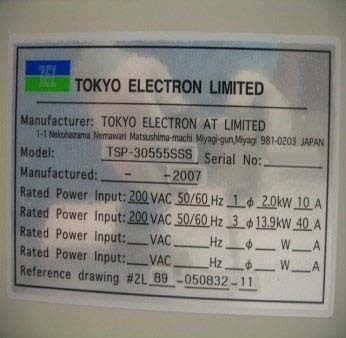

Used TEL / TOKYO ELECTRON Telius SP 305 SCCM TE #9282473 for sale

URL successfully copied!

Tap to zoom

ID: 9282473

Wafer Size: 12"

Vintage: 2007

Dielectric etcher, 12"

Process: Contact etcher

CIM

SMIF System: (4) Shinkos

Handler system:

Shinko

Orient

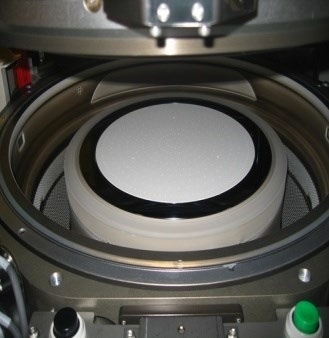

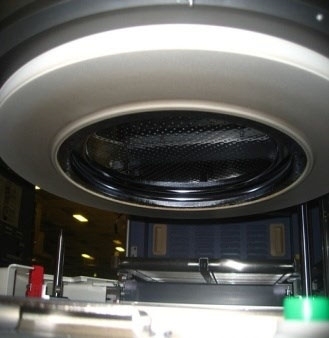

Process chamber 1:

Pendulum valve

Turbo pump

Shutter assembly

RF Generator

ESC Assembly

Process kit

Gauge

Process chamber 2:

Pendulum valve

Turbo pump

Shutter assembly

RF Generator

ESC Assembly

Process kit

LLM CM VAC Valve

ARM Drive

ARM Fork

Gauge

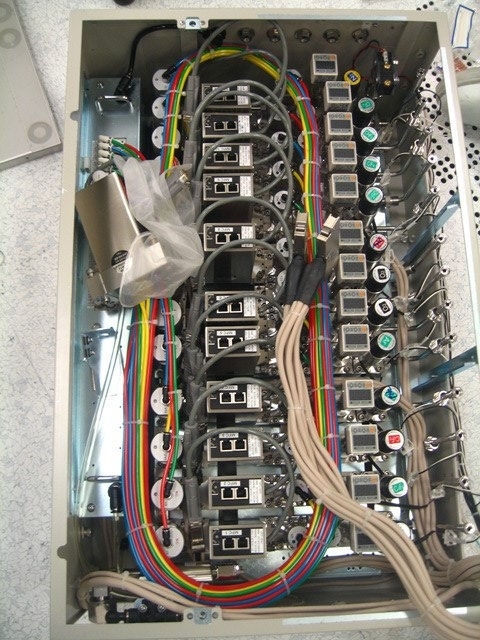

Power rack

Gas panel for PM1/PM2: H2, CH2F2, CH3F, CF4, O2, C4F6, C4F8, CHF, CO, Ar, N2

End point detection: SE2000

Missing parts:

(5) Dry pump lacks

(2) Fault chillers

Abatement lack

(6) MFC Lacks

(2) Fault chamber process kits

(2) Fault ESC assemblies

Hard Disk Drive (HDD)

2007 vintage.

TEL / TOKYO ELECTRON Telius SP 305 SCCM TE is a module that integrates state-of-the-art technology for controlling chemical etching and ashing processes. As an etcher/asher, TEL Telius SP 305 SCCM TE is designed to provide precise control over substrate etching, ashing and cleaning activities. Built with a flexible equipment architecture, TOKYO ELECTRON Telius SP 305 SCCM TE offers superior control over direct current etching (DCE) and alternating current etching (ACE) processes. It is capable of running both processes in unison, allowing for optimal control over etch uniformity and yield. Telius SP 305 SCCM TE includes a two-month control interface with automated system communication which simplifies the set-up and use of the etcher/asher. This control unit pairs with integrated monitoring and data logging, which reads etch variables such as temperature, pressure, and current in real-time. It is also capable of choosing the right recipes for material processing and is programmed with digital edge control to optimize process uniformity. The etcher/asher design of TEL / TOKYO ELECTRON Telius SP 305 SCCM TE is capable of sandvikadiabatic etching (SAE). It has the ability to maximize the aspect ratio in deep high aspect ratio etching with minimized cooling time. This device also offers etching capabilities at temperatures up to 150℃ as well as temperature controlled anisotropic etching (TCAE) in order to control undercut or hollowing. TEL Telius SP 305 SCCM TE comes with a variety of pre-programmed etch recipes that allow users to achieve complex structures with minimal adjustment. It is also designed with an advanced safety machine to protect users from any contact with the etchant and provides activity monitoring to minimize etching and ashing process anomalies. These unique attributes combine to make TOKYO ELECTRON Telius SP 305 SCCM TE one of the most technologically advanced etchers/ashers available on the market. By offering superior control over the etch/ash process, the user can be assured of consistent, repeatable process control that results in higher yields and higher product quality.

There are no reviews yet