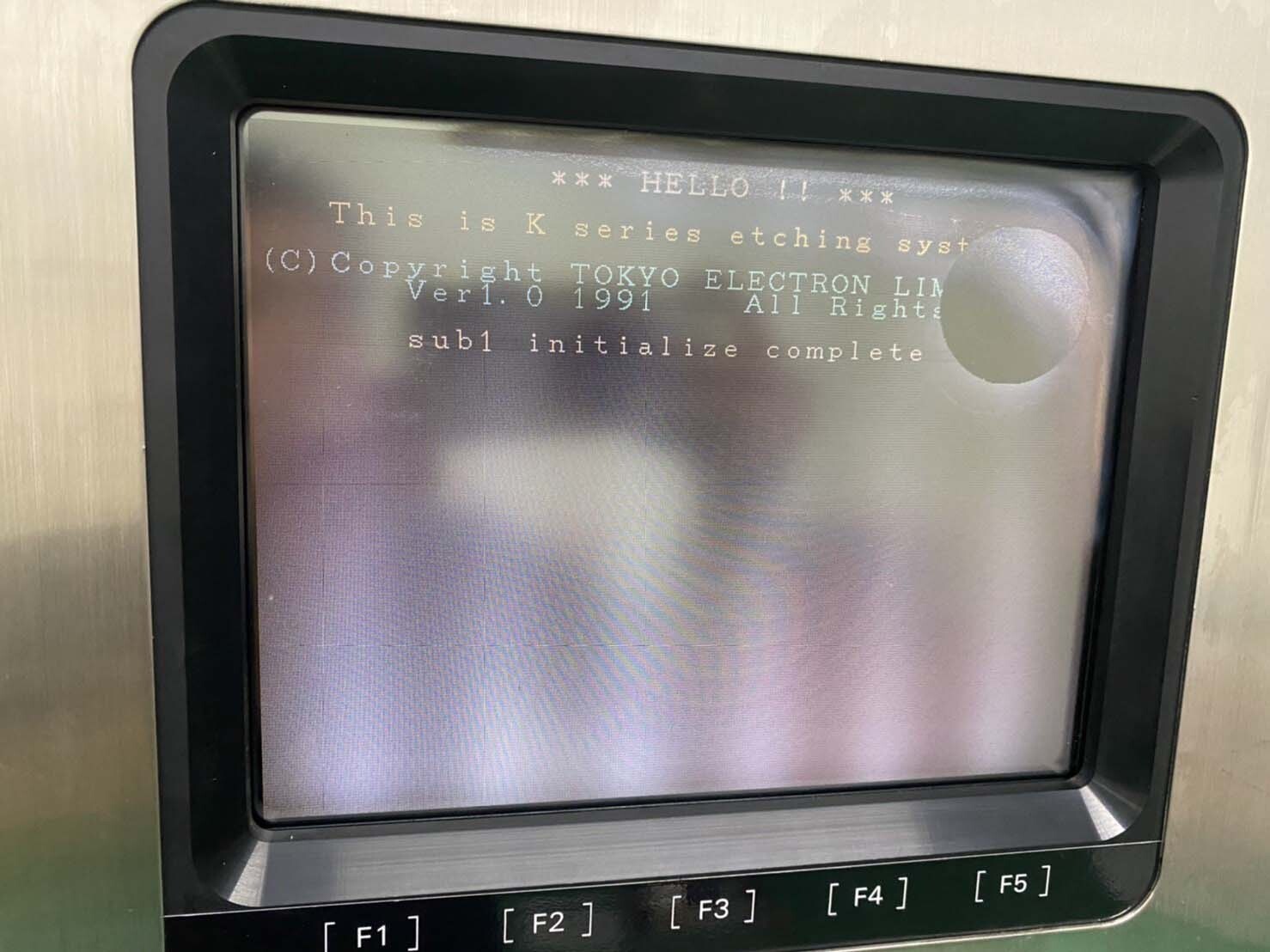

Used TEL / TOKYO ELECTRON TE 8500P #293668446 for sale

URL successfully copied!

Tap to zoom

ID: 293668446

Wafer Size: 6"

Vintage: 1996

Dry etcher, 6"

Process: Etch oxide

Main body

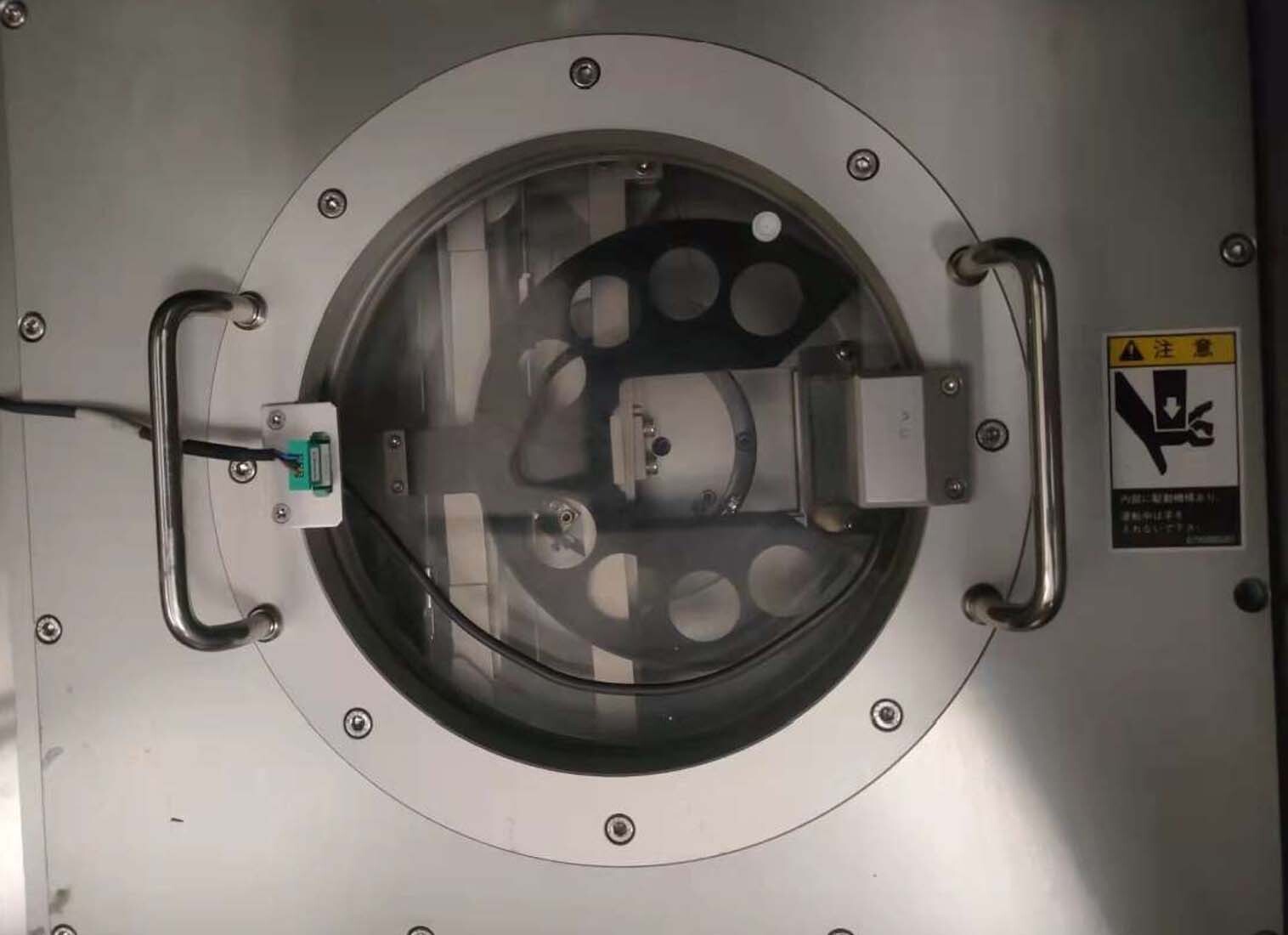

Load lock

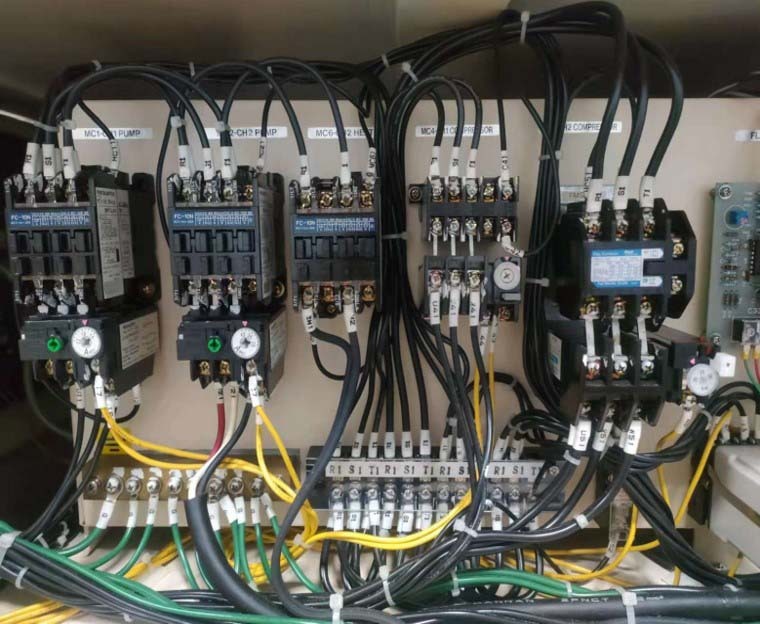

Facilities connections

Dry pump

Gas panel

Chamber

Endpoint monitor

Power supply: 208VAC, 50 / 60 Hz

1996 vintage.

TEL / TOKYO ELECTRON TE 8500P etcher/asher is a state of the art lithography equipment used in the manufacture of integrated circuits, microelectronic products and flat panel displays. It utilizes Carbon dioxide (CO2) lasers as the primary source of energy to create micro-structures in silicon wafers. The CO2 laser beam is generated quickly and accurately, with a pulse width of less than a nanosecond and a fluence of up to 1.8 J/cm2. The laser beam can be adjusted for size, shape and intensity to generate the desired micro-structure. The laser beam is directed and controlled with high precision via the use of two integrated galvanometer mirrors and two zoom lenses. TEL TE 8500 P etcher/asher also features a sophisticated pattern recognition system. This unit utilizes an algorithm for recognizing patterns in incoming images and adjusting the laser beam accordingly. This ensures that the targeted pattern is accurately reproduced in the wafer. TOKYO ELECTRON TE-8500 P offers users a wide range of processes, from dry etching to chemical vapor deposition. It can be used with a variety of substrates, including silicon, sapphire and germanium. It also offers a range of materials optimized processes, such as wet etching, dry etching, rapid thermal annealing and single-wafer liftoff. In addition, the machine is capable of identifying the optimal range of levels and control parameters for each particular process. This ensures that production yields are maximized and maintained, while minimization of errors and defects is achieved. TOKYO ELECTRON TE 8500 P is also compatible with numerous robotics systems, allowing manufacturers to use automation for production. The etcher/asher is equipped with a wide range of maintenance and fault-monitoring systems, which enable it to be operated continuously with a high degree of success. TE 8500P is an advanced etcher/asher tool which utilises a powerful CO2 laser to create precise micro-structures in substrates. It features sophisticated pattern recognition and optimal control parameters, making it ideal for the manufacture of small, intricate components. It is also compatible with a number of robotics systems, allowing for automated production. In addition, its numerous fault monitoring systems ensure reliable, continuous operation.

There are no reviews yet