Used TEL / TOKYO ELECTRON TE 8500S #293608636 for sale

URL successfully copied!

Tap to zoom

ID: 293608636

Vintage: 1996

Oxide etcher

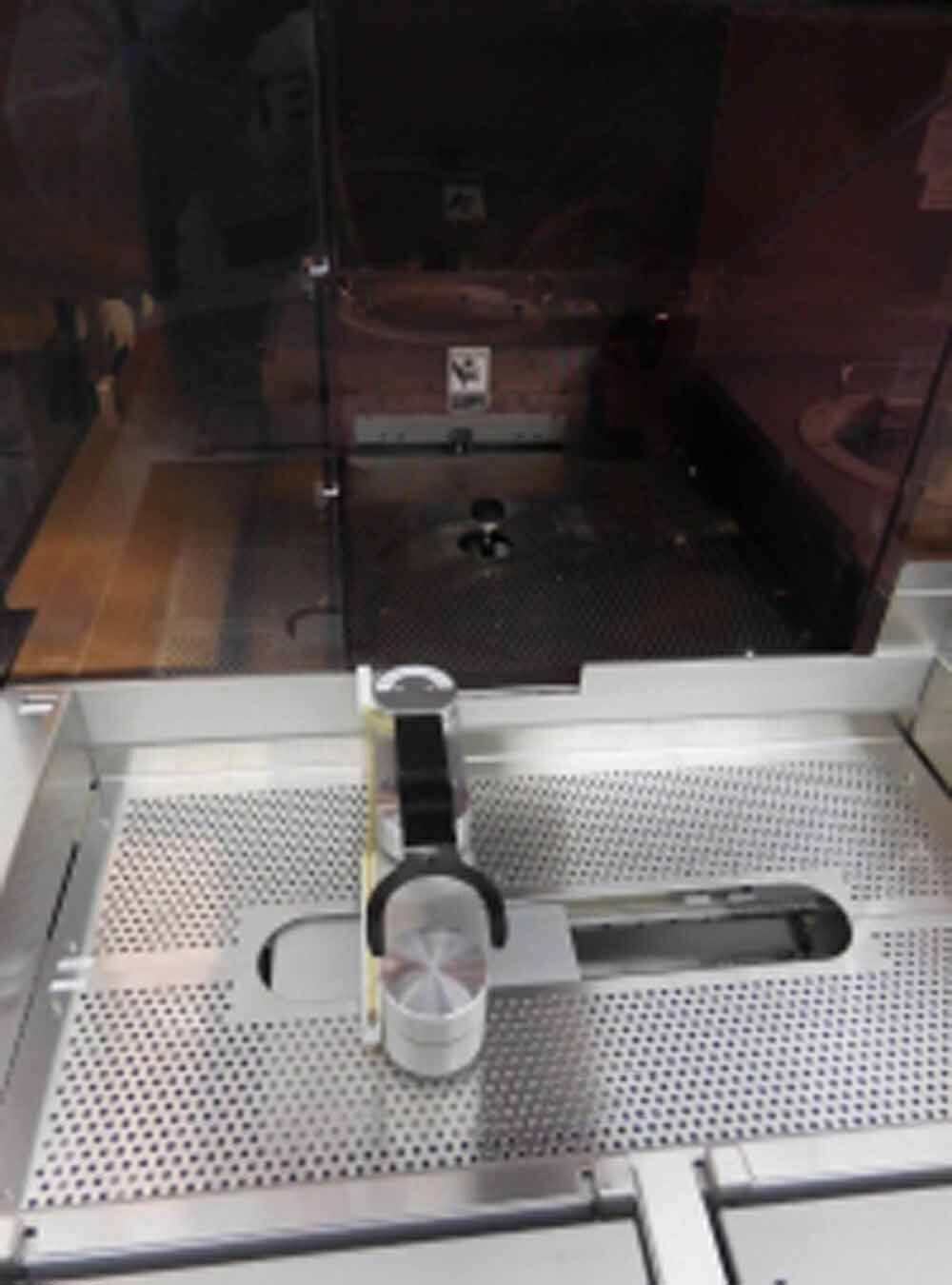

Wafer type: Flat

Chuck type 1: Polymide

Chuck type 2: ESC

Cassette, 6"

Monitor type: LCD

Signal tower: PATLITE SLF-V (R / Y / G / B)

Wafer transfer module:

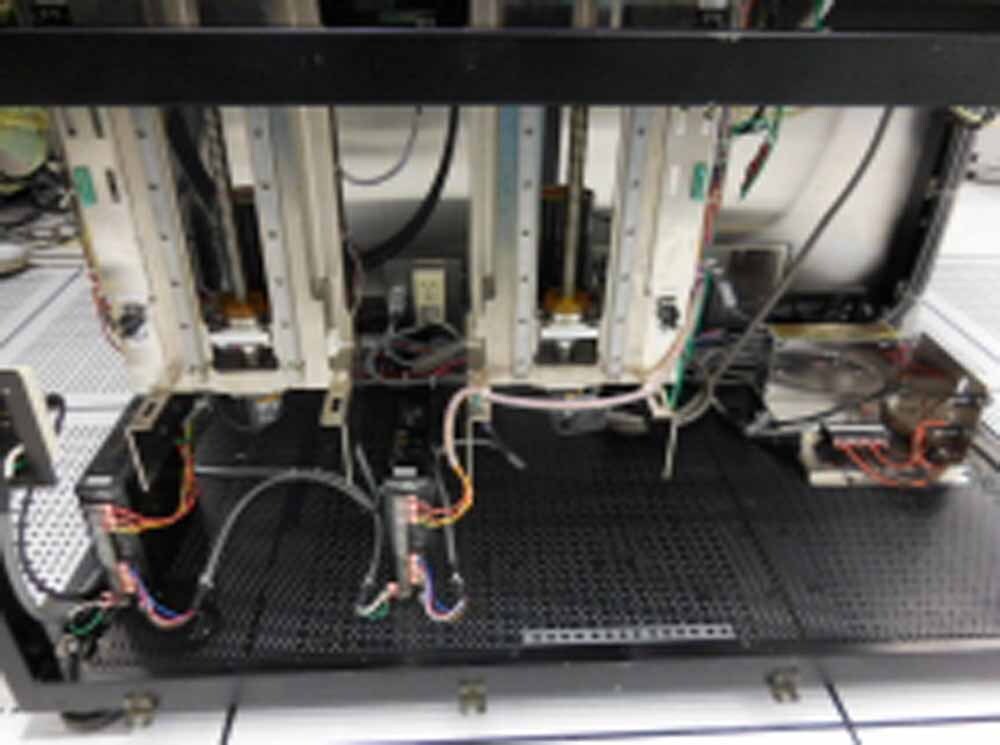

Transfer robot: Load lock 1, 2, 3 / 6" or 8"

Transfer robot motor: R-Motor, E-motor (L/L 1,2,3)

Transfer robot driver: R-Driver, E-driver (L/L 1,2,3)

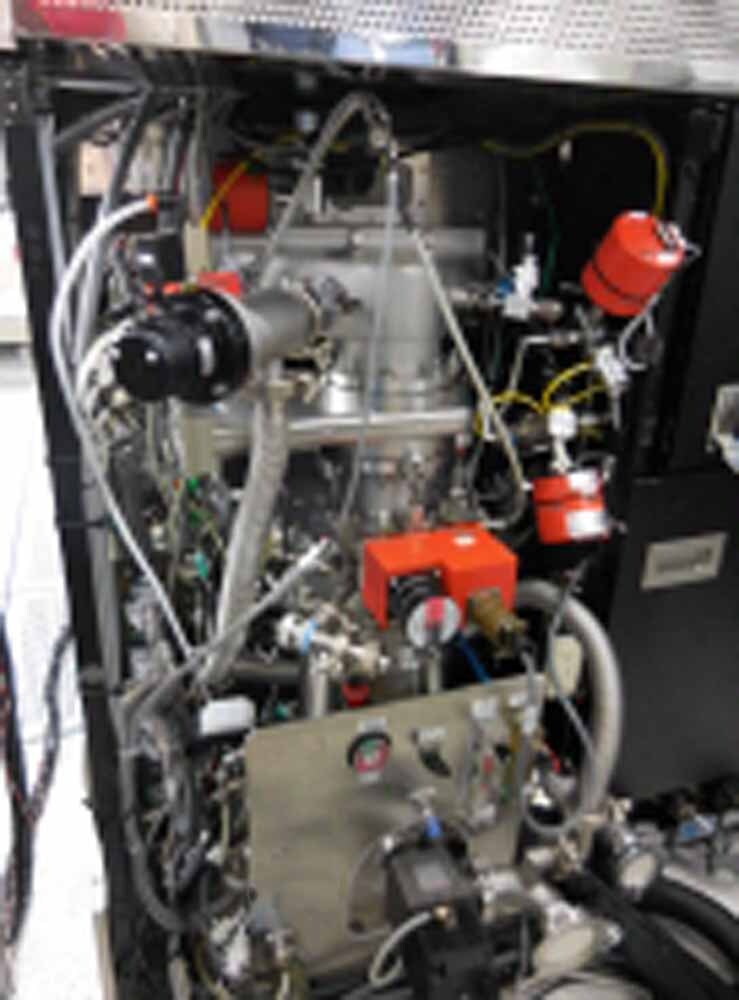

Process module 1:

APC Valve: TYLAN MDV-108

APC Heater and heater controller: Heater type

DAIHEN MEM-20SA Matcher

DAIHEN MFT-20SB Power splitter

VACCUM GENERAL CMLA-11 C/M (Baratron): 10 Torr

B.P He Control (Edge):

C/M (Baratron): TYLAN CMLA-21 100 TORR

PCV Unit / He controller: AERA PV-104C

MFC: SEC-7440

SEIKO SEIKI STP-H600C-T107 TMP

GAP

DC HV Module

Gas module: P/C1

MFC / Gas1: O2 / 20 SCCM / STEC / SEC-7440

MFC / Gas2: N2 / 100 SCCM / STEC / SEC-7440

MFC / Gas3: AR / 2 SLM / STEC / SEC-7440

MFC / Gas4: CF4 / 200 SLM / STEC / SEC-7440

MFC / Gas5: CHF2 / 200 SCCM / STEC / SEC-7440

DAIHEN MFG-20SA P/C Power generator

LASEM TECH BCU-L152 Dual chiller

EDWARDS iQDP80 P/C Pump

EDWARDS iQDP80 L/L Pump

JOBIN YVON H-10VIS EPD

1996 vintage.

TEL / TOKYO ELECTRON TE 8500S is a state-of-the-art etching/ashere equipment that is often used in the semiconductor production process. It utilizes advanced technology to provide a high level of precision, accuracy, and speed for etching and ashing processes. The innovative design of TEL TE 8500(S) allows for highly automated and accurate etching and ashing processes. This is accomplished with various equipment, such as wafer-level surveillance cameras and special types of etching/ashers agents. Additionally, the system can be operated remotely and can be programmed to perform different etching/ashers processes quickly and accurately with very minimal human input. Moreover, the process is highly efficient with its vacuum etching/ashers process, which decreases substrate damage and improves etch uniformity. The machine is also equipped with a range of sensors, such as total pressure gauge, O2 content sensor, and film thickness monitor, which allows for precise and accurate process monitoring. Furthermore, the unit is designed for easy maintenance, which decreases downtime for production lines. TOKYO ELECTRON TE 8500 (S) is capable of working with an extensive range of materials, such as polysilicon and silicon oxide, bipolar, CMOS, and analog devices, allowing for greater versatility for production lines. It can also work with a range of diameters, such as 200mm, 300mm, and 450mm sizes, as well as offers a range of wafer carriers, from 2-inch to 8-inch square wafers. In terms of process control, TE 8500(S) offers a wide range of options, such as improved process control and limited monitoring. The machine is also designed with user safety in mind, and certain safety features, such as the front line of safety, can be activated in order to protect operators from environmental hazards. TE 8500 (S) etching/ashere tool is a reliable and flexible solution for any production line, offering a range of functions and capabilities that are hard to match. Its advanced design provides high standards of accuracy, speed, and precision for a variety of different etching and ashing processes. Its remote operation, automated process control, and user-friendly design make it a highly effective tool for any production line.

There are no reviews yet