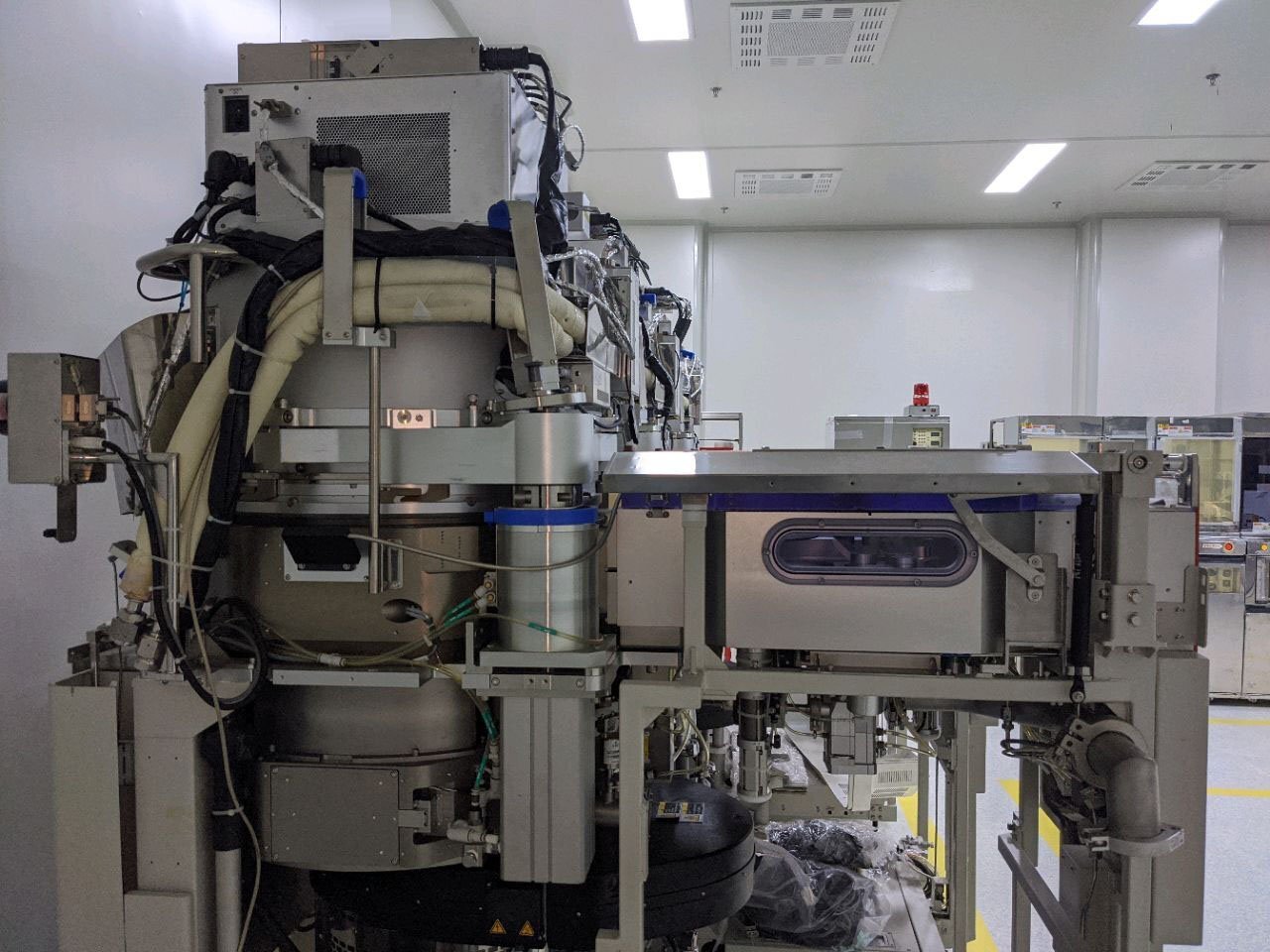

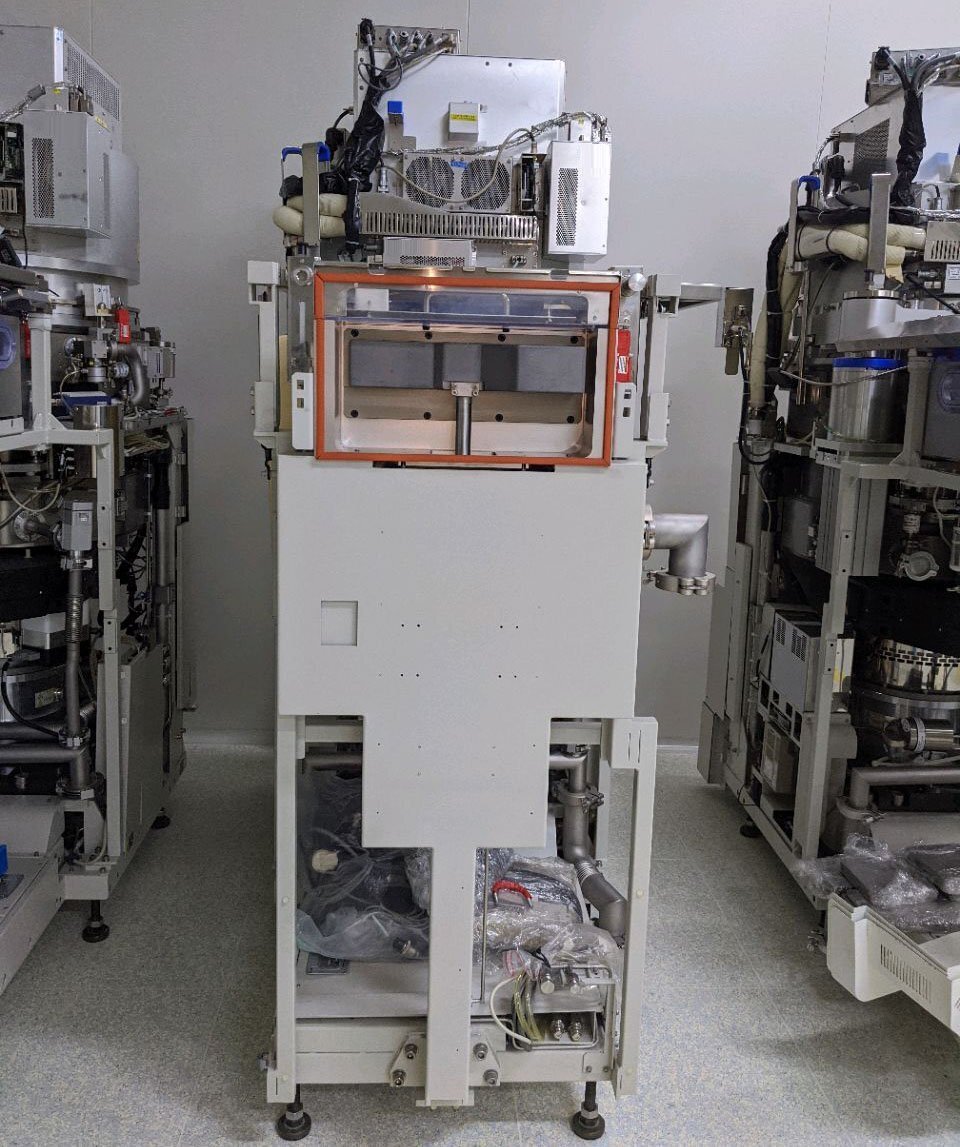

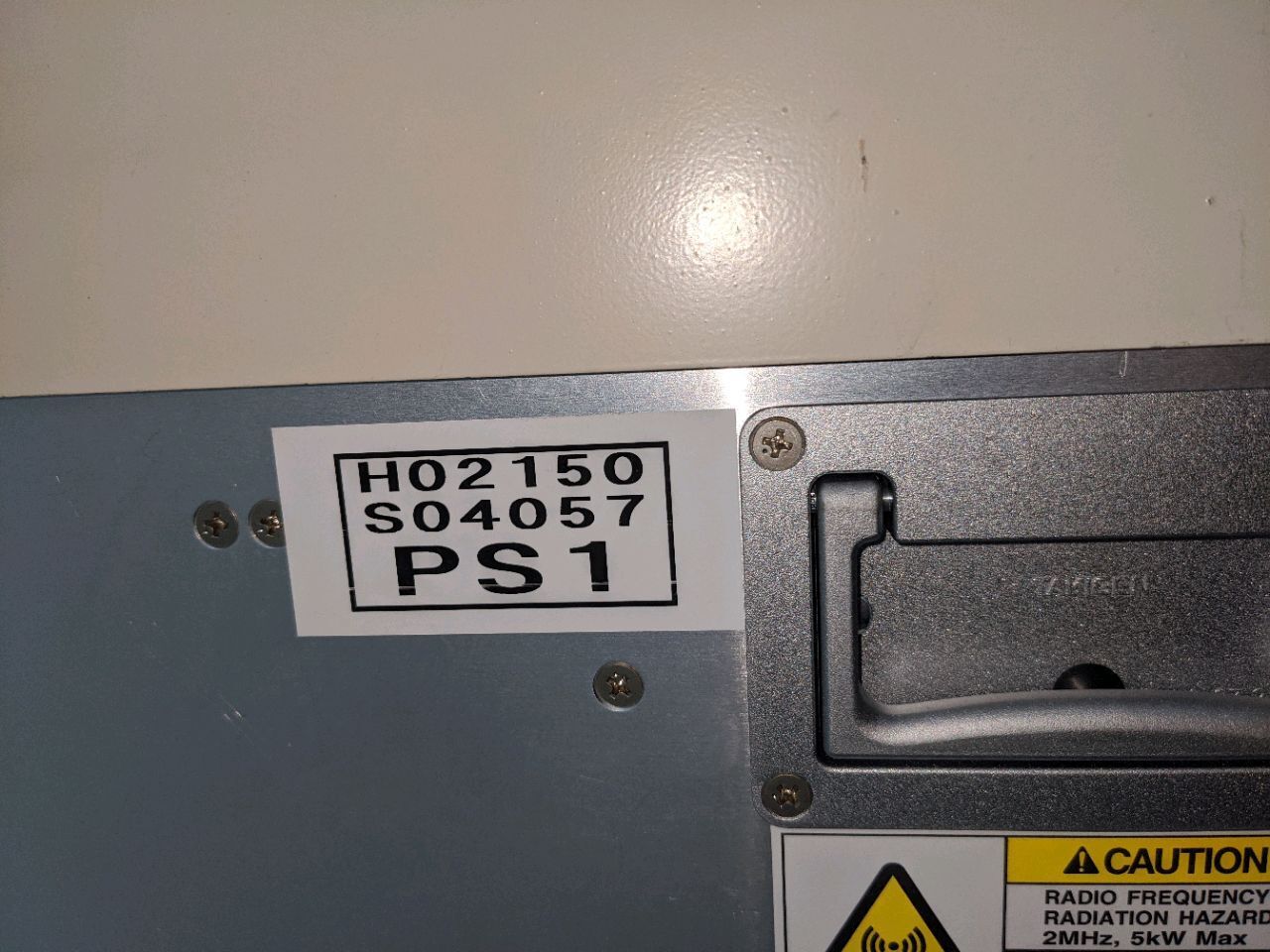

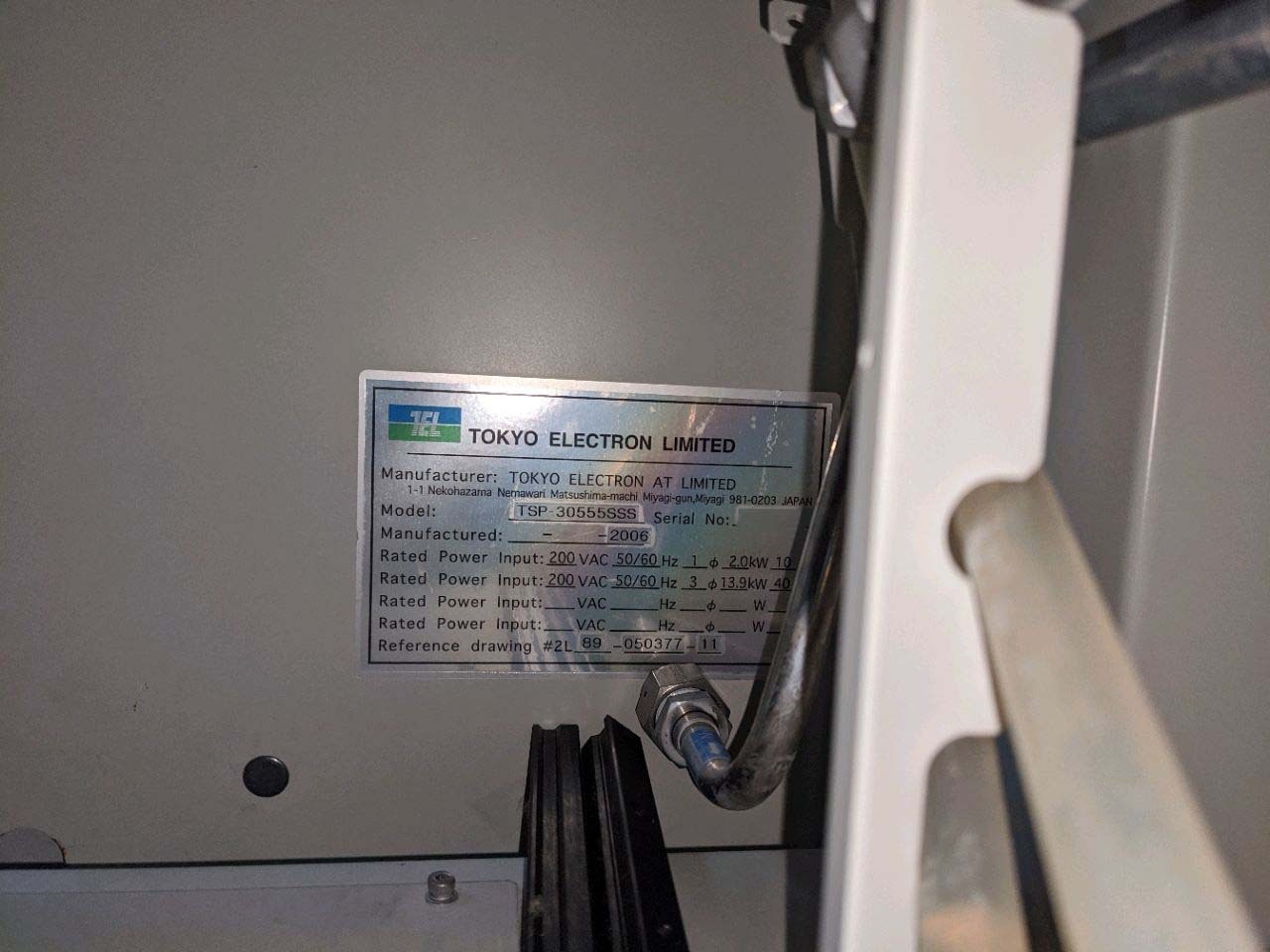

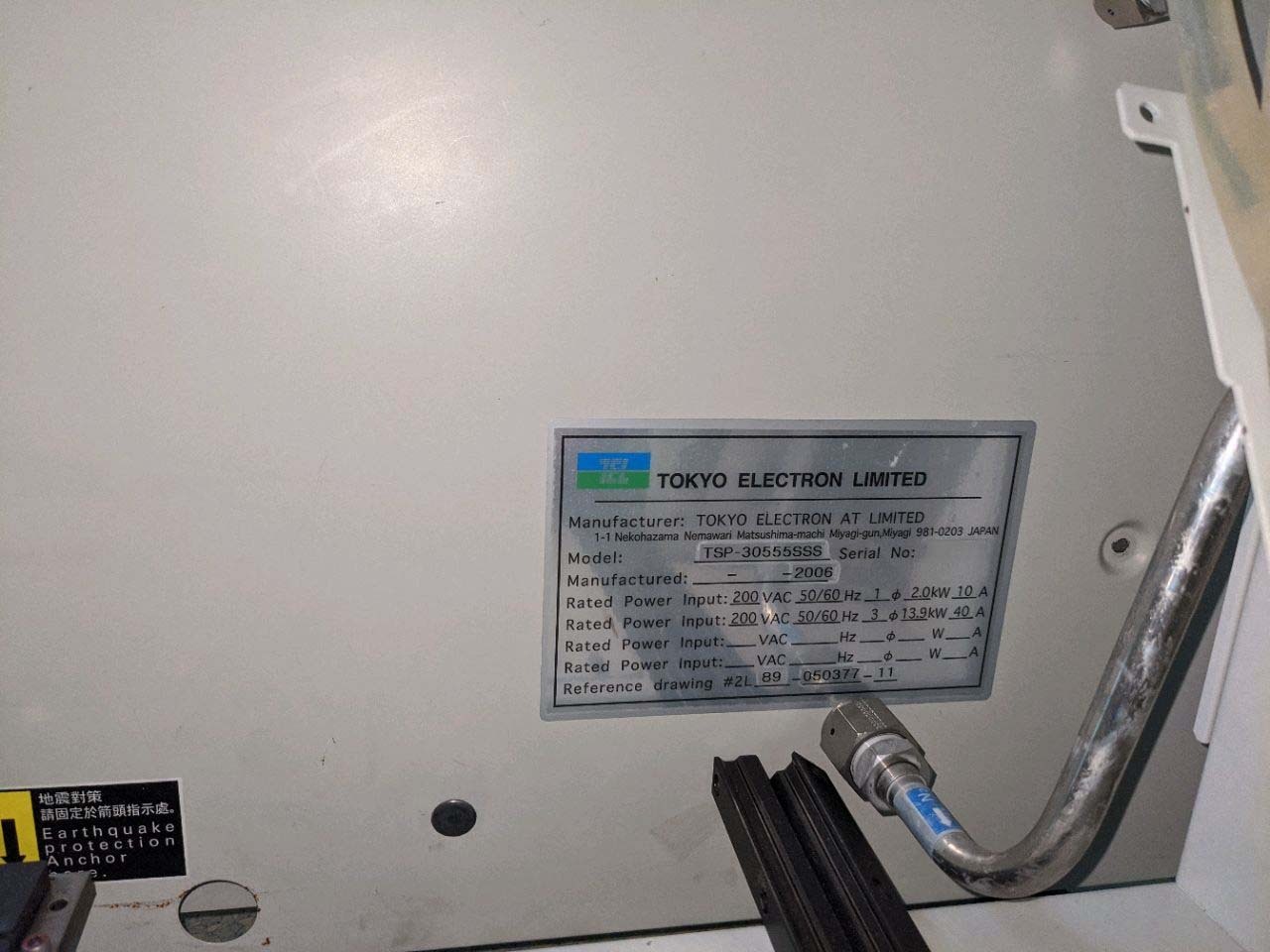

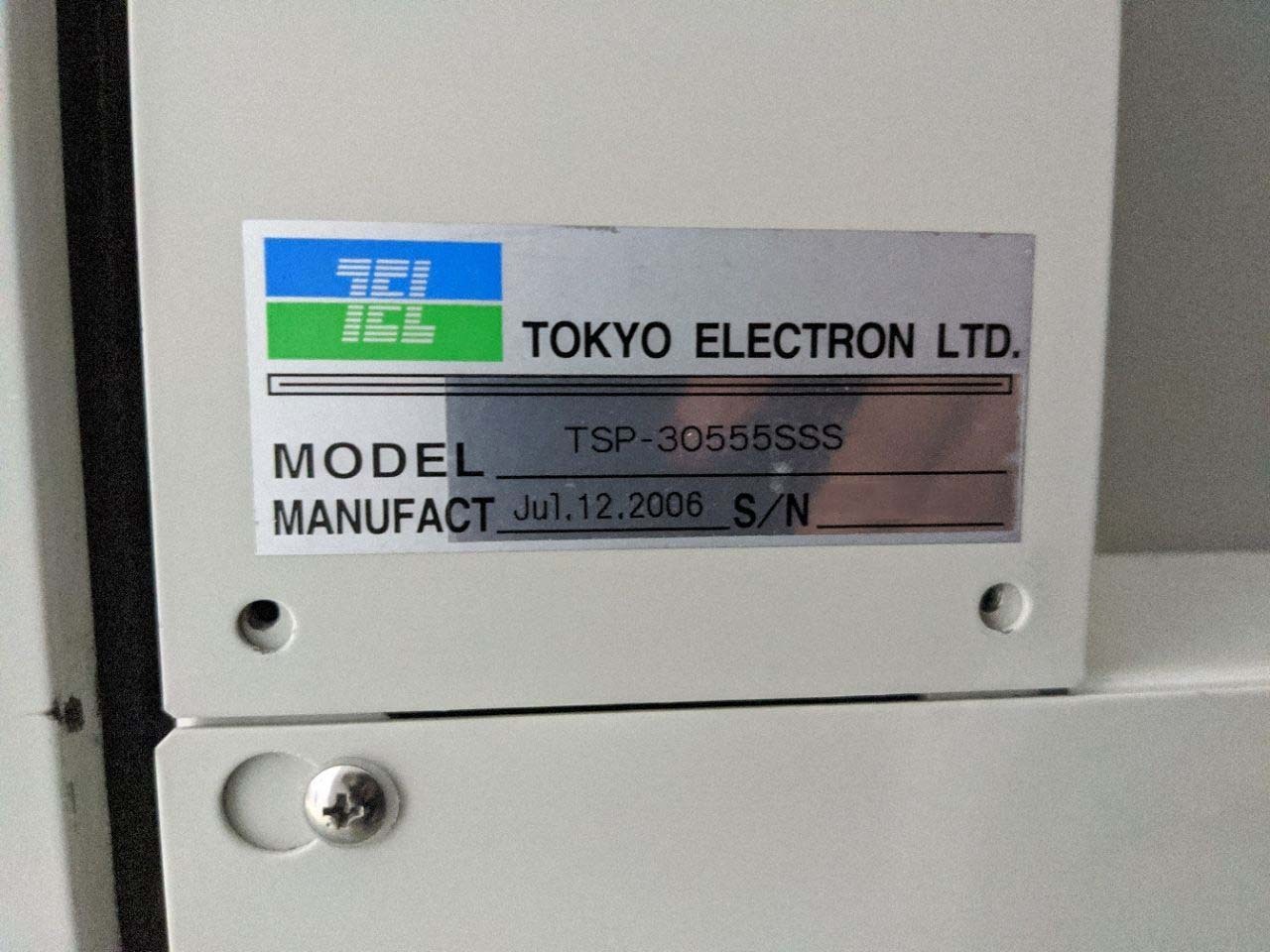

Used TEL / TOKYO ELECTRON TSP-30555SSS #9352959 for sale

URL successfully copied!

Tap to zoom

ID: 9352959

Wafer Size: 12"

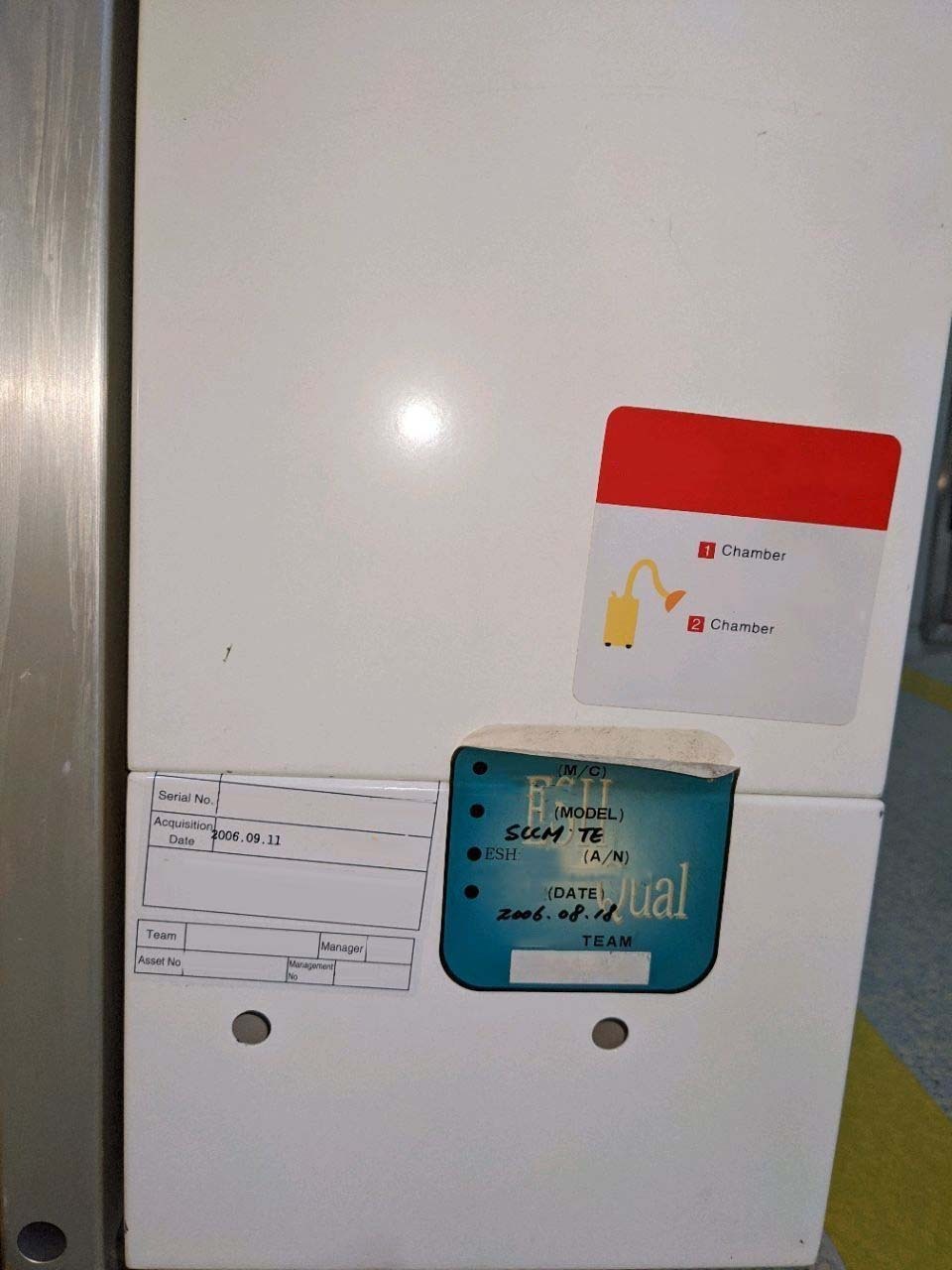

Vintage: 2006

Etcher, 12"

Model: SCCM Shin

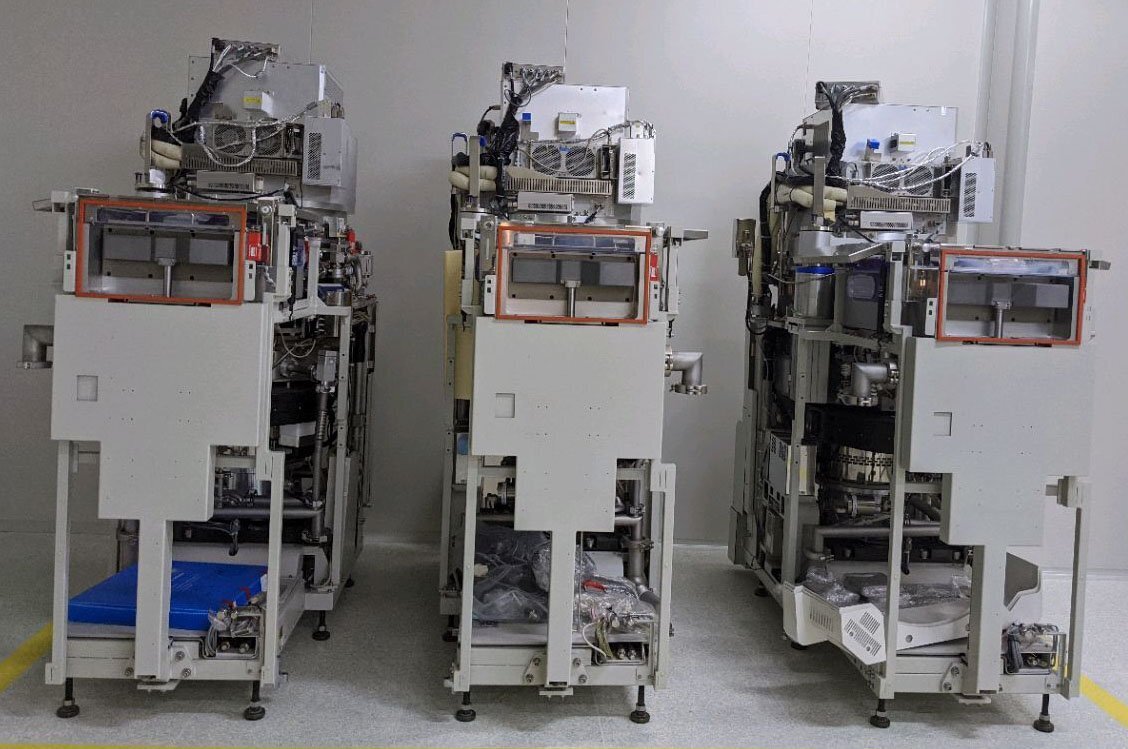

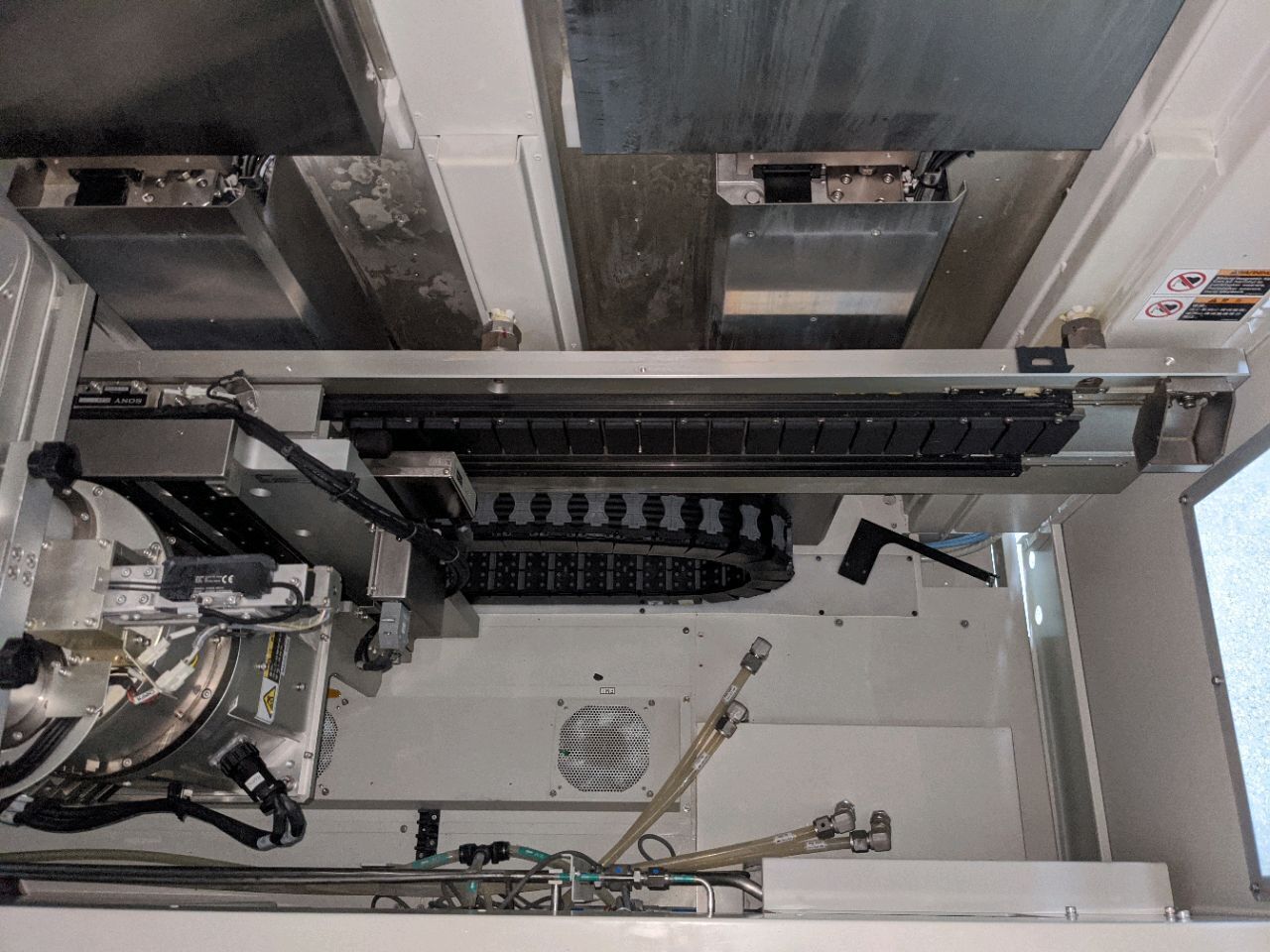

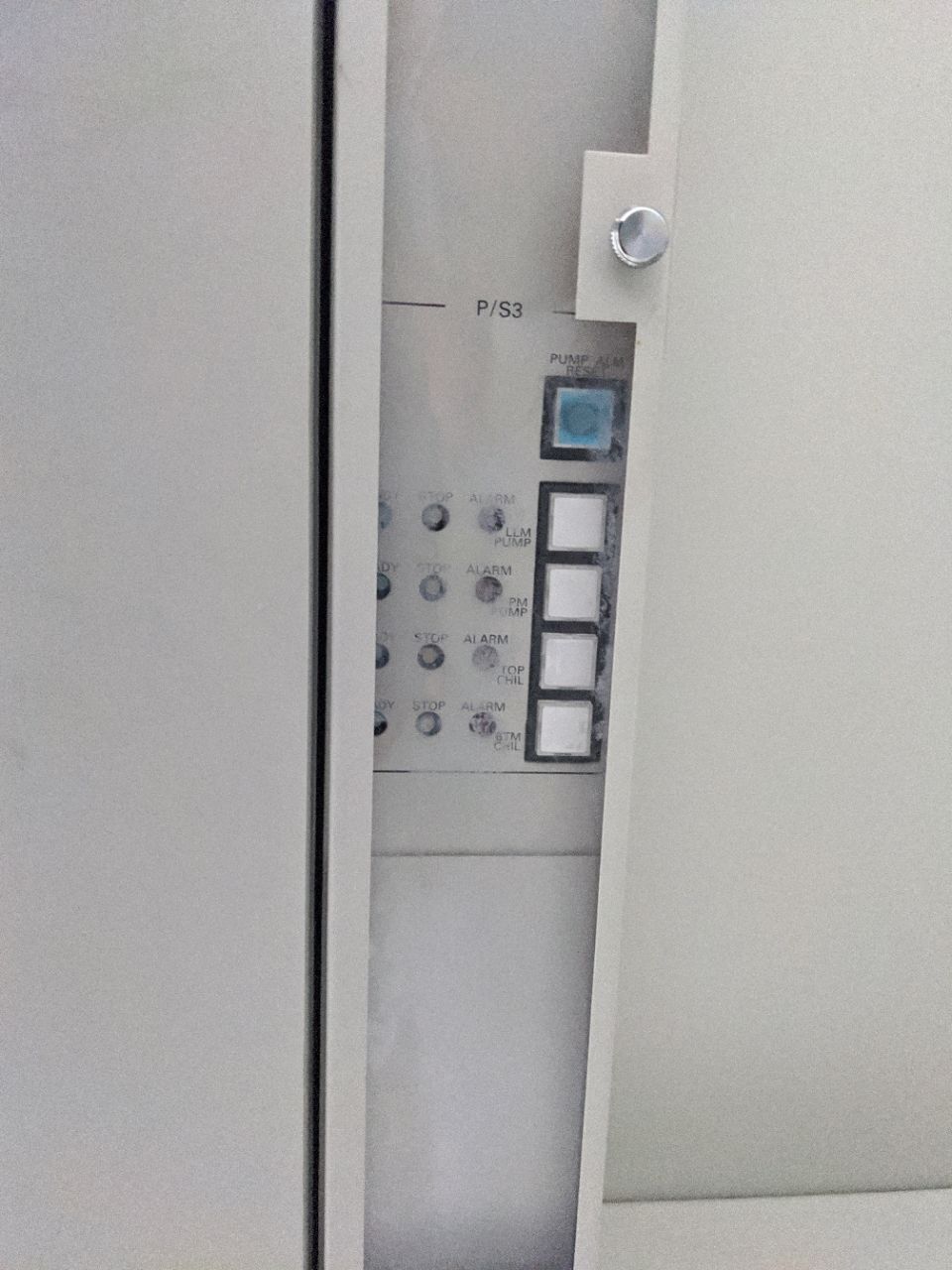

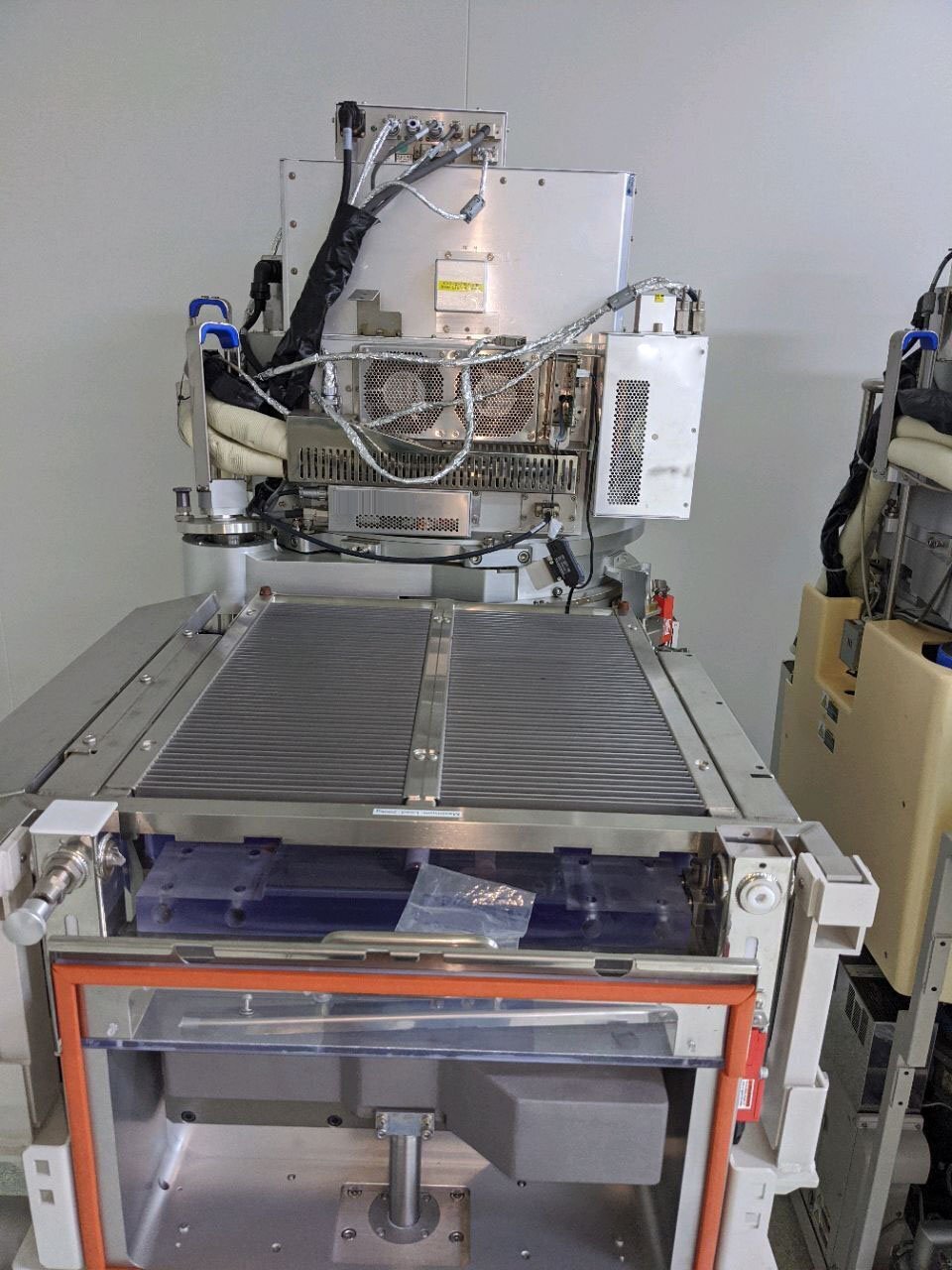

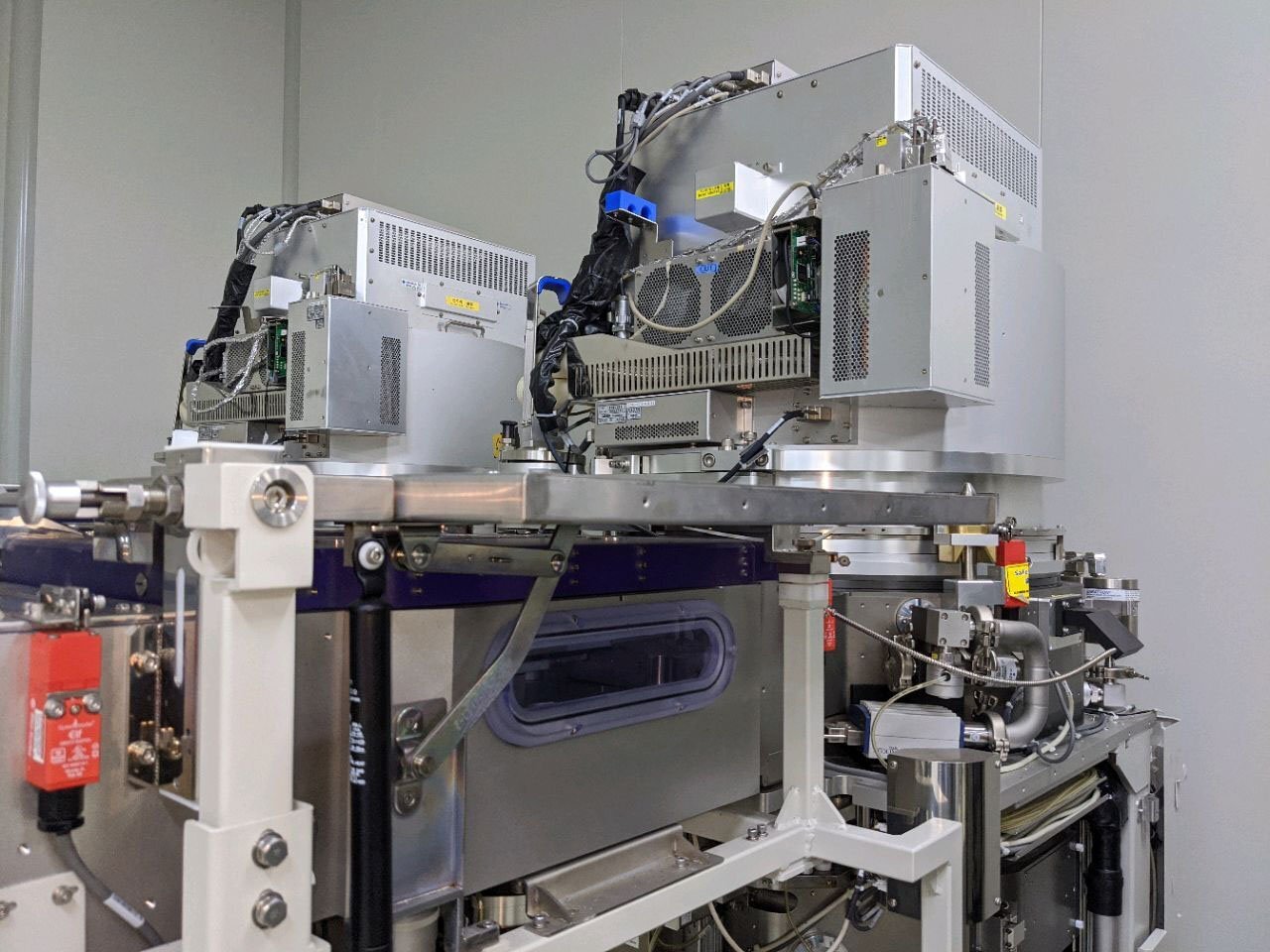

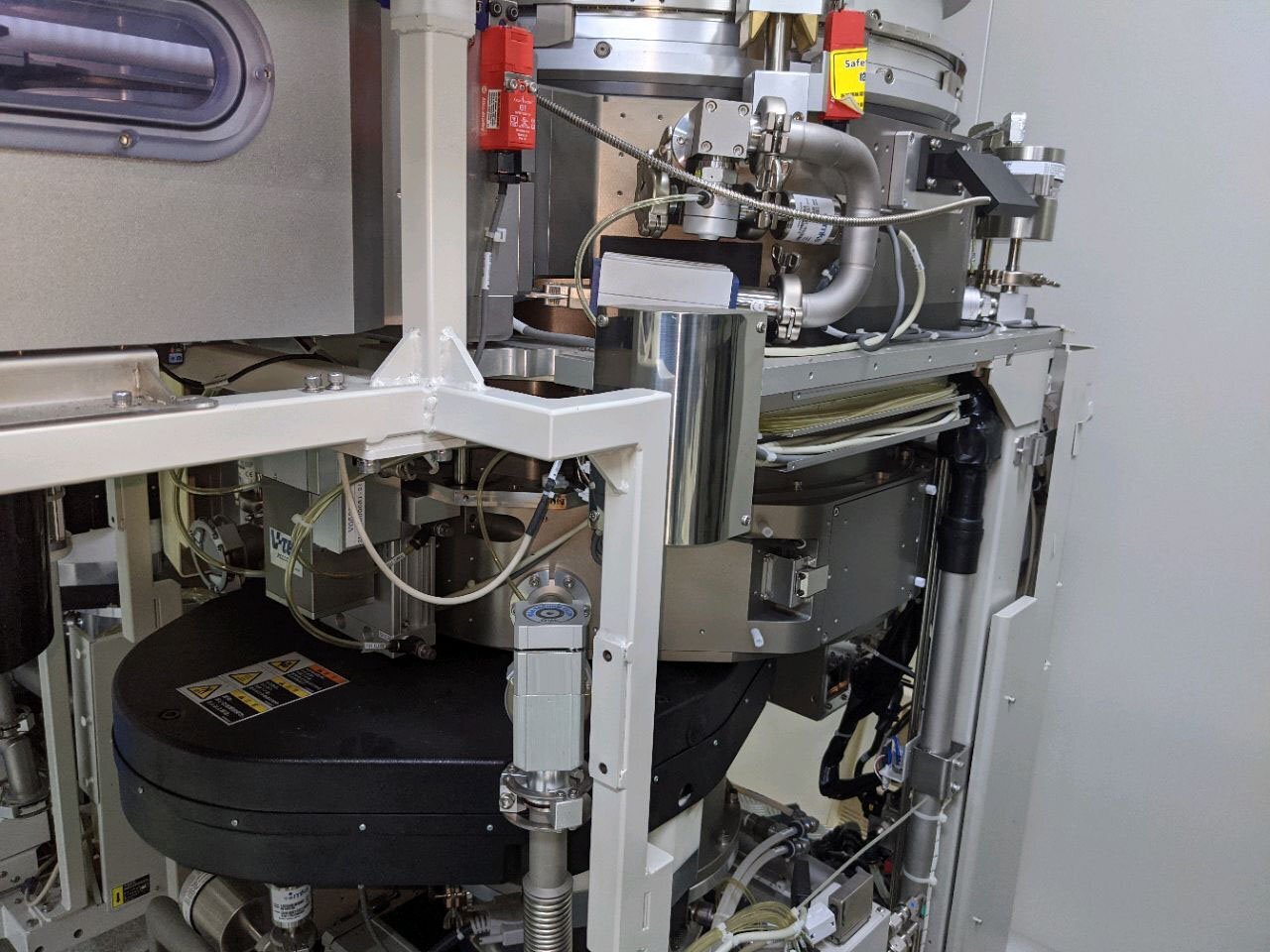

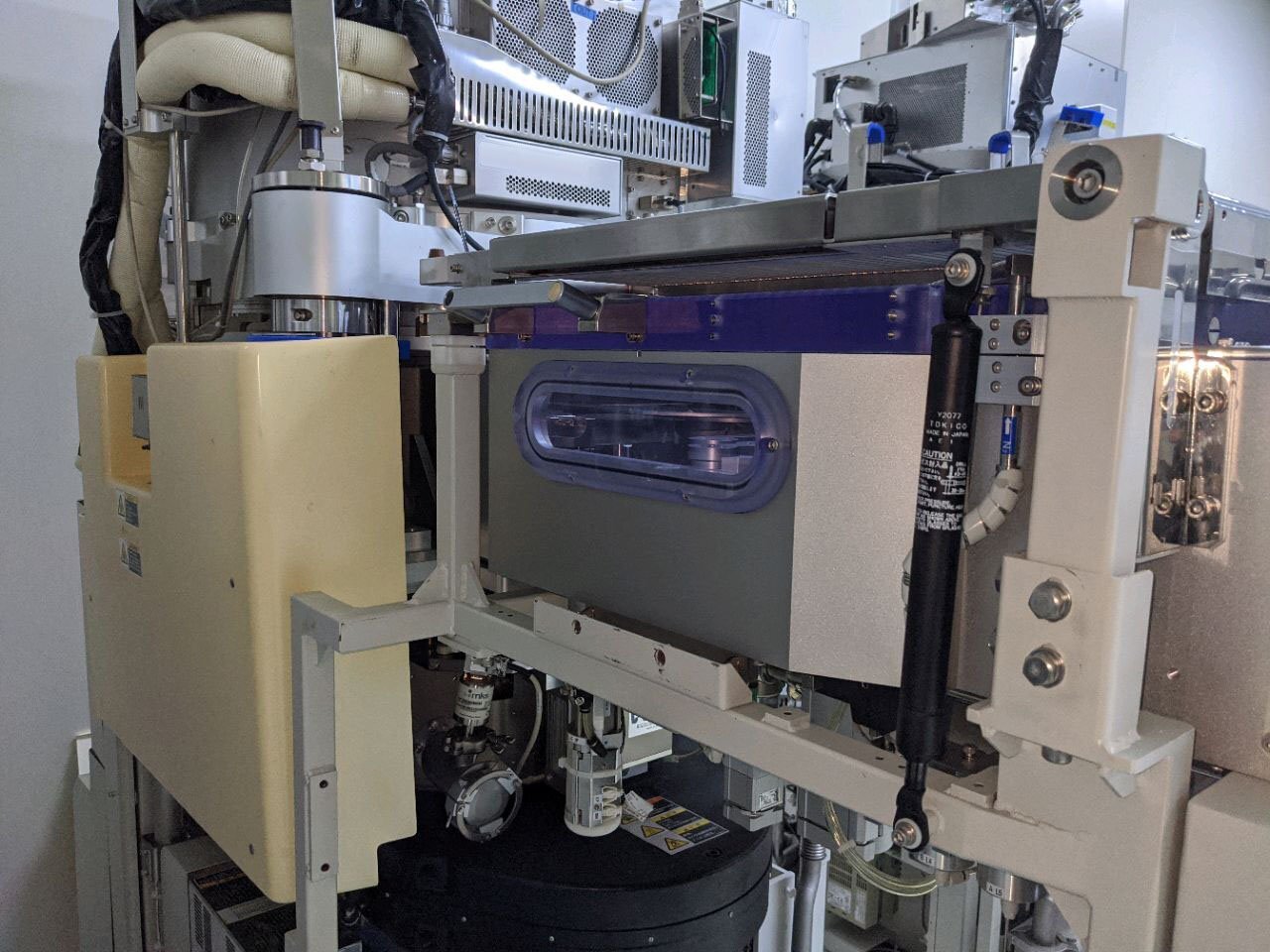

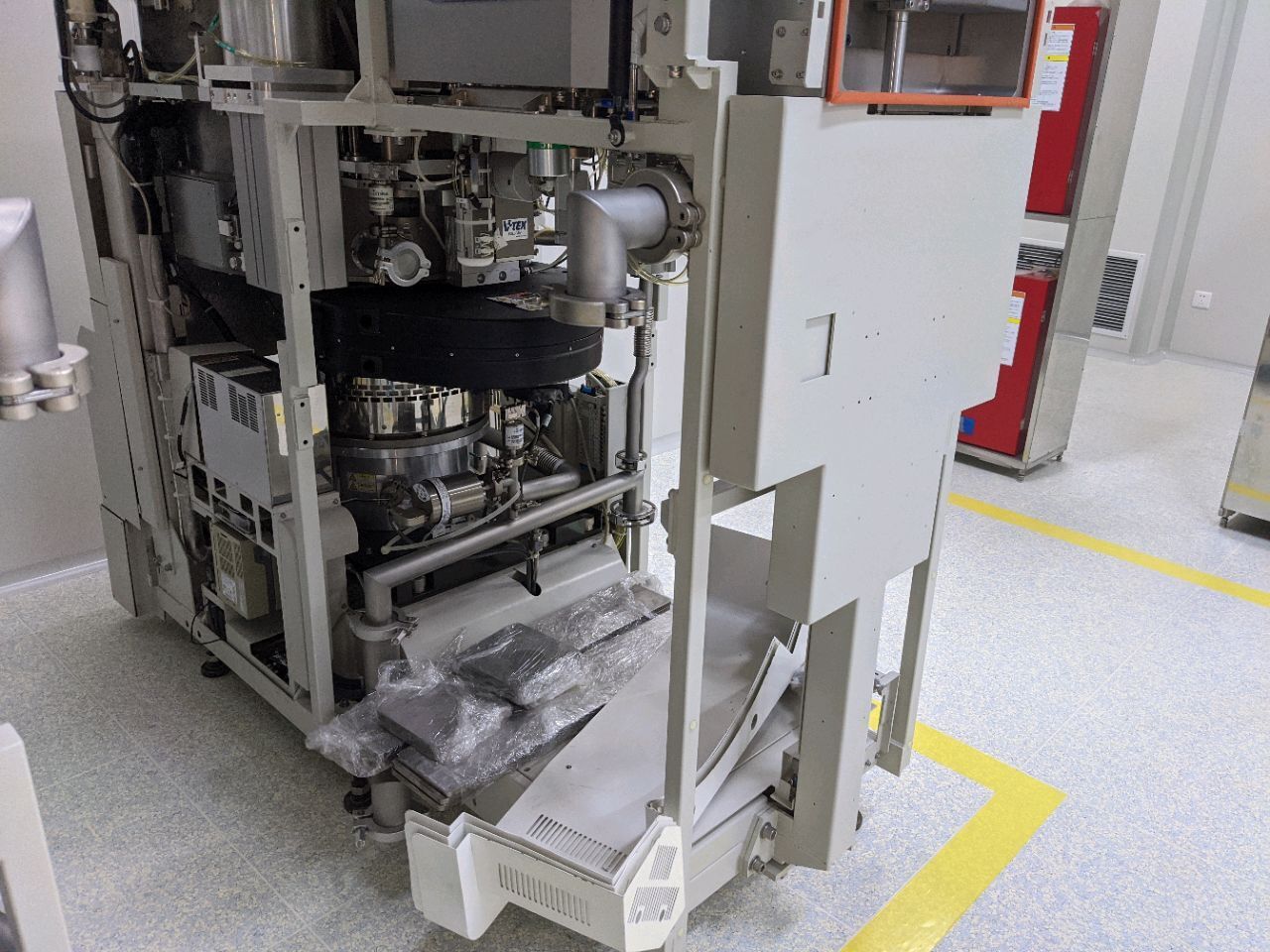

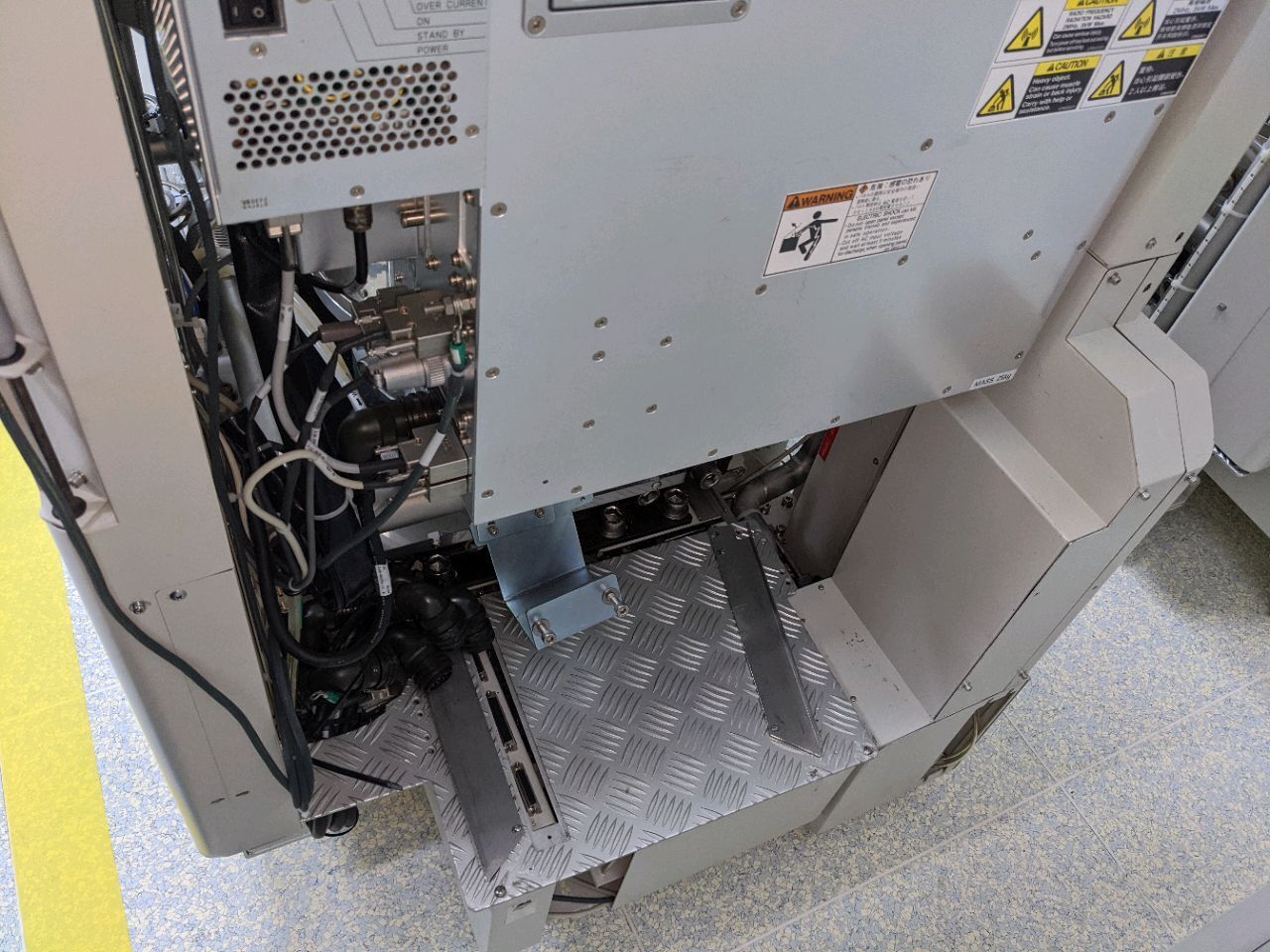

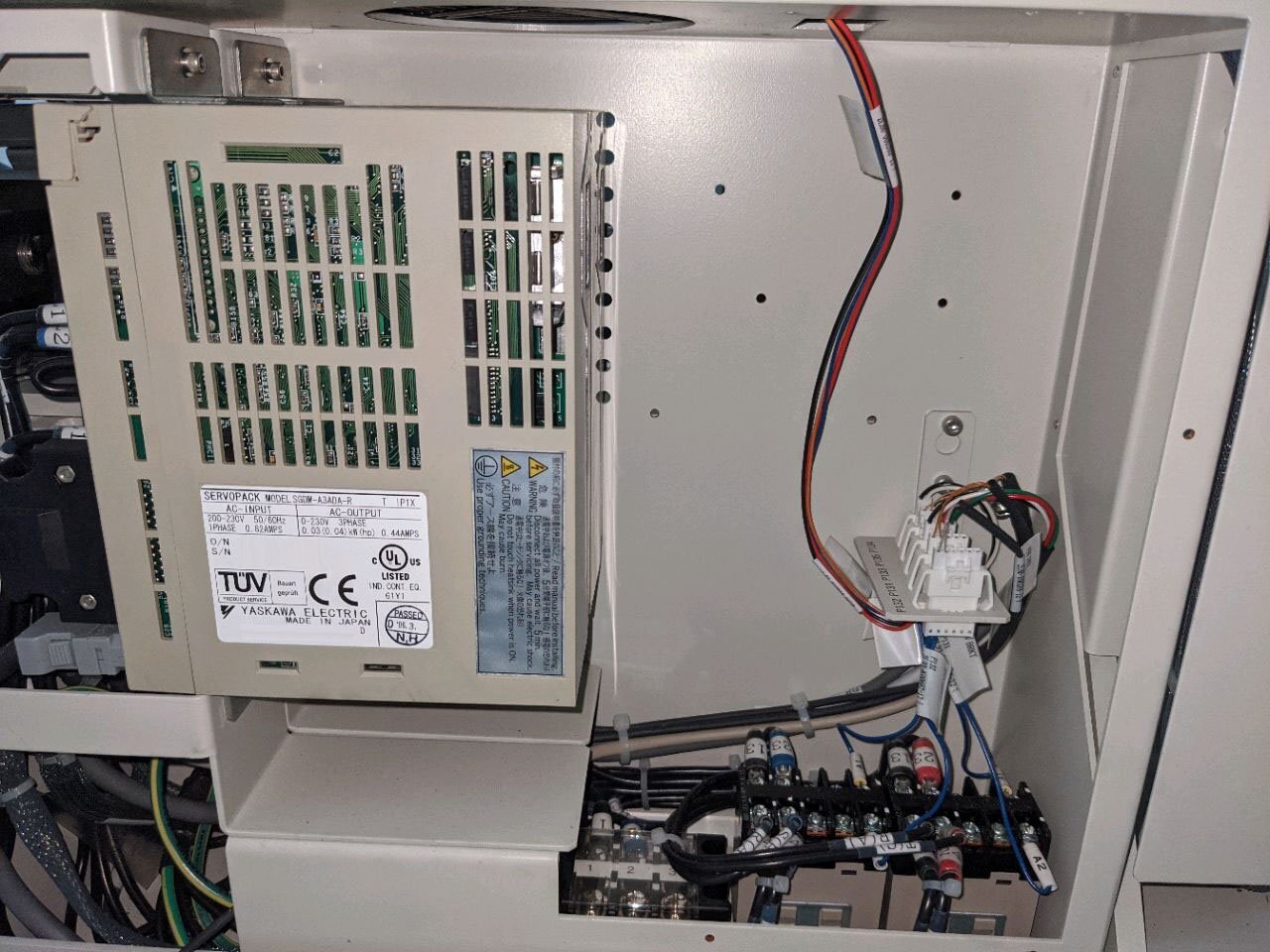

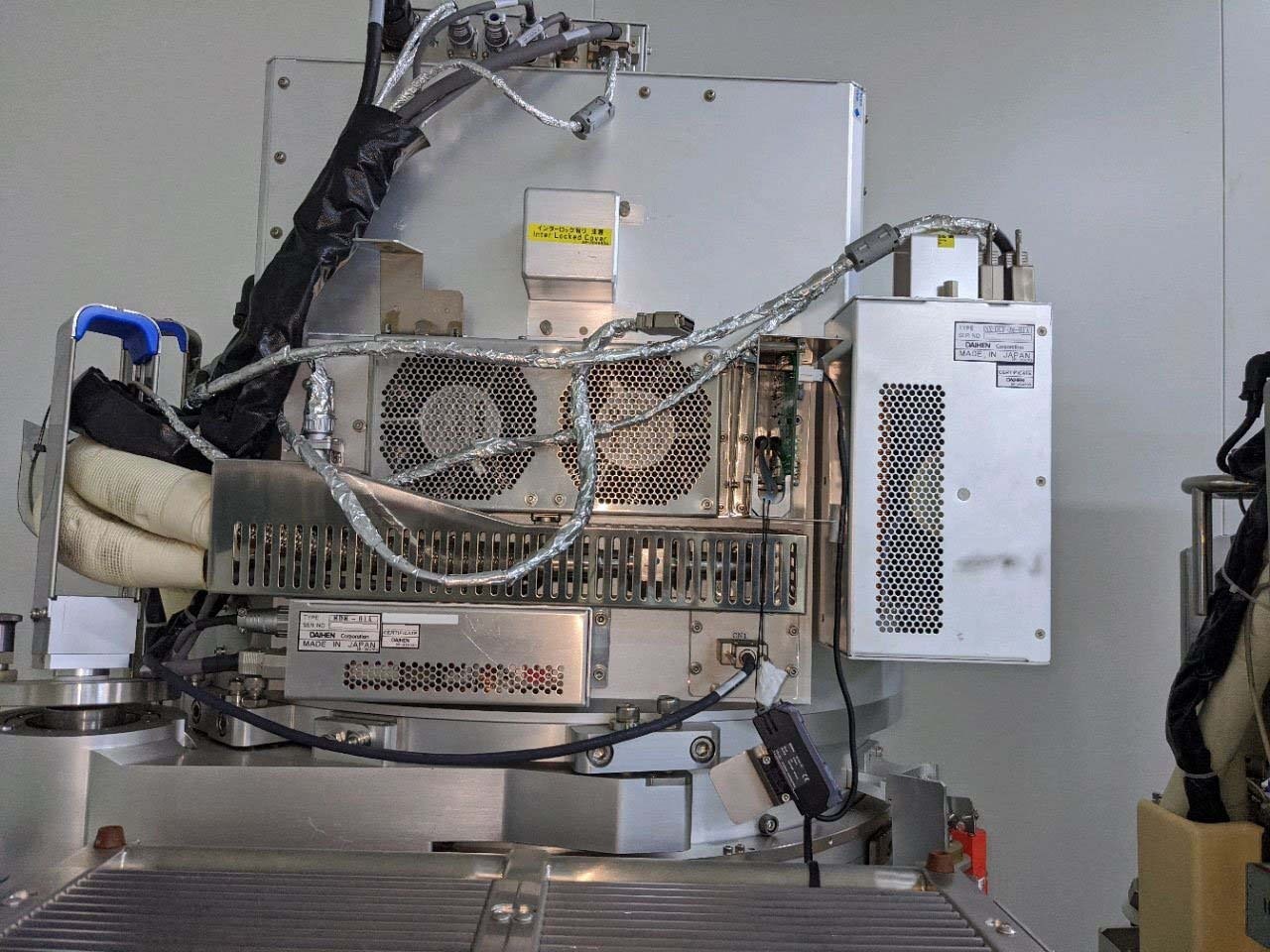

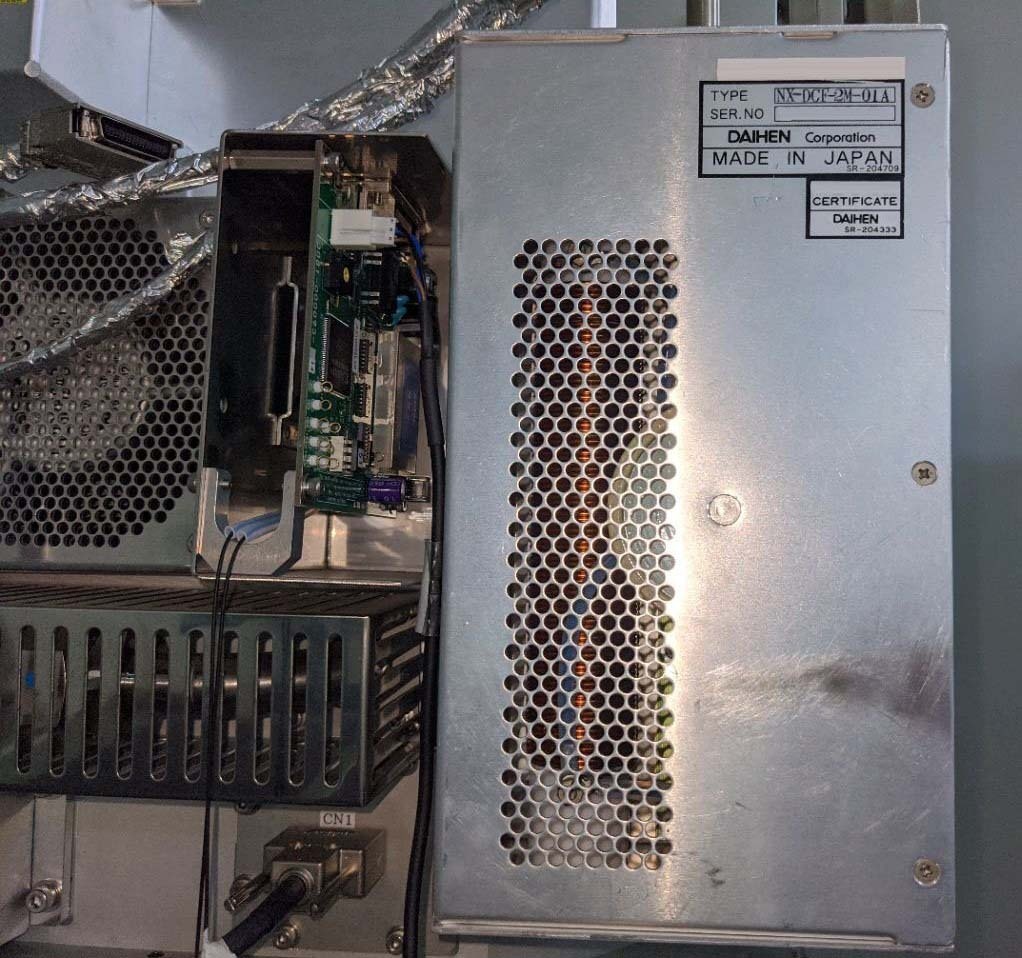

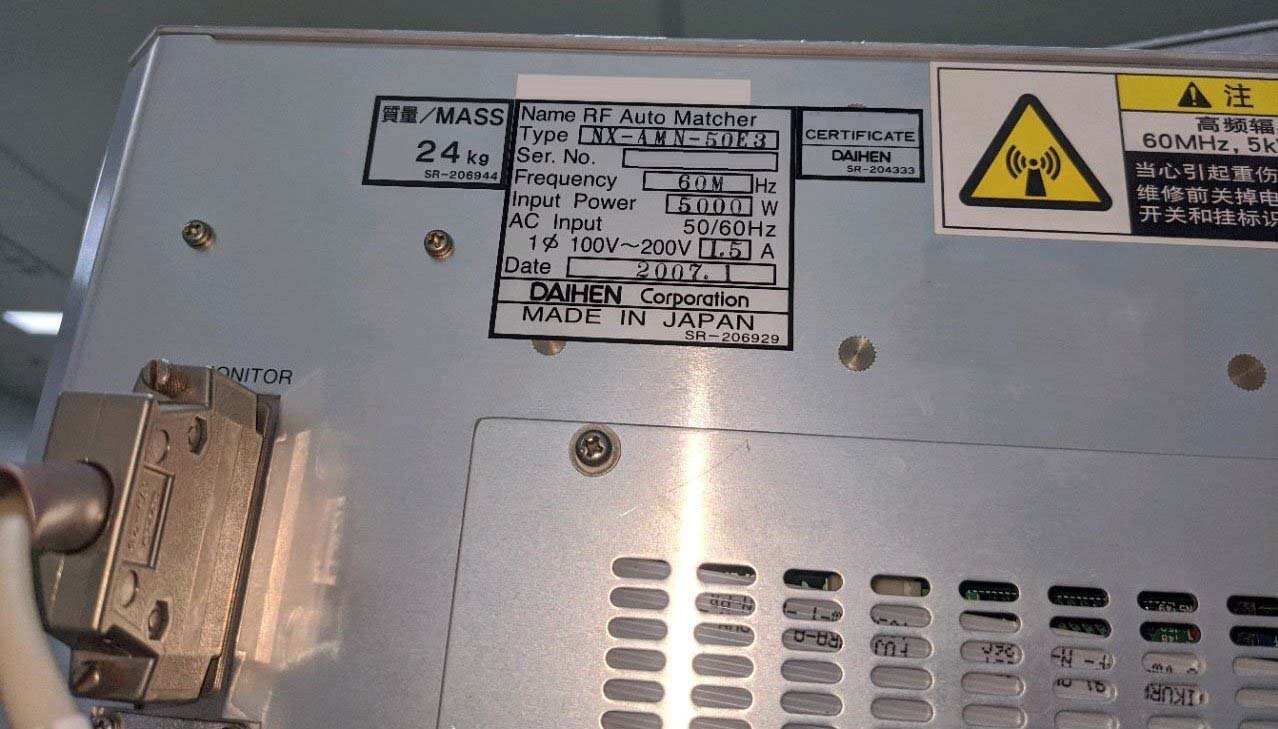

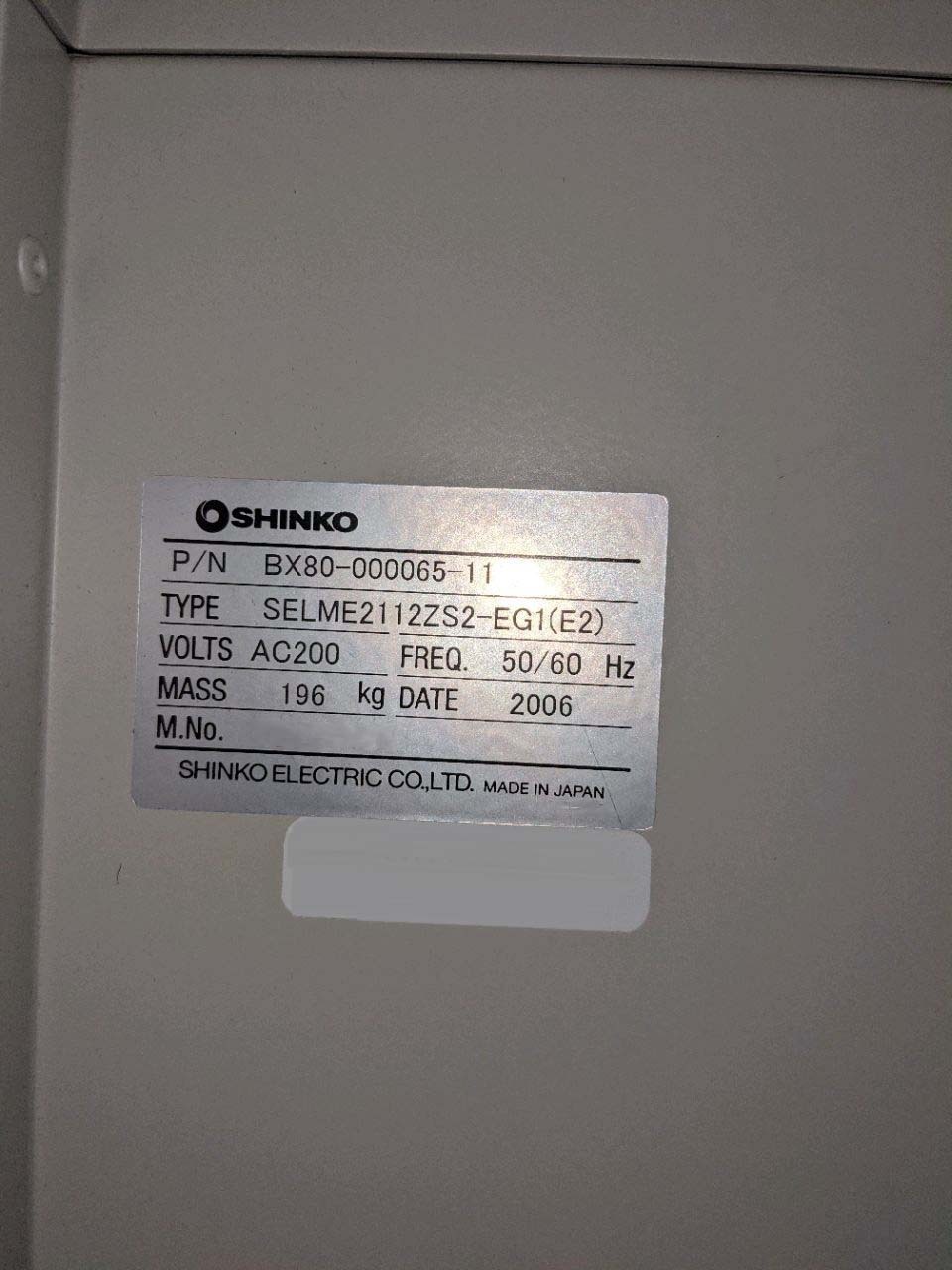

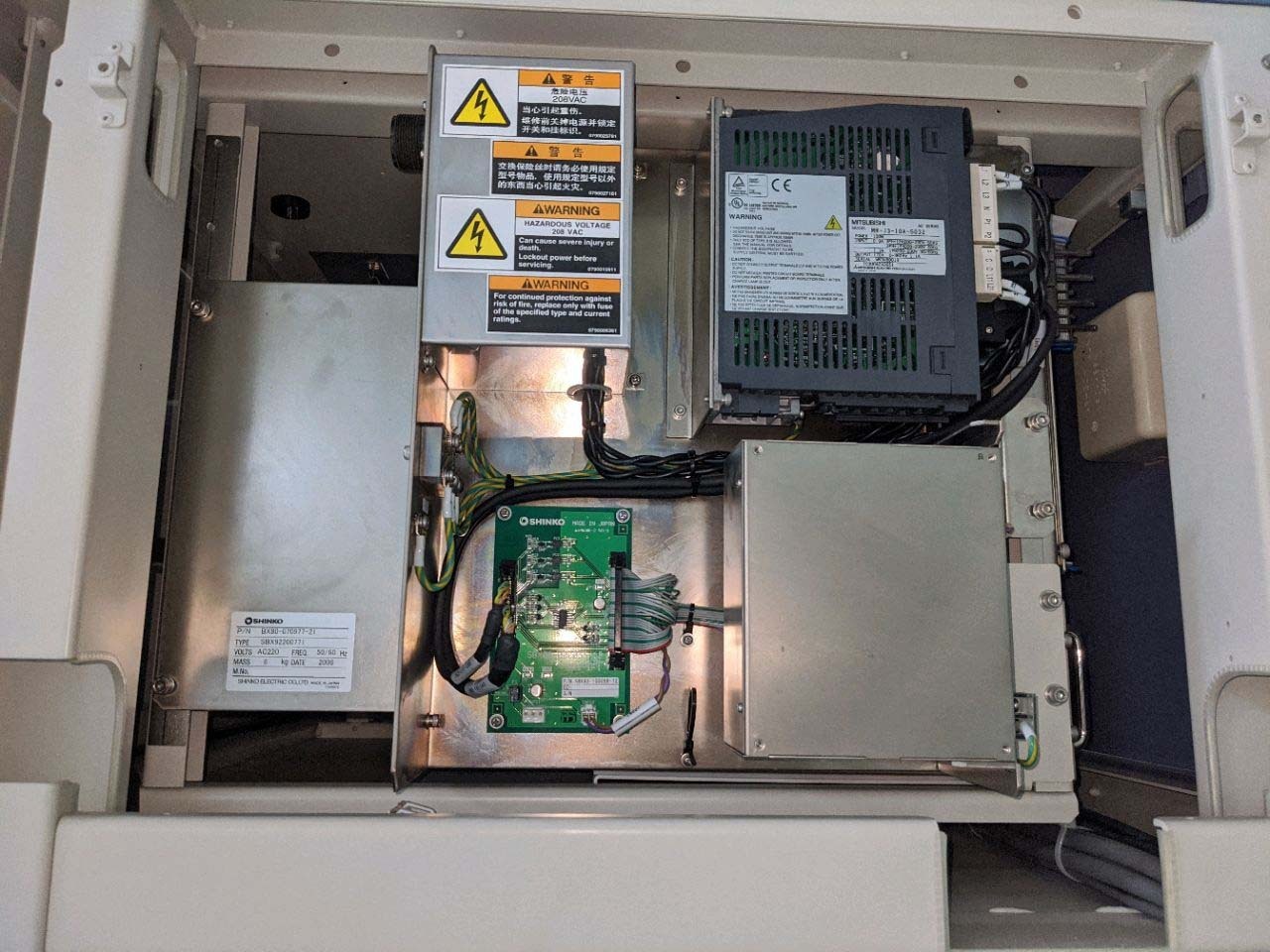

Main frame

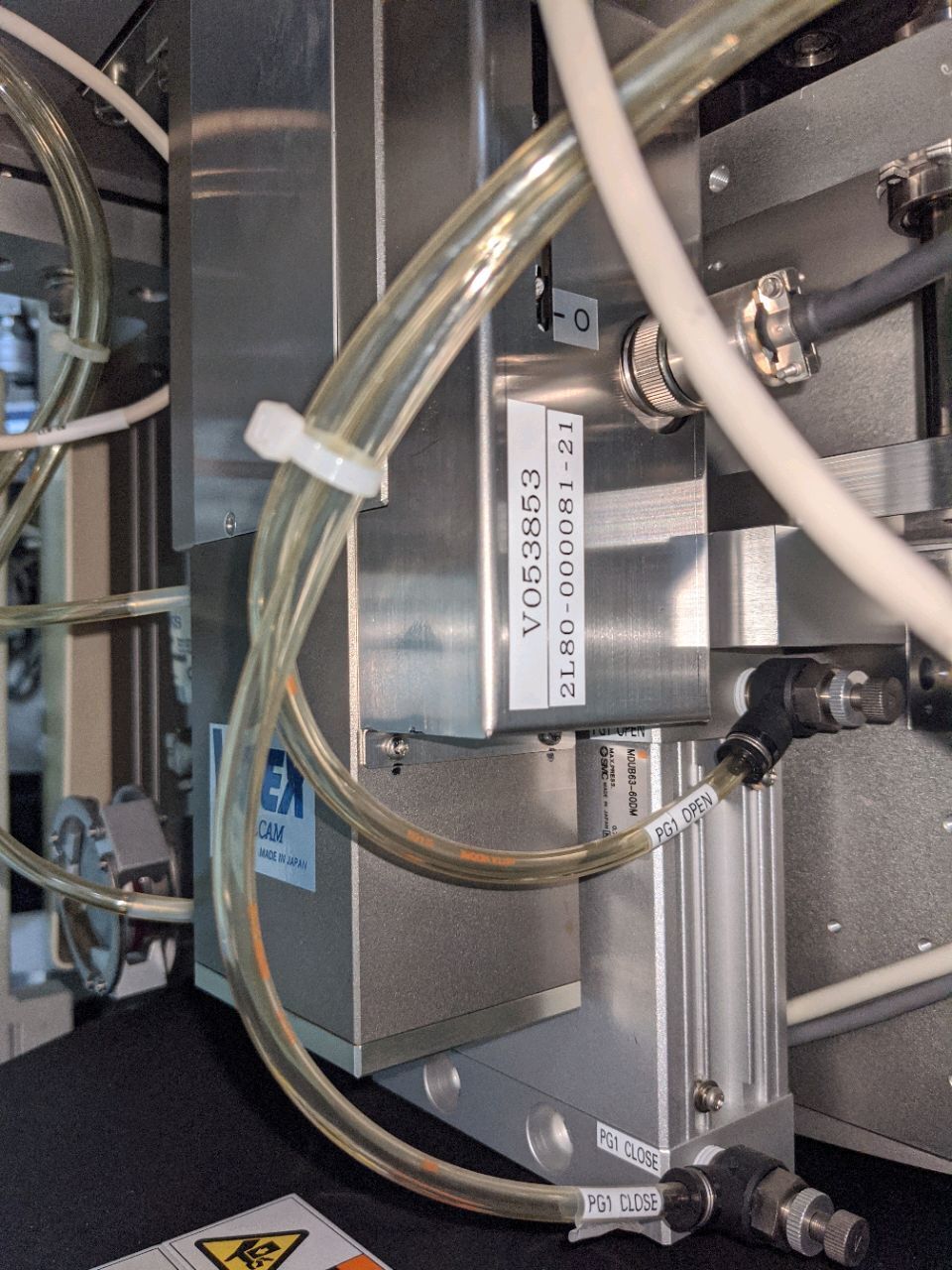

(3) Chambers

2006 vintage.

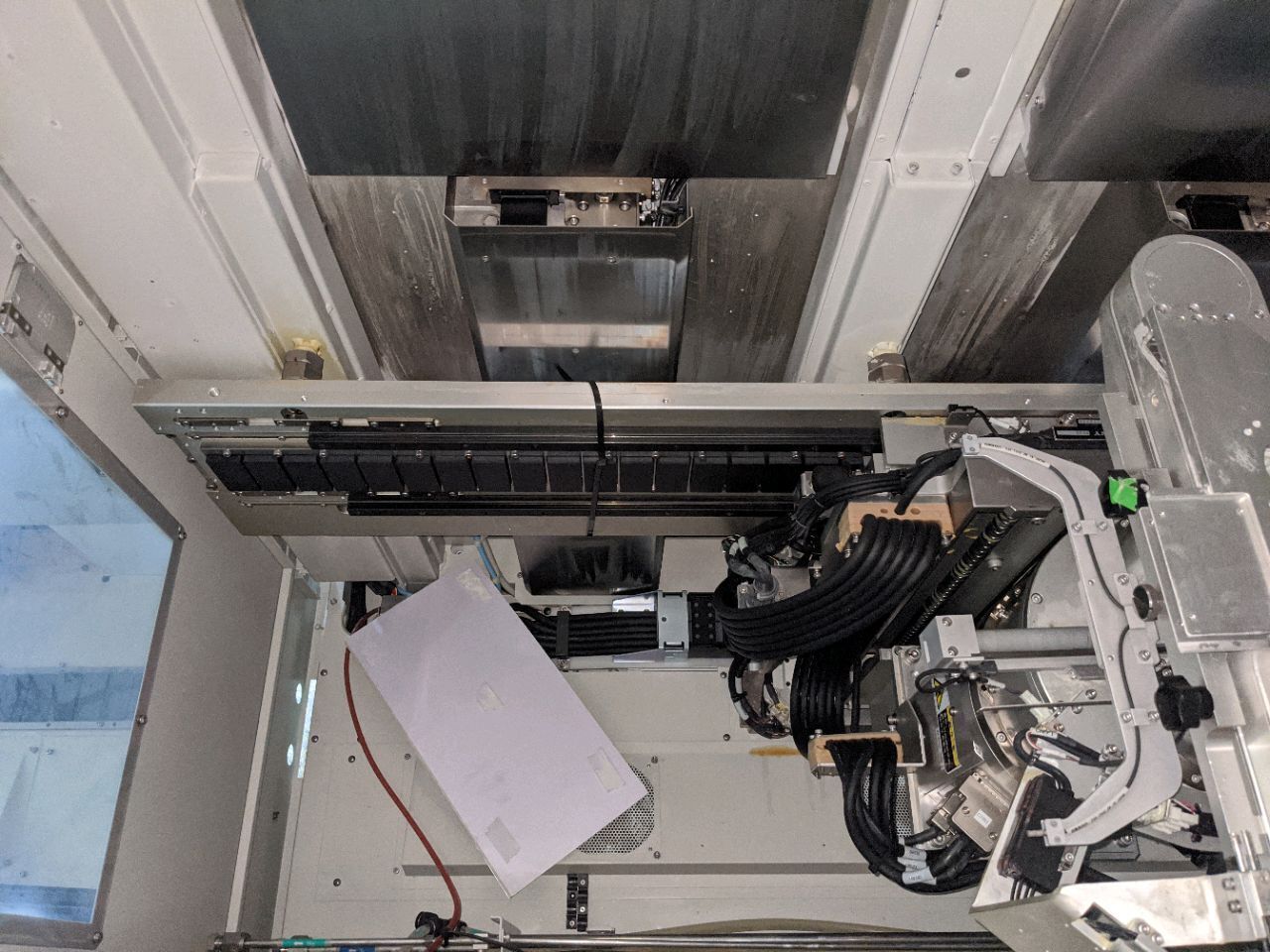

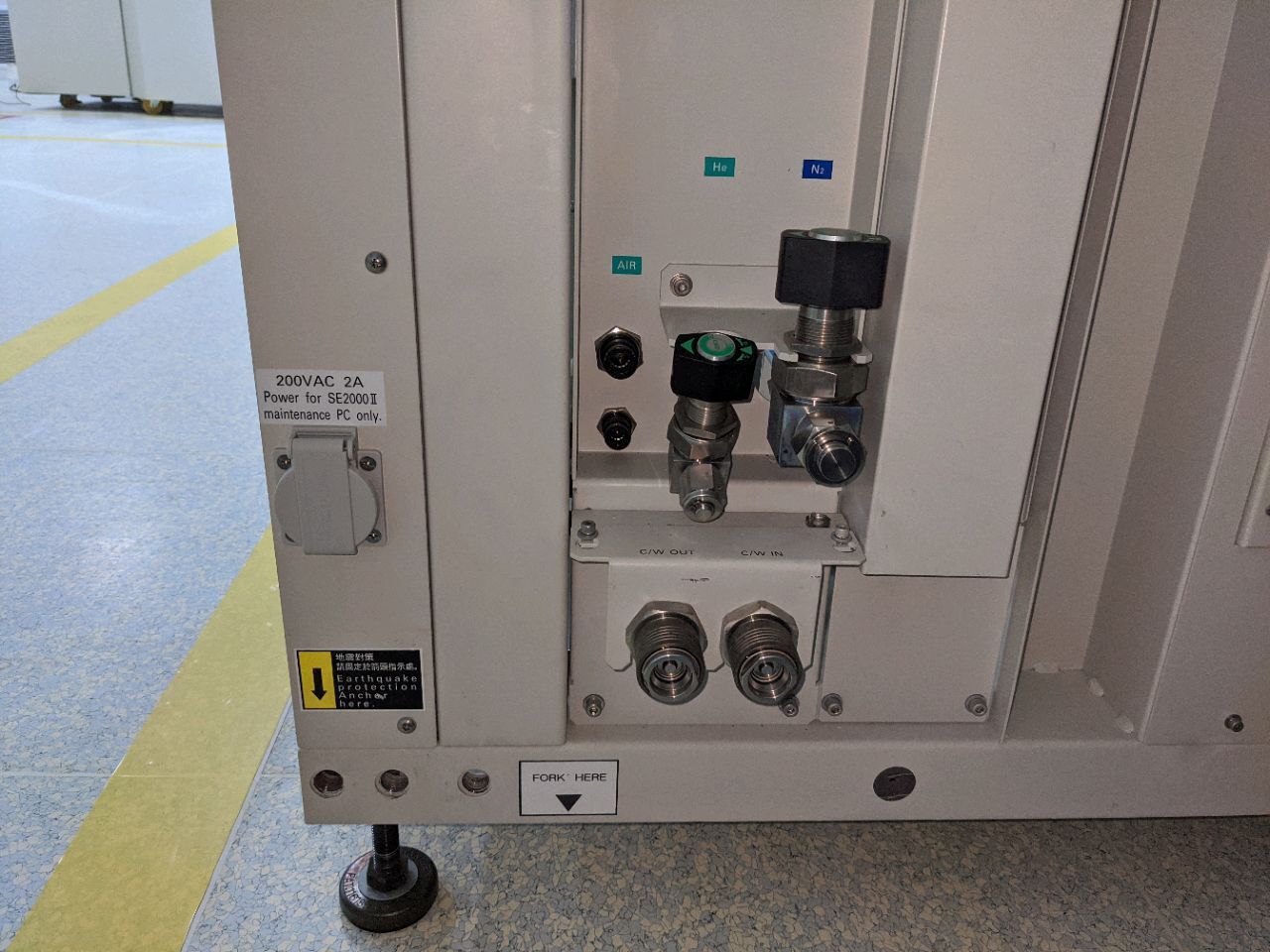

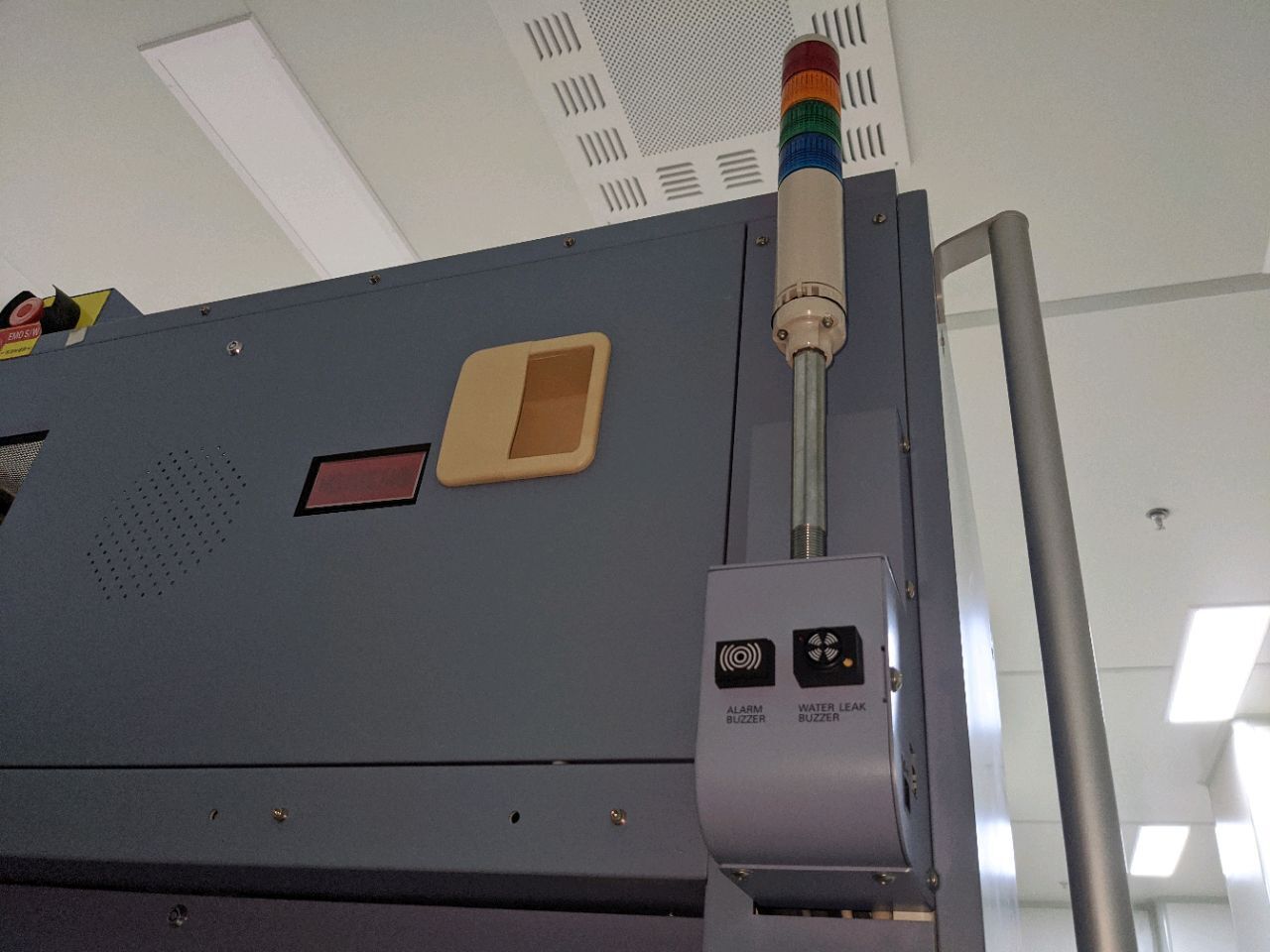

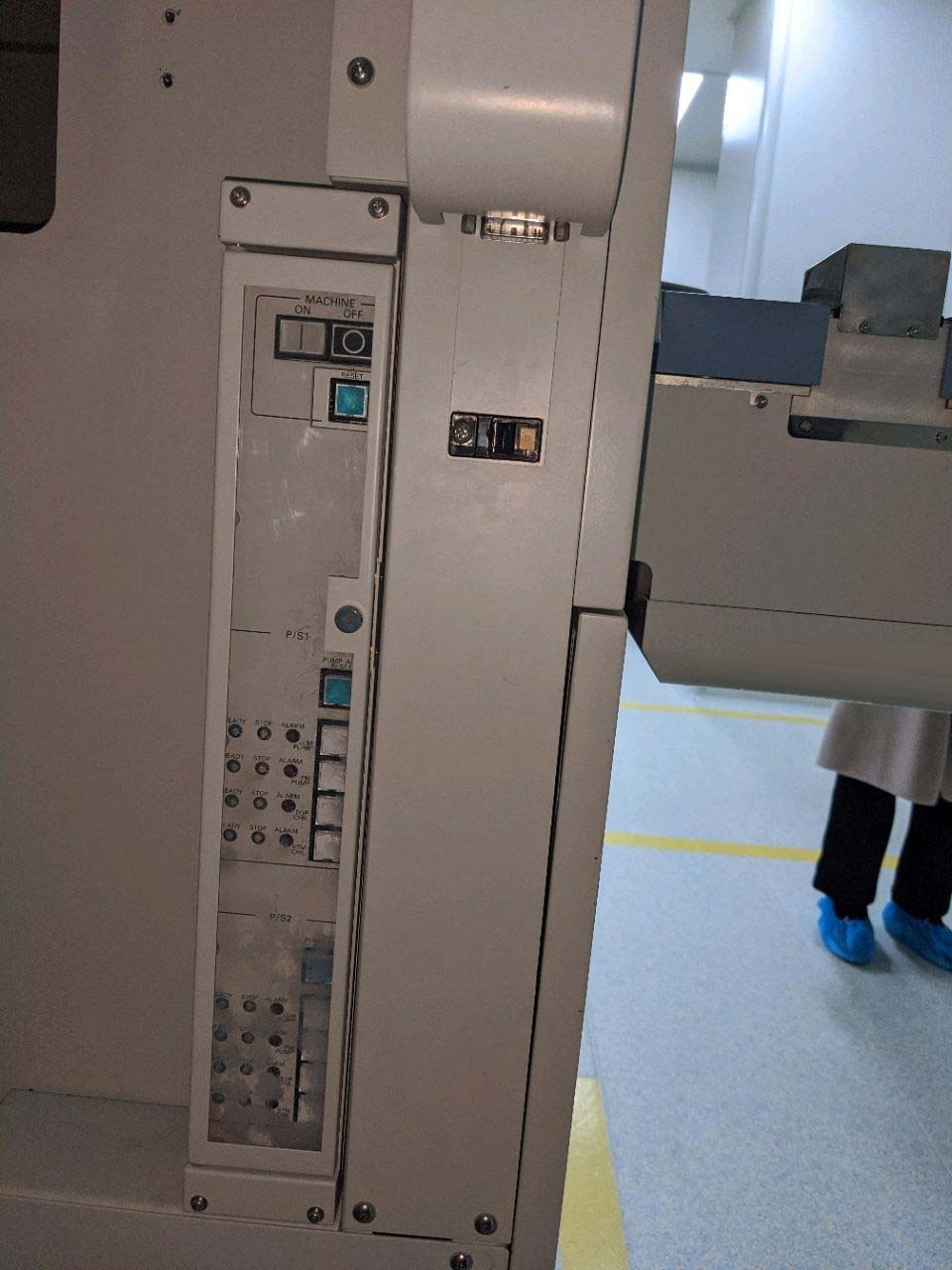

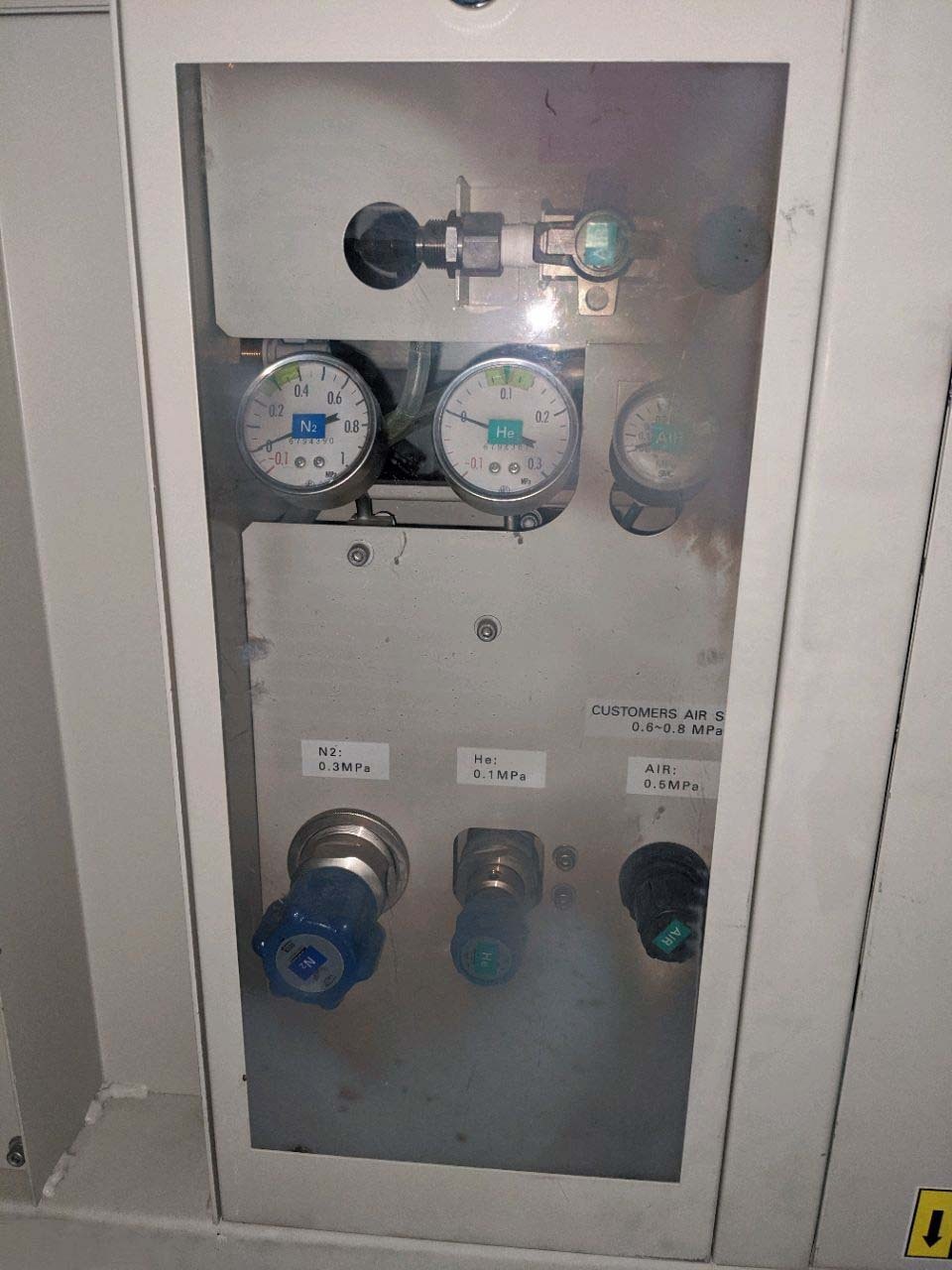

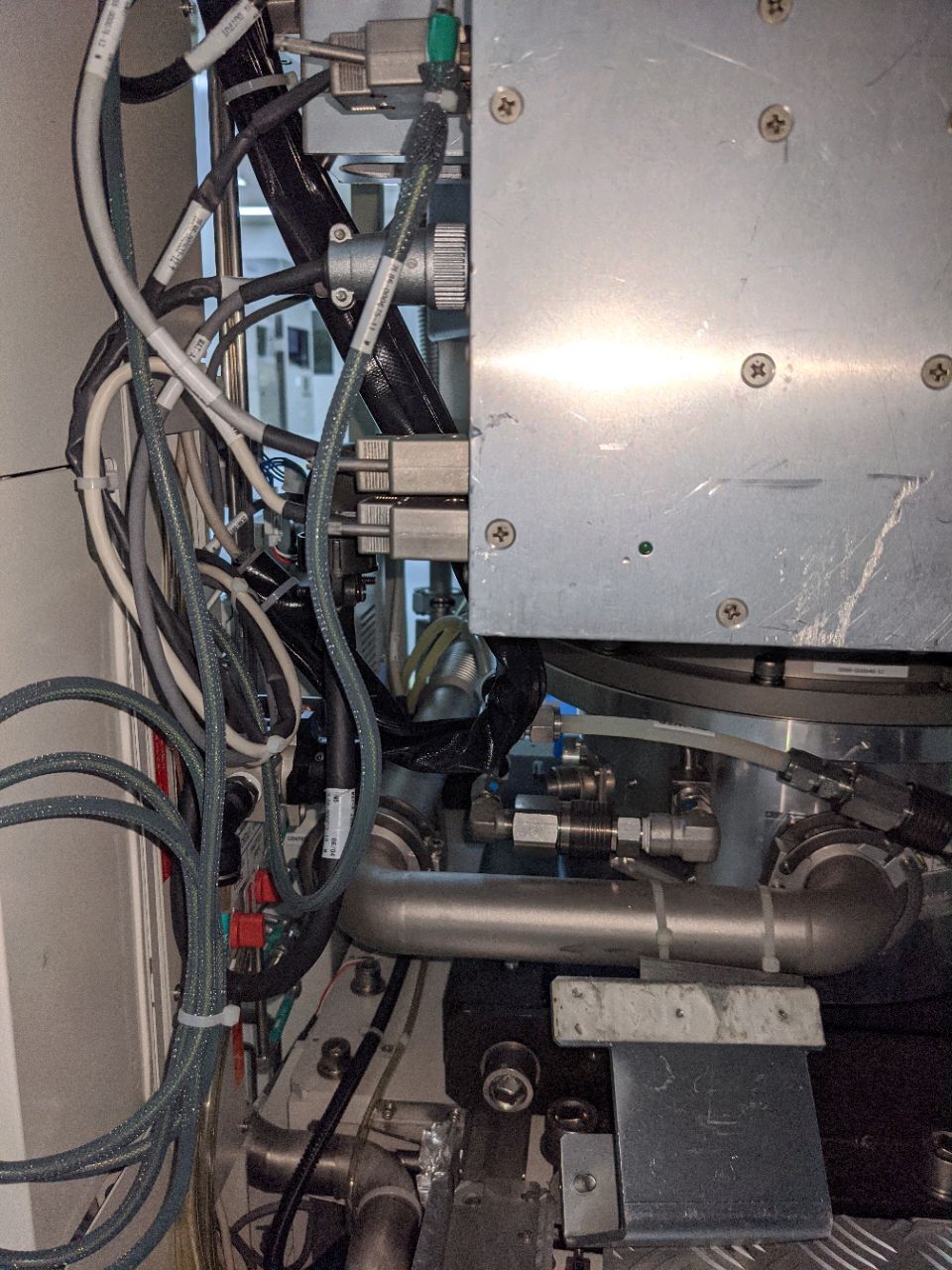

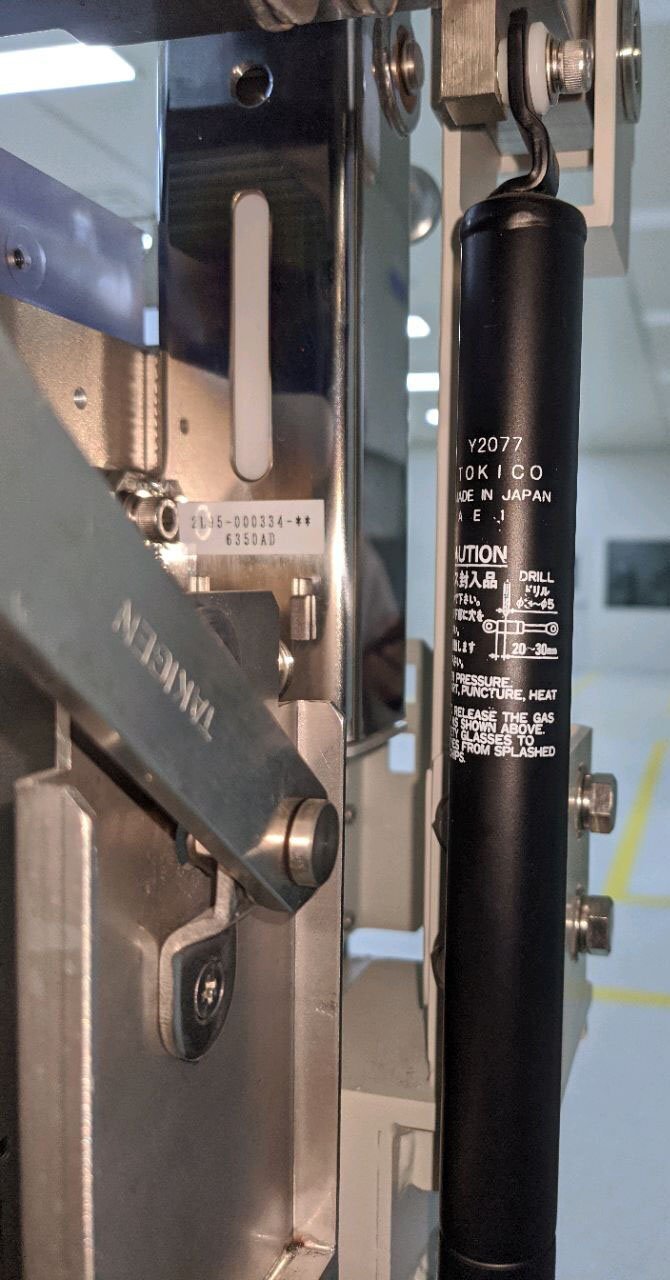

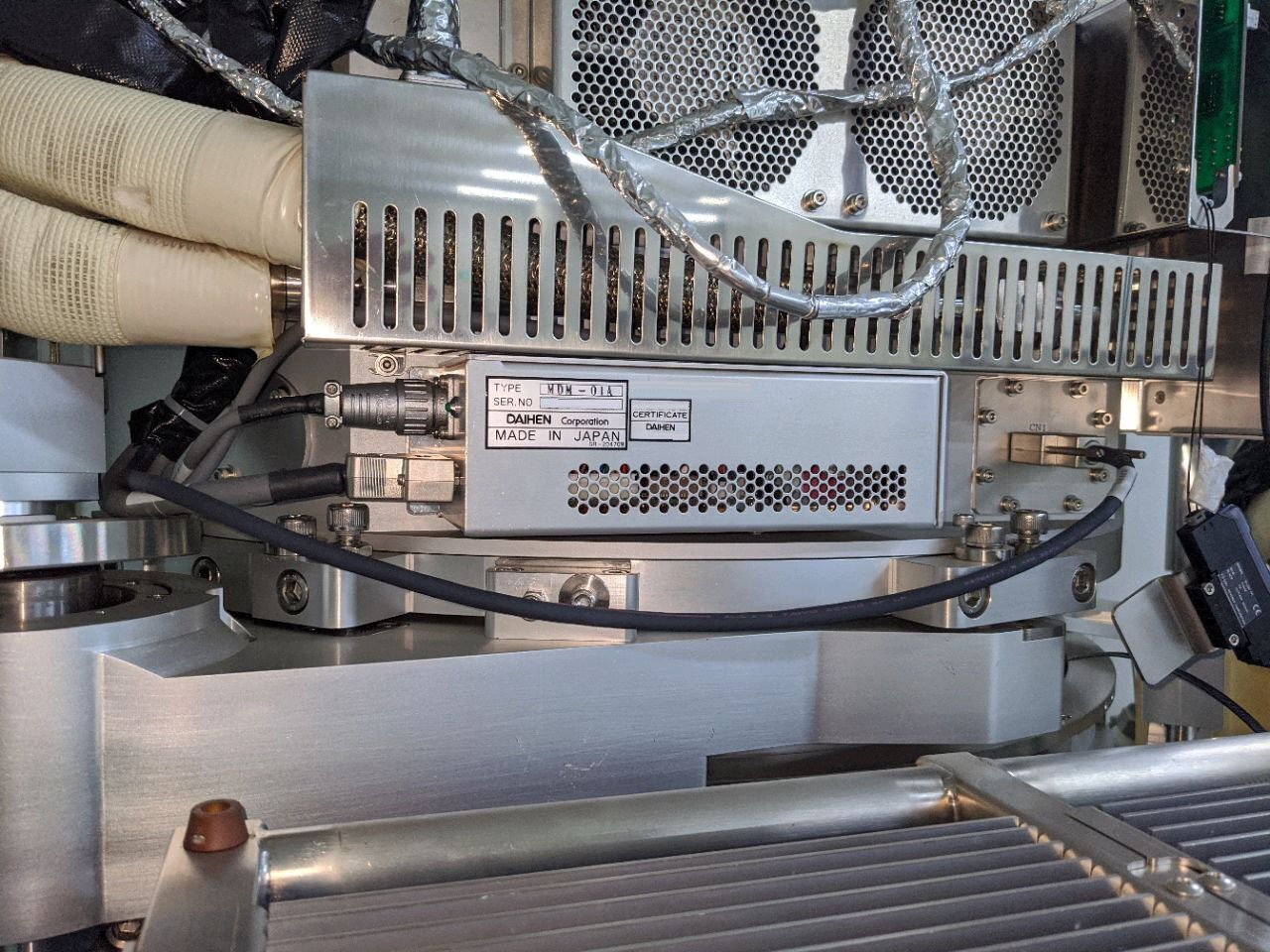

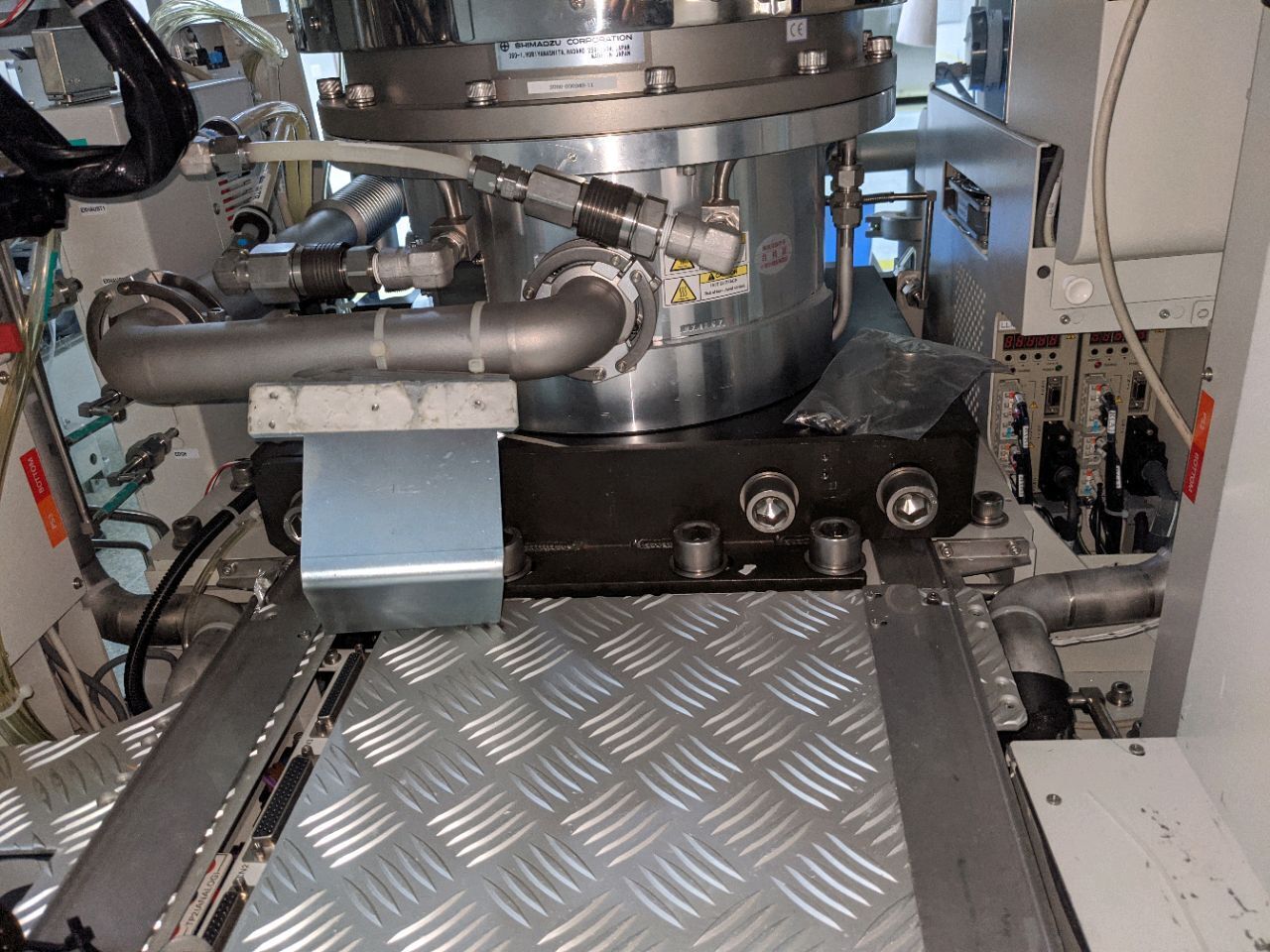

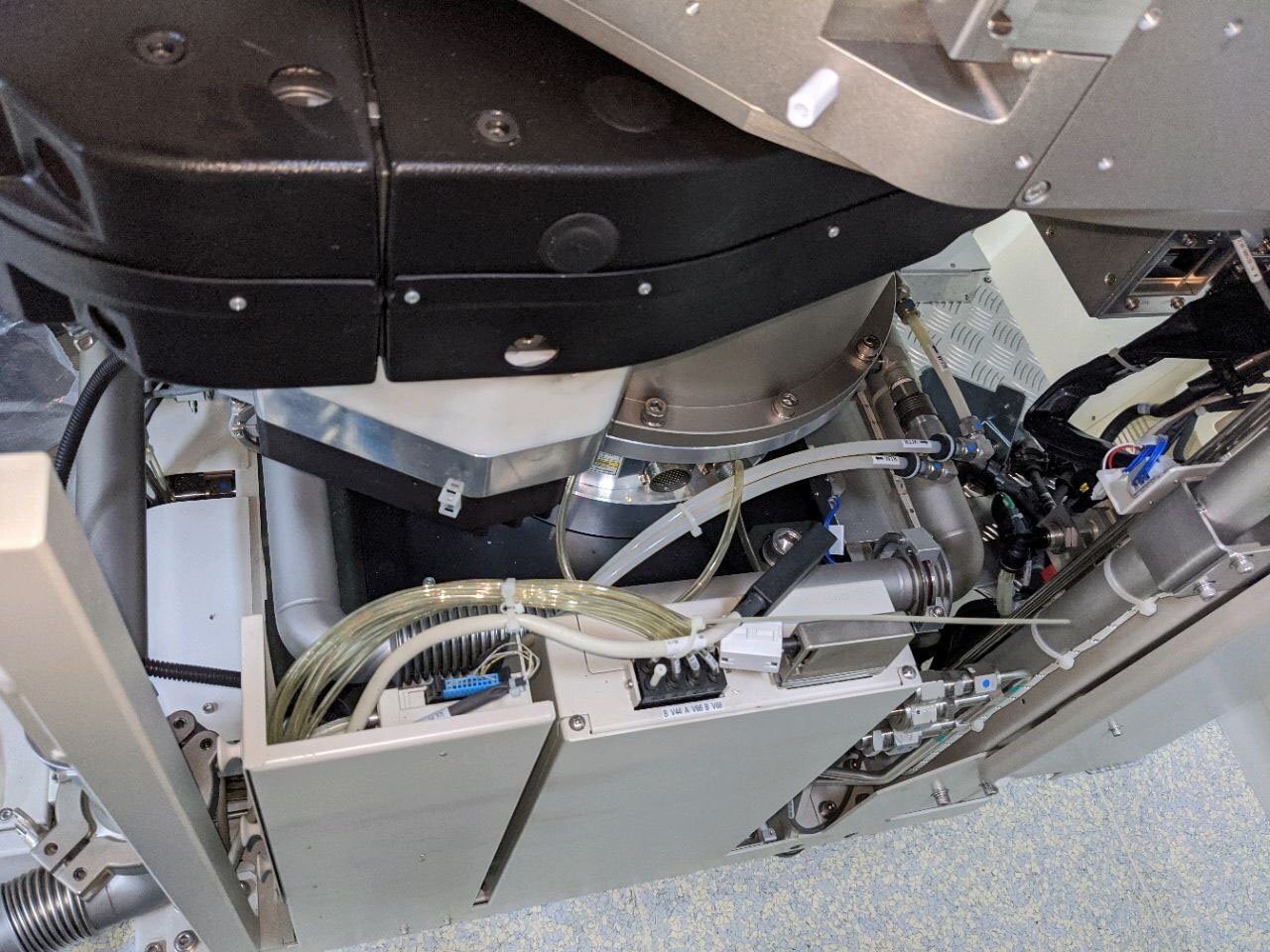

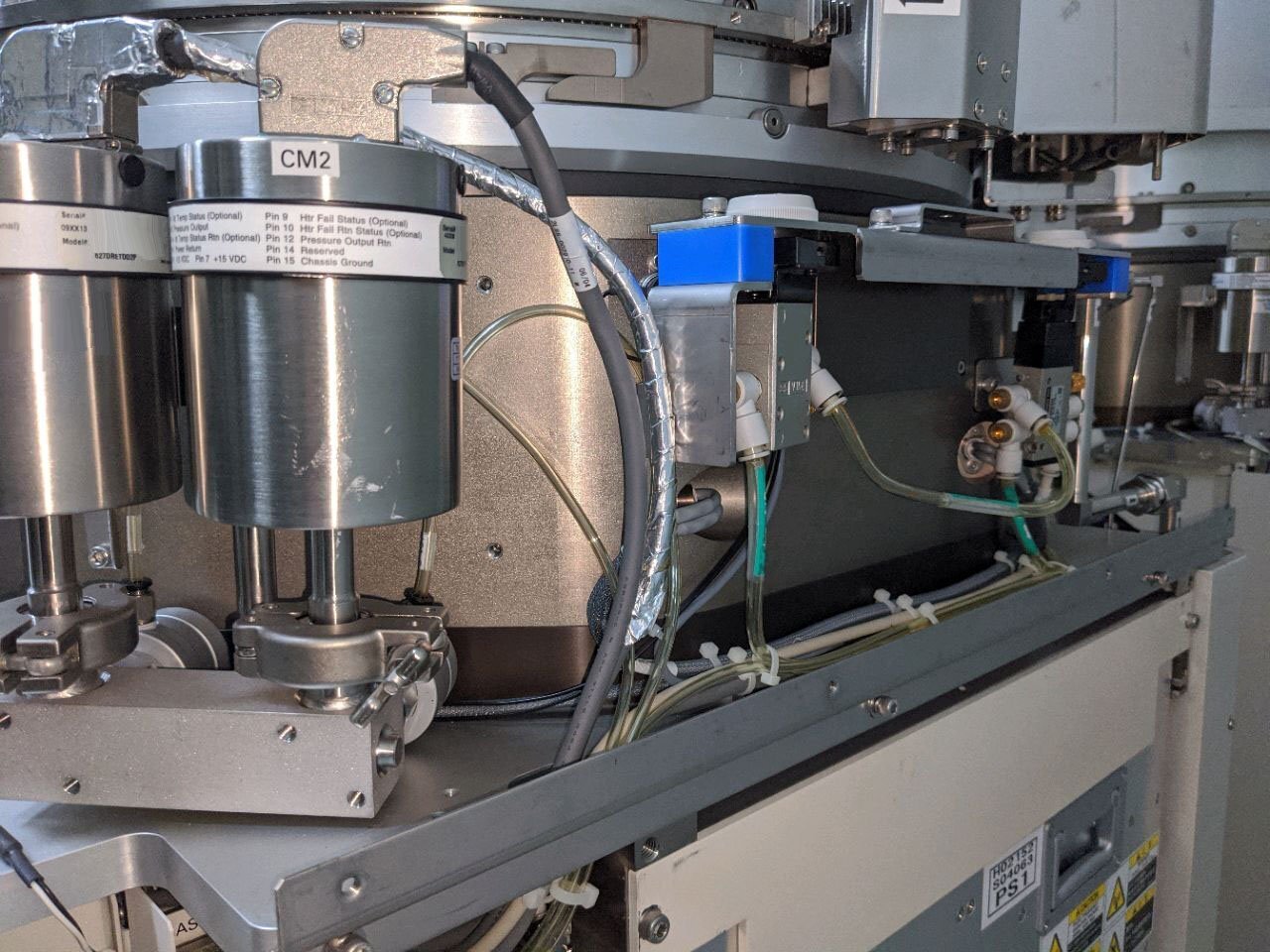

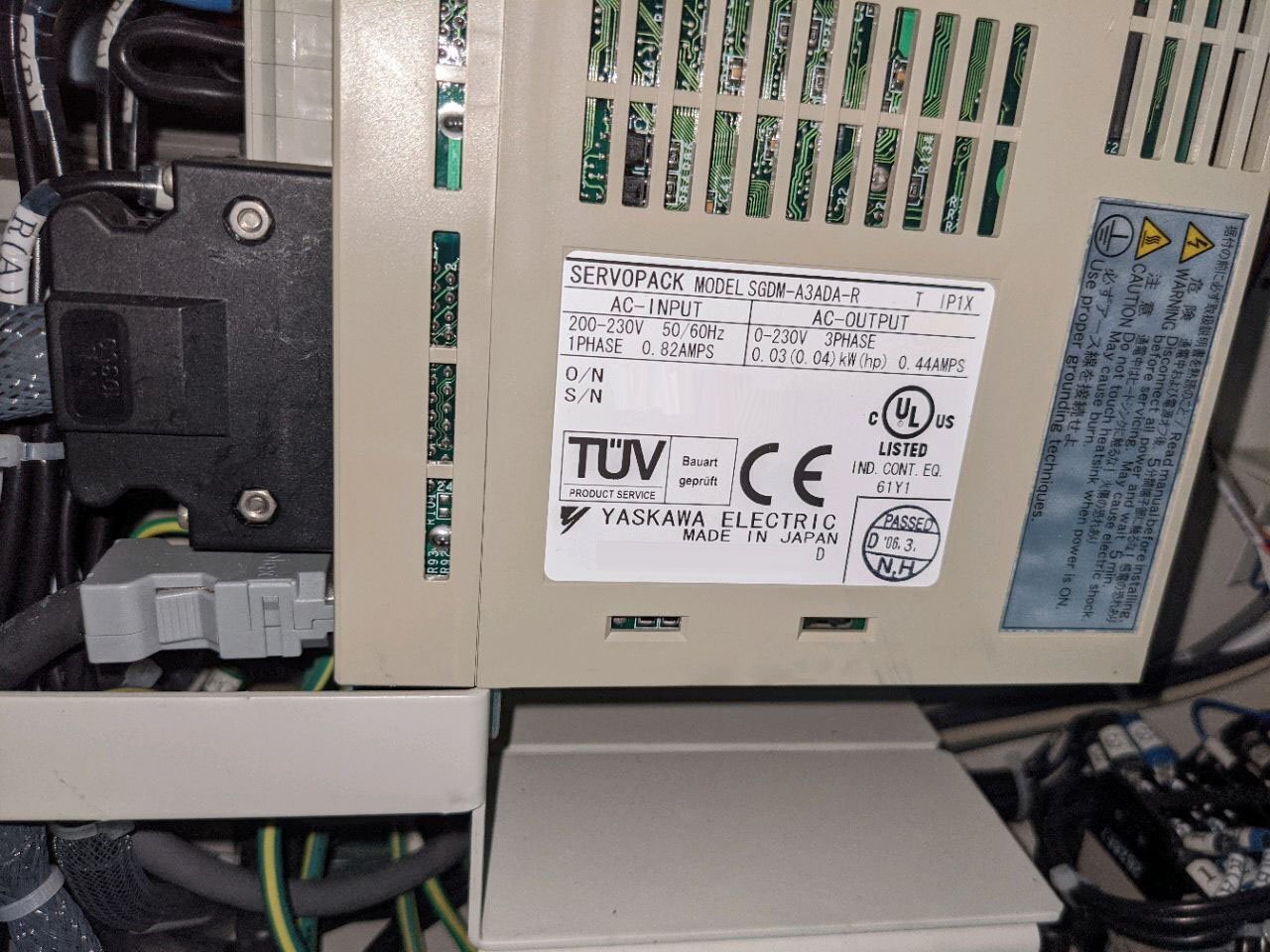

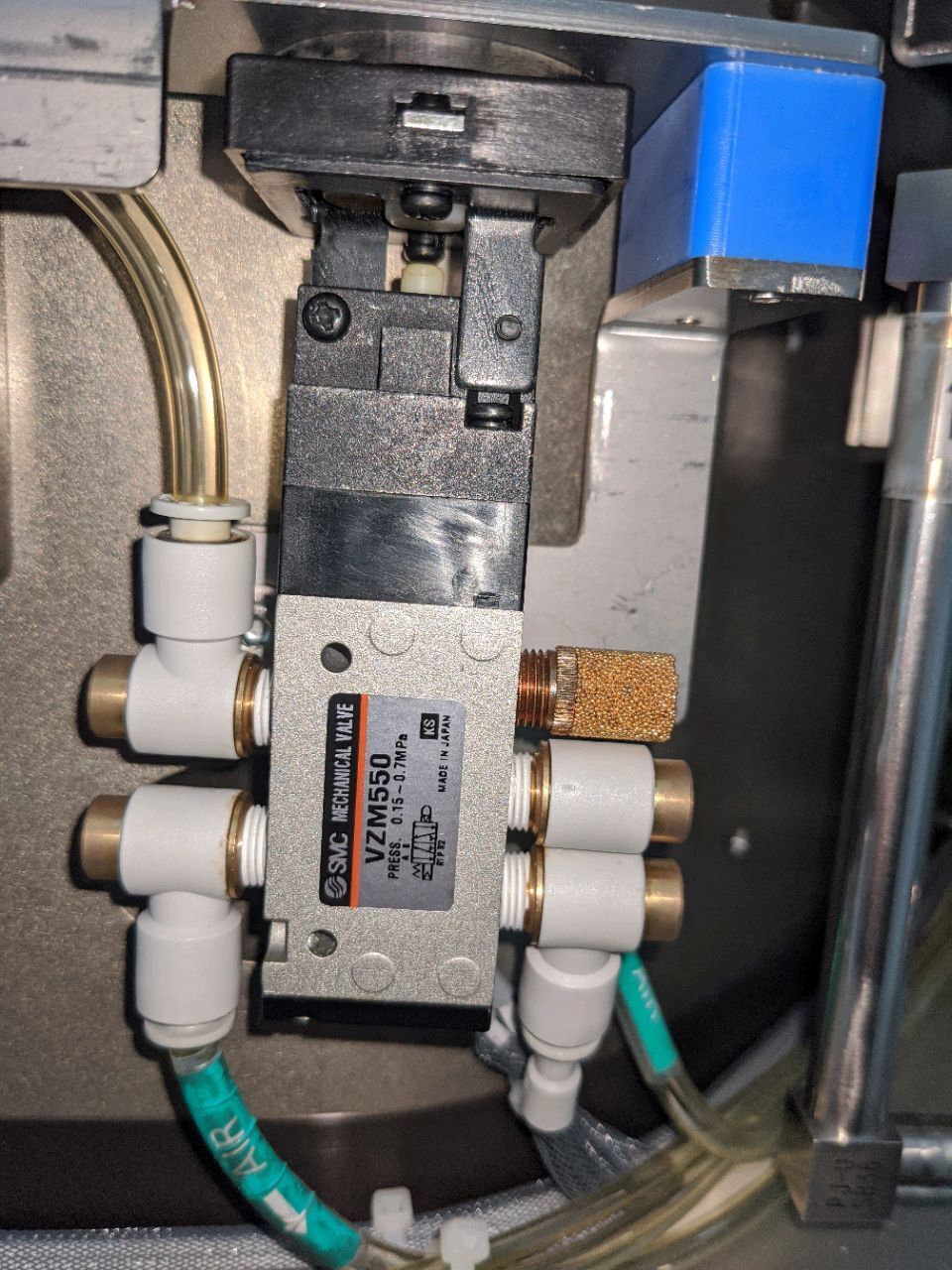

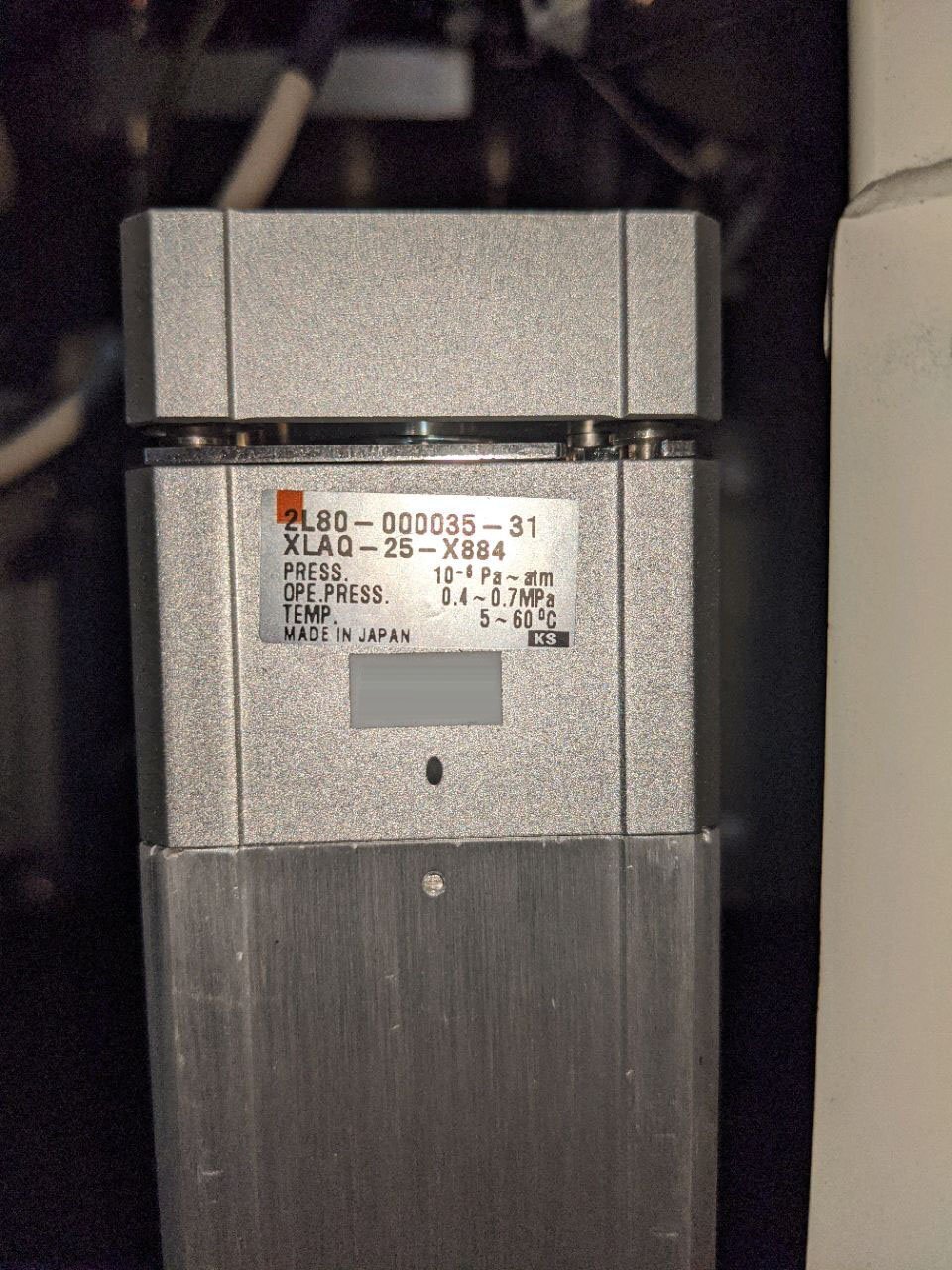

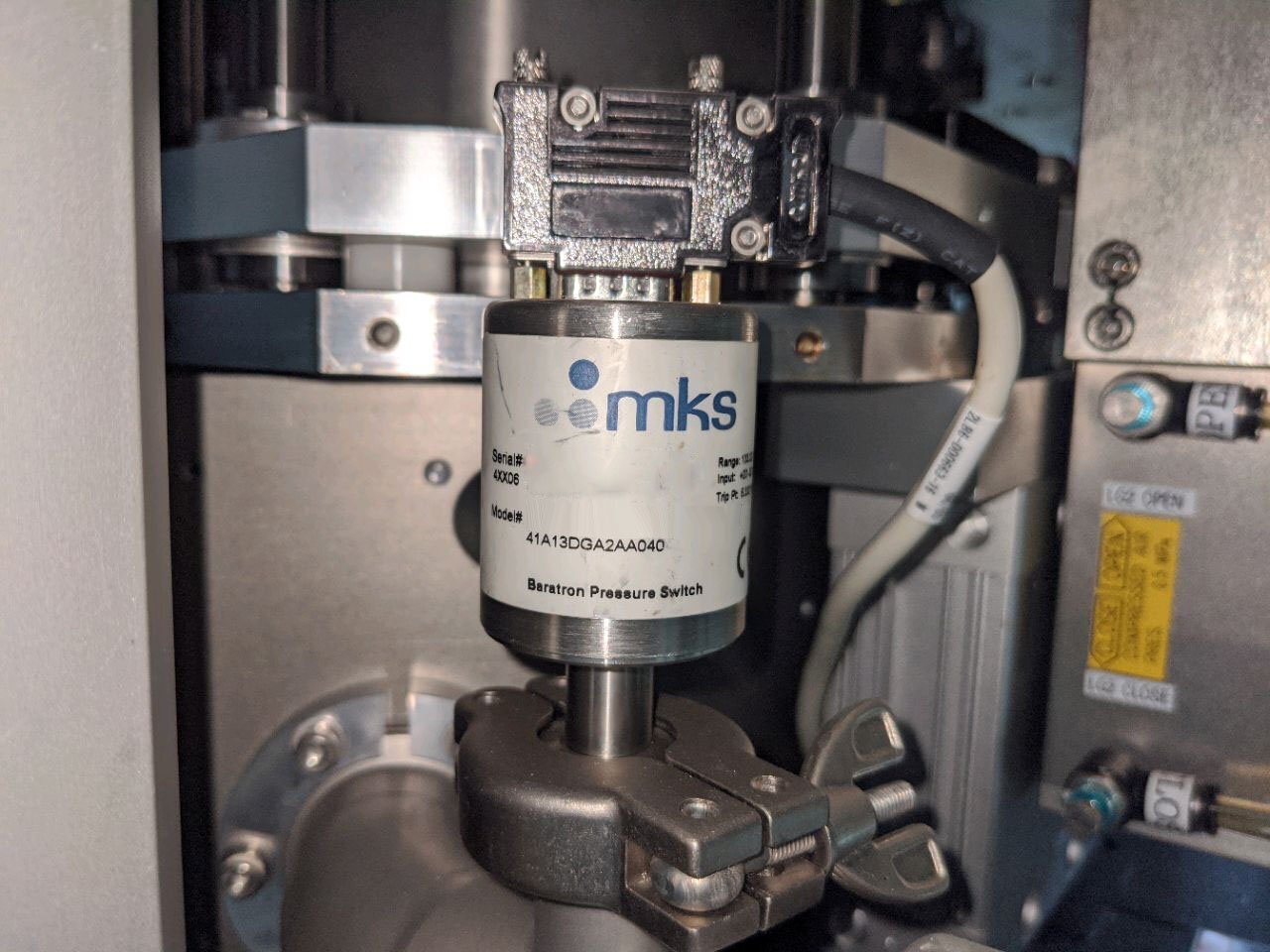

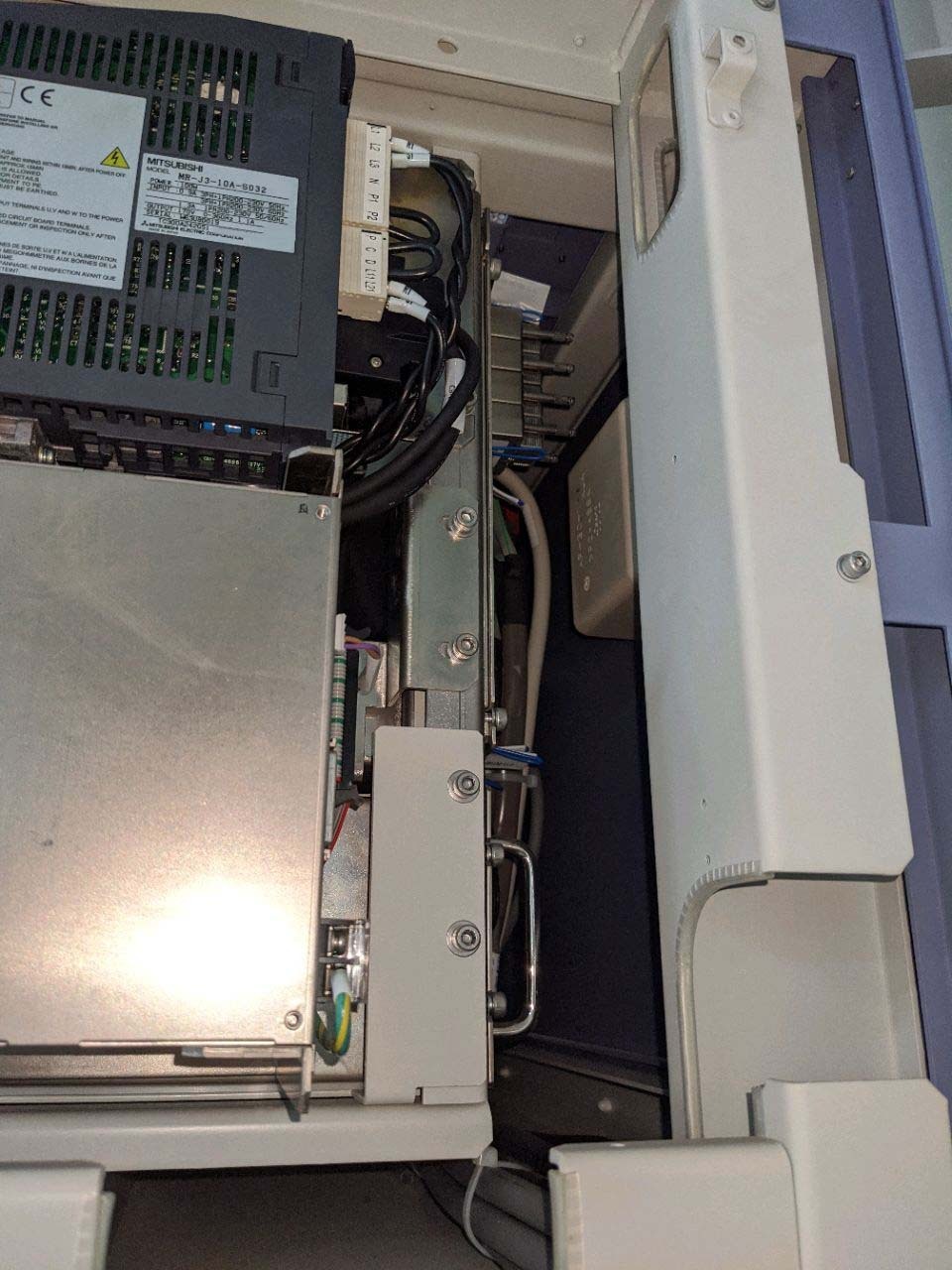

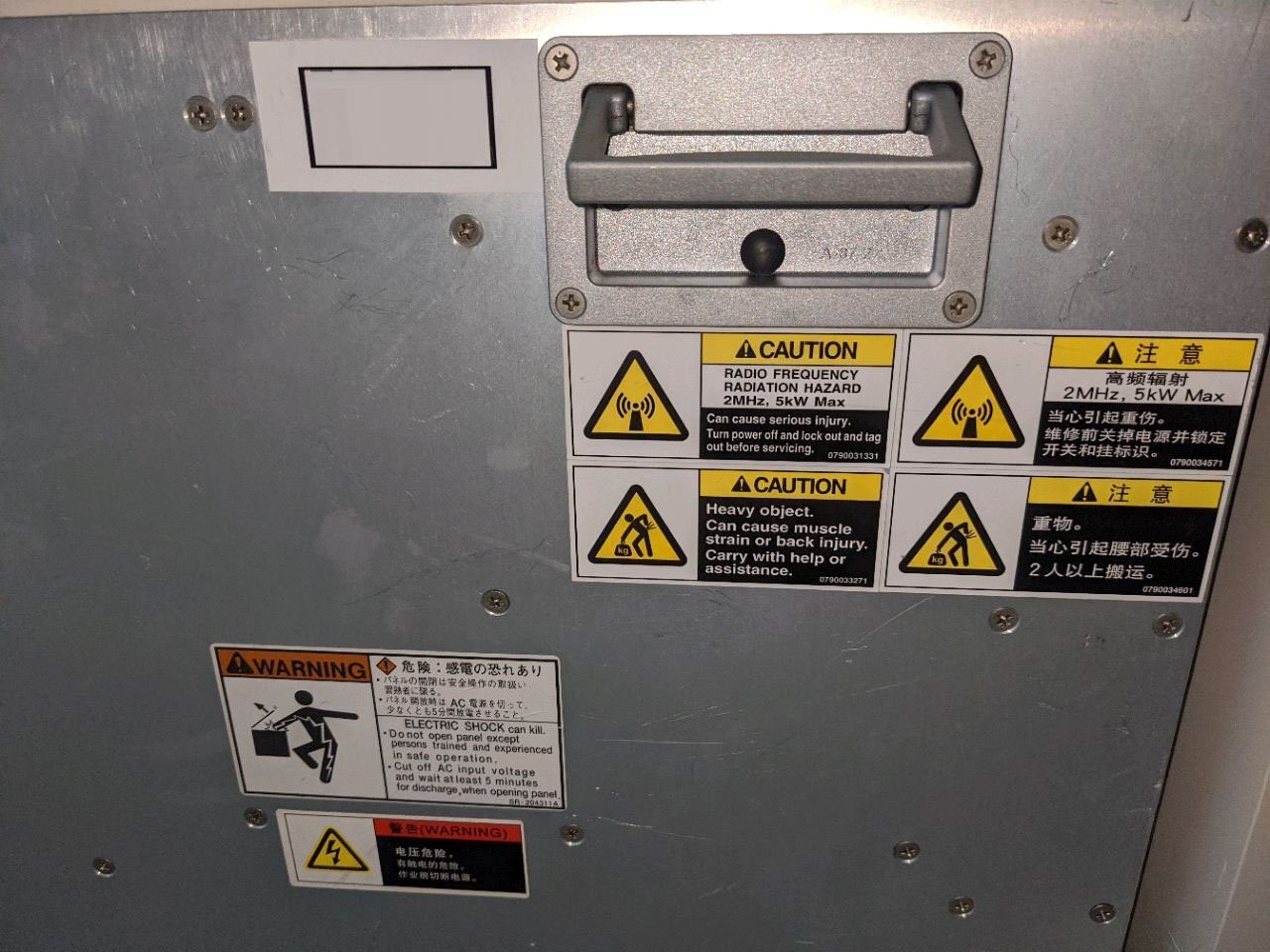

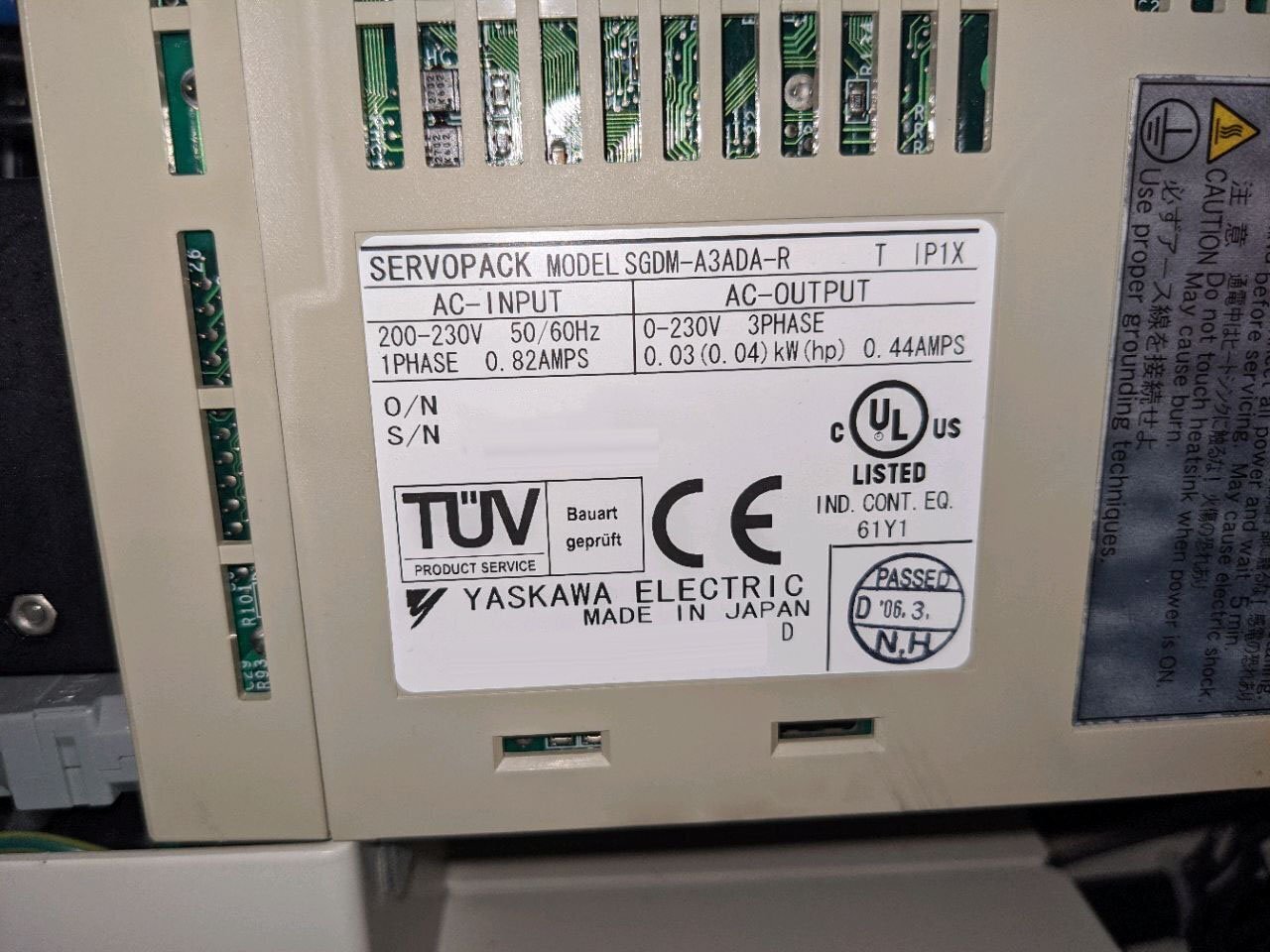

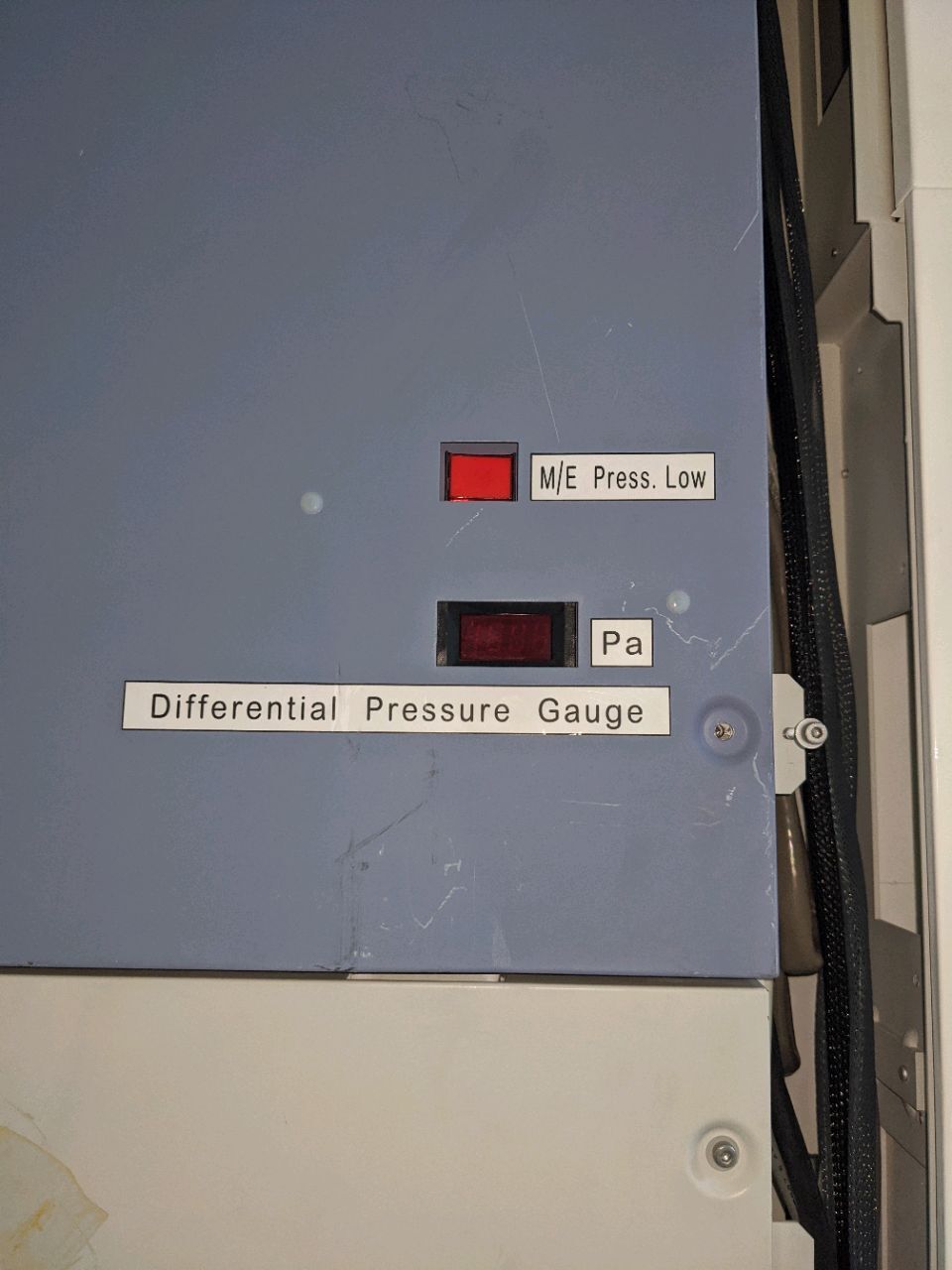

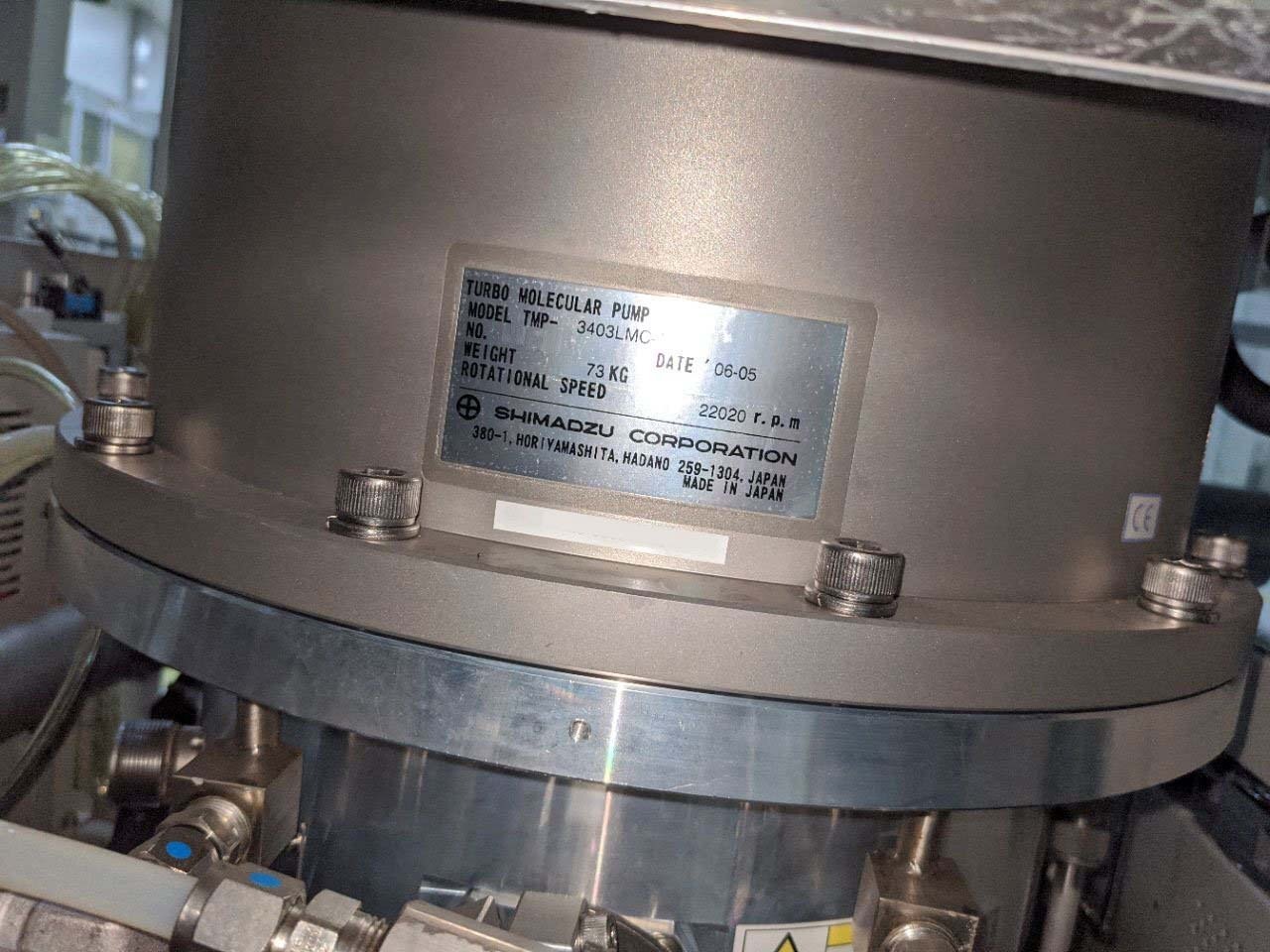

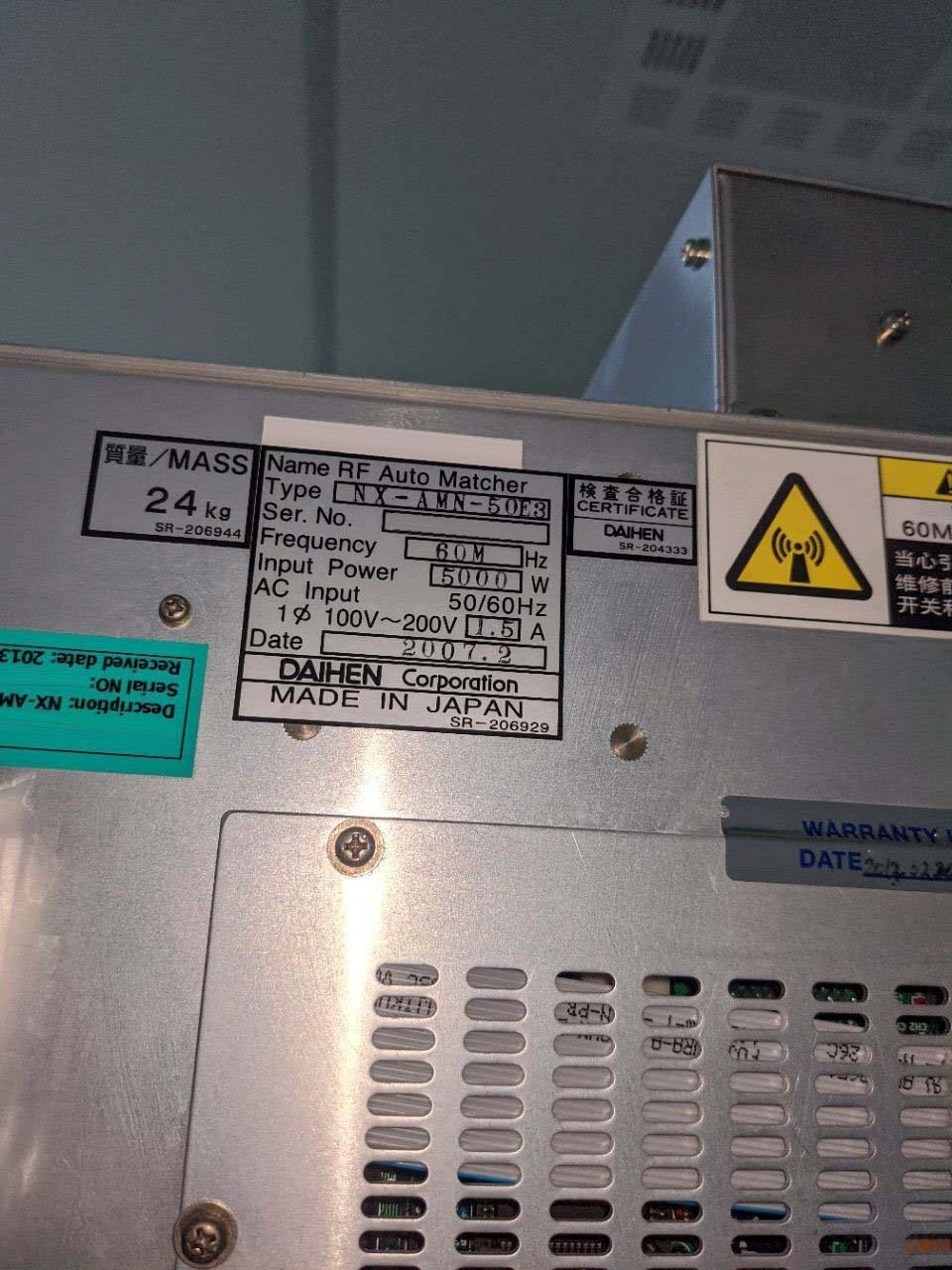

TEL / TOKYO ELECTRON TSP-30555SSS is an etcher / asher designed to provide users with fast and efficient wafer patterning capabilities. It is a single wafer system with a substantial processing area enabling it to accommodate large-sized wafer substrates, such as 2-inch, 4-inch and 6-inch wafers. This etcher/asher is equipped with a RIE (Reactive Ion Etch) processing chamber, which is capable of performing high-precision etching of various materials on the surface of the wafer substrate. Its ability to perform dry etching with high precision and wide range of process conditions makes it suitable for producing fine features on wafers. TEL TSP-30555SSS has an automated process controller, which allows users to preset multiple process options for the process cycle. It also features an interface for controlling the conditions of the chamber during etching and a diagnostic system which enables visual monitoring of pressure, temperature and process status. In addition, TOKYO ELECTRON TSP-30555SSS is equipped with a number of other features to improve its performance. These include an advanced Auto Tune Facility, an Multi-Chamber/Multi-Stack facility and an automated heating/cooling system which controls substrate temperature to optimize etch results. In addition to this, it is equipped with extra-large endurides, OFE pumps, and high vacuum (HV) components, all of which are designed to maintain high precision and reliability throughout the process. TSP-30555SSS is also highly compatible with a wide range of etch processes, such as plasma, ion beam etching, and sputter etching. It is also capable of performing both single-and multiple-step processes. It has a very short cycle time and can handle production of up to six wafers per cycle. Overall, TEL / TOKYO ELECTRON TSP-30555SSS is an excellent etcher/asher designed to offer users high-precision results with fast and efficient operation. Its robust construction, automated process controller, and numerous features make it an ideal choice for etching of a wide range of materials for use in the semiconductor and other related industries.

There are no reviews yet