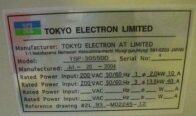

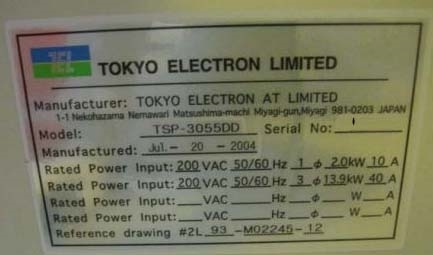

Used TEL / TOKYO ELECTRON TSP-3055DD #9252311 for sale

URL successfully copied!

Tap to zoom

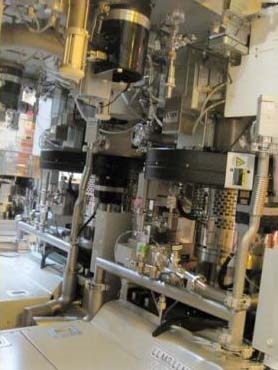

TEL / TOKYO ELECTRON TSP-3055DD is a high-precision etcher / asher manufactured by TEL. It is used as a tools for semiconductor or microelectronic device fabrication, is a powerful platform for advanced etching or ashing technology. TEL TSP-3055DD is a dry etch equipment which utilizes both the inductively coupled plasma (ICP) and dielectric barrier discharge (DBD) etching modes. The ICP etching mode is used to etch small patterns with high selectivity, while the DBD etching mode is used for through etching of thin films. Additionally, the system is equipped with a dose management unit, which ensures a high selectivity ratio and a well-defined etch process. TOKYO ELECTRON TSP-3055DD has a maximum wafer size of 300mm and a maximum process pressure up to 10 Pascal. It is equipped with a 100kHz - 3MHz RF generator which provides a wide frequency range, allowing for etching at various depths and selectivity. Additionally, the machine comes with a quartz-made plasma reactor with up to 2kW of power, allowing for a high substrate-to-torch distance and uniformity. TSP-3055DD's automation scheme is designed to provide unparalleled repeatability in process control. The Automation Manager (AM) software package enables a wide variety of custom parameter adjustment and process monitoring, providing fine control of etch time, etch pressure, etch rate, overetching and end point control. Additionally, the tool is equipped with an in-situ spectroscopy asset, which allows real-time measurement of etch results. In addition to the etch functions, TEL / TOKYO ELECTRON TSP-3055DD also has a Combiner Option, which allows simultaneous ashing of a wafer. This wafer ashing technology is extremely useful for photoresist removal as it utilizes a combination of dry etching and plasma vaporization. TEL TSP-3055DD offers a reliable and accurate etching and ashing technology. Its high-precision etching processes and automated control model provide a whole new level of lithography capability and flexibility, making it a perfect choice for the most demanding applications.

There are no reviews yet