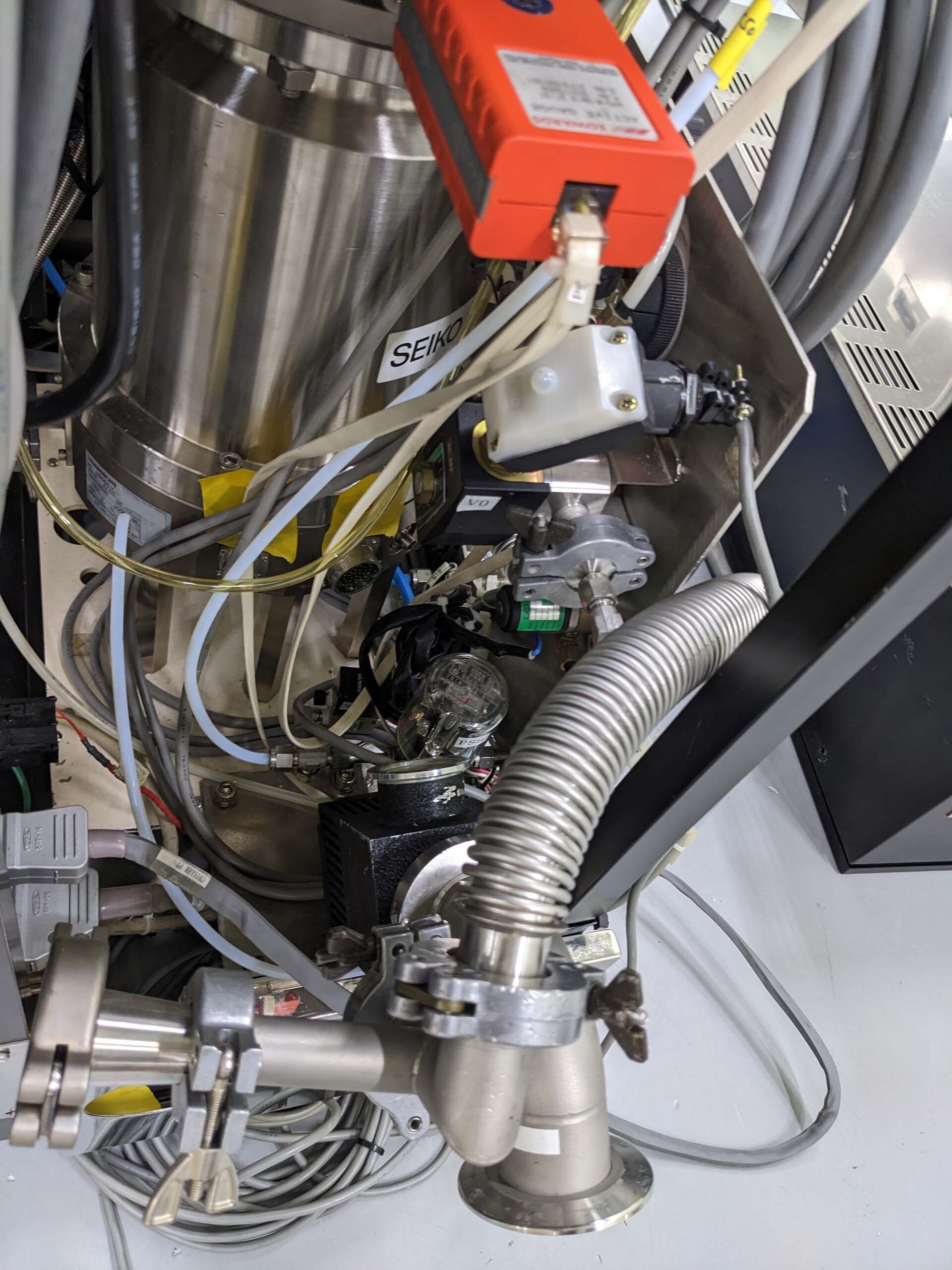

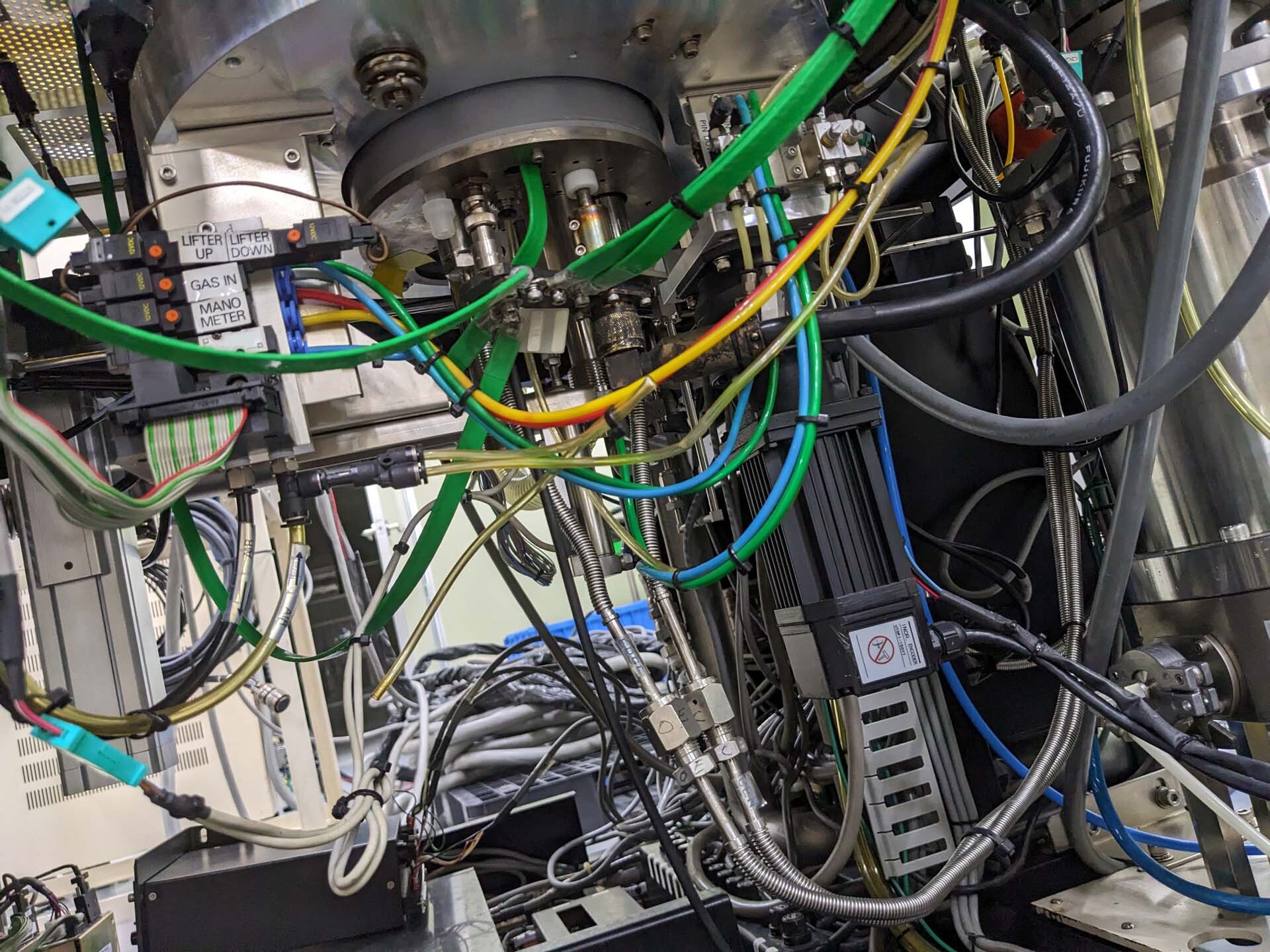

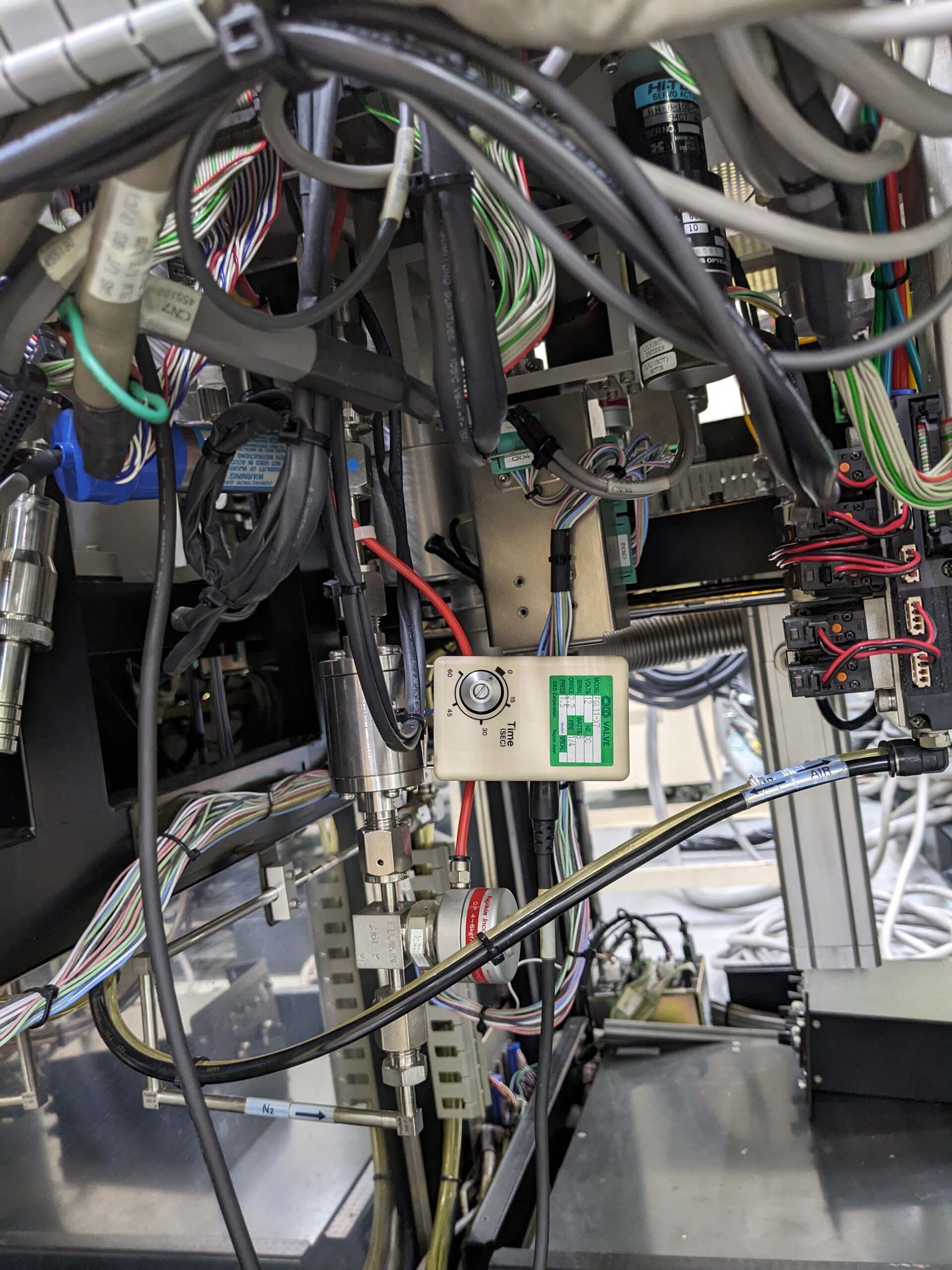

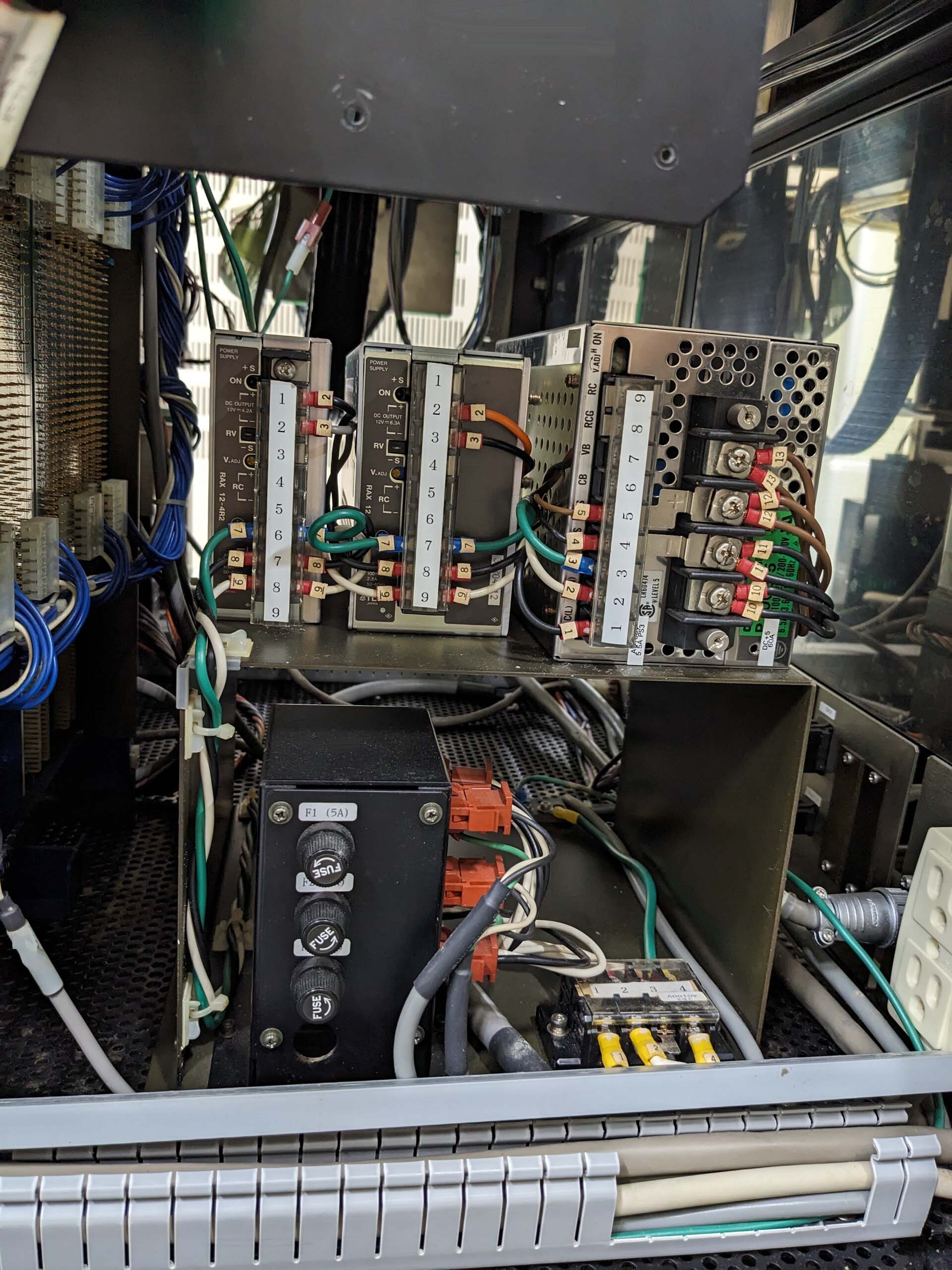

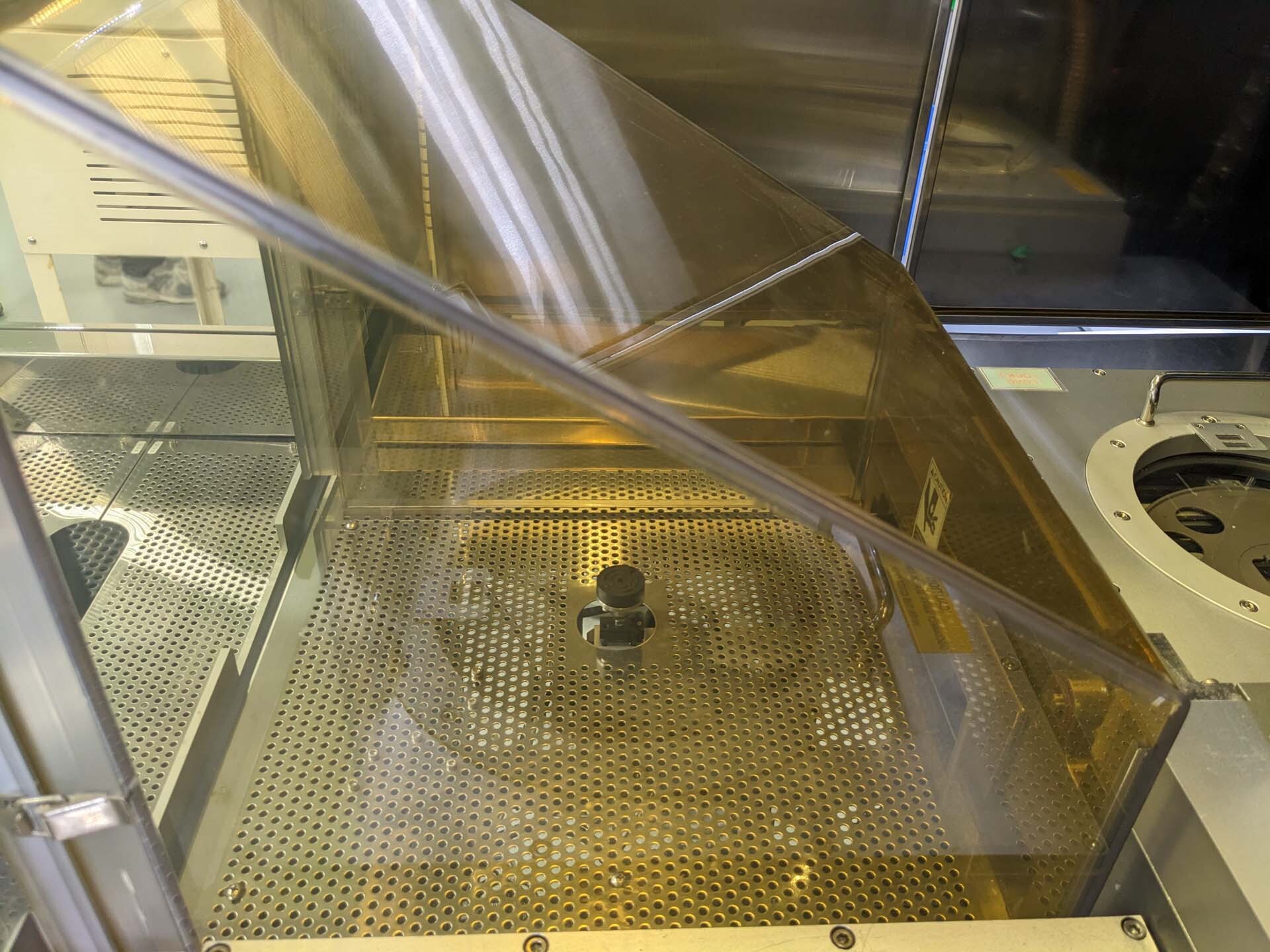

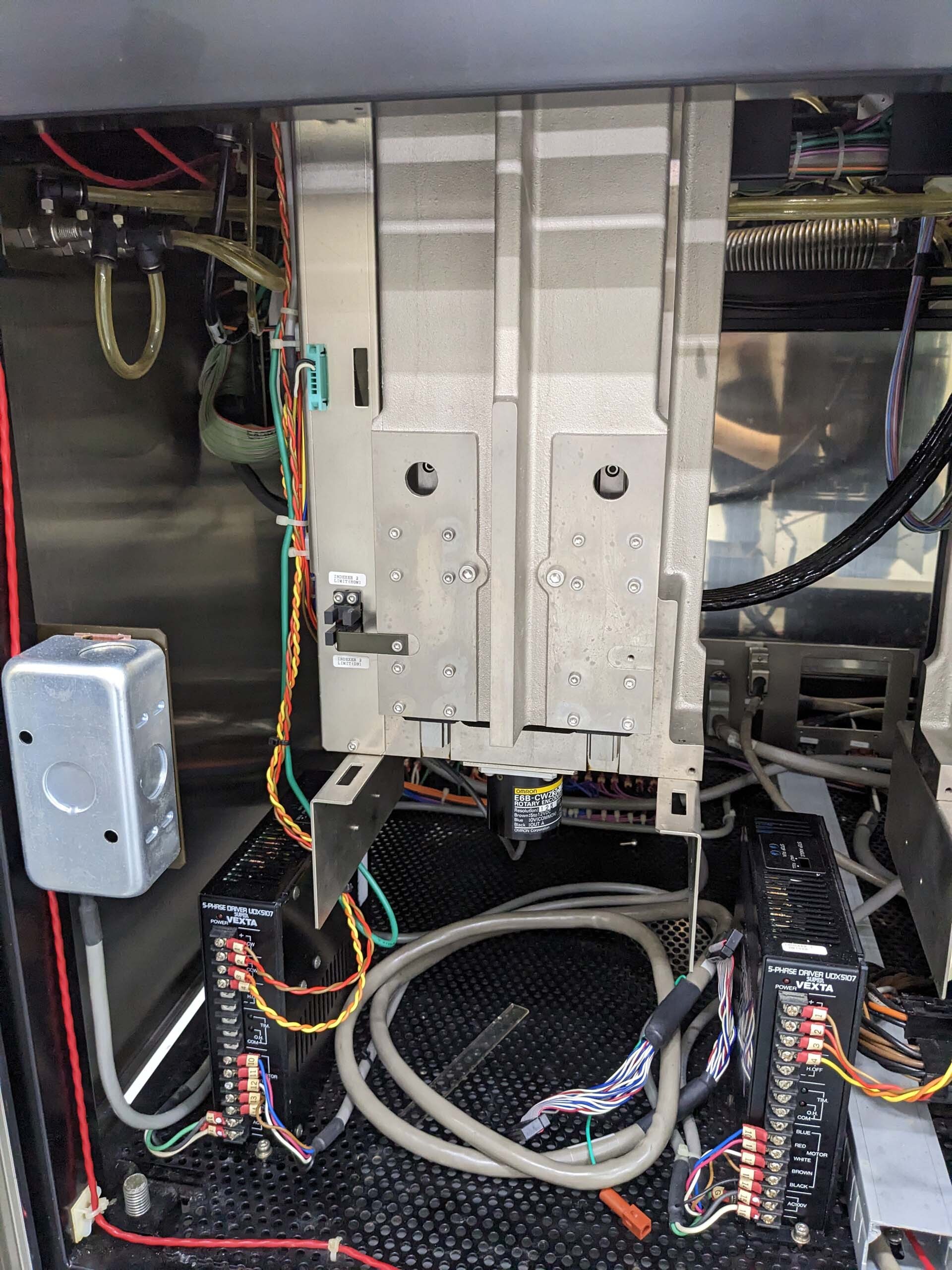

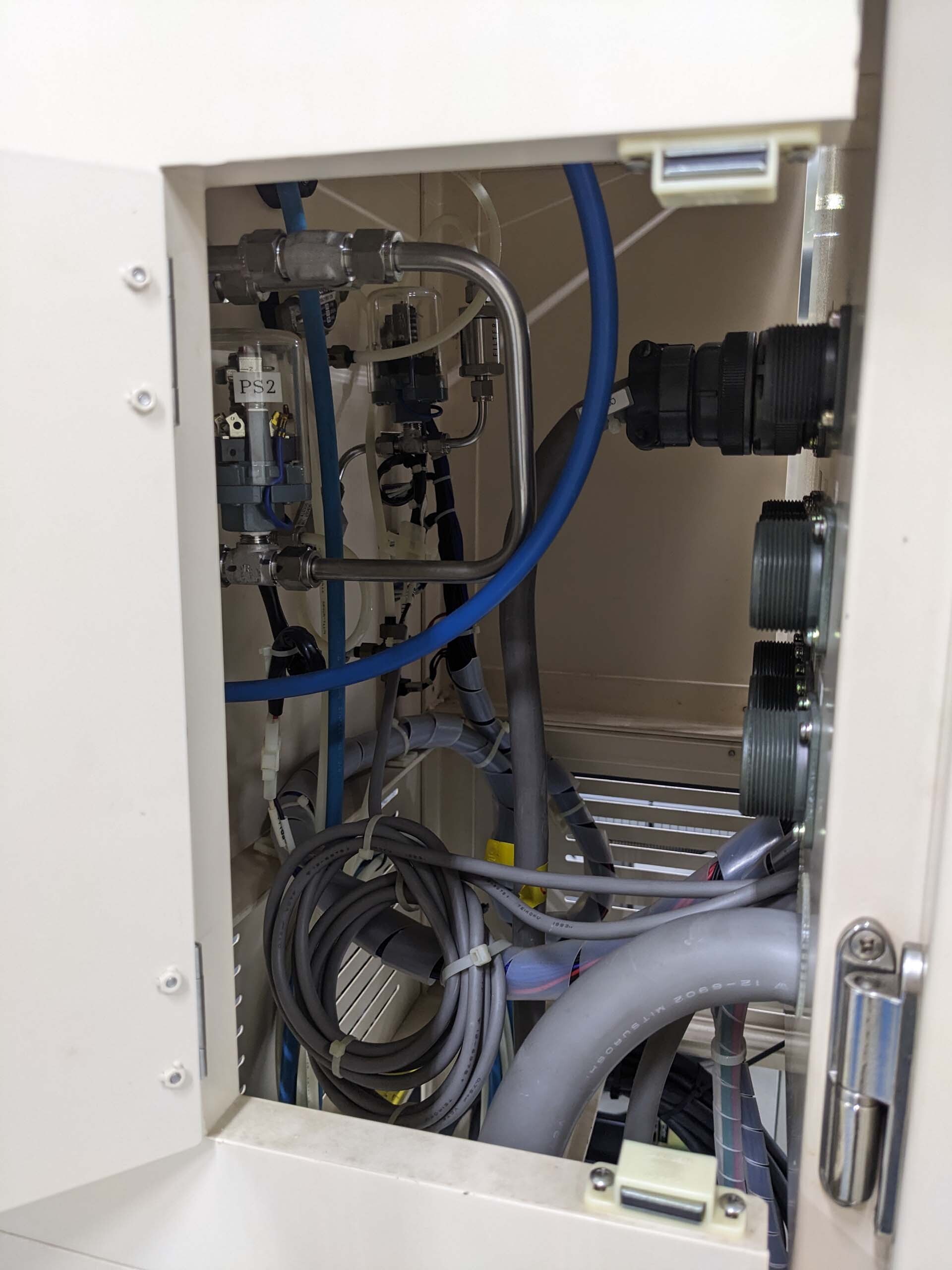

Load lock:

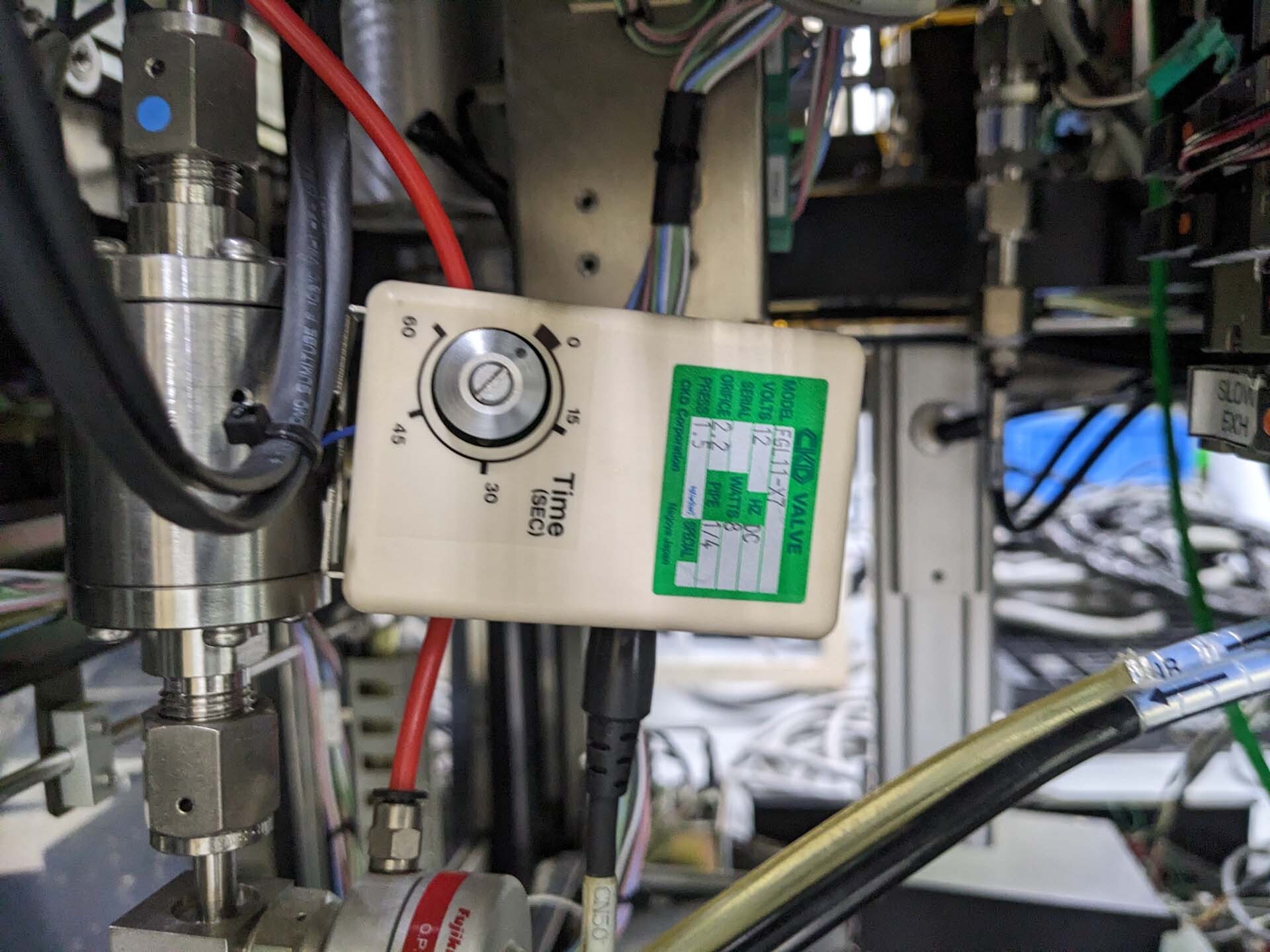

FGL11-X7 CKD Leak valve: 12 V, 8 W, 3.5-5 kg/cm²

Orifice: 2.2

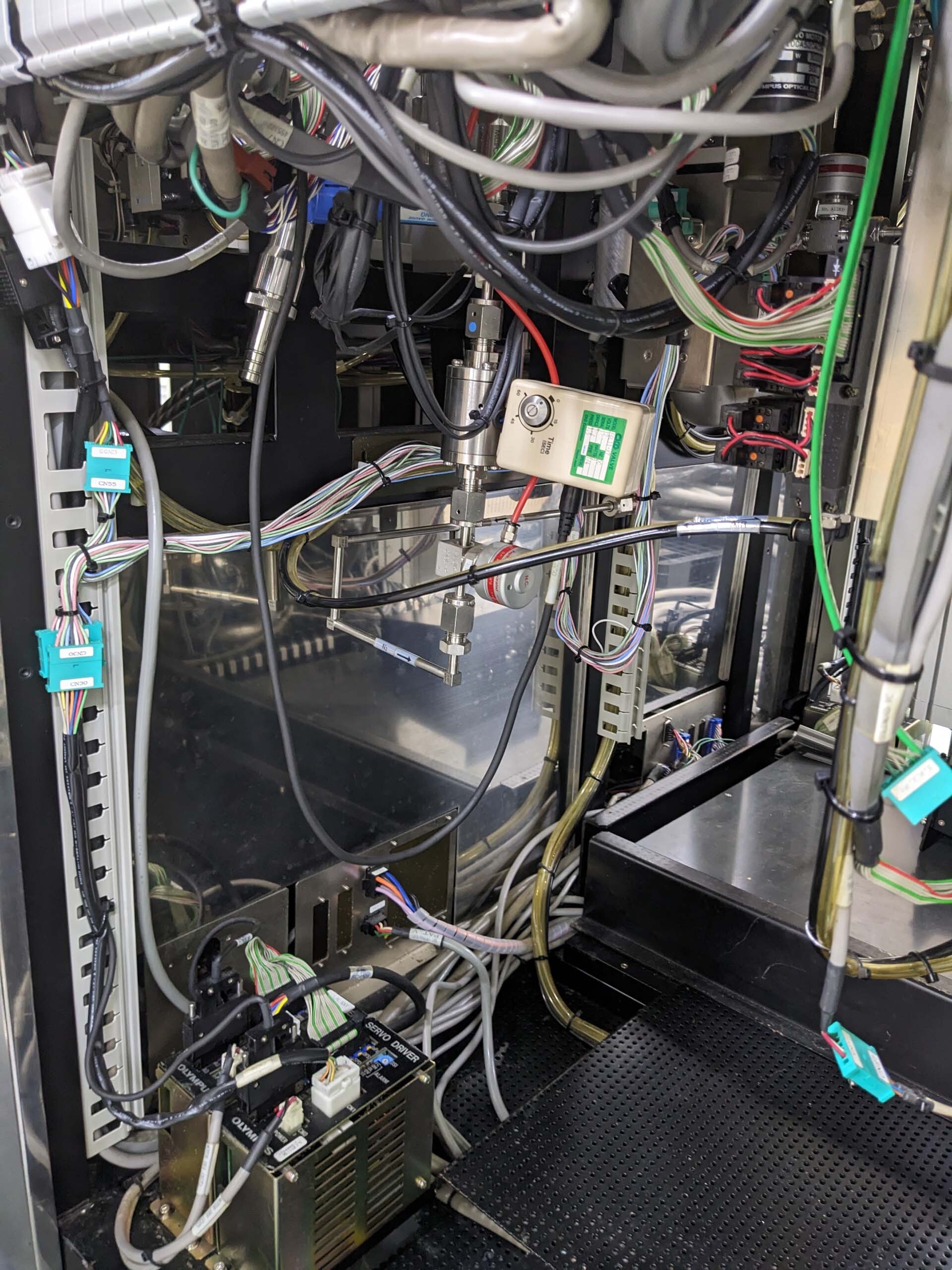

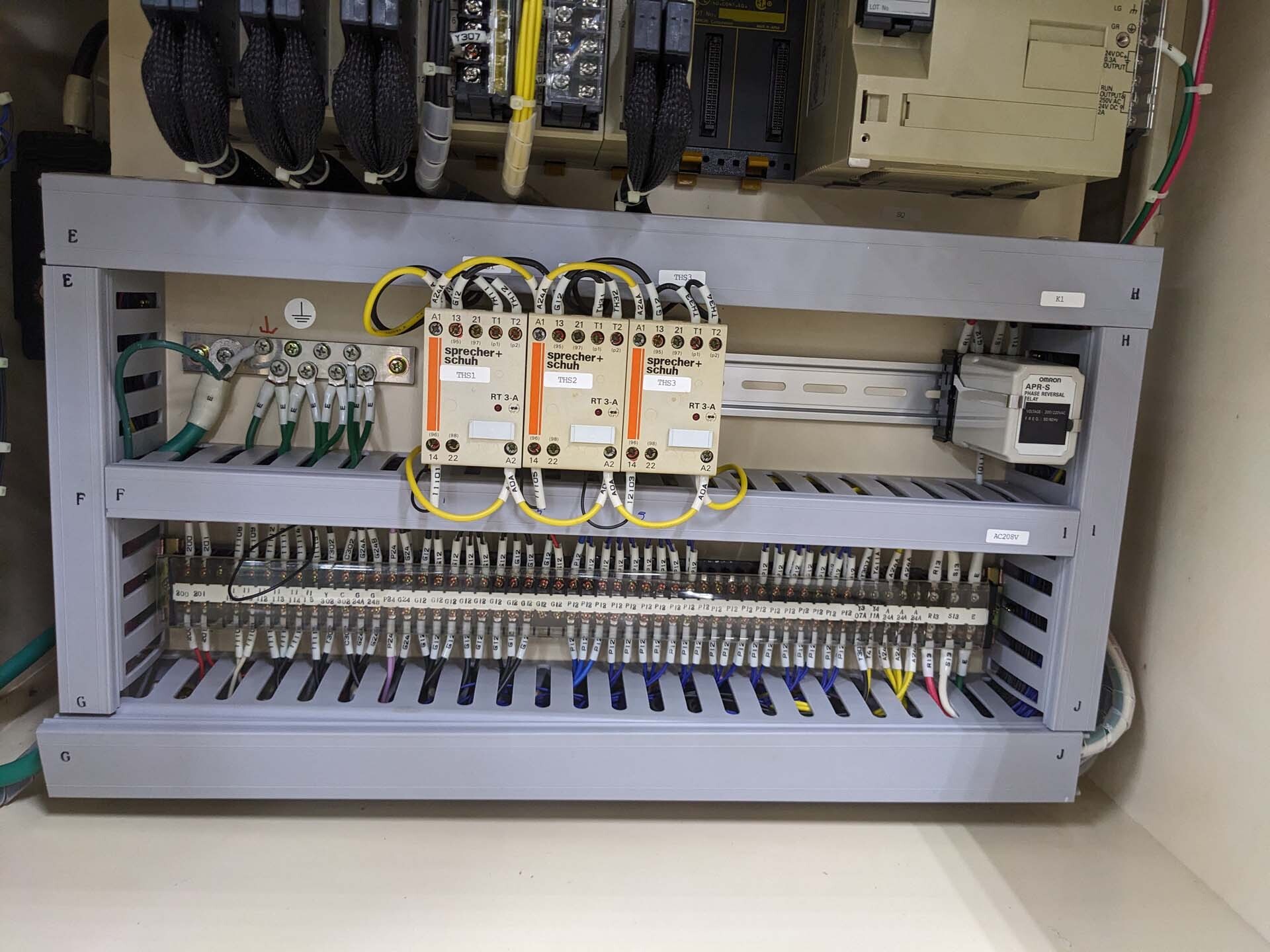

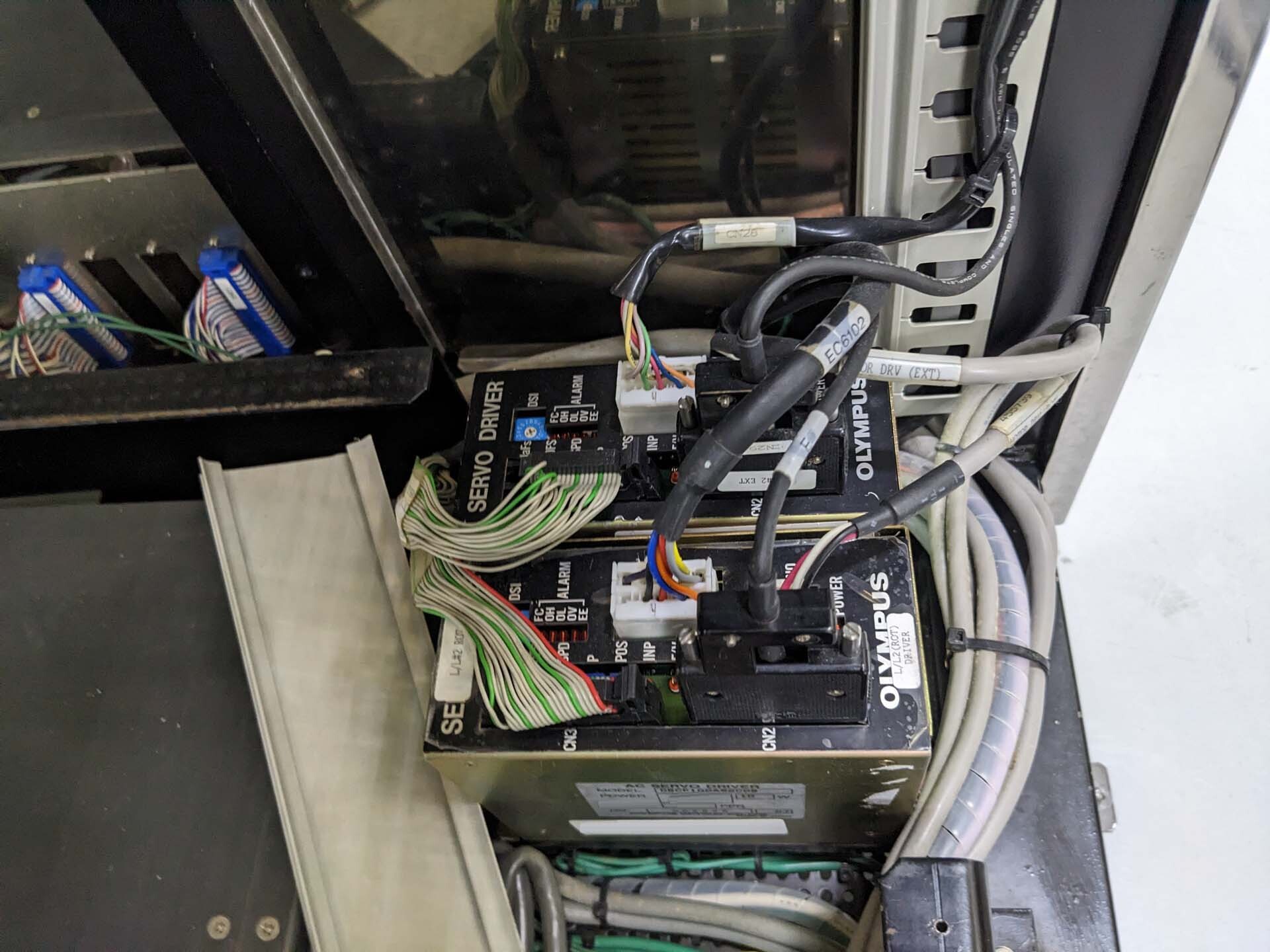

(2) External motor driver: DBAP10CA52CS536 AC Servo driver

(2) Rotor motor driver: DBCP10CA52CDB AC Servo driver

(2) Load lock motor: BC10CA52CACDN AC Servo driver

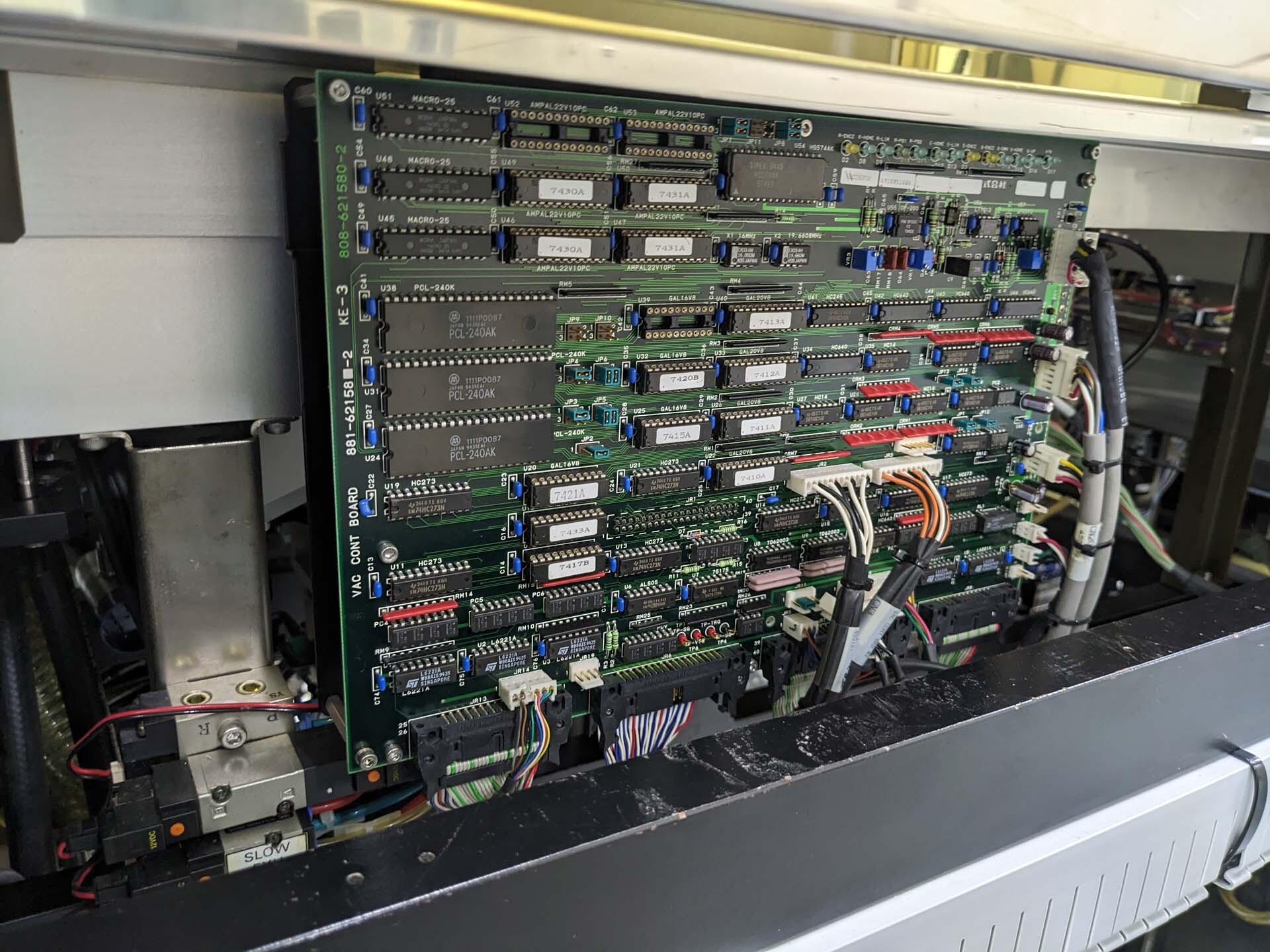

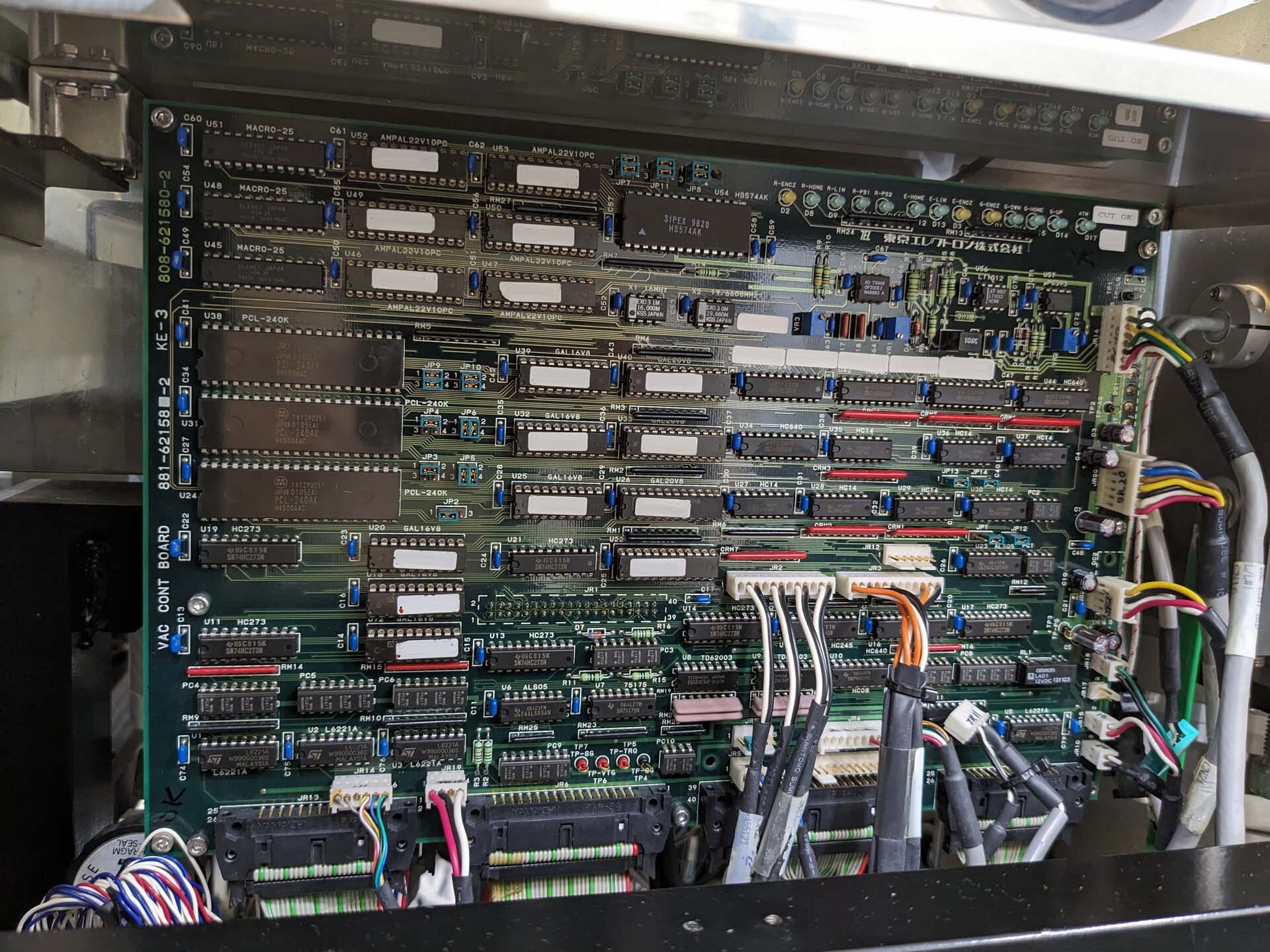

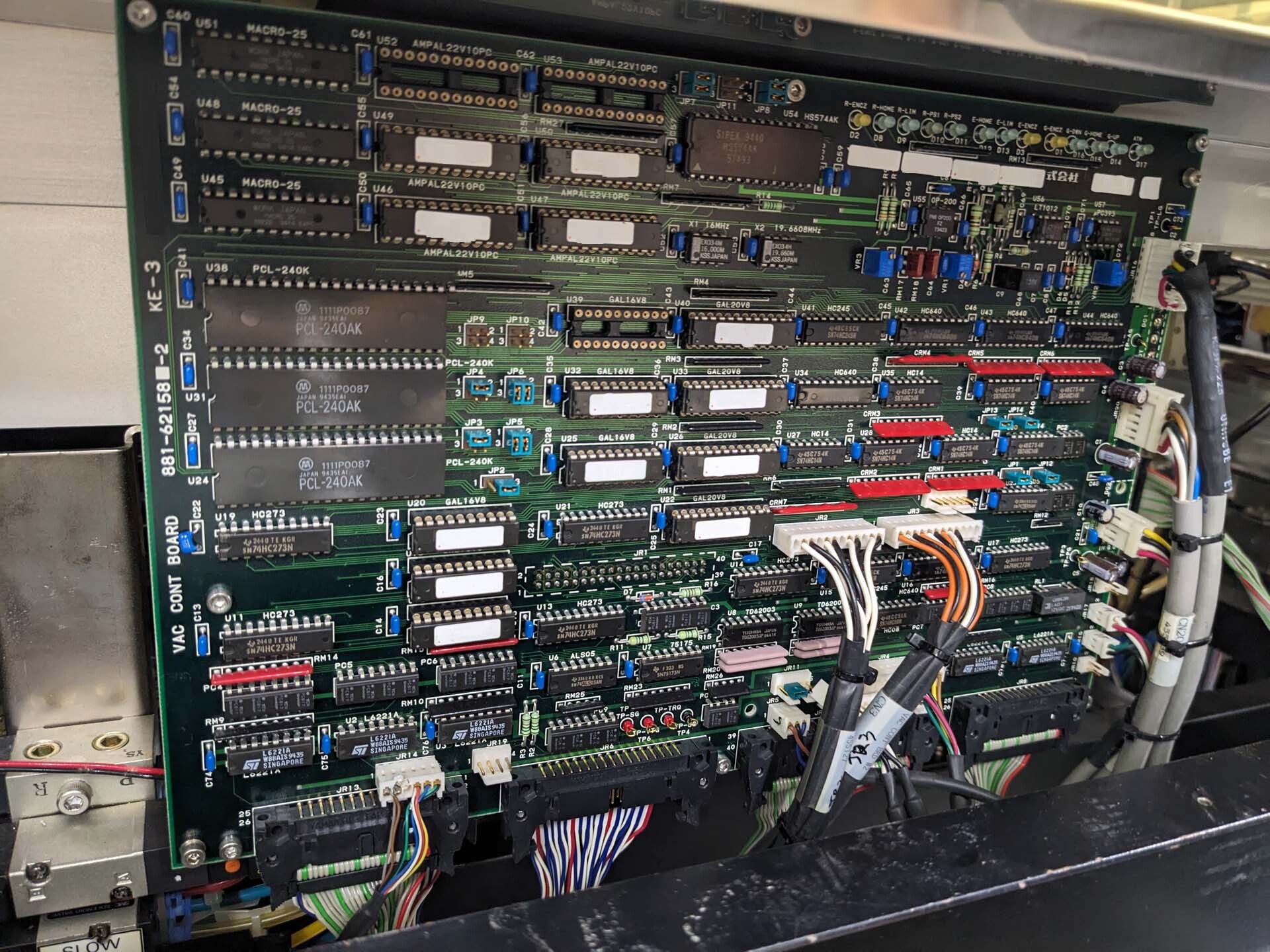

(2) Board: 1881-022047-11 Vacuum control board

(3) C-2-FA-50-60-R3 Load lock cylinders

C-2-50-60-R Load lock cylinder

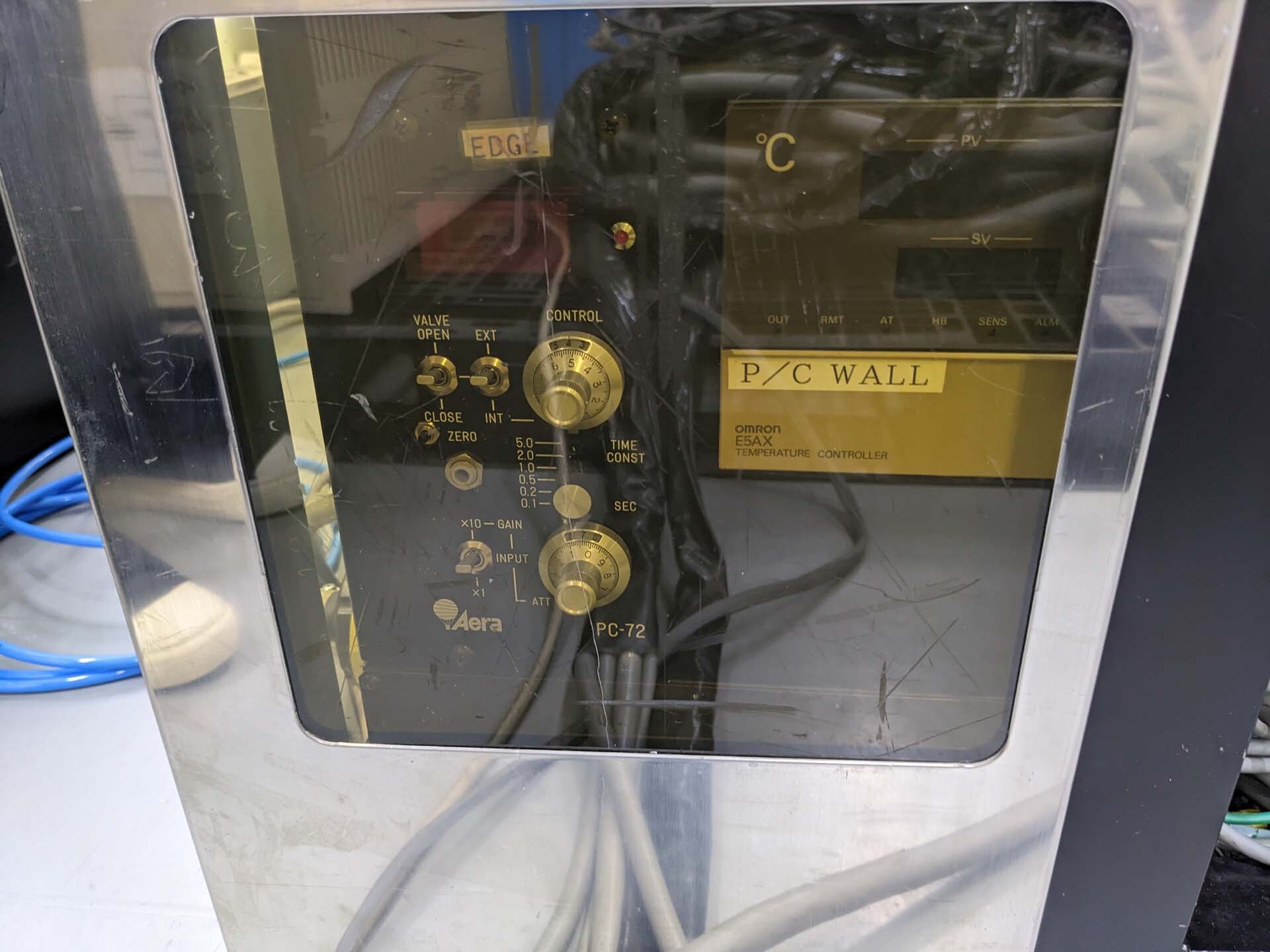

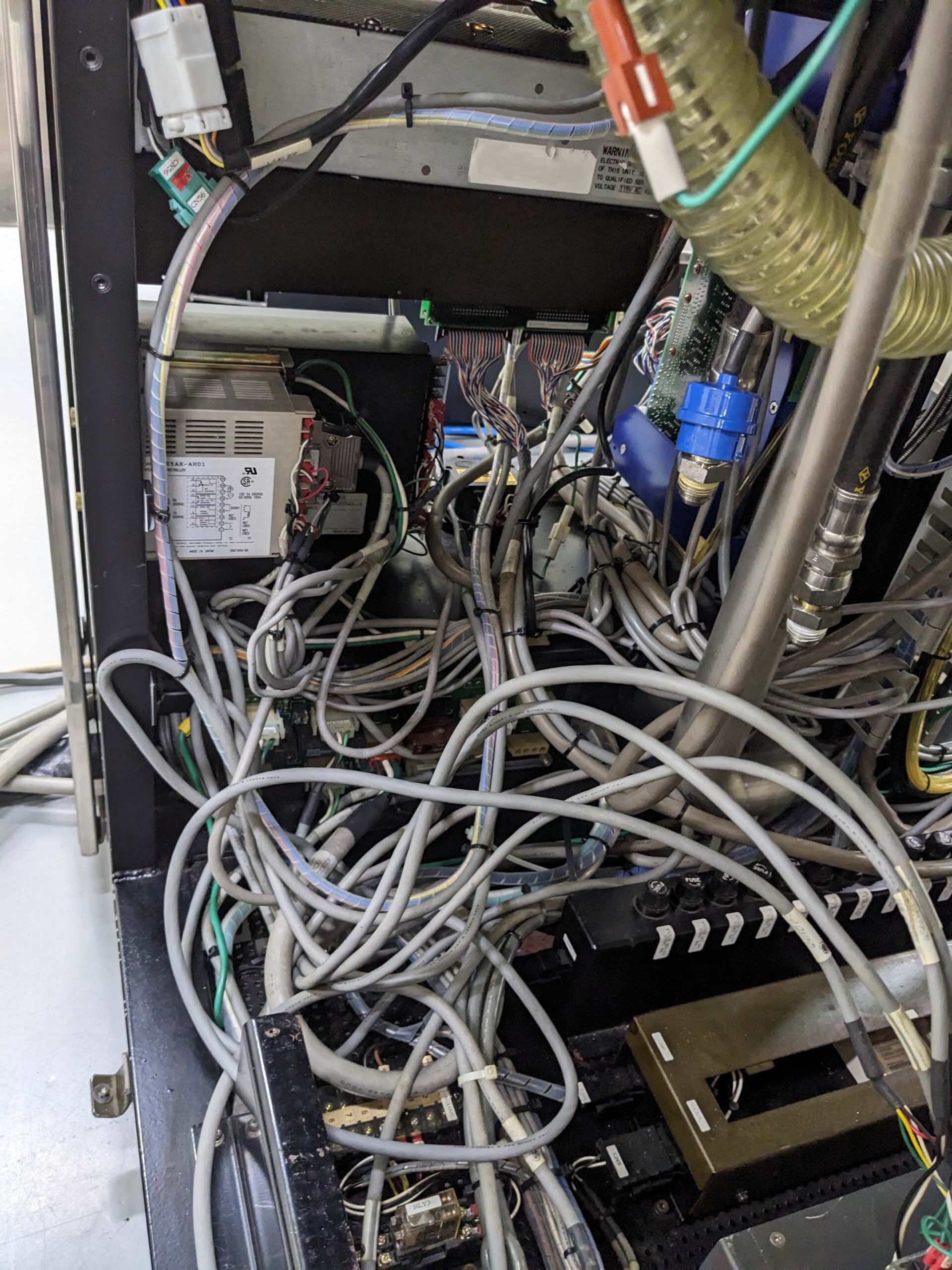

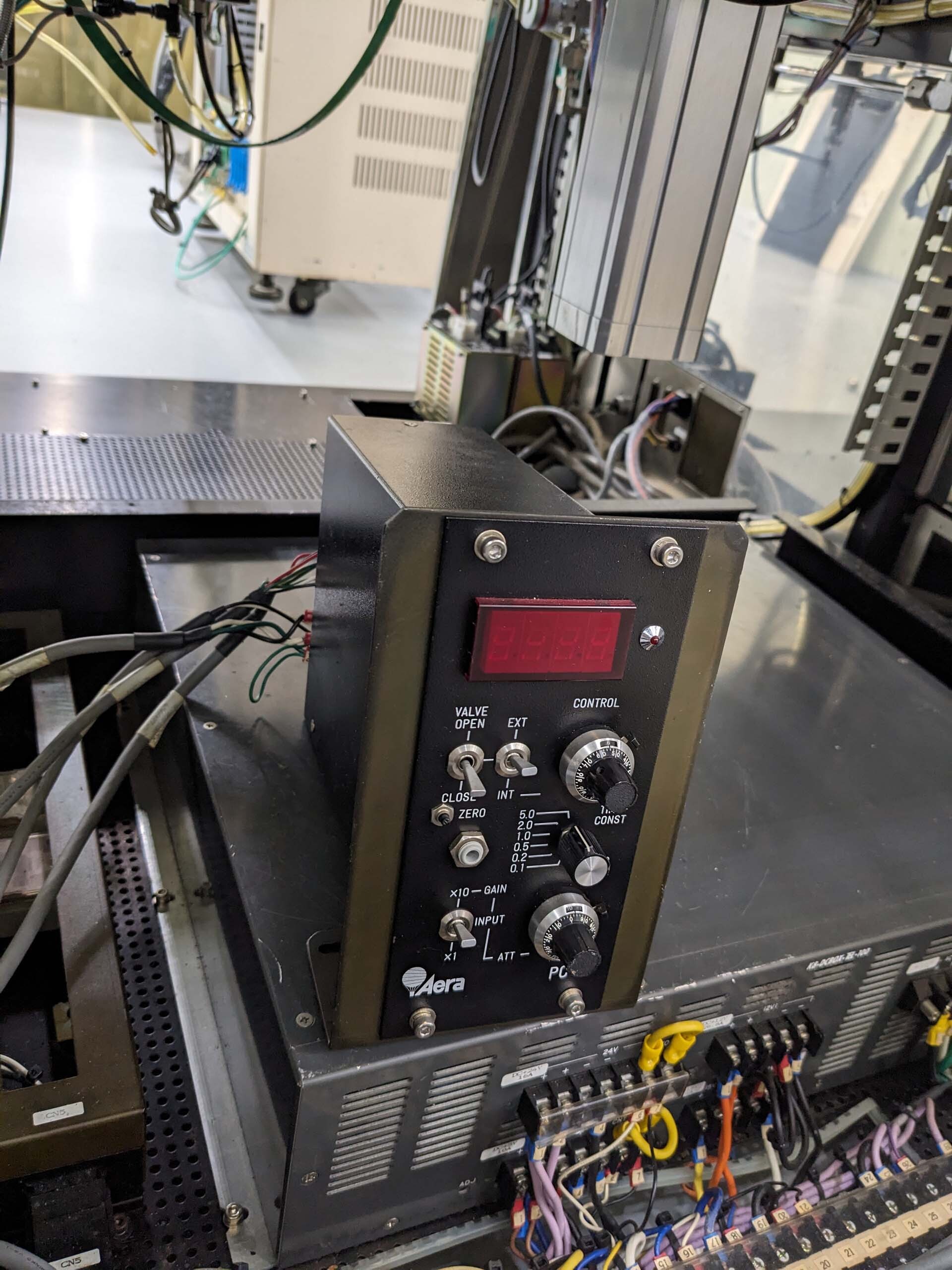

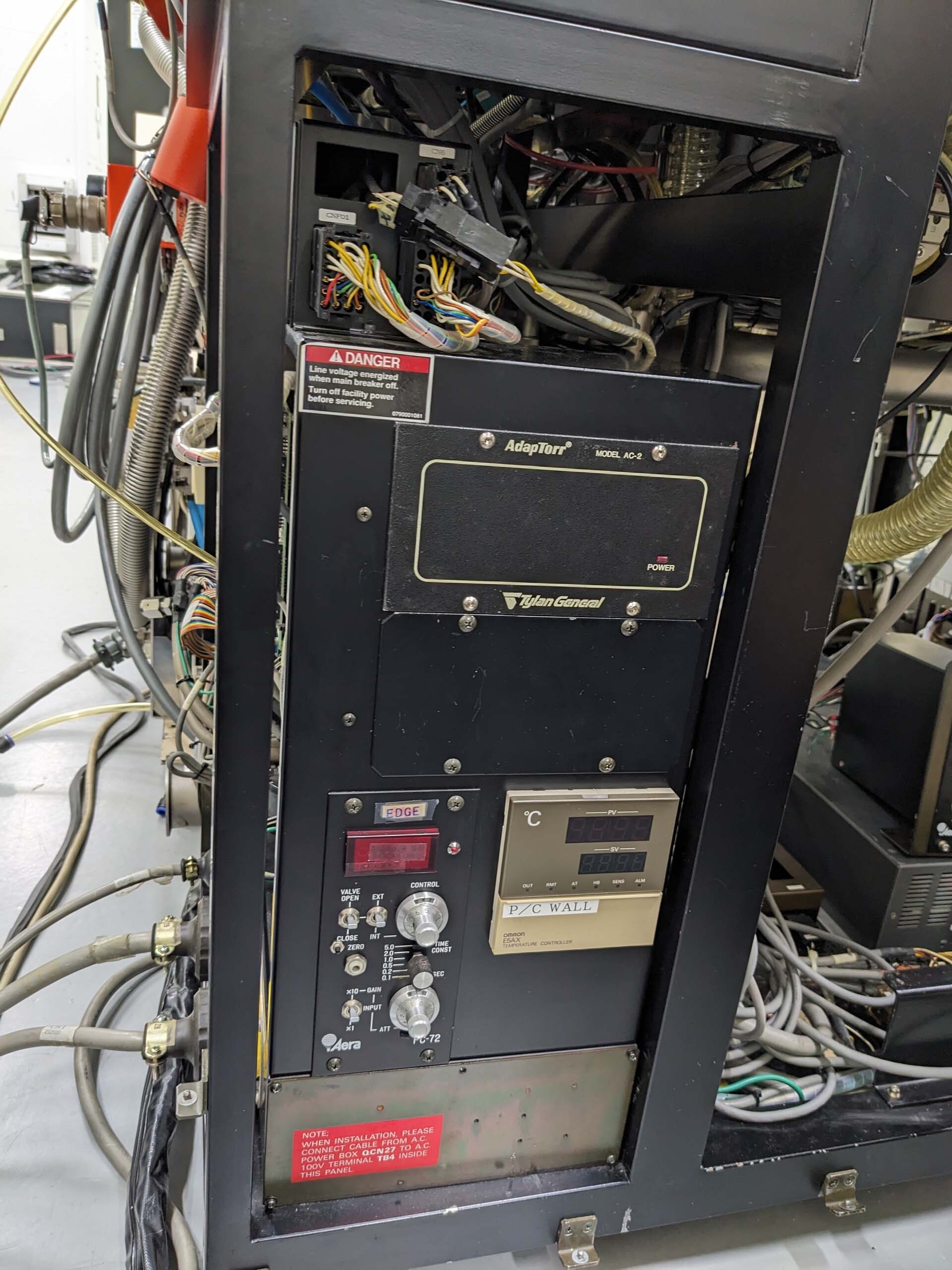

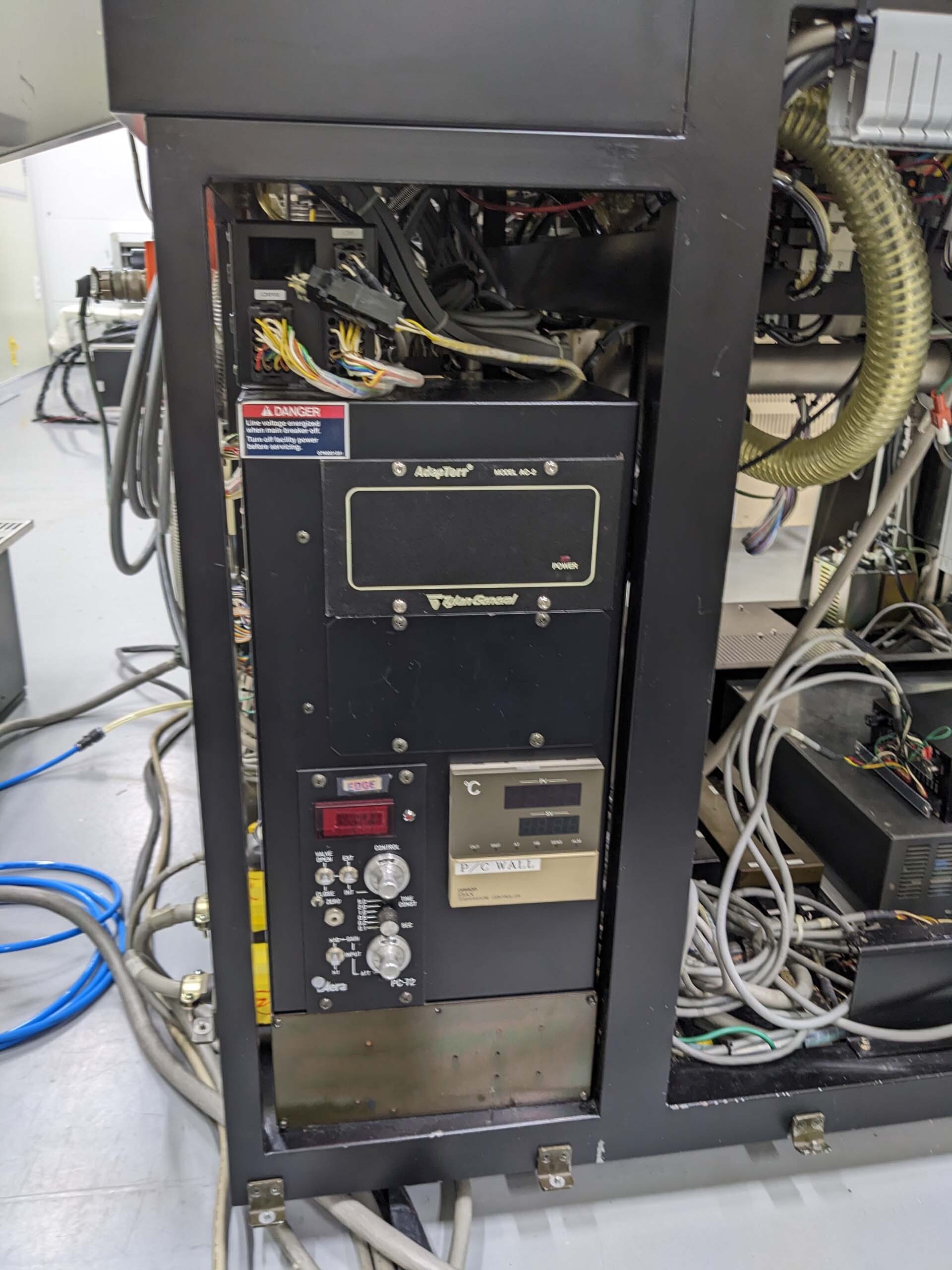

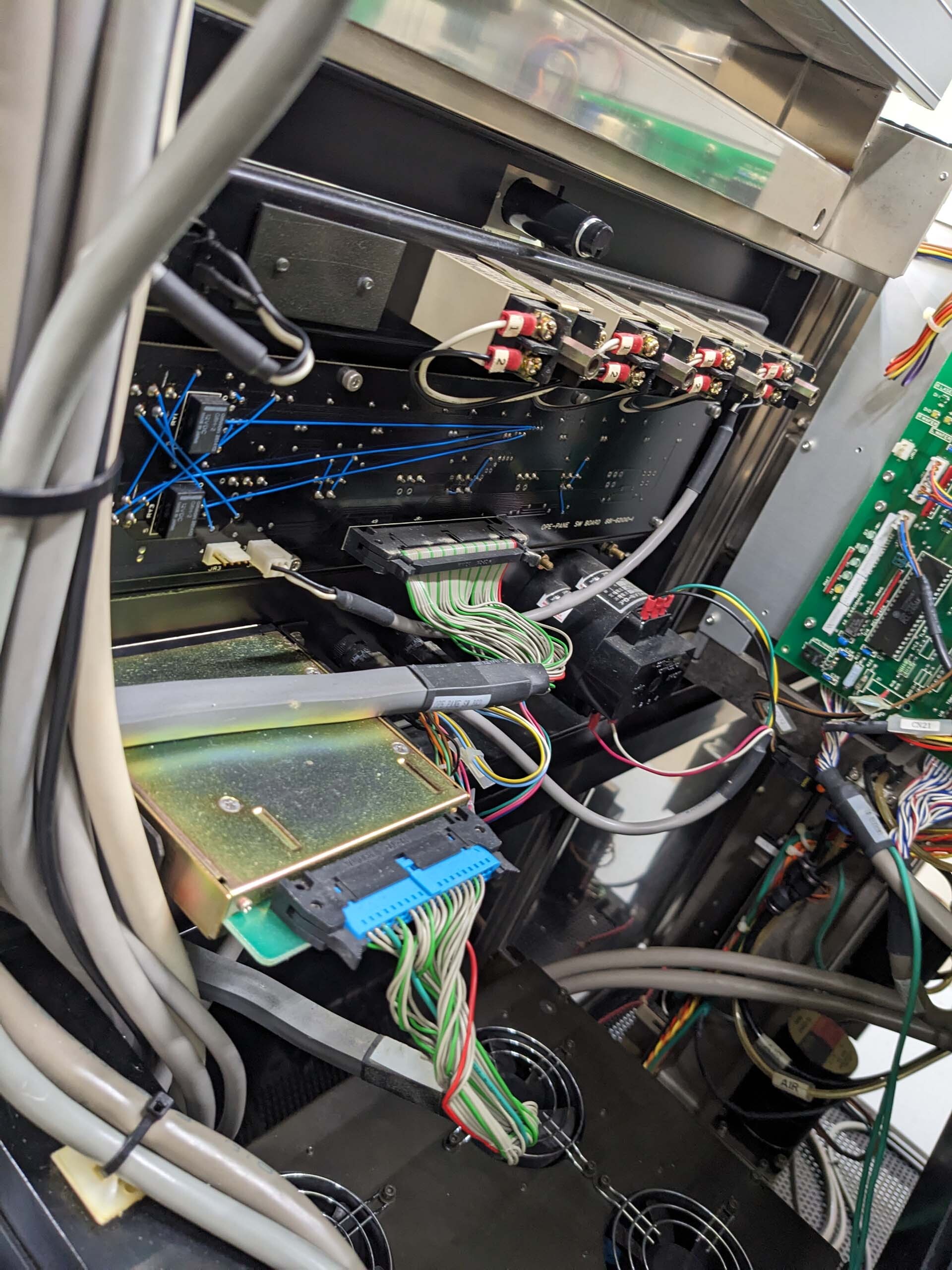

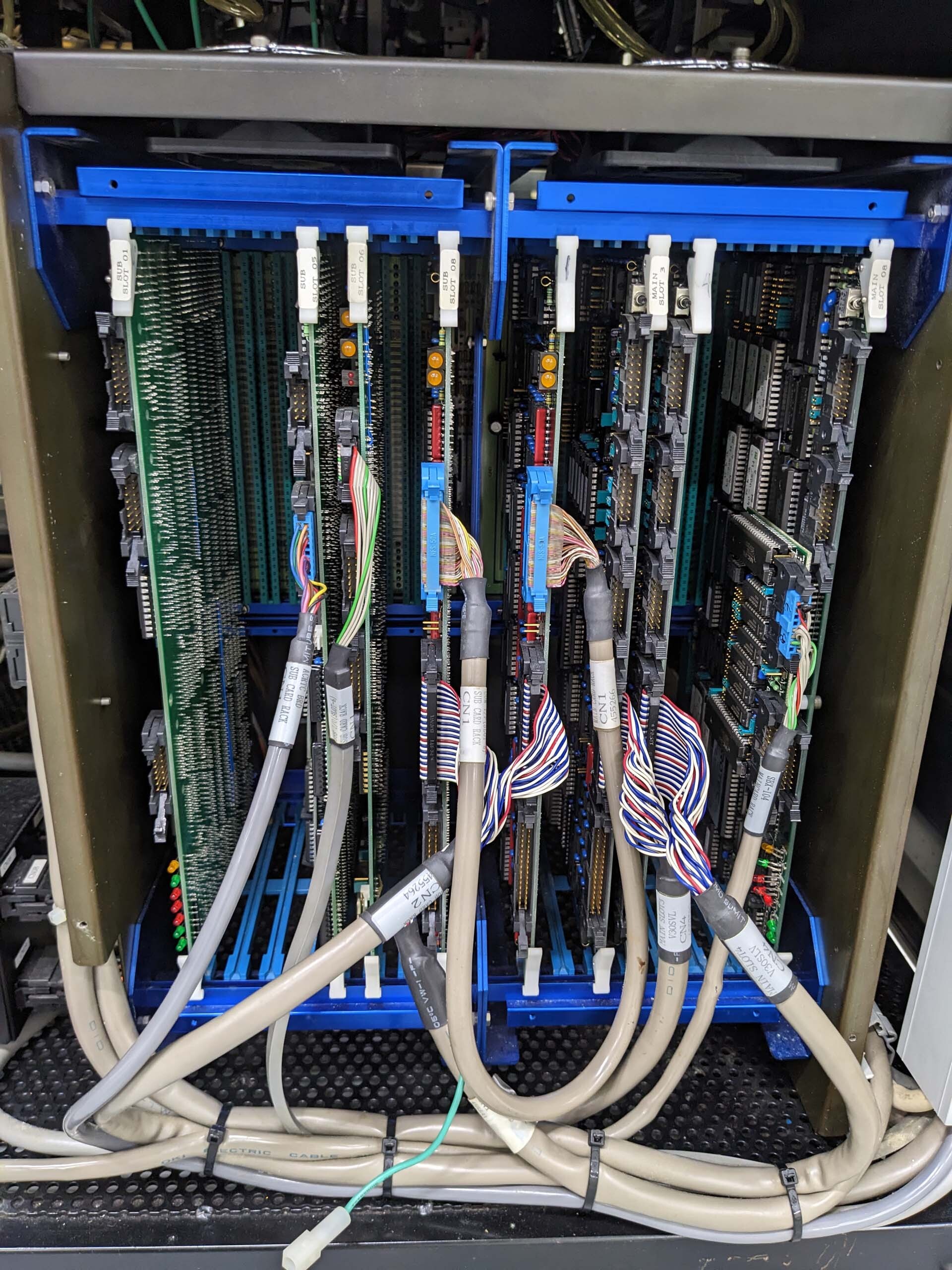

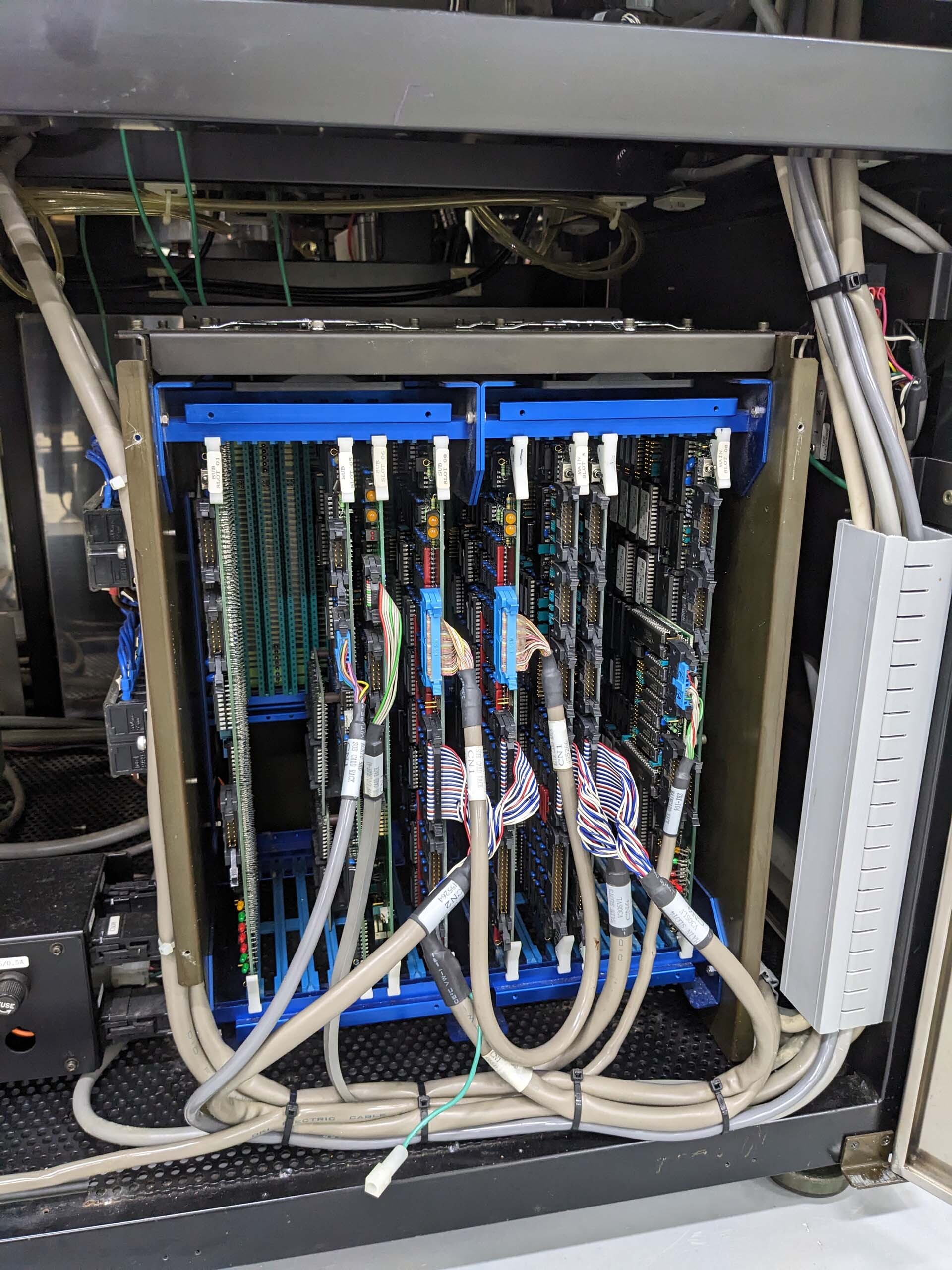

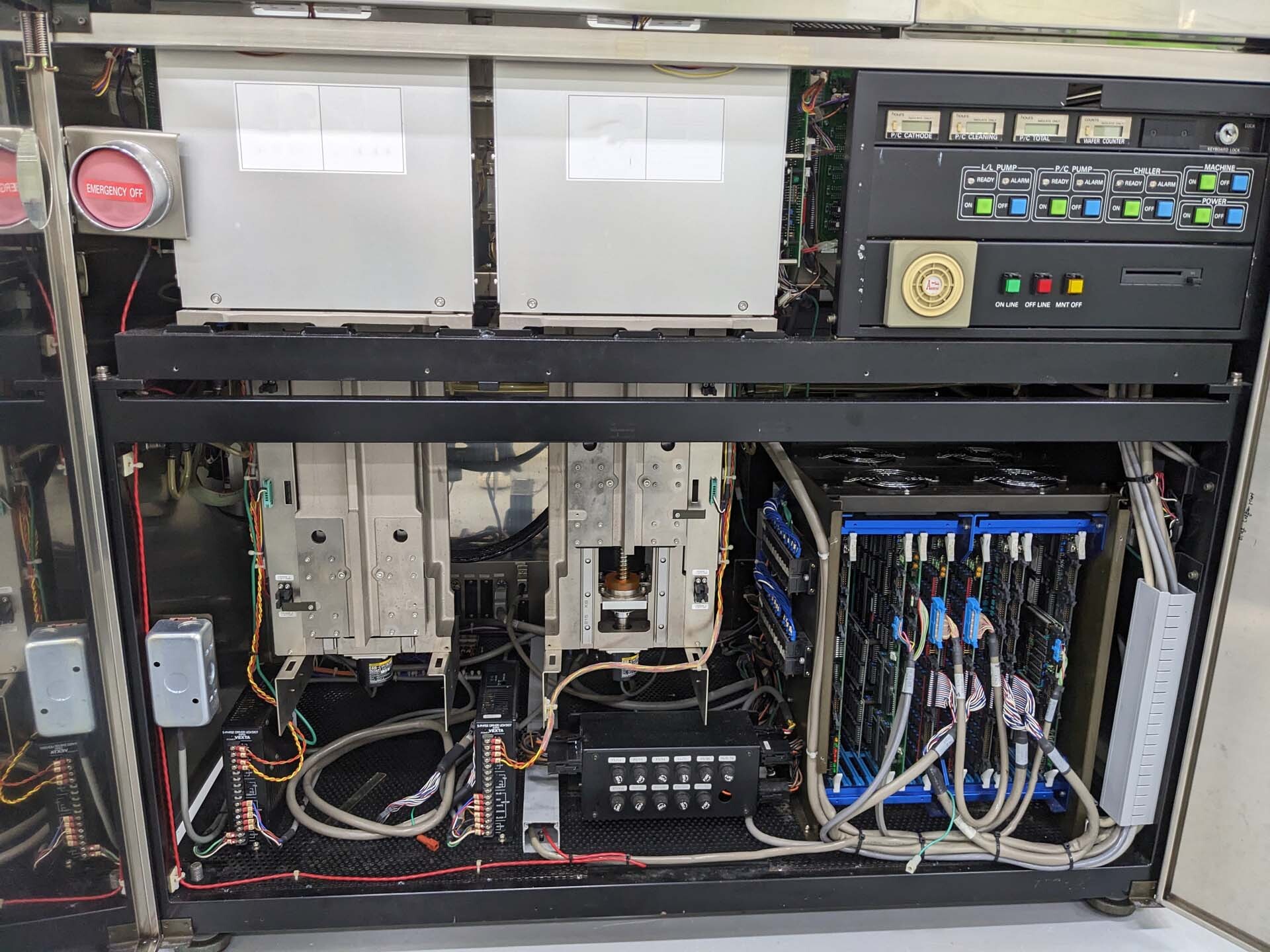

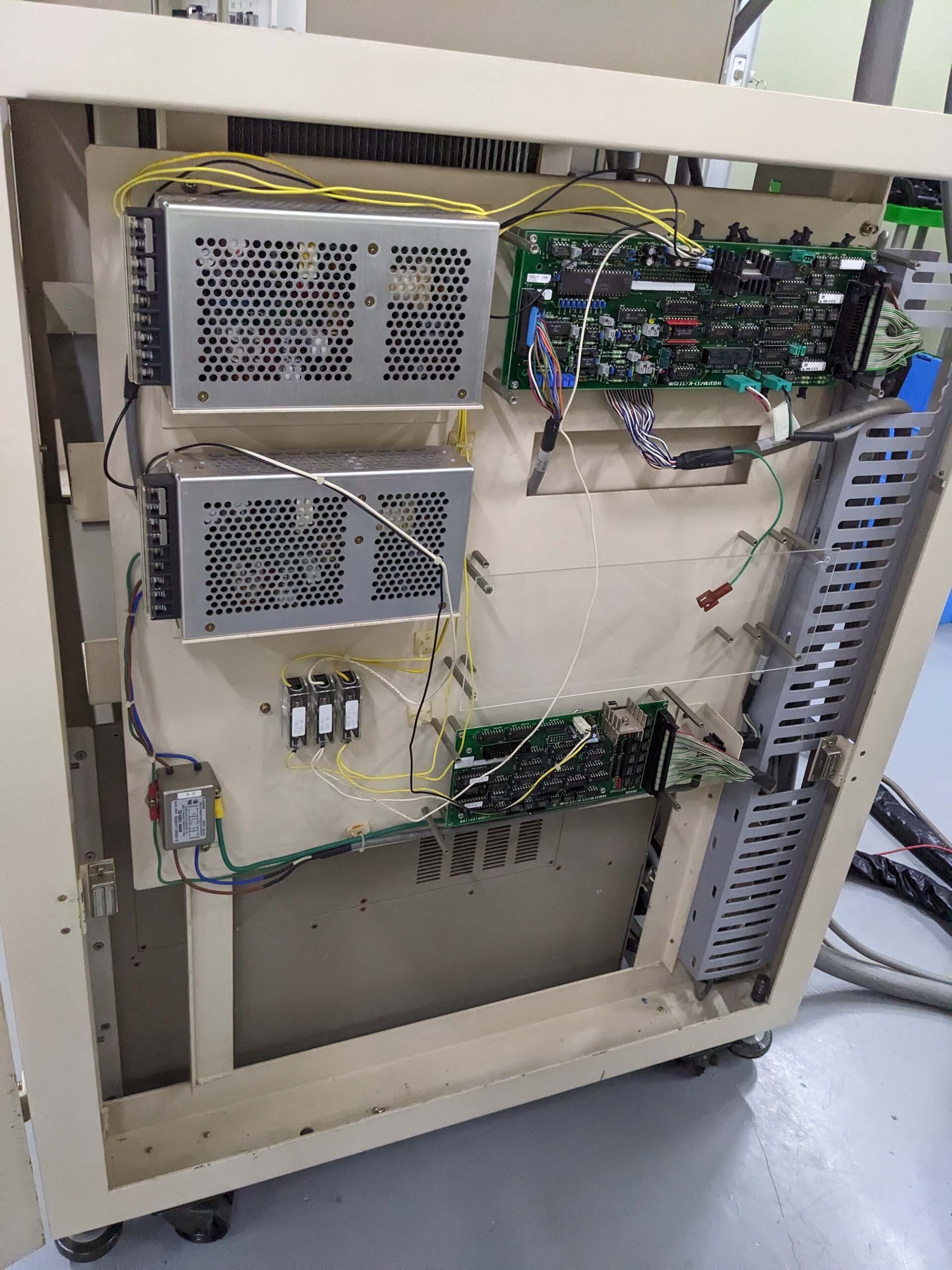

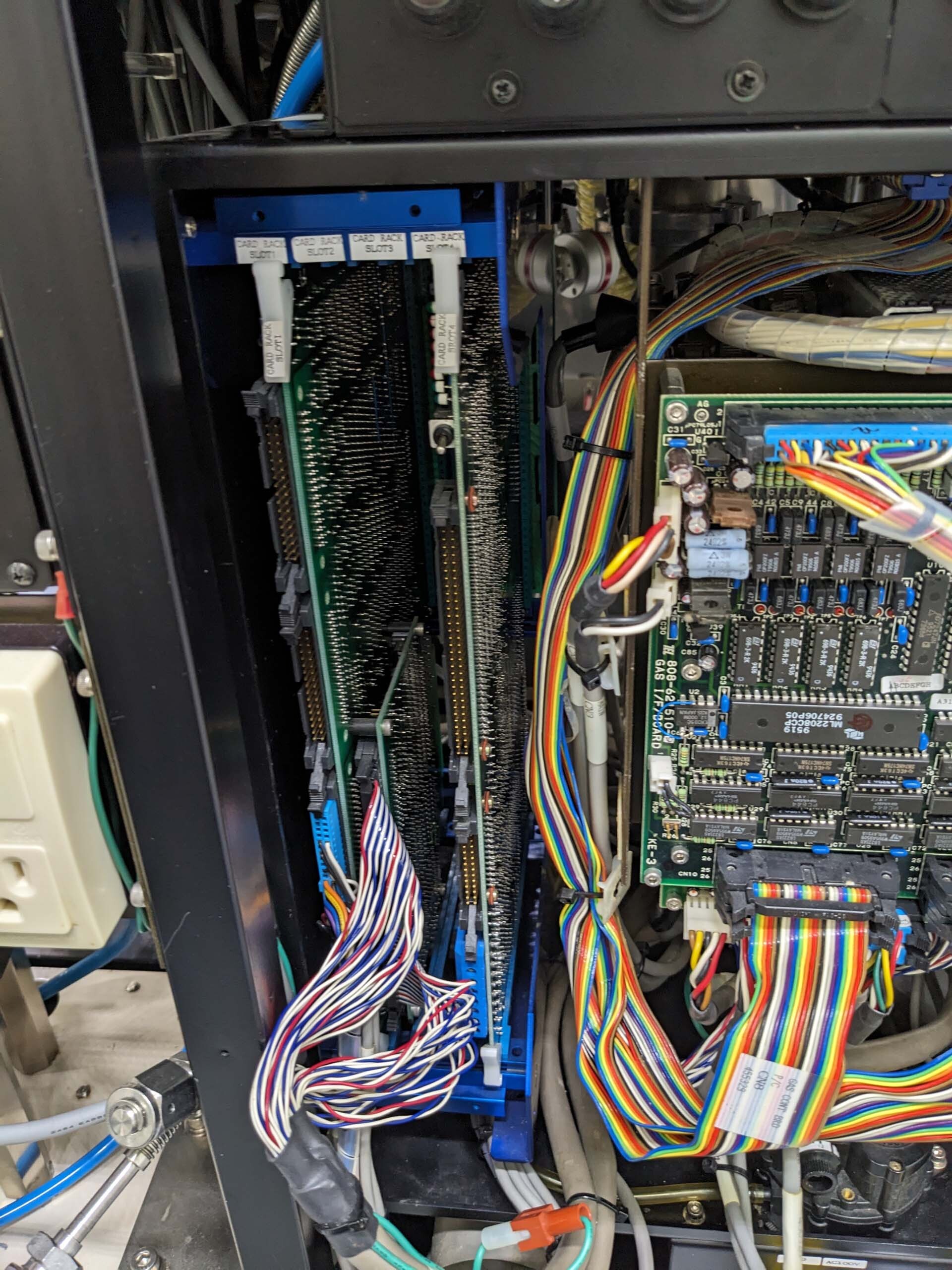

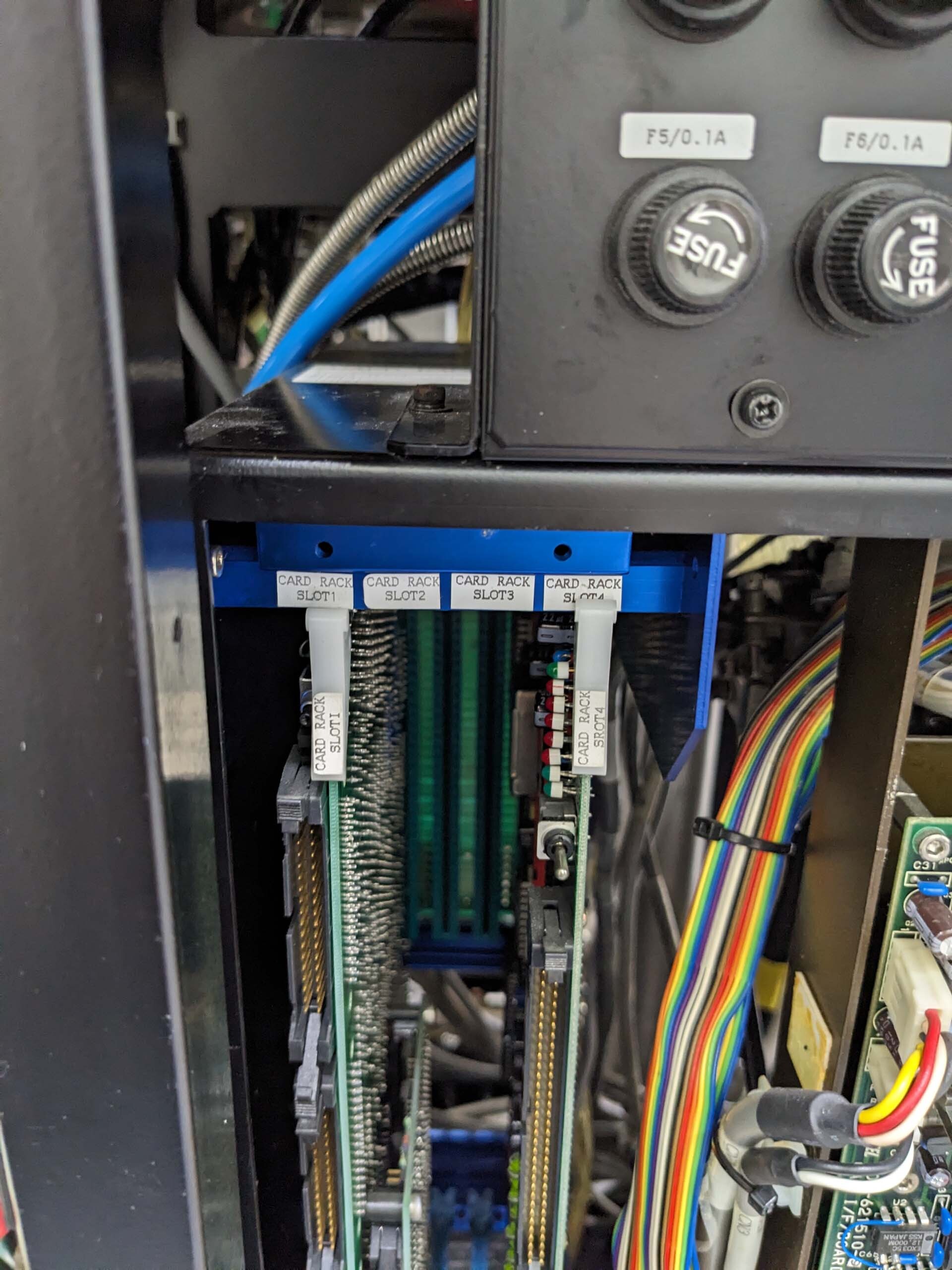

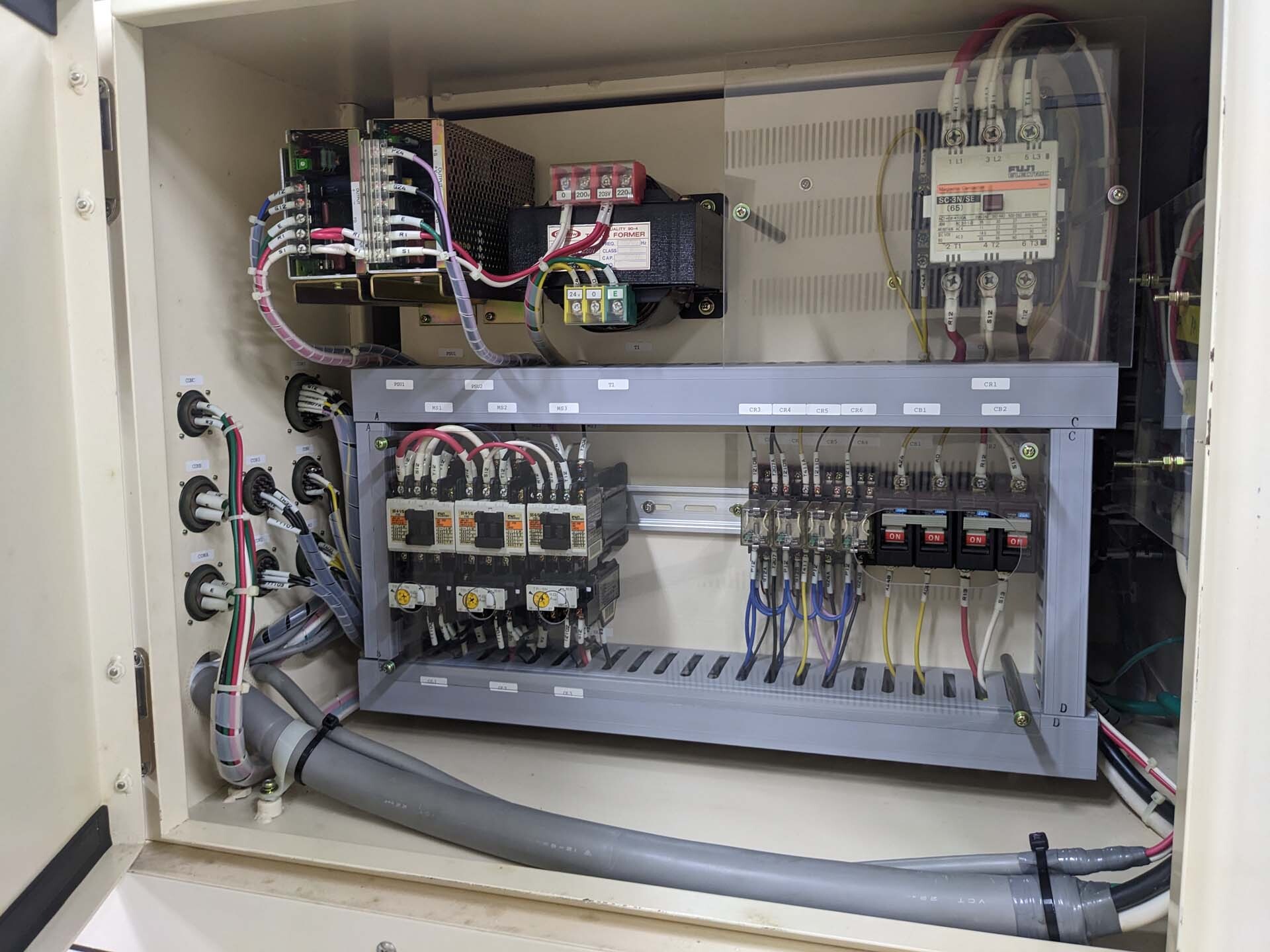

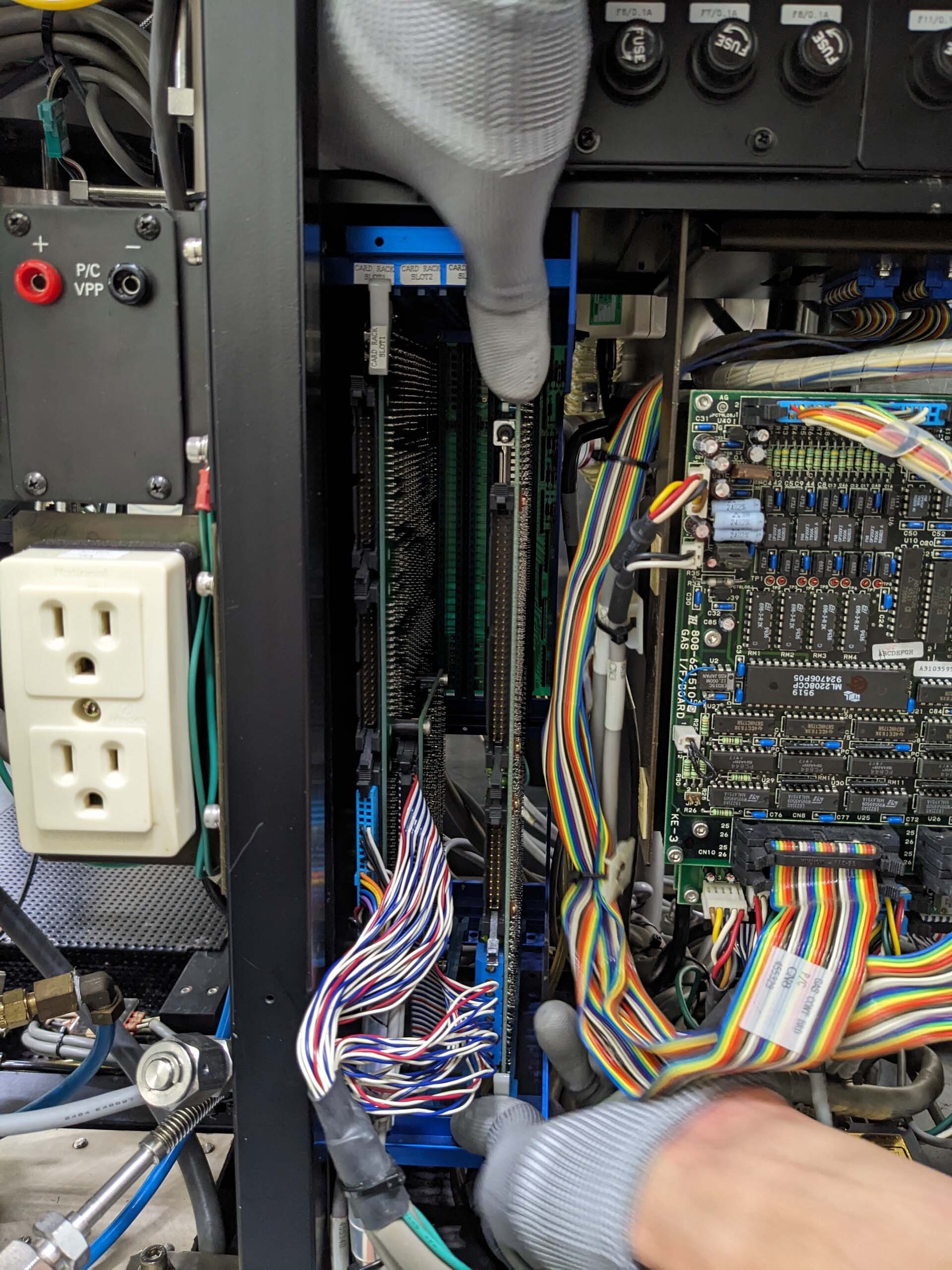

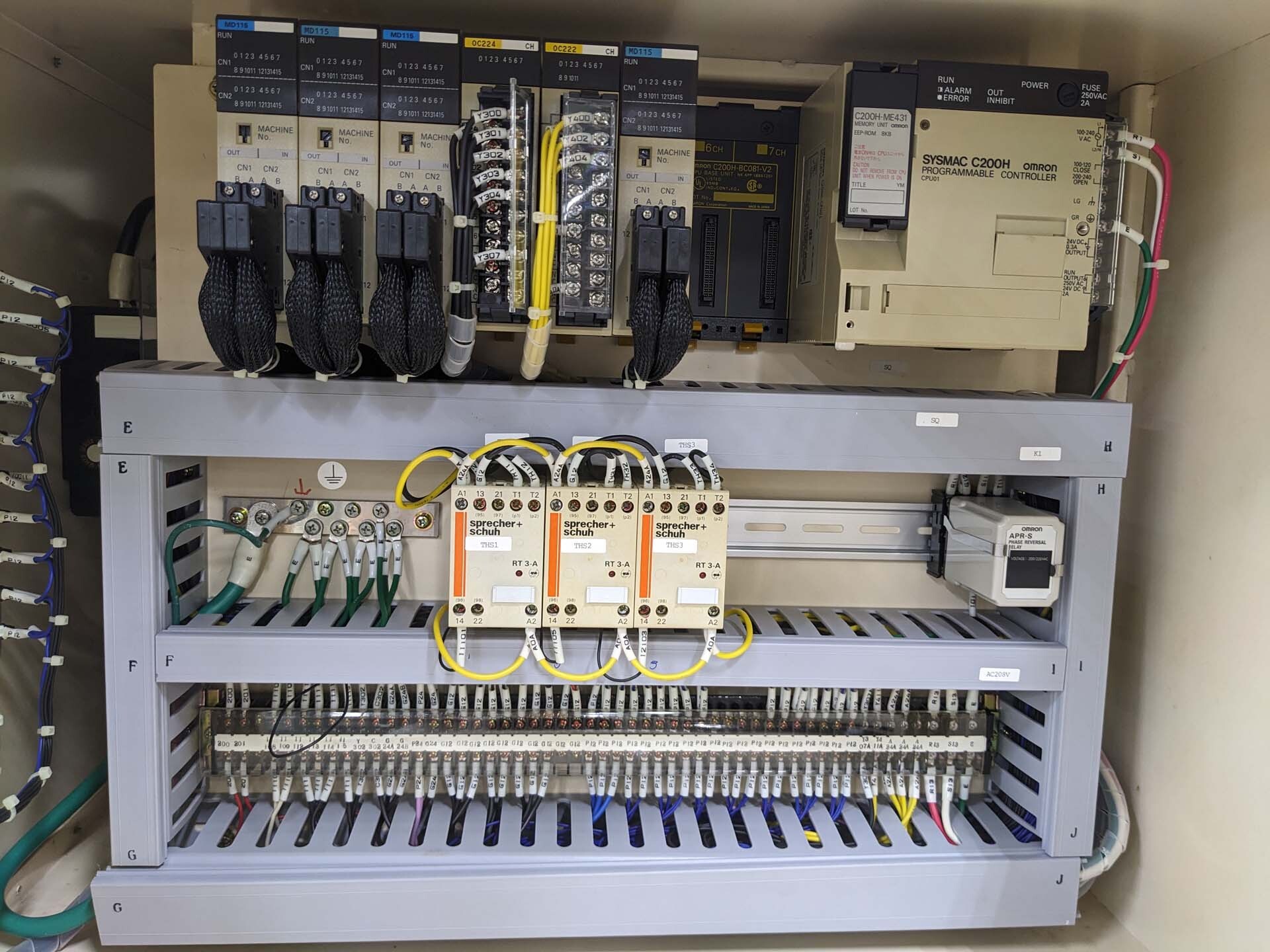

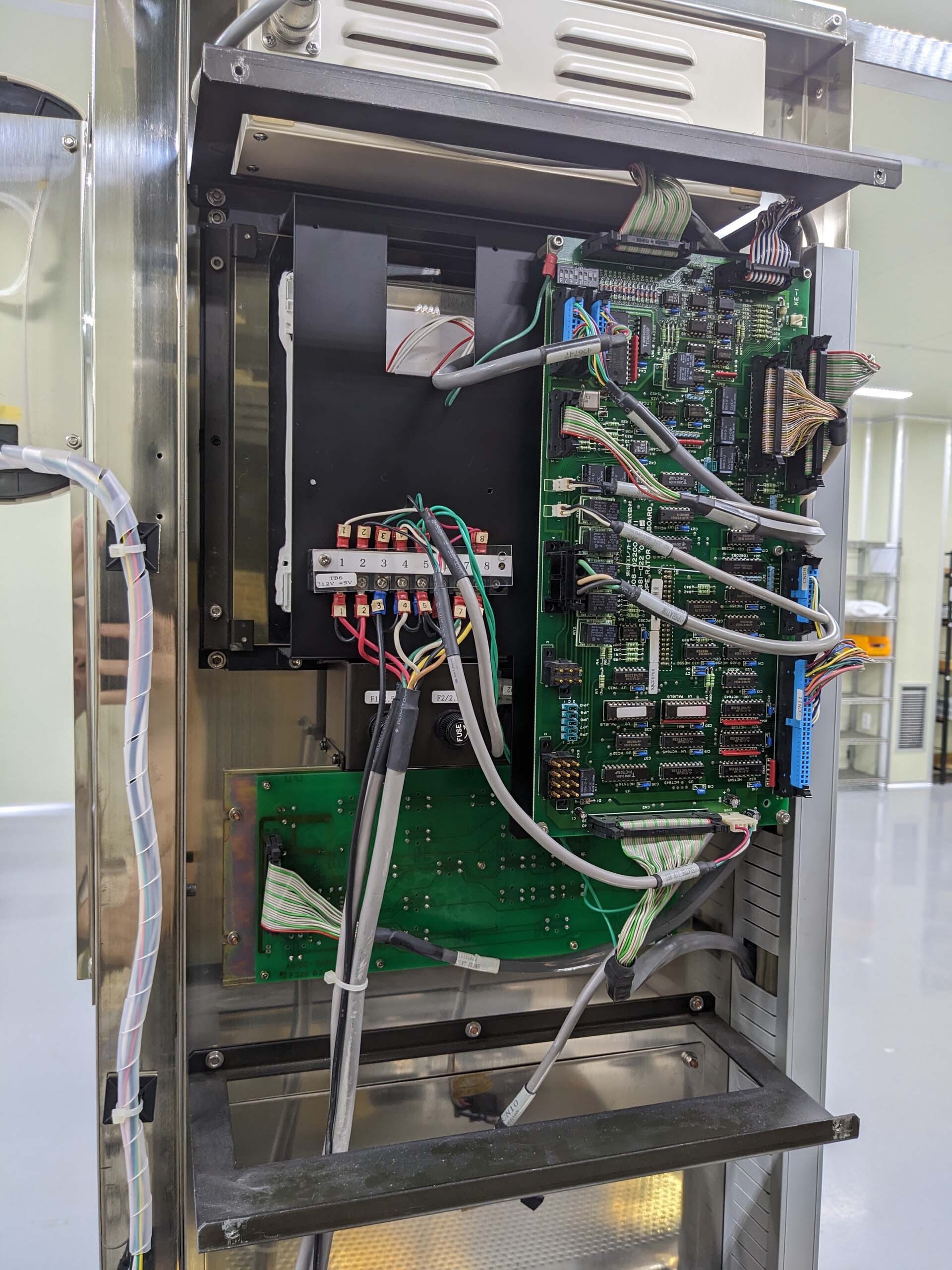

VAC Card rack:

Manostar switch: MS61L Differnetial pressure switch, 2-22 mmHg

E5AX-AH01 Temperature controller: 100-240 VAC, 15 VA, 50/60 Hz

808-62150-1 Gas I/F Board

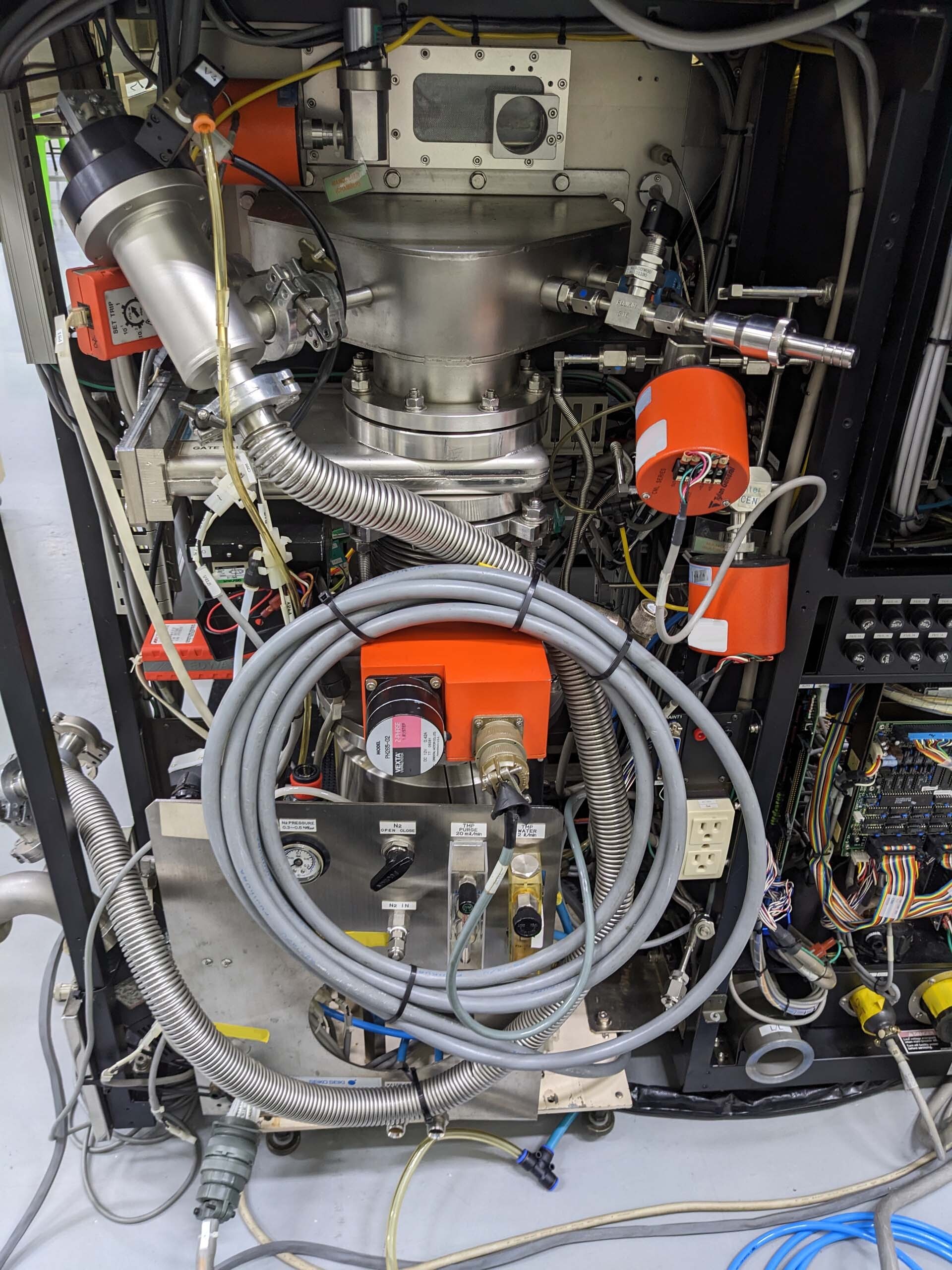

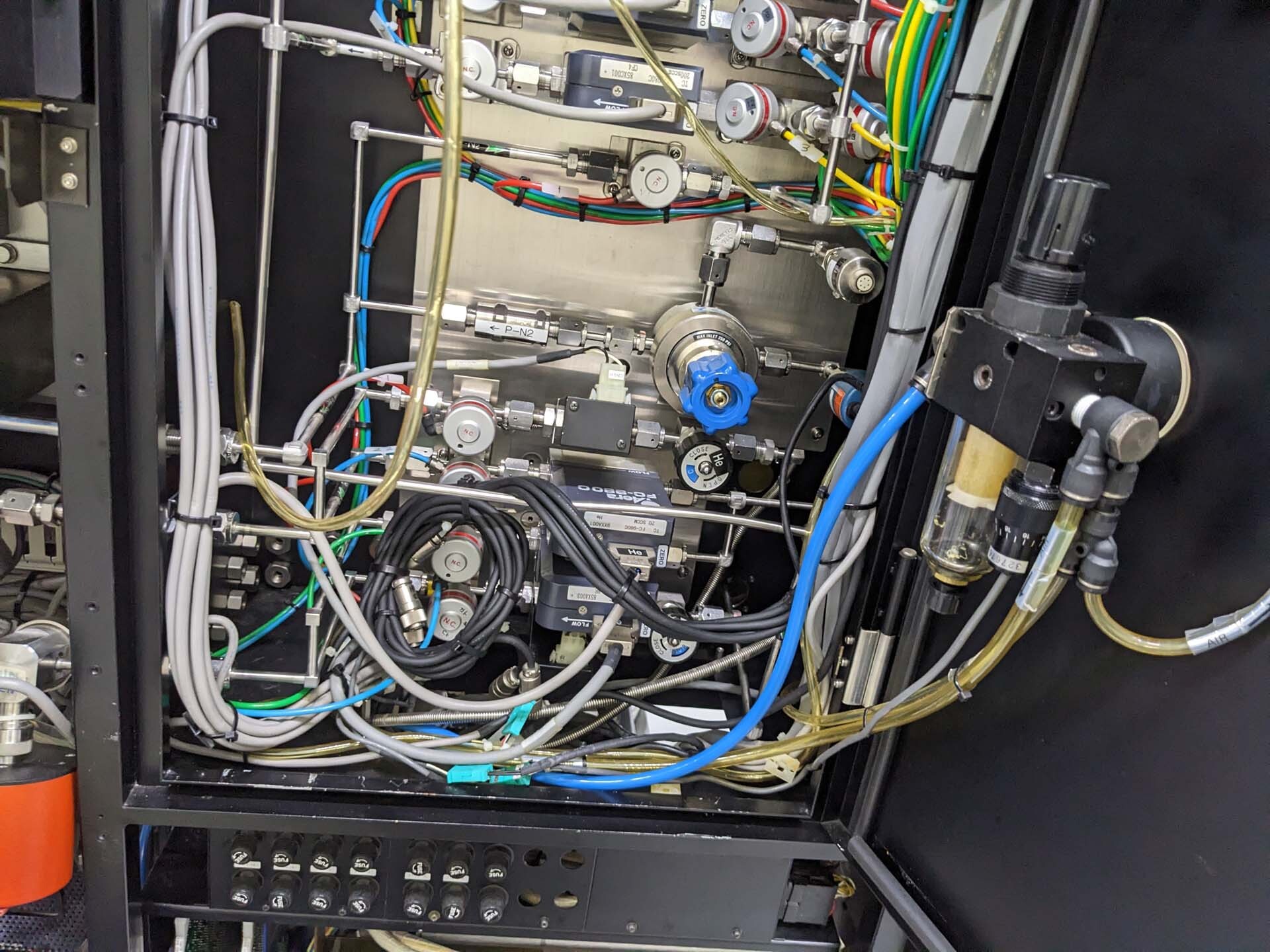

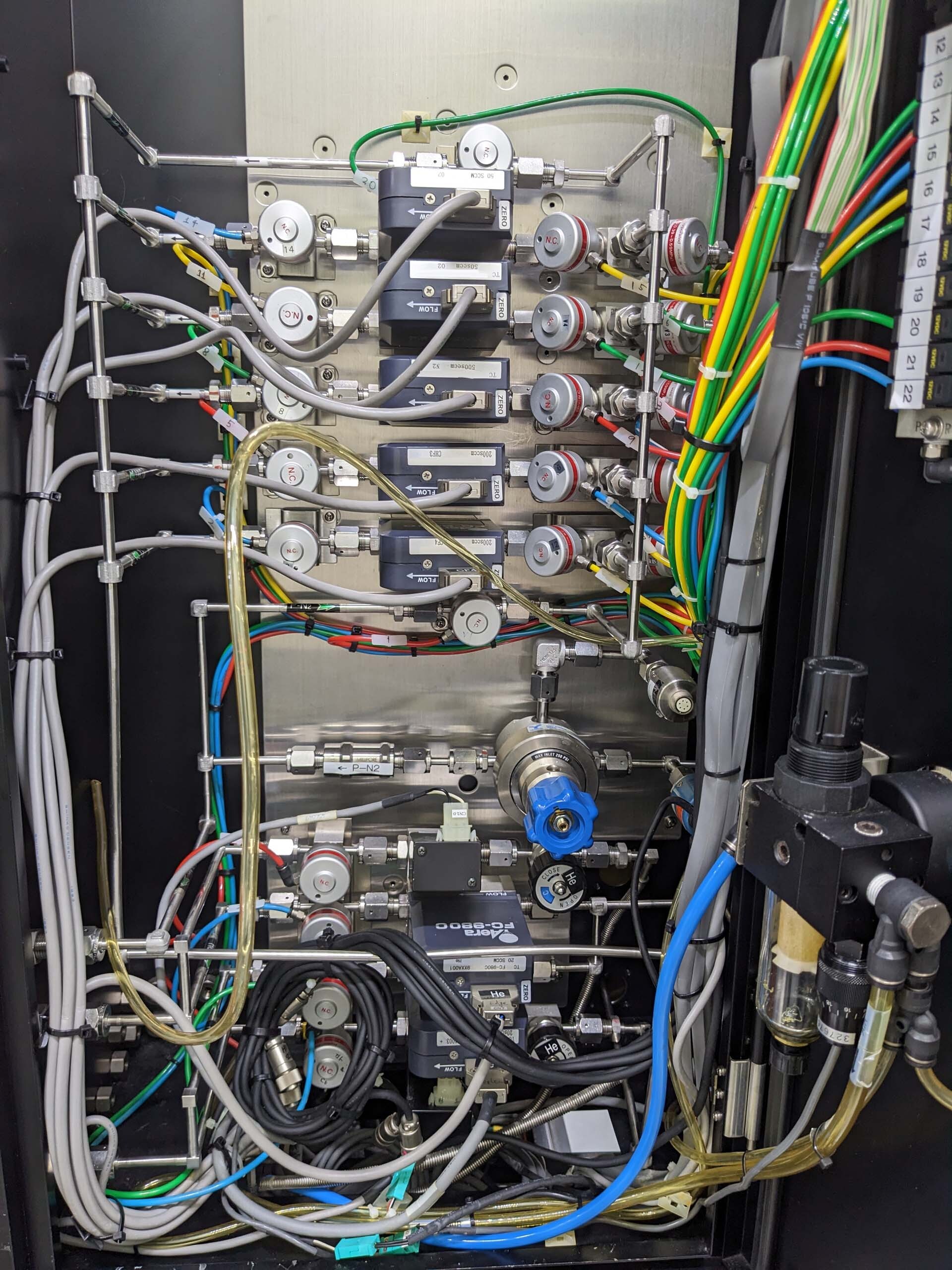

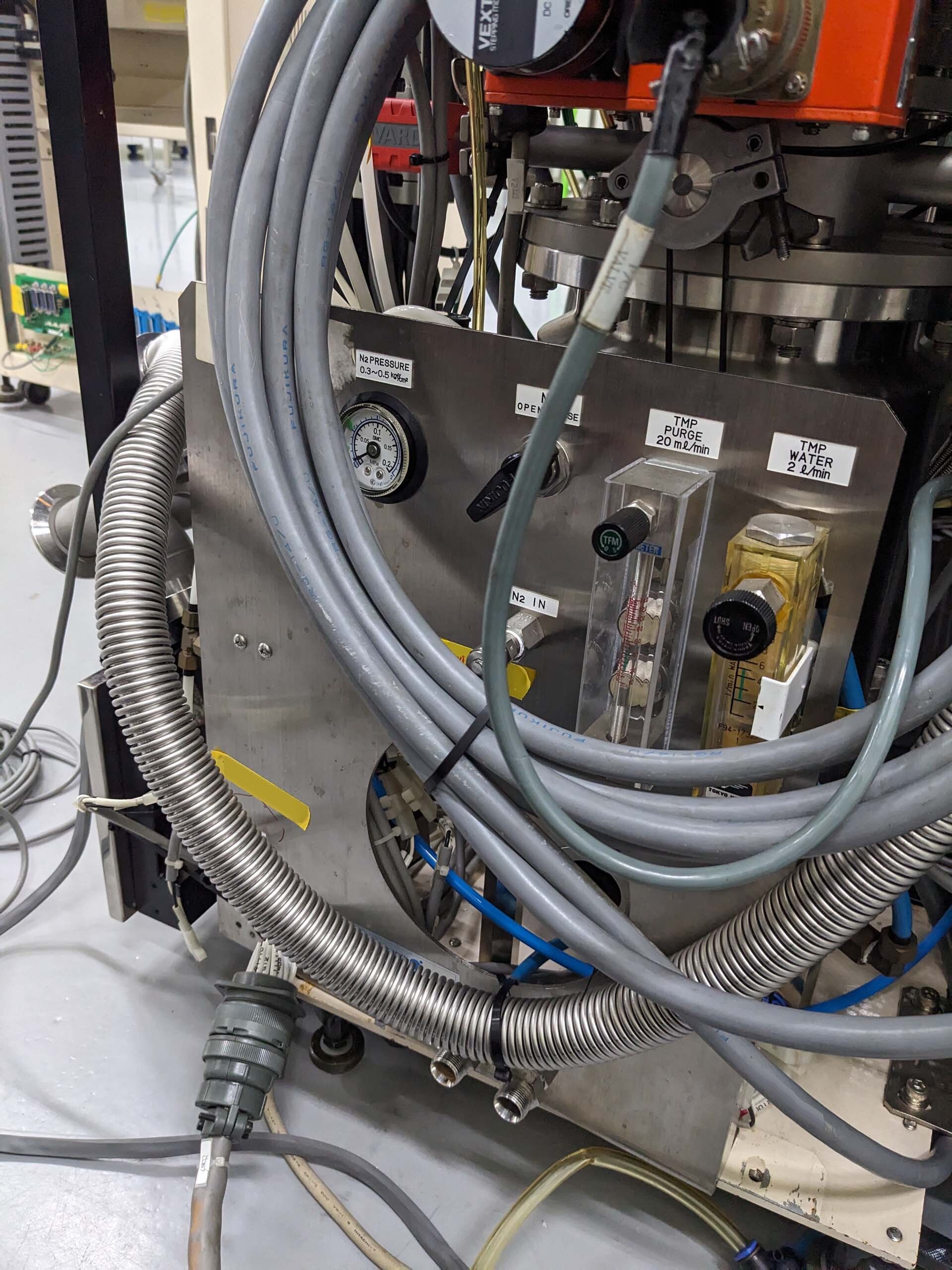

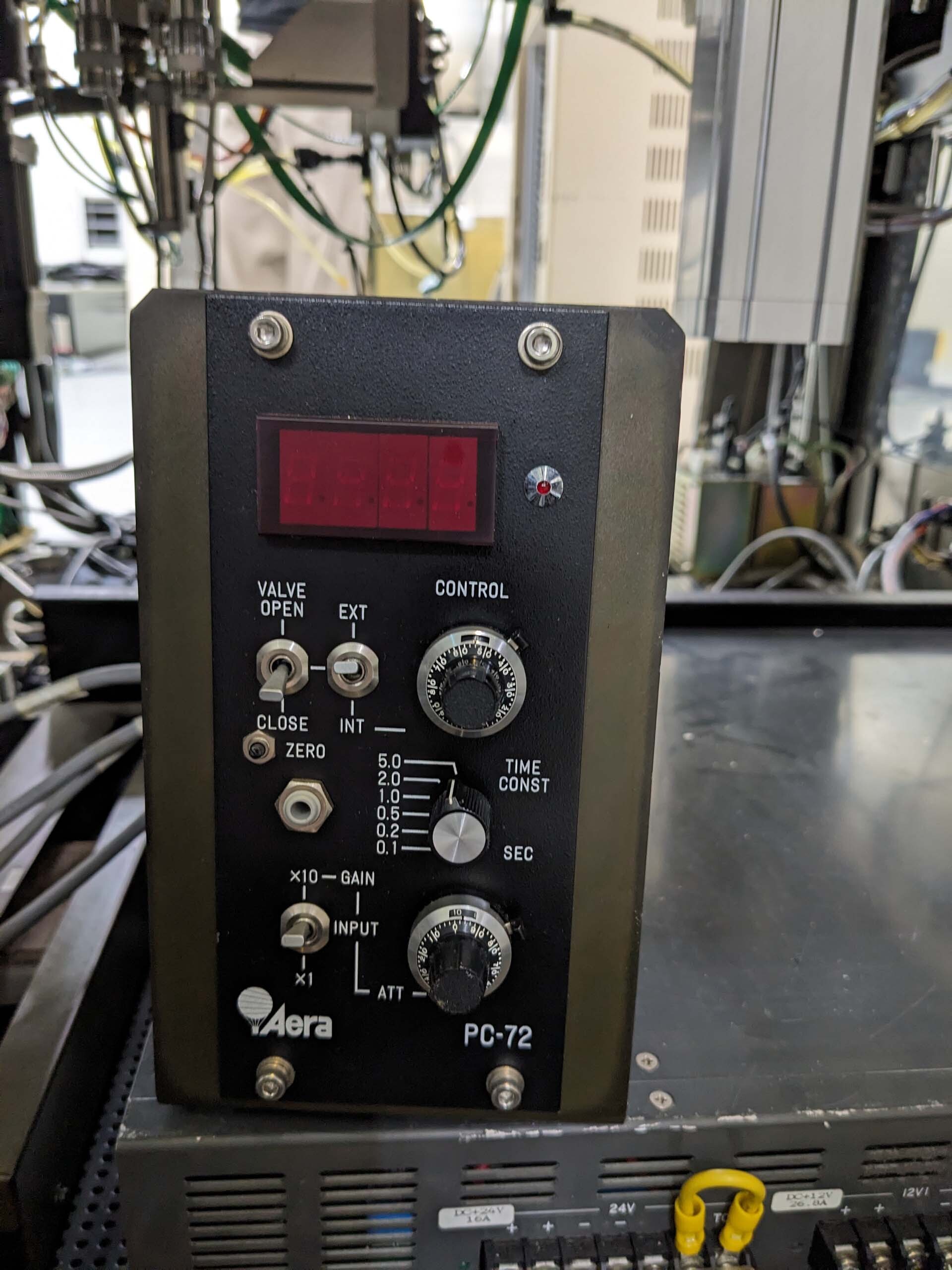

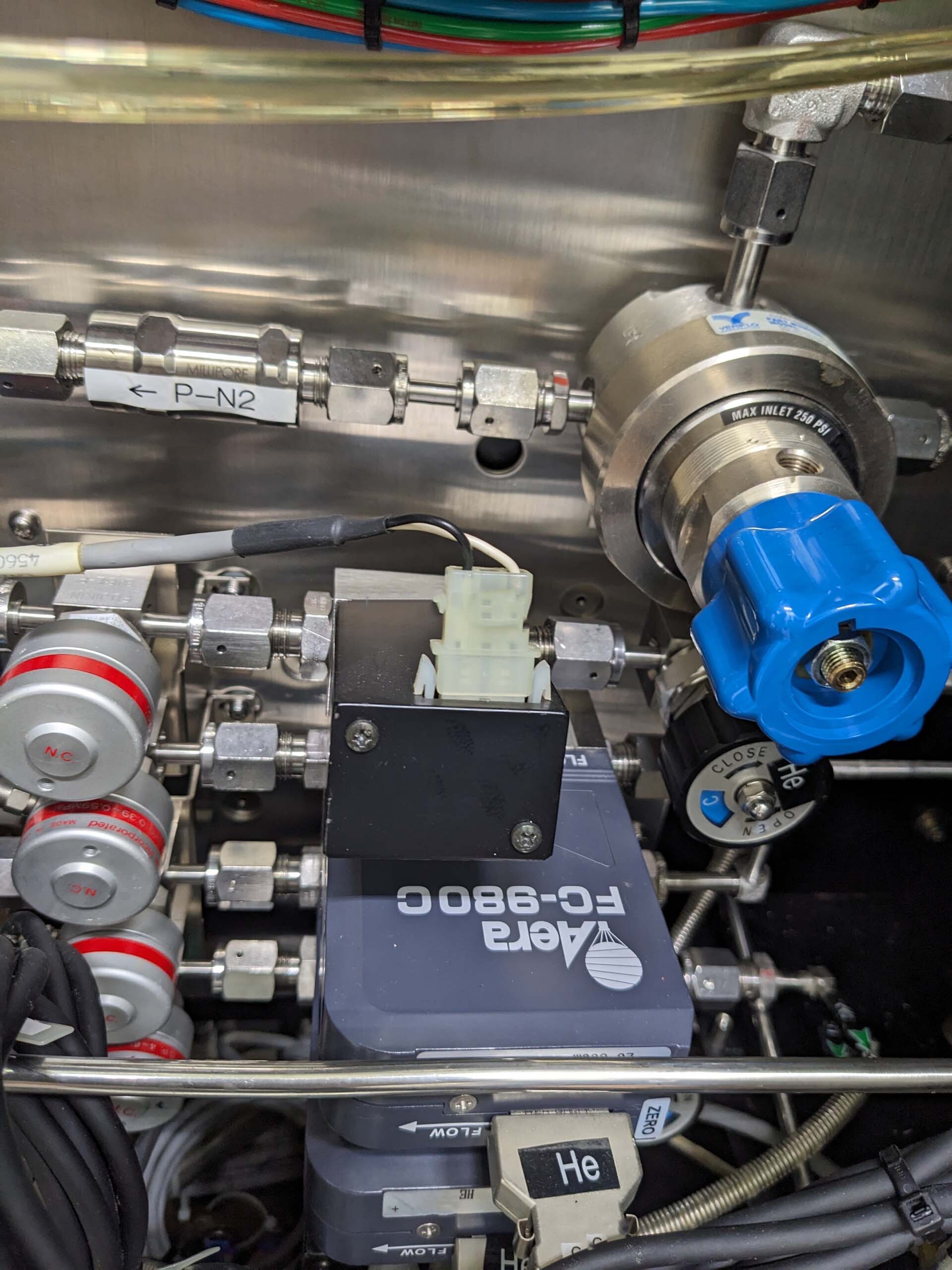

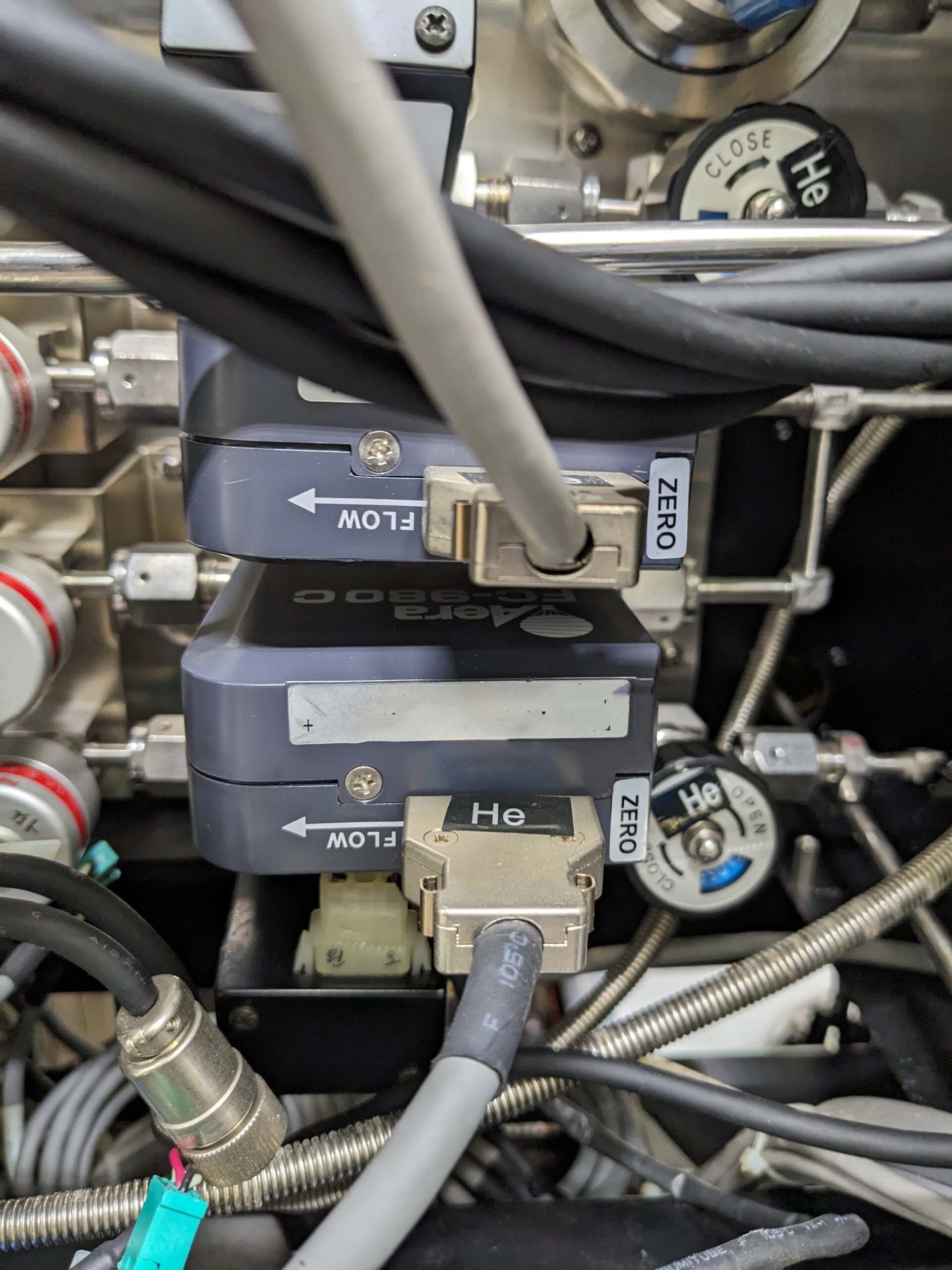

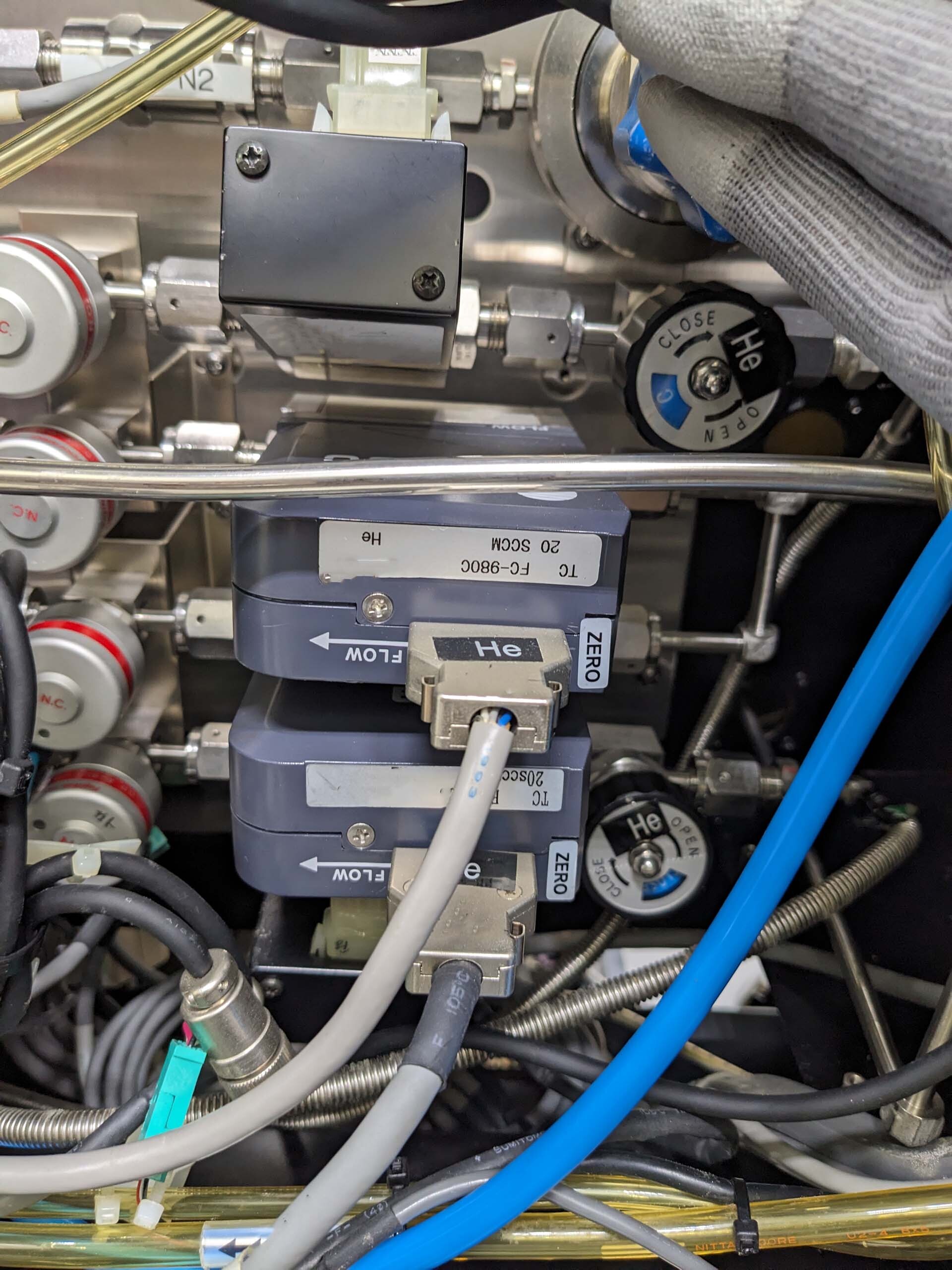

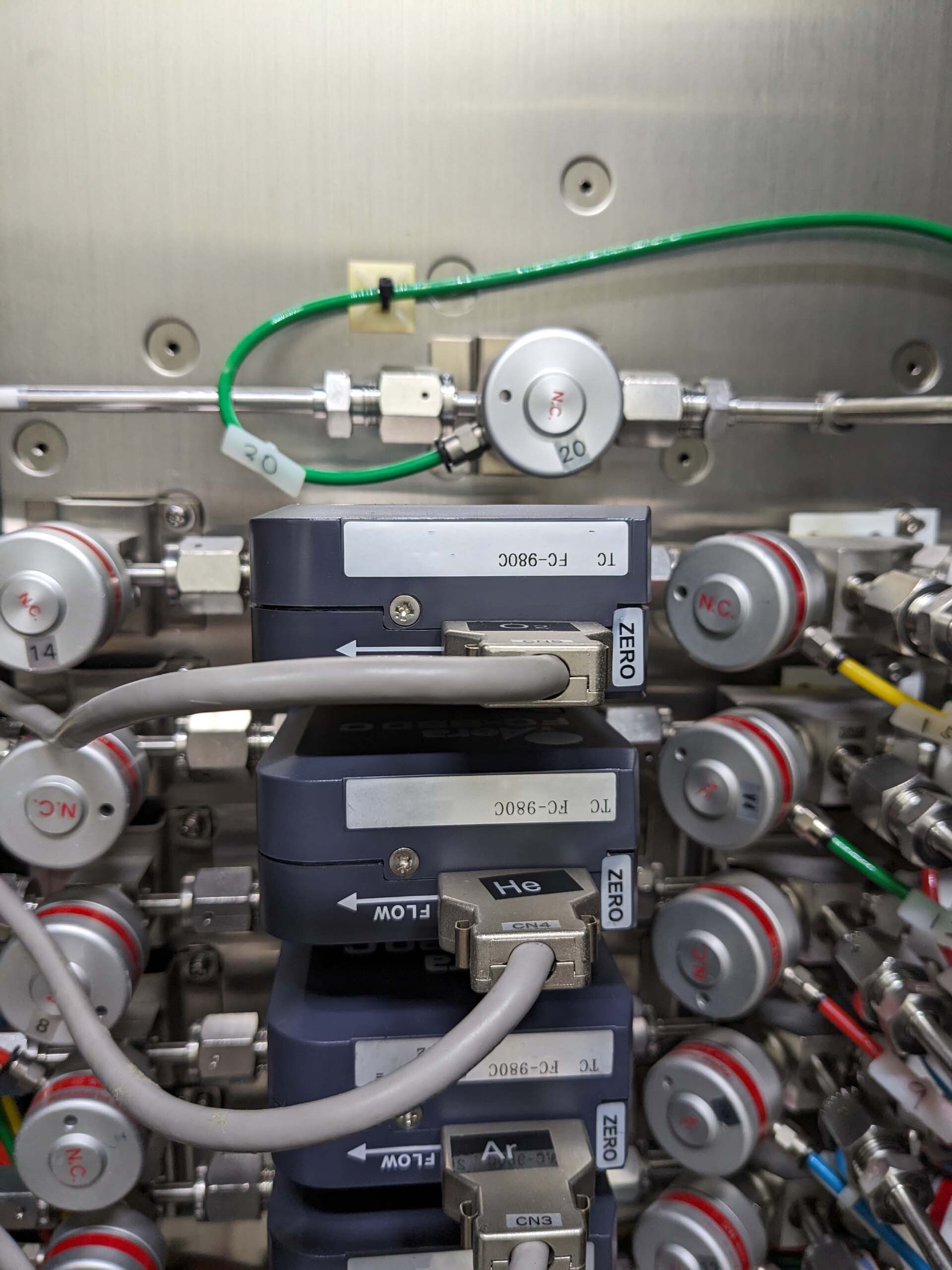

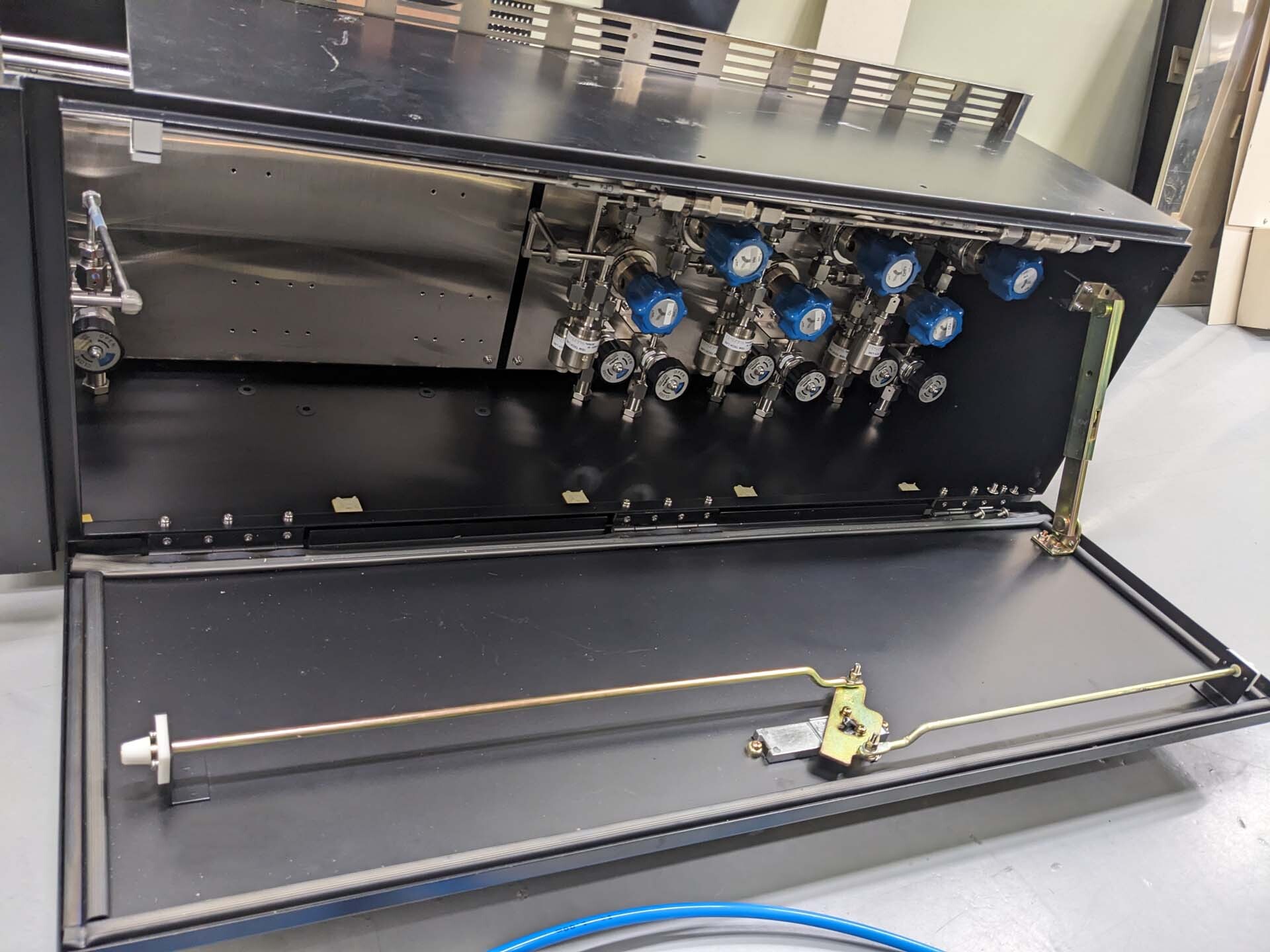

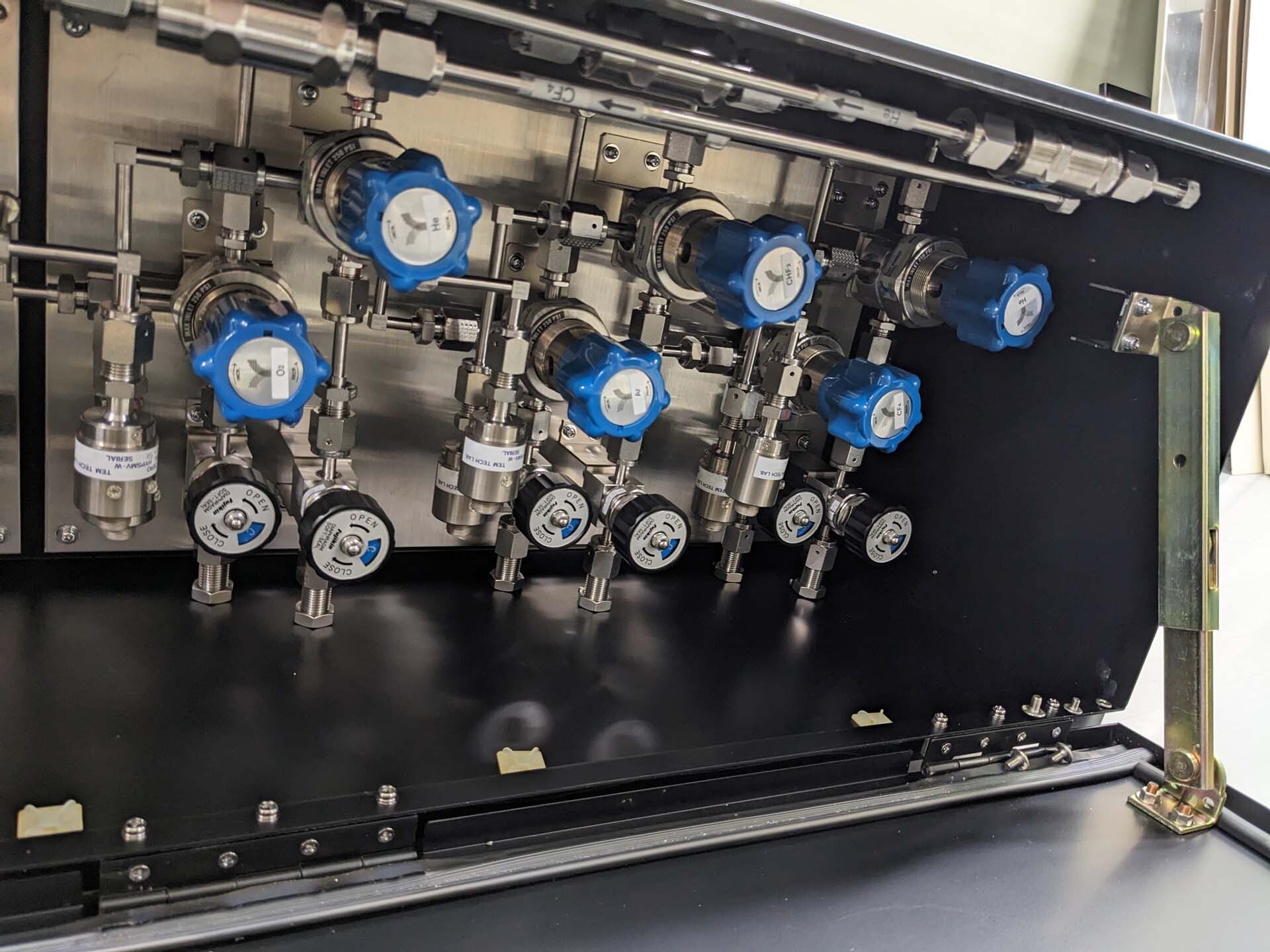

Gas boxes:

Valve / Model / Gas / Flow rate

Pressure switch / FC-980C / - / -

MFC / FC-980C / N2 / 2 SLM

MFC / FC-980C / O2 / 100 SCCM

MFC / FC-980C / HE / 1 SLM

MFC / FC-980C / AR / 2 SLM

MFC / FC-980C / CF4 / 100 SCCM

MFC / FC-980C / CHF3 / 100 SCCM

MFC / FC-980C / HE / 20 SCCM

Regulator / SQ140-50-3P / - / -

1994 vintage.

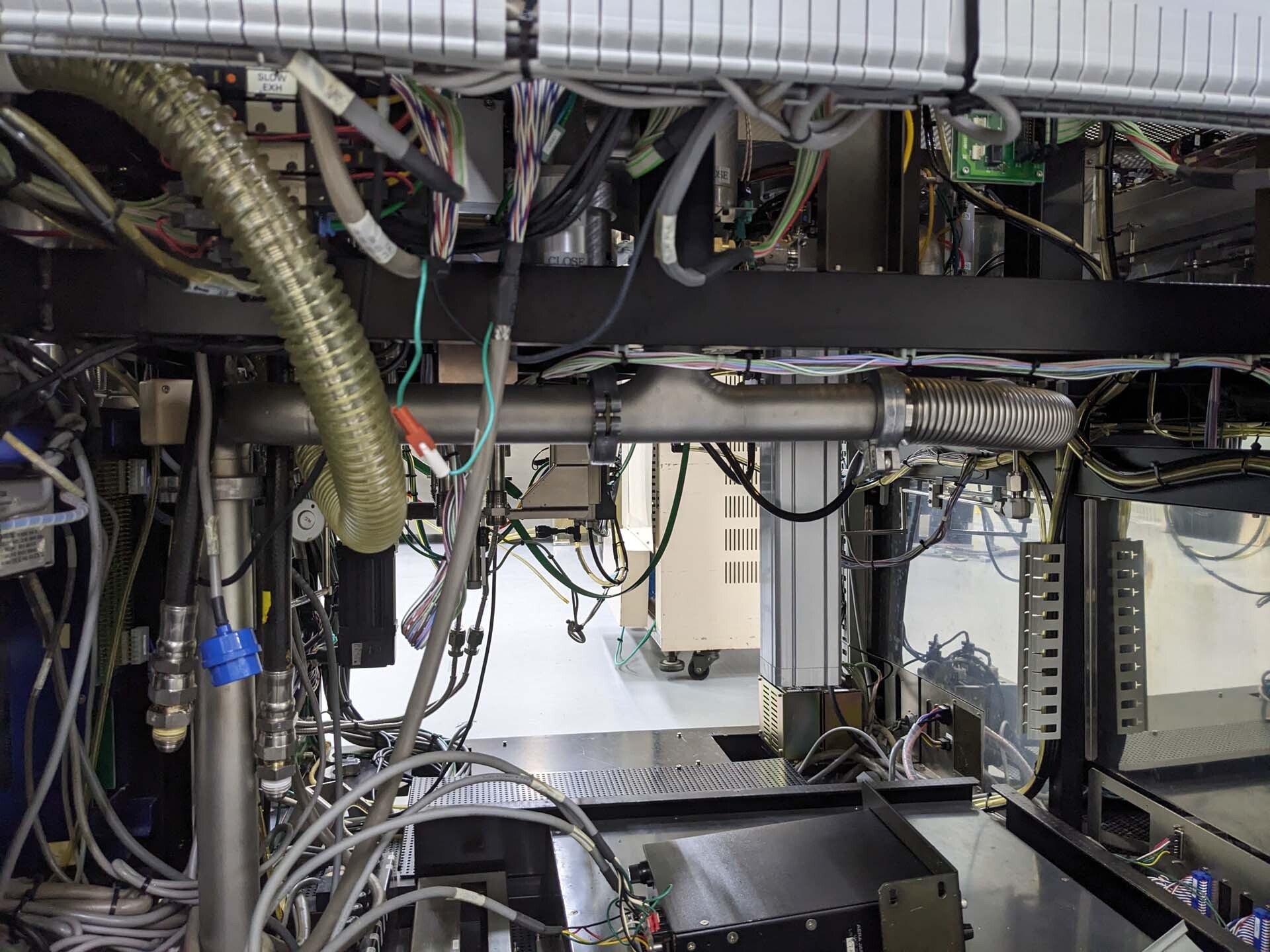

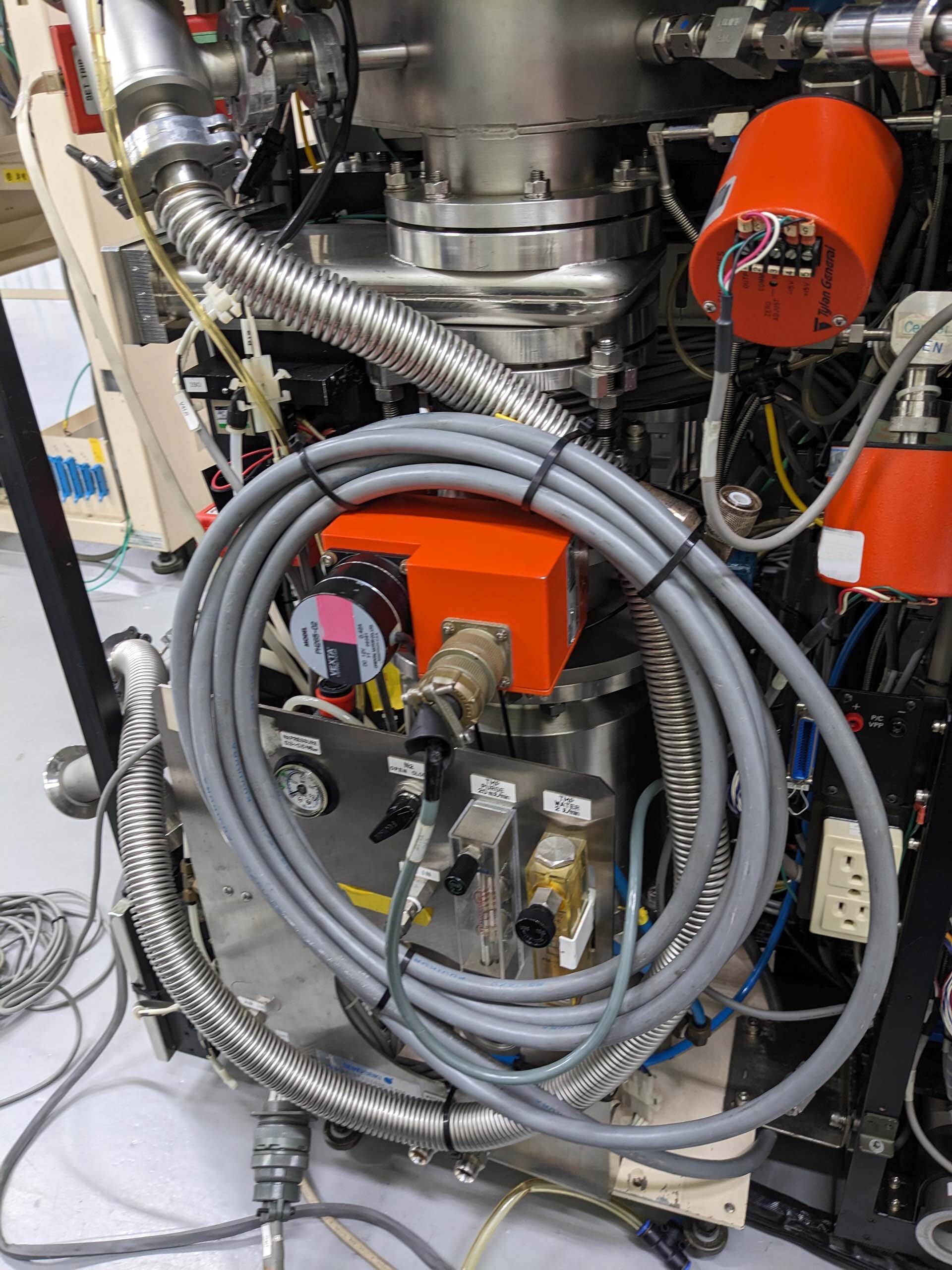

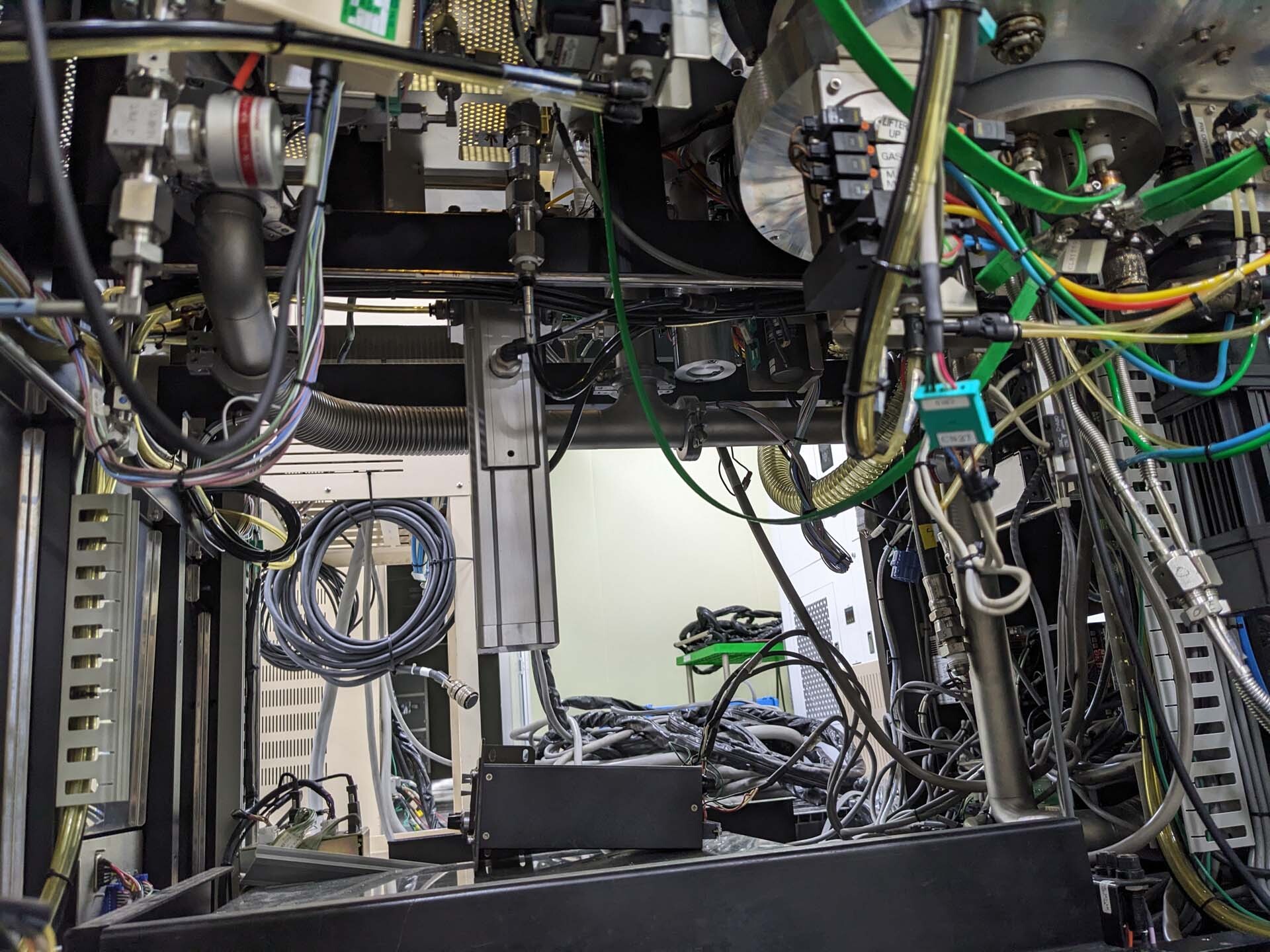

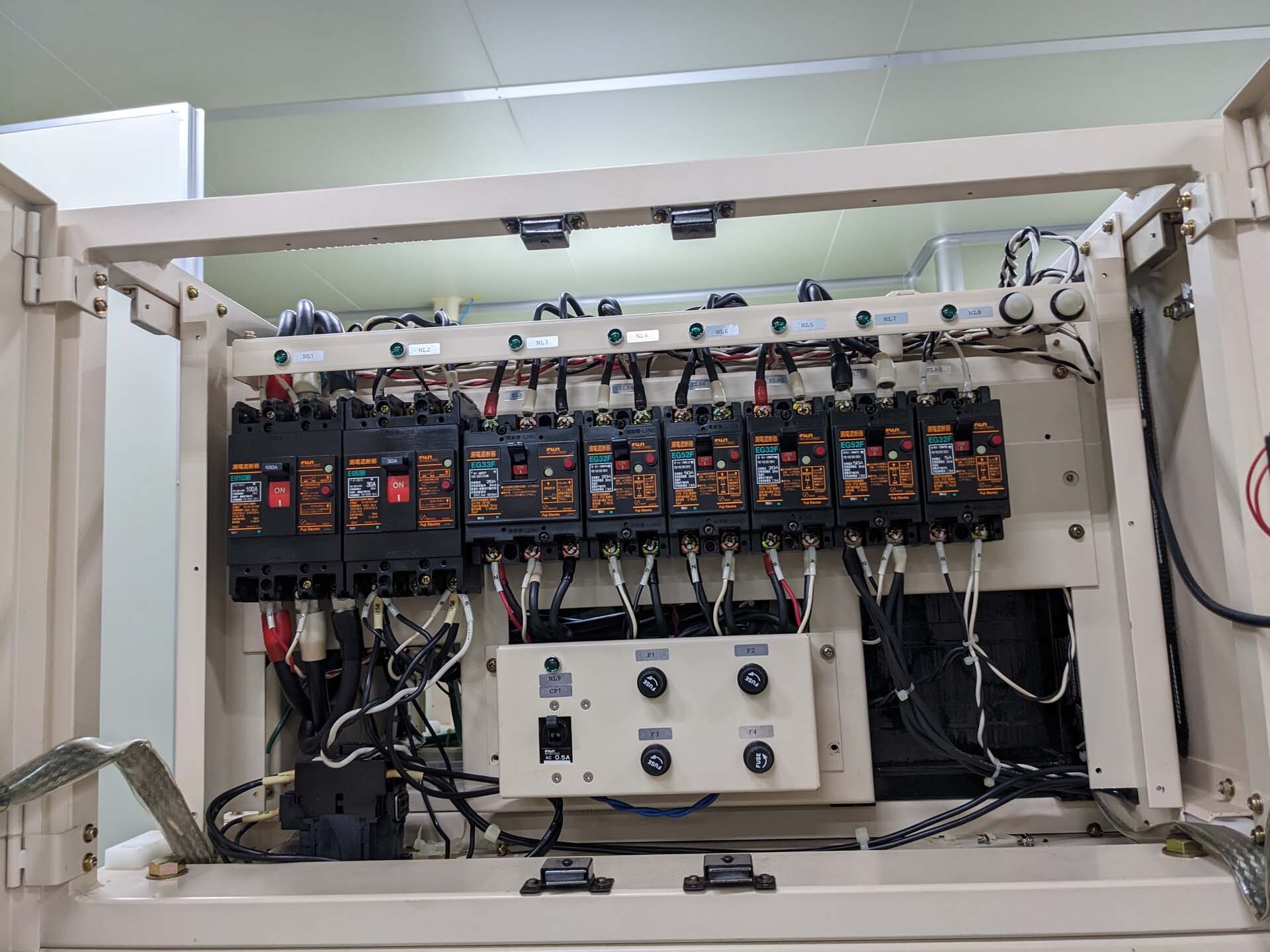

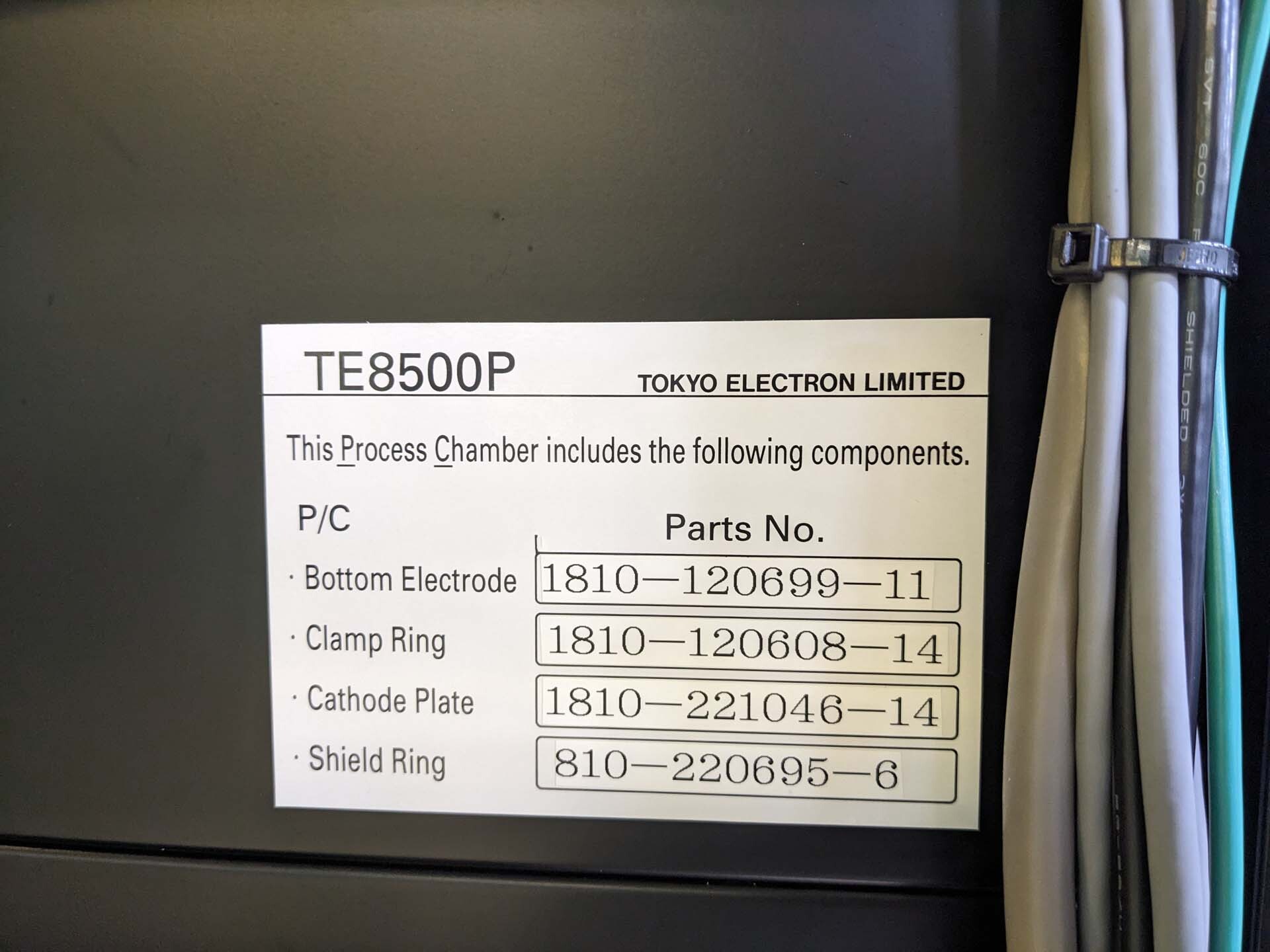

TEL / TOKYO ELECTRON TE 8500 is an etcher (or asher) used in silicon fabrication processes to selectively remove material from a substrate. This is accomplished by exposing the substrate to reactive plasma or chemical compounds engineered to alter the material's surface properties. TEL TE 8500 is capable of performing standard etch applications using multiple etch techniques, including plasma etch, reactive-ion etch (RIE), and combinations of both. TOKYO ELECTRON TE 8500's advanced wafer alignment equipment provides excellent pattern maintenance across multiple substrates, and its process controllers enable down-stream process optimization. TE 8500 has multiple pods that are used depending on process needs. Each pod contains multiple electron cyclotron resonance (ECR) etch sources, which generate the required plasma. The chamber can be configured with different ECR sources and operating parameters, thereby providing users with a wide range of process options. TEL / TOKYO ELECTRON TE 8500 also features multiple sources for reactive-ion etching (RIE). The RIE sources enable users to tailor the etch to the exact needs of their application, resulting in improved etch selectivity and controllability, as well as excellent throughput. TEL TE 8500 has a built-in process monitoring system that helps users measure and analyze etch processing. This unit allows for real-time process optimization, wherein process variables can be quickly and precisely adjusted in order to maximize yield and throughput. TOKYO ELECTRON TE 8500 also has a digital video monitoring machine that provides an unparalleled level of precision and repeatability during the etch process. The video monitor ensures that all batches of wafers have undergone the same etching conditions, eliminating variability between batches and improving reproducibility of results. TE 8500 is an effective and accurate solution for semiconductor etching applications. With its combination of advanced automation and adaptable process parameters, TEL / TOKYO ELECTRON TE 8500 is an invaluable tool for silicon fabrication processes.

There are no reviews yet