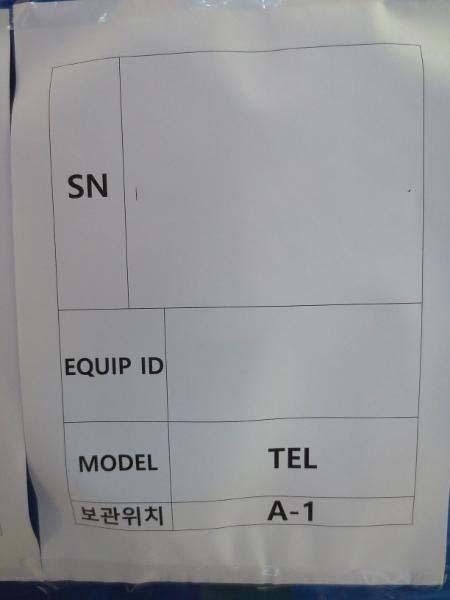

Used TEL / TOKYO ELECTRON Telius SCCM Shin #9353062 for sale

URL successfully copied!

Tap to zoom

TEL / TOKYO ELECTRON Telius SCCM Shin is an etcher / asher used for processing semiconductor substrates. It is part of the Telius series of high precision etch systems from TEL. The SCCM Shin utilizes deep reactive-ion etching (DRIE) technology to etch patterns onto wafers with high speed, accuracy, and repeatability. The equipment is equipped with a fully integrated process control system, allowing for a variety of precise etching recipes. The SCCM Shin is loaded with a chamber capable of processing either 8 inch or 12 inch silicon wafers, as well as gallium arsenide and indium phosphide wafers. It is equipped with one or two regular ICP (Inductively Coupled Plasma) sources, along with a unique second source option, the RF bias, for better etching control and accuracy. The unit also features a fast wafer rotation machine to increase its etching speed, and an ambient centrifuge source to make the DRIE process more efficient. The SCCM Shin is highly flexible and customizable. It can be integrated with a variety of other equipment, such as load locks, exhausts, and a remote plasma source to further streamline its processing capabilities. The tool is also capable of precise automated sample tracking and wafer handling. In its process chamber, the SCCM Shin utilizes a unique combination of three gas sources to produce various etching recipes, including isotropic and anisotropic etch processes. With this capability, it is able to precisely etch patterns onto wafers with unsurpassed quality and accuracy. The SCCM Shin is designed to maximize efficiency and minimize waste. It incorporates a dedicated exhaust asset to reduce gas consumption and increase throughput. In addition, its process control model is integrated with intelligent monitoring systems and feedback systems to guarantee optimum performance and repeatability. Overall, TEL Telius SCCM Shin is a powerful and reliable etcher / asher that provides precise etching of wafers with outstanding features and capabilities, making it an ideal choice for semiconductor processing.

There are no reviews yet