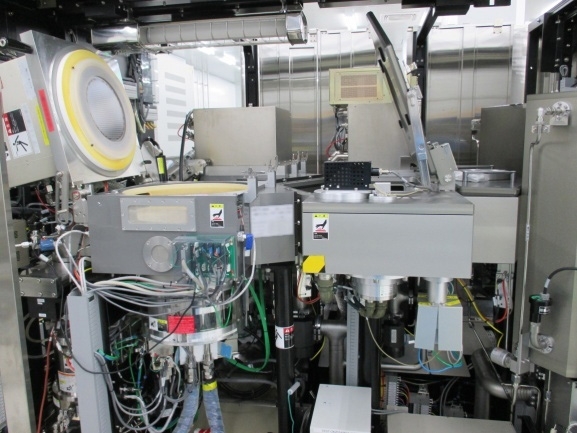

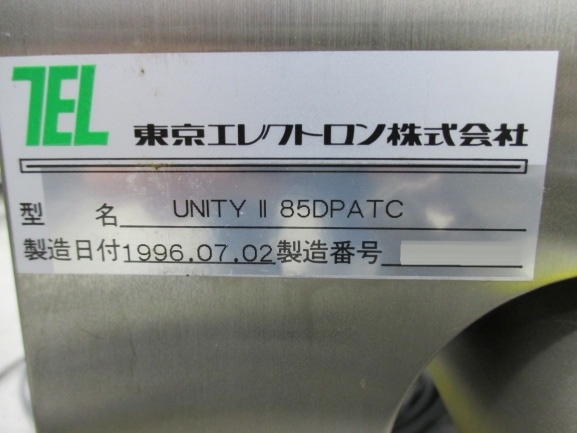

Used TEL / TOKYO ELECTRON Unity IIe 85 DPATC #9091881 for sale

URL successfully copied!

Tap to zoom

ID: 9091881

Wafer Size: 6"

Vintage: 1996

Etcher, 6"

Wafer type: Flat-zone

Processing type: Vacuum

Wafer loading type: Normal

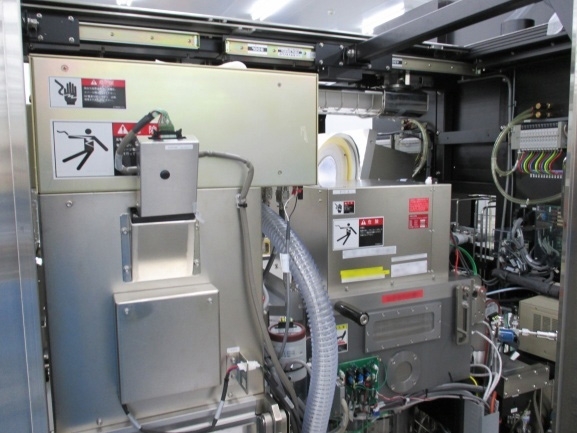

(2) Chambers

Mass flow controller:

Gas No / Gas Name / MFC Size (SCCM)

Gas #1 SF6, 200

Gas #2 HE, 1 SLM

Gas #3 O2, 20

Gas #4 AR, 1SLM

Gas #5 CHF3, 100

Gas #6 CF4, 100

Pressure controller V/V:

Item / Make / Model

ISO V/V (PC1), FUJI SEIKI, 6000729

ISO V/V (PC2), FUJI SEIKI, 1616812

APC (PC1), VAT, 61140-PH52

APC (PC2), VAT, 61140-PH52

Gauge:

Unit / Make / Model / Range

Baratron, MKS, 622A02TAB, 2 Torr

Baratron, MKS, 622A02TAB, 2 Torr

Baratron, MKS, 622A11TAE, 10 Torr

Baratron, MKS, 622A01TAE, 1 Torr

System:

Description / Make / Model

Robot, YASKAWA, VS2A

Robot controller, YASKAWA, SRC-II 004

TMP (PC1), SEIKO SEIKI, STP-H751E

TMP controller (PC1), SEIKO SEIKI, STP-H751E

TMP (PC2), EDWARDS, STP-H751E2

TMP controller (PC2), SEIKO SEIKI, STP-H751E

Generator (PC1), DAIHEN, MFG-20SA

Generator (PC2), DAIHEN, MFG-20SA

Matcher (PC1), DAIHEN, MFM-20AS

Matcher controller (PC1)

Matcher (PC2), DAIHEN, MFM-20AS

Matcher controller (PC2)

EPD (PC1)

EPD (PC2)

HDD (Data): HDS728080

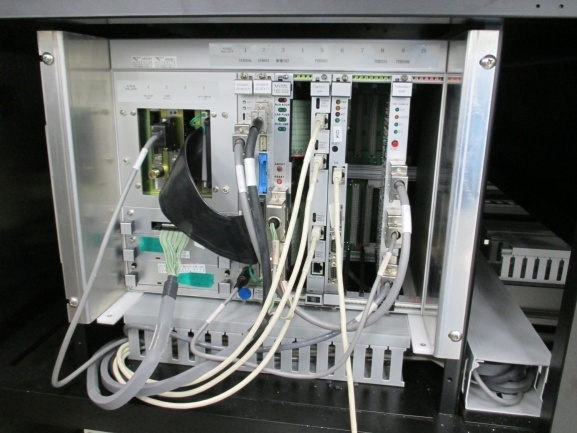

AC rack (PCB):

SVA004a

SVA603

MVME162

TVB0002

TVB3101

TVB0008

TC (PCB):

COM

DIO1

DIO2

MAIO

ILK

PC1:

APC

DIO

MAIO

COM

TEMP

PC2:

APC

DIO

MAIO

COM

TEMP

1996 vintage.

TEL / TOKYO ELECTRON Unity IIe 85 DPATC is a plasma-enhanced reactive ion etcher (PE-RIE) designed for use in semiconductor device fabrication and other related industries. The equipment is designed to provide maximum performance, accuracy and repeatability for etching of wafers or other work pieces. The Unity IIe 85 features a precision high-vacuum chamber, a high-capacity throughput transport and an advanced control system. The chamber is coating-resistant and designed for long-term reliability and highly-precise etching. The Unity IIe 85 PE-RIE has a large-capacity, 3-axis transport unit with a maximum temperature of 450°C. This horizontal transportation machine offers precise wafer transport and positioning, maintaining a uniform, constant and repeatable etch rate across the wafer. The chamber also provides precise pressure control, ensuring the process parameters are maintained without any variance. The etch rate can be adjusted in real-time, allowing precise control over the parameters of the etching process. The etching process is automated with the Unity IIe 85, simplifying the process to ensure repeatable and reliable results. The tool is equipped with the Offline Parameters Setup feature which allows the data for each etch process to be inputted and optimized before any wafers are loaded. The etching process is then monitored and adjusted from within the chamber with a real-time monitoring asset that can be monitored both in-chamber as well as remotely. The Unity IIe 85 uses advanced control technology to maintain its high precision and repeatability. The model utilizes an RF generator to create the plasma which is then regulated by a wide range of parameters such as pressure, temperature, gas flow and current. The equipment also utilizes an IIe controller to adjust the inductance of the RF generator. The Unity IIe 85 is an advanced, reliable PE-RIE system designed for use in semiconductor fabrication and related industries. It provides the highest level of performance, accuracy and repeatability and is capable of automated etch processes with real-time monitoring and control, allowing users to achieve the highest level of precision and production throughput.

There are no reviews yet