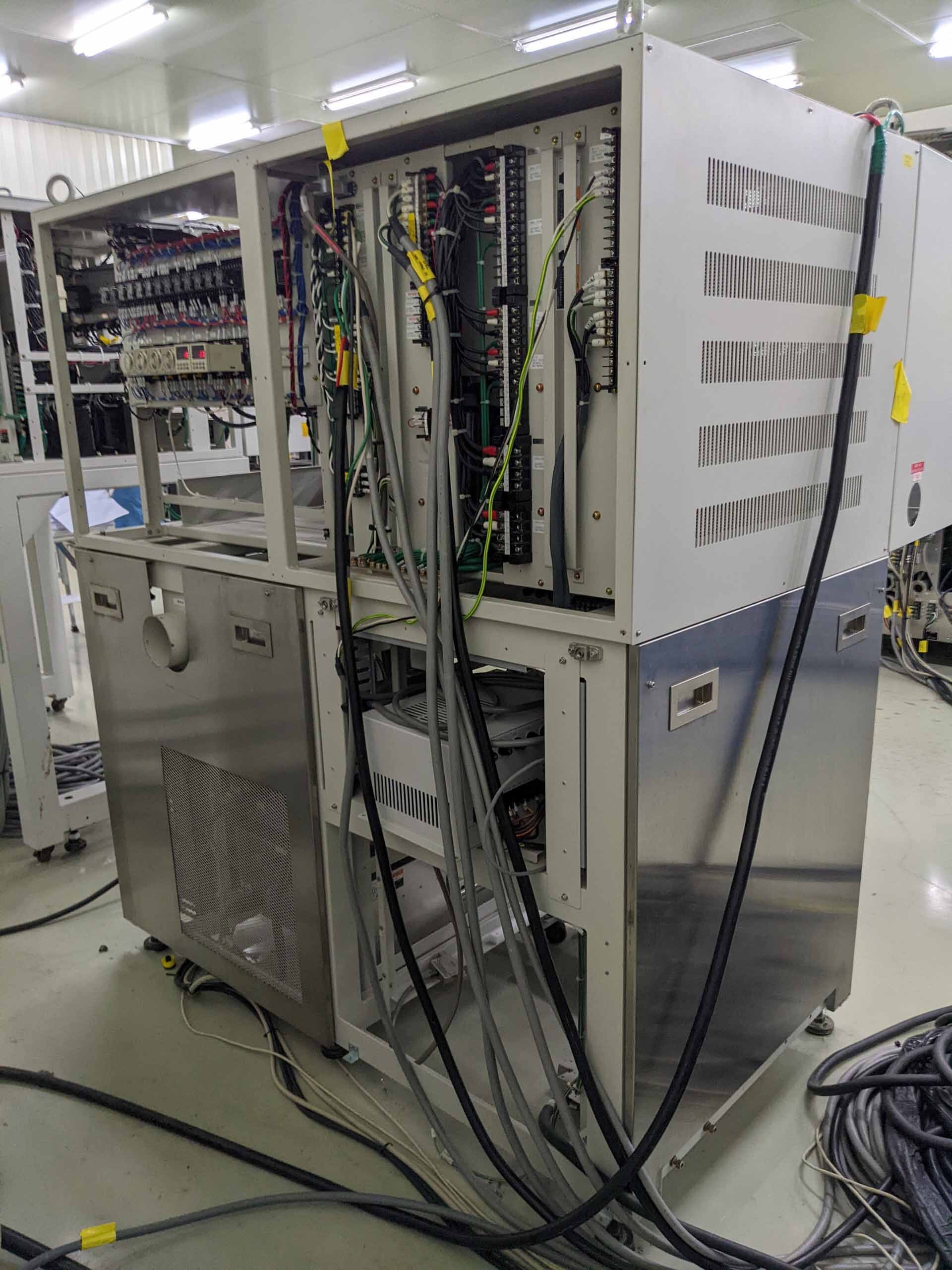

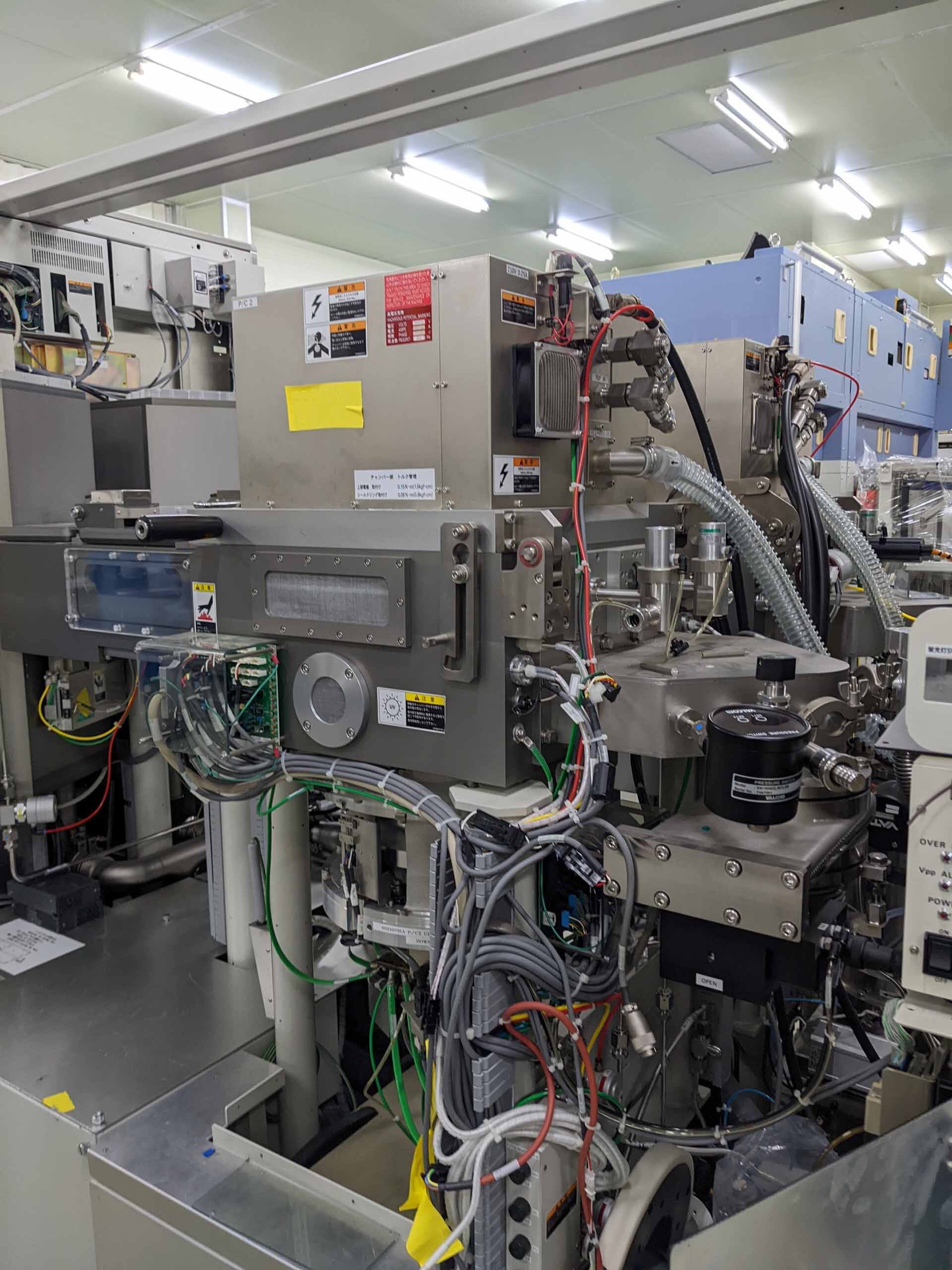

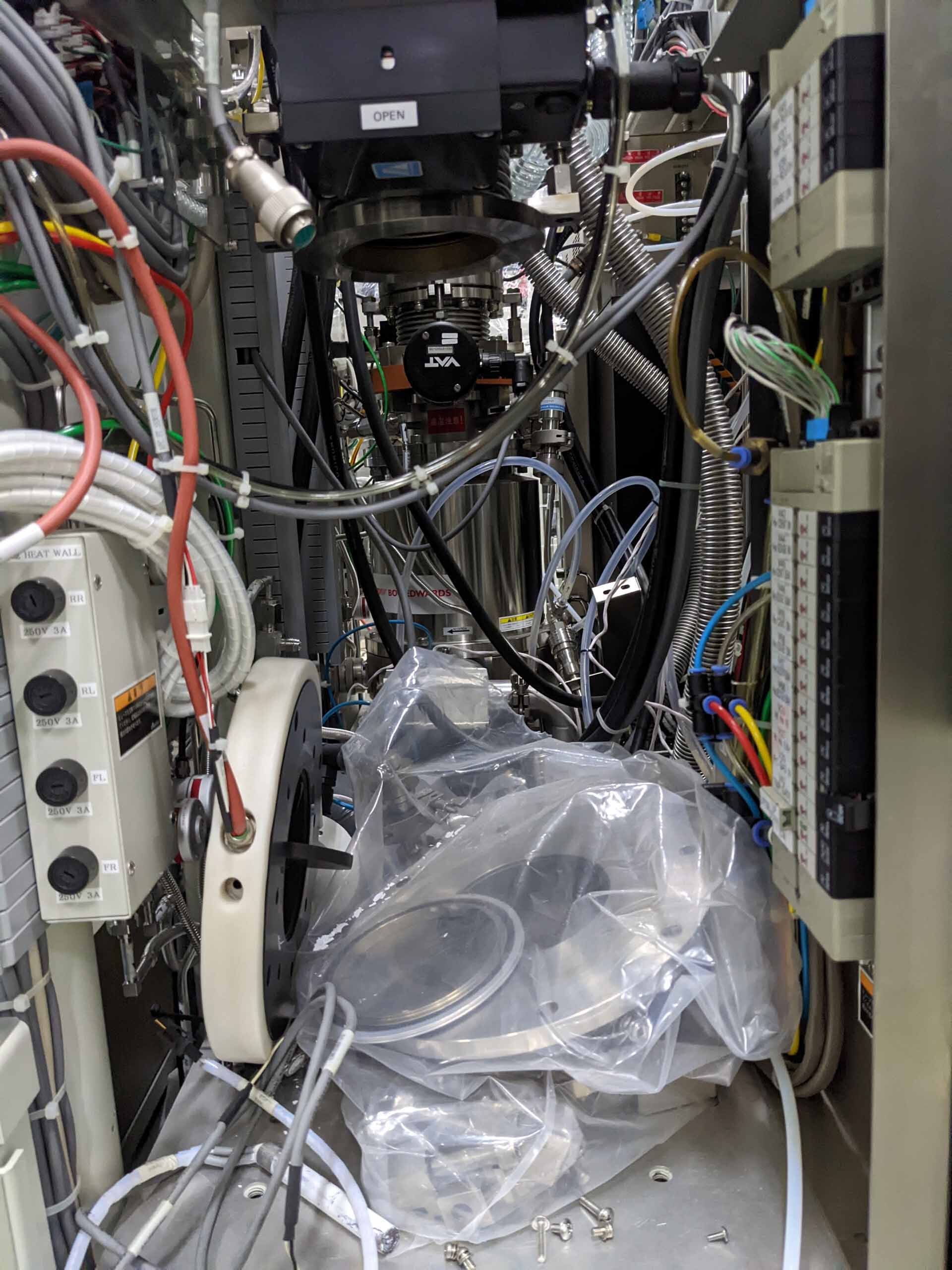

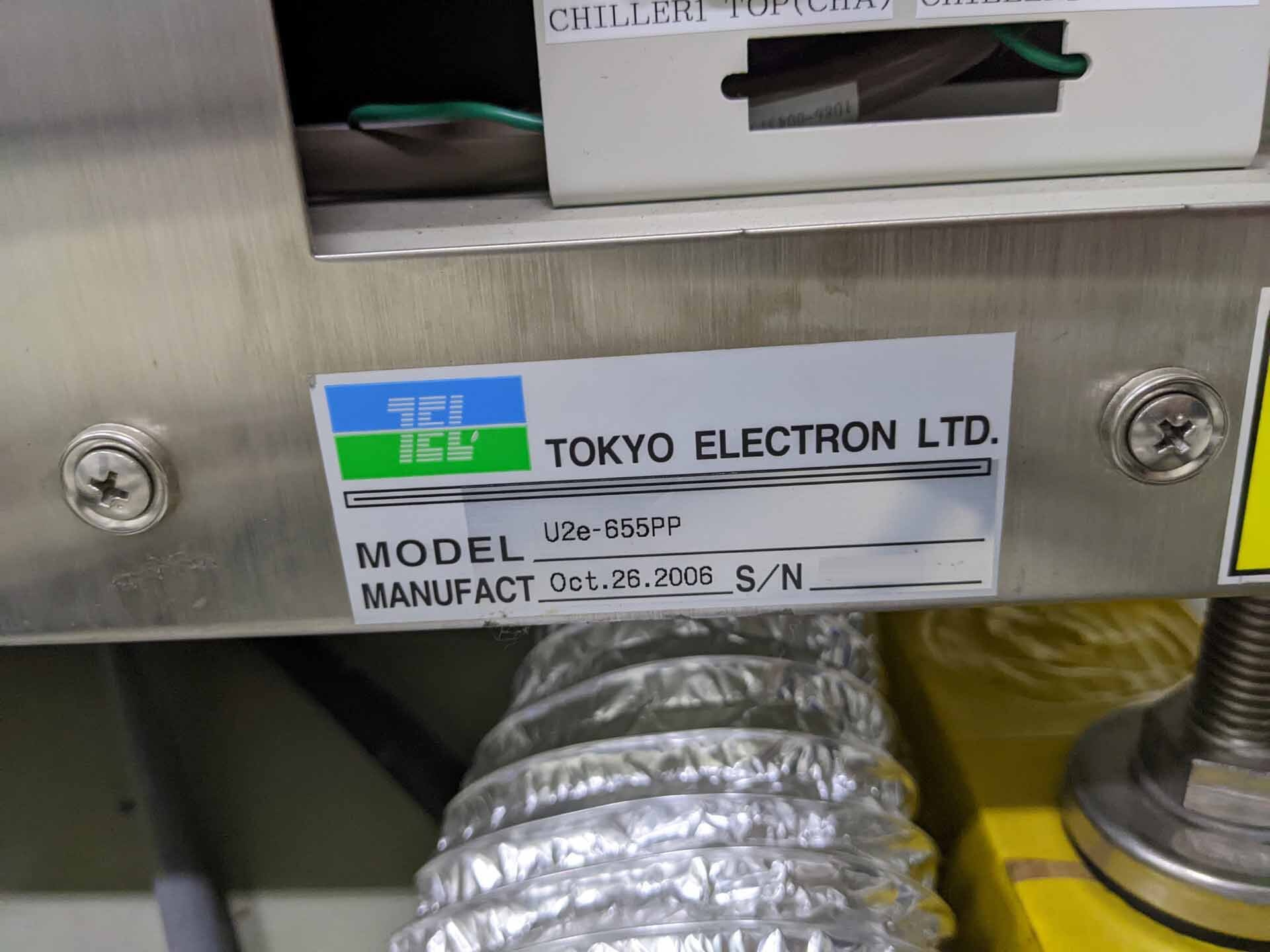

Used TEL / TOKYO ELECTRON Unity IIe 855DP #293645124 for sale

URL successfully copied!

Tap to zoom

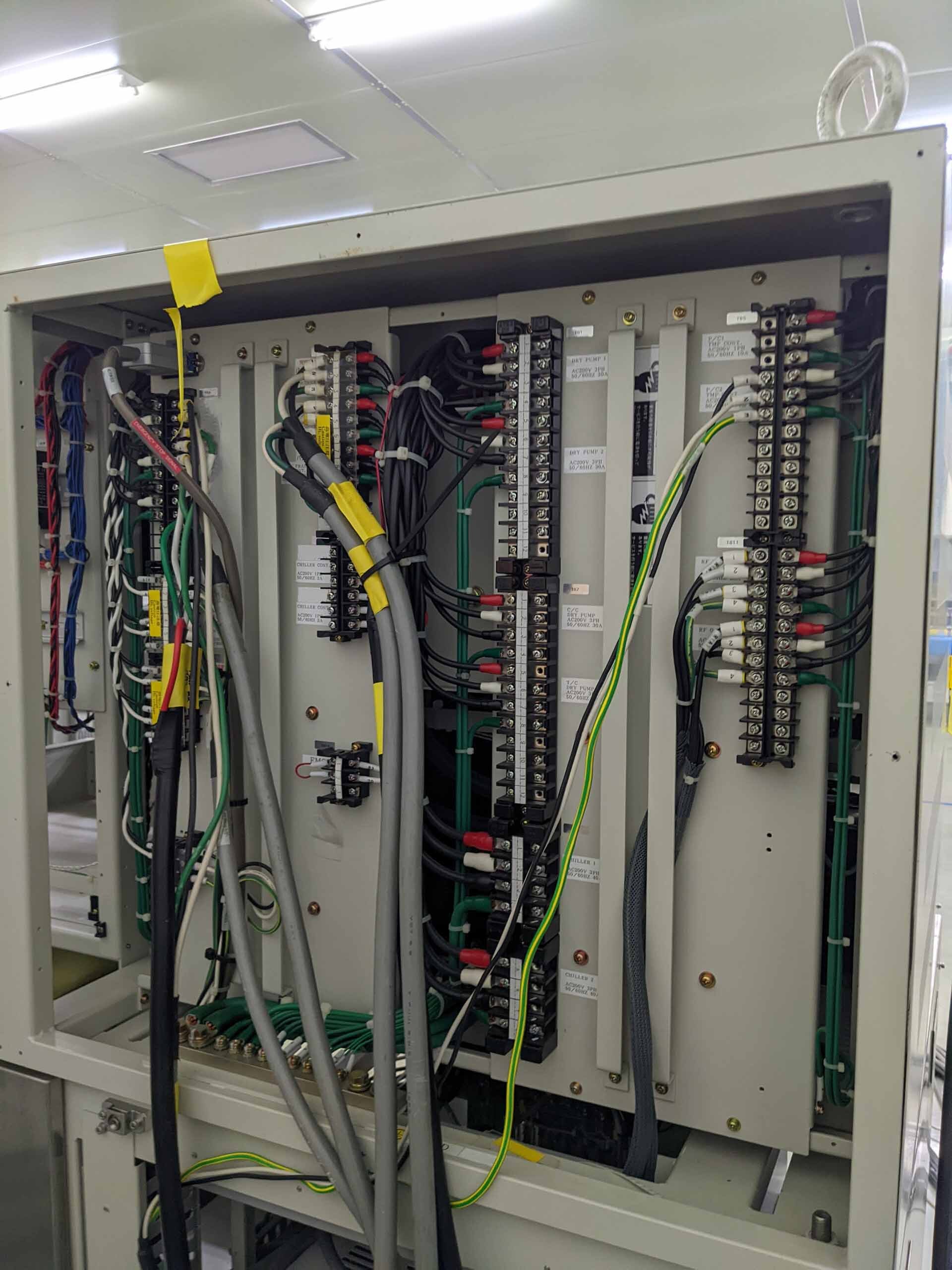

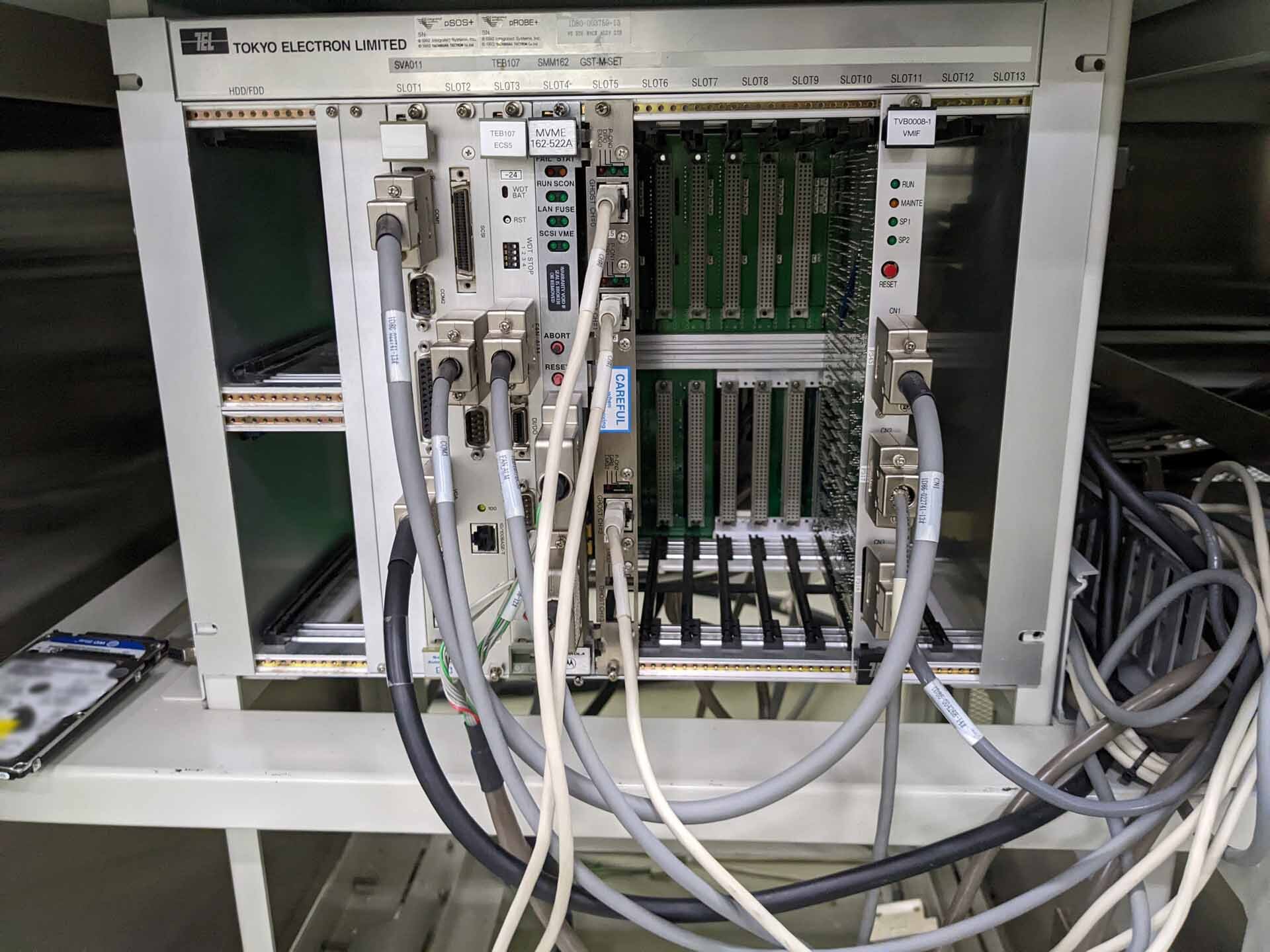

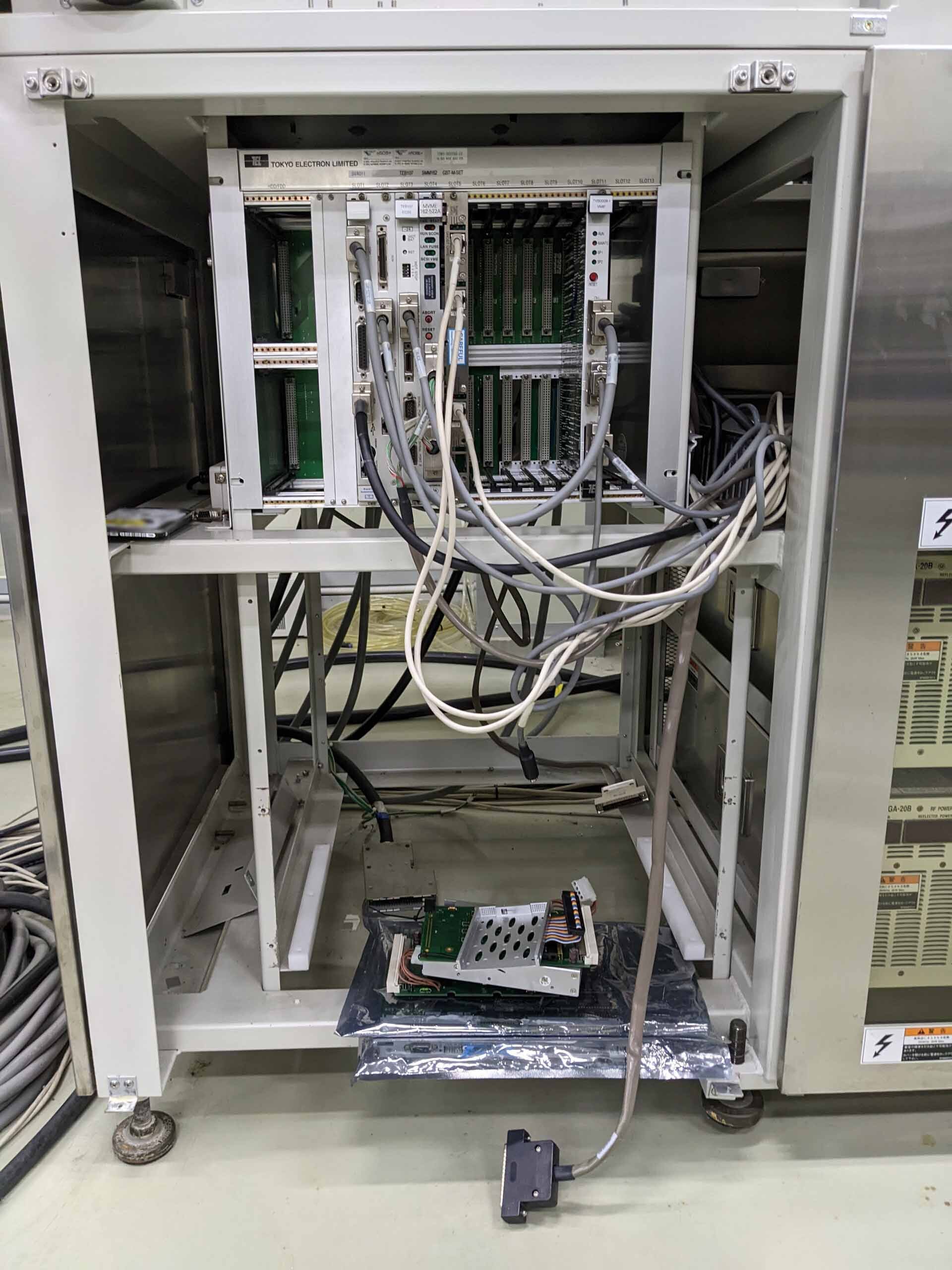

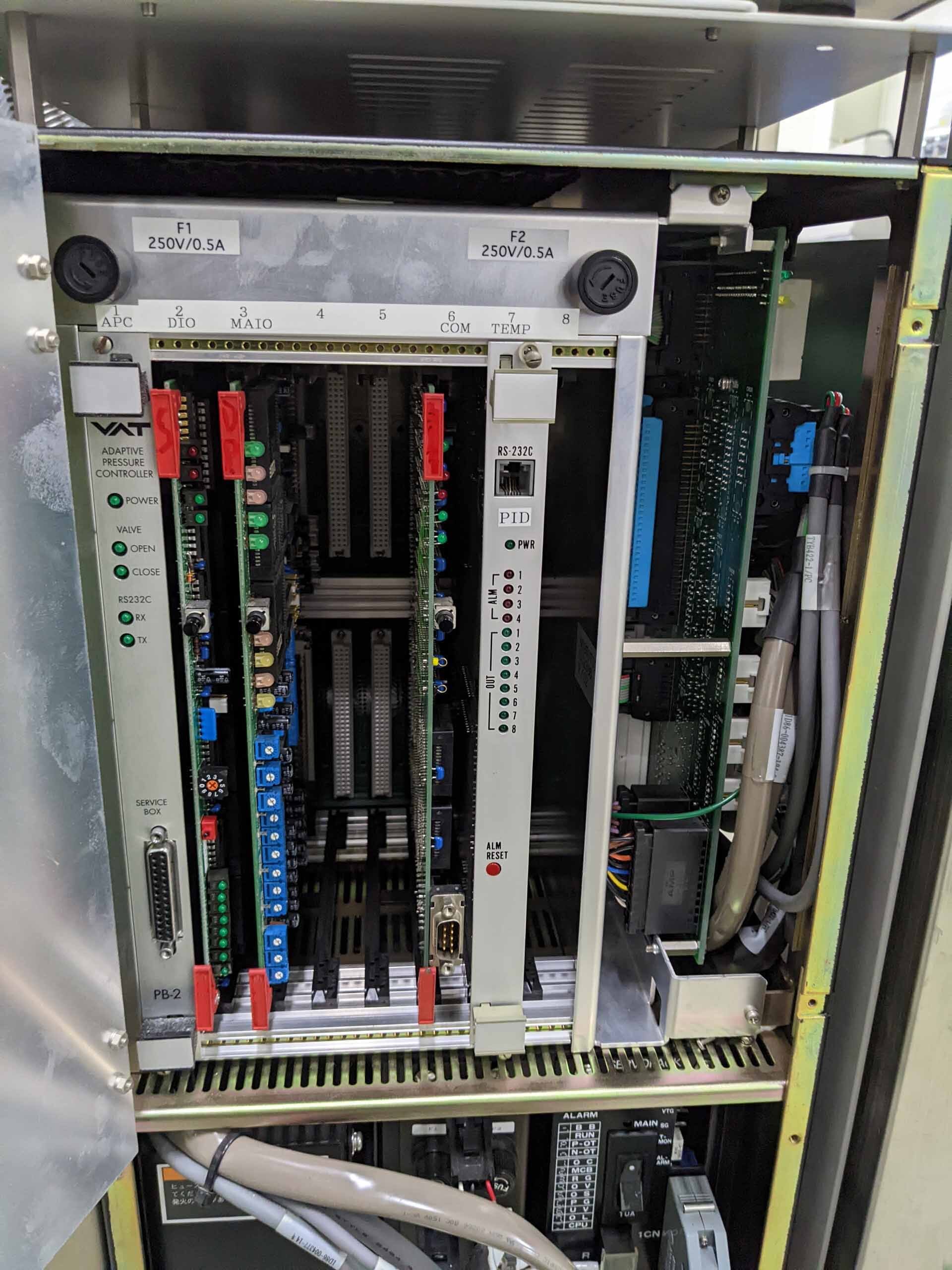

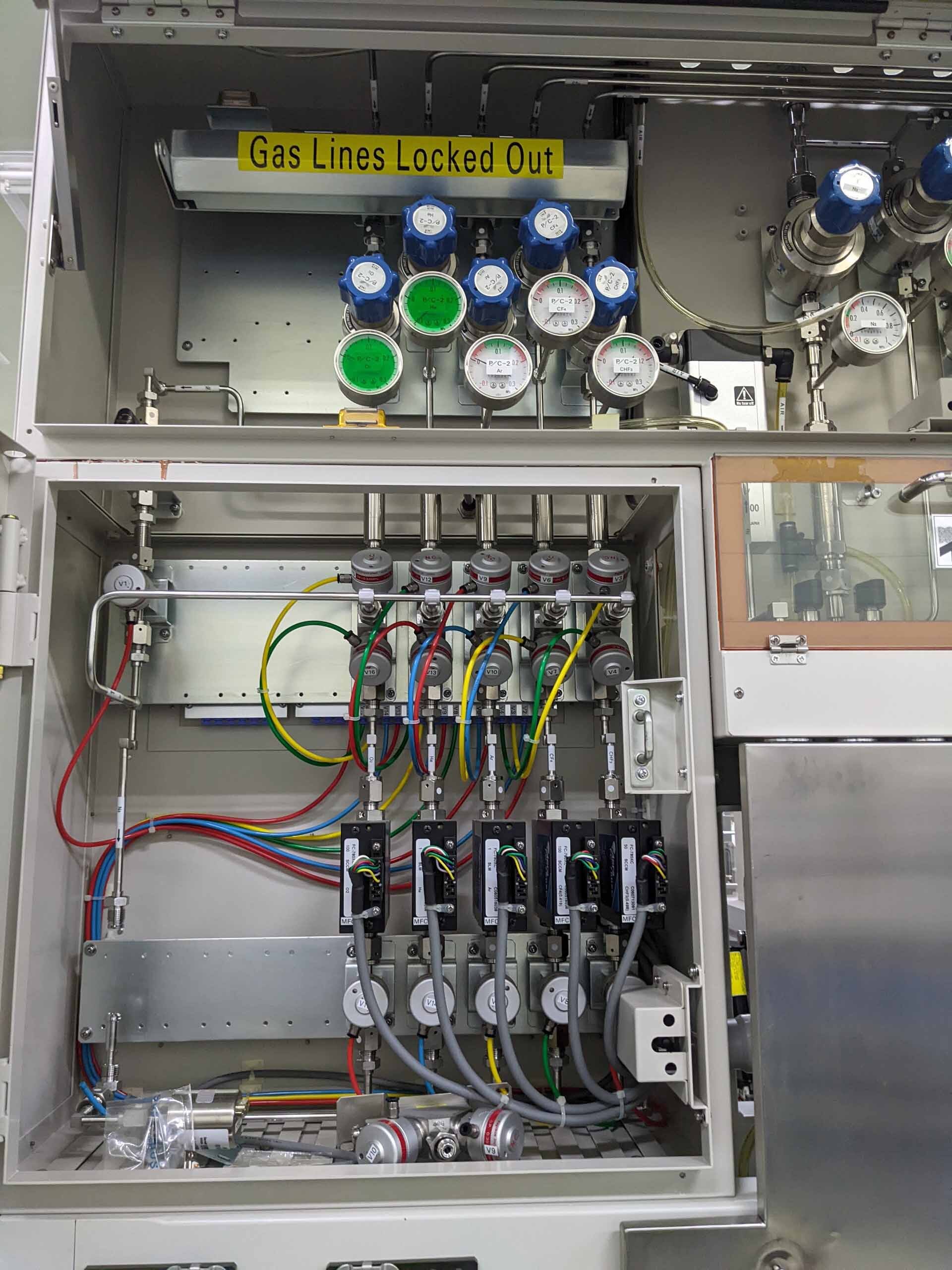

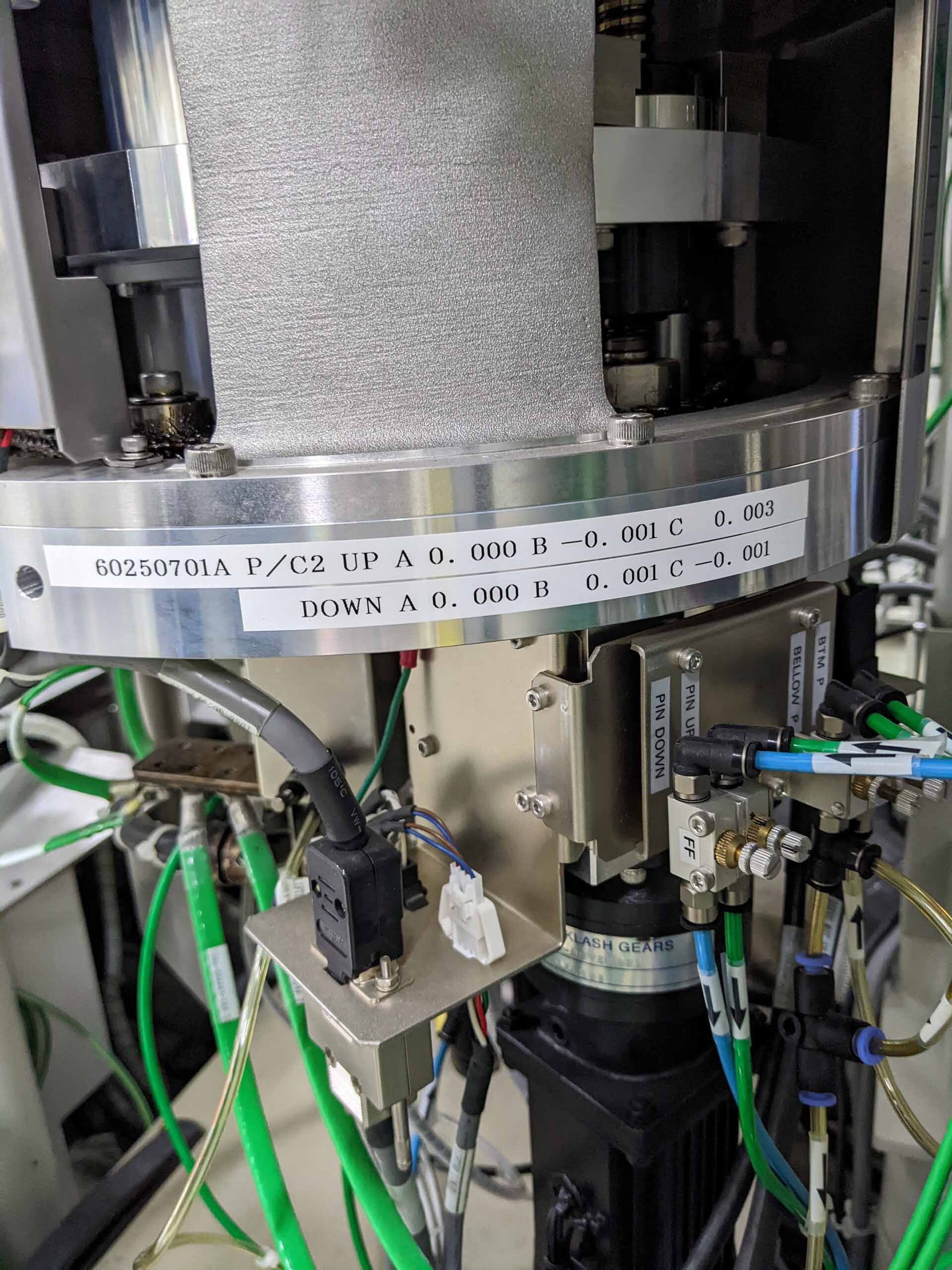

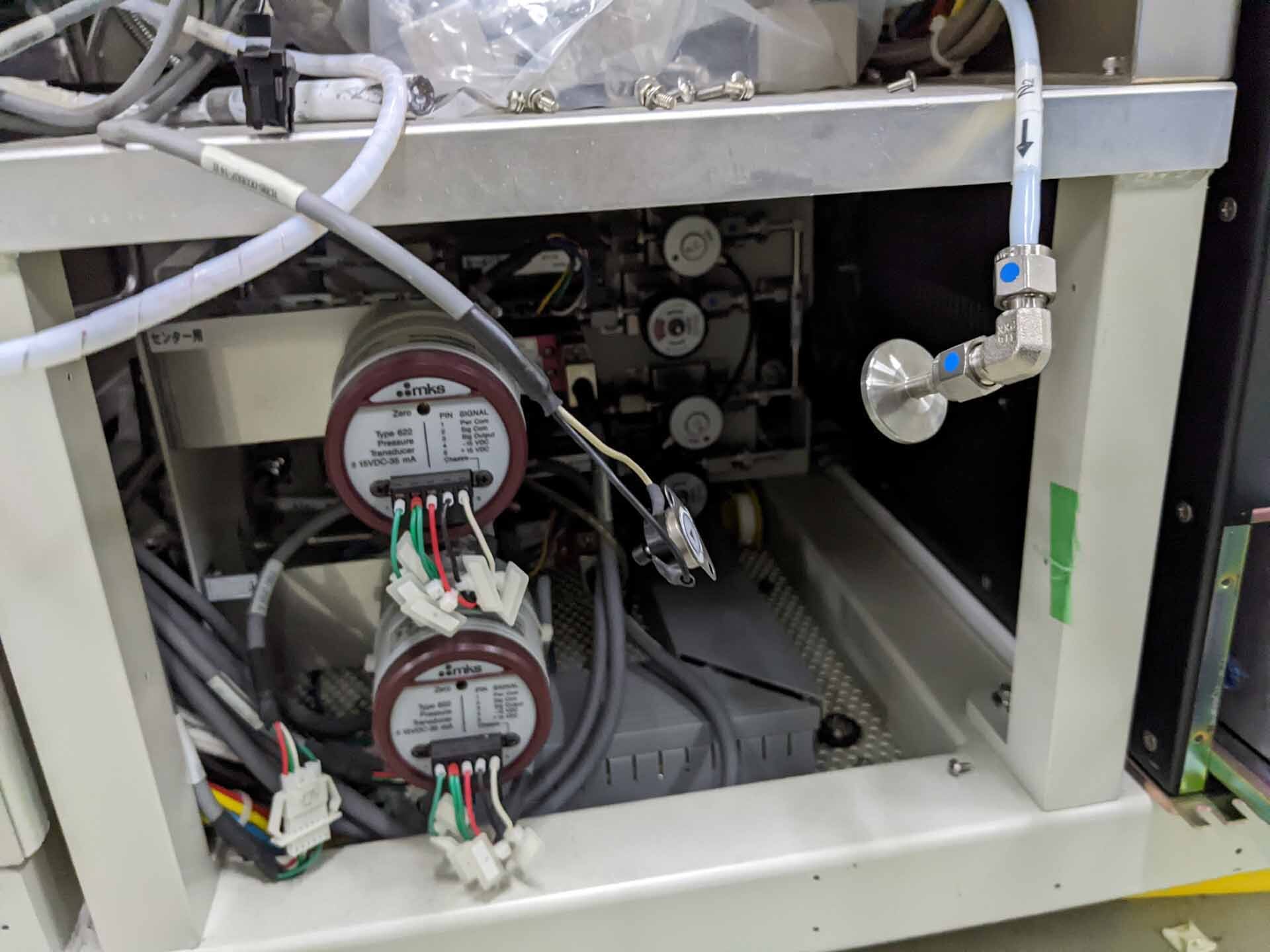

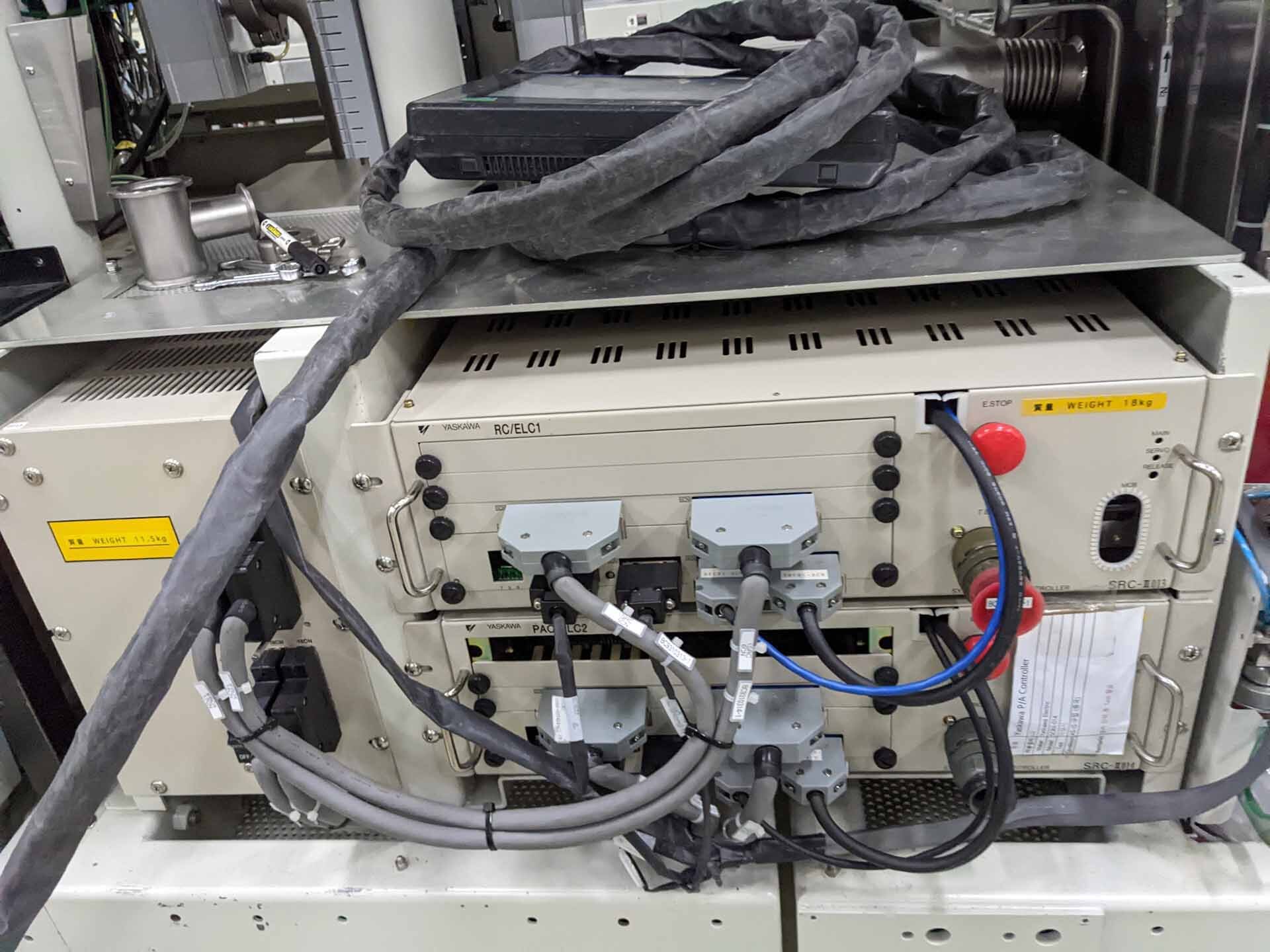

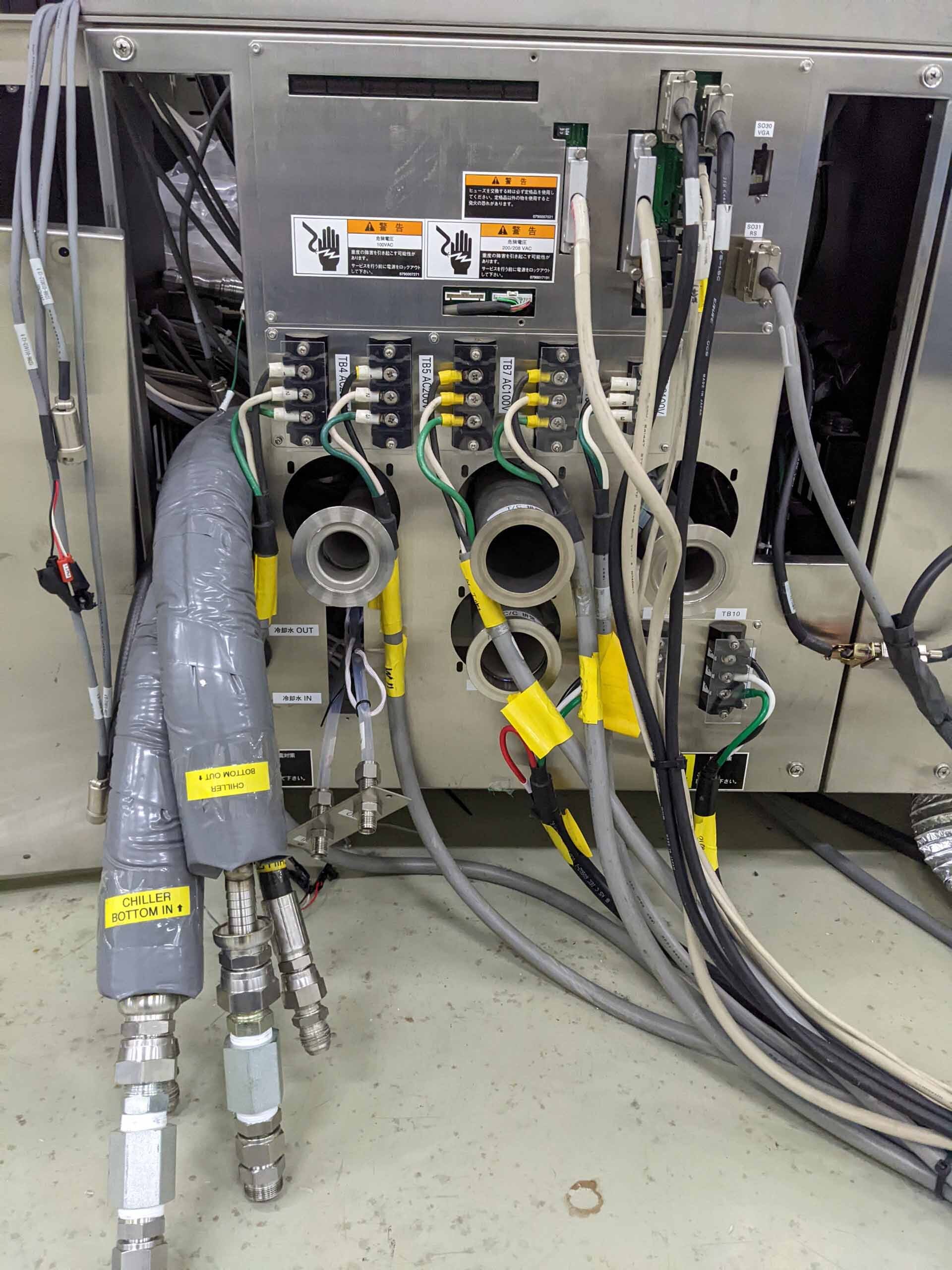

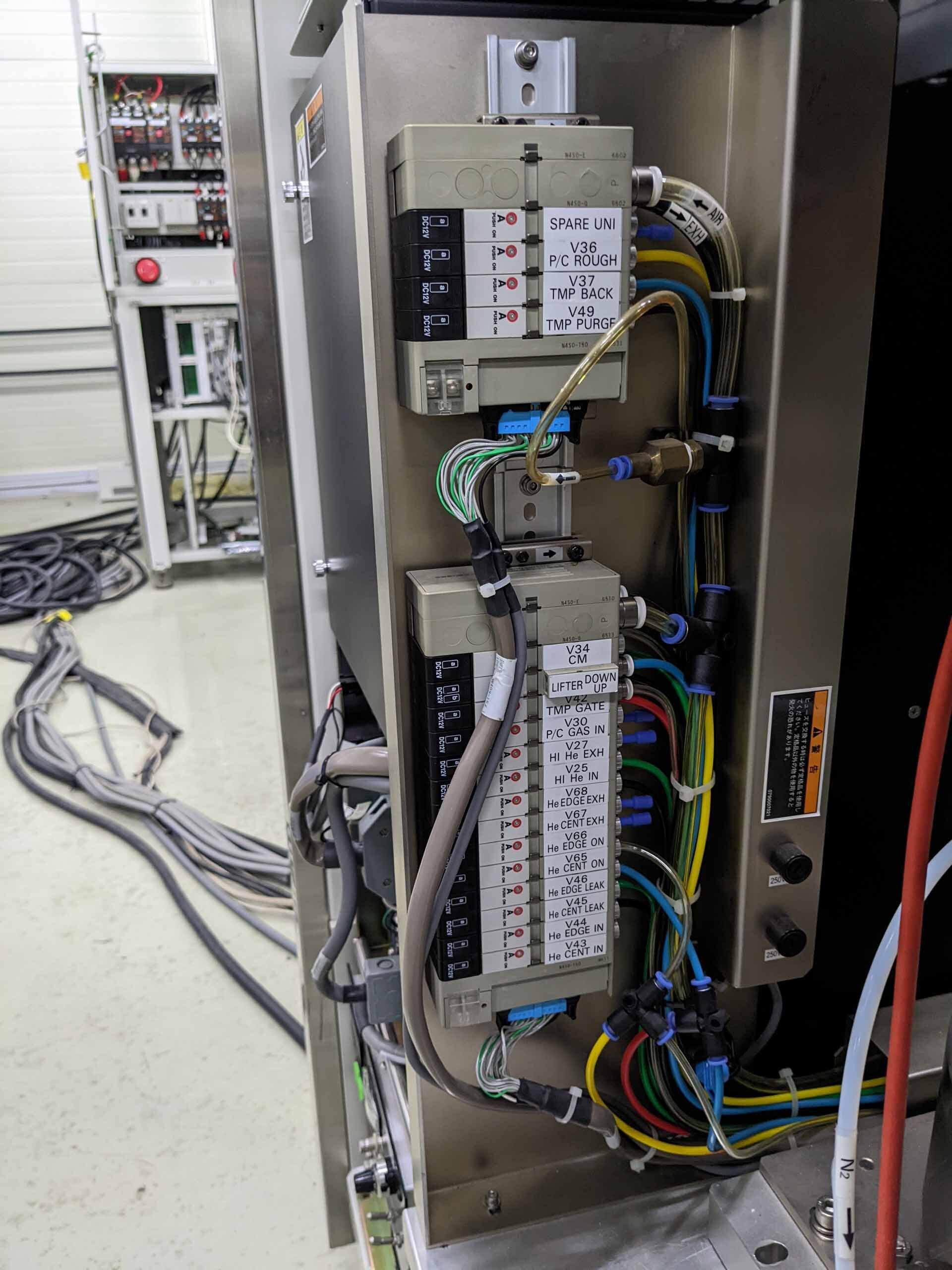

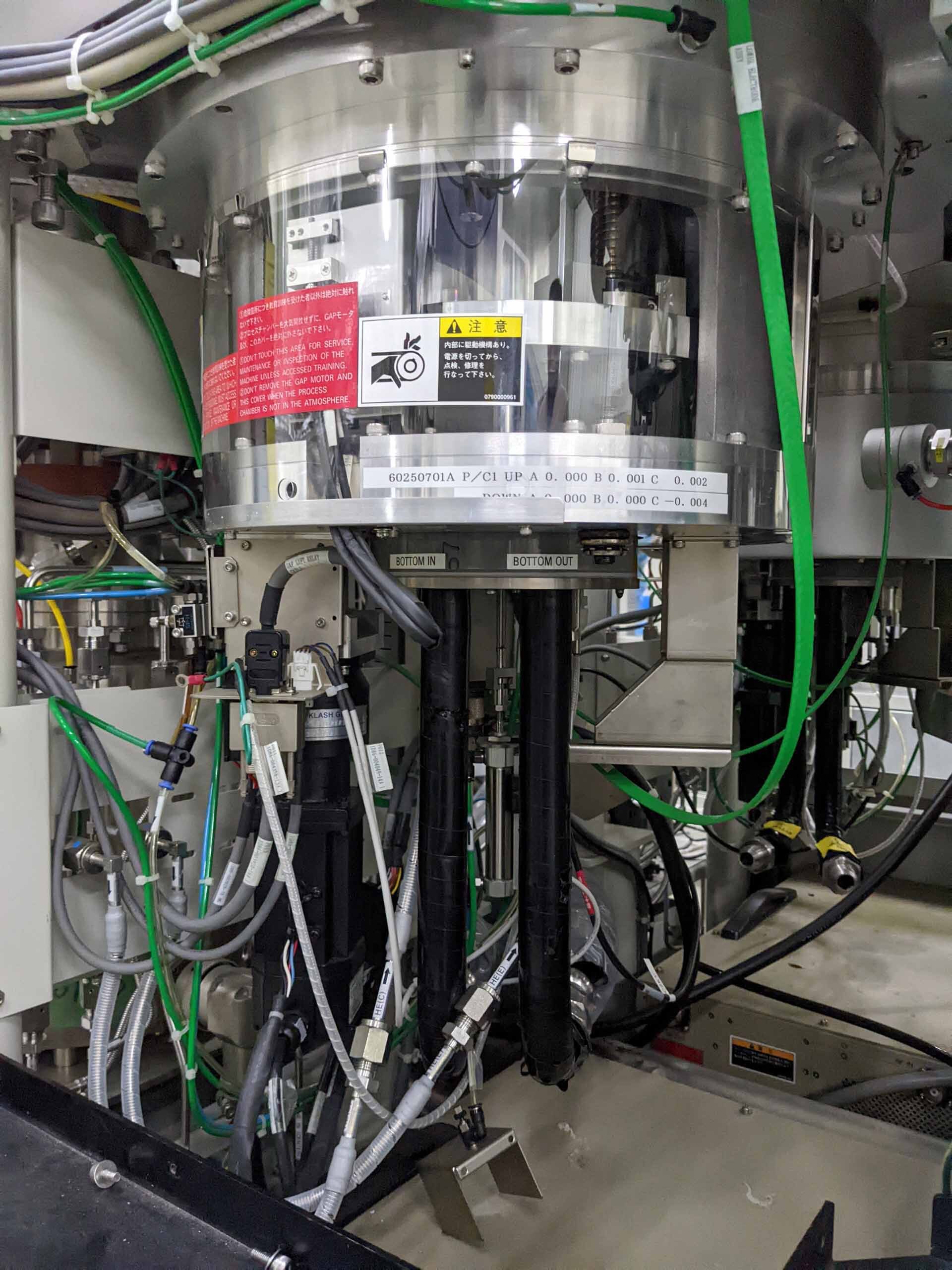

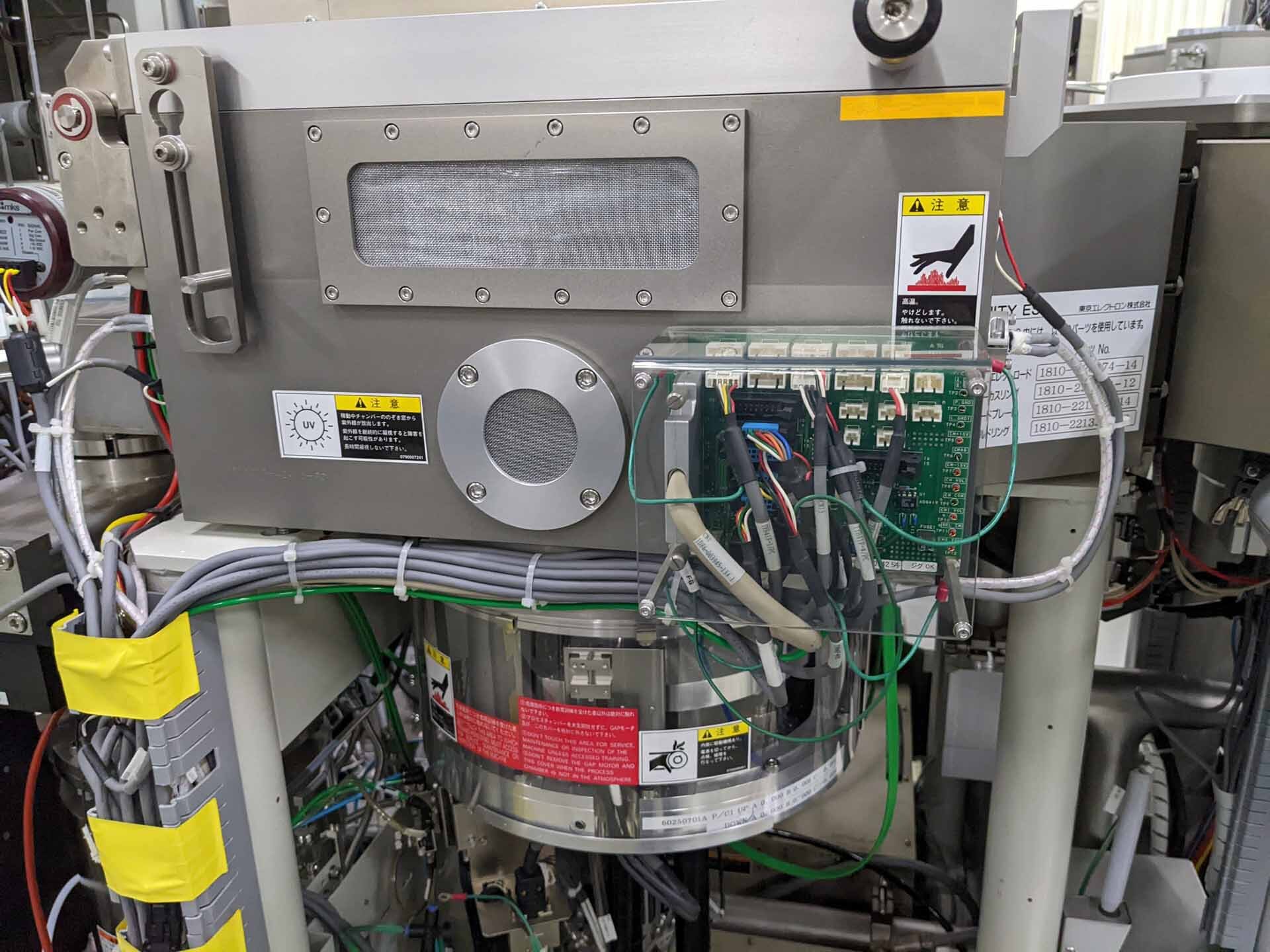

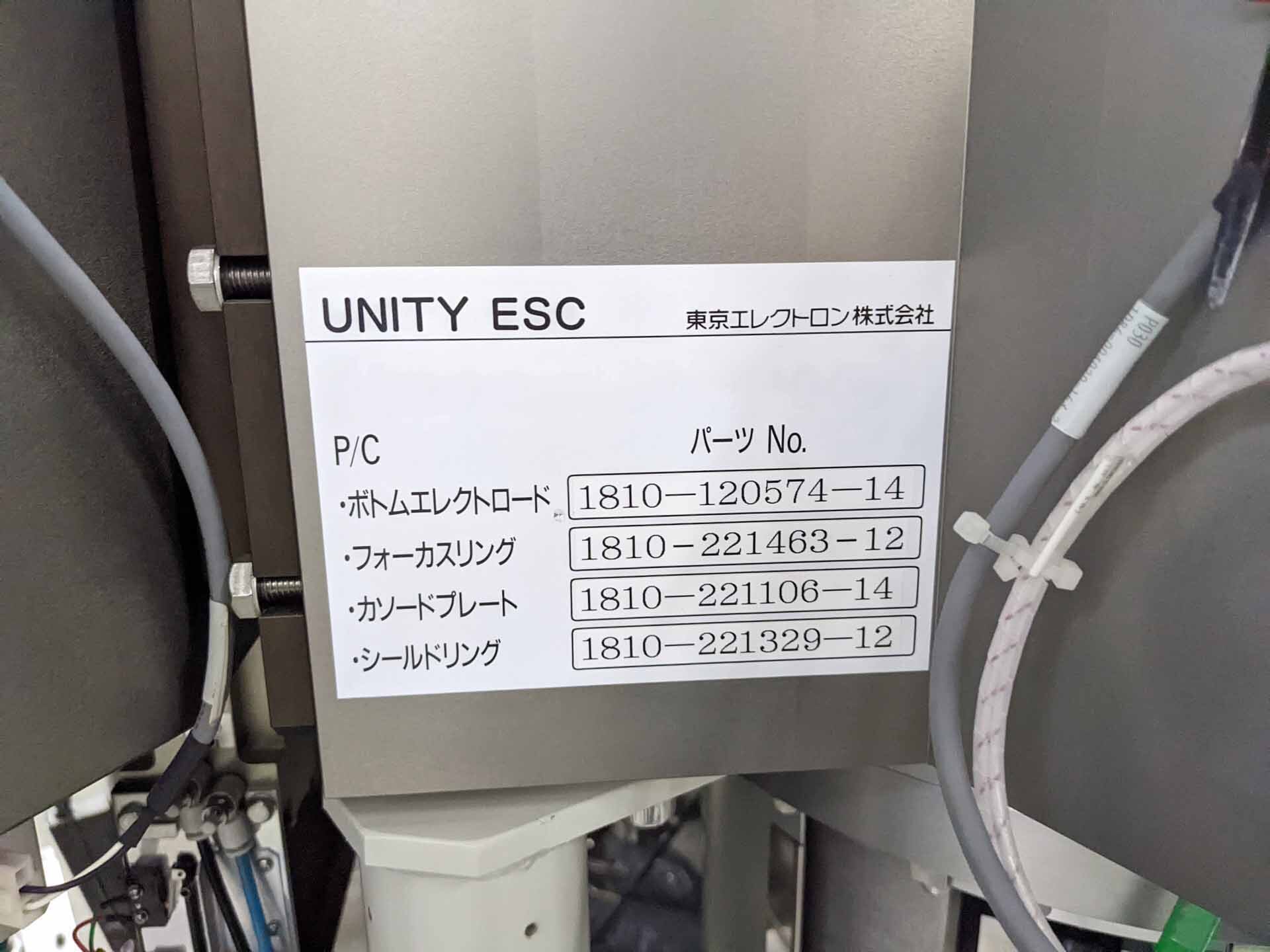

TEL / TOKYO ELECTRON Unity IIe 855DP is an advanced etcher/asher equipment designed for microelectronic device fabrication. The system has many advanced capabilities that set it apart from its competitors. It is designed for optimal efficiency and throughput by integrating an adjustable wafer lift with a process control unit that allows automatic adjustments to optimize film growth homogeneity. The machine also has a large chamber size, which offers more flexibility and workspace for processing larger wafers. TEL Unity IIe 855DP has a unique dual-frequency etching process, allowing it to etch at both high and low frequencies, eliminating the need for multiple etchers. This feature ensures complete etch uniformity on different wafer sizes while also allowing a higher throughput. Additionally, the tool's software is versatile and can accommodate custom recipes depending on the application. TOKYO ELECTRON UNITY IIE 855 DP is capable of etching high-quality films at fast processing speeds. It can etch films up to 8" in diameter and 8" in thickness in as little as 3.5 minutes per wafer. The asset is also compatible with numerous process gases, such as CF4, CHF3, SF6, Ar/N2, and He/N2, allowing it to etch different materials. It also has high current design (up to 500A) and a precise matching network to help reduce high frequency noise in the film. The model also includes a variety of sensors, such as an eddy current sensor, an ion gauge, a dual pressure ionization chamber, and a digital capacitance EV equipment to measure dose feedback from the etching process. This allows for accurate etching conditions and improves uniformity on wafers. TEL / TOKYO ELECTRON UNITY IIE 855 DP also has two built-in process end monitors to provide precise control of film deposition and etch depths. Unity IIe 855DP etcher/asher has been designed for maximum performance and accuracy for etching and ashing microelectronic devices. Its dual-frequency etching process, high current design, large chamber size, and variety of sensors make it well suited for a wide range of etching and ashing applications. Its fast etching cycle time and compatibility with many process gases make it an ideal choice for high-throughput device fabrication.

There are no reviews yet