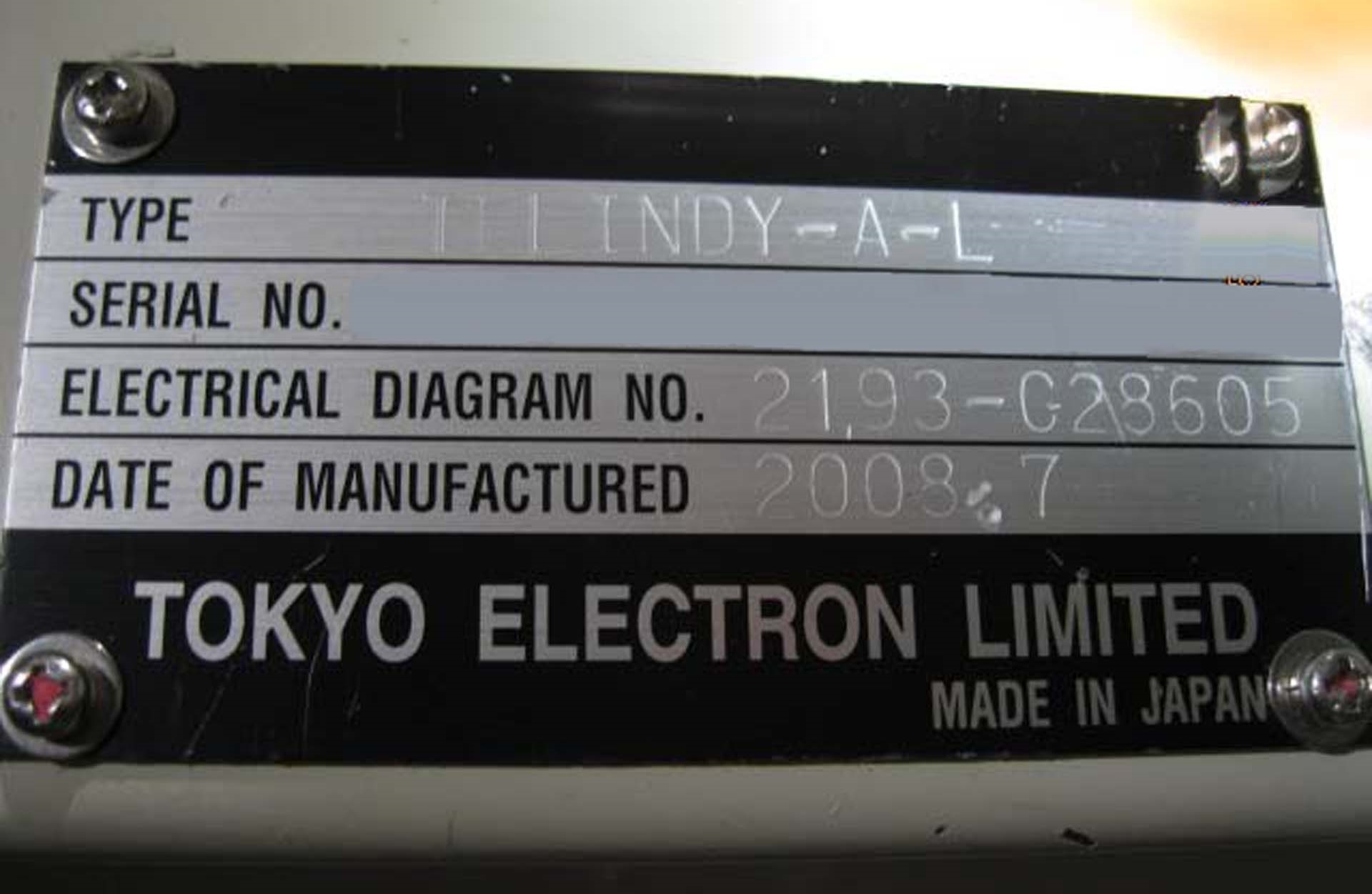

Used TEL / TOKYO ELECTRON TELINDY Oxide #9194459 for sale

URL successfully copied!

Tap to zoom

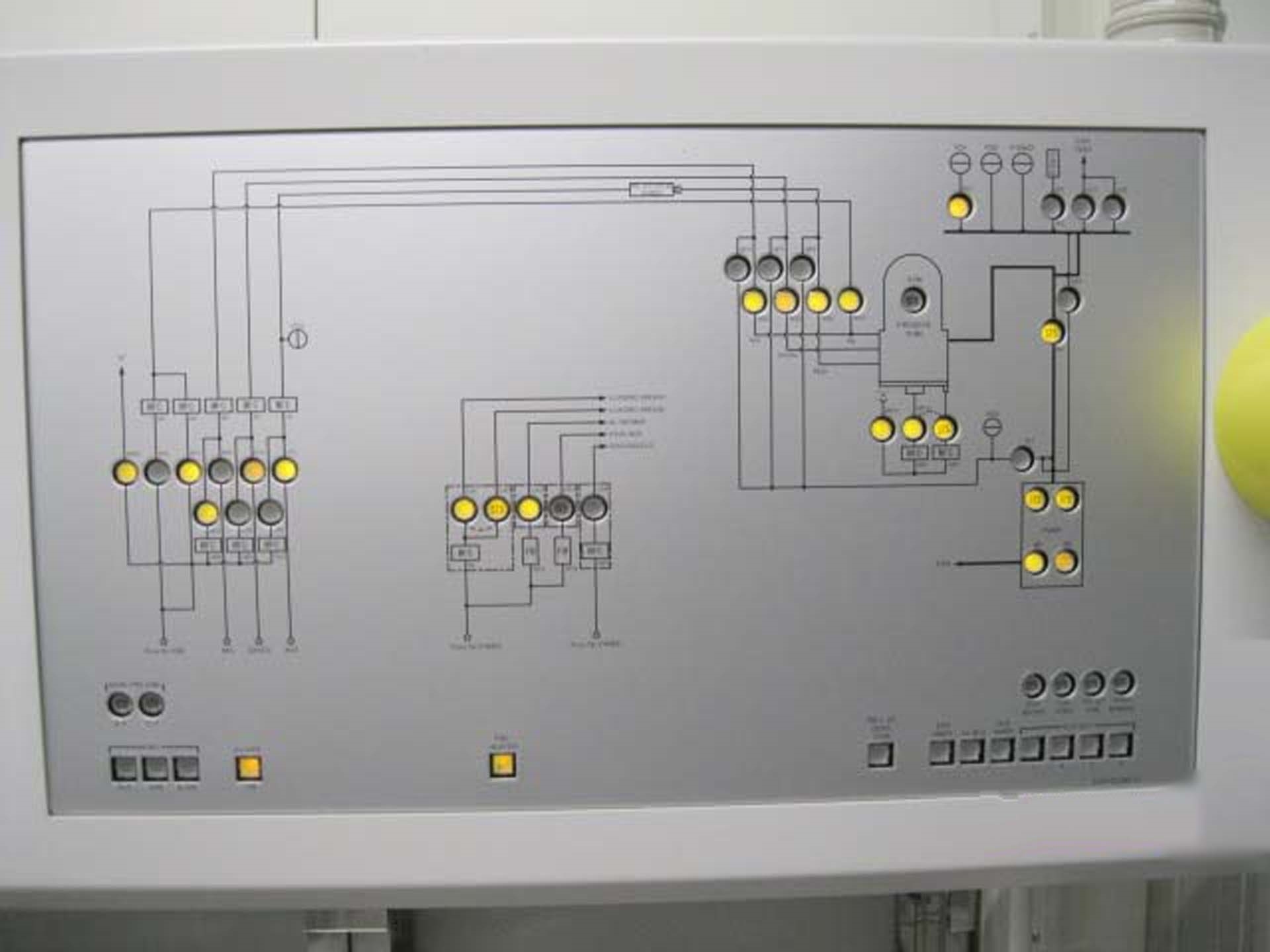

TEL / TOKYO ELECTRON TELINDY Oxide is a highly versatile etching and ashing equipment capable of operating in both a wet and dry environment. TEL TELINDY Oxide is designed to handle a variety of process applications, such as oxide etching, oxide ashing, and planarization. TOKYO ELECTRON TELINDY Oxide system features a fully automated unit for efficient etching and ashing processes. Its automated features, coupled with a powerful thermal plasma source and an efficient gas delivery machine, make TELINDY Oxide Tool well suited for a variety of production situations and applications. TEL / TOKYO ELECTRON TELINDY Oxide etcher/asher offers complete process flexibility including high etch rates, low temperature operation, and long etch times. TEL TELINDY Oxide asset is programmed to etch and as using a wide array of process parameters to enable the user to customize process conditions for their specific needs. The Oxide Model is capable of temperature-controlled dry etching to more than 1500°C and is capable of producing high-quality results at anisotropic, isotropic, or ultra-selective etch rates. The Oxide equipment also incorporates an advanced plasma source and gas delivery system to create a highly efficient etch process. TOKYO ELECTRON TELINDY Oxide unit offers a broad range of enabling technologies for etching and ashing processes. It features a patented electrodynamic gas sweep technology for controlling gas dispersion during etching. Additionally, its plasma source incorporates multiple specialized cartridges that are designed to produce high-quality etching and ashing. Finally, its high-speed wafer transport components provide fast wafer load/unload throughput as well as thermos-regulated temperature and precise gas flow control for specialized heating and cooling. TELINDY Oxide machine also features an advanced process monitoring tool that enables real-time monitoring of process parameters in the etching and ashing process. This asset with its wafer-by-wafer process control capabilities allows for improved process optimization, increased yield, and better performance. TEL / TOKYO ELECTRON TELINDY Oxide model offers outstanding performance, reliability, and value in etching and ashing processes. Cost-effective and efficient, the Oxide equipment is perfect for applications where accuracy and consistency in film etching and ashing are essential. With its advanced process control features, TEL TELINDY Oxide system provides the most effective and precise etching and ashing available in the industry today.

There are no reviews yet