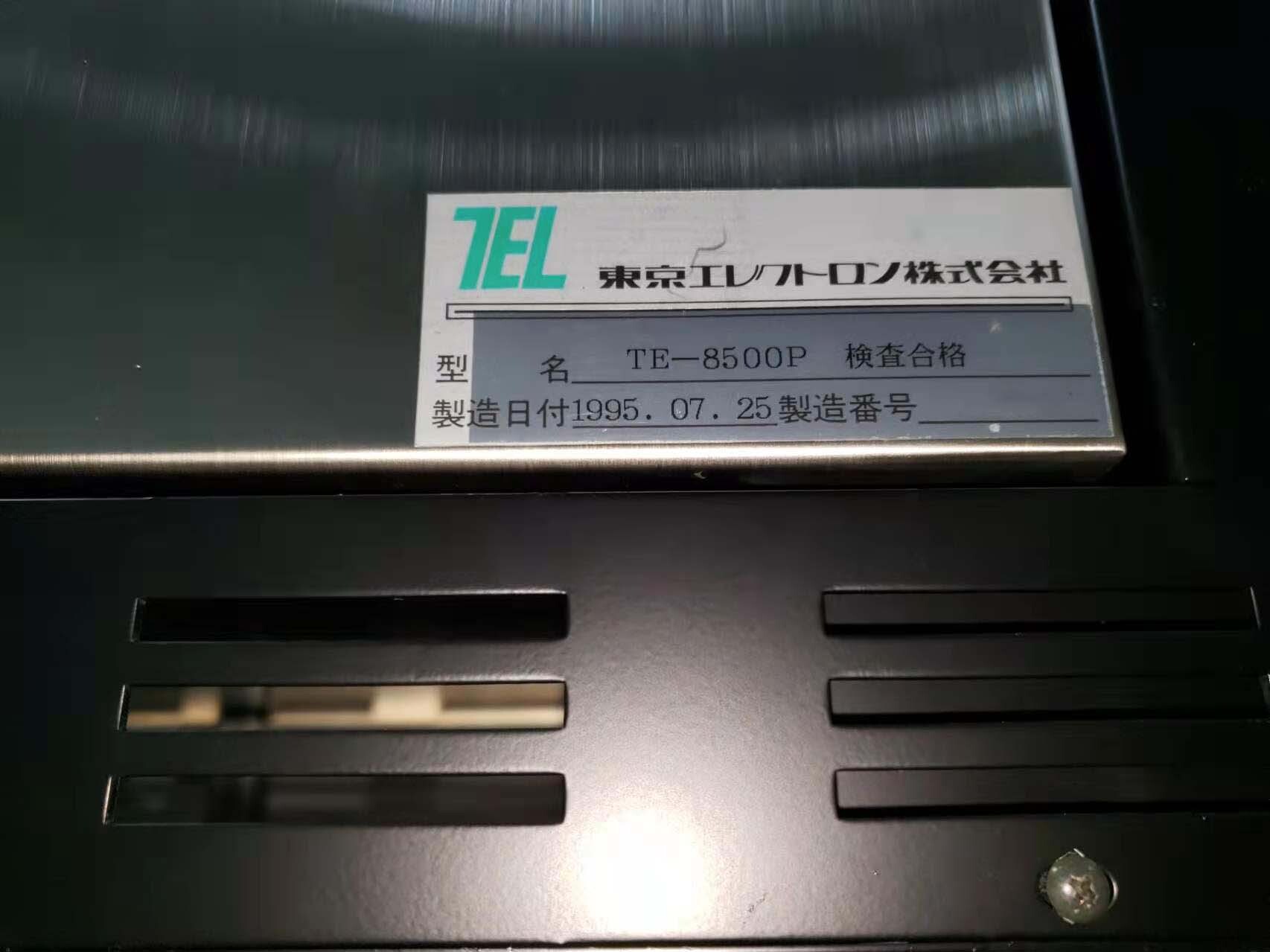

Used TEL / TOKYO ELECTRON TE 8500P #293585750 for sale

URL successfully copied!

Tap to zoom

ID: 293585750

Wafer Size: 8"

Vintage: 1995

Dry etcher, 8"

Process: Oxidized film dry

Non-SMIF Type

AC Rack

EBARA A30W Dry pump

Pump control rack

AERA FC-720AC MFC

Gas: CHF3, CF4, O2, Ar, O2, CO

Back pressure: He

Treatment chamber: (3) Gases

Chiller

Power cable

Chiller cable

Power supply: AC 200V, 50/60 Hz, 3-Phase.

1995 vintage.

TEL / TOKYO ELECTRON TE 8500P is a highly advanced etcher / asher equipment that has been designed to meet the needs of a range of critical micro-machining applications. The system is equipped with full-featured process control and a wide range of sophisticated hardware and software options. The unit can be customized to meet specific customer requirements. TEL TE 8500 P is a fully integrated device designed for high etch rate, tight process control, and efficient handling of a variety of process steps including etching, ashing and stripping applications. The machine has a wide range of customizable options that allow users to tailor it to their specific needs. TOKYO ELECTRON TE-8500 P is equipped with a powerful, high-speed micro-machining tool. The asset is capable of executing the most complex etching, ashing and stripping operations in a single process step. The model is equipped with two independent, full-featured imager channels providing high resolution, real-time imaging and imaging analysis of micro-machined features. TEL / TOKYO ELECTRON TE-8500 P also features an interactive graphical user interface, allowing users to access and control the equipment with intuitive and powerful features. The system has various process control features including automated recipe storage, process parameter optimization, and adjustment of recipes based on real-time process feedback. TEL TE 8500P's hardware is designed to be suitably robust for precision micromachining. The unit comprises of a number of components including the mainframe, operator console, and the power supply, each of which is designed for maximum performance and reliability. High-speed cooling is also included for increased safety and accuracy of operations. Finally, TE-8500 P has an extensive suite of software, services and support available from the manufacturer. This makes it easy for customers to take advantage of advanced machine capabilities, include new development and engineering services, and get personalized assistance with the tool's operations, allowing users to maximize the results of their micro-machining activities.

There are no reviews yet