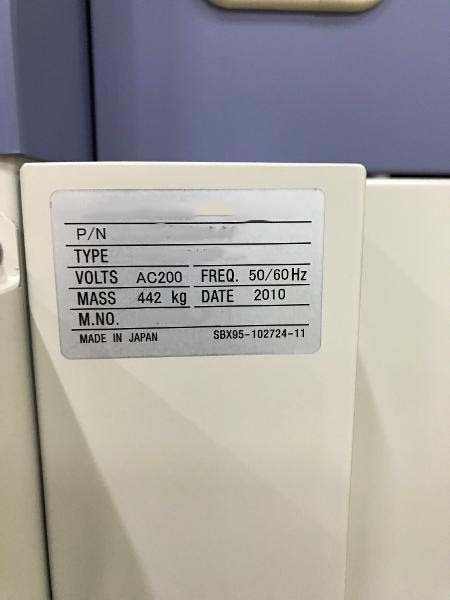

Used TEL / TOKYO ELECTRON Trias #9294442 for sale

URL successfully copied!

Tap to zoom

TEL / TOKYO ELECTRON Trias is an industry leading etcher/asher used for semiconductor fabrication. This etcher/asher features the ability to process a wide range of materials including silicon, copper, tungsten, titanium, etc. It uses two distinct processes - one in which material is deposited on the substrate and the other in which the material is etched away from the substrate - to pattern features with resolutions of up to 70 nanometers. This makes it an ideal choice for the advanced technology nodes used in today's semiconductor production. TEL Trias is a semiautomatic tool featuring a highly efficient and precise digital control. With its patented semiconductor technology, it can achieve a high degree of repeatability and accuracy when etching and ashing features. The tool incorporates a number of features and accessories that allow for increased automation and customization, including embedded pre-calibration routines and network connectivity options. It also has a modular design and flexible process chamber making it a tool that can easily be adapted to different user requirements. TOKYO ELECTRON Trias also features an intuitive graphical user interface (GUI) that allows users to quickly set up different processing parameters and monitor tool performance. It utilizes embedded atomic force microscopy (AFM) technology, allowing for high-resolution imaging of nano-patterning results. Finally, it has integration with multiple industry leading software packages including CAD/CAM, EDA, and PDK software as well as direct support for GDSII/OASIS format files. In conclusion, Trias is an advanced and versatile etcher/asher. Its efficient digital control, modular design, intuitive GUI, and multiple integrated features make it an excellent choice for production of small and complex patterns in semiconductor fabrication processes. Its high-end features and capabilities allow users great flexibility and control during the ashing and etching processes, resulting in high levels of accuracy and repeatability.

There are no reviews yet