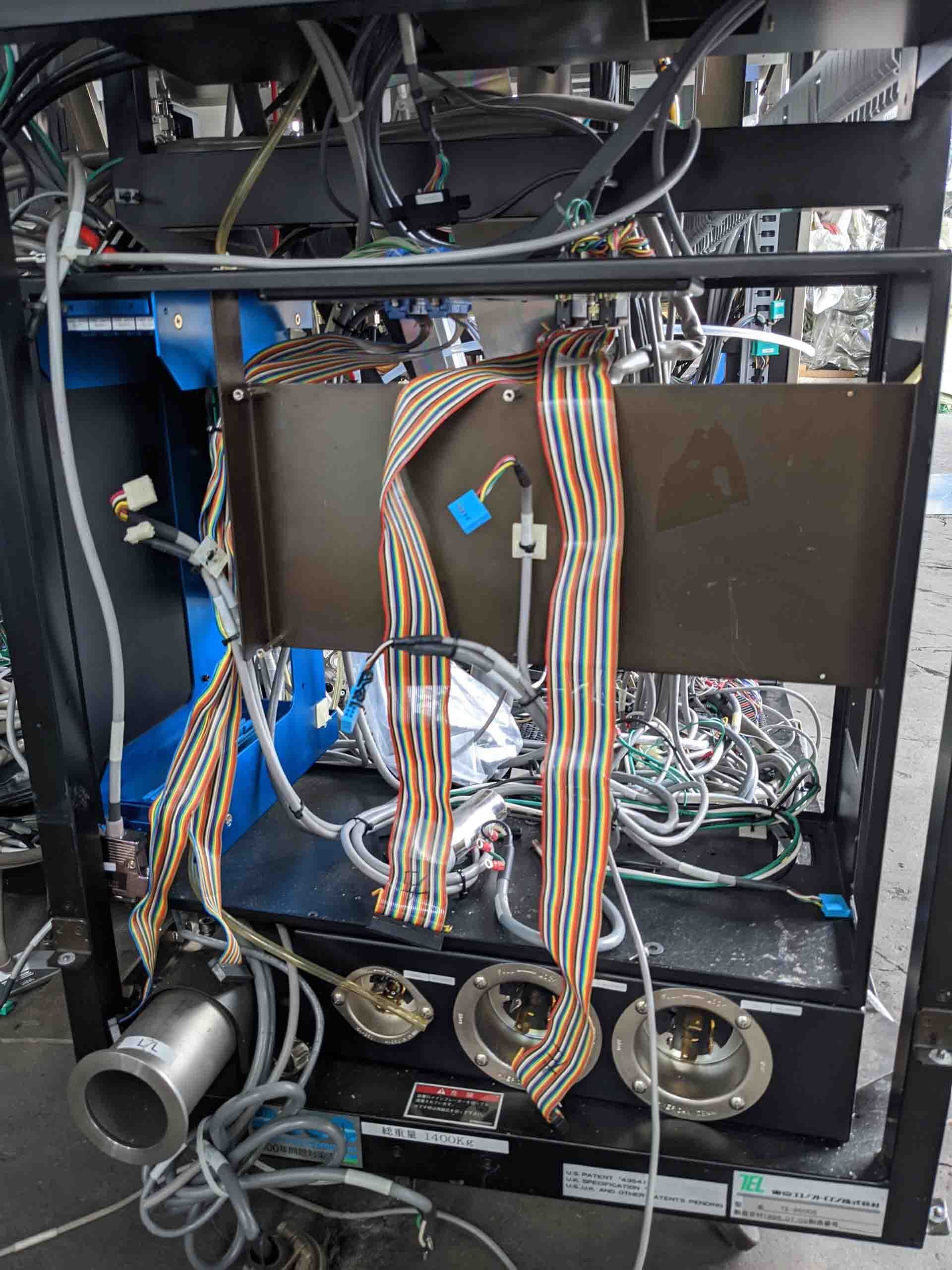

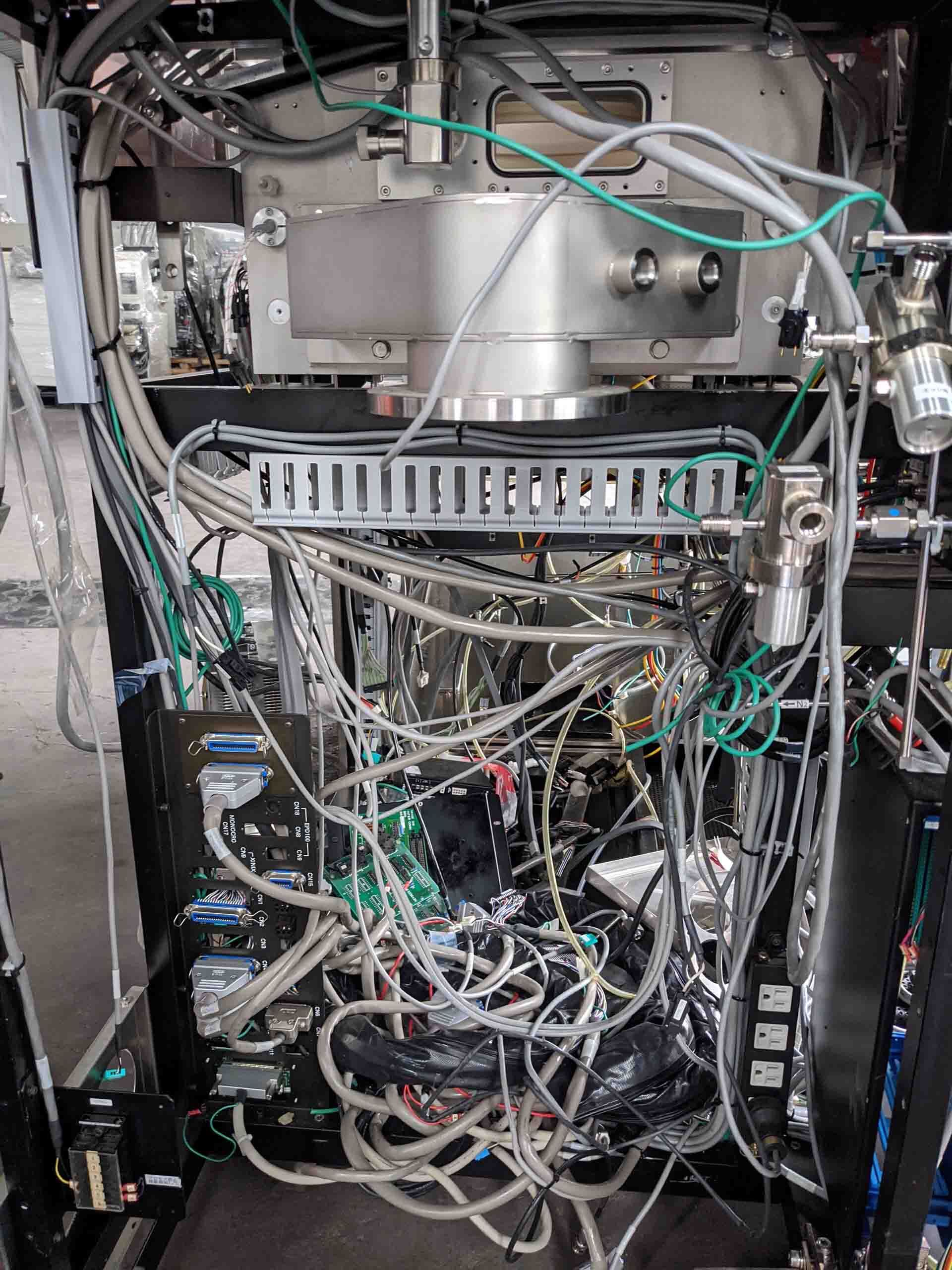

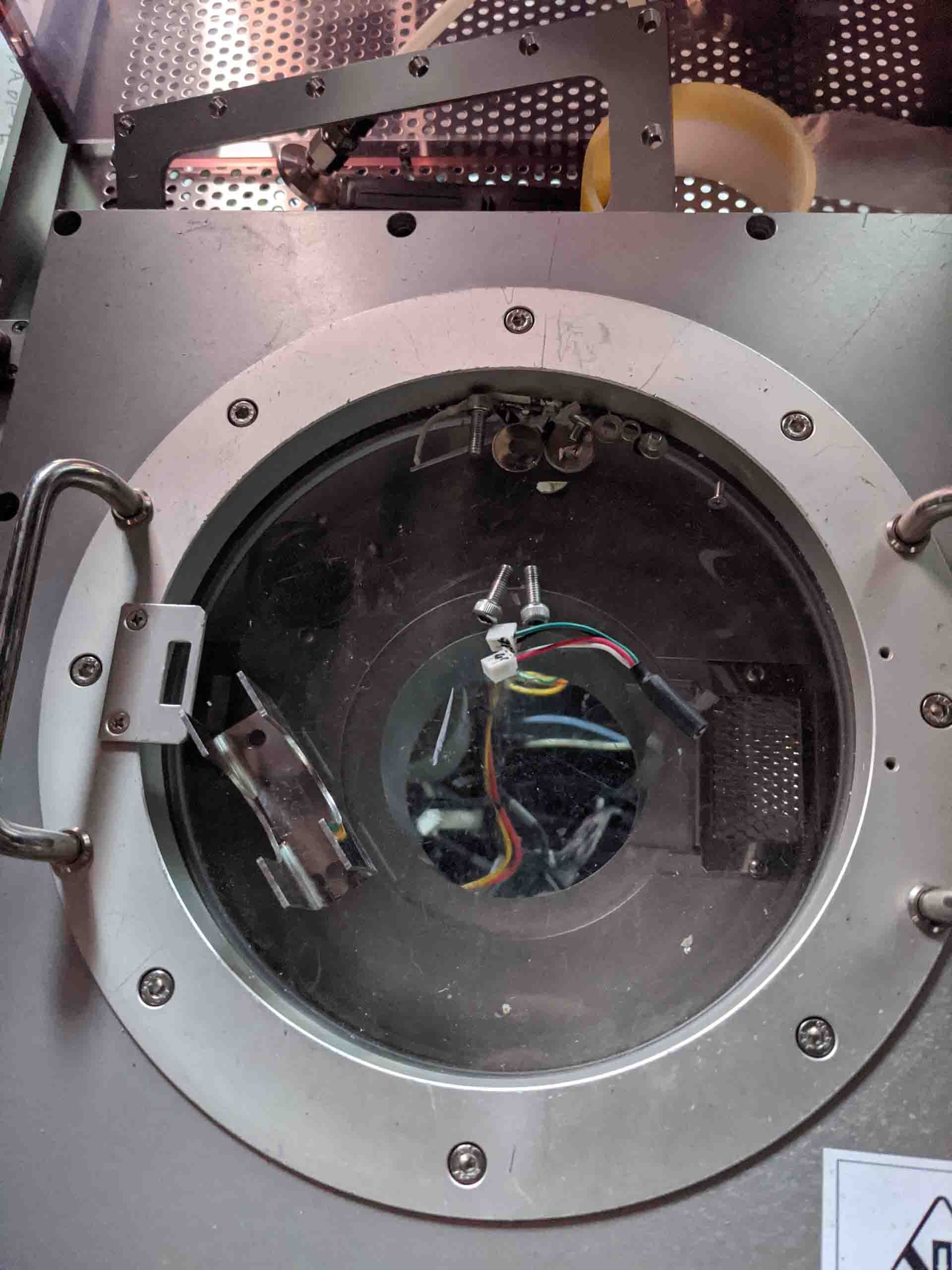

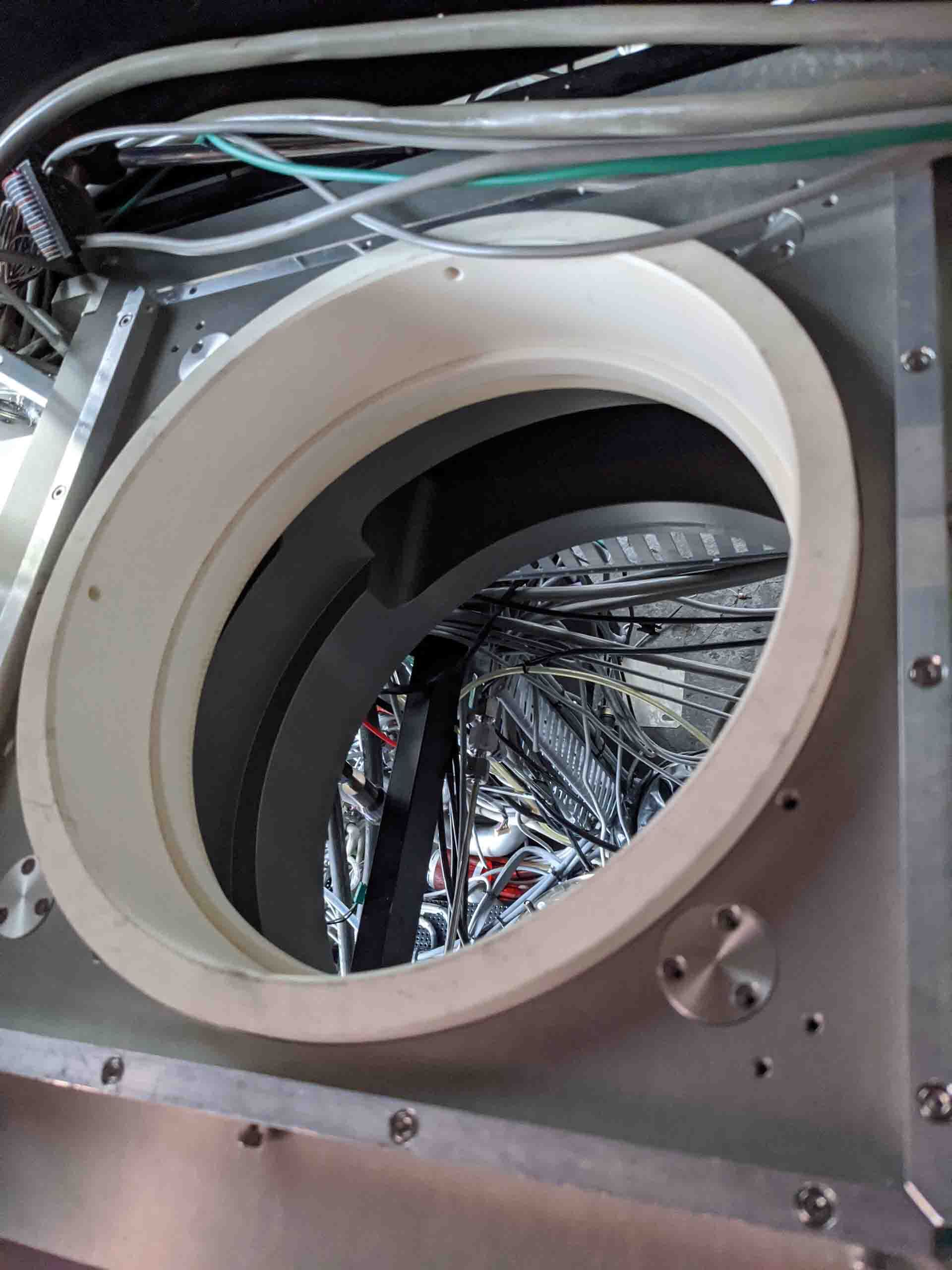

Used TEL / TOKYO ELECTRON TE 8500 #9407682 for sale

URL successfully copied!

Tap to zoom

ID: 9407682

Vintage: 1996

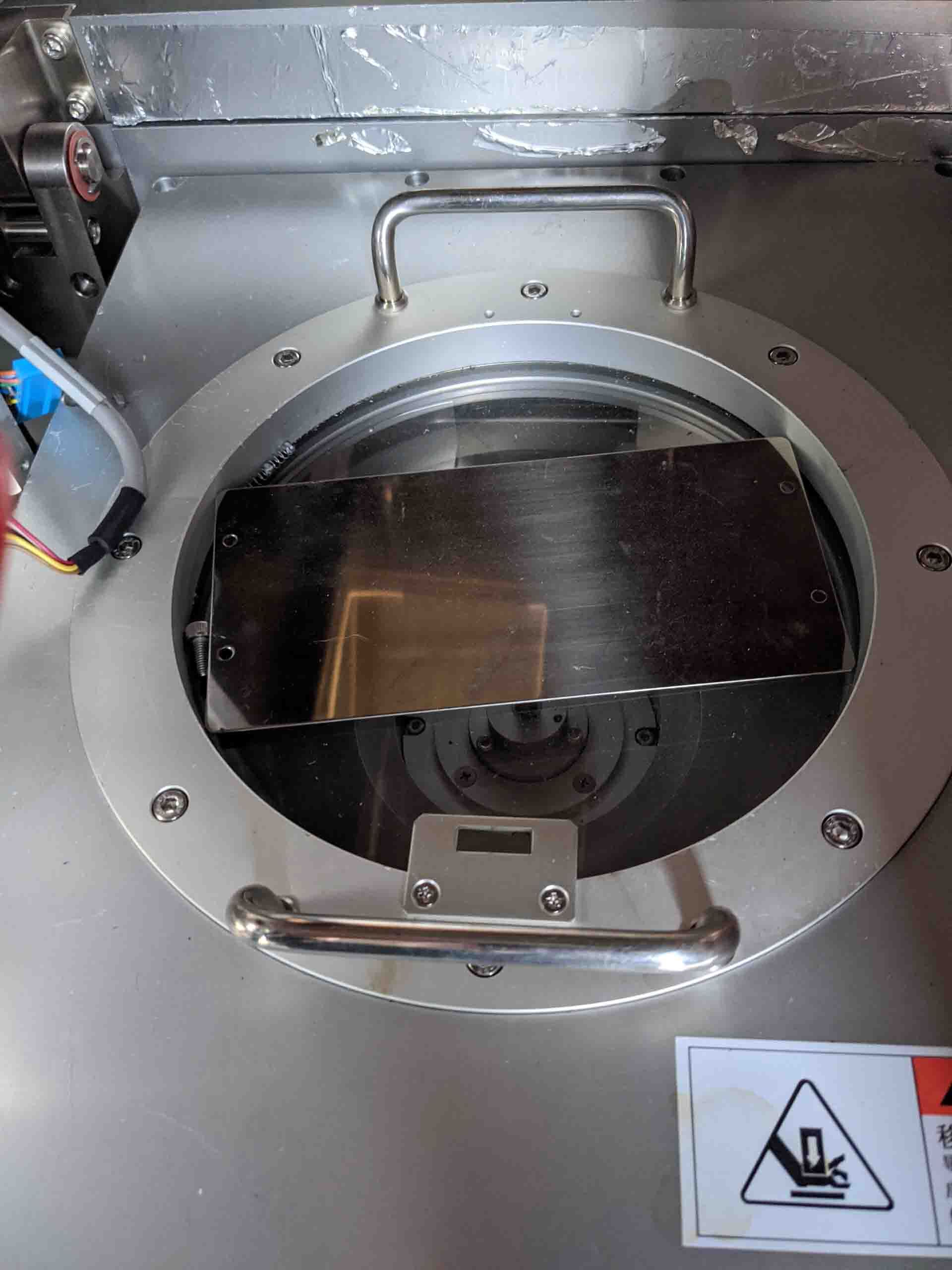

Oxide etcher

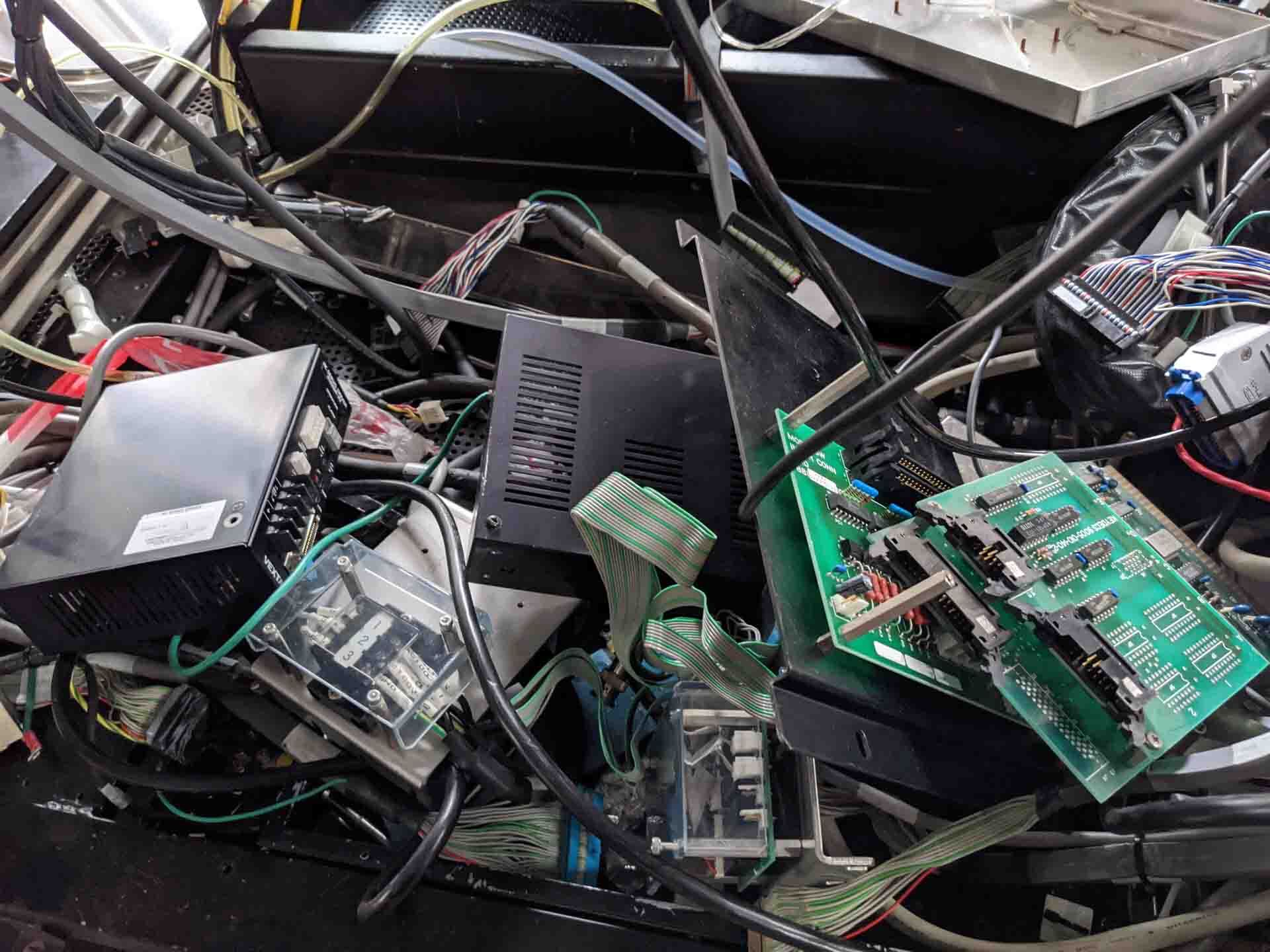

Does not include chamber and robots

1996 vintage.

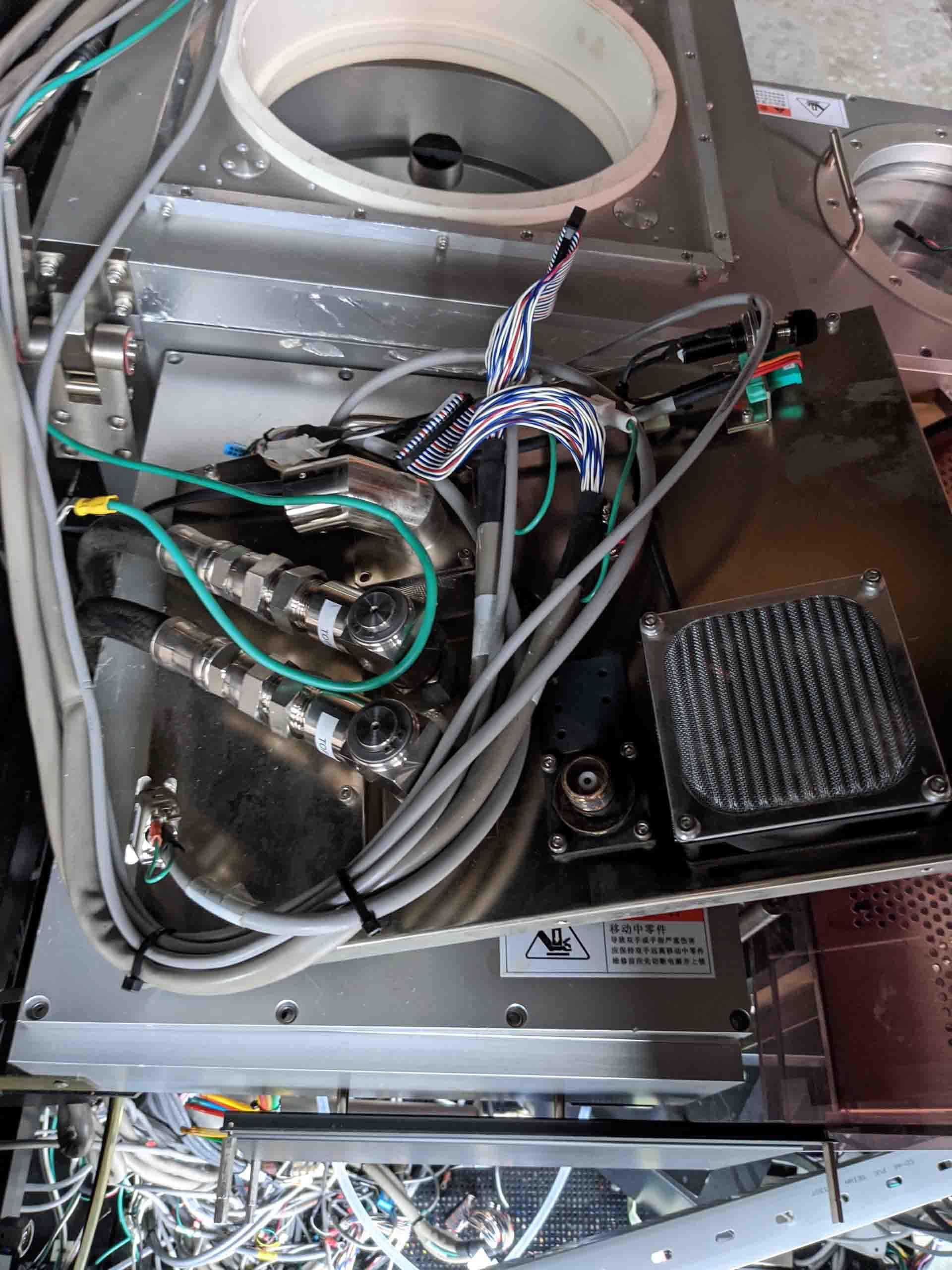

TEL / TOKYO ELECTRON TE 8500 is an advanced etching machine, offering users increased efficiency and performance in their production processes. This precise equipment offers high accuracy and repeatability during etching and ashing processes, allowing users to achieve the desired results with minimal wastage of resources. TEL TE 8500 features a precision of 0.04 microns in abrasive etching and 0.2 microns in limestone etching. This efficacy is thanks to the use of a multi-stage etching process which ensures that the desired results are achieved quickly, effectively and consistently for each production run. This accuracy also enables superior mechanical surface finishes which makes the device highly suitable for performance-critical components such as engines, car parts and artillery shells. The multi-stage etching process feature also allows users to choose the order of etching and ashing, as well as the parameters of each stage; this means that operators can program the etching cycle to suit the type of material, layer and size requirements of their components. TOKYO ELECTRON TE 8500 features highly customisable settings and material management which allows users to adjust the process to the required specifics. In terms of safety, TE 8500 is equipped with an automated safety shutoff feature which will interrupt production in the event of any unsafe conditions. This is particularly useful in organisations that utilise etching/ashing in their production cycle, as it ensures that safety is adhered to at all times. Finally, the device also includes a range of automated maintenance options which will ensure that the equipment is optimised and running smoothly at all times. This includes regular equipment checks and servicing, as well as the ability to edge-select, trim, cap and dress the materials used in production. Overall, TEL / TOKYO ELECTRON TE 8500 is an advanced etching machine that offers users high accuracy, repeatability and customisation for their production processes. Its range of automated maintenance and safety features make it suitable for commercial and industrial applications, while its high precision ensures superior results for each production run.

There are no reviews yet