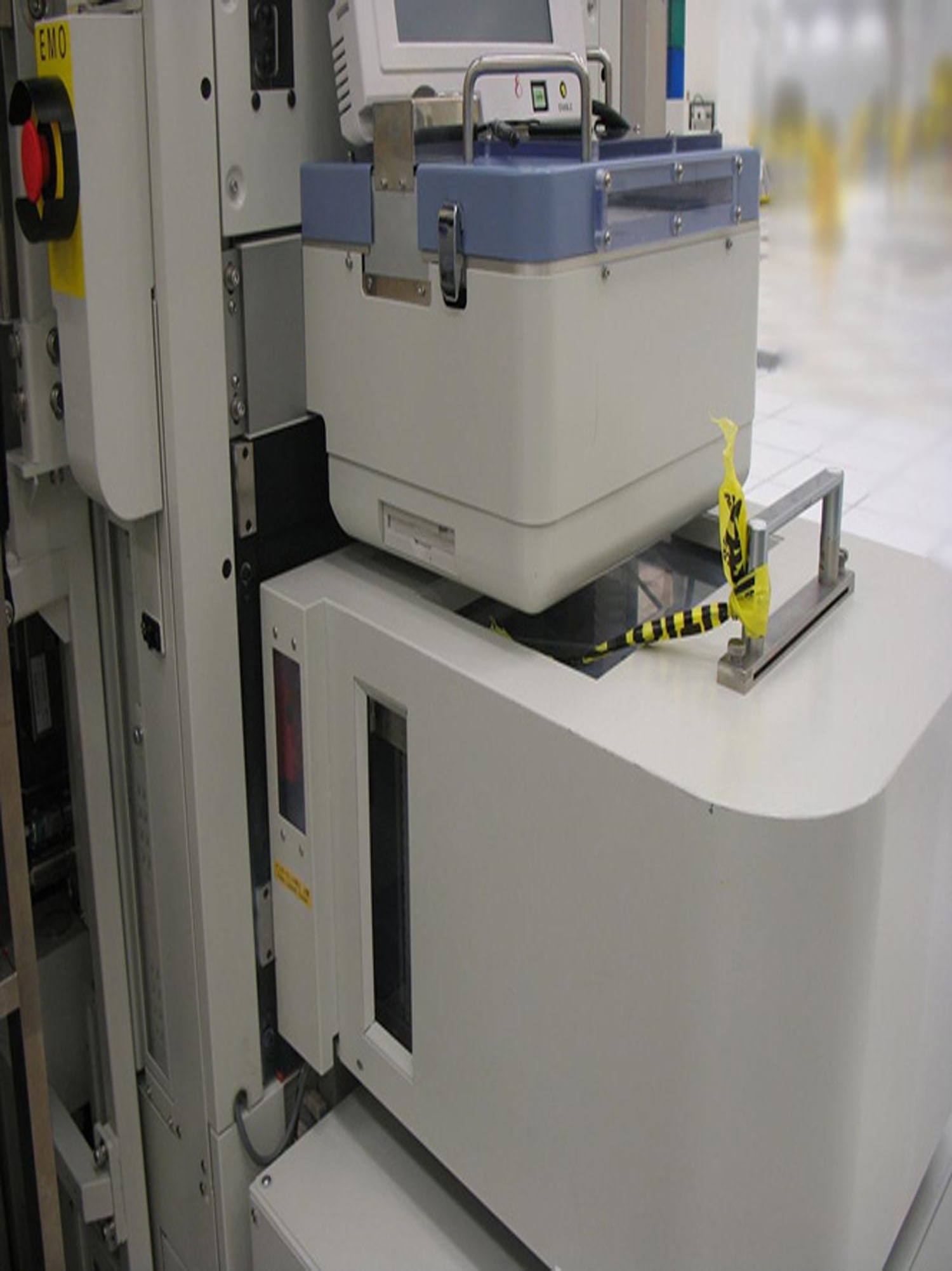

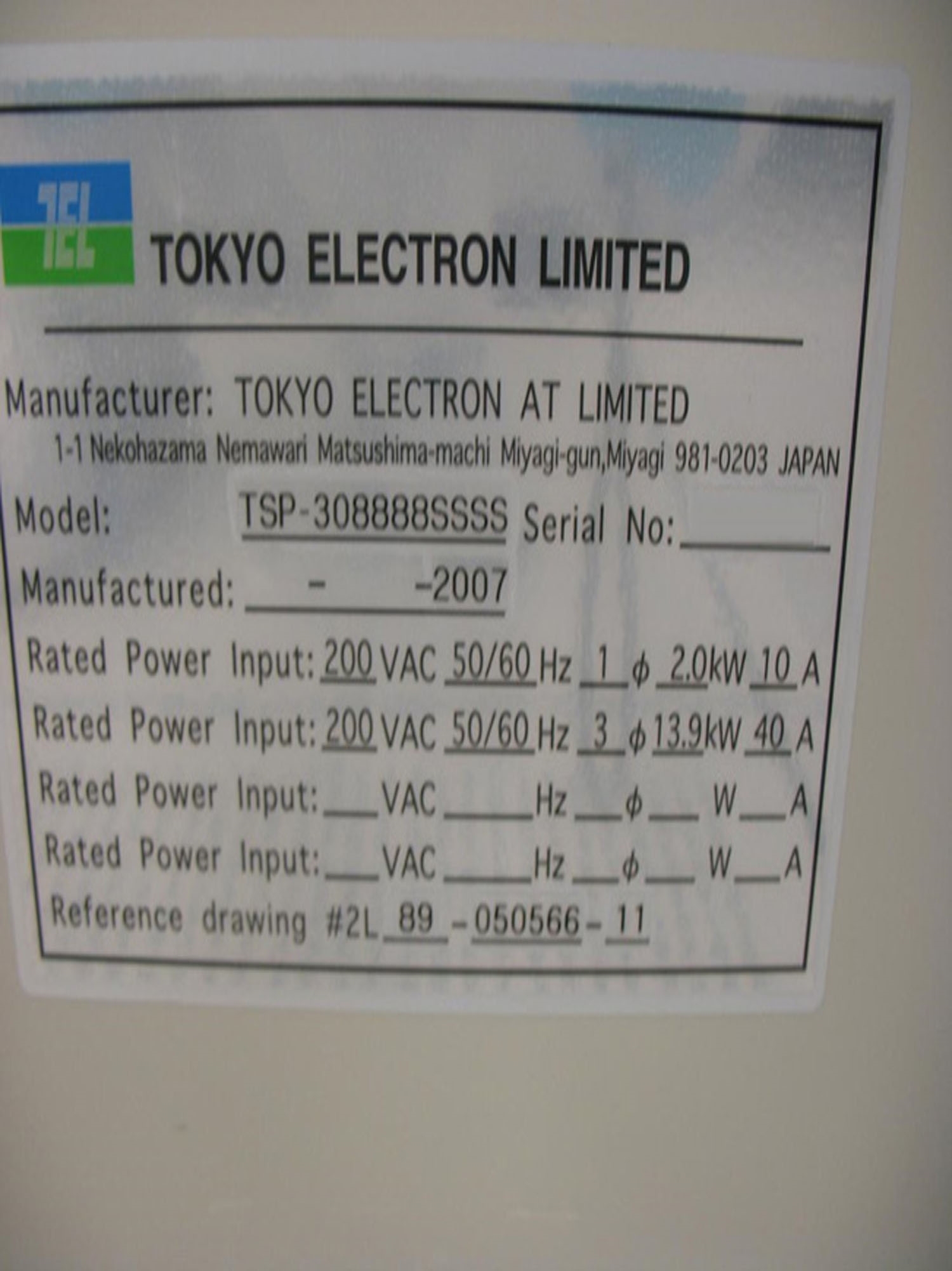

Used TEL / TOKYO ELECTRON Telius SP 308QS #9213296 for sale

URL successfully copied!

Tap to zoom

ID: 9213296

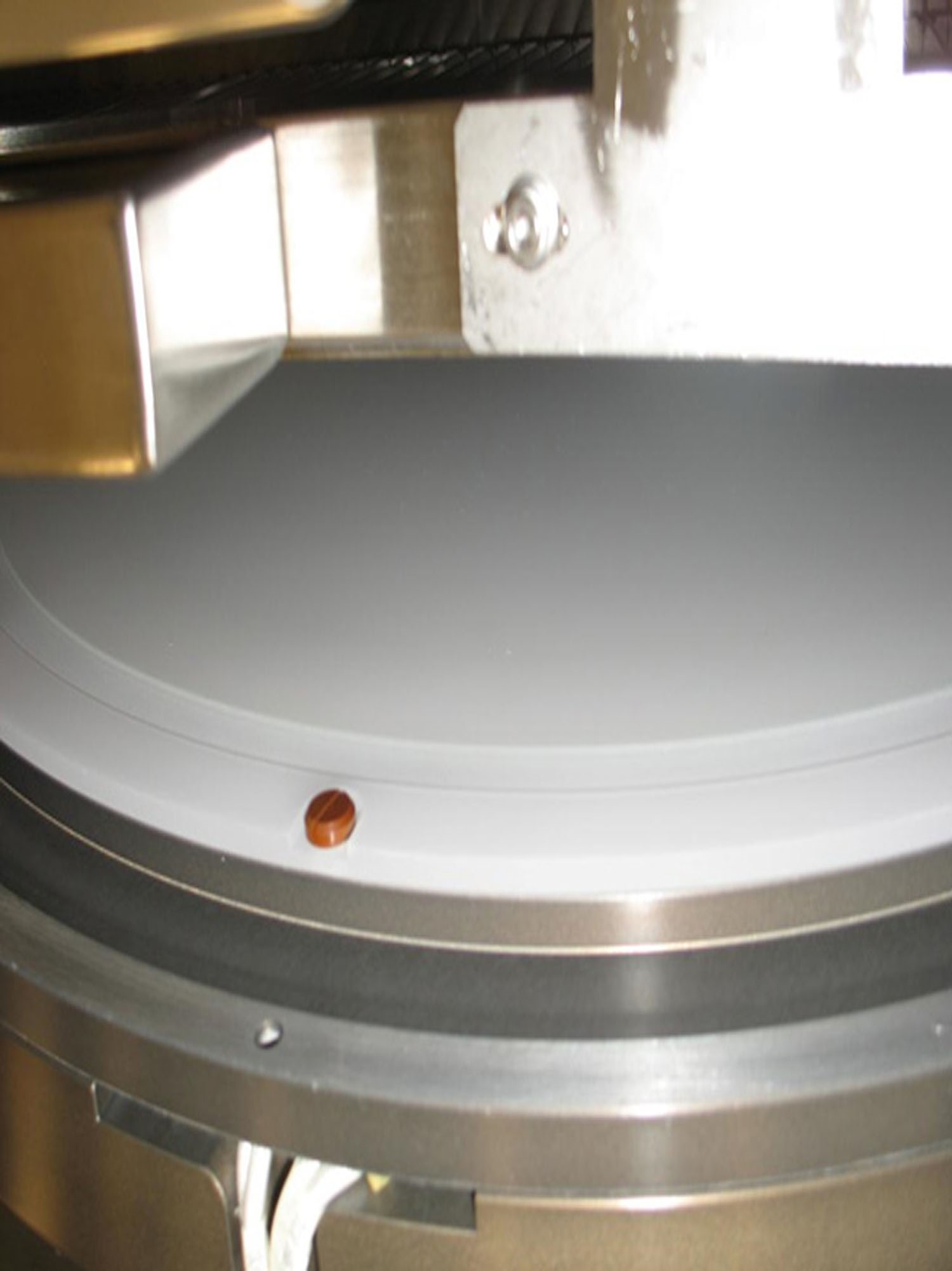

Deep trench silicon etchers

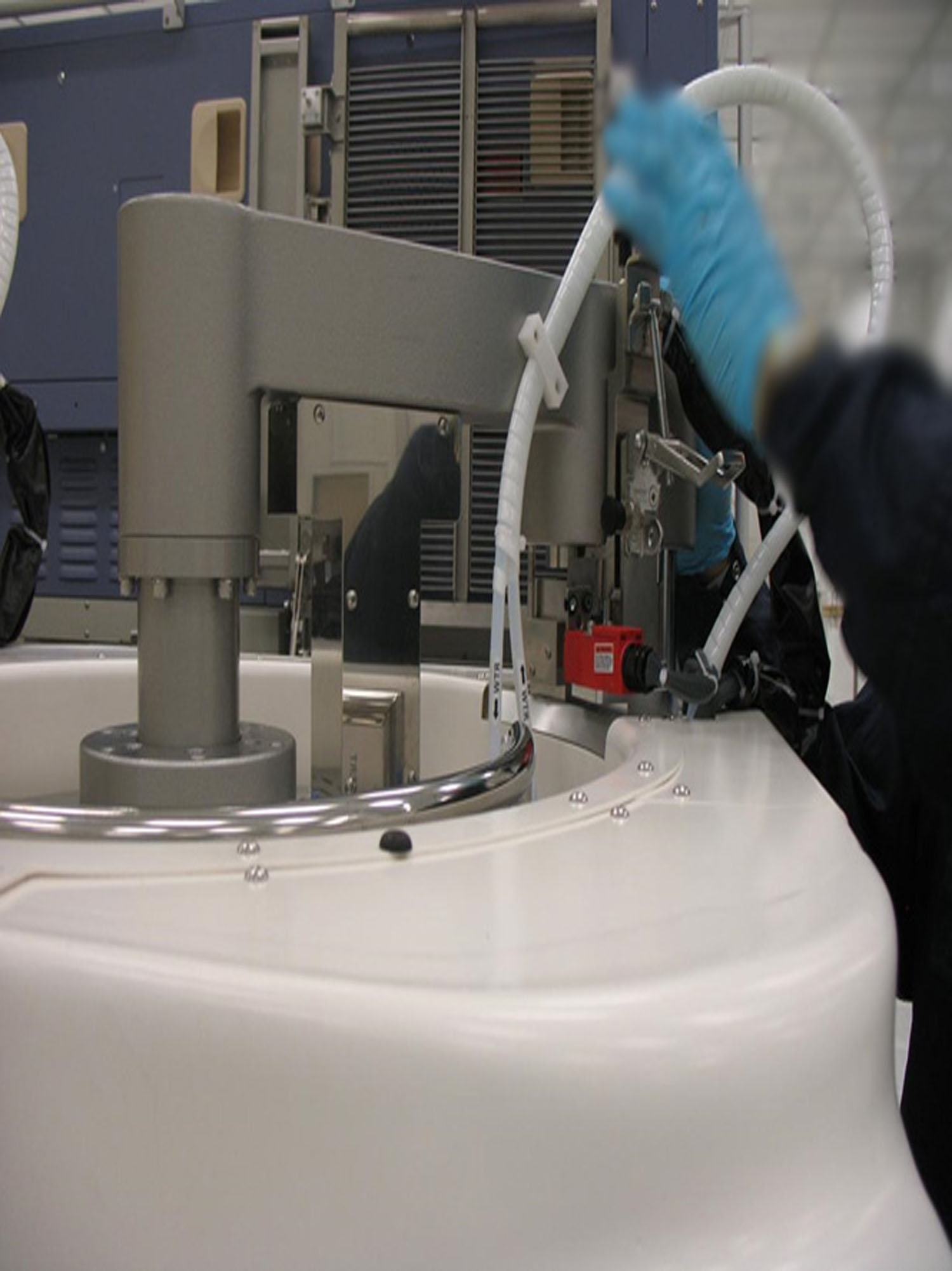

12" FOUP

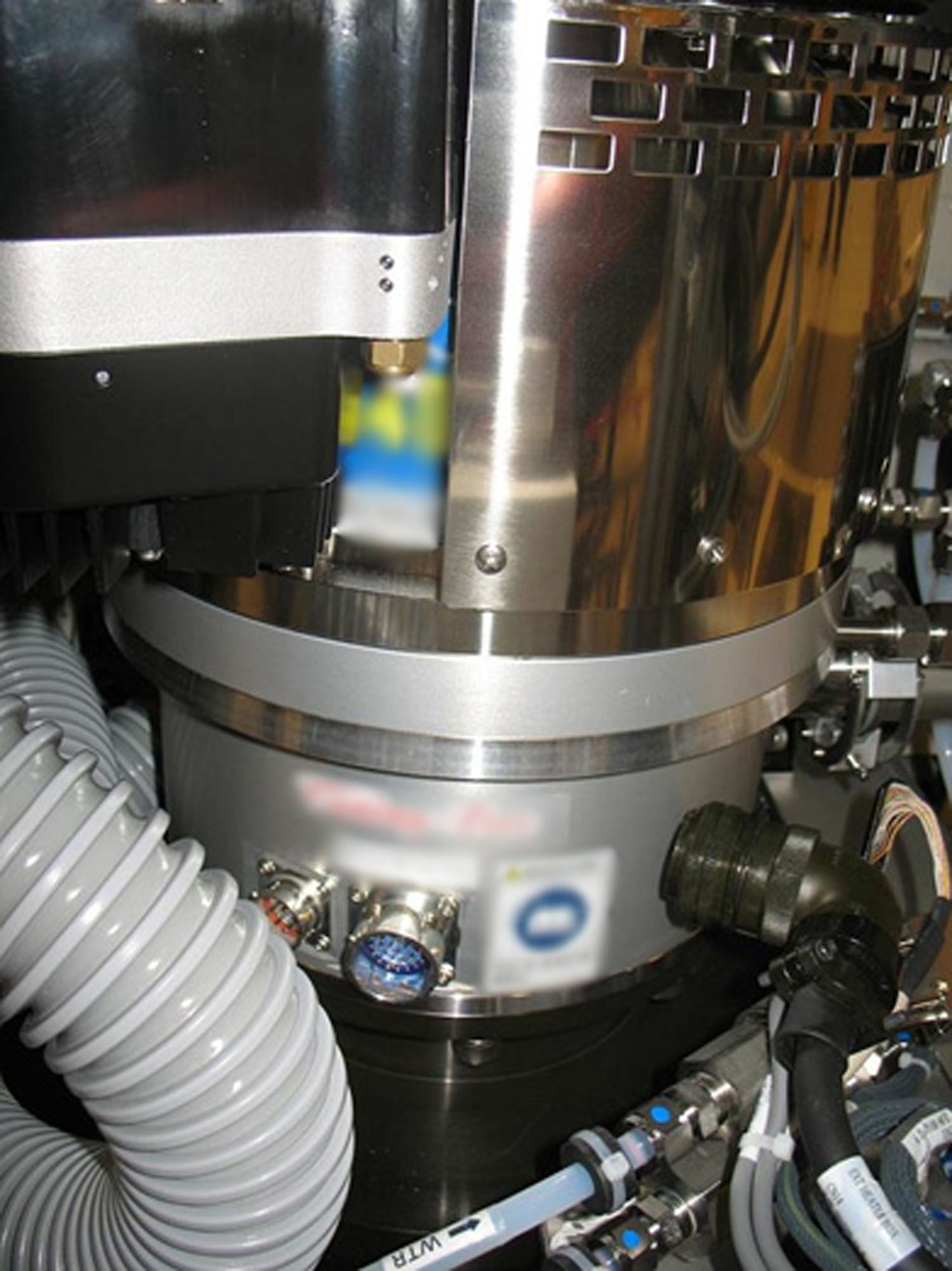

(4) Chambers (SCCM)

(5) Loader ports

Load locker modules

GEW3040 and NOVA50A 40MHz and 3.2MHz dual frequency source

ESD Chuck

Temperature control

RF Application method

Process: 80um deep 90nm wide via silicon etch

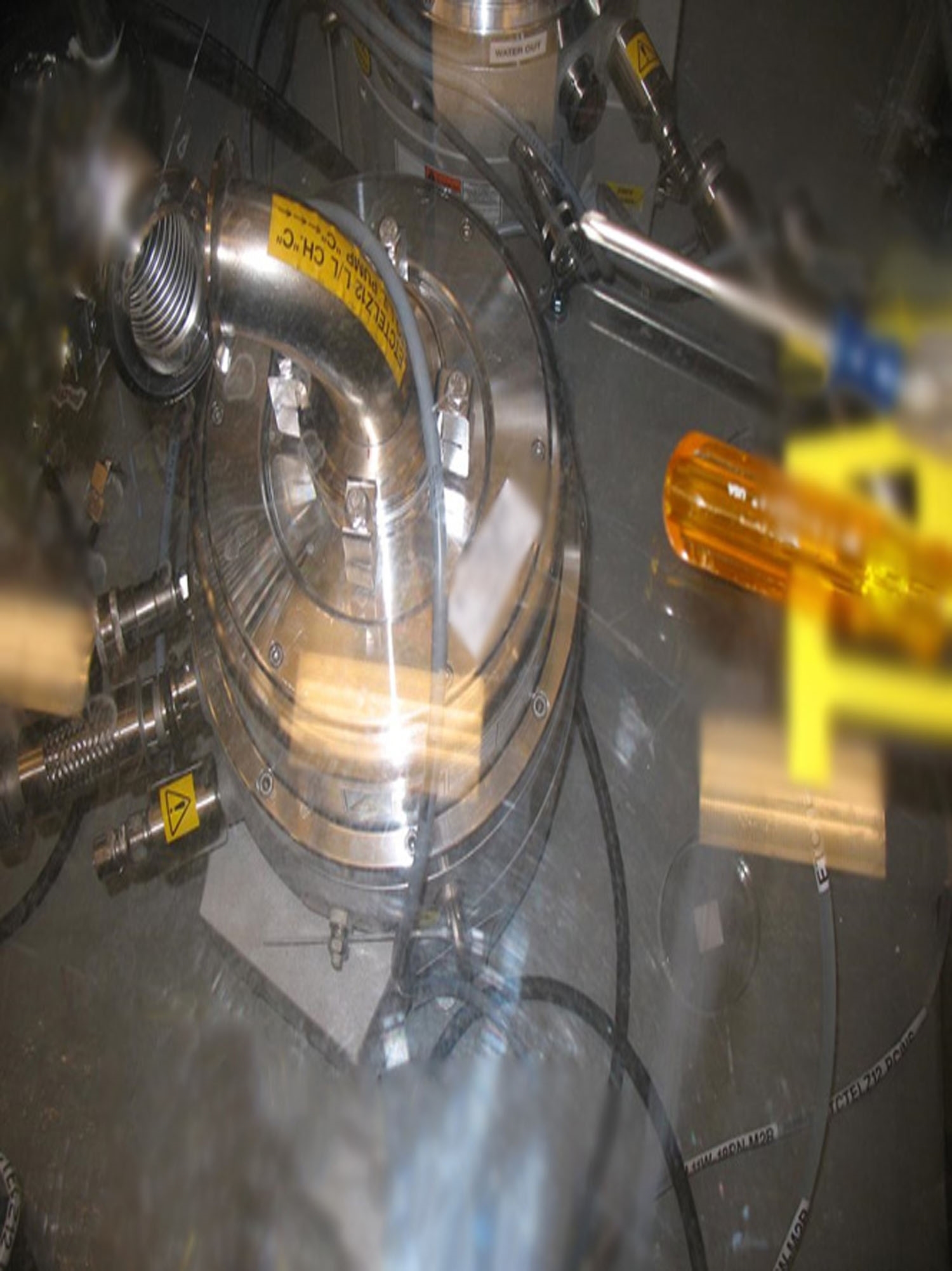

Chamber:

Aluminum alloy chamber

Material: Aluminum alloy (A6061)

Surface finishing: Hard sulfuric acid anodizing

RF Application method: Apply upper RF to lower electrode

Discharge method: SCCM Type

Temperature control:

Upper electrode: Temperature control by heater and cooling water

Lower electrode: Temperature control by circulating coolant

Side wall: Temperature control by heater

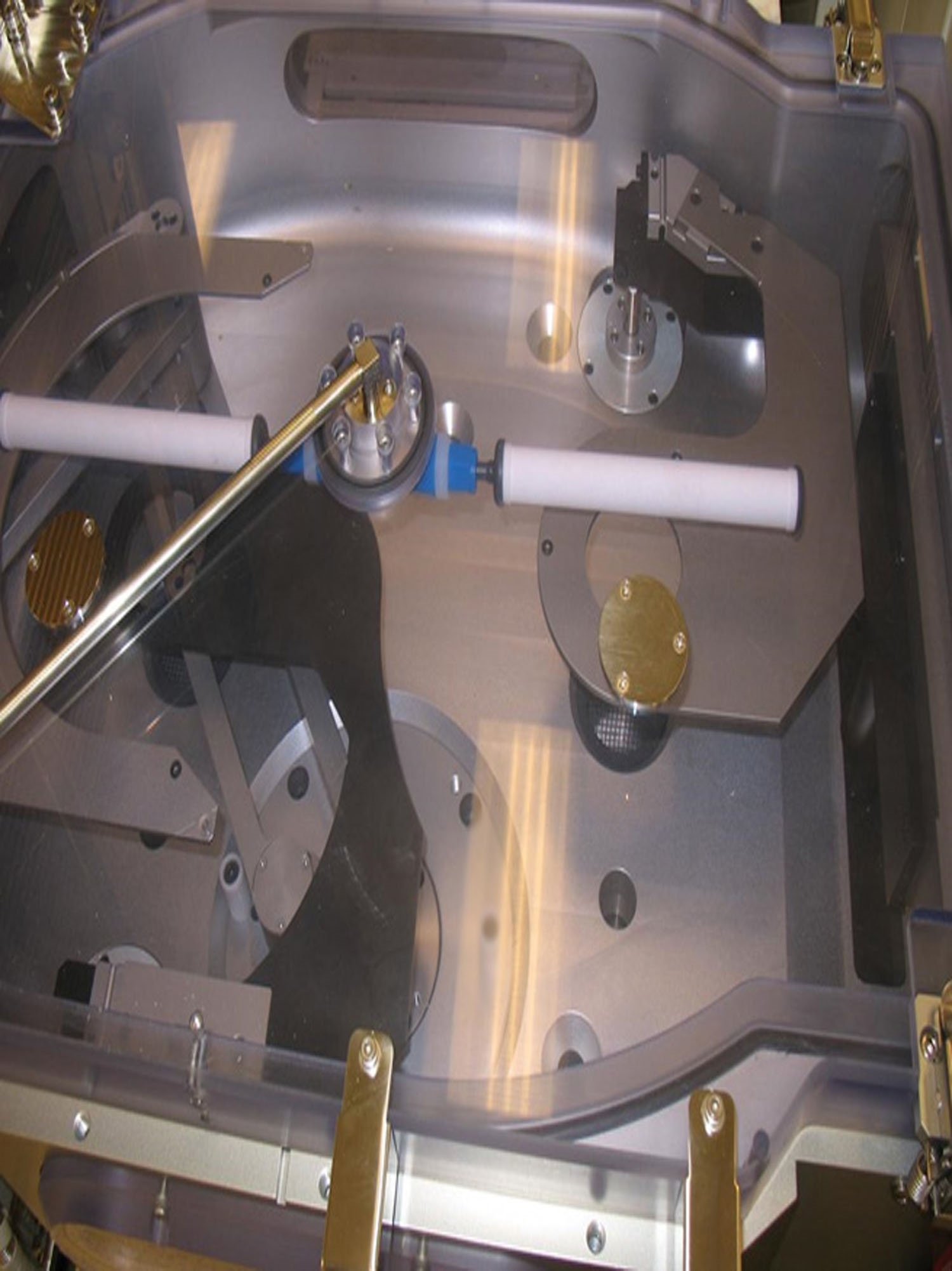

Upper electrode:

Quartz cover or aluminum alloy (A6061) with hard sulfuric acid anodizing

Shield ring

Lower electrode:

Ceramics electro static chuck

Thermometer

Wafer holding method: Electrostatic chuck(φ300) mechanism

Lifter: Resin

Focus ring: Qz

Exhaust plate: Aluminum alloy with hard sulfuric acid anodizing

Insulation ring: Quartz cover or aluminum alloy (A6061) with hard sulfuric acid anodizing

Distance between electrodes: 30~35 mm

Magnet:

Intensity: 170G (center)

Rotation: 20± 1rpm

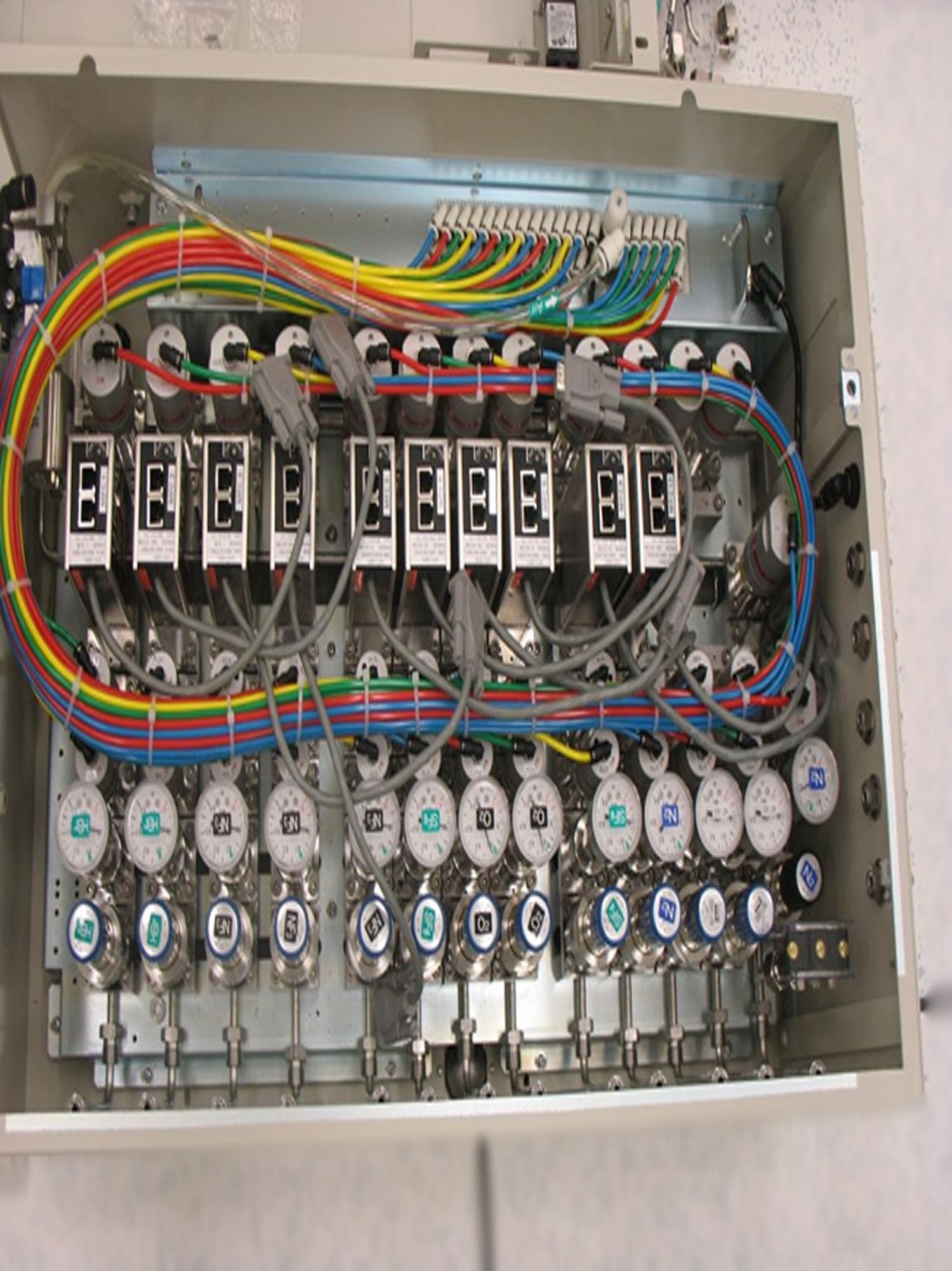

Pressure monitor: (3) Types

He B.P unit: Cooling gas for wafer back

Pressure switch: PCV (STEC)

Number of line: (2) Lines

Control range of pressure:

(Center / Edge): 0~7980Pa(0~60Torr)

He monitor: Leakage monitor

Detection of valve open / close: Valve ON/OFF sensor

End point detection: SE2000

Confirmation of luminescence

Window: Orifice (Quartz)

Deposition shield: Removable depo-shield

Material: Quartz

Shutter:

Plate: Aluminium alloy with hard sulfuric anodizing

Drive: Air cylinder

Final valve: Diaphragm type mega-one (Fujikin)

Manifold: Aluminium alloy with hard sulfuric anodizing

O-ring for chamber: Chemratz

Specifications for performance:

Ultimate vacuum: 0.0133 Pa (7.5*10-2 mTorr) or less

Leak back: 0.133 Pa/min (1 mTorr/min) or less

2007 vintage.

TEL / TOKYO ELECTRON Telius SP 308QS is a high-precision etcher / asher that is designed to enable precise film thickness control and fast substrate processing. The machine utilizes a variety of advanced technologies to achieve high-quality results while also delivering remarkable throughput speeds. TEL Telius SP 308QS features an intuitive graphical user interface that makes the etching process simple and straightforward. The etch chamber is designed with flexibility and ergonomics in mind, and is suitable for a variety of etching applications. It has an advanced four-laser interferometry equipment for precise control of film thickness. This system is capable of measuring and measuring film thicknesses from 0.2 nm to 70 mm. It also has an automatic i-LINE mode for high-precision etching with a simple one-button operation. The unit comes with a graphical pattern editor that allows you to easily edit etch patterns for advanced application requirements. The etching process is carried out in a thermally-controlled, ultra-high vacuum etch chamber. This vacuum chamber is capable of reaching vacuum levels of up to 10-7 Torr. It has an auto-optimization feature that can be used for adjusting etching conditions automatically to achieve higher etch rates and lower etch selectivity. The auto-optimization feature can also be used to fine-tune the etch conditions for more precise process control. TOKYO ELECTRON Telius SP 308QS is equipped with advanced process monitoring and data logging features that enable process yield analysis. It has a high-precision ion monitor that ensures a consistent and repeatable etching process. The etcher also features an advanced graphics processor unit, which allows for higher performance during throughput, while also providing high-quality data output. Telius SP 308QS is a highly advanced etching machine that delivers reliable, repeatable etch results with remarkable throughput speeds. Its innovative design and advanced technologies make it an ideal solution for a variety of etching applications.

There are no reviews yet