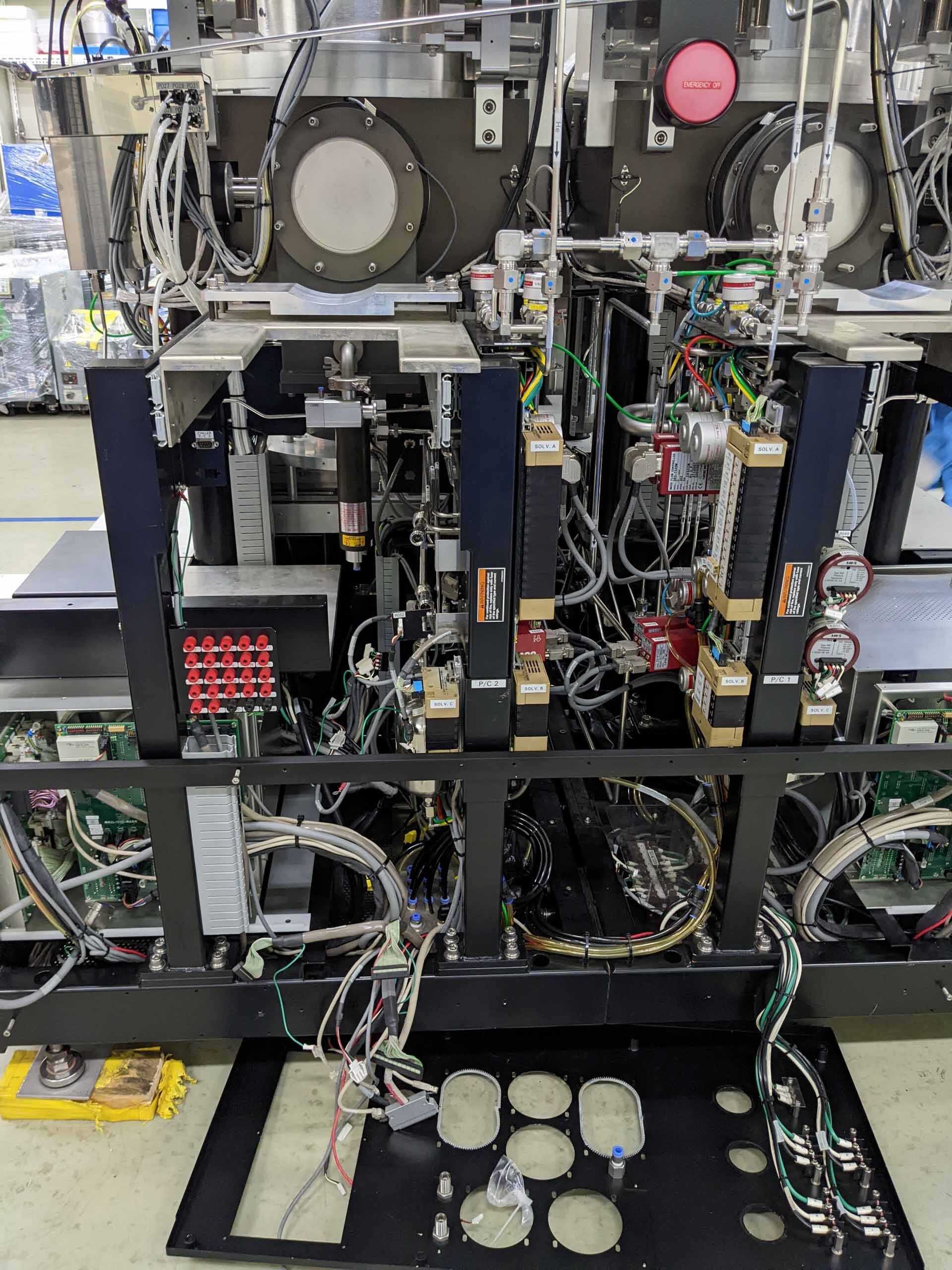

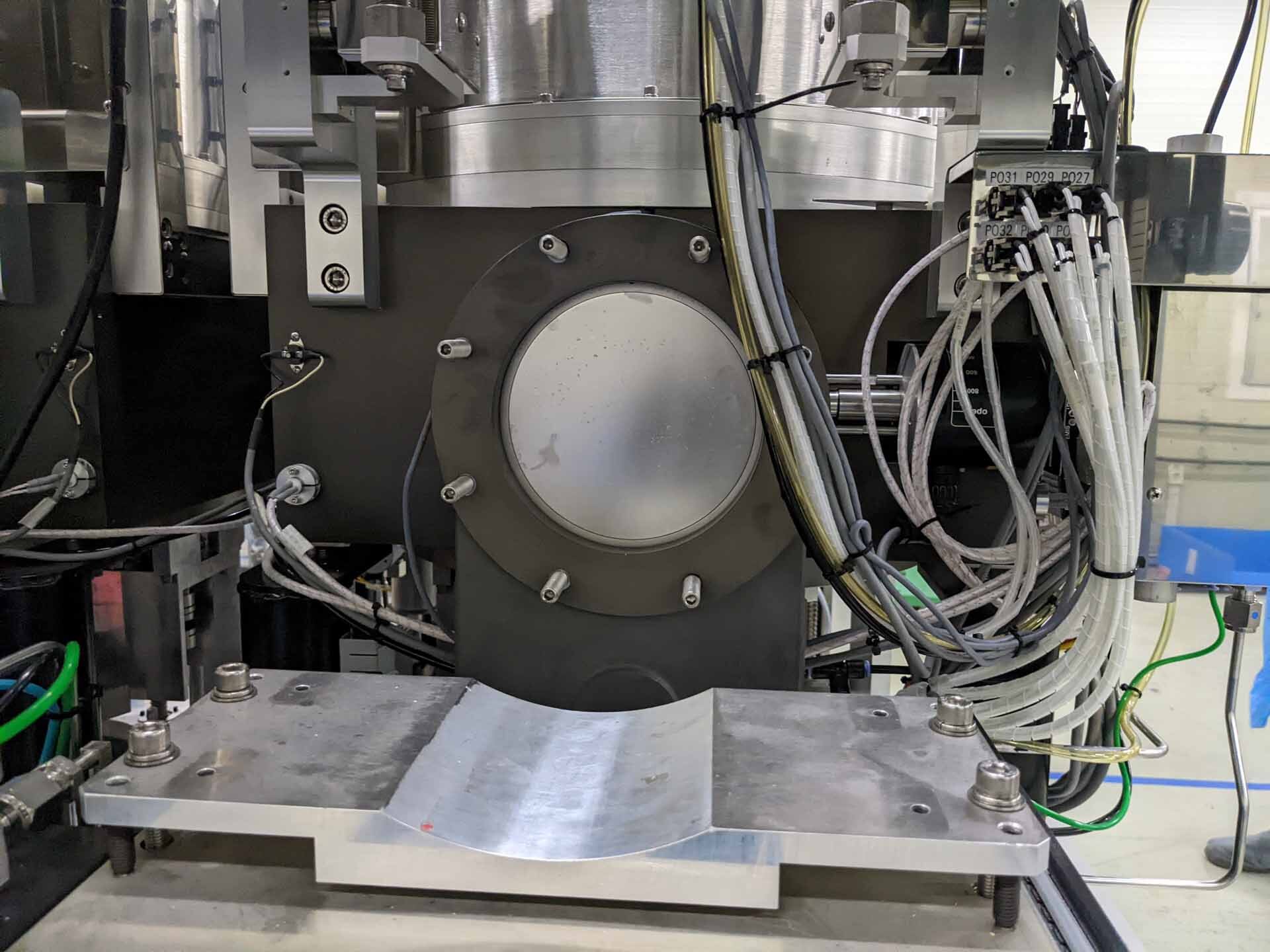

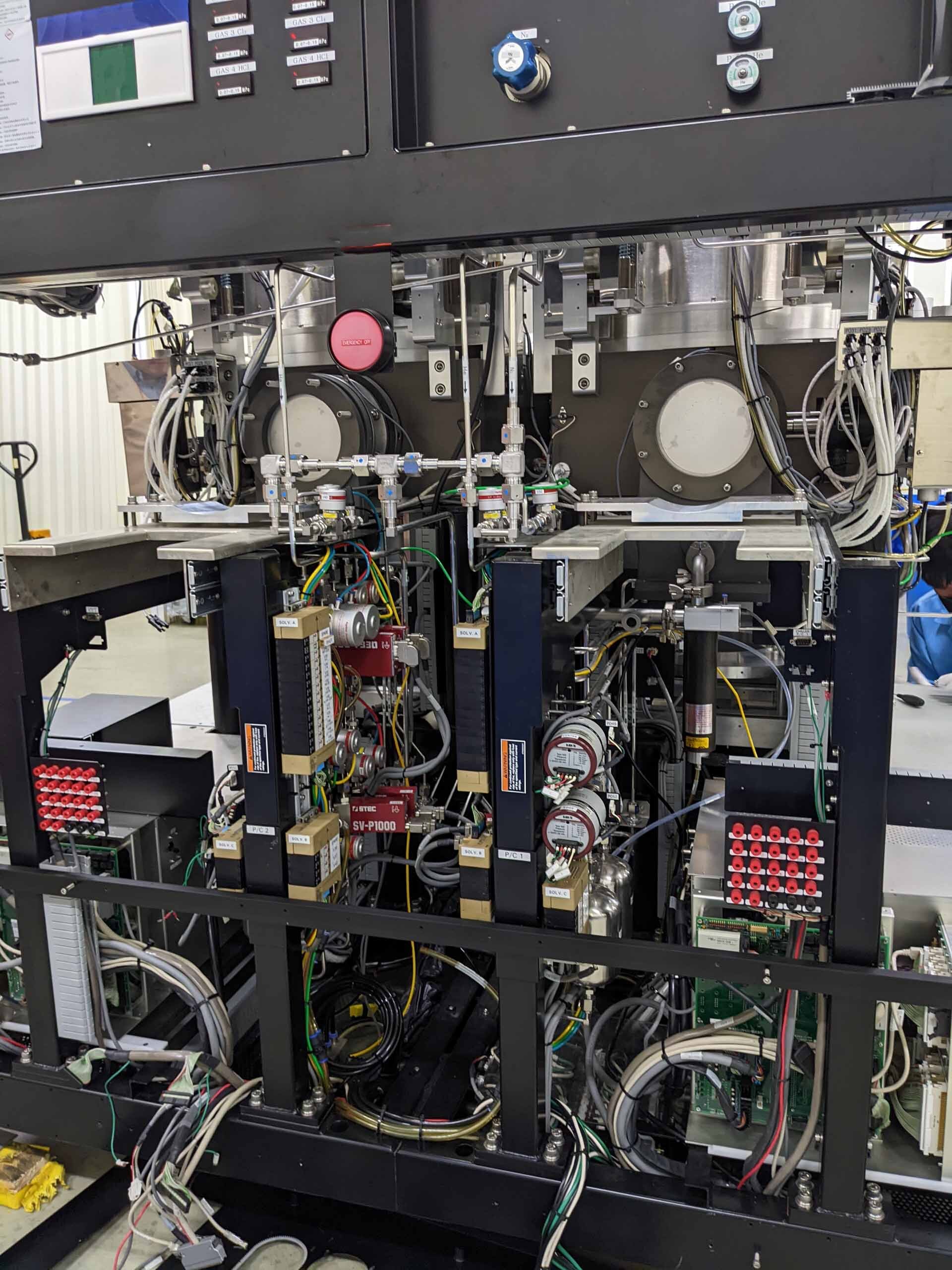

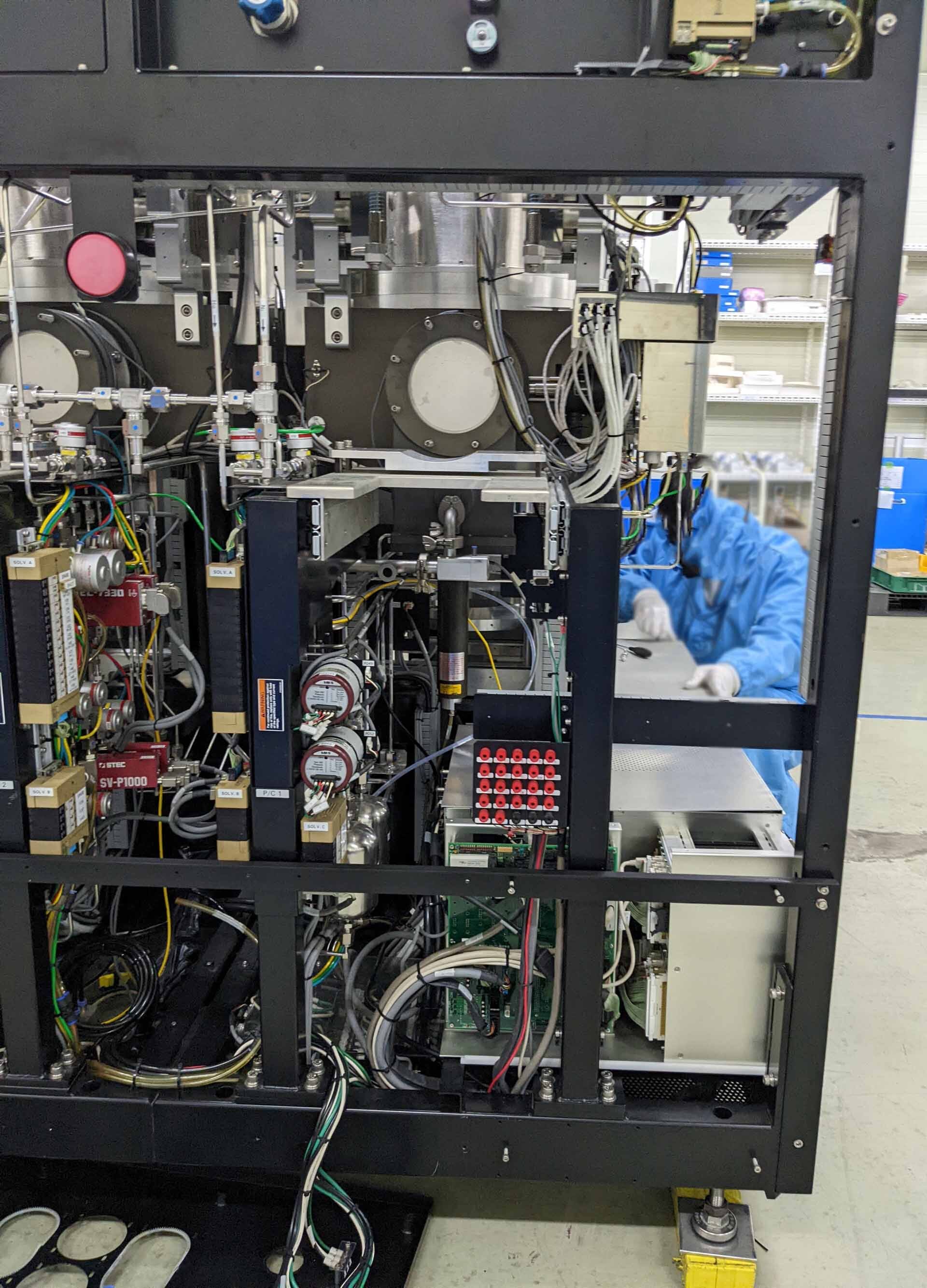

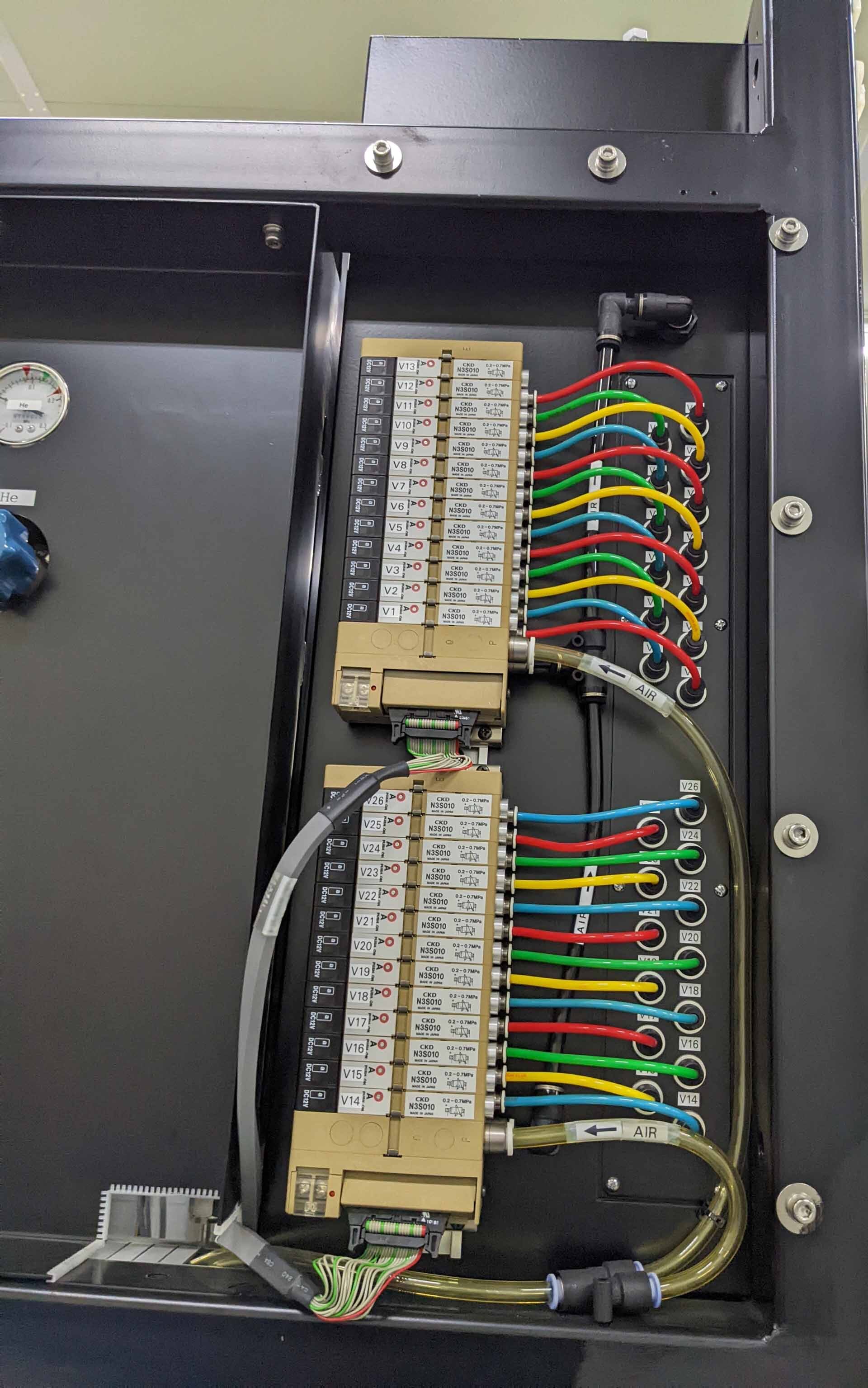

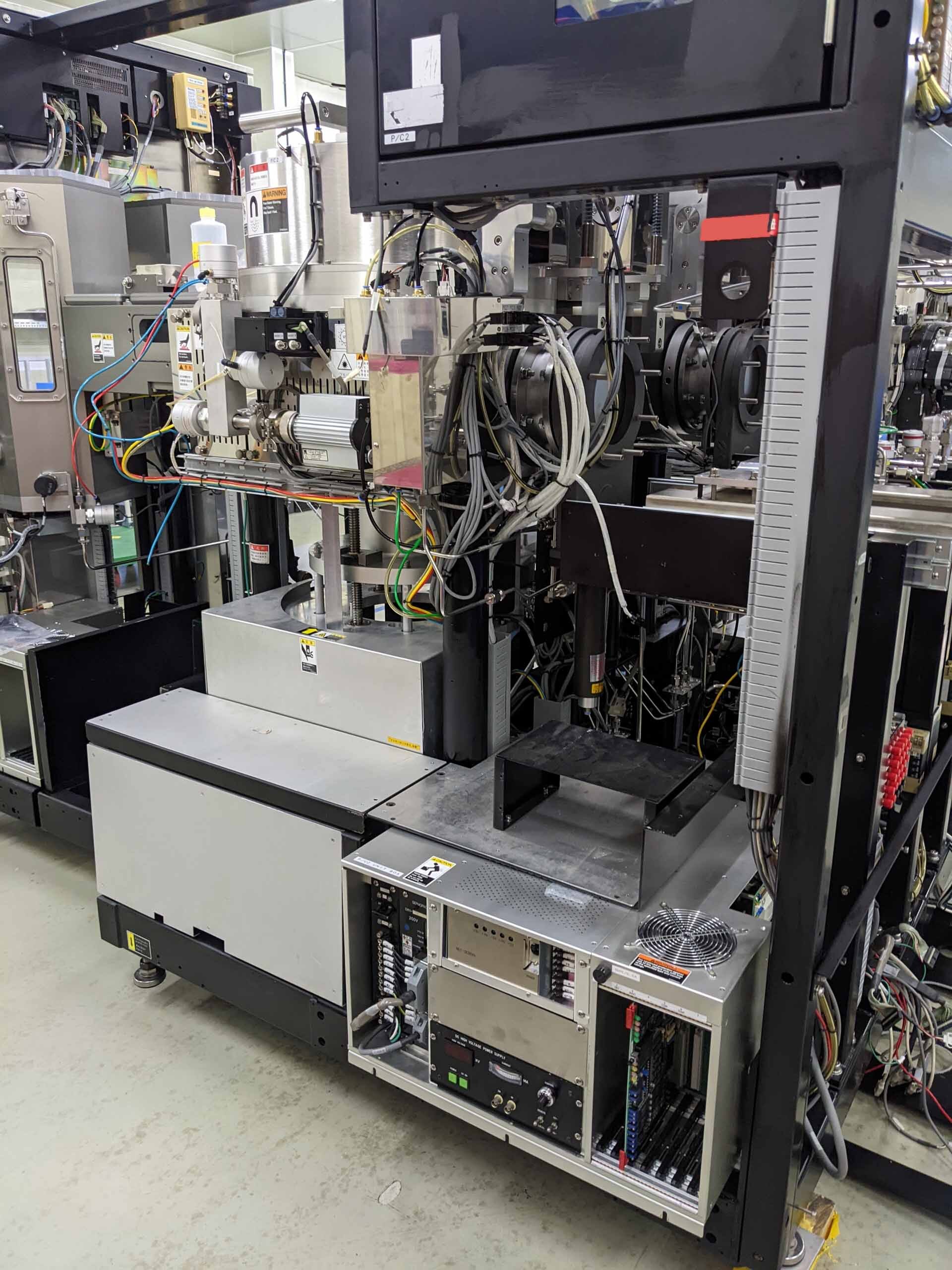

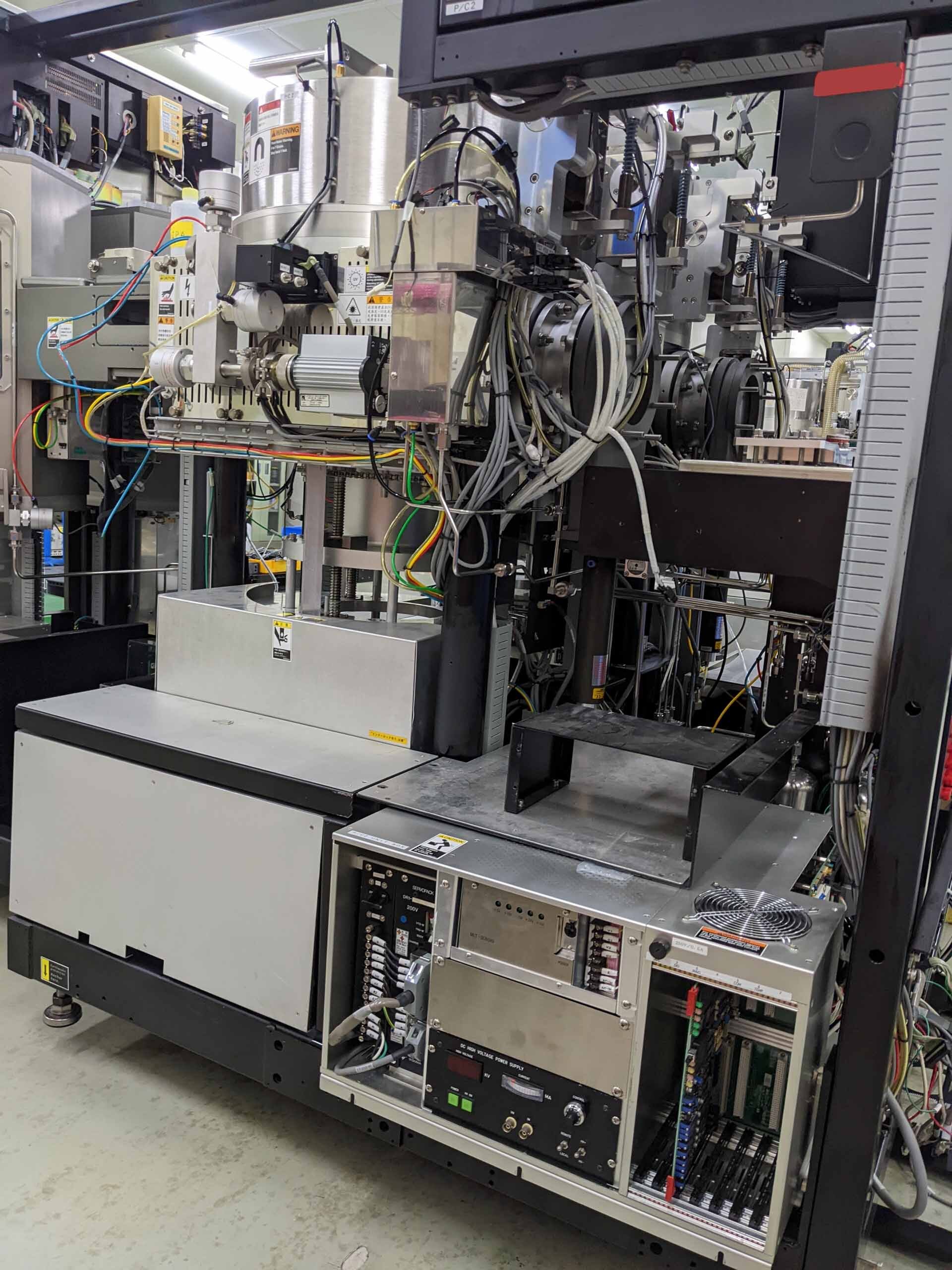

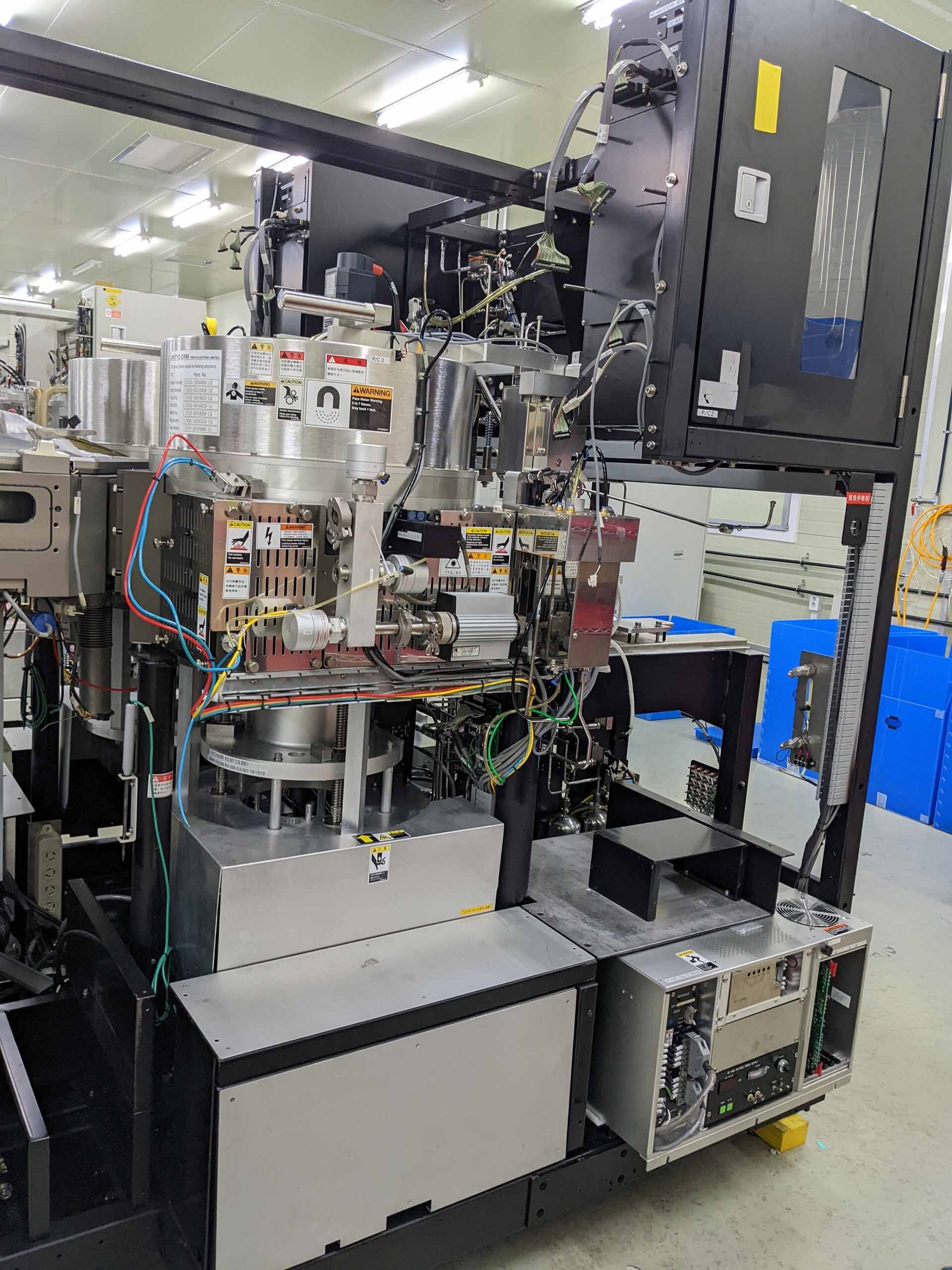

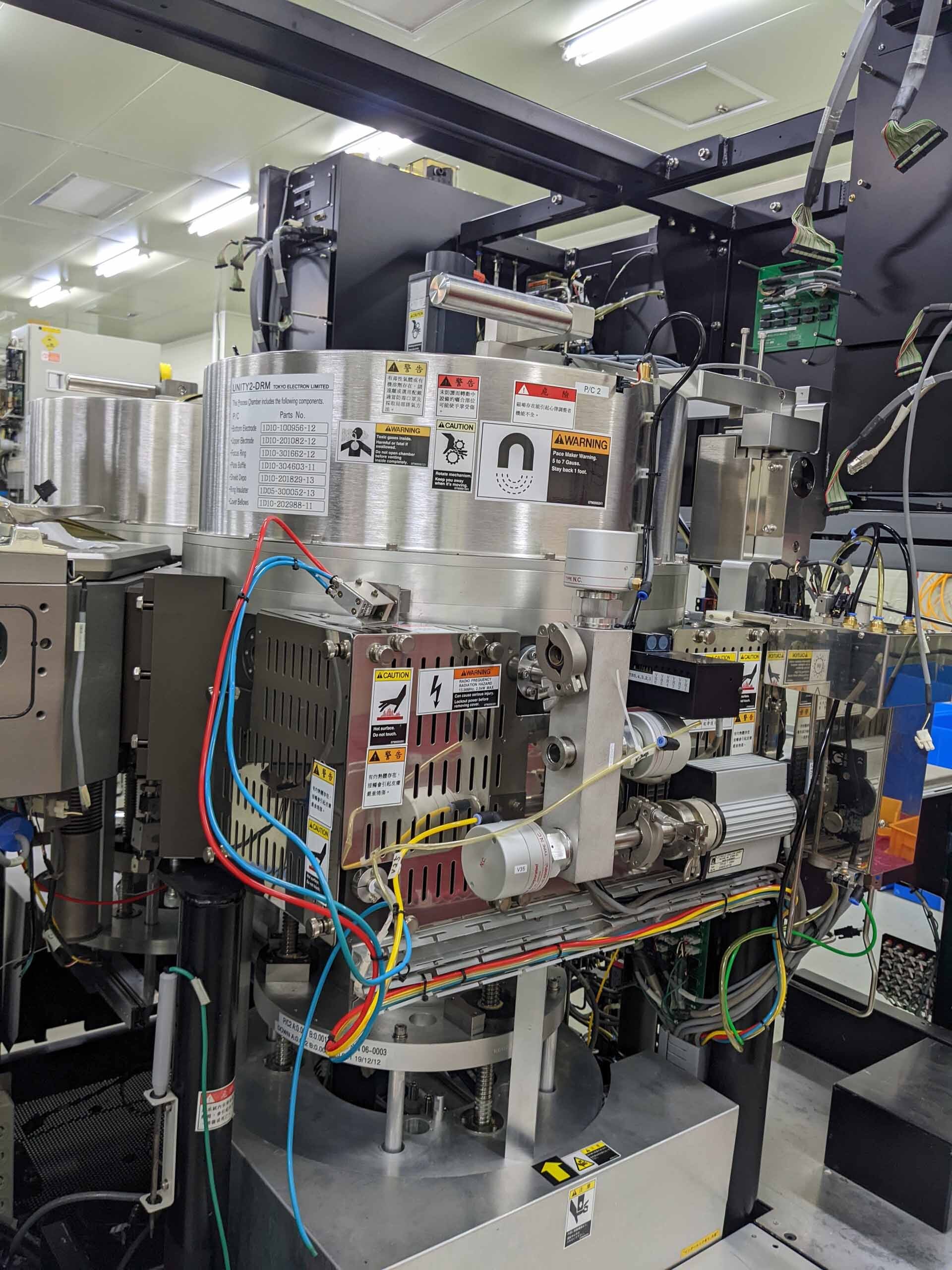

Used TEL / TOKYO ELECTRON Unity IIe 855DD #293646424 for sale

URL successfully copied!

Tap to zoom

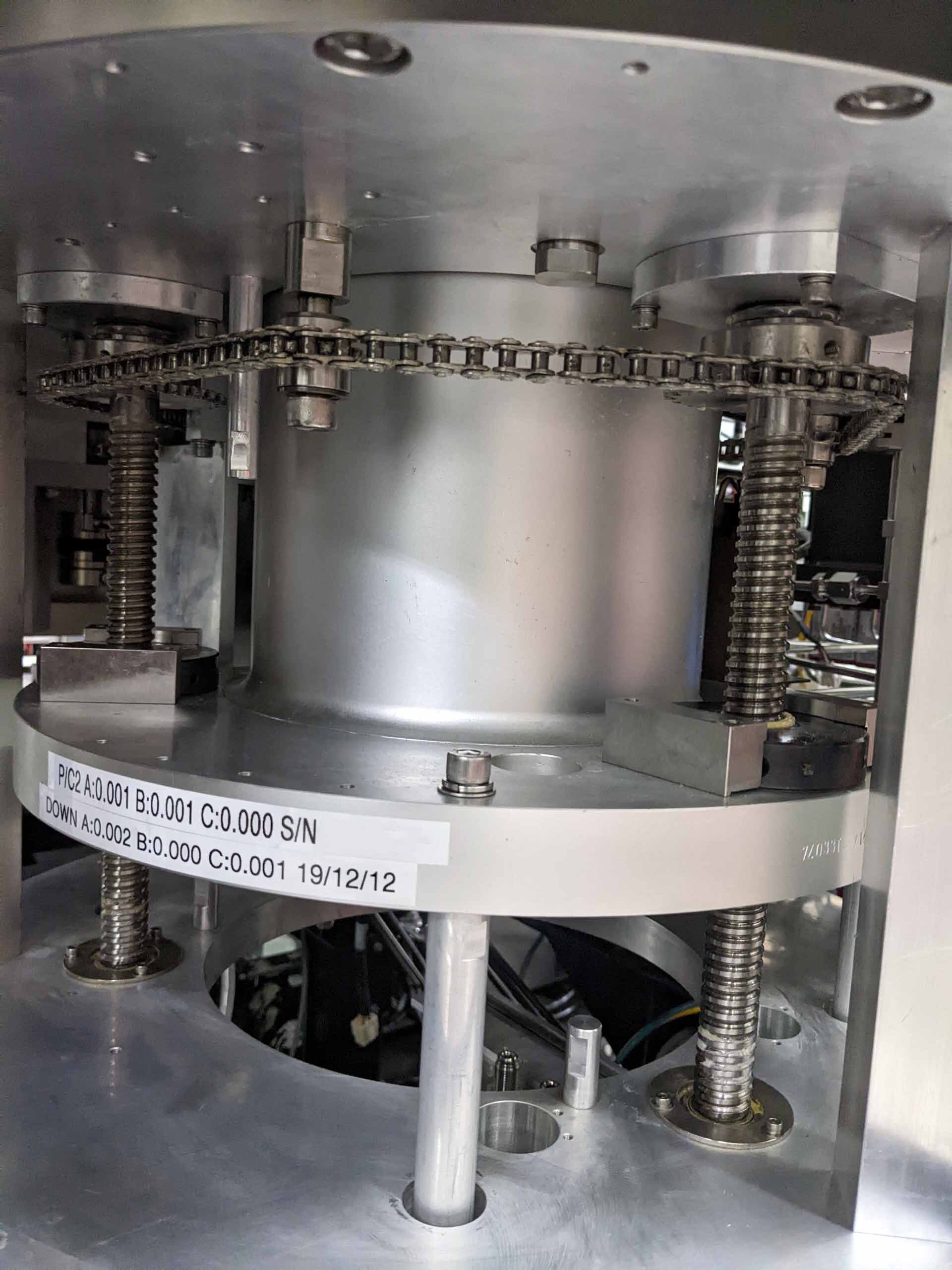

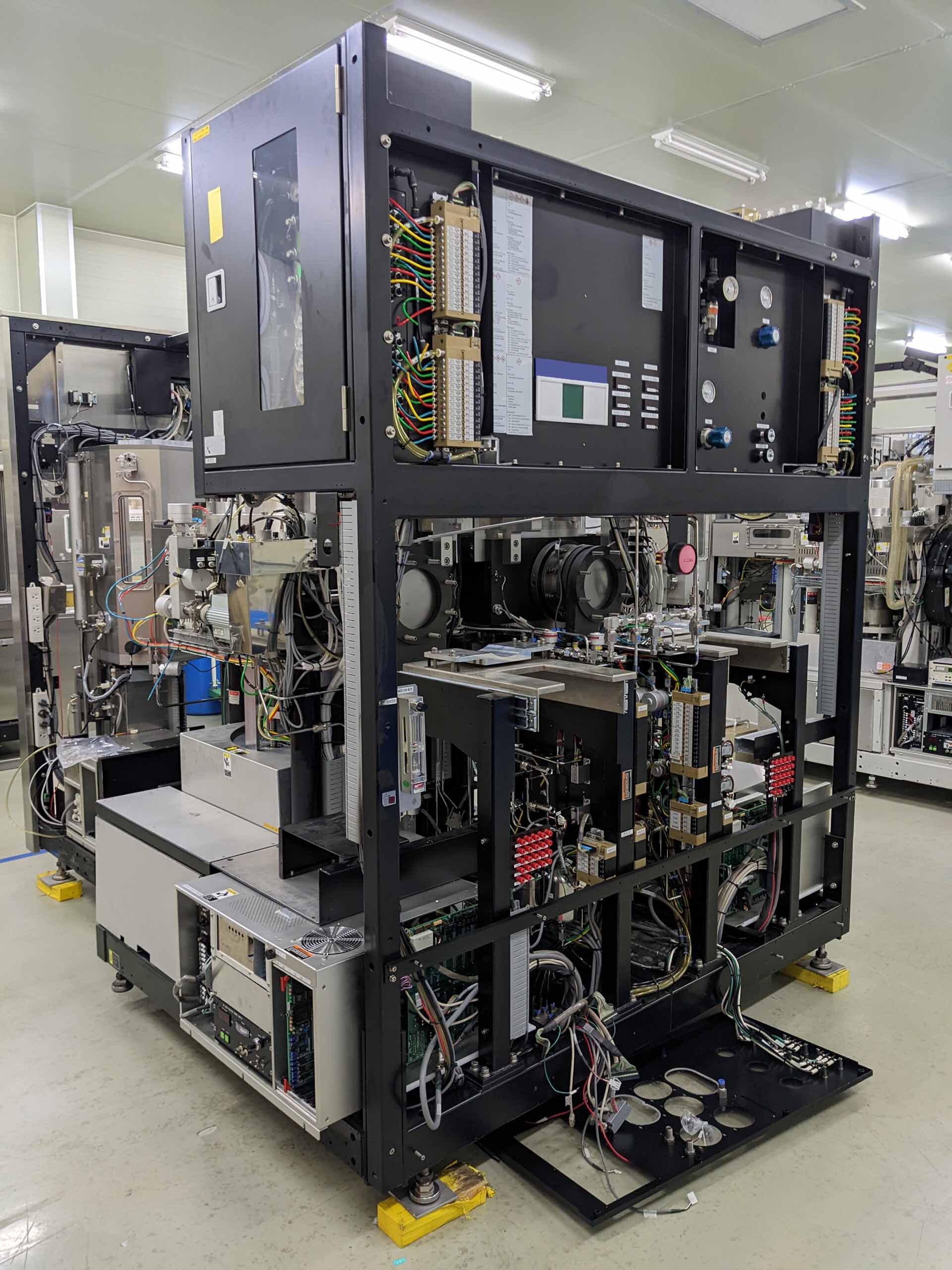

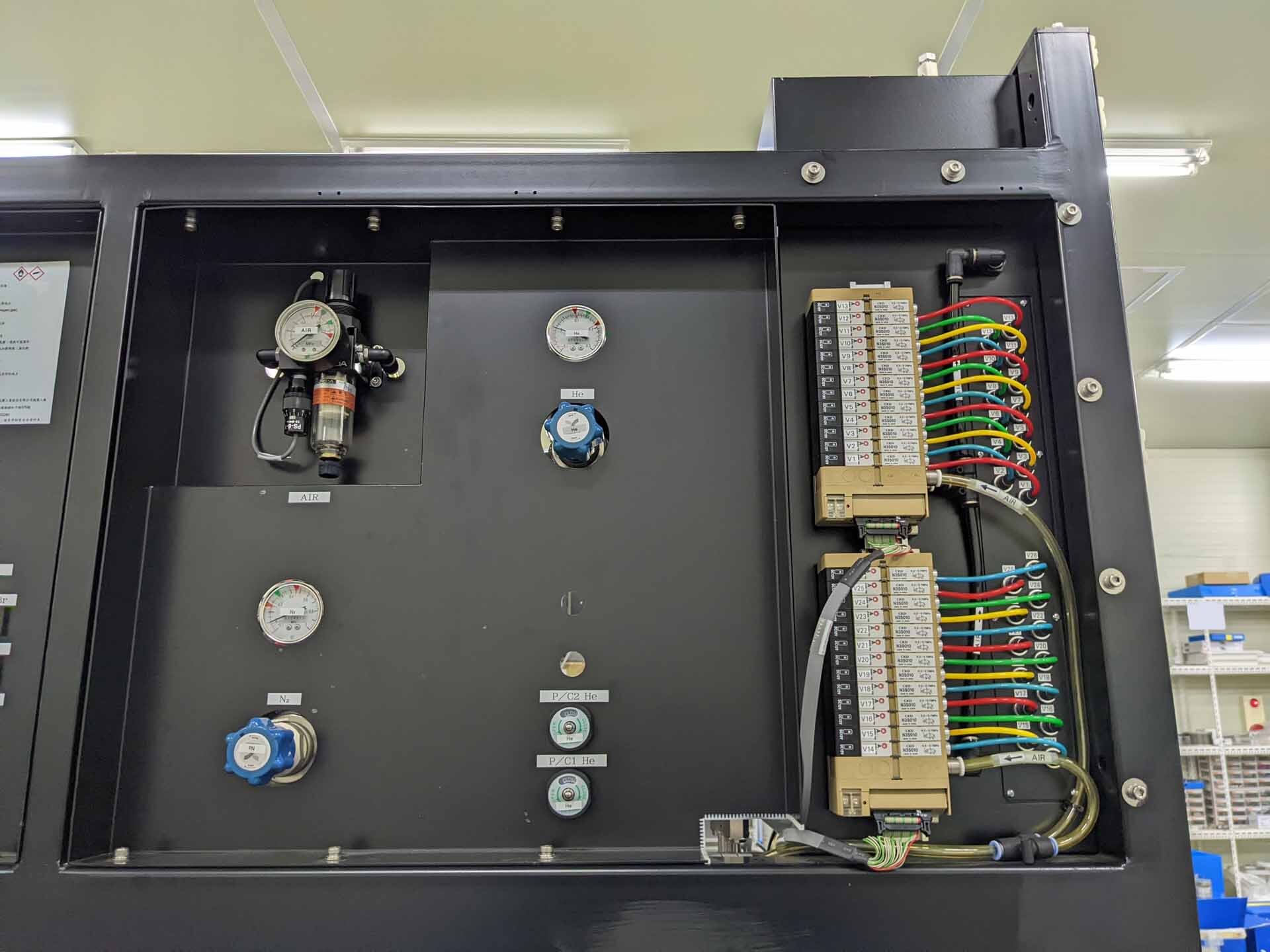

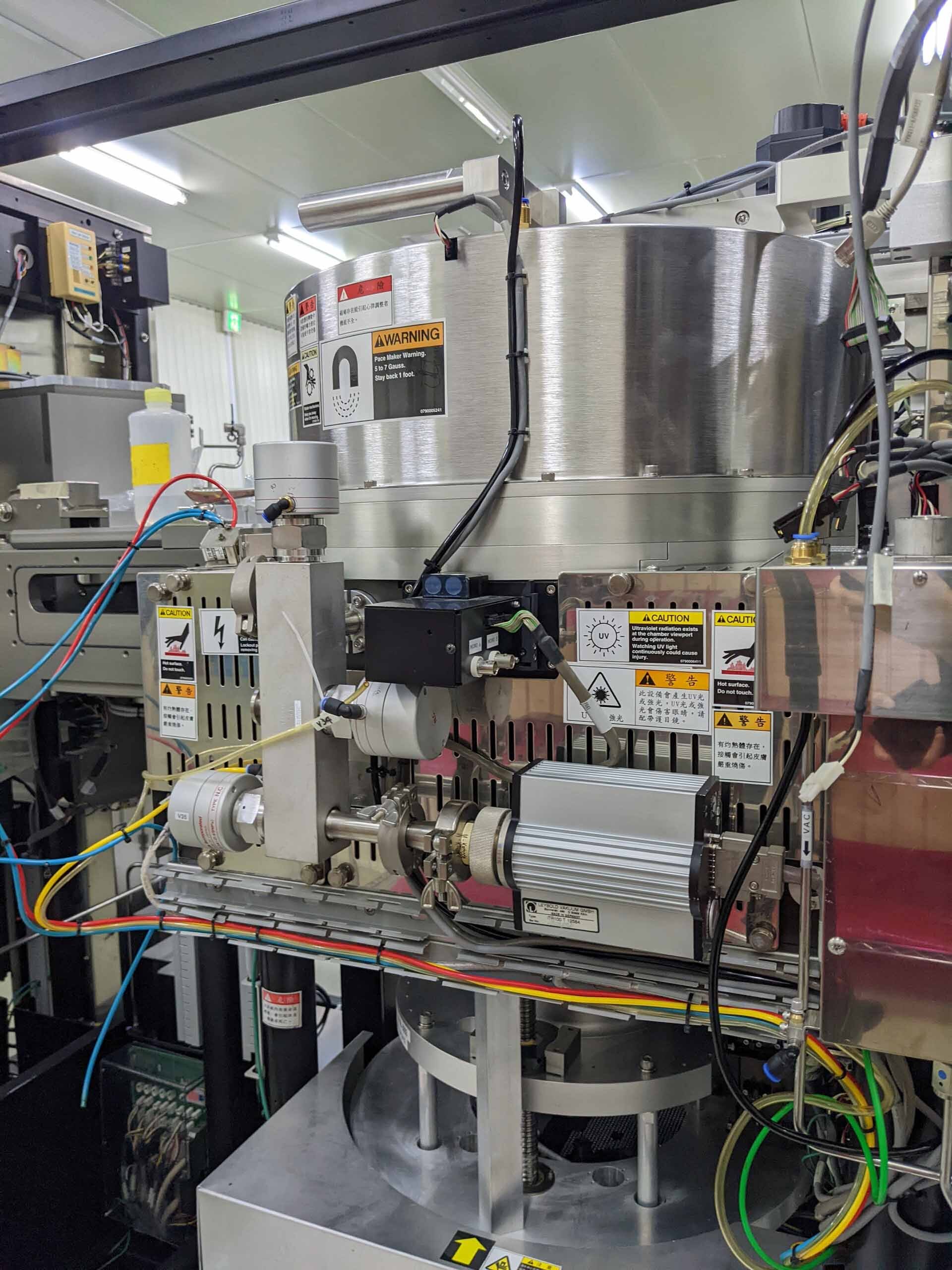

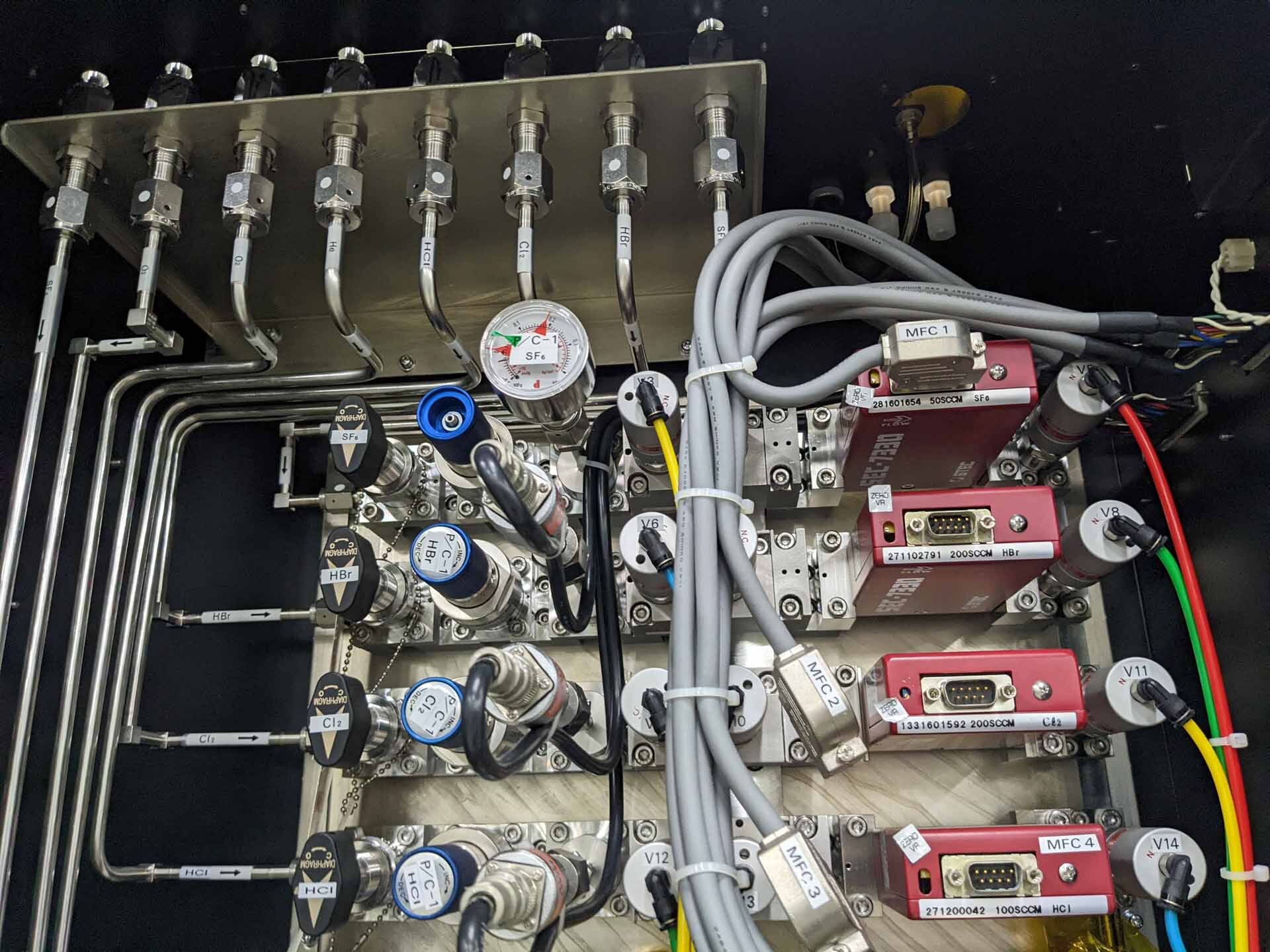

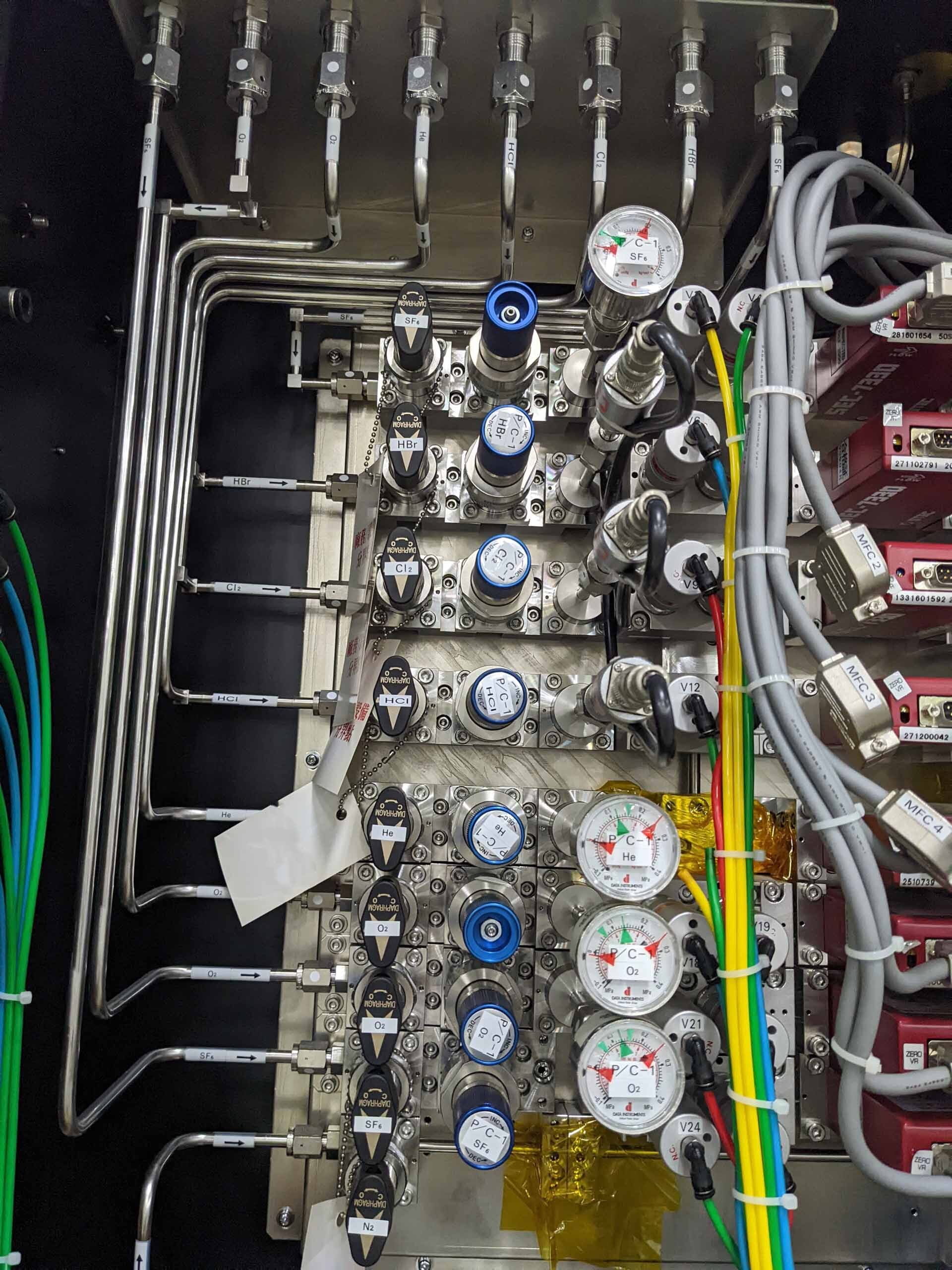

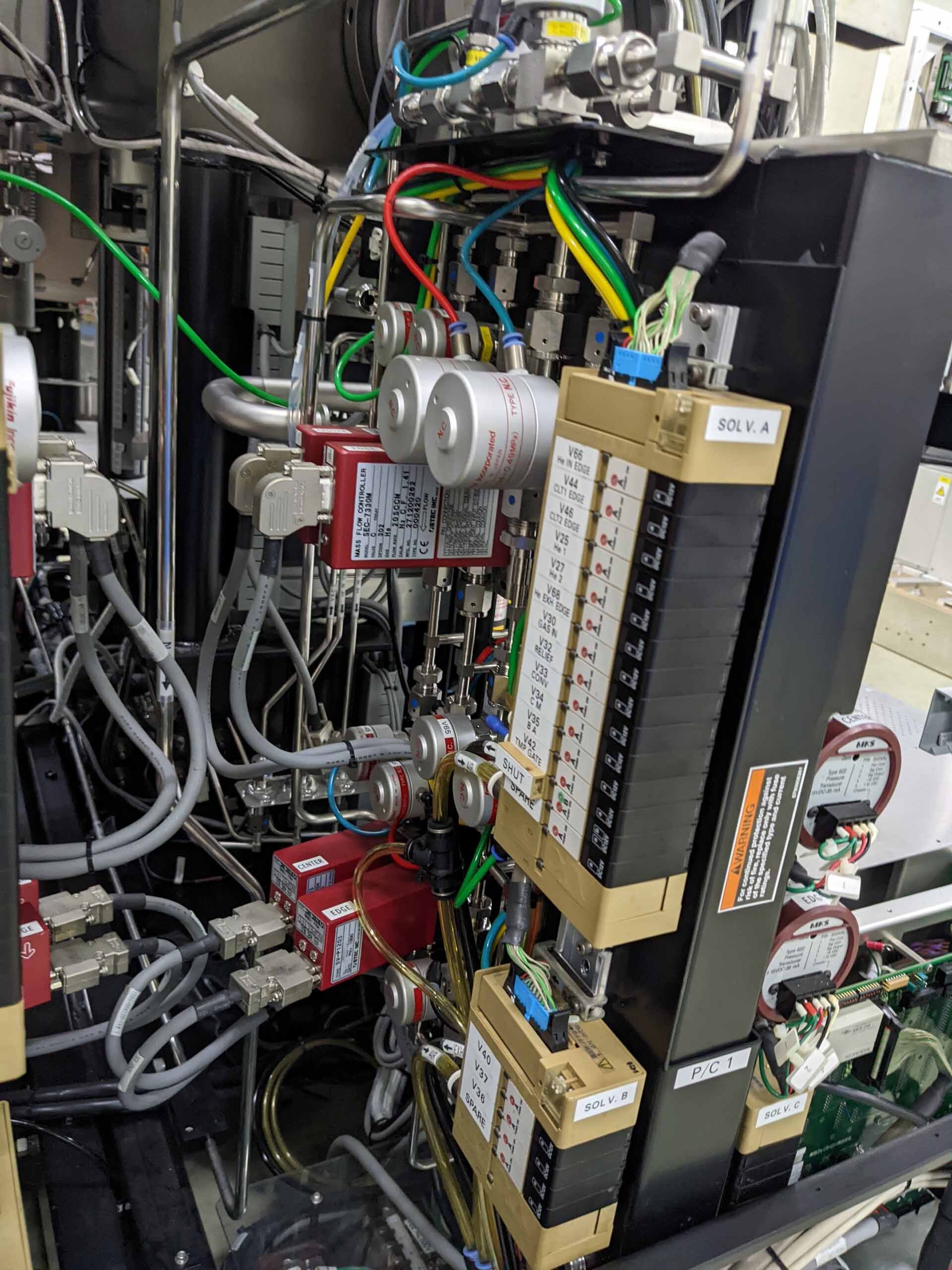

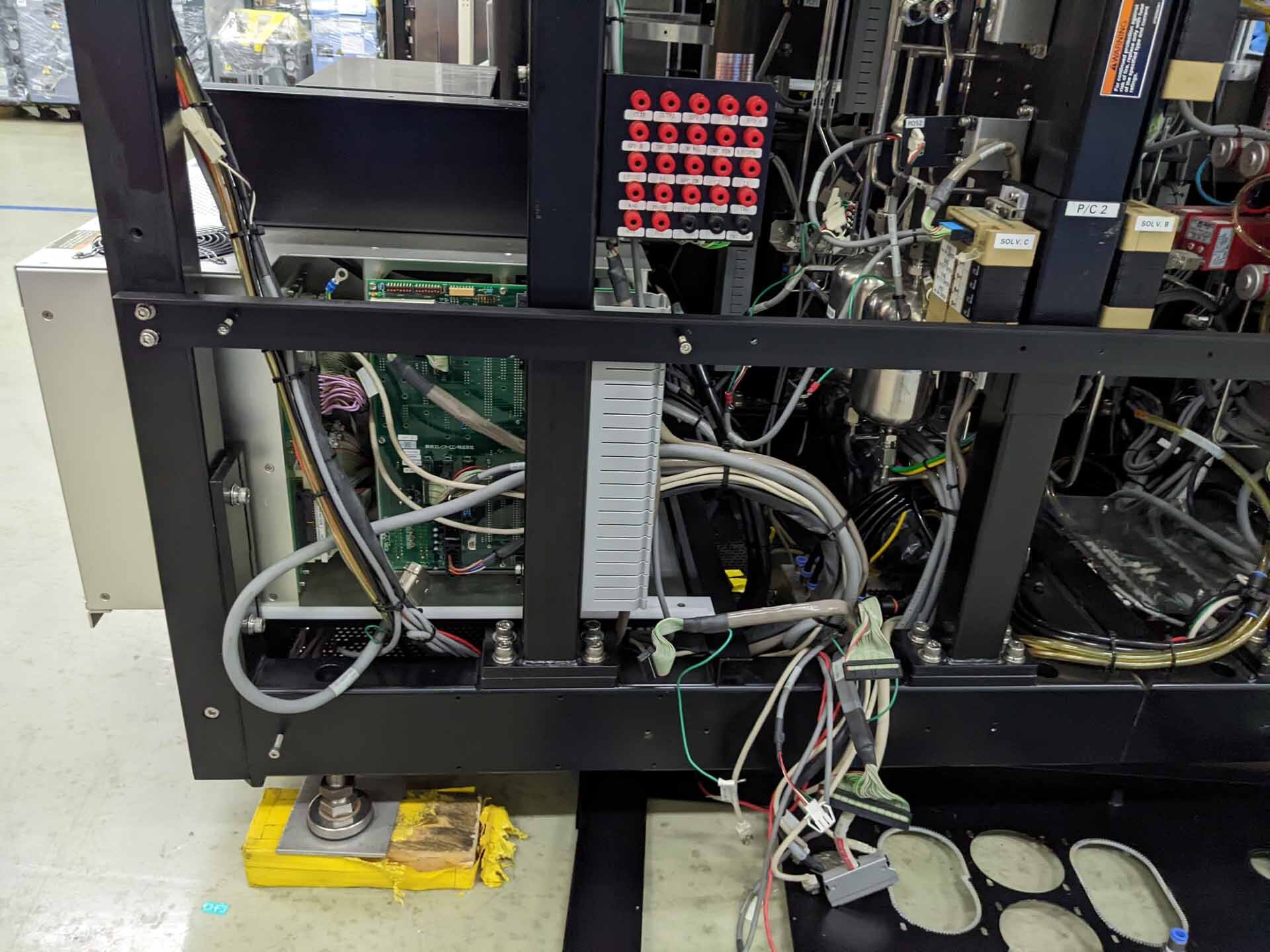

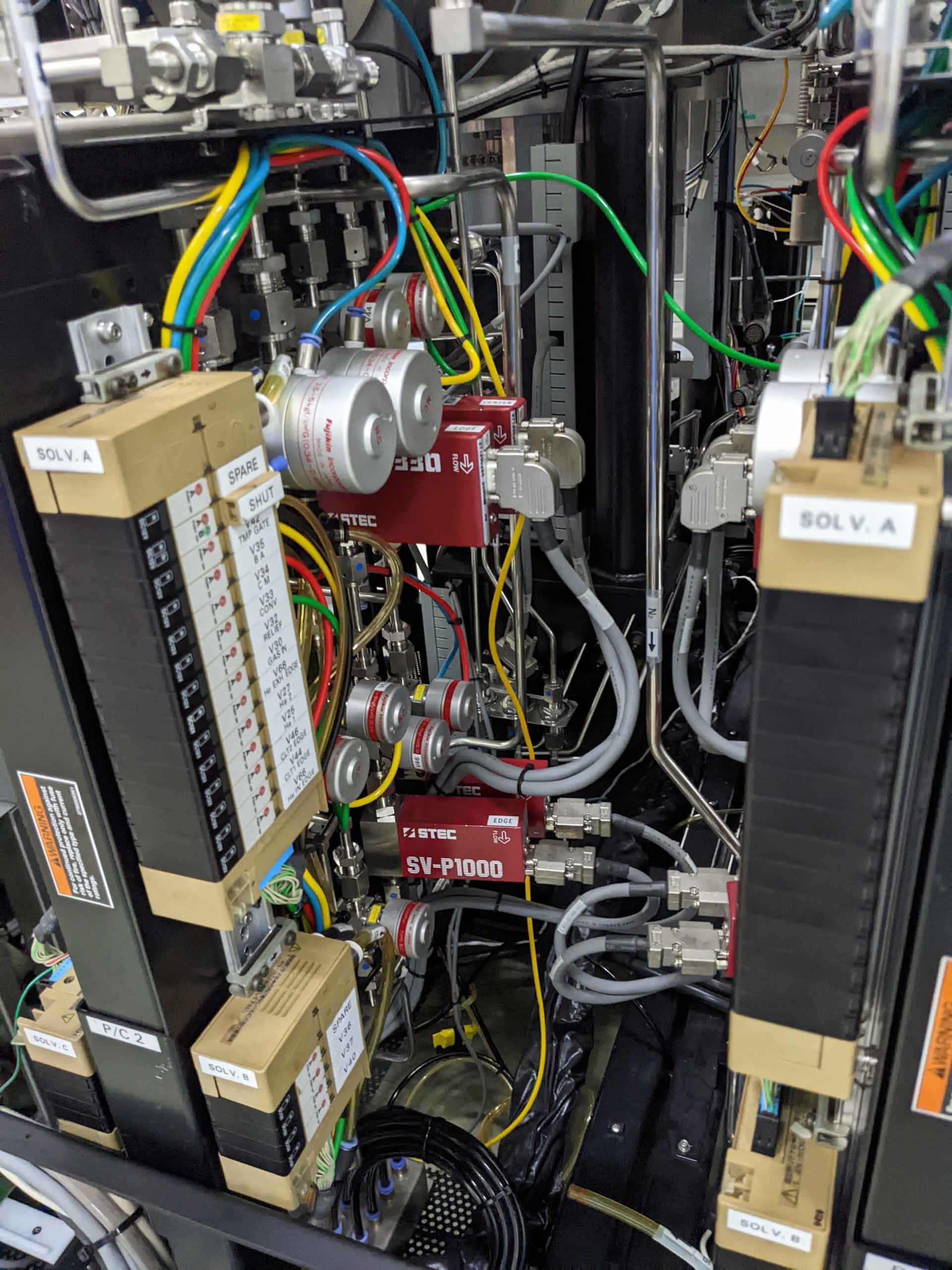

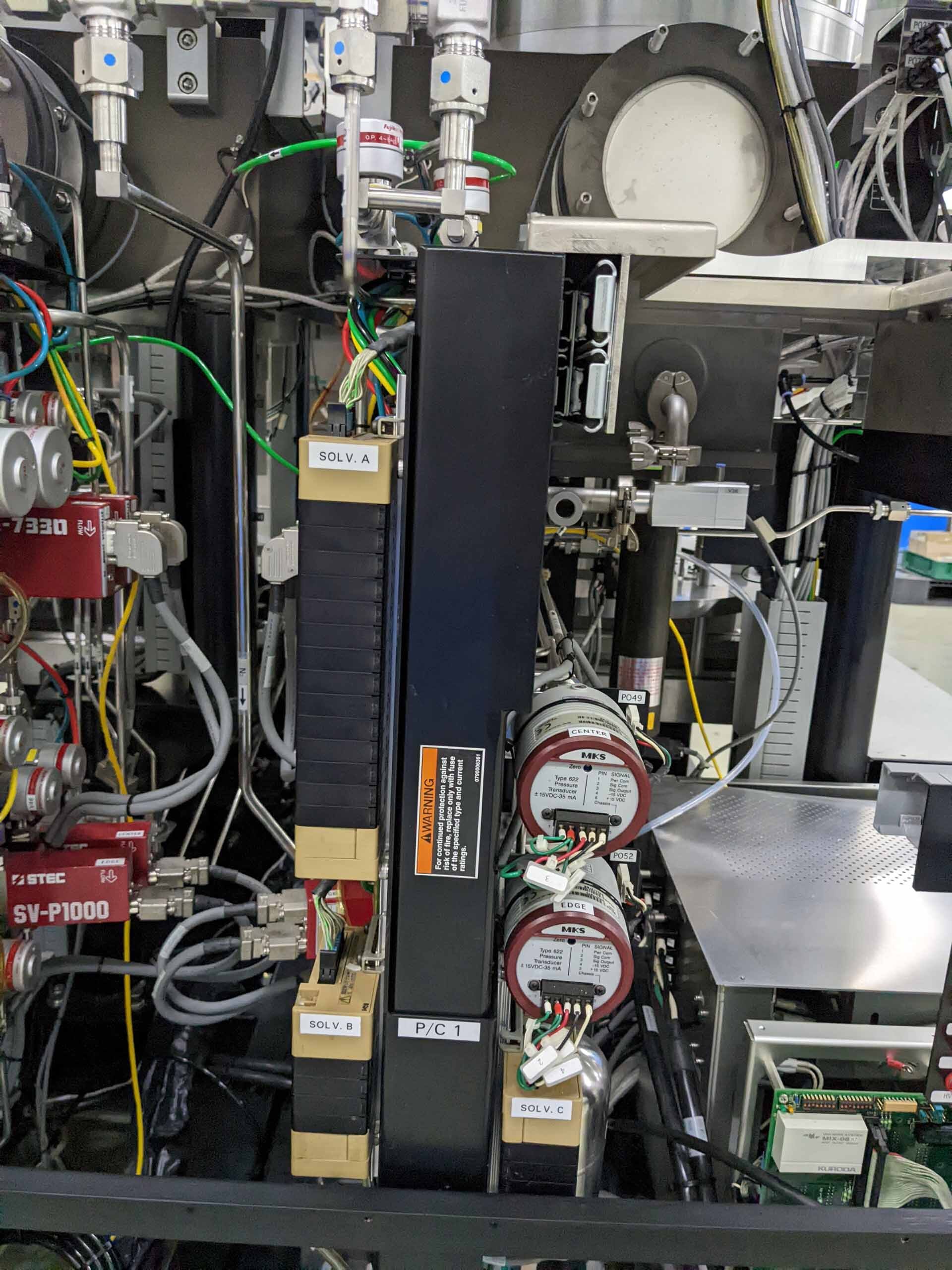

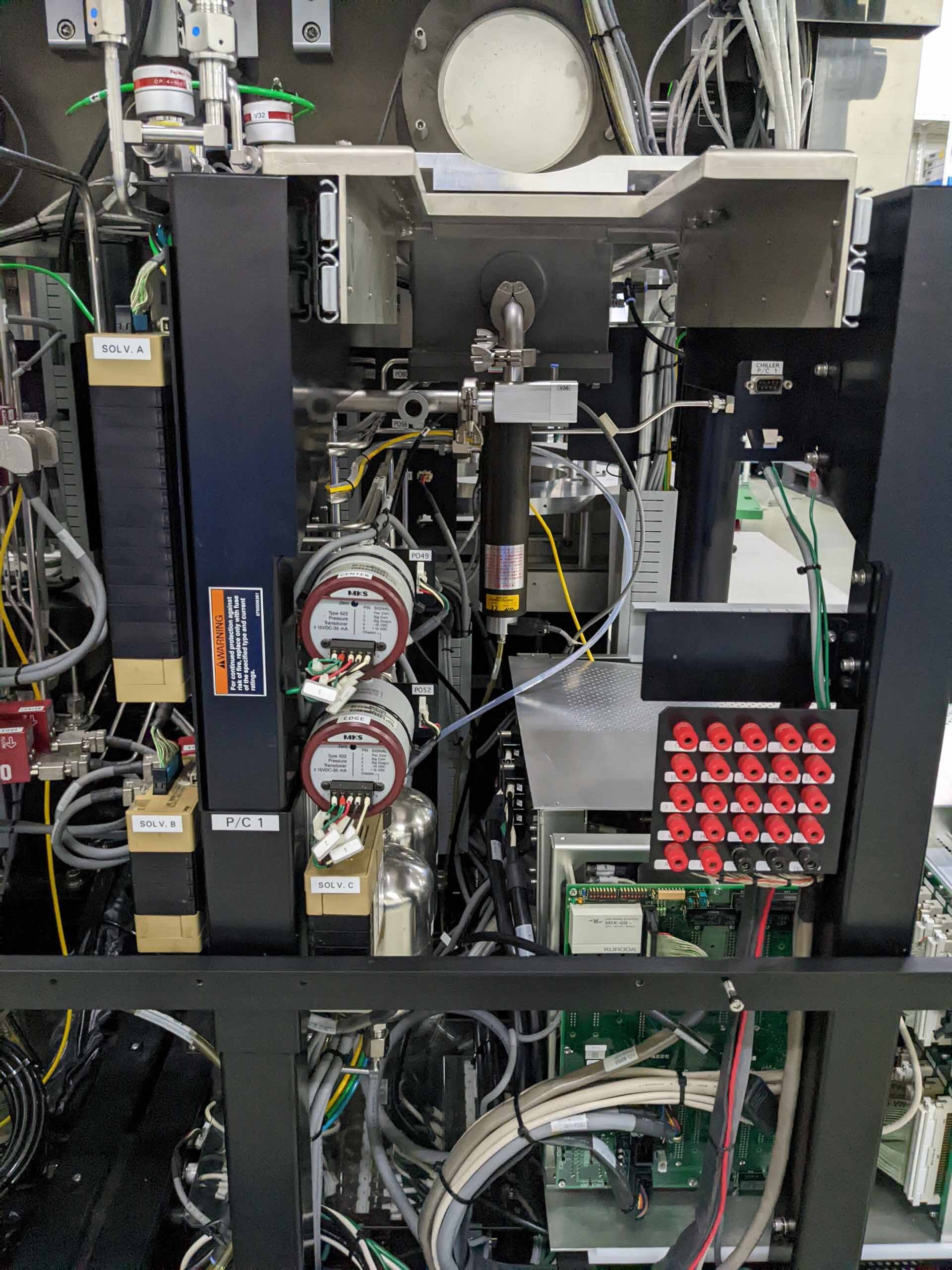

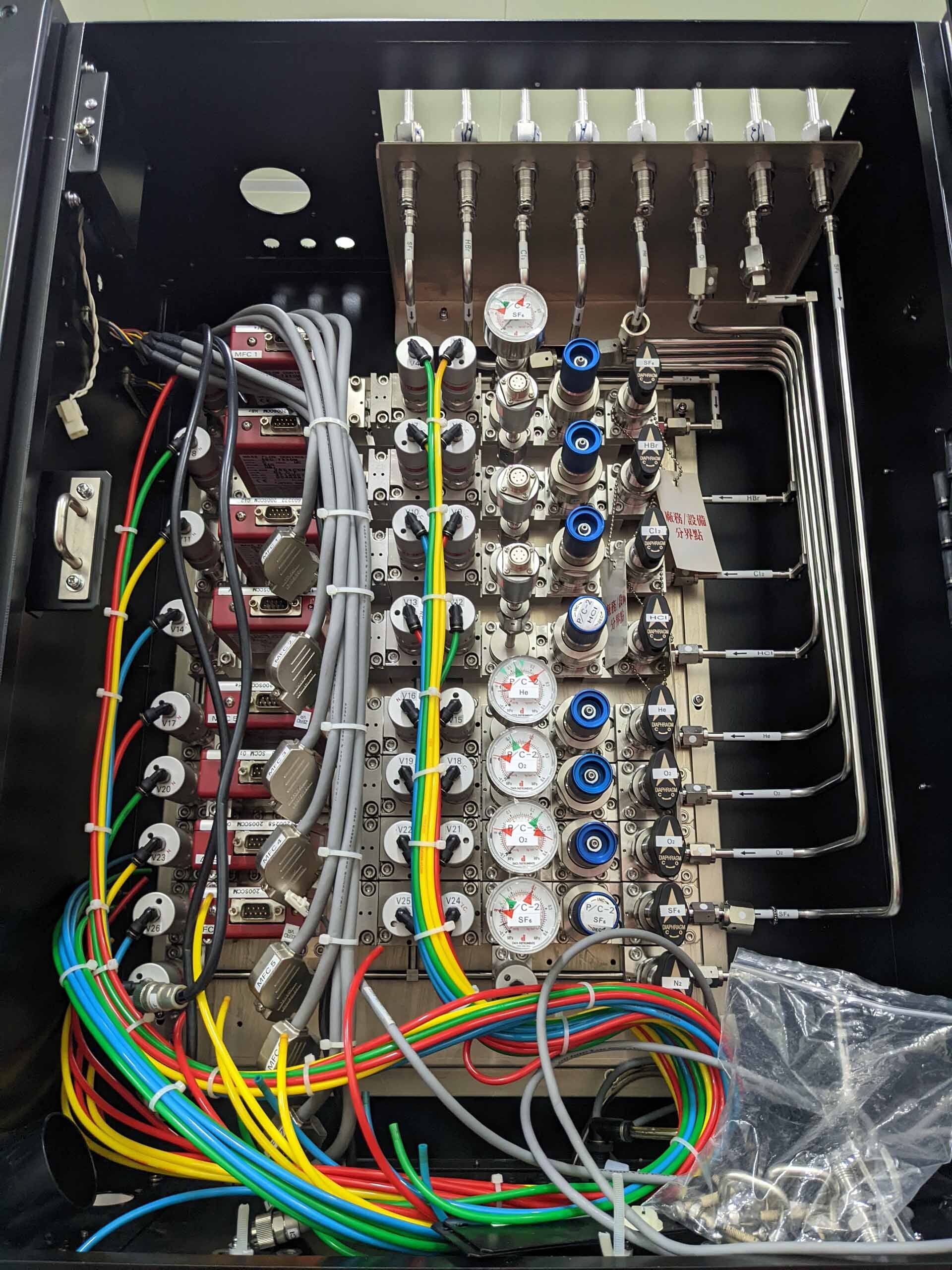

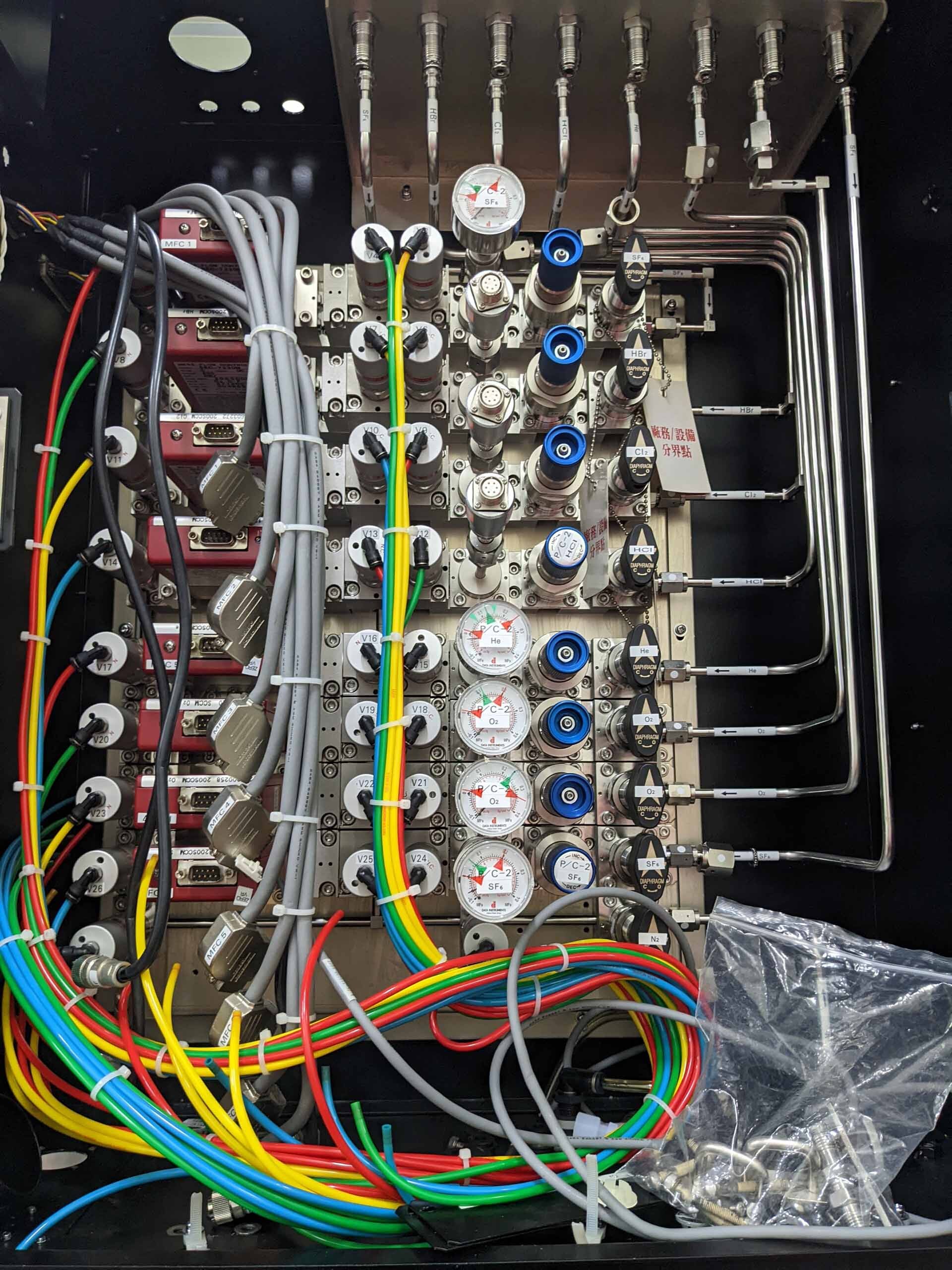

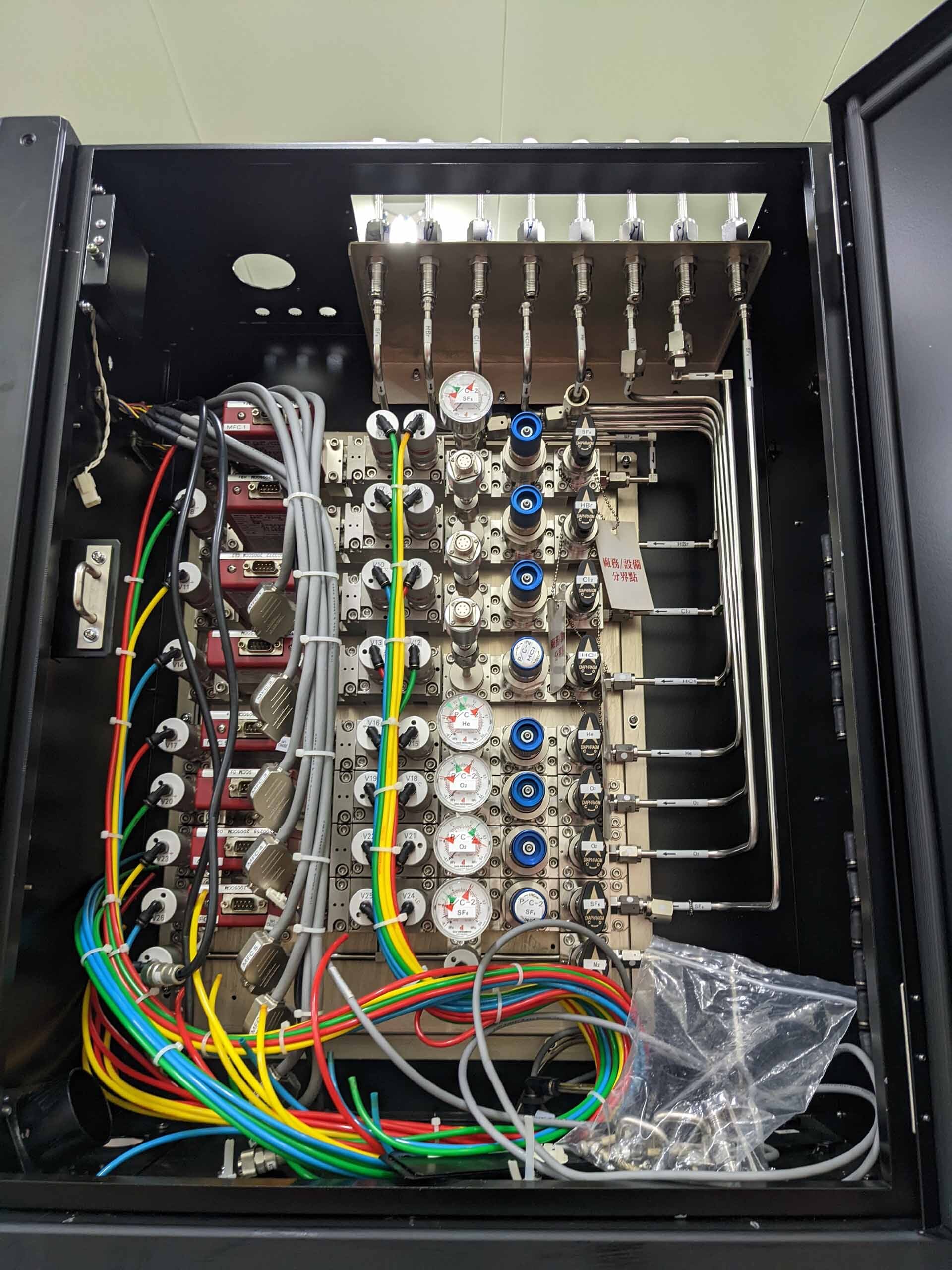

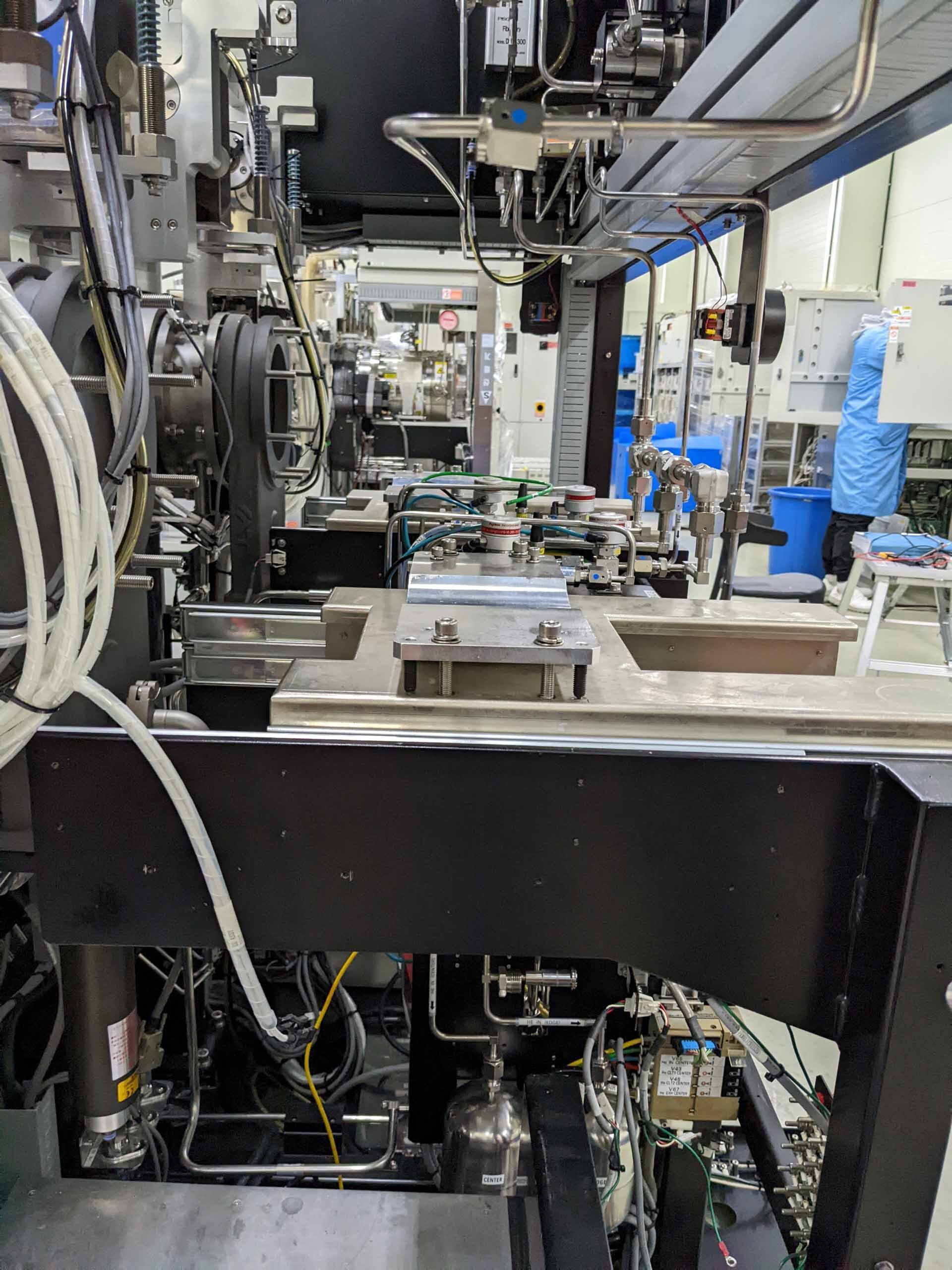

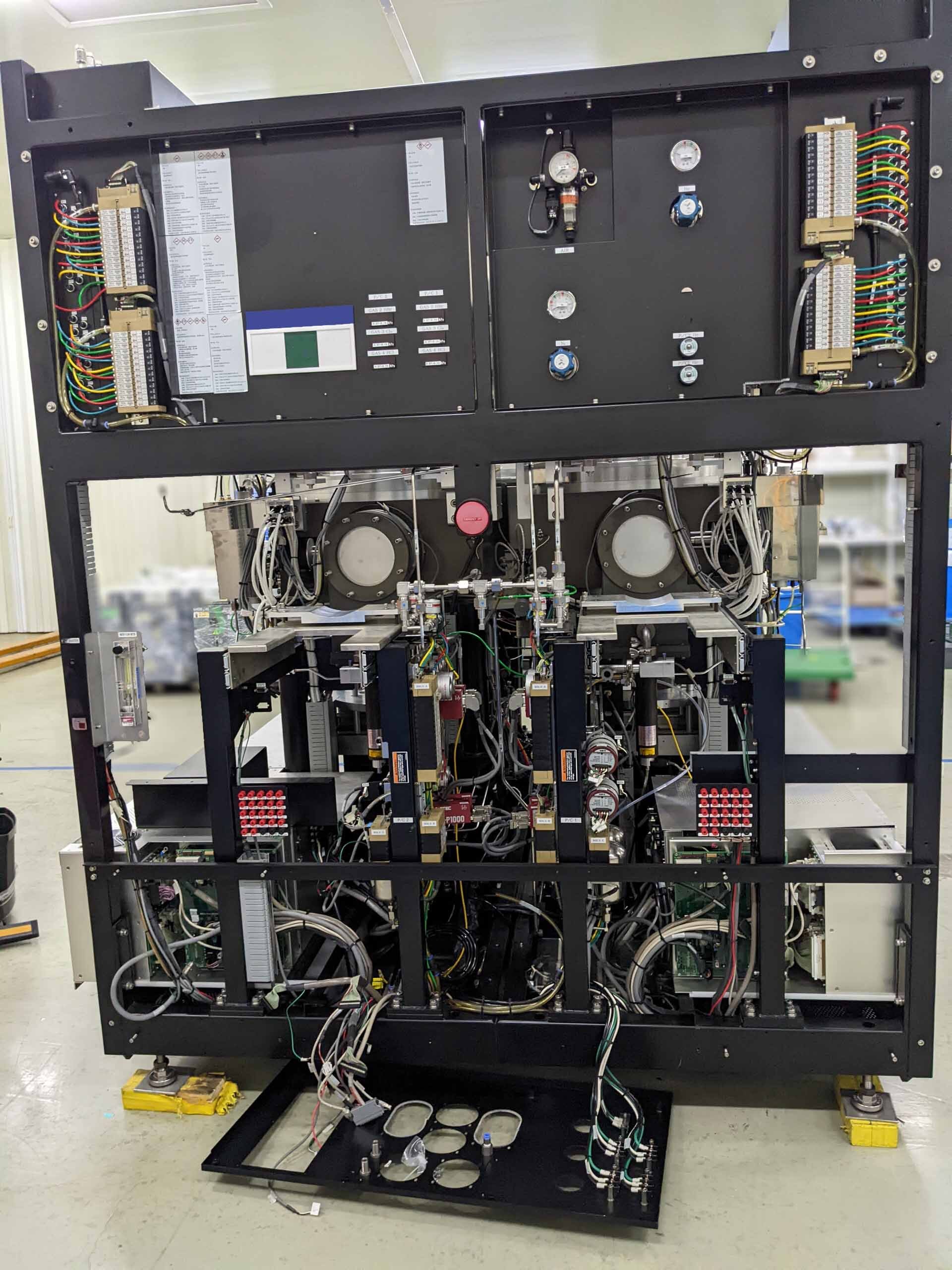

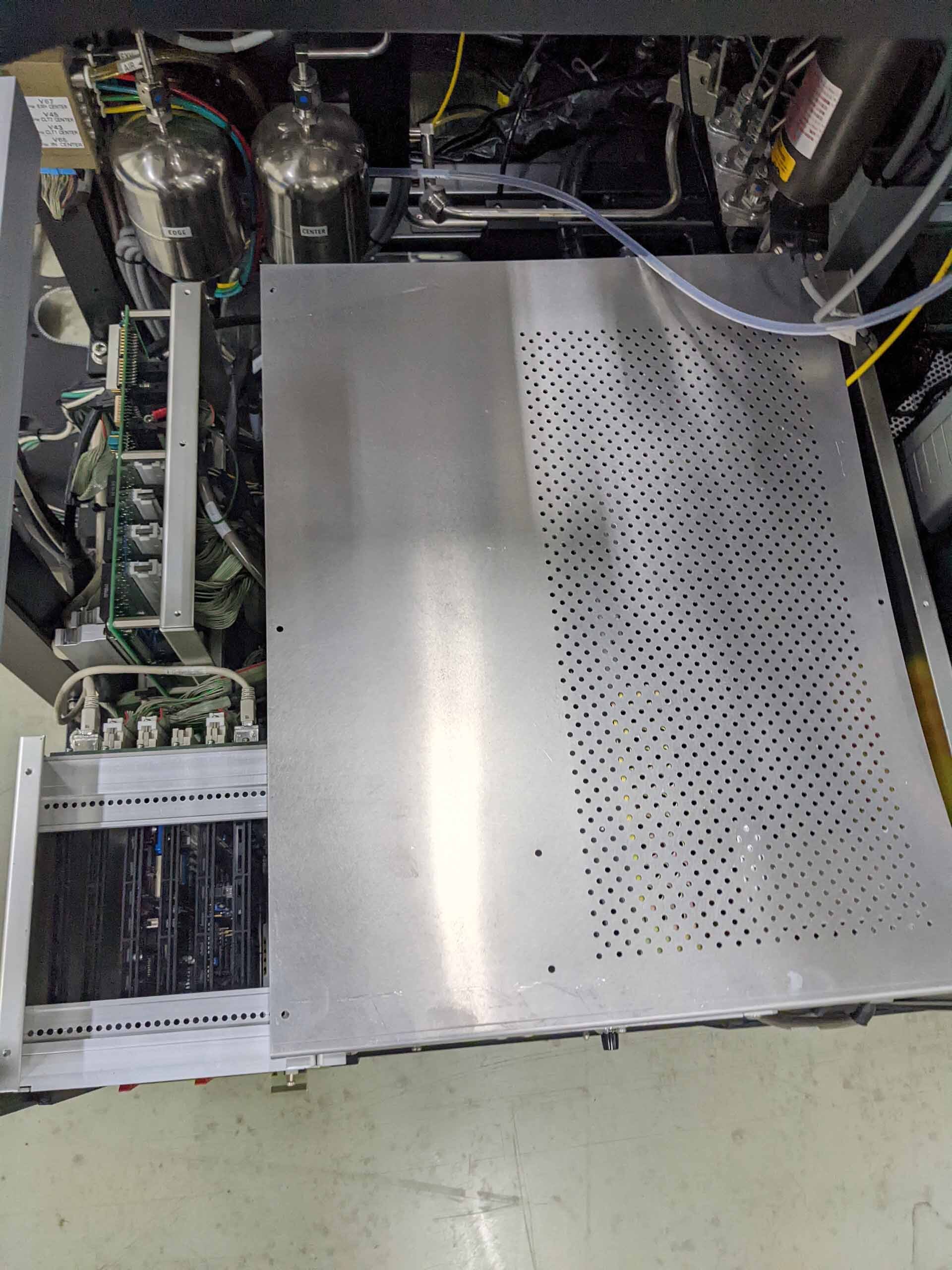

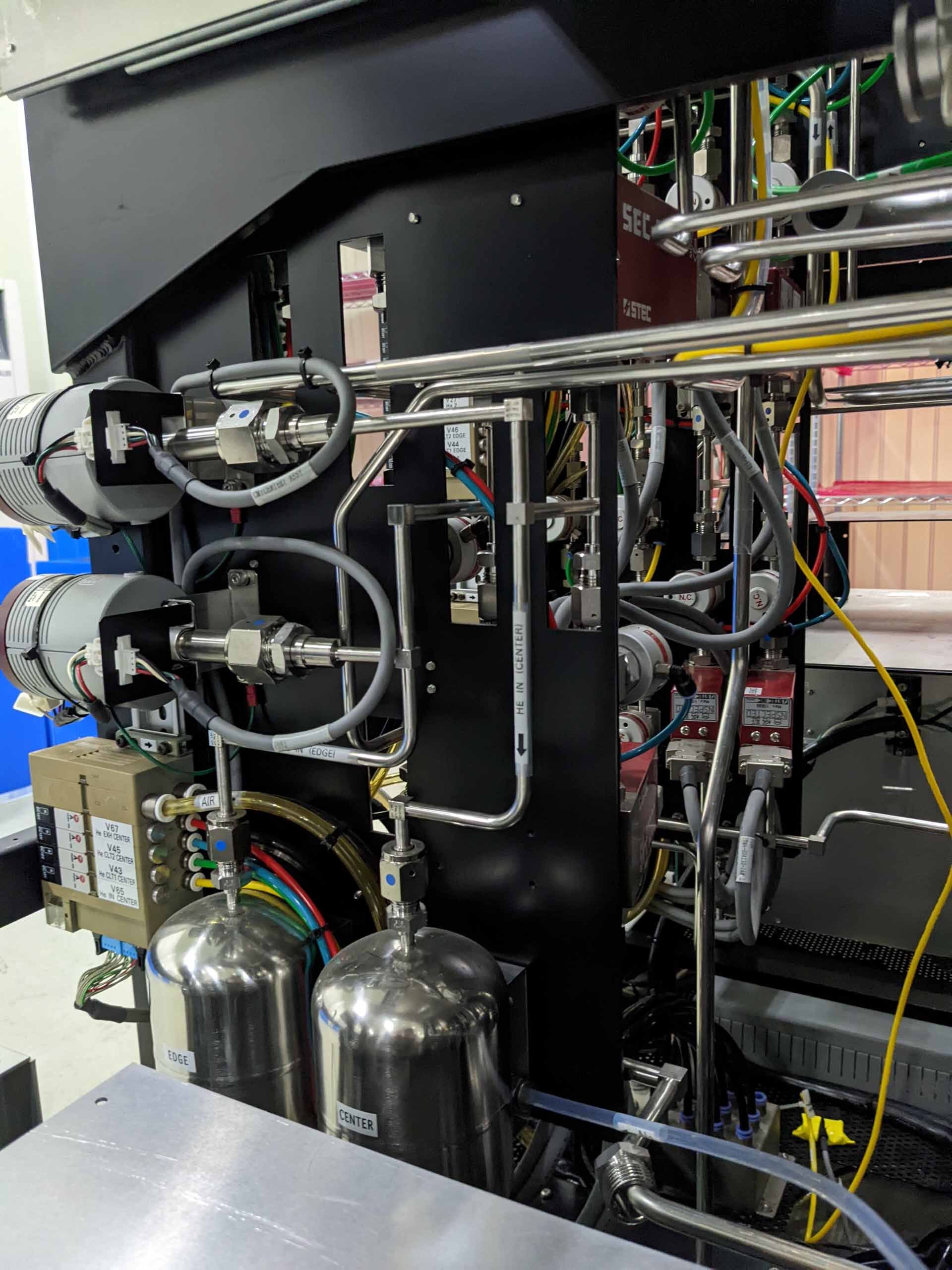

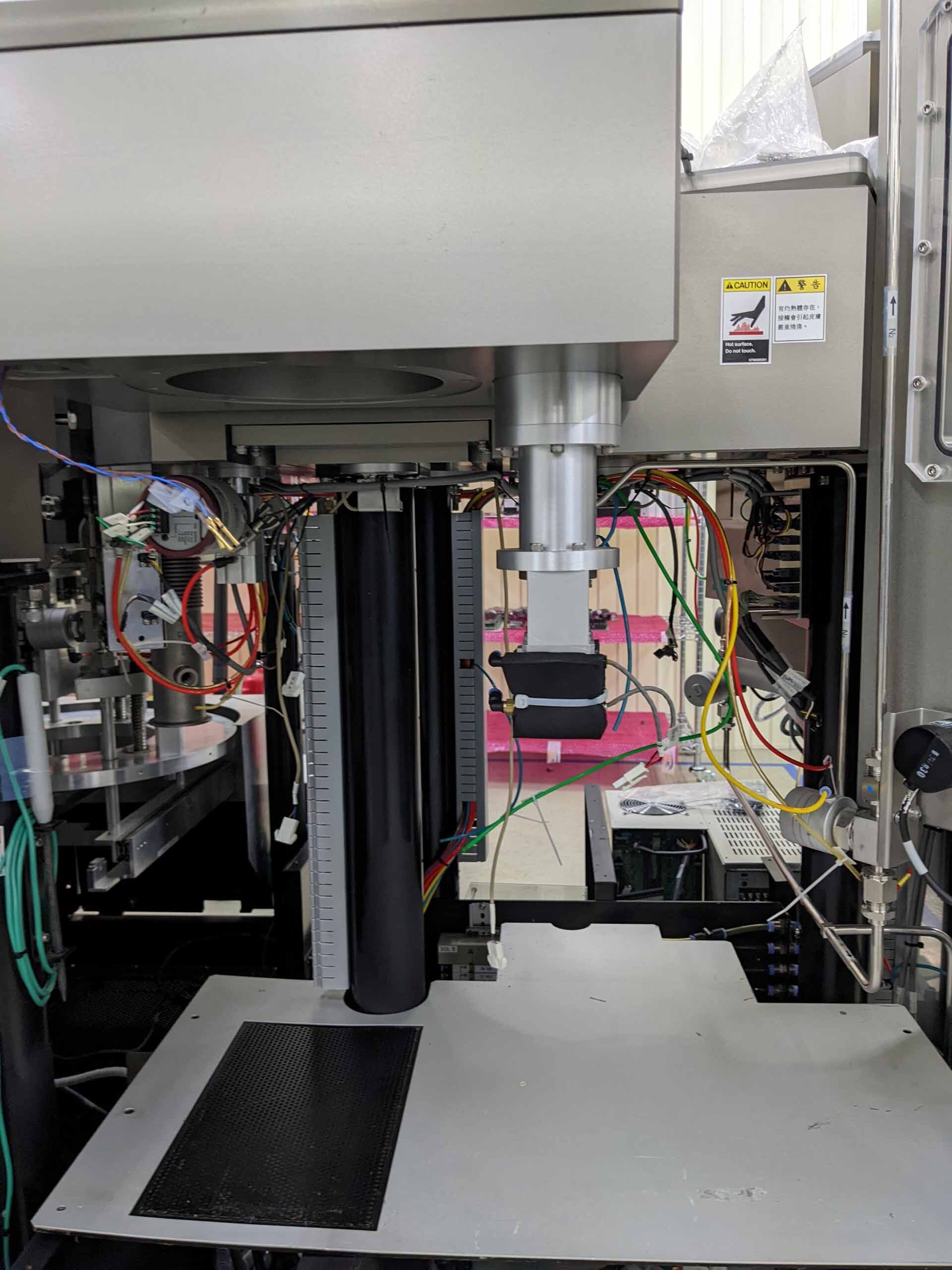

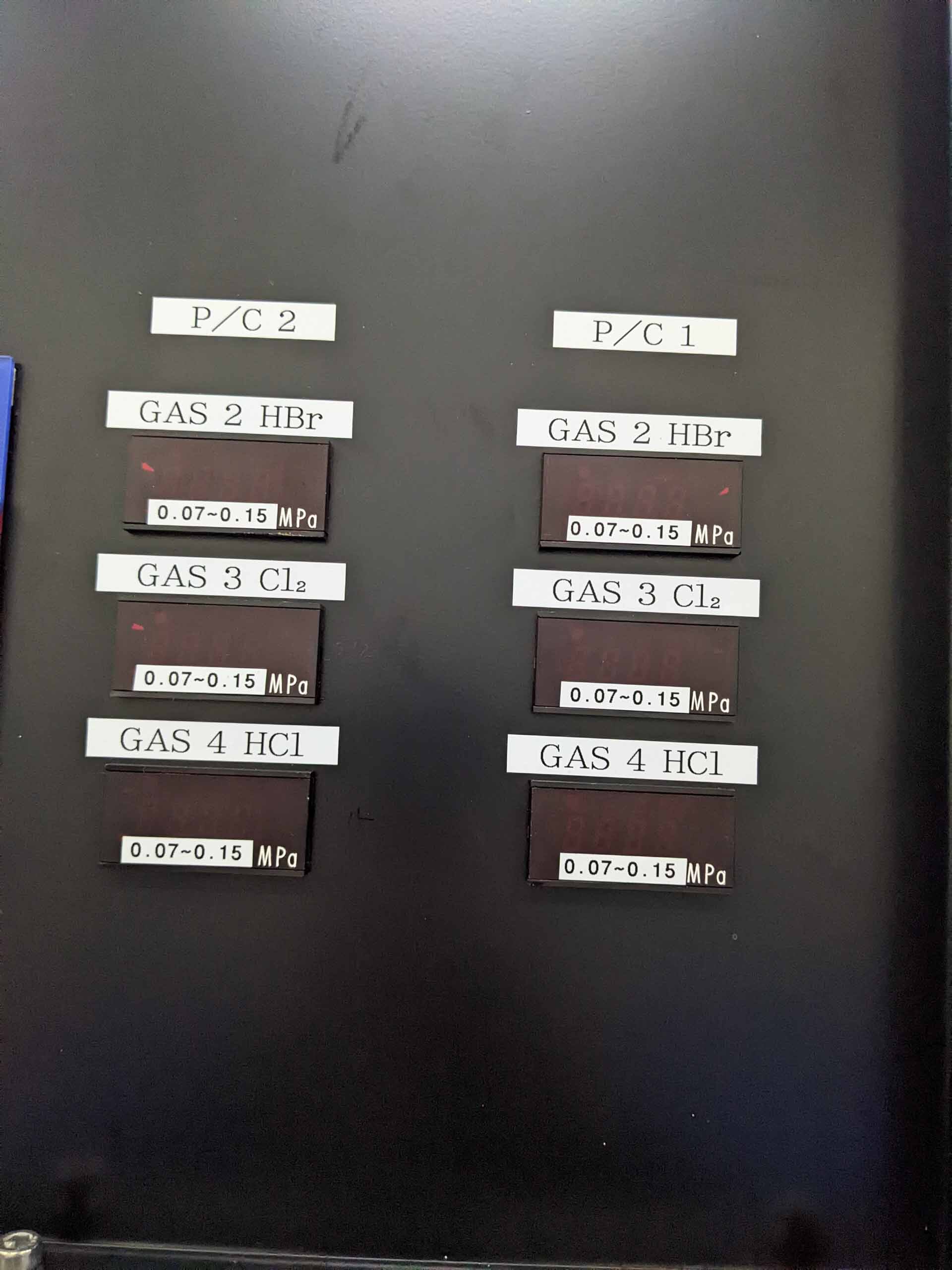

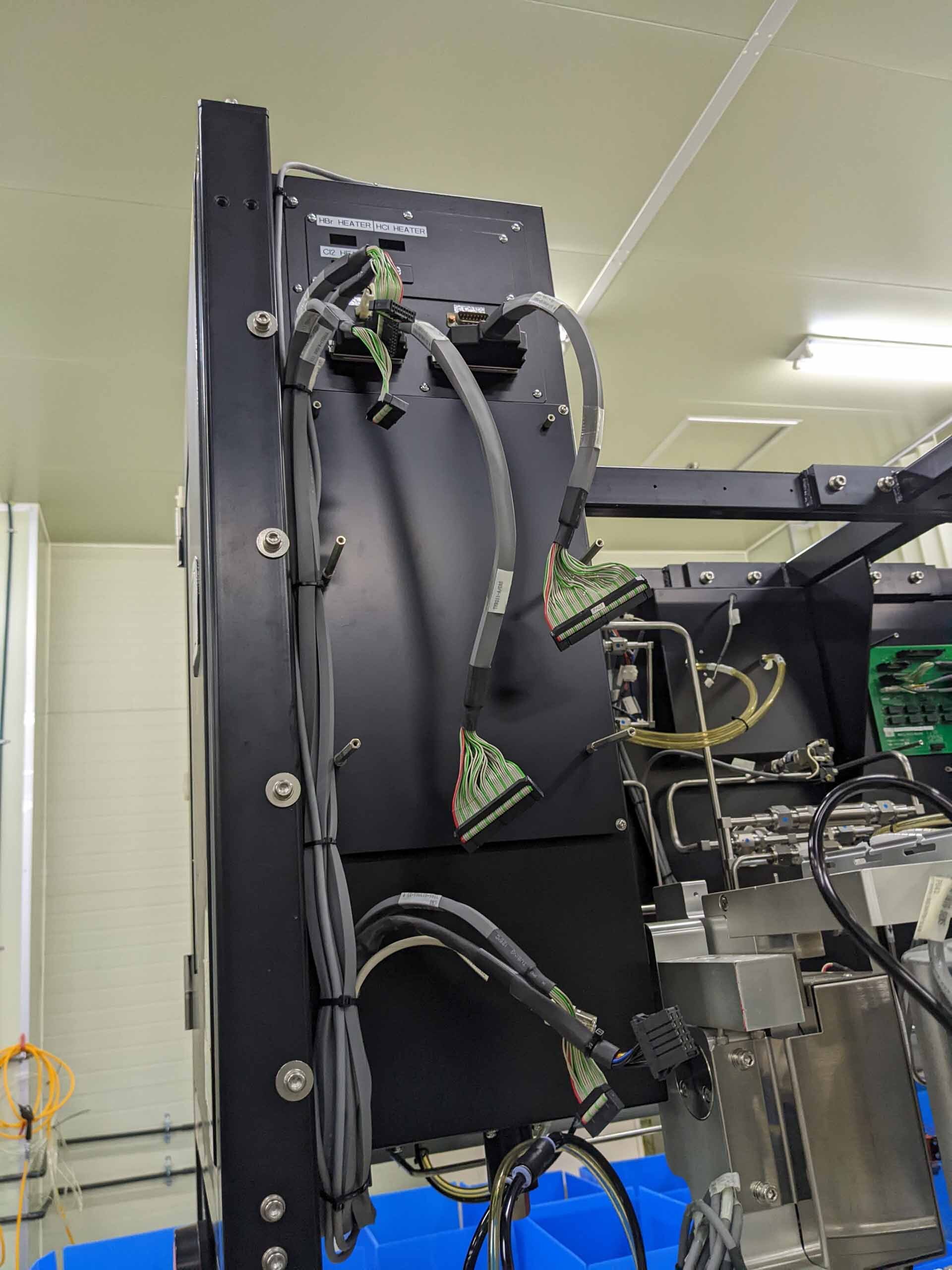

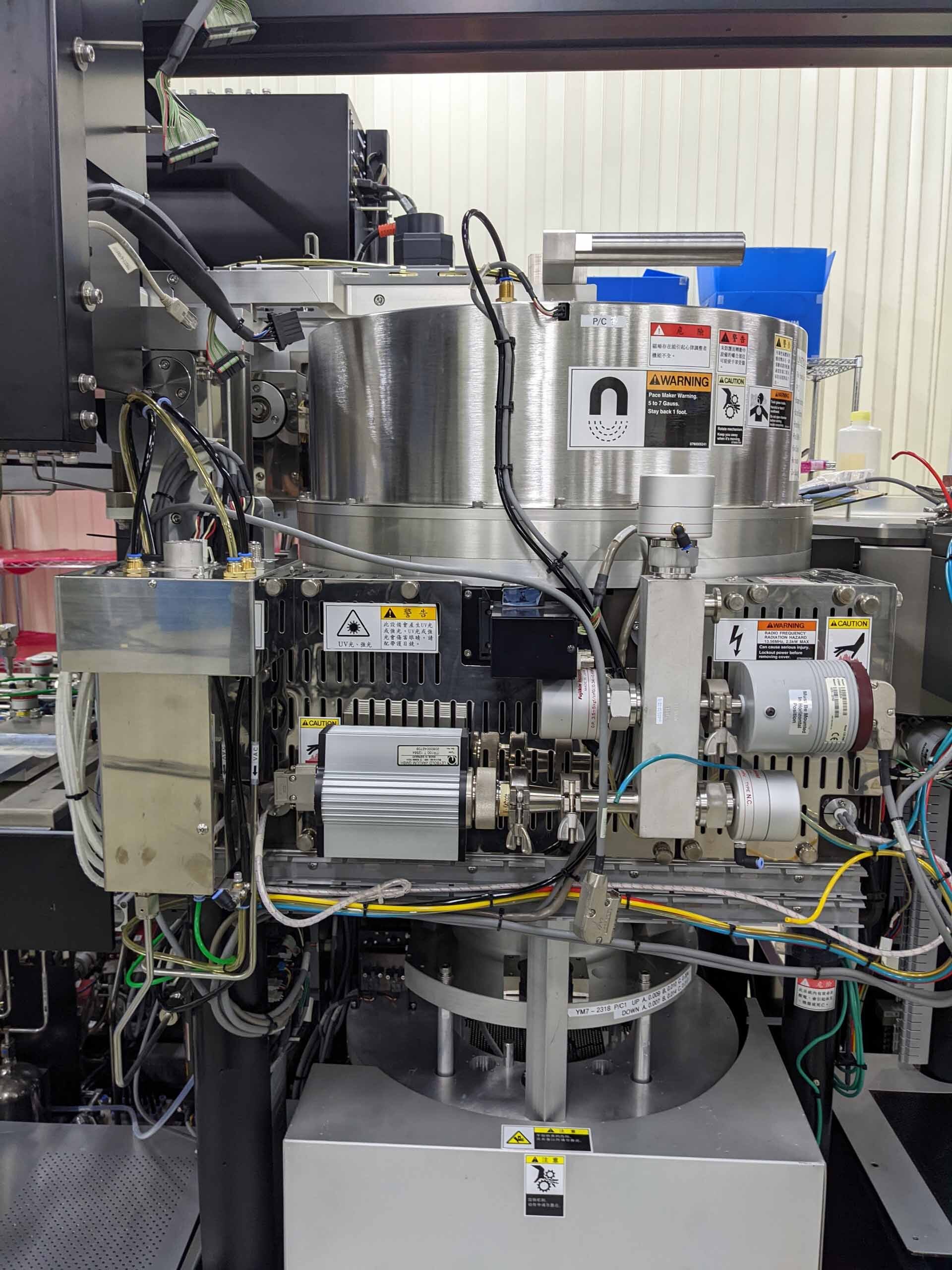

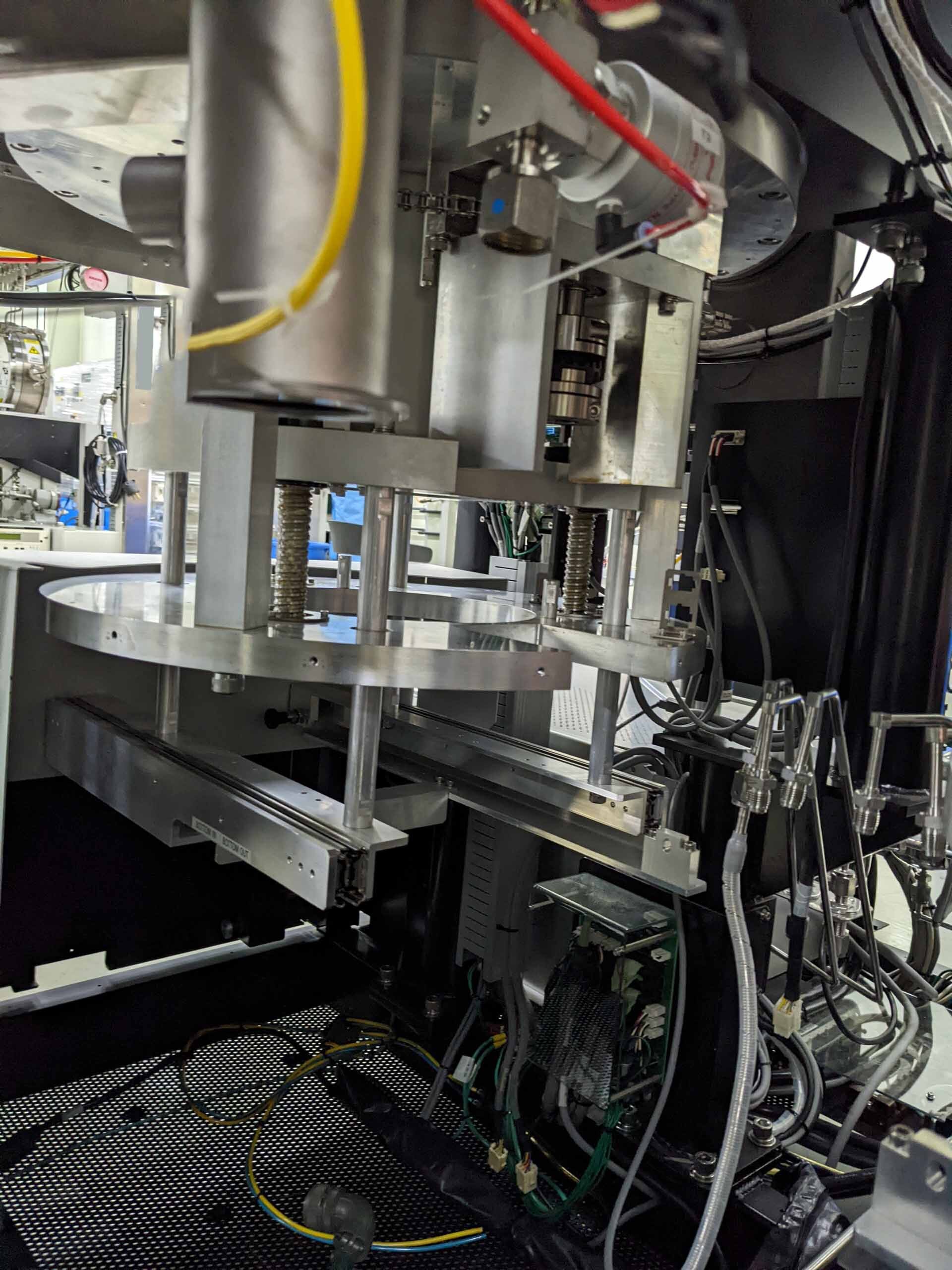

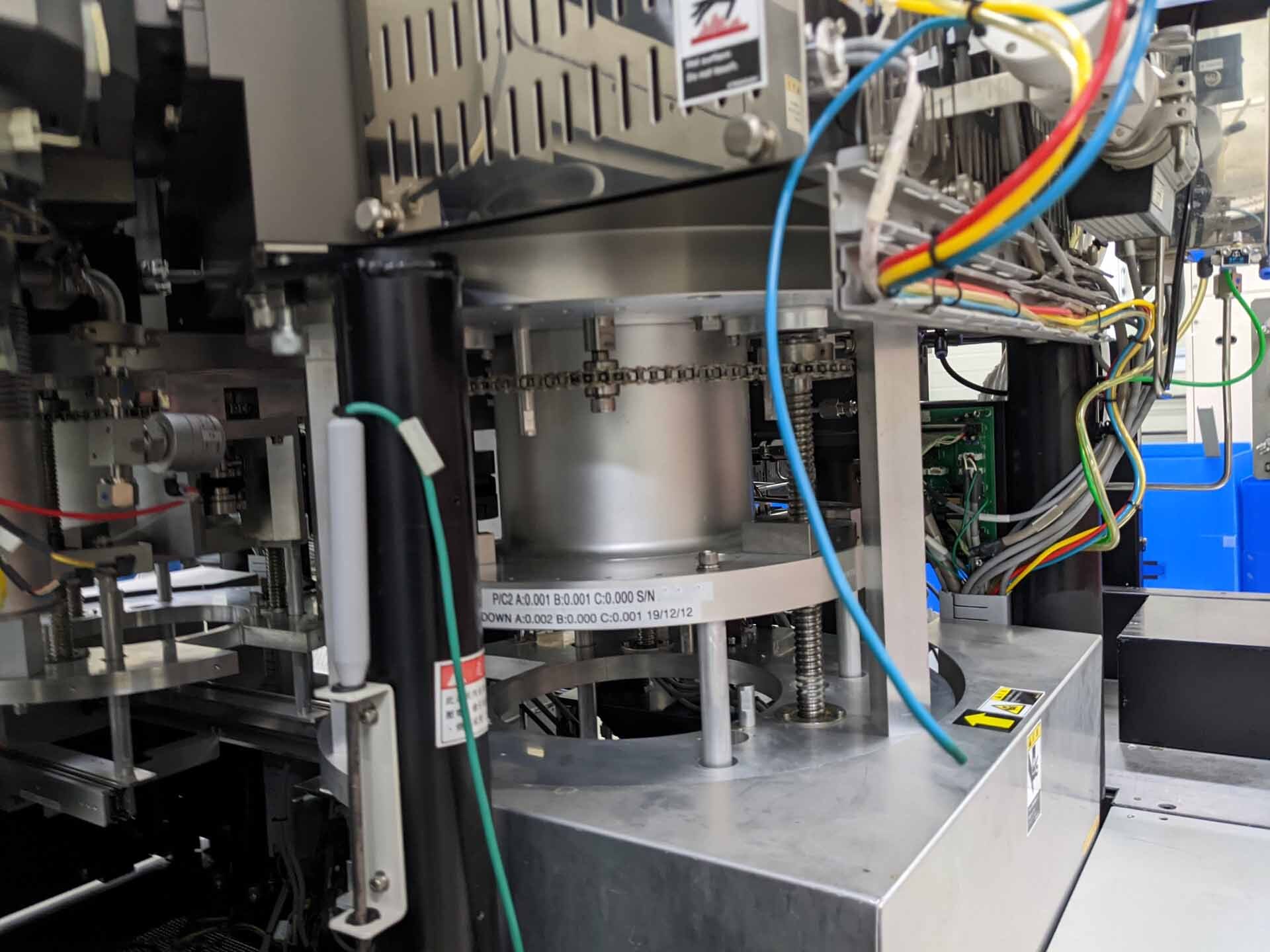

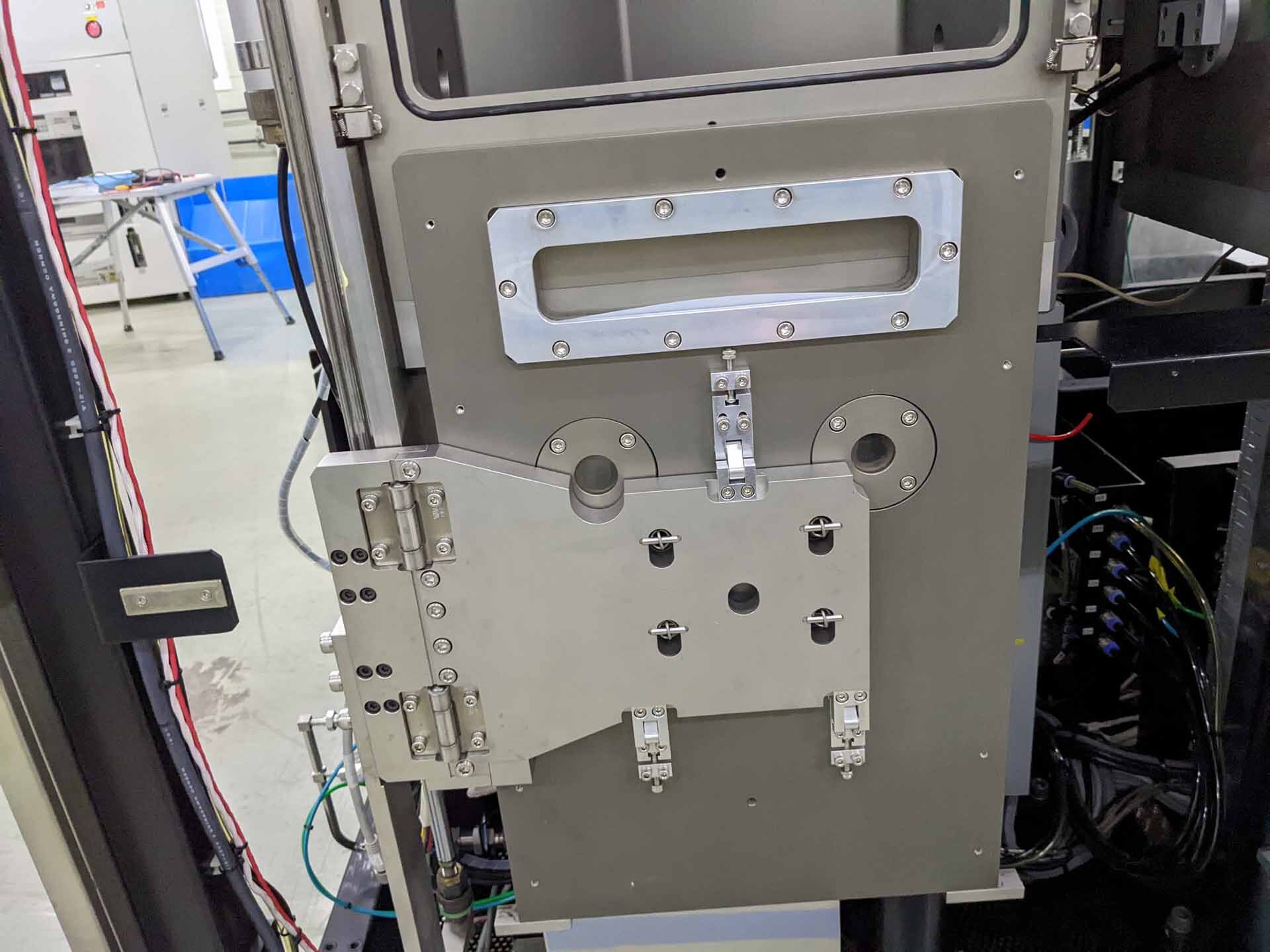

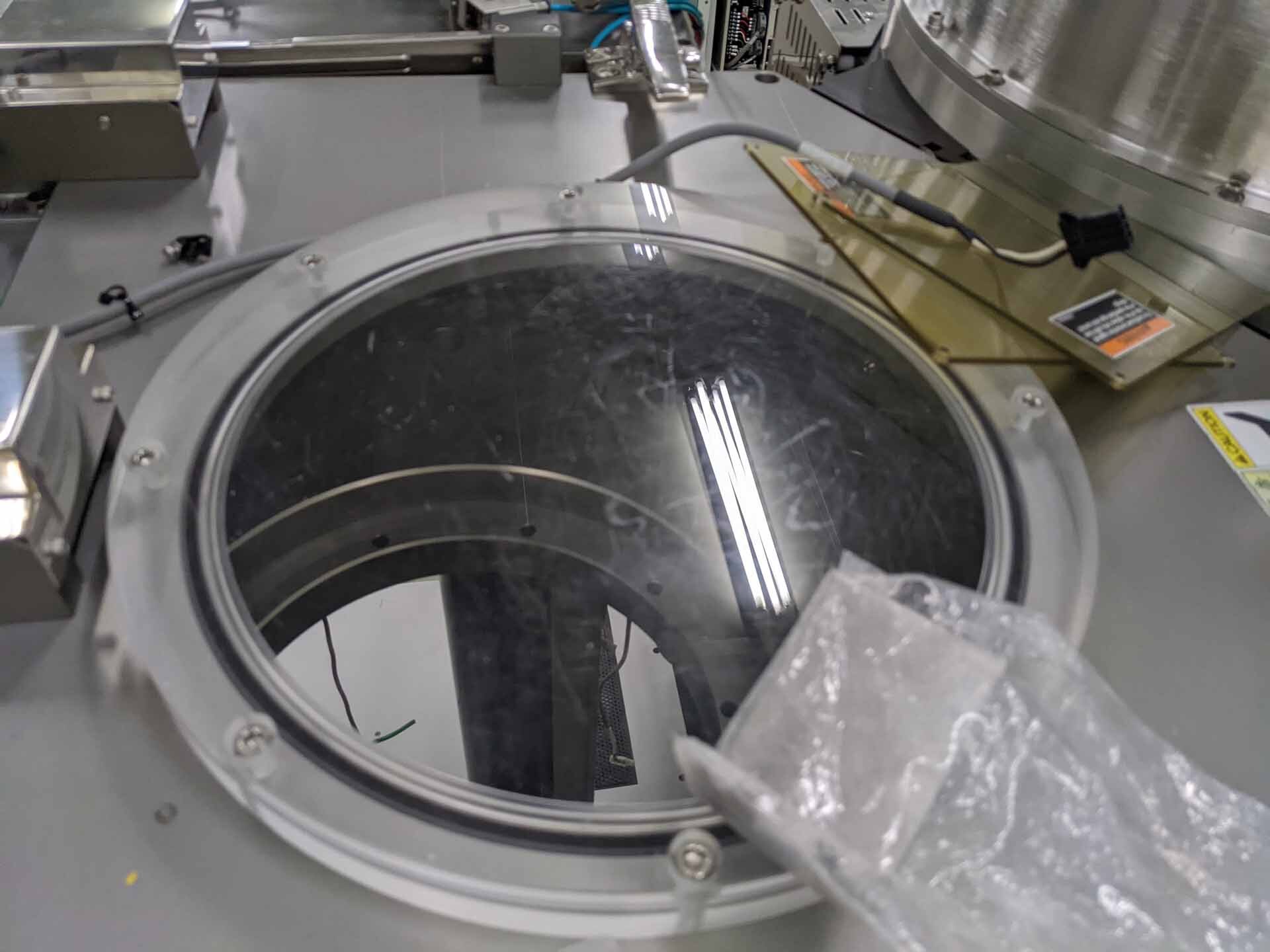

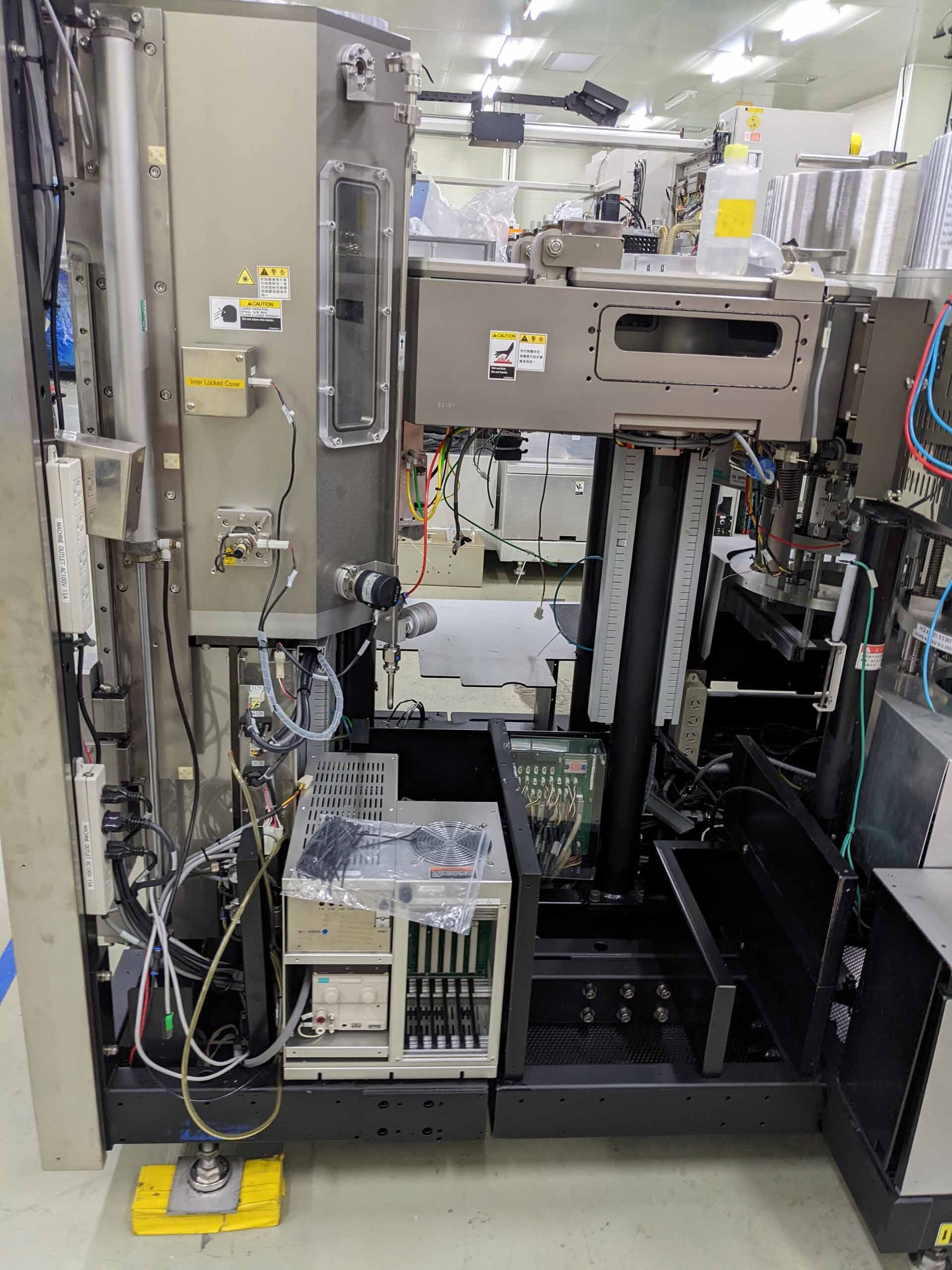

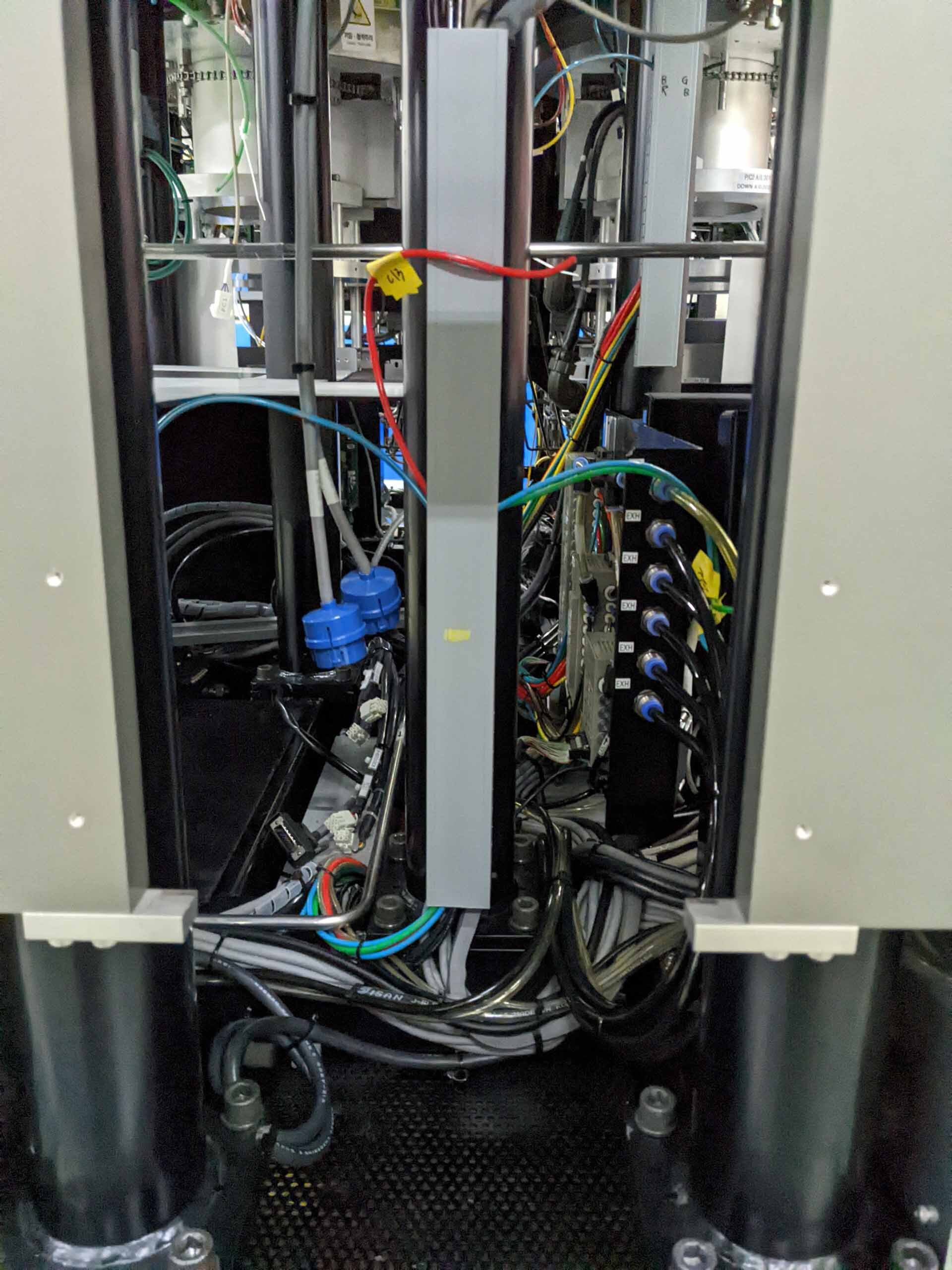

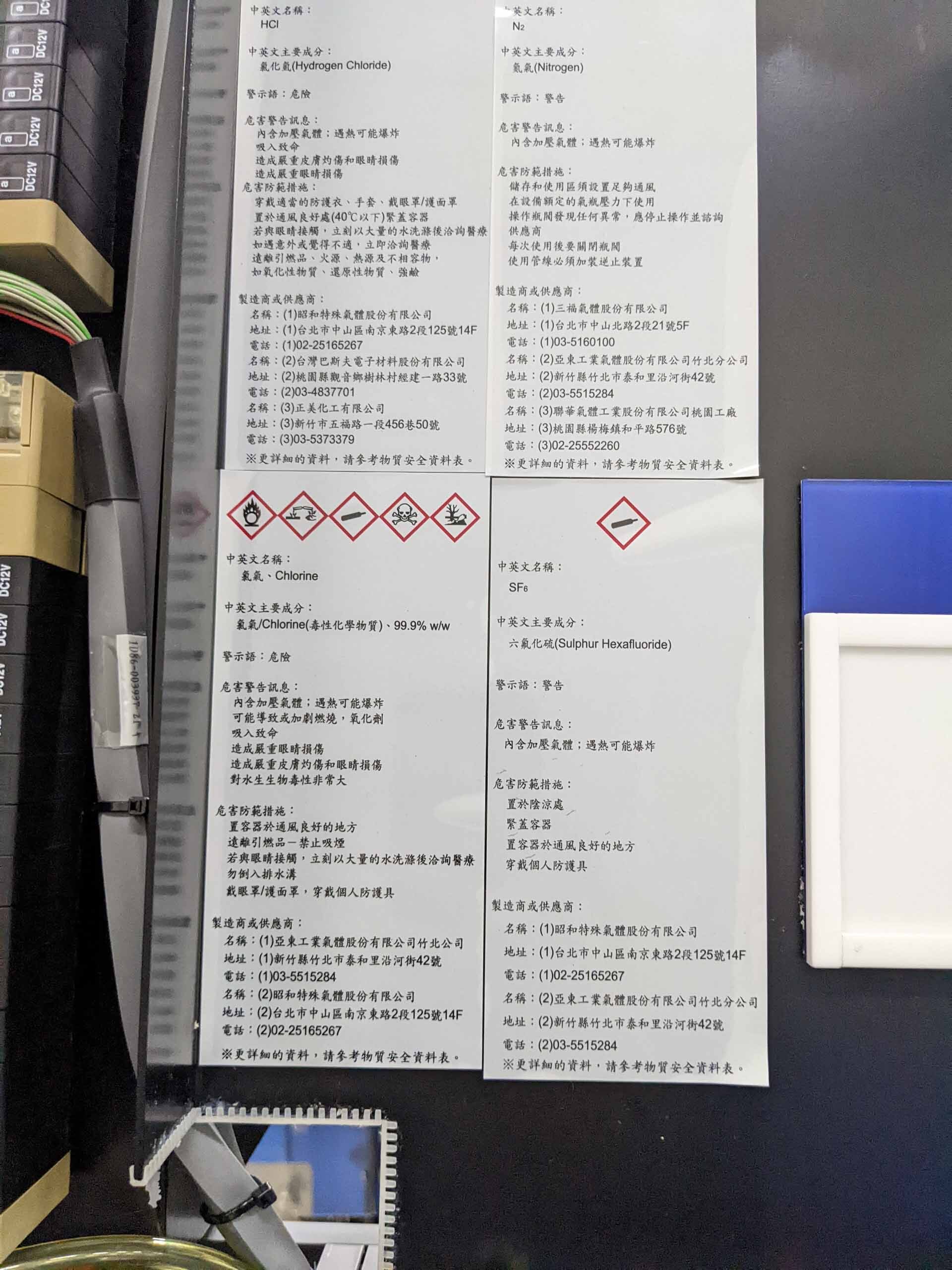

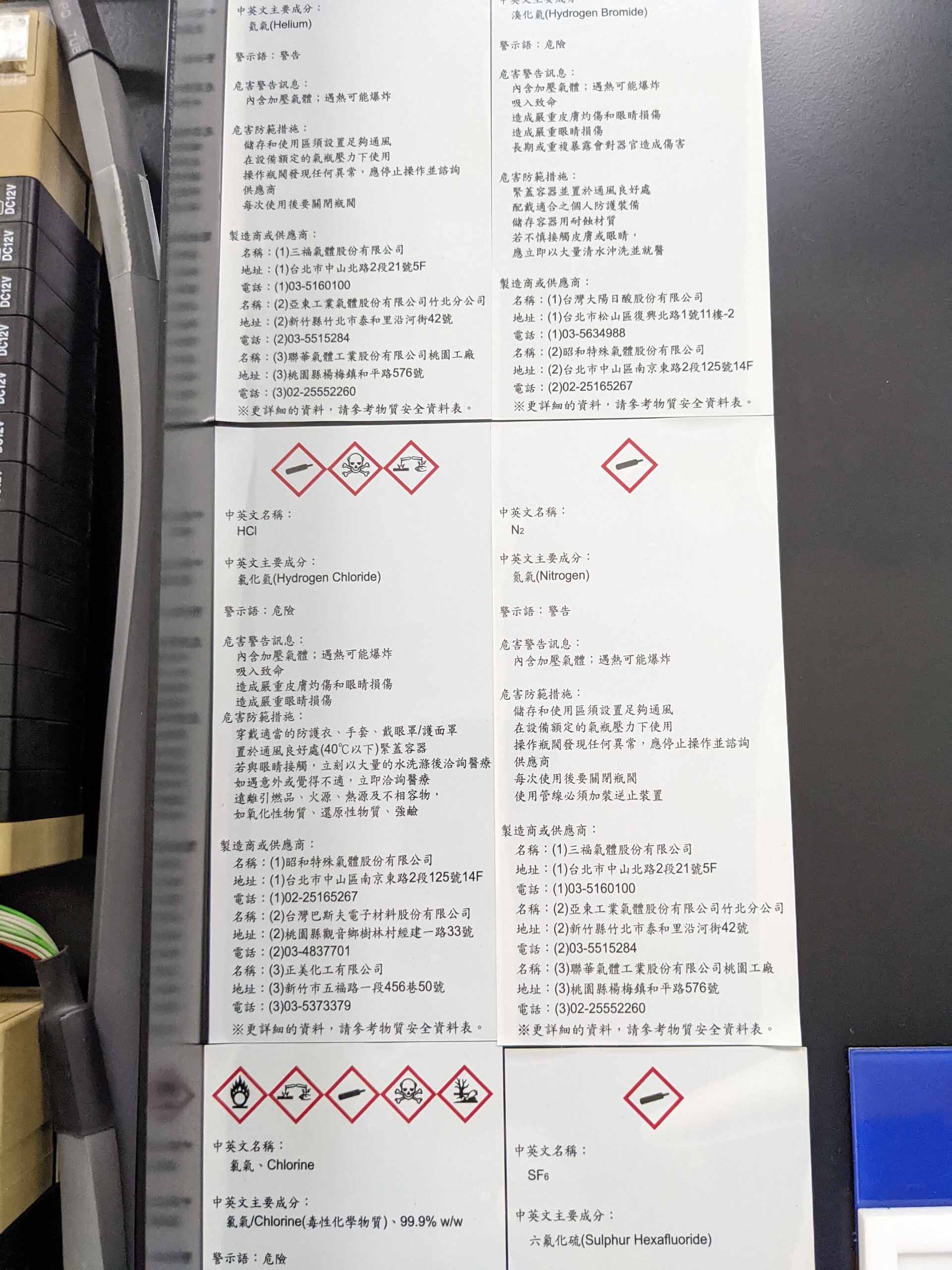

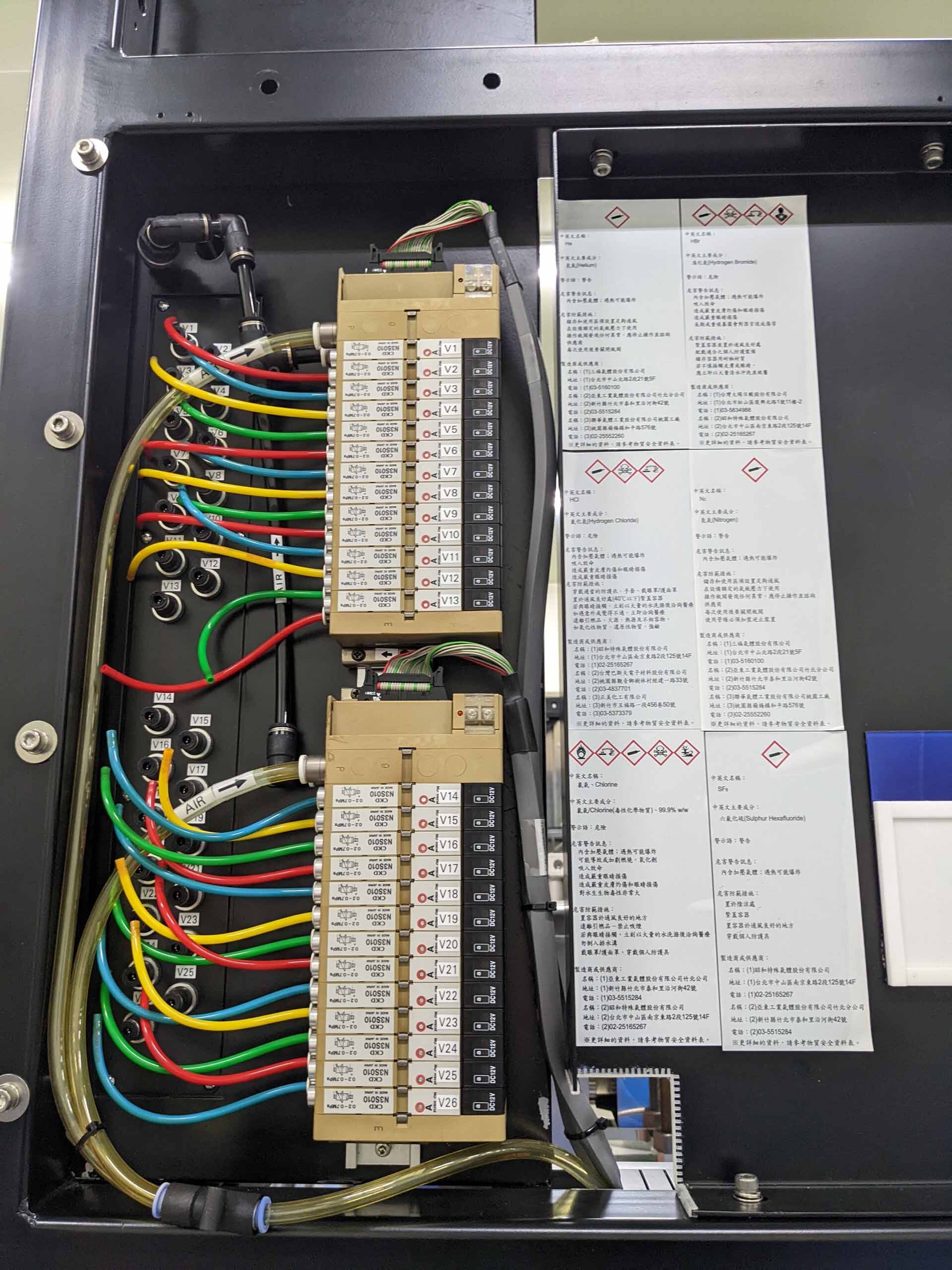

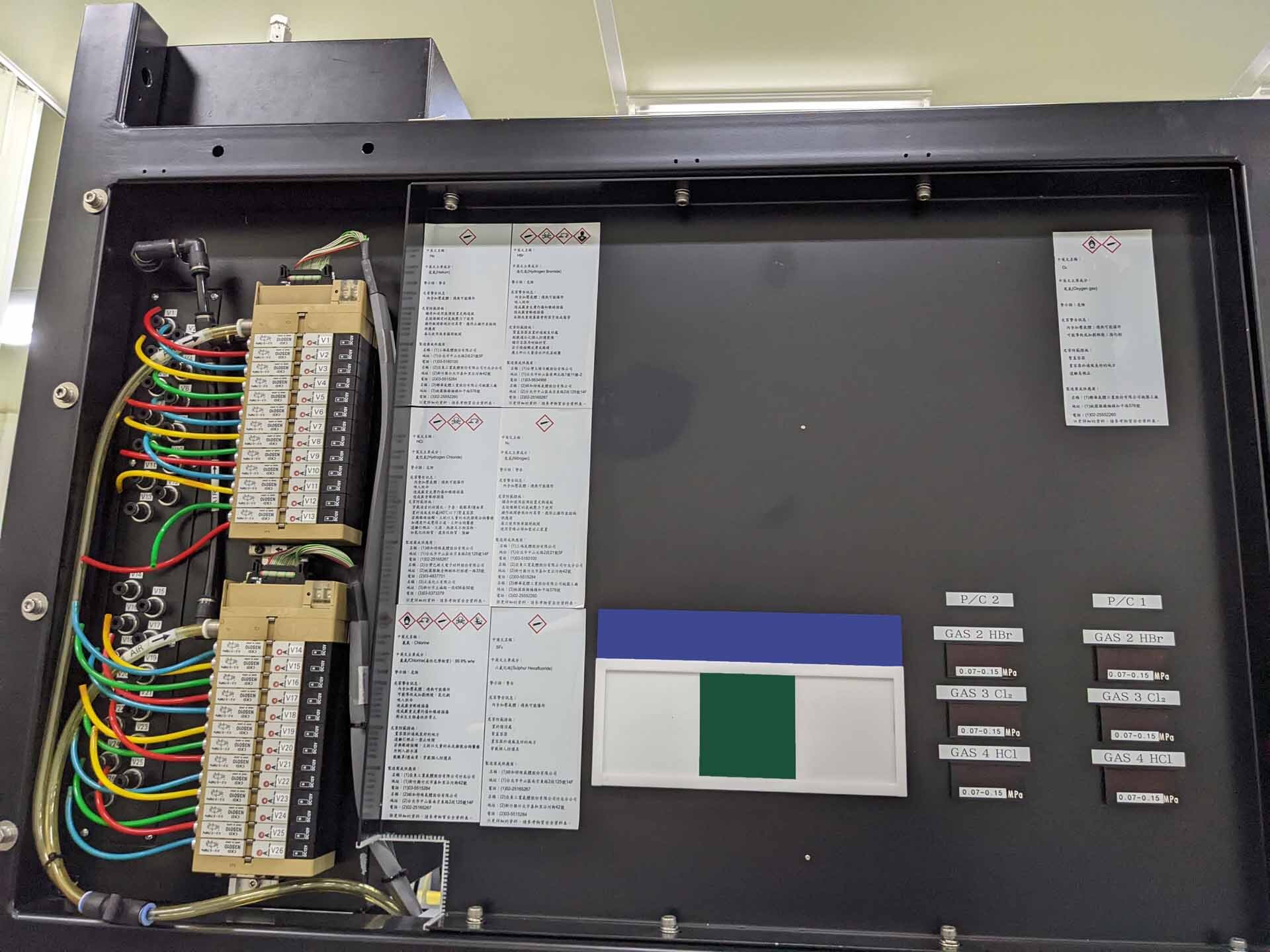

TEL / TOKYO ELECTRON Unity IIe 855DD is a type of etcher/asher equipment utilized to create high-quality semiconductor films for a multitude of applications. The system consists of two main components - a plasma etch chamber and a hot-wall deposition chamber. The etch chamber utilizes a pre-programmed recipe to etch patterns with plasma biasing, while the deposition chamber can create ultra-thin films via one of several plasma sources. Additionally, the unit is equipped with an automated wafer cassette loader, allowing seamless wafer transfers. TEL UNITY IIE 855 DD is built-in with a process monitor and curve tracer, providing users with a five-inch colour LCD display that can be used to monitor process conditions in-situ. The machine is also equipped with an in-situ monitor, providing precision control over substrate temperature, pressure, oxygen flow rates and other process parameters to create the desired film for a given application. TOKYO ELECTRON UNITY II E-855DD is an integrated etcher/deposition tool, allowing users to batch etch and deposit in a single run. It includes an integrated Mass Flow Controller that is used to precisely adjust and monitor both the mixture of gases sent to the plasma-forming zone and the total flow rate. The asset is capable of generating plasma densities of up to 10^13 cm^-3 over a wide range of frequencies and mini self-bias plasma etch potentials with tuning accuracy of up to 0.5V. To reduce particle contamination and improve film quality, TEL Unity IIe 855DD utilizes an advanced plasma source cleaning technology that does not use any harsh chemicals or chemicals from outside the etching chamber. This model includes an automatical in-situ cleaning procedure that can clean the plasma source both prior to and during the etching cycle. Finally, the equipment includes the advanced DOVE high rate deposition technology, which combines a unique high-density plasma source with a low-pressure etch chamber. This technology allows for the deposition of tighter conformal films with higher etch rates and improved step-coverage. Unity IIe 855DD is an ideal tool for users operating in the fields of semiconductor film deposition and etching.

There are no reviews yet