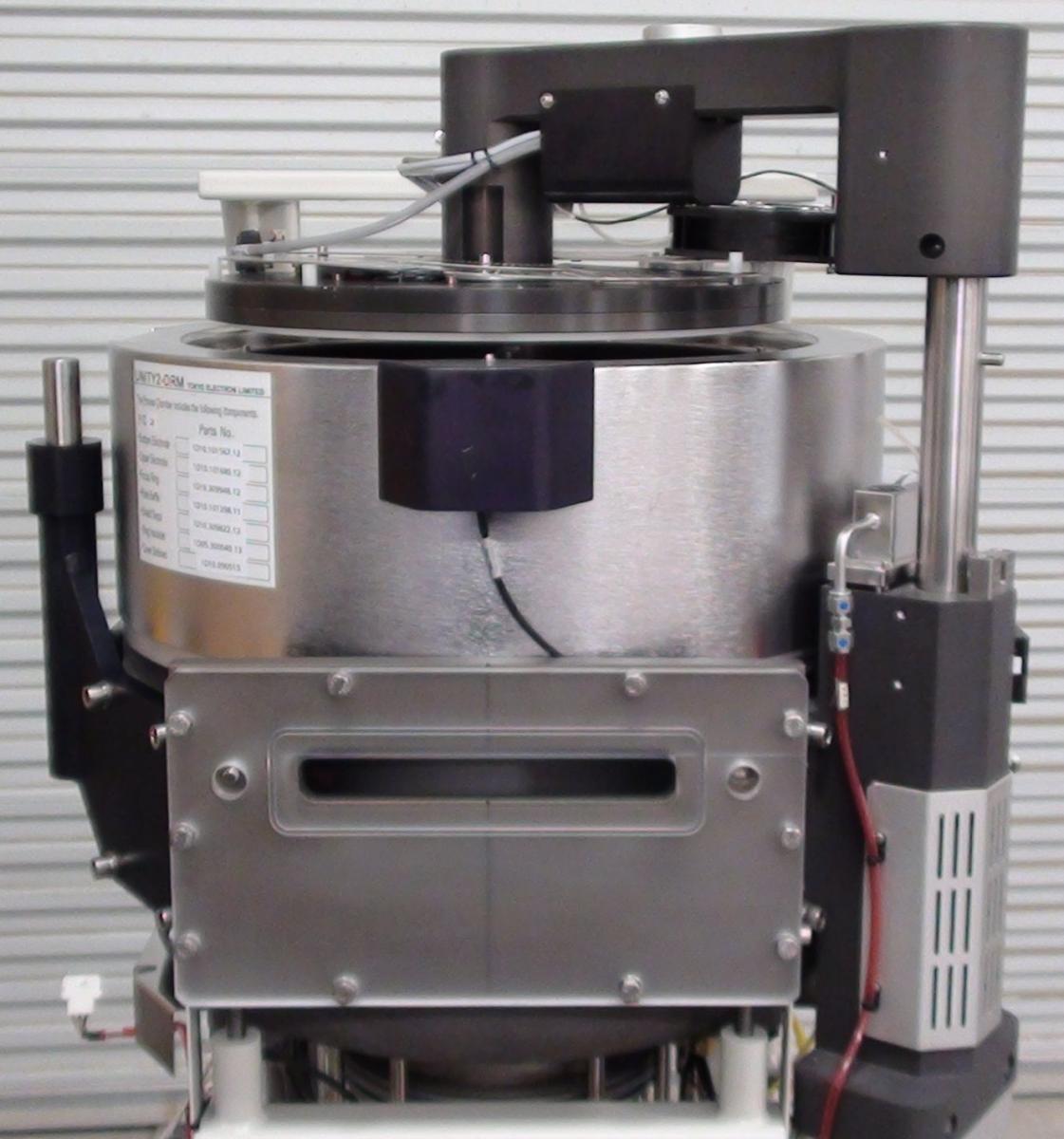

Used TEL / TOKYO ELECTRON Unity II 85DRM #9112879 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9112879

Wafer Size: 8"

Chamber, 8"

Turbo molecular pump: SEIKO SEIKI STP-A803C

With valve 65044.

TEL / TOKYO ELECTRON Unity II 85DRM is an etcher/asher designed to deposit and etch a variety of materials onto substrates. The instrument uses two sets of reactive gases: low pressure area (LPA) for etching and high pressure area (HPA) for deposition, both provided through an end-mounted ultrahigh vacuum chamber. The internal pressure of the chamber is controlled to ensure that chemical reactions occur at the ideal rate and temperature. The system utilizes two independent process modules to provide effective material processing. The first module, a e-beam evaporator, operates in a broad range of pressures and temperatures to deposit multi-layer films of just a few nanometer thick on the substrates. The e-beam evaporator is capable of depositing metals, oxides, and dielectrics or materials which may be subject to further and complex treatments. The second module, an integrated end station, consists of a set of physical and chemical etching tools such as plasma etching, sputter etching, ion milling and sputter etching with cold plasma. Plasma etching, also known as chemical vapor deposition (CVD), utilizes high energy ions to break chemical bonds and create a plasma field which can be tailored to the desired material. In sputter etching, the material is eroded by the application of a high voltage electric field. Ion milling and sputter etching with cold plasma act similarly except at much lower temperatures. TEL Unity II 85DRM also includes several additional features, such as multiple process nozzle configurations, process control and gun control systems, as well as a motion control system. The process nozzle configuration can be used to configure the number and type of holes, as well as the distance between them, allowing users to generate lines, circles or other structures. The process and gun control systems allow users to adjust the process parameters to accurately deposit material in a desired pattern, while the motion control system provides two linear axes, enabling precise movement of the substrates during processing. Overall, TOKYO ELECTRON UNITY II 85 DRM is an efficient and reliable tool for etching and coating processes and provides users with an array of features to help them perform accurate and reliable processes. With its two independent modules, it is well-suited for creating and patterning nanostructures, and it is an excellent way to save on both time and cost.

There are no reviews yet