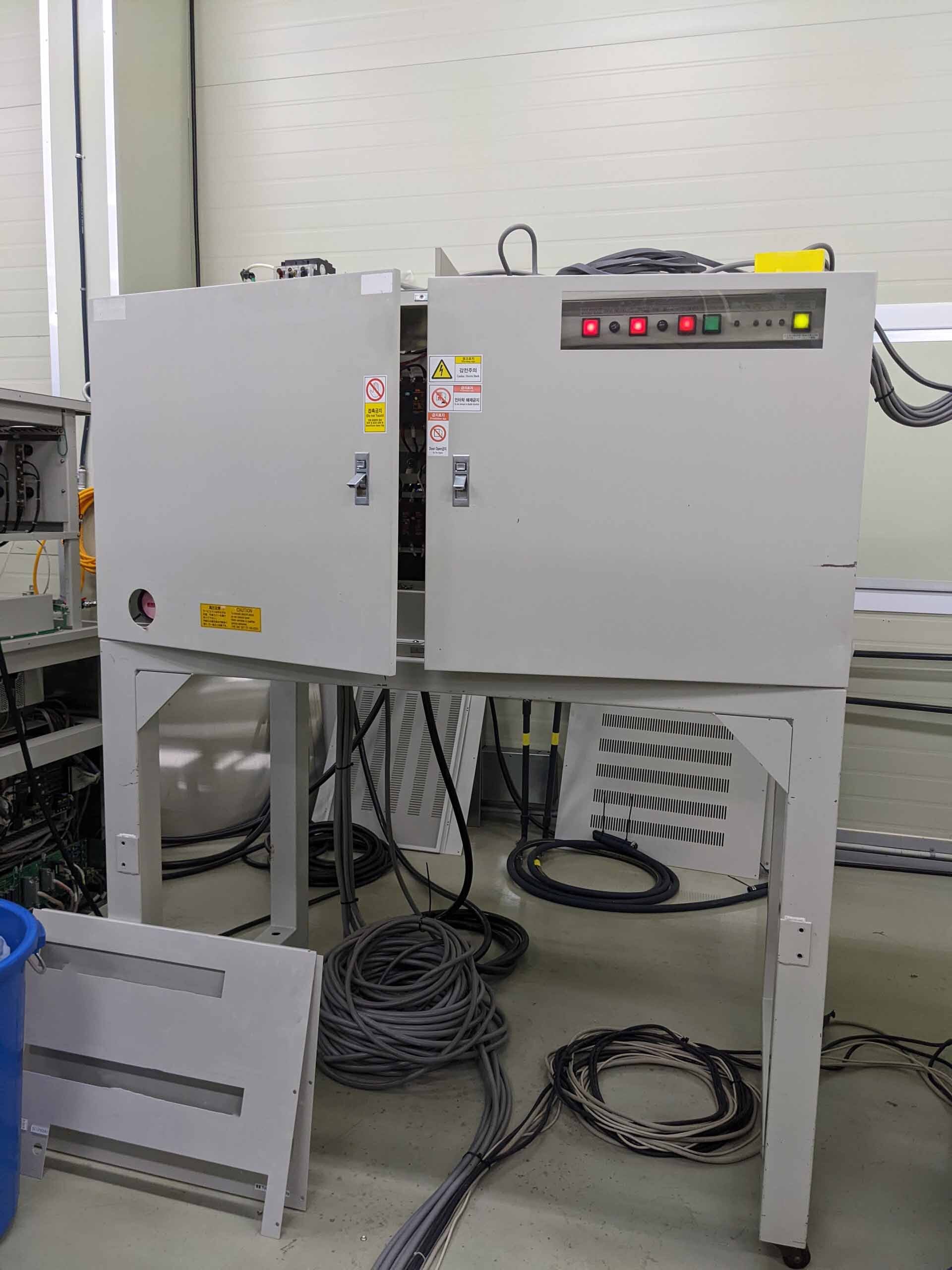

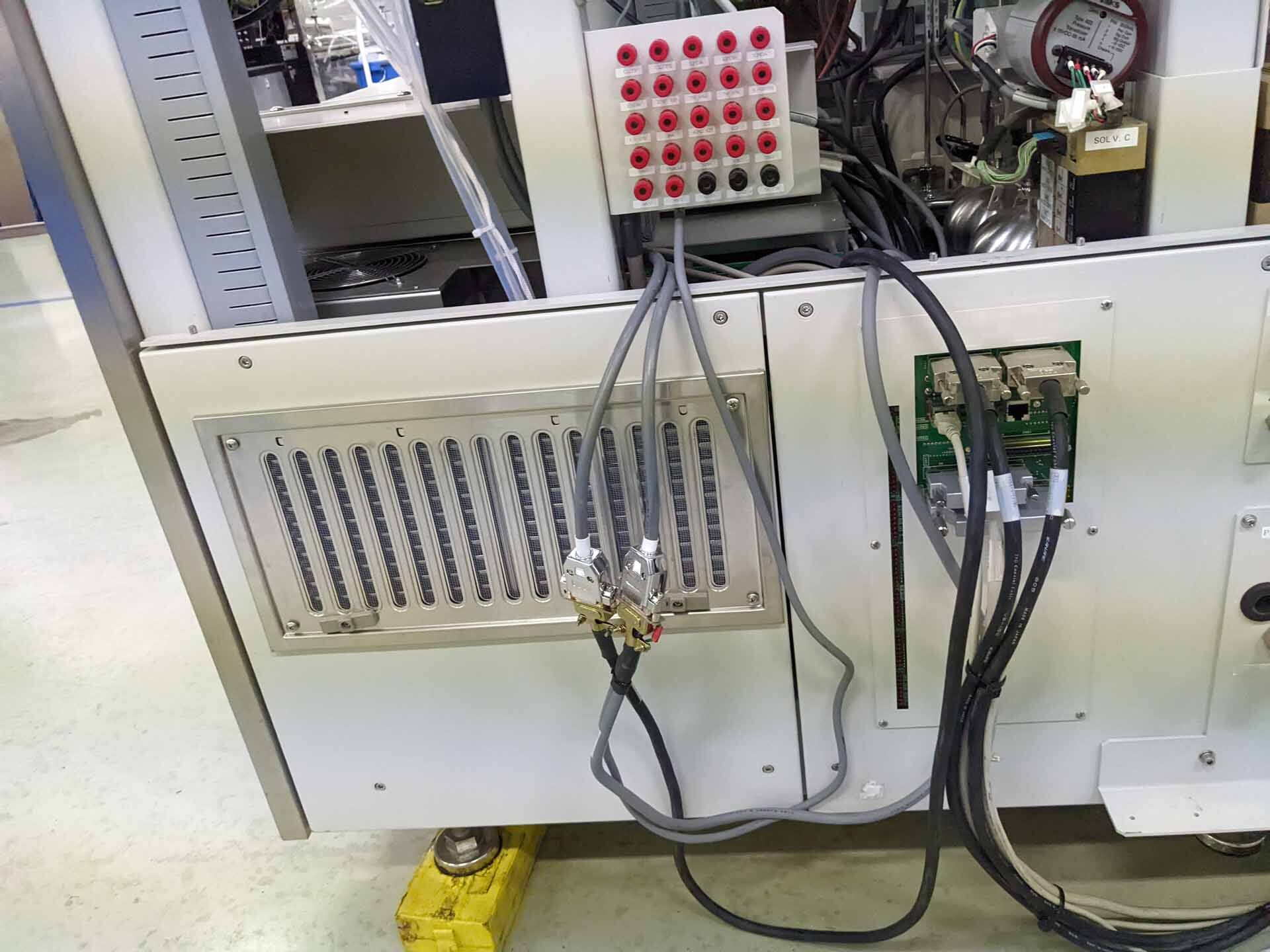

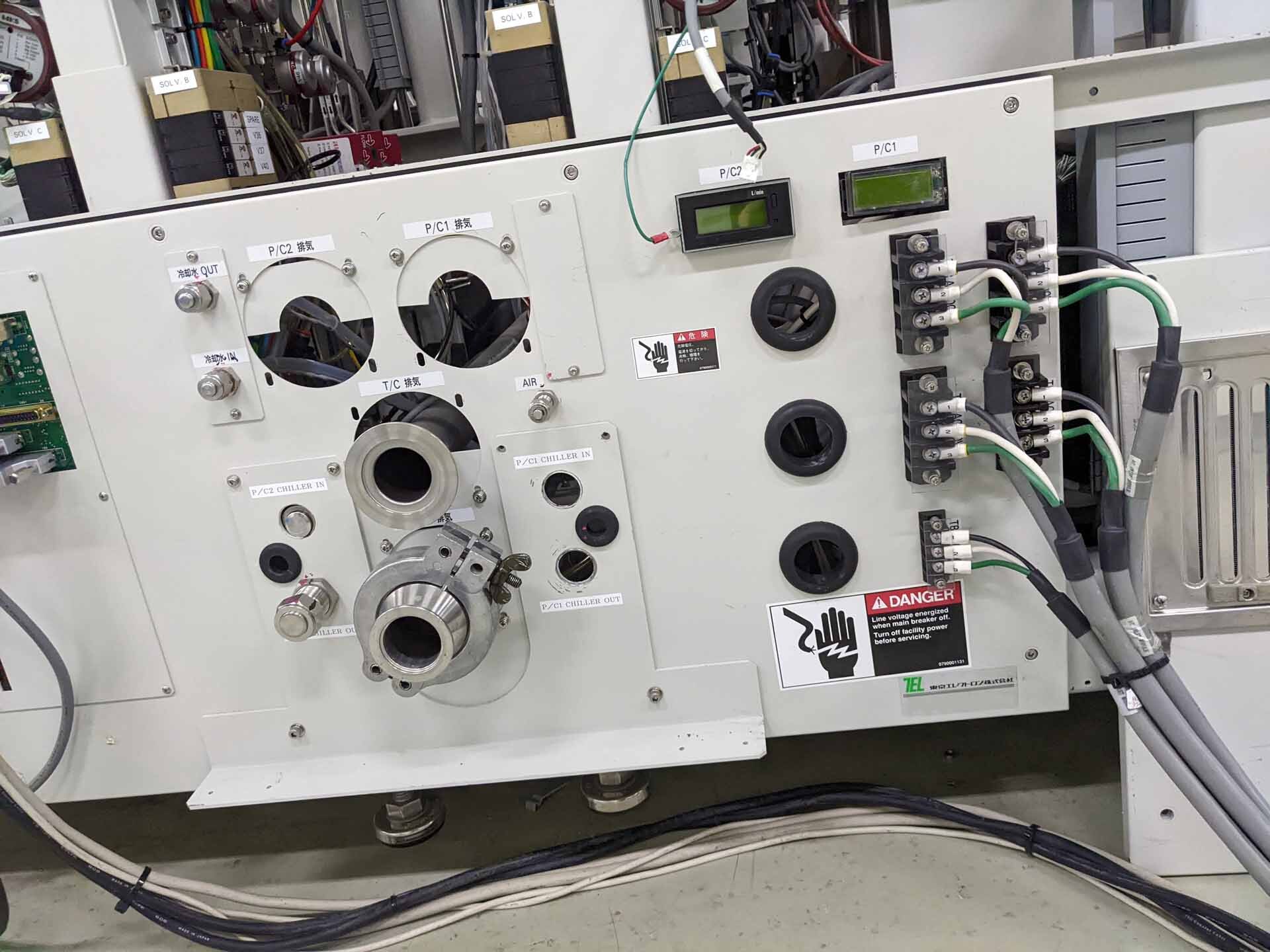

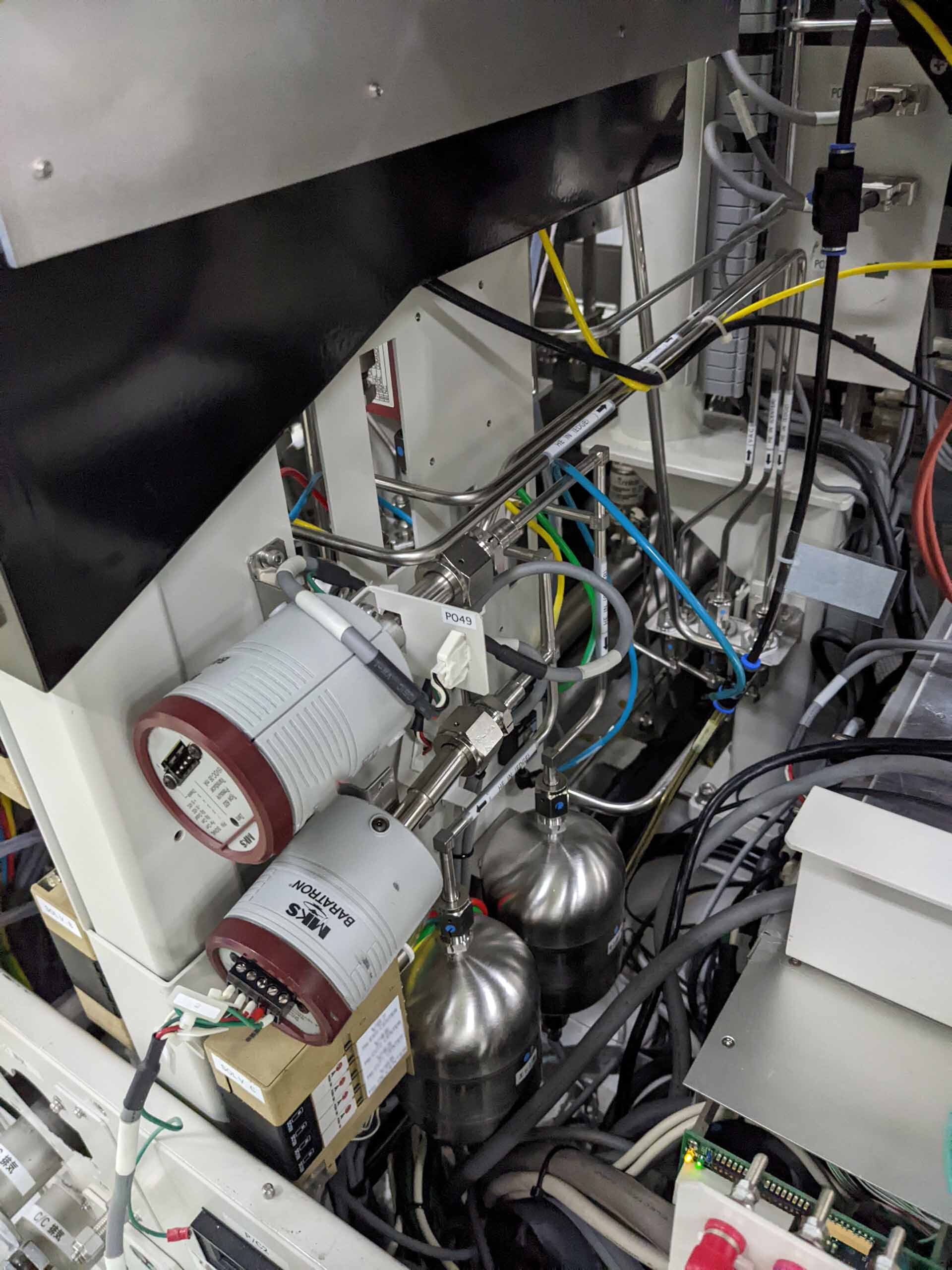

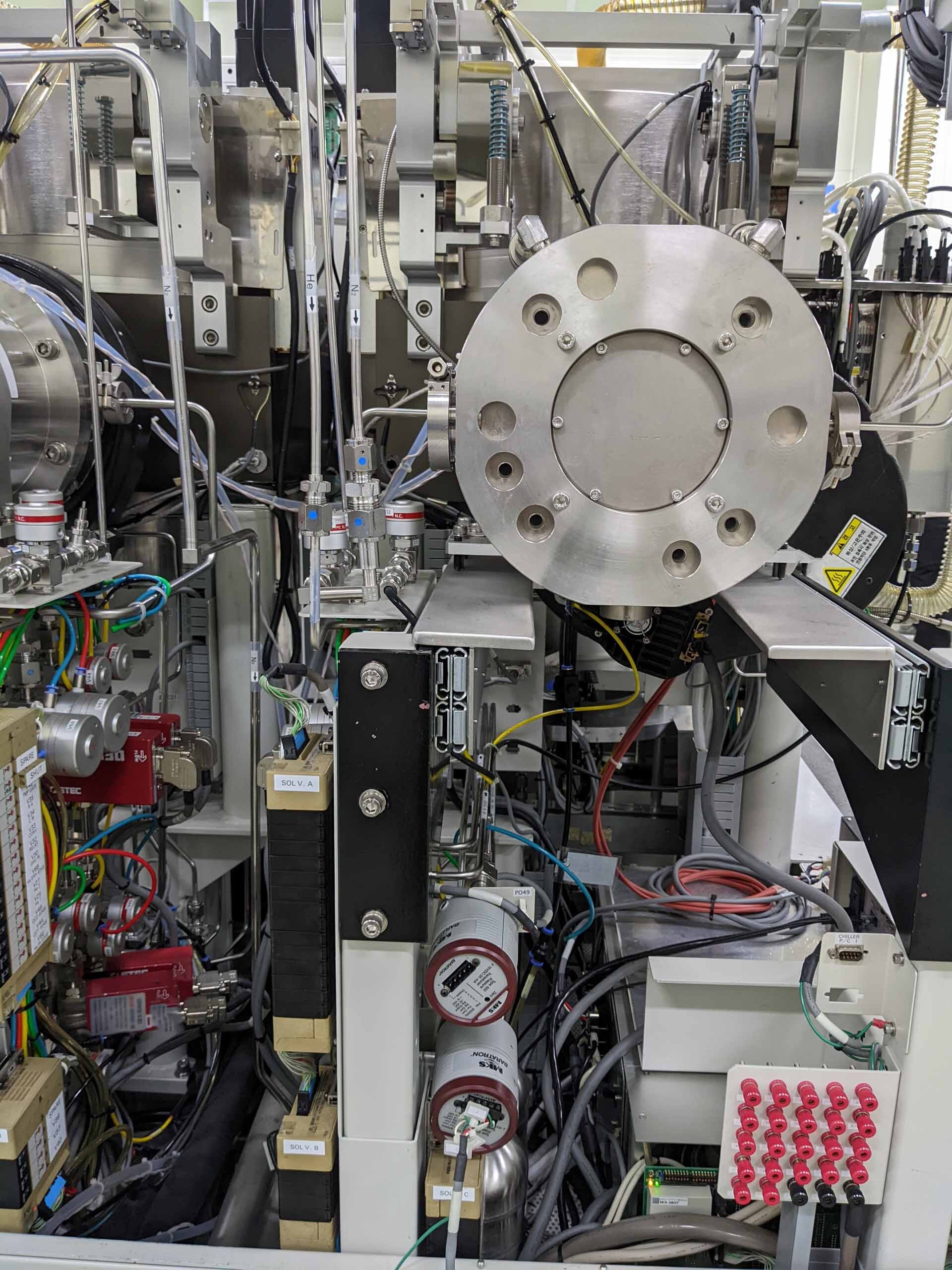

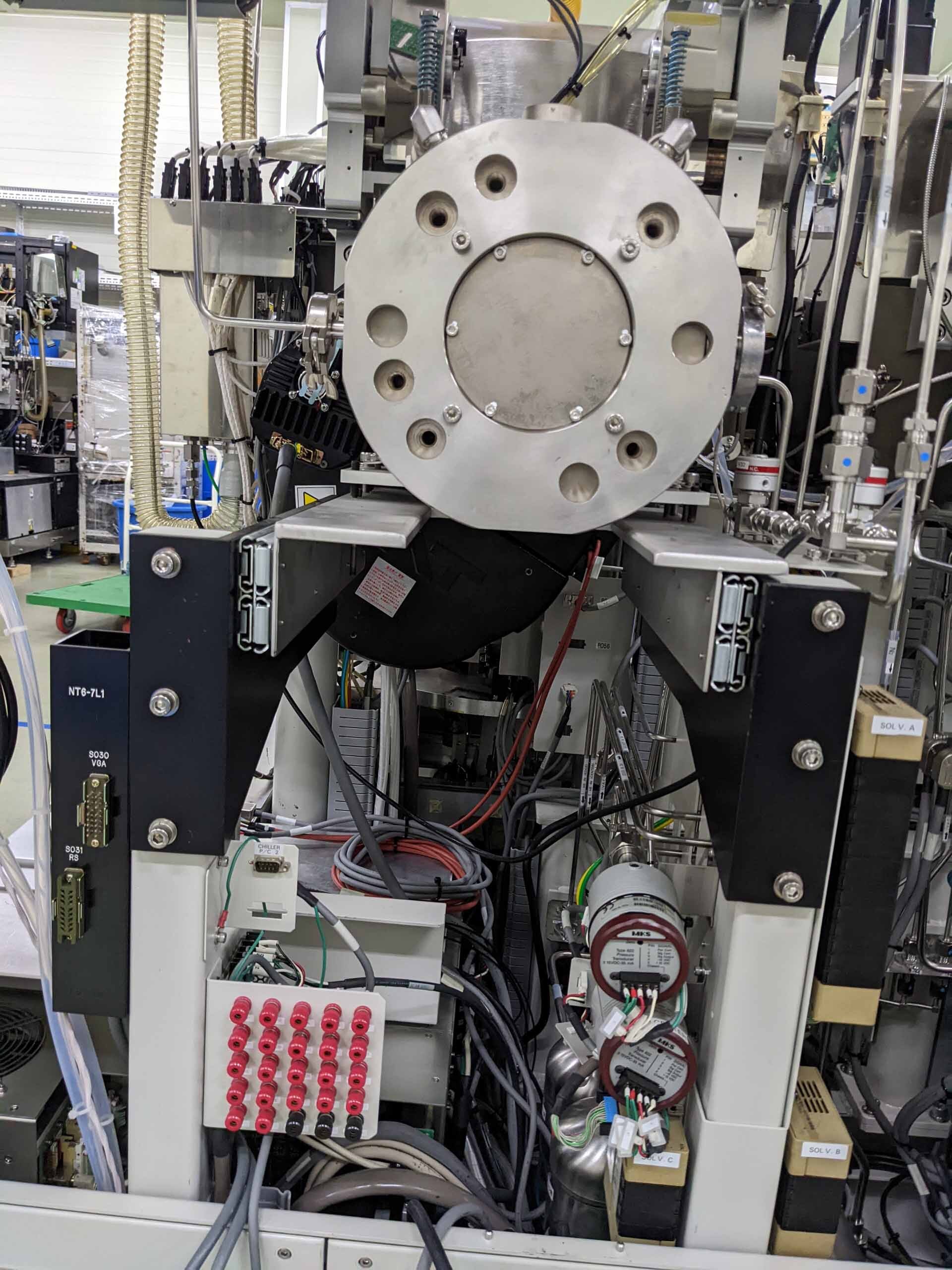

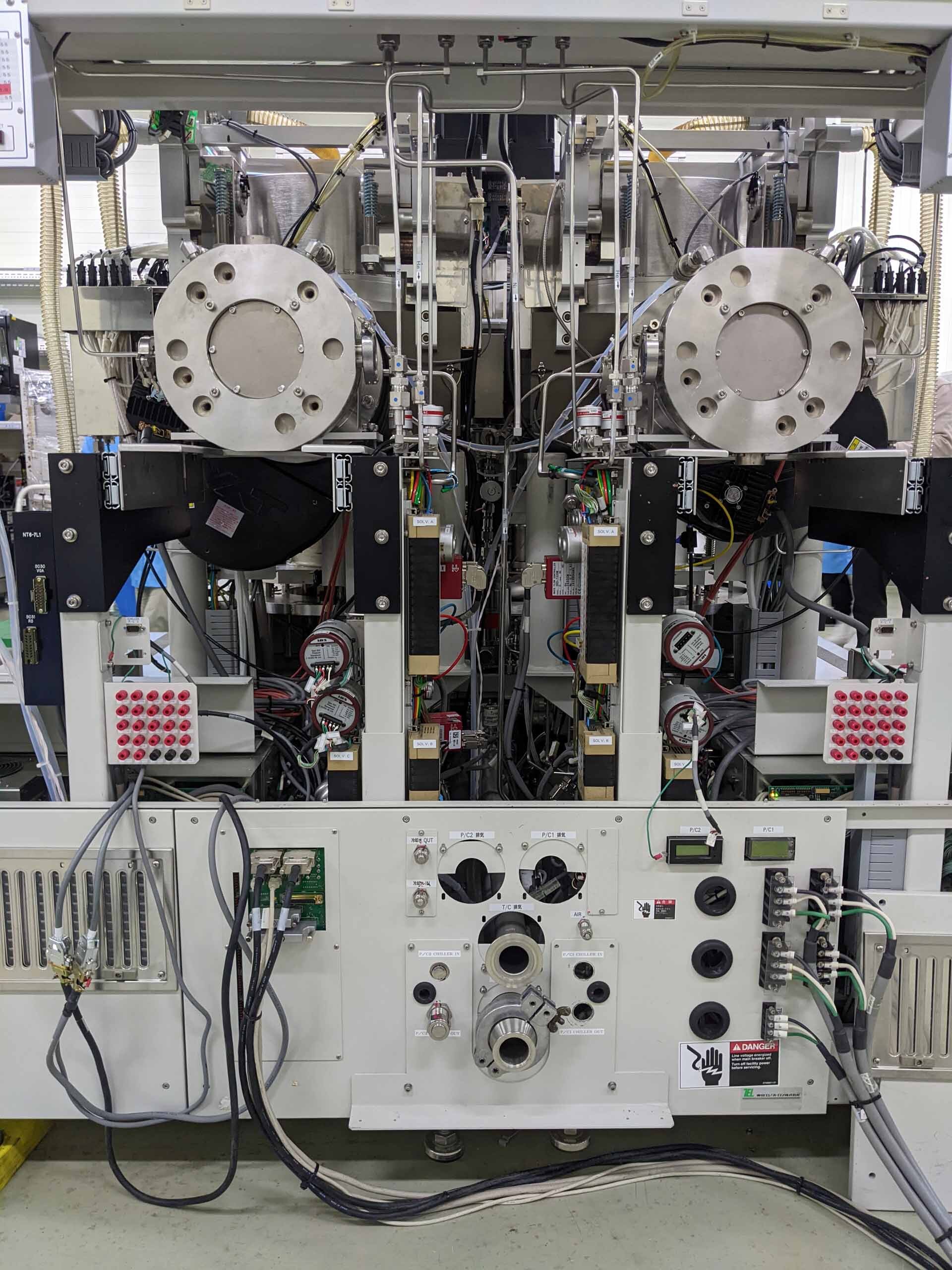

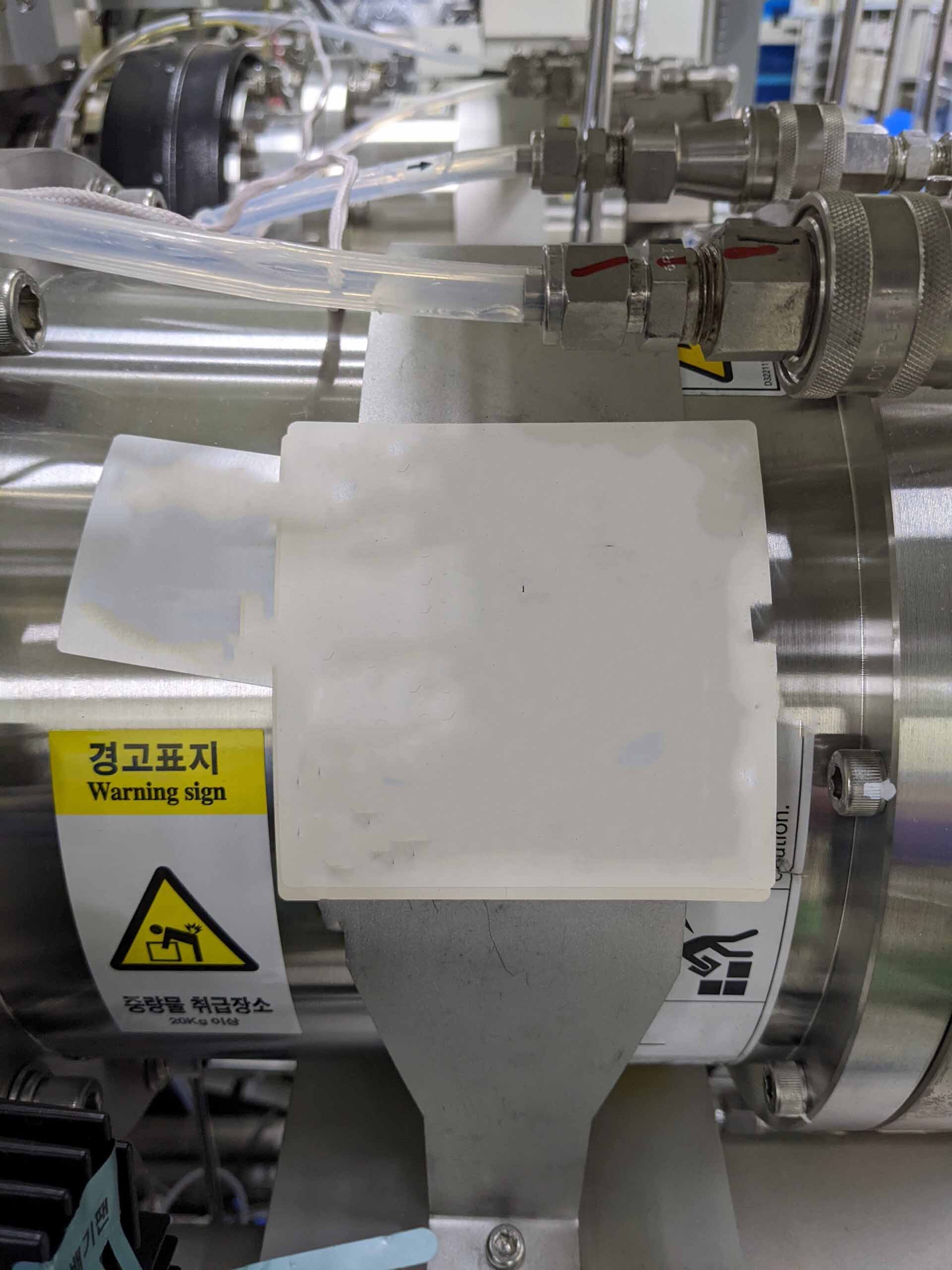

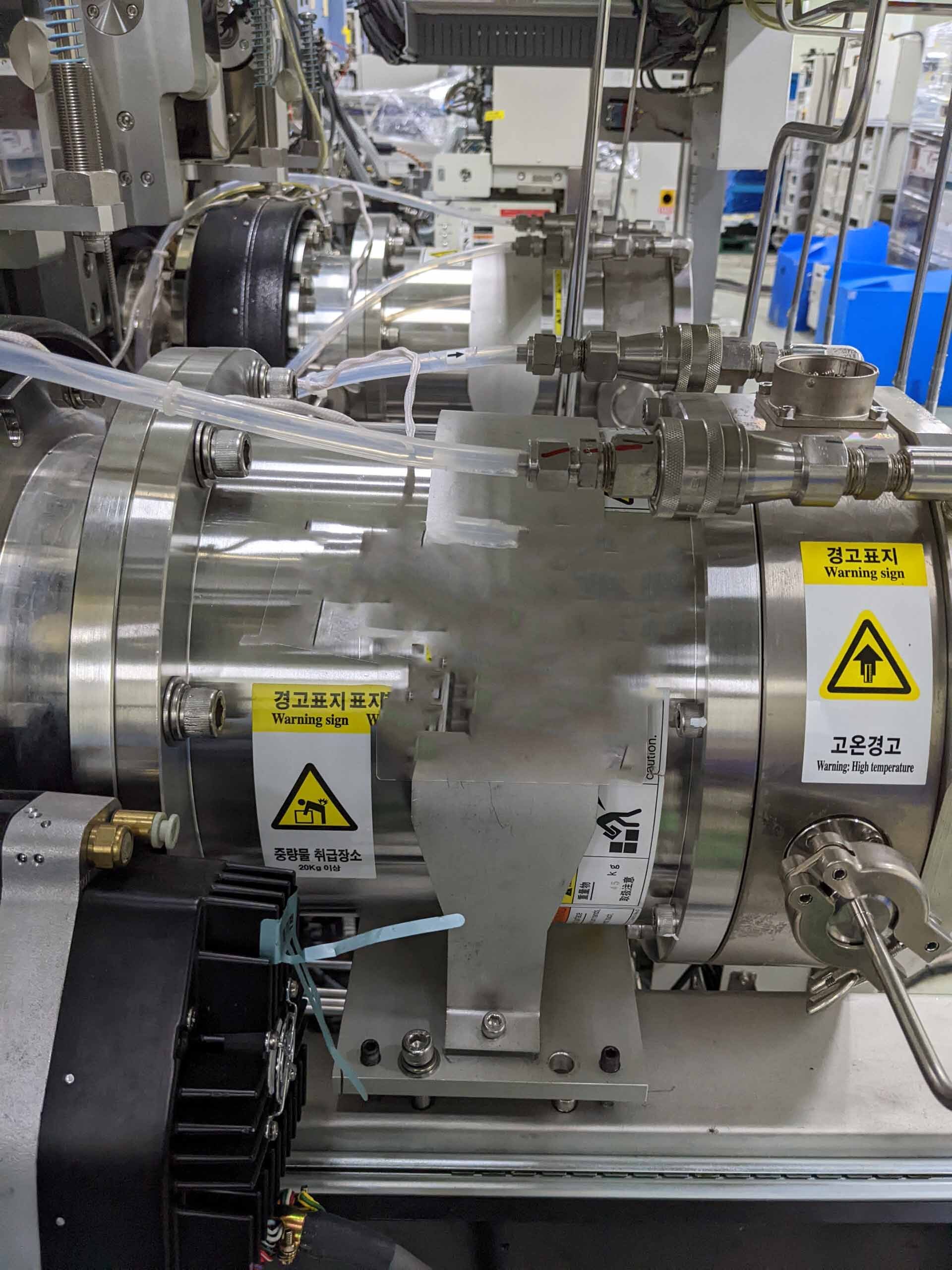

Used TEL / TOKYO ELECTRON Unity IIe 855DD #293645122 for sale

URL successfully copied!

Tap to zoom

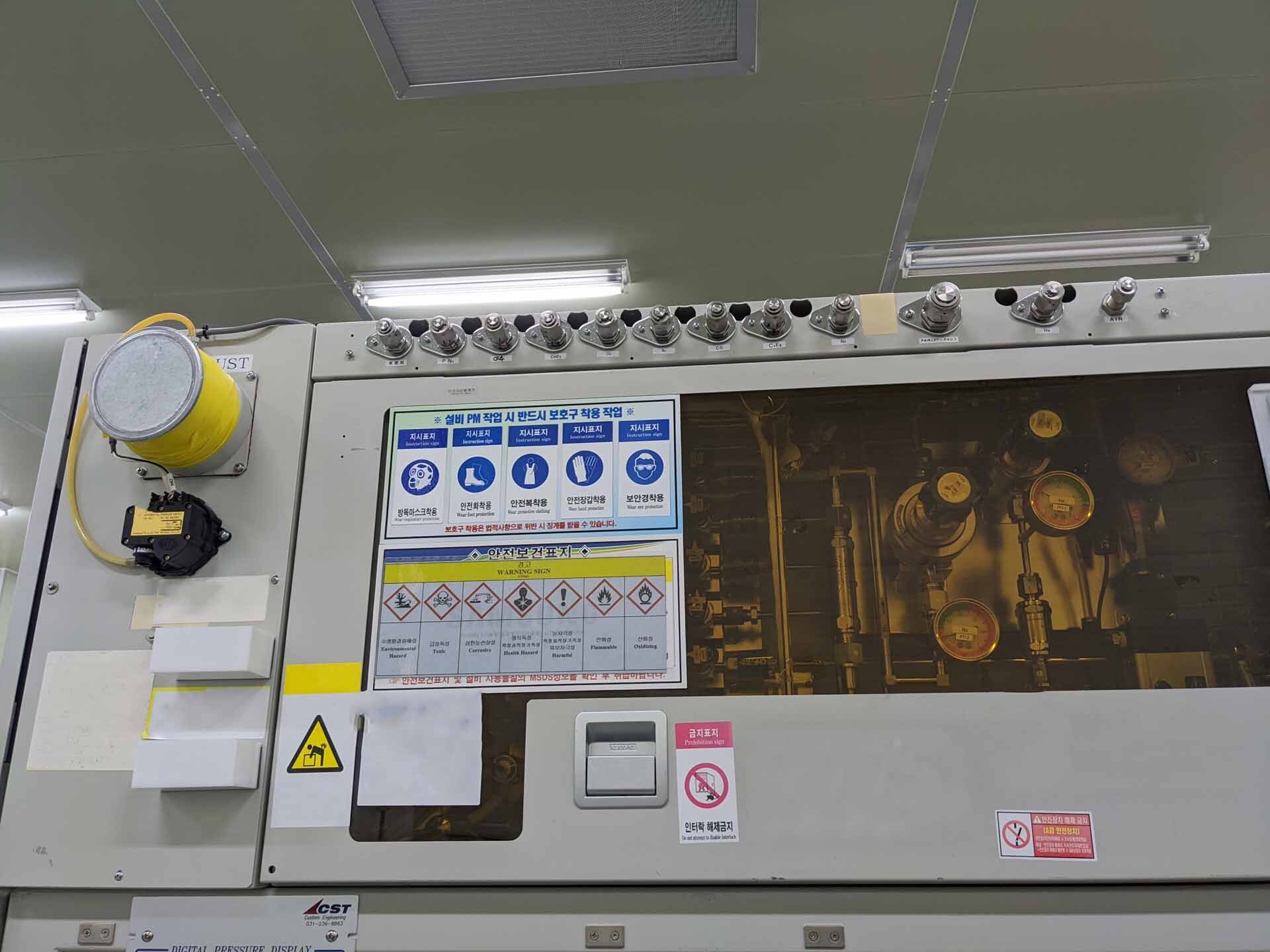

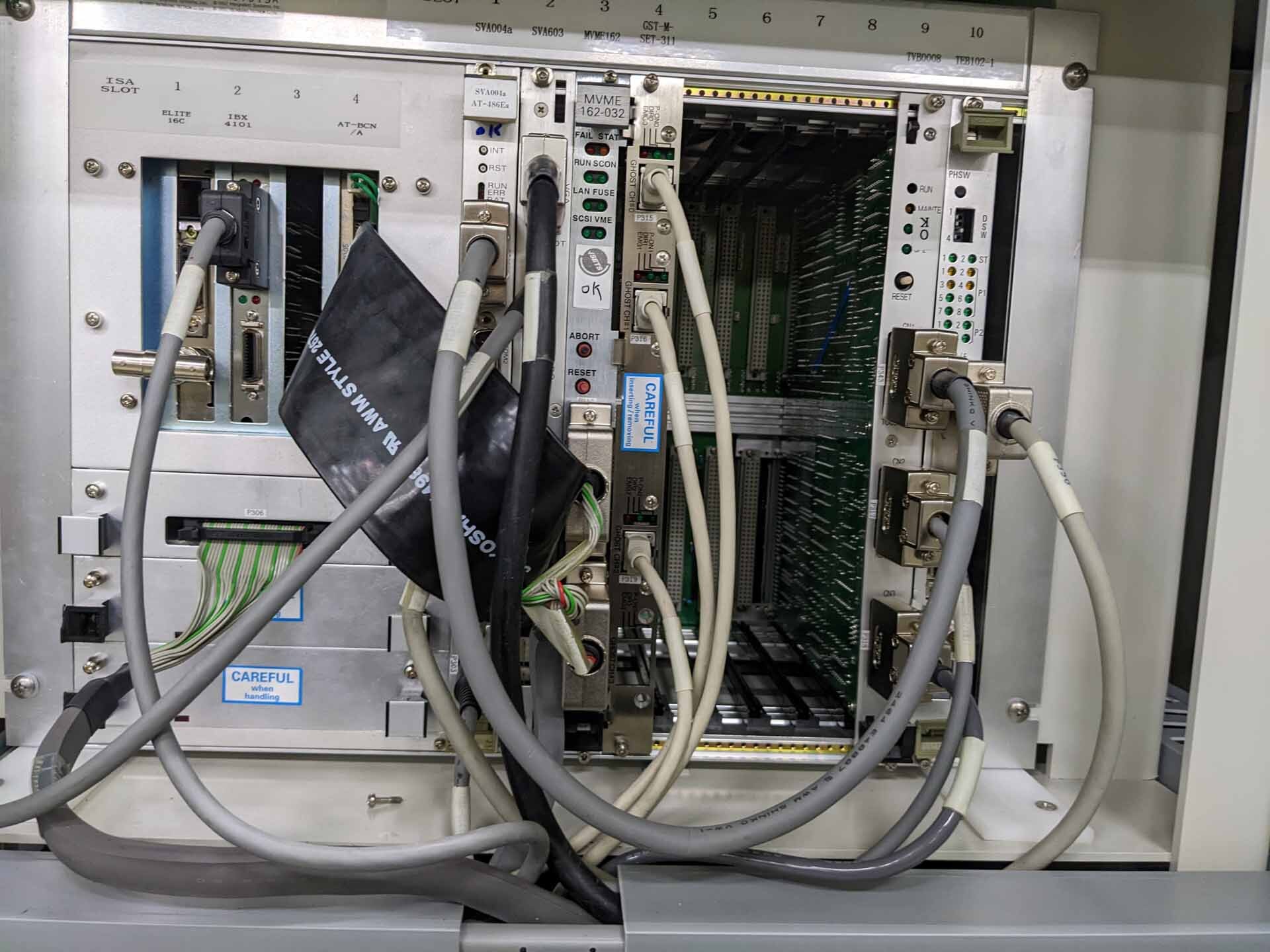

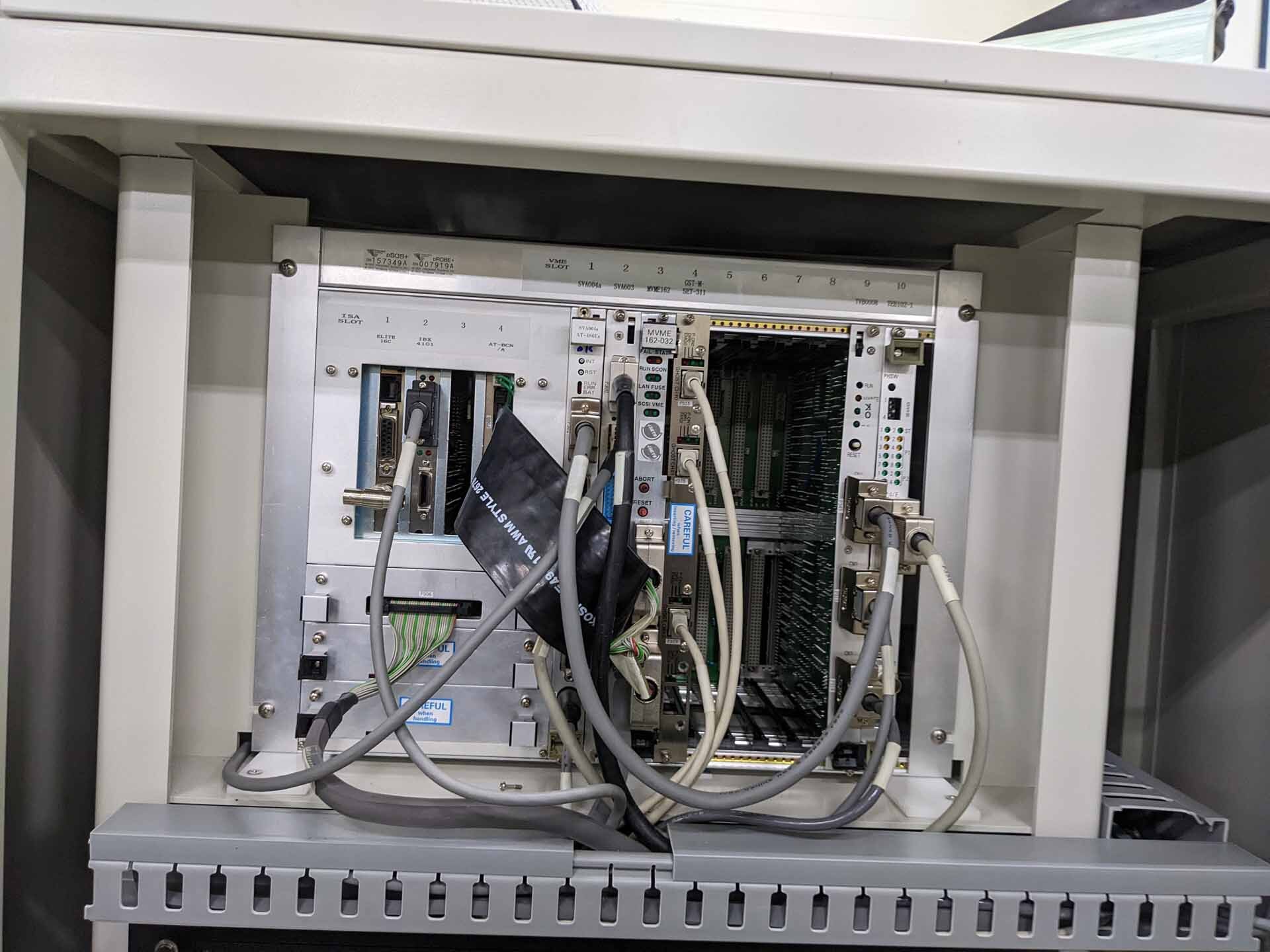

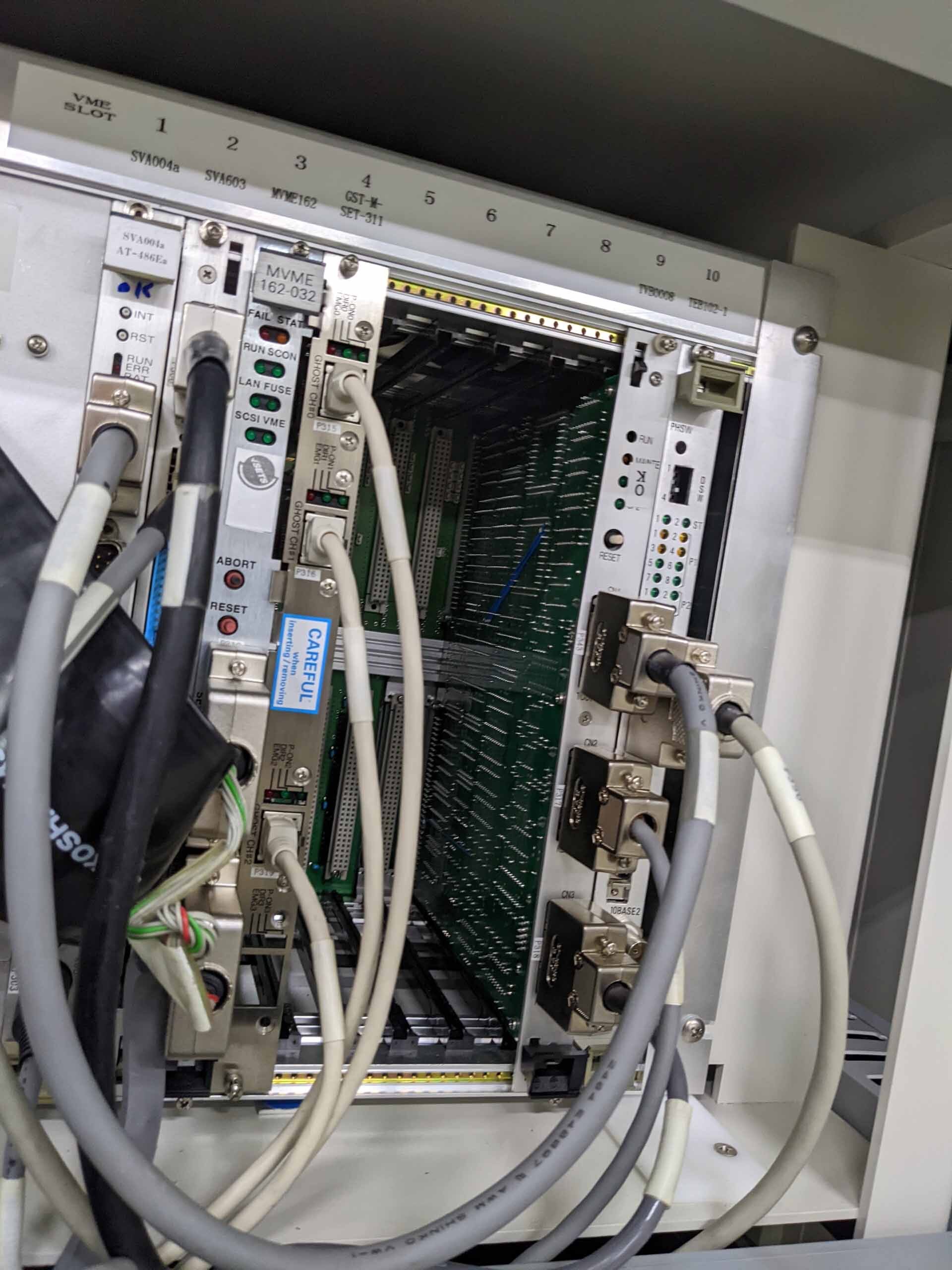

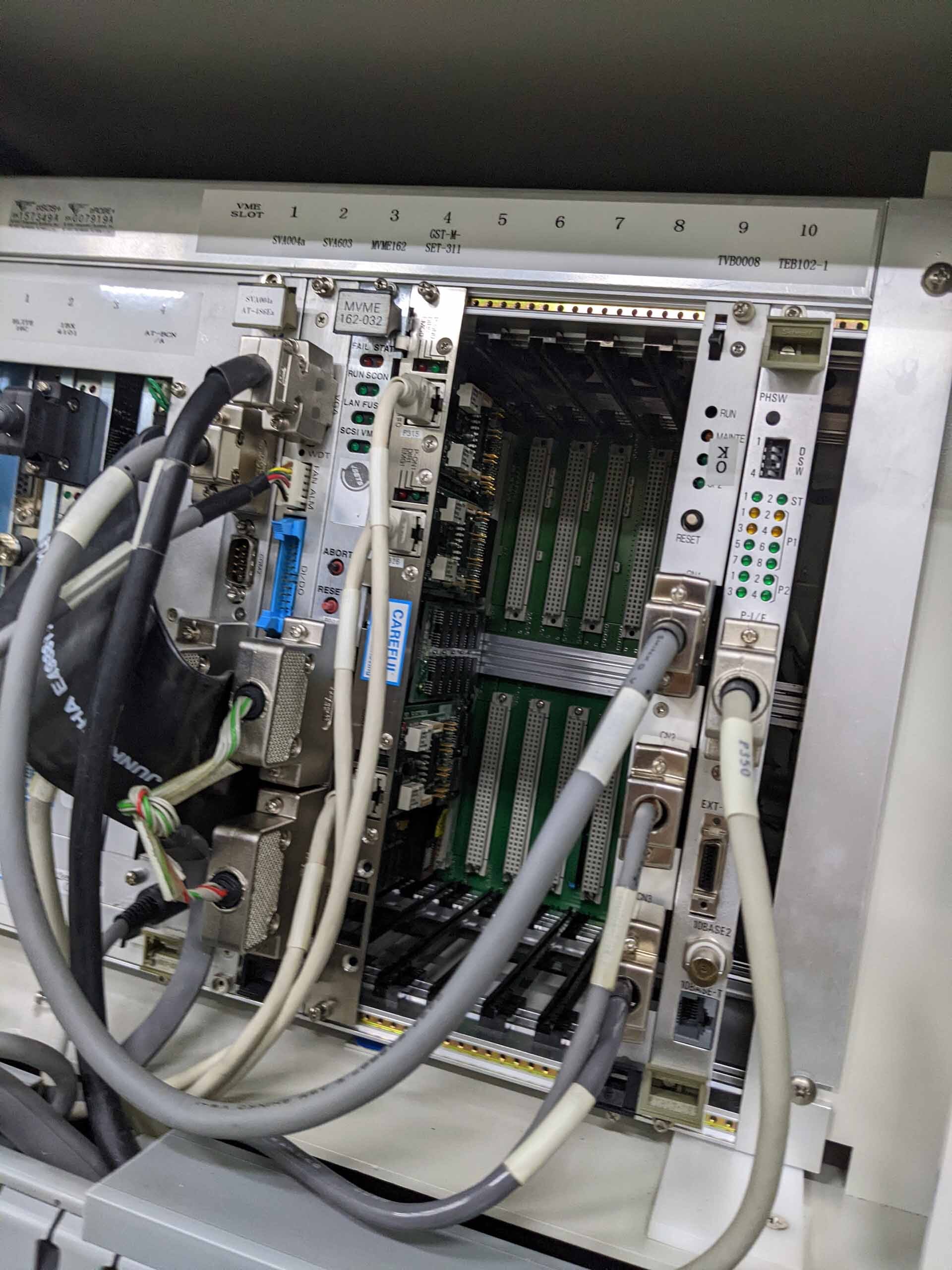

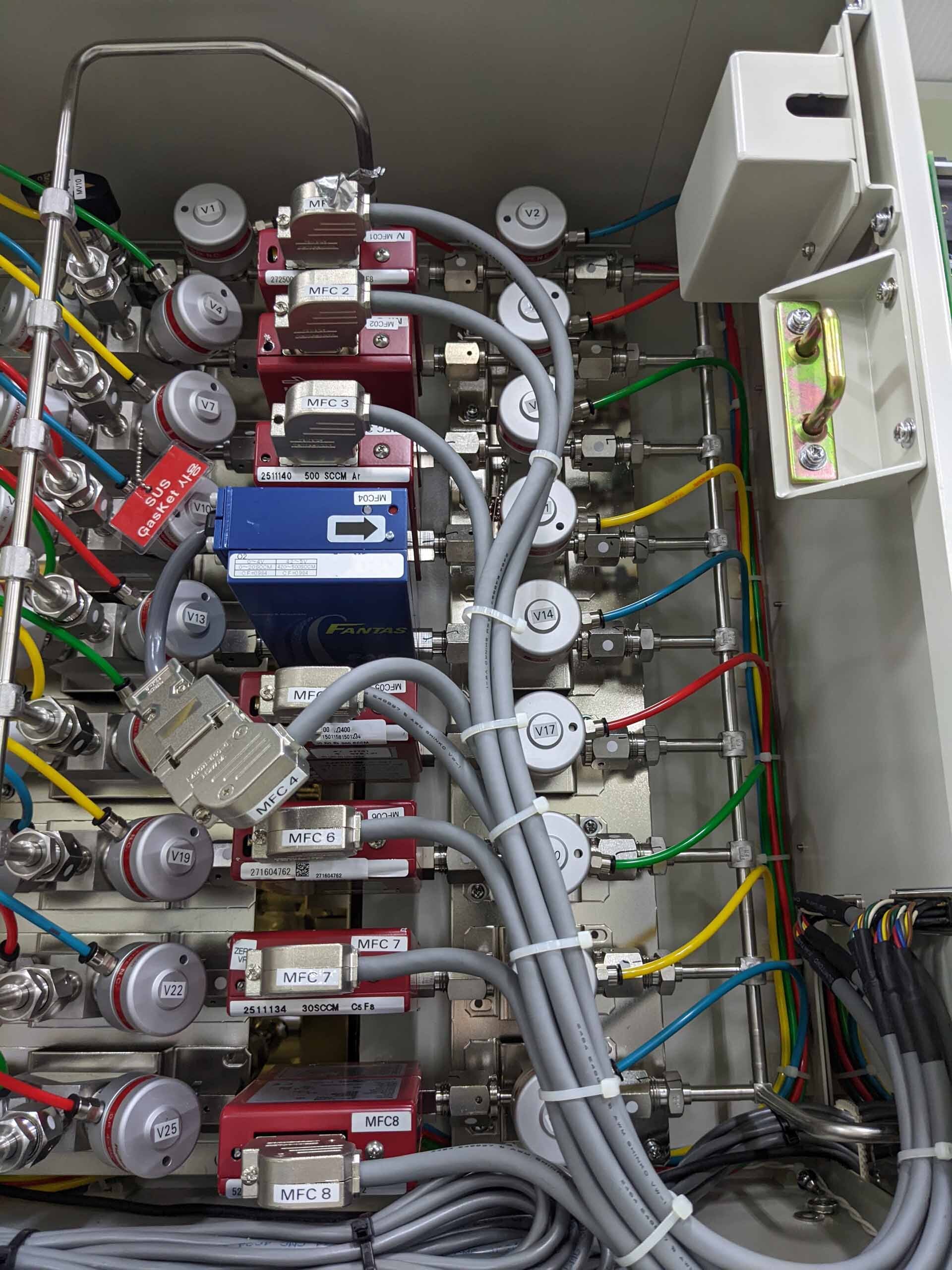

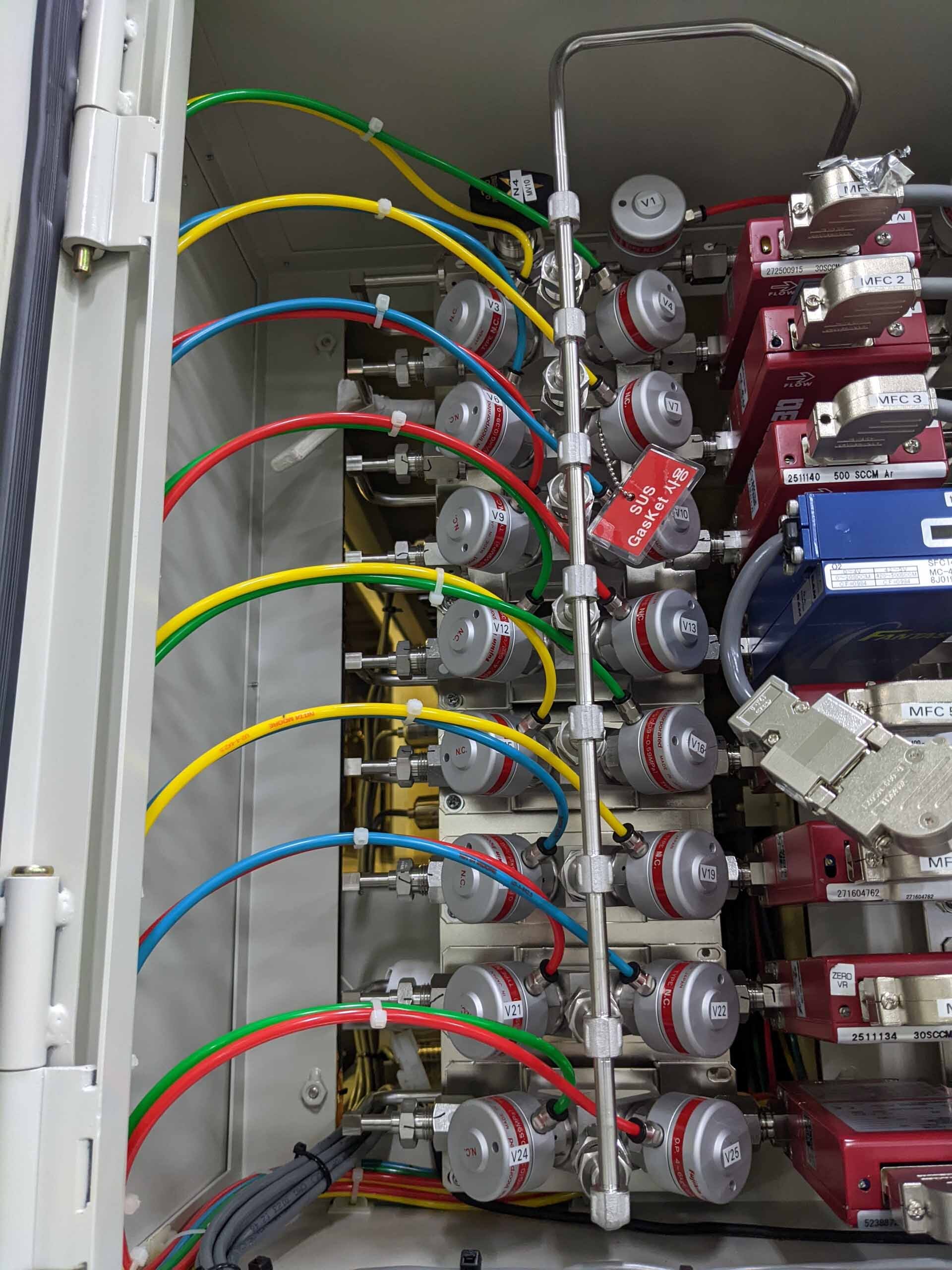

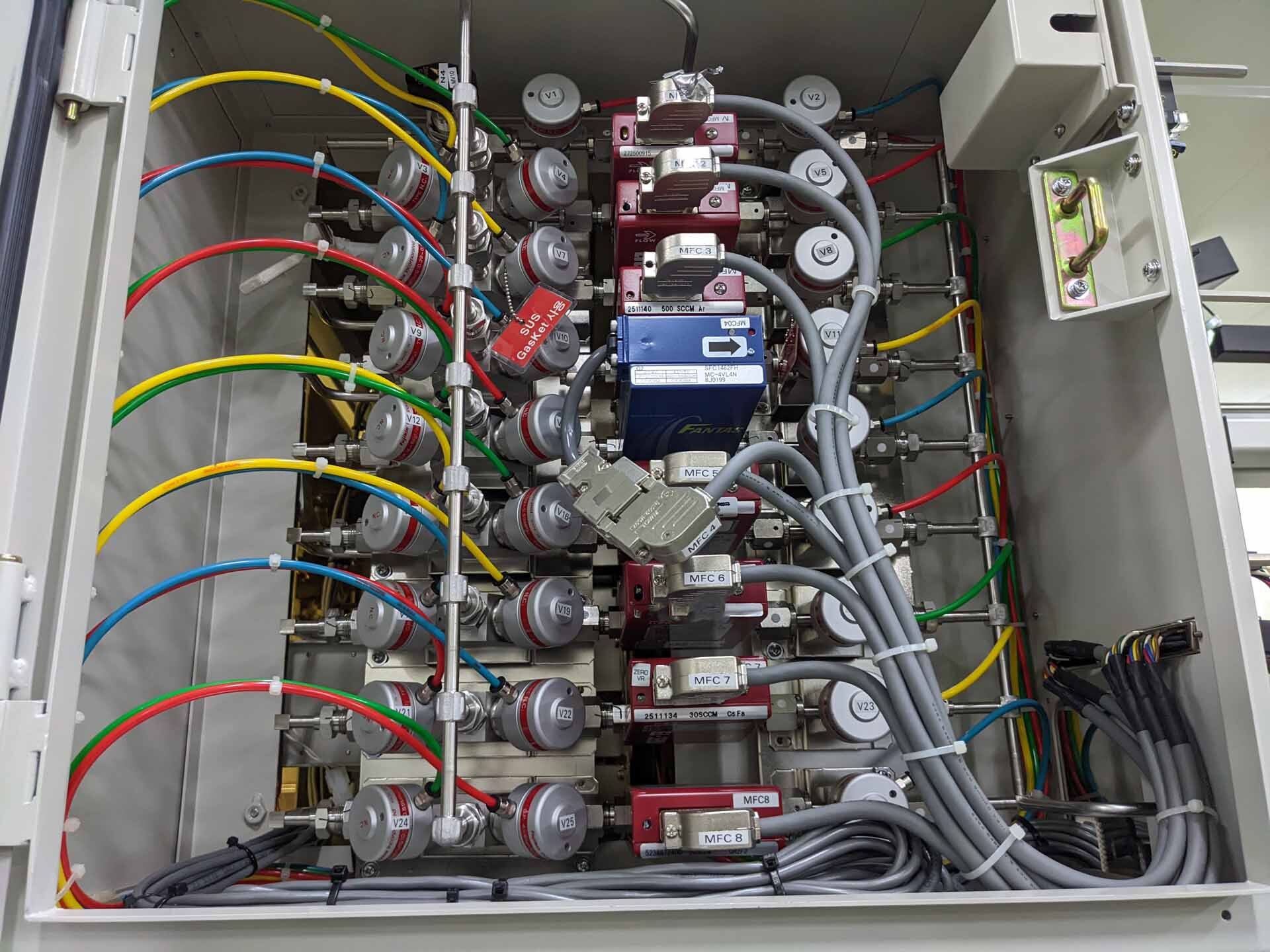

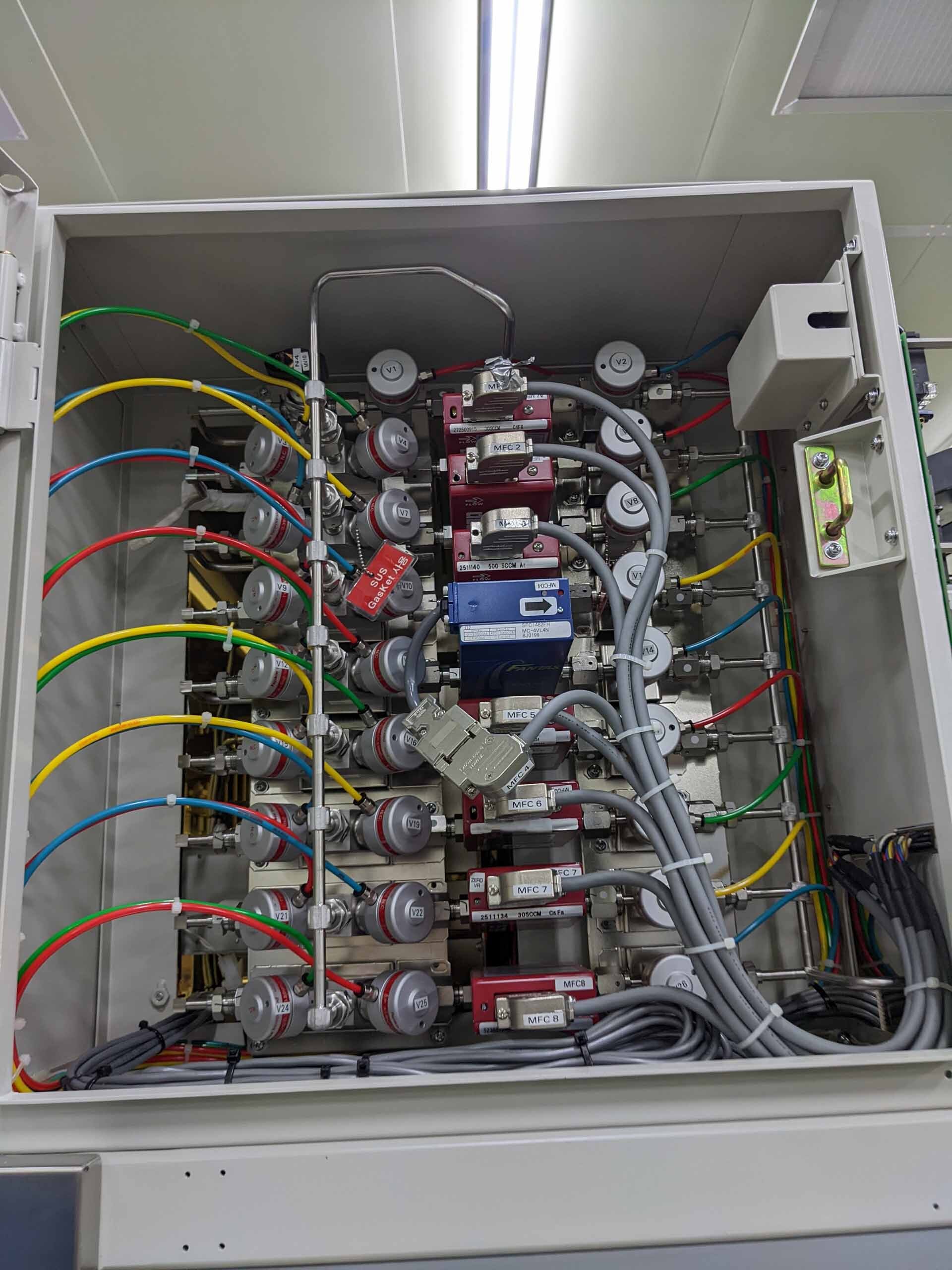

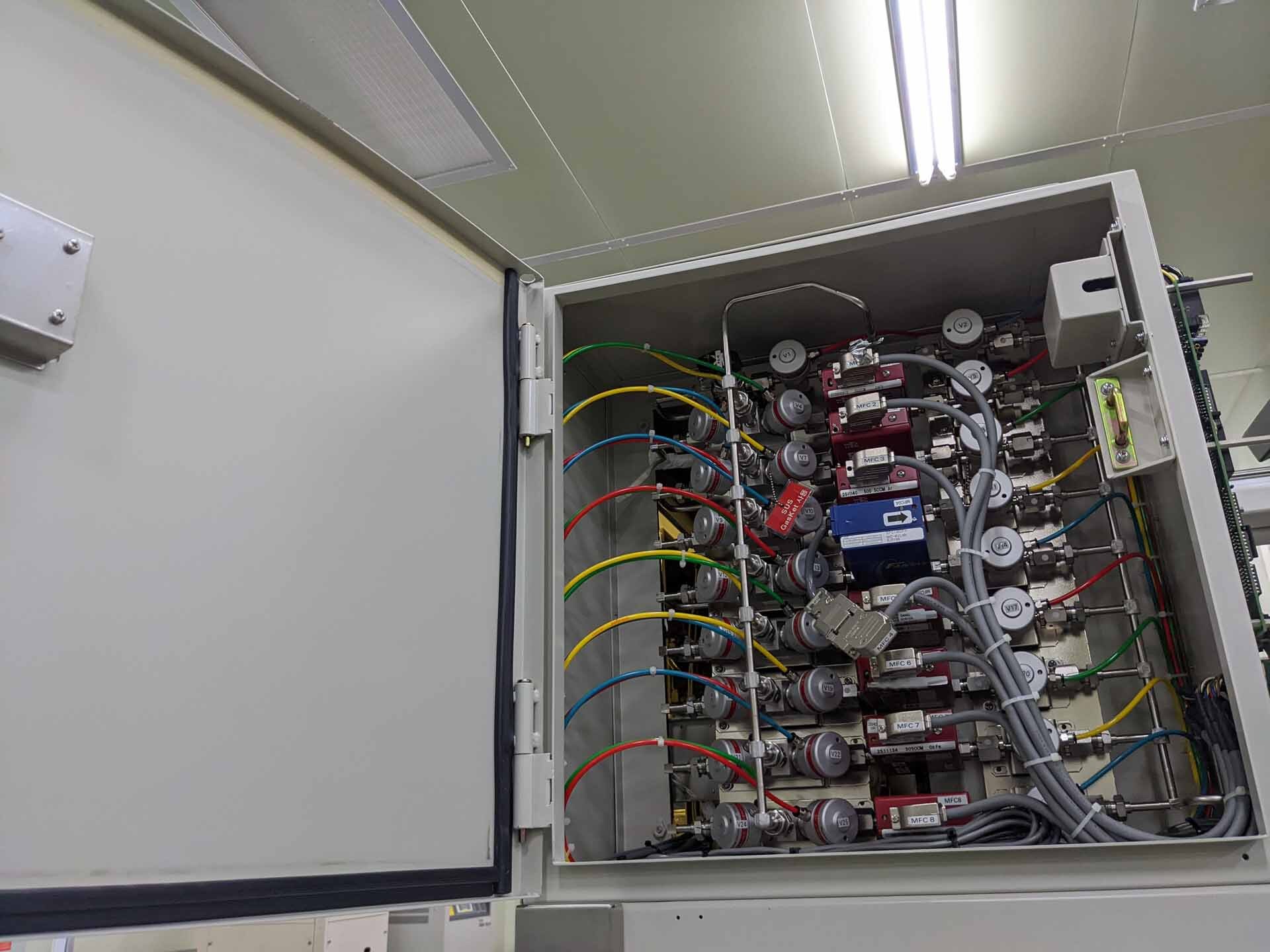

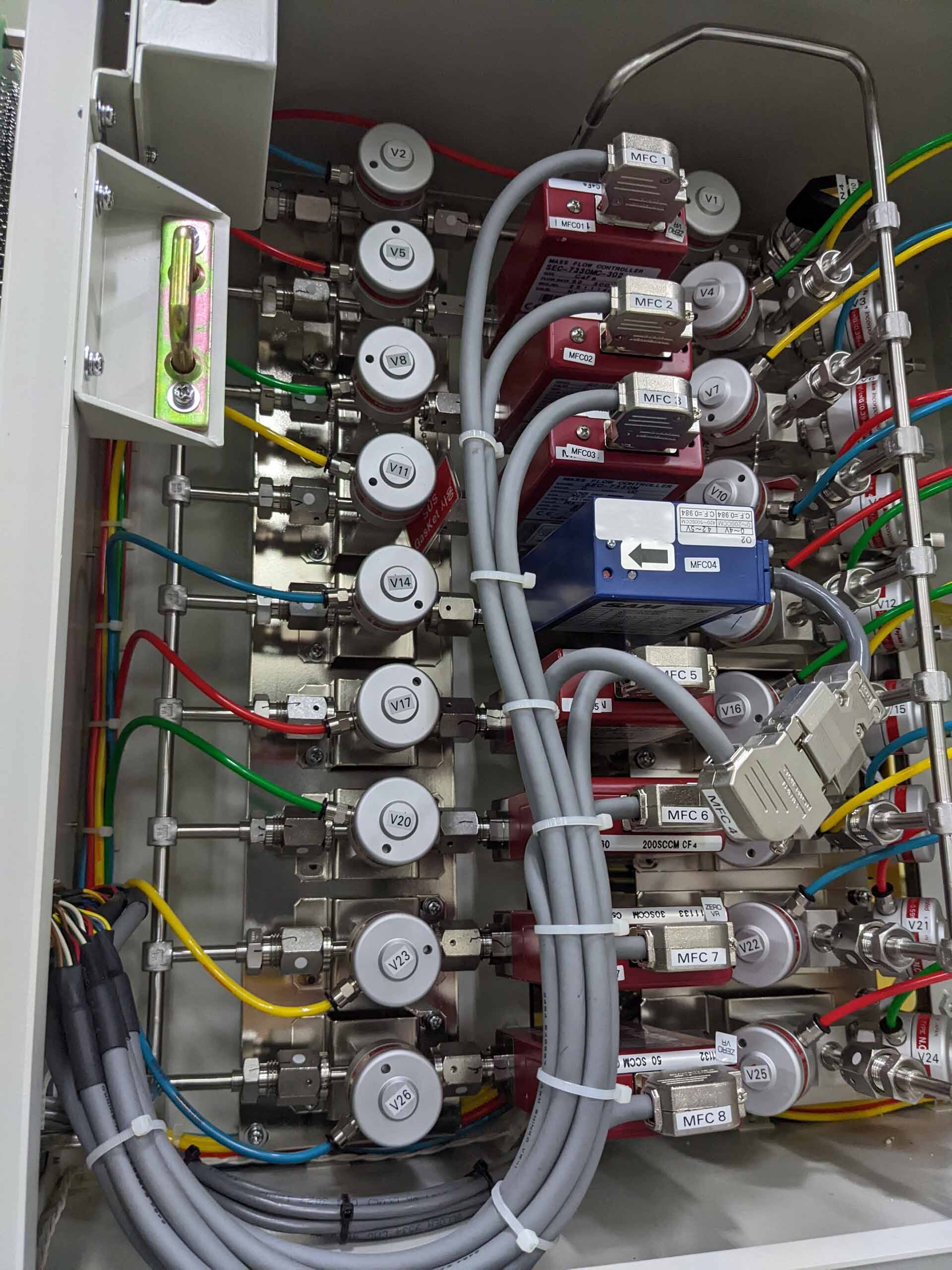

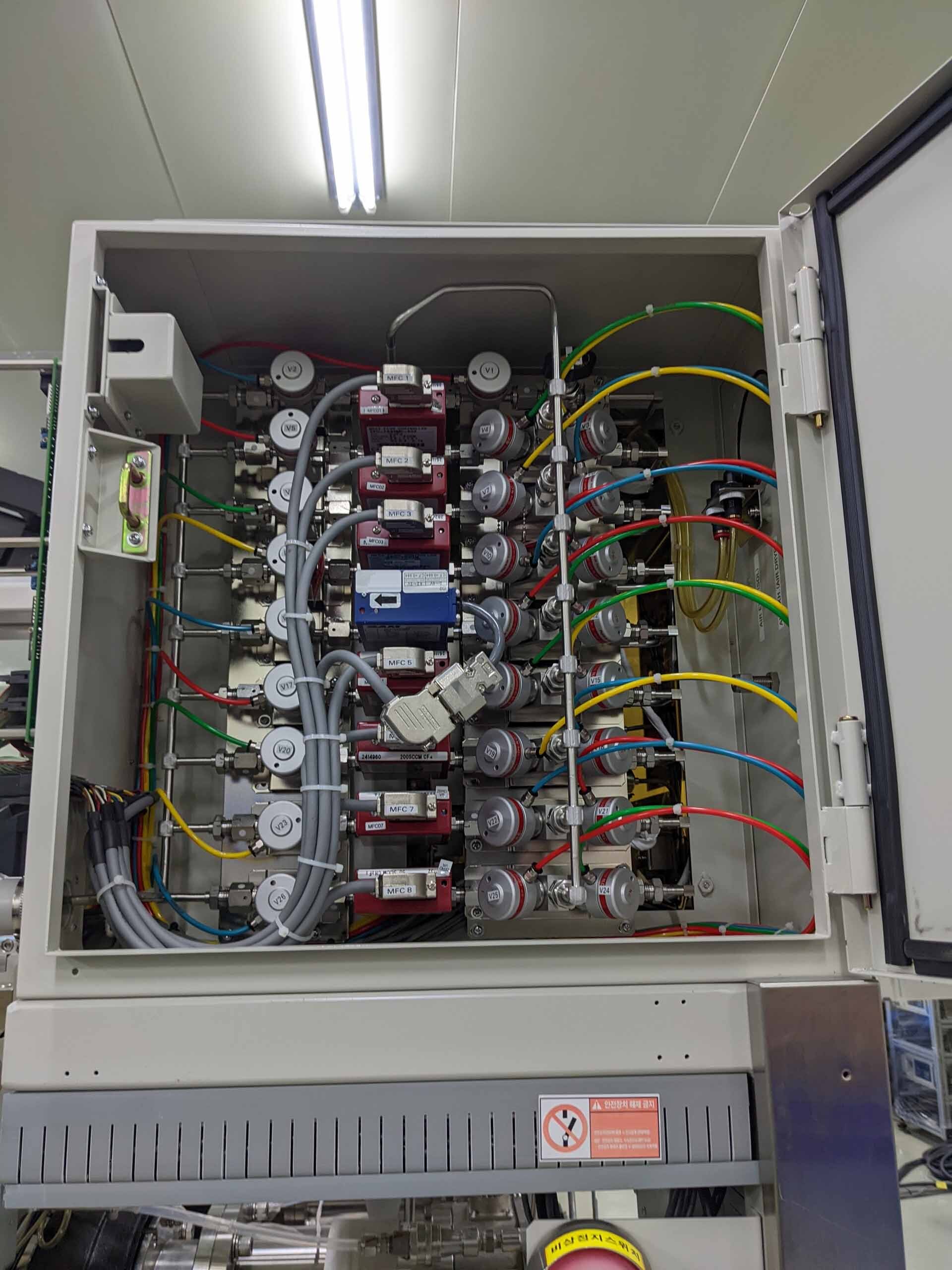

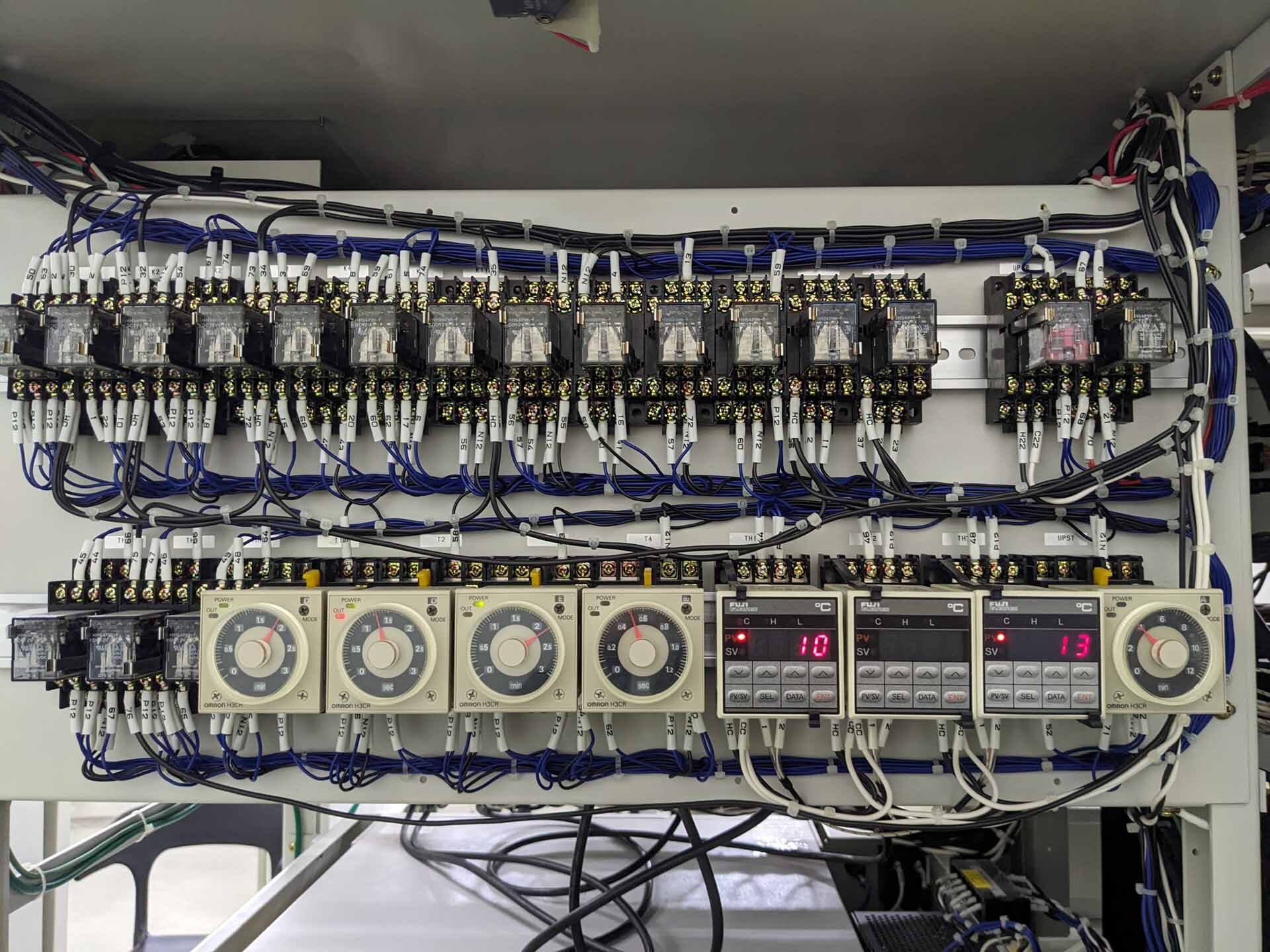

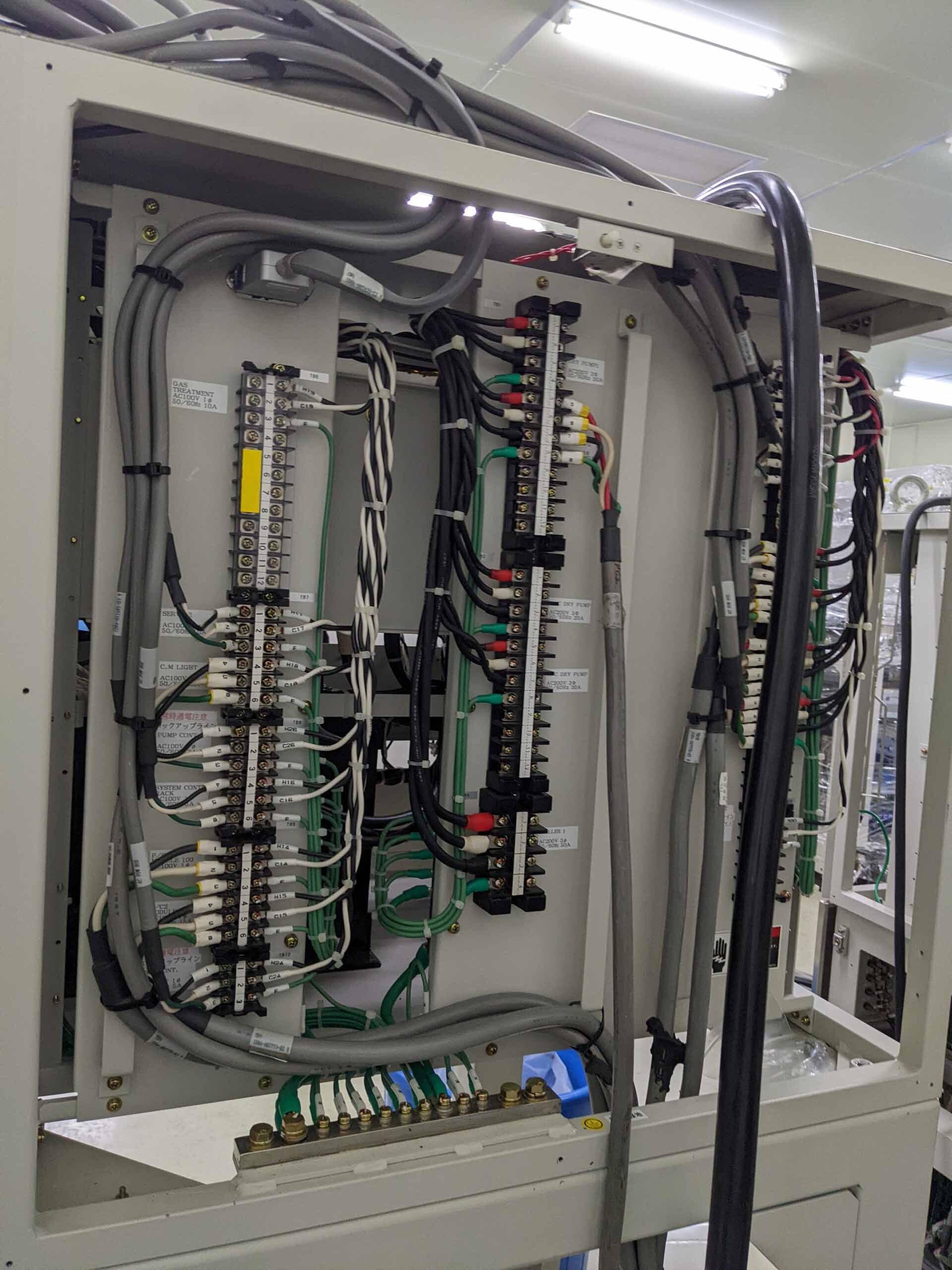

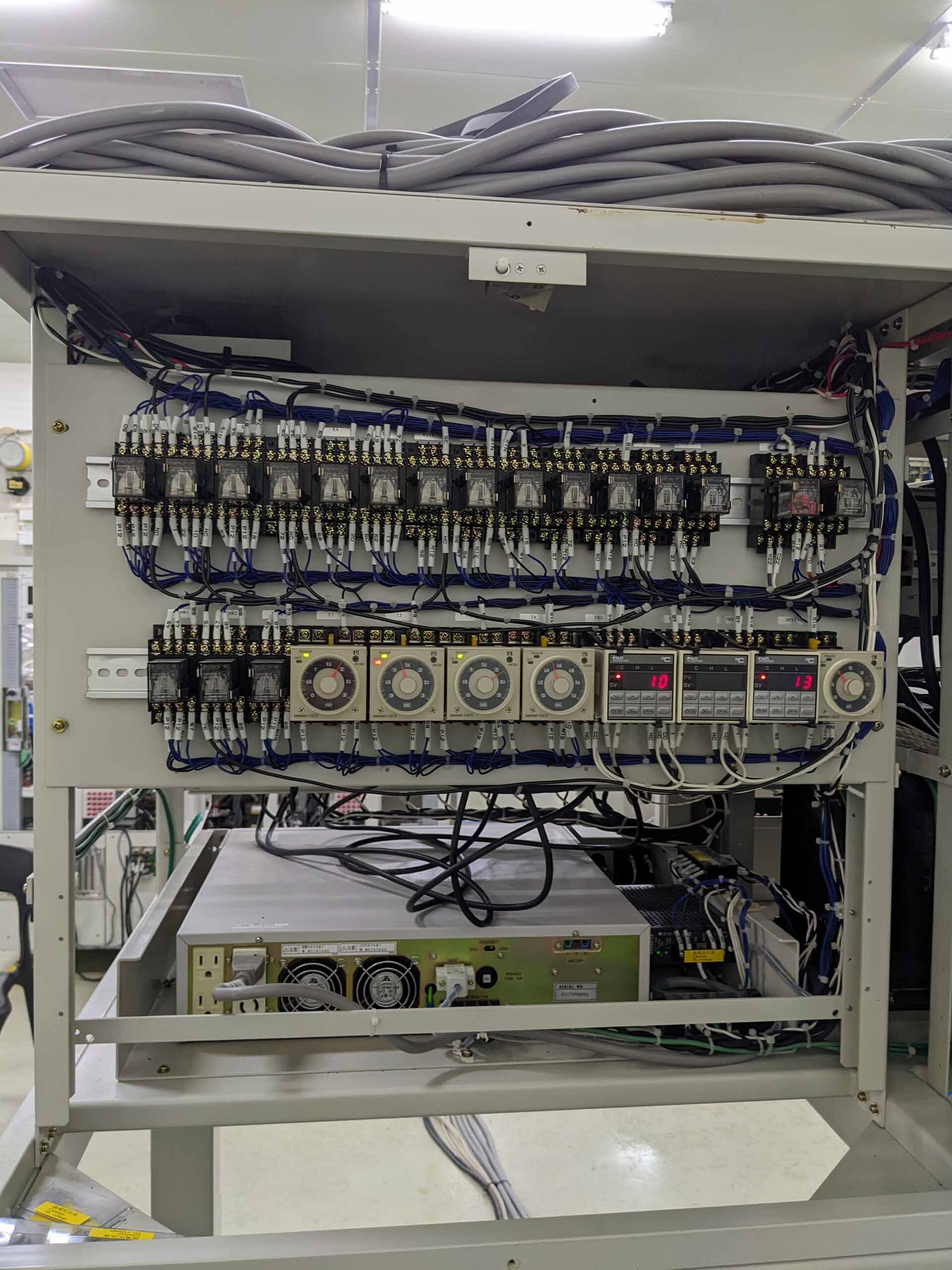

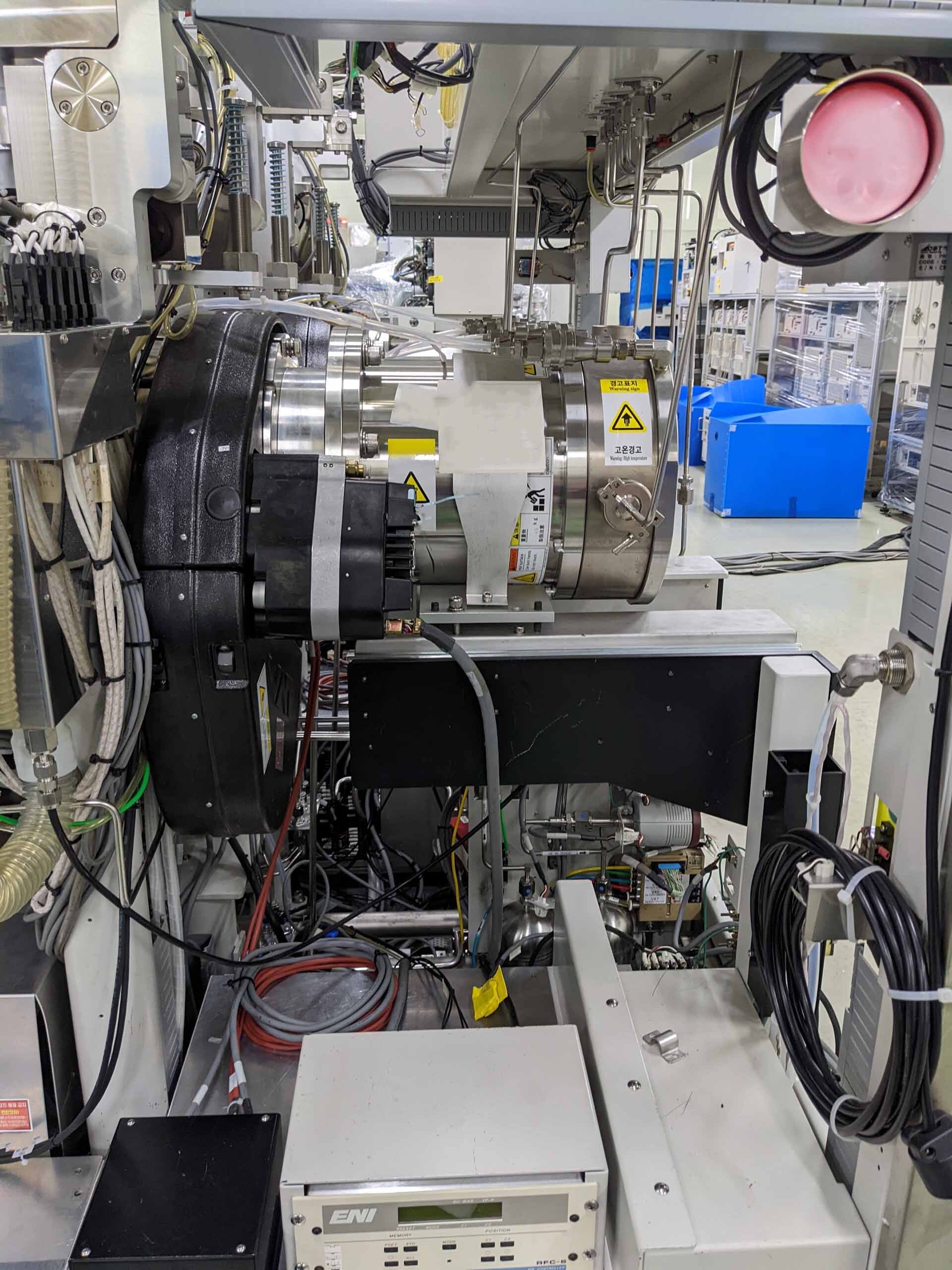

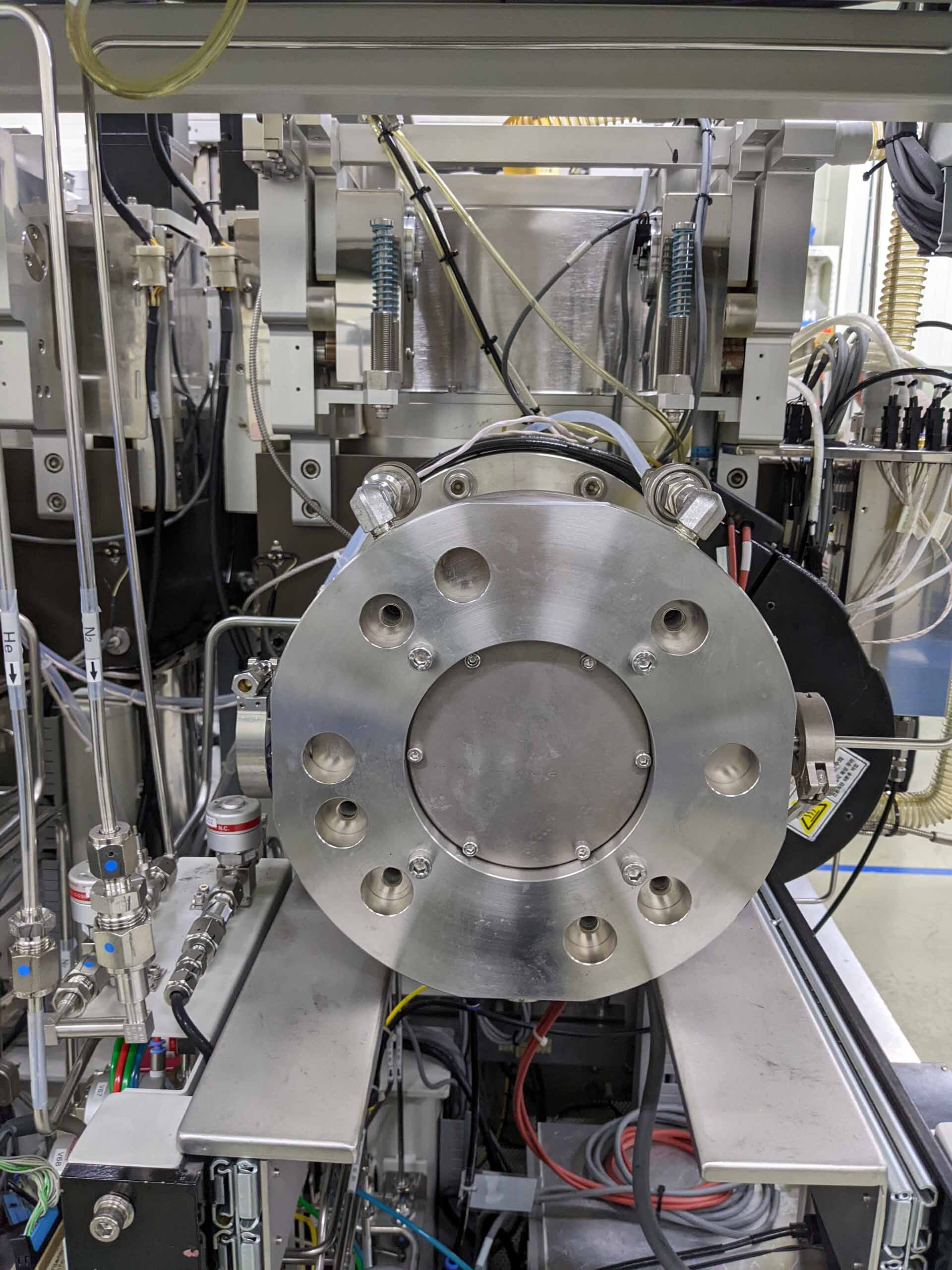

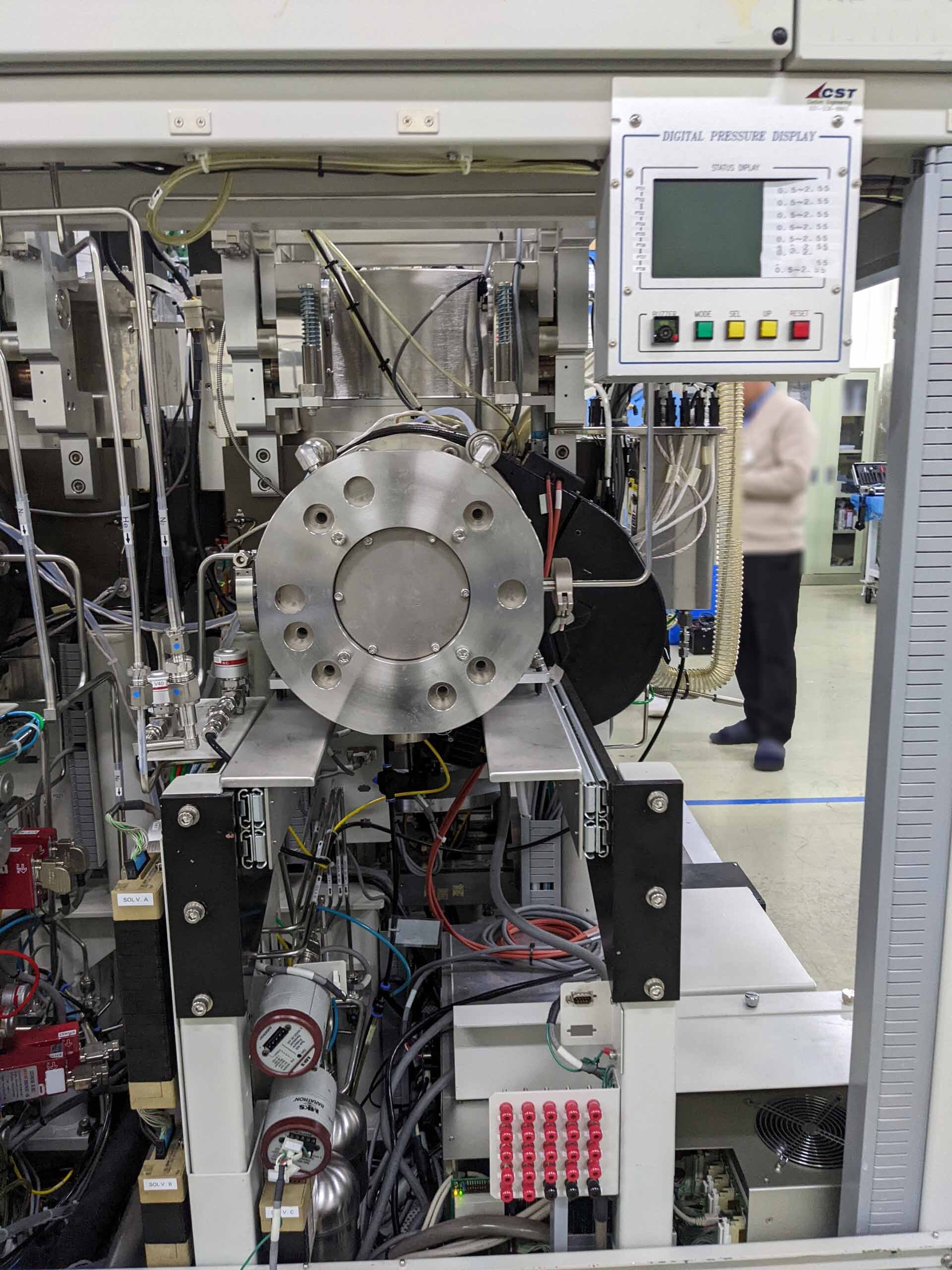

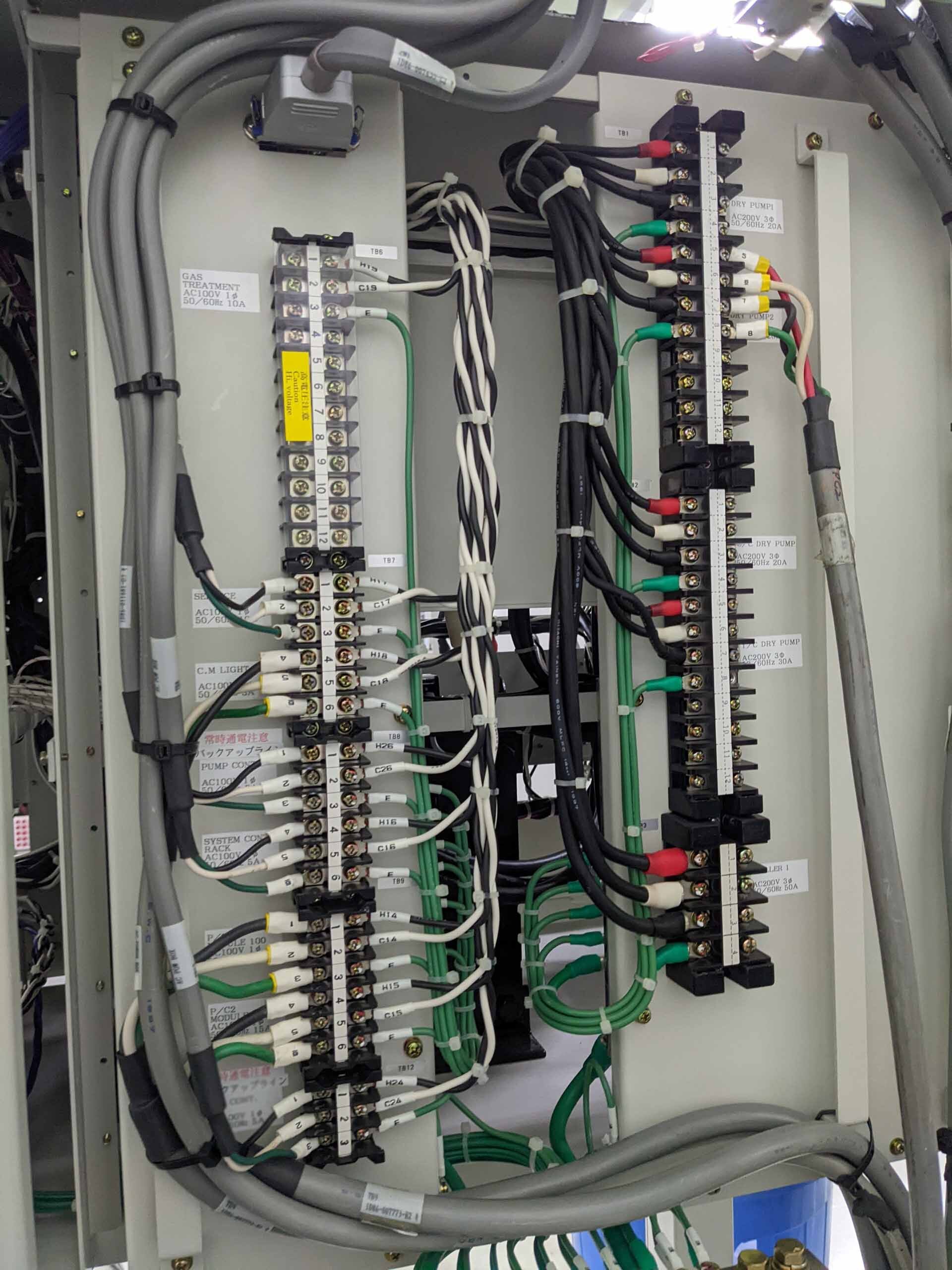

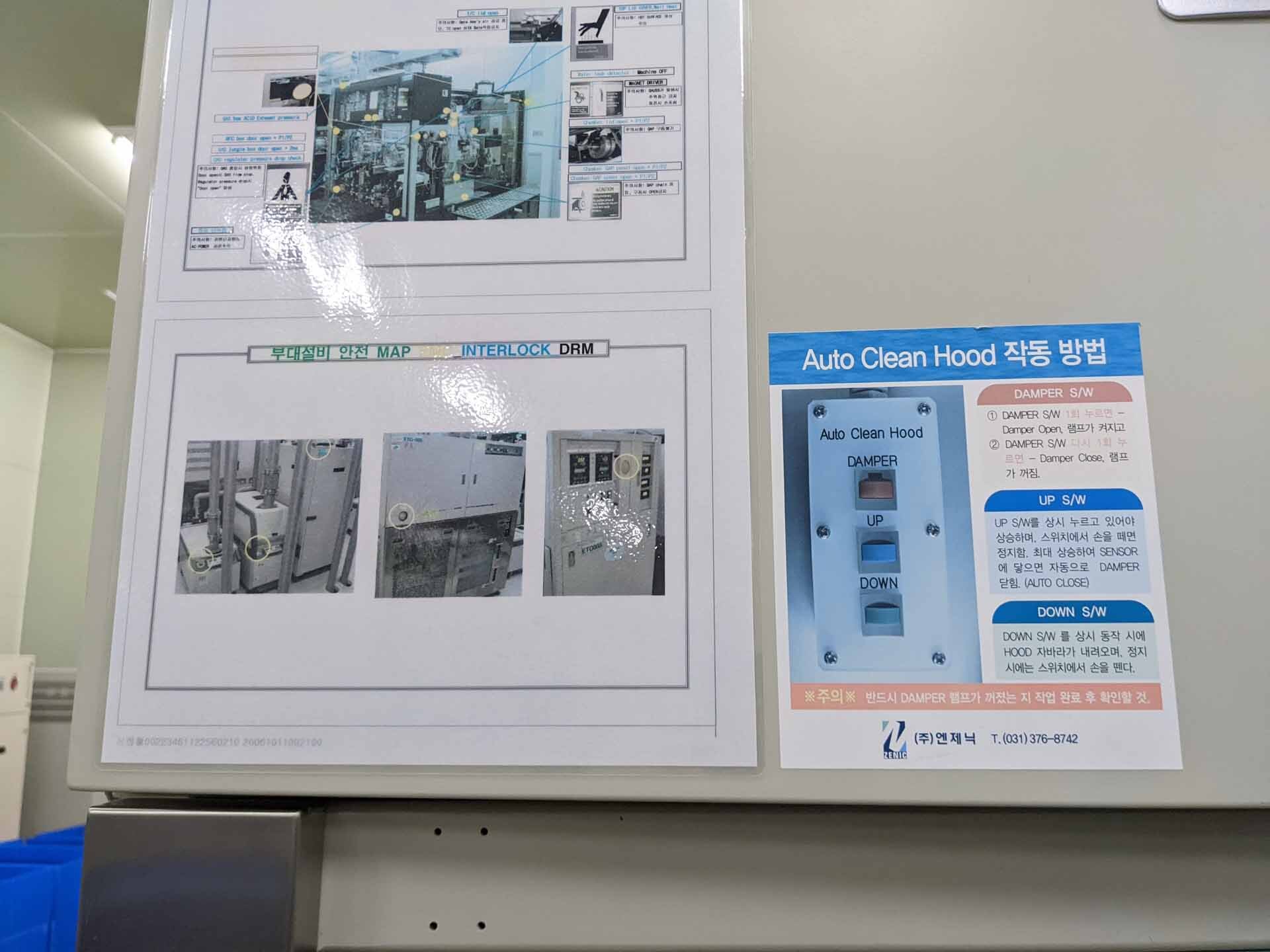

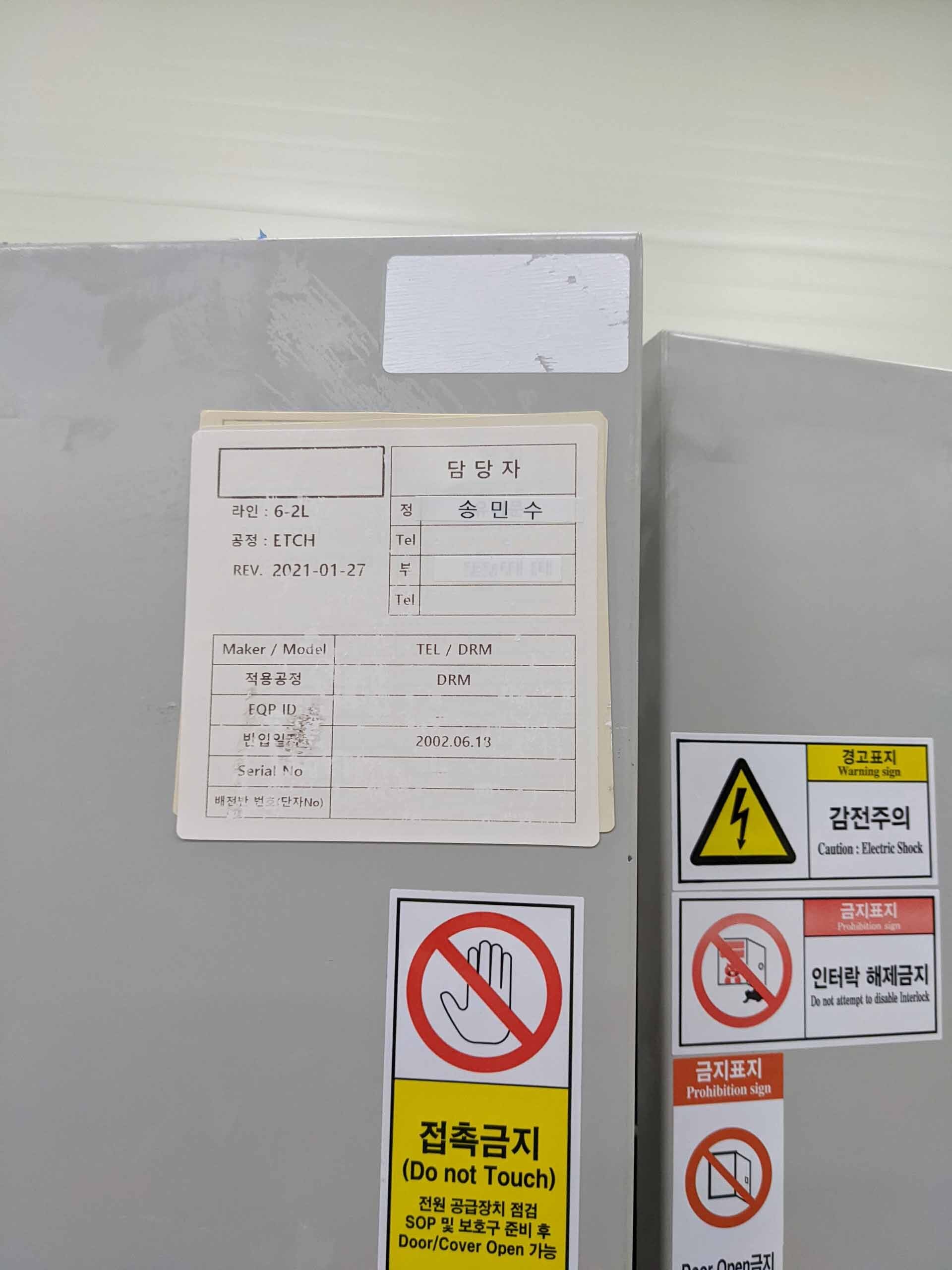

TEL / TOKYO ELECTRON Unity IIe 855DD is an advanced production-level single-wafer rinsing, etching, and ashing tool for sub-45nm process nodes and less. This etcher/asher provides benefits including minimized fragmentation of particles, ultra-low volume of residues, a high throughput of up to 25 wafers per hour, a maximum wafer size of 8-inch (200mm), and an improved uniformity of surface properties. TEL UNITY IIE 855 DD has an advanced production level on-board gas distribution equipment to optimize ultra-high vacuum (UHV) processing performance. This system is enabled through the use of internal gas dynamic valves (GDV) functioning at pressures ranging from 20 Torr to below 10-9 Torr. It also features a Pulsed RF Plasma Removal Unit (PRFS) which improves the etching process by controlling the amount of chemicals released, as well as by increasing the pulse rate. Lastly, TOKYO ELECTRON UNITY II E-855DD is equipped with a multiple-showerhead design to achieve a 3-dimensional uniform film deposition. TOKYO ELECTRON Unity IIe 855DD delivers tight film thickness control with various features to support high-thickness precision. These features include High Voltage Co-Deposition (HVCD), Bias Enhanced High Density Plasma (BEHDP), and Multi-Mode Plasmatron (MMP). The HVCD enables ultra-precise thickness control, while the BEHDP controls the amount of reactants. With the MMP function, the deposition rate can be ramped up or down to enable fine-tuning of film characteristics. This enables different film thickness to be applied to different sections of a substrate, in order to maximize the etching process. TEL / TOKYO ELECTRON UNITY II E- 855DD also provides a unique cleaning power through the combination of etching, ashing, and dampening processes. The etching process concentrates on removing unwanted elements on the substrate surface. The ashing process removes dirt and other organic contaminants. Finally, the dampening process uses airknives at low-pressure to effectively dry the substrate after etching and ashing. TEL UNITY II E- 855DD also offers an Effluent Monitor Control (EMC) to accurately detect and monitor Cd, Hg, and Pb particles in real time during the etching and ashing process. This monitoring function is integrated with the monitor control unit, and filters the hazardous materials automatically. In short, UNITY II E-855DD is an advanced production-level etcher/asher that provides excellent performance and accuracy to ensure the highest quality etching and ashing results for ultra-low-volume process nodes. Its advanced production-level on-board gas distribution machine and unique cleaning power, along with its integrated Effluent Monitor Control (EMC), make Unity IIe 855DD the ideal tool for producing crisp and clean etching and ashing films for ultra-fine substrates.

There are no reviews yet