Used TEL / TOKYO ELECTRON Trias #9234139 for sale

URL successfully copied!

Tap to zoom

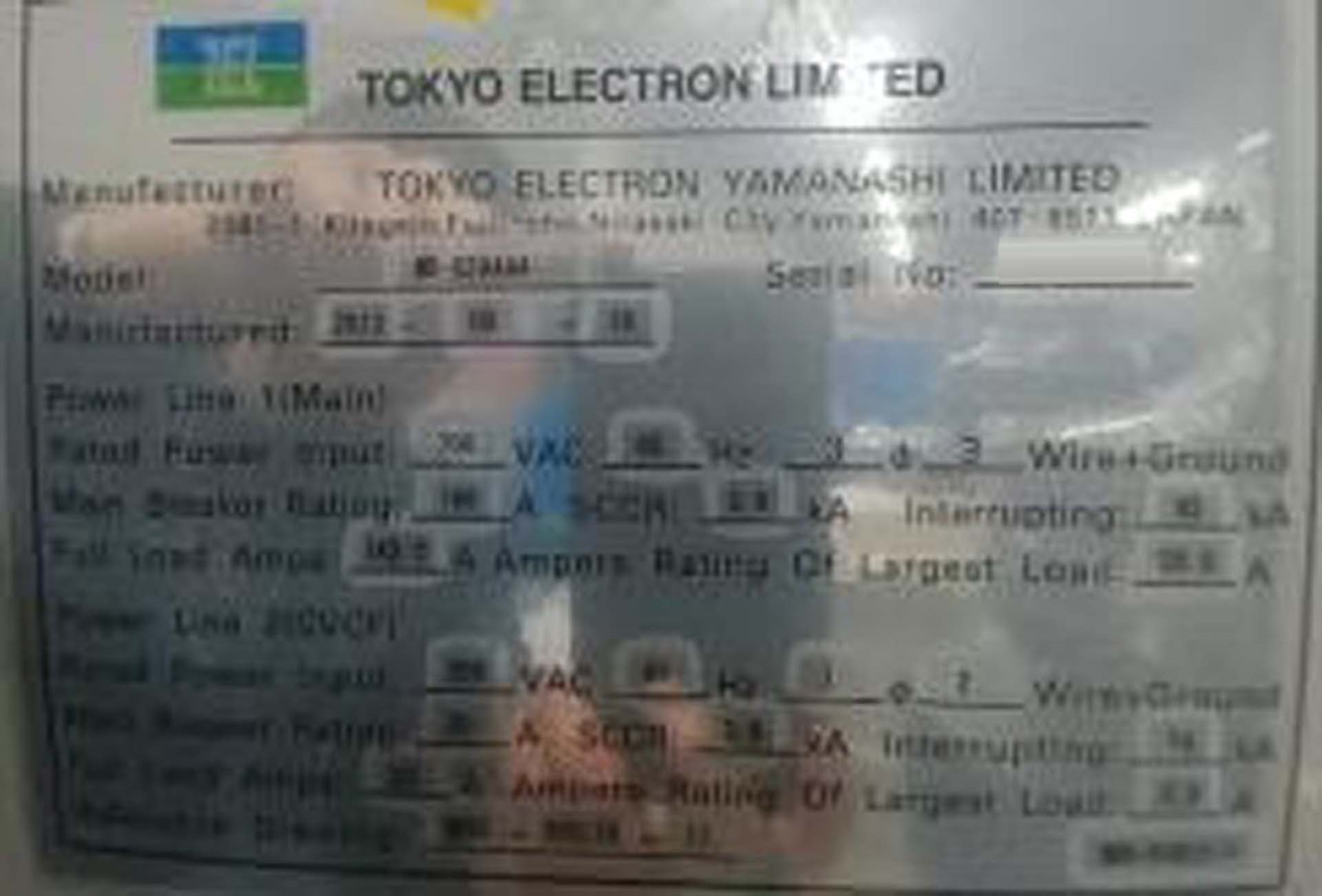

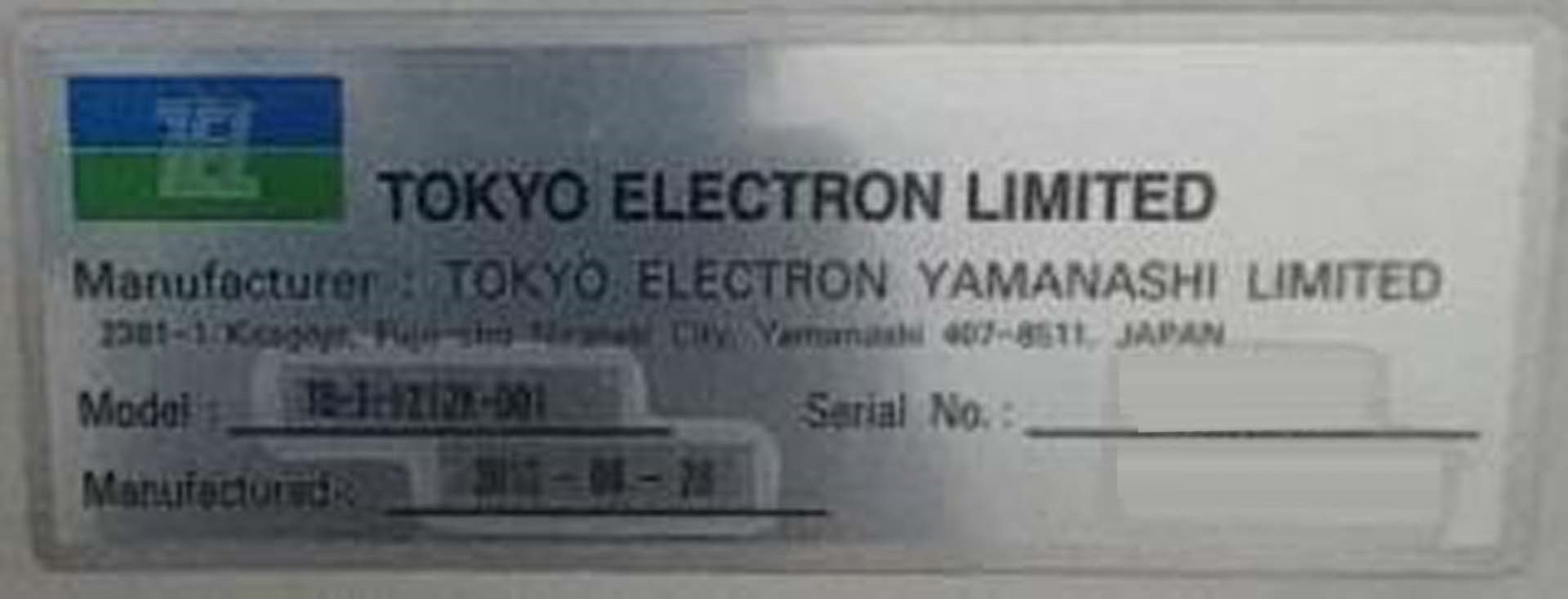

ID: 9234139

Vintage: 2013

System, parts machine

Missing parts:

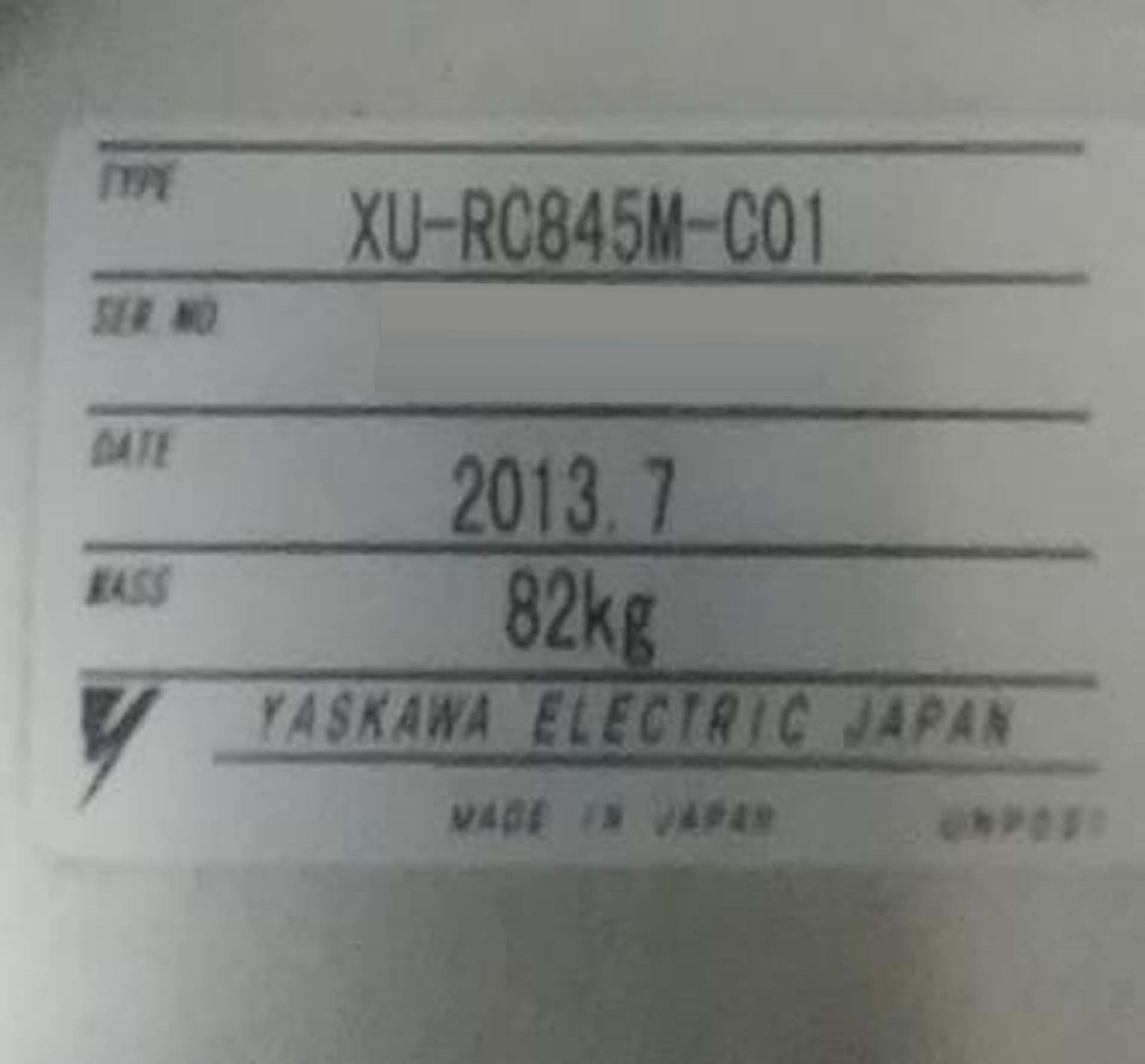

EFEM: Main PC / Robot controller

Transfer module: TM Robot / Robot controller

Process chamber: ESC

2013 vintage.

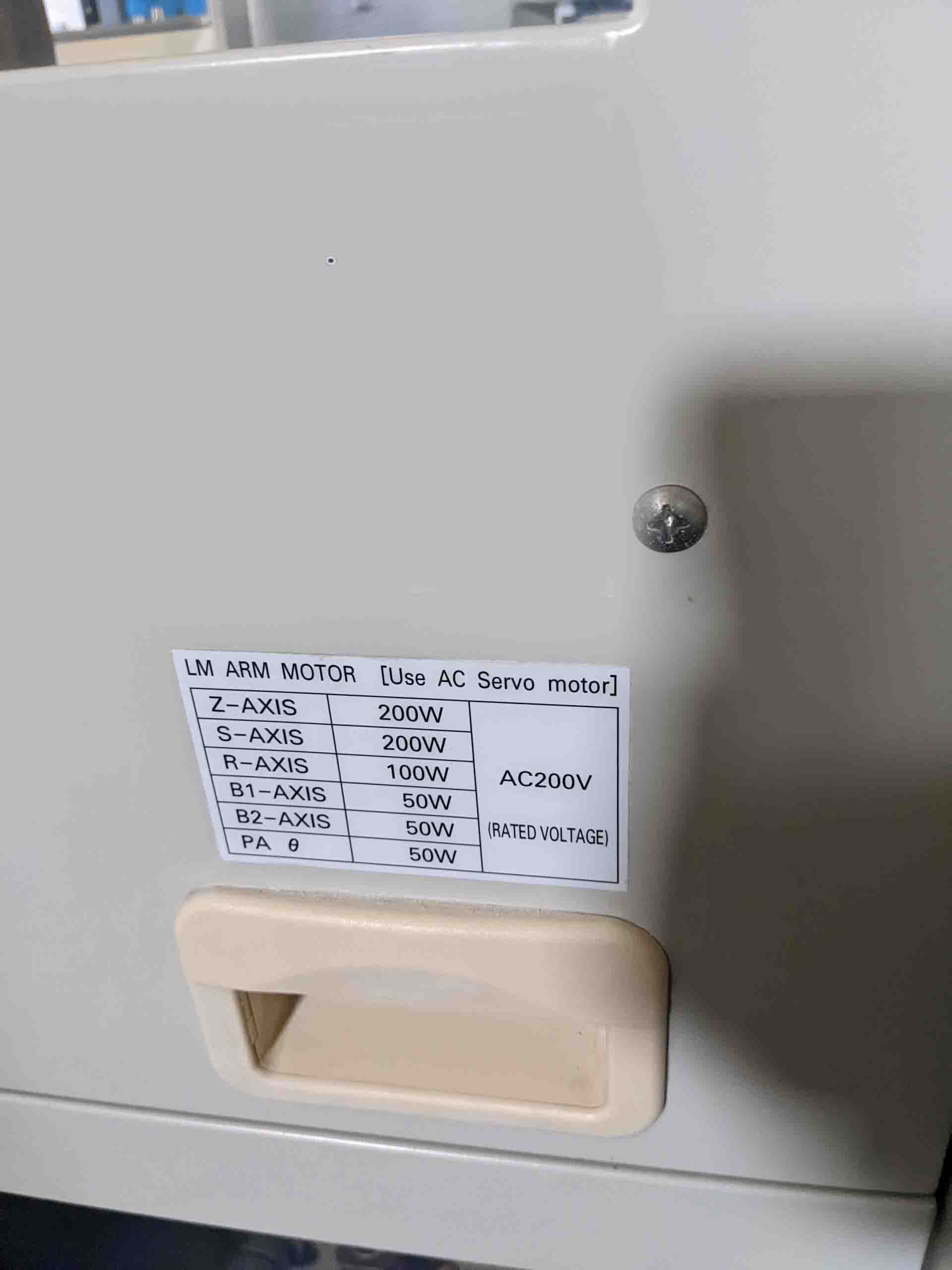

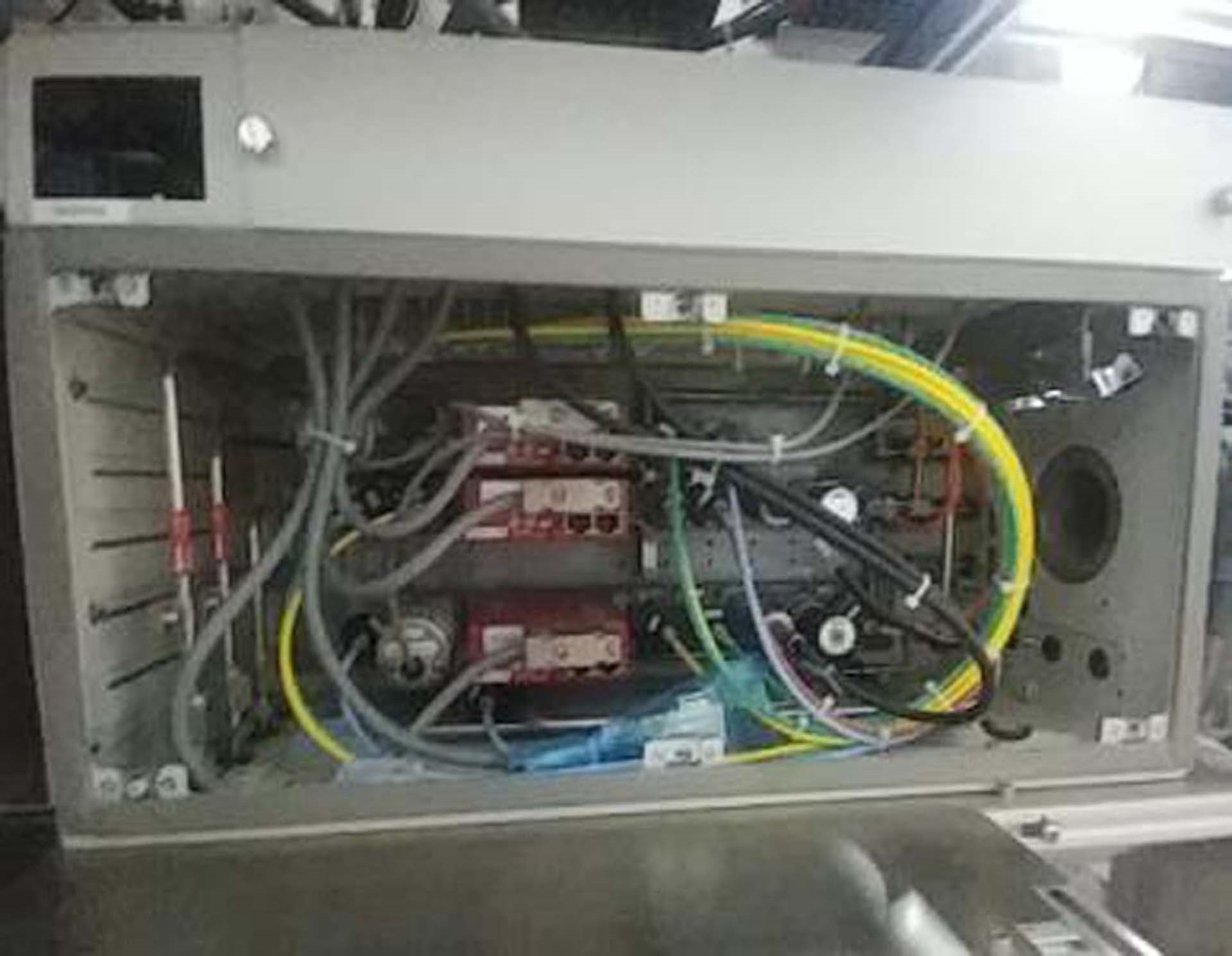

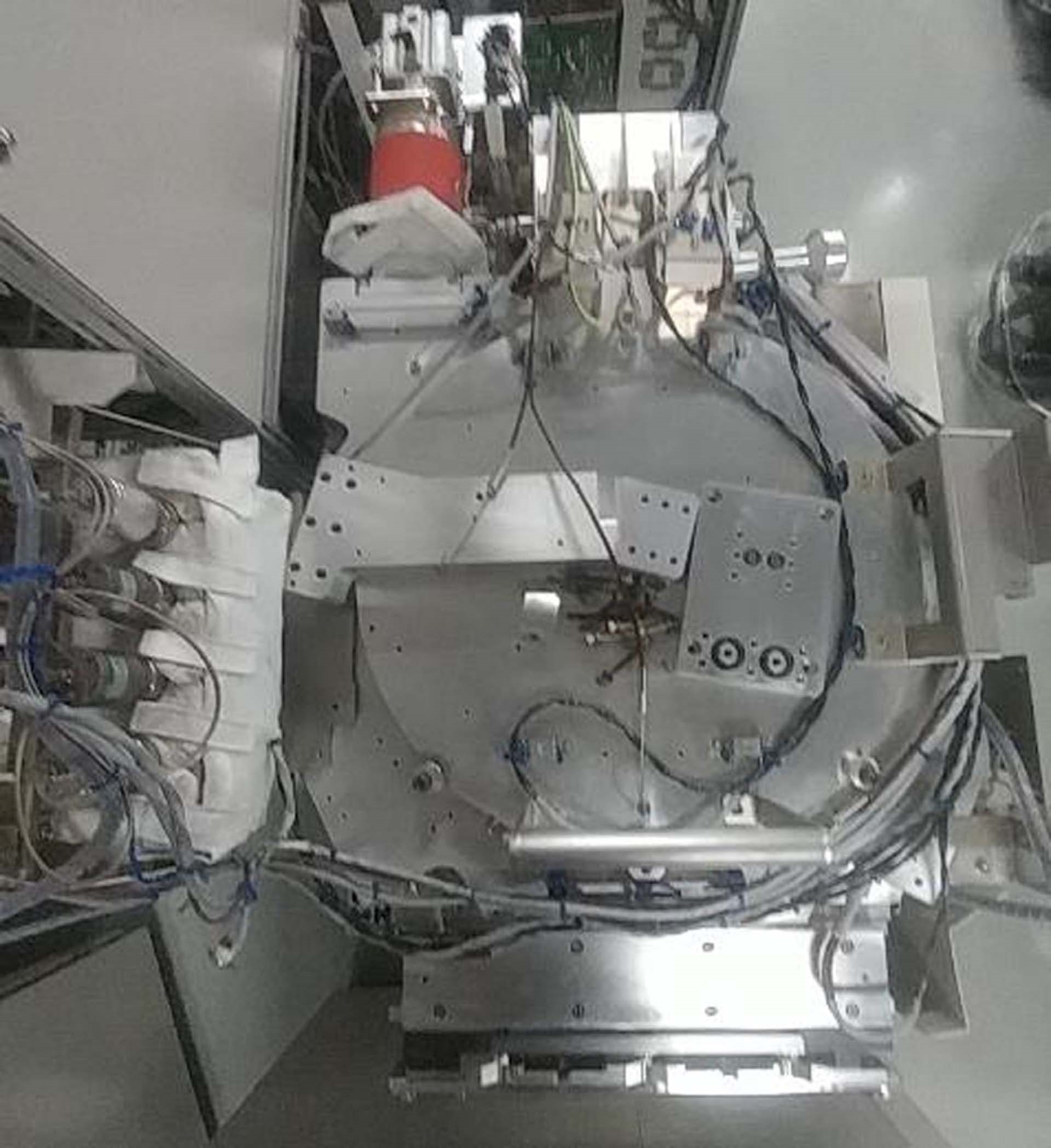

TEL / TOKYO ELECTRON Trias is an etching/asher equipment that is used for active layer creation on wafer surfaces prior to metal deposition. The system is an in-line etch/fermentation chamber using dry plasma technology for anion deposition, and utilizes a custom-source gas mixture from the inlet to the reaction chamber. TEL Trias unit is suited for fabrication of highly precision devices such as Field Effect Transistors (FETs). It is capable of handling wafer diameters from 18 mm to 800 mm, with 300 mm and 450 mm being the standard sizes used in production. Processes ranging from oxide etching, nitride etching, polysilicon etching, and metal sputter etching can all be performed with precise control over etch rate, selectivity, uniformity, and ion impurity; as well as minimizing contamination from the fluids and utilizing pre-set recipes. TOKYO ELECTRON Trias machine is able to deliver etching profiles in the range of 0.3 μm to 10 μm, or higher, in terms of feature control without the need for assistant tools. It utilizes two-frequency source power to generate intense, self-stable dry plasma in the reaction chamber, while controlling the ion generation. This, along with the customizable source gas mixture, enables highly efficient and precise etching results. The tool also offers wafer stepper compatibility, allowing for rapid wafer transfer and the assurance of good overall wafer process results. The asset also allows for a throughput of up to 20 wafers per minute and full wafer mapping capability. Moreover, Trias in-line etch/fermentation chamber enable controlling a variety of reaction parameters. It comes with a number of monitoring options to ensure repeatability, including pressure and temperature measurement, mass spectroscopy, and graphite furnace operation. Thanks to its highly efficient and precise etching results, TEL / TOKYO ELECTRON Trias model is widely utilized in semiconductor fabrication, making it one of the most popular etch/asher systems in the field. It has been proven to be capable of creating thermal oxide layers with excellent gapfill and topography capabilities, as well as excellent mobility and selectivity values. Its combination of accuracy and reliability makes it a valuable tool in the production of advanced electronic devices.

There are no reviews yet