Used TEL / TOKYO ELECTRON Unity EP #9366422 for sale

URL successfully copied!

Tap to zoom

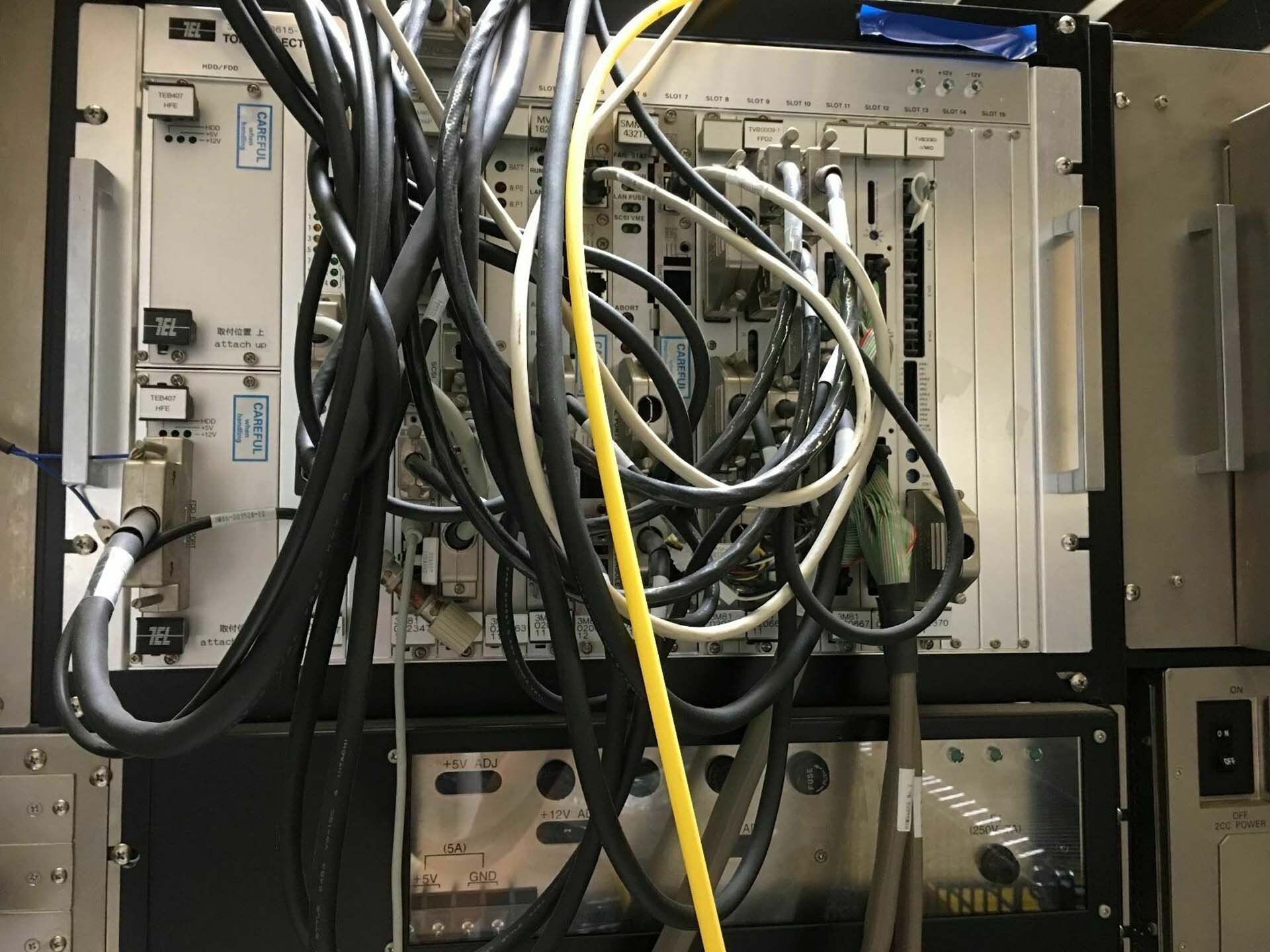

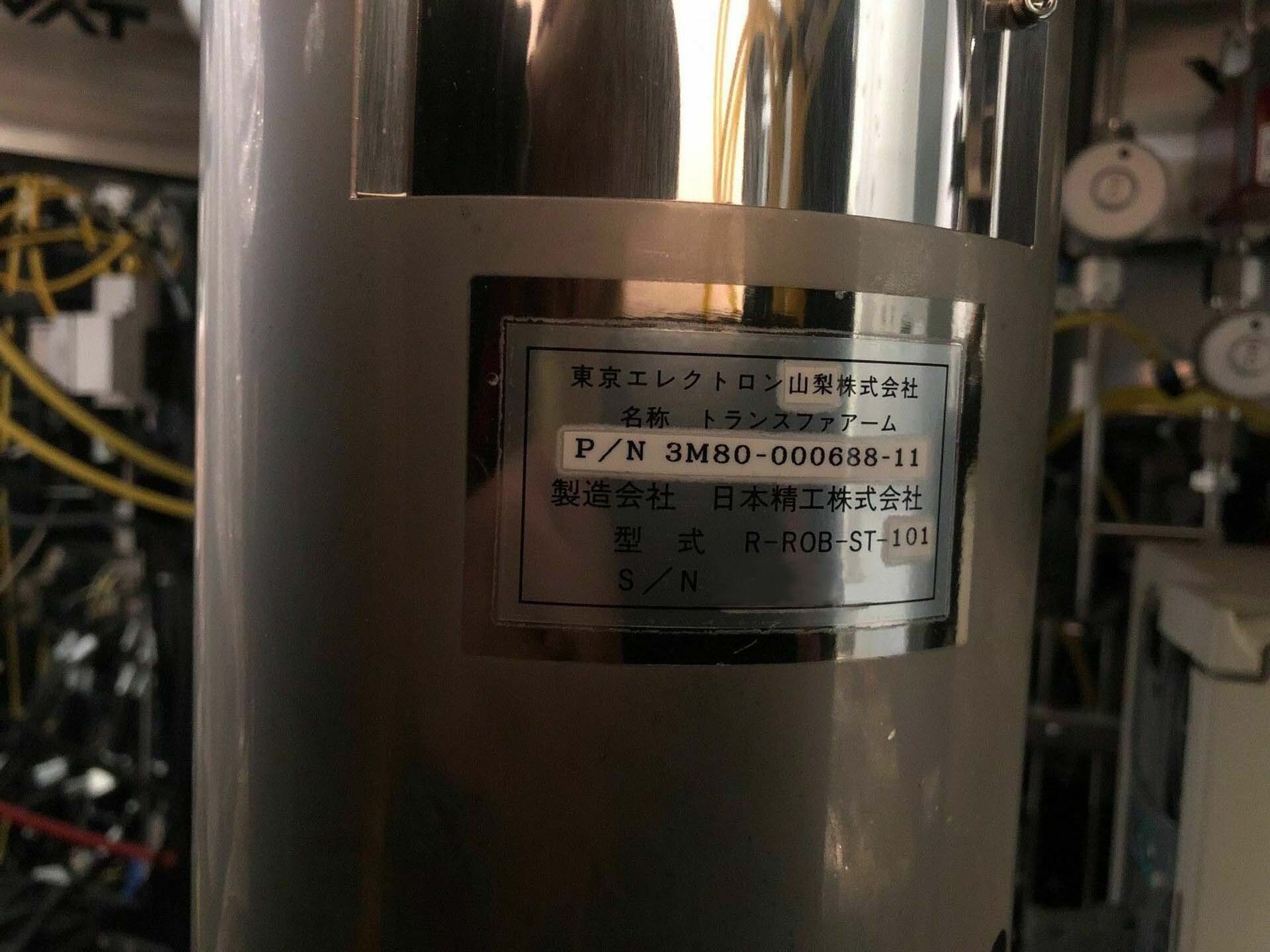

TEL / TOKYO ELECTRON Unity EP is a highly reliable, automated etcher/asher equipment used for semiconductor wafer fabrication. It uses ultraviolet light source systems, photo resist measurement systems, and conveyor systems to etch, deposit, and strip patterns on wafers. The result is improved product yield and quality. TEL Unity EP system features an E-beam etching chamber with a maximum capacity of 200mm wafers, and a plasma asher with a maximum capacity of 300mm wafers. It is suitable for etching and ashing a variety of materials, including GaN, Ga As, and SiC. The unit also features a PAR (Photo/Acid/Resist) APx measurement machine for measuring resistivity and exposed areas on the wafers. The tool is highly modular, meaning components can easily be swapped, allowing for higher levels of flexibility. Components include an ultraviolet light source, a mask aligner, a photoresist delivery asset, a UV curing model, a conveyor equipment, an edge bead removal system, a laser microphone, an infrared scanner, and a wafer cooling unit. All components are programmed to optimize etching, ashing, and data collection processes. This, in turn, enables improved product yields and quality. TOKYO ELECTRON UNITY-EP is equipped with TEL "Real-Time Etch Monitoring" (RETM) Technology, which allows users to monitor etching progress in real time. This enables users to make quick adjustments that help reduce defects and improve product quality. The unit also features a remote process monitoring and logging machine, allowing users to log and monitor etching processes and results. The unified platform combines the etcher, plasmas asher, and post-ash process equipment into a single platform, providing a high degree of flexibility and cost efficiency. The integrated architecture allows for fast processing and low maintenance, making it an ideal choice for semiconductor wafer manufacturing operations.

There are no reviews yet