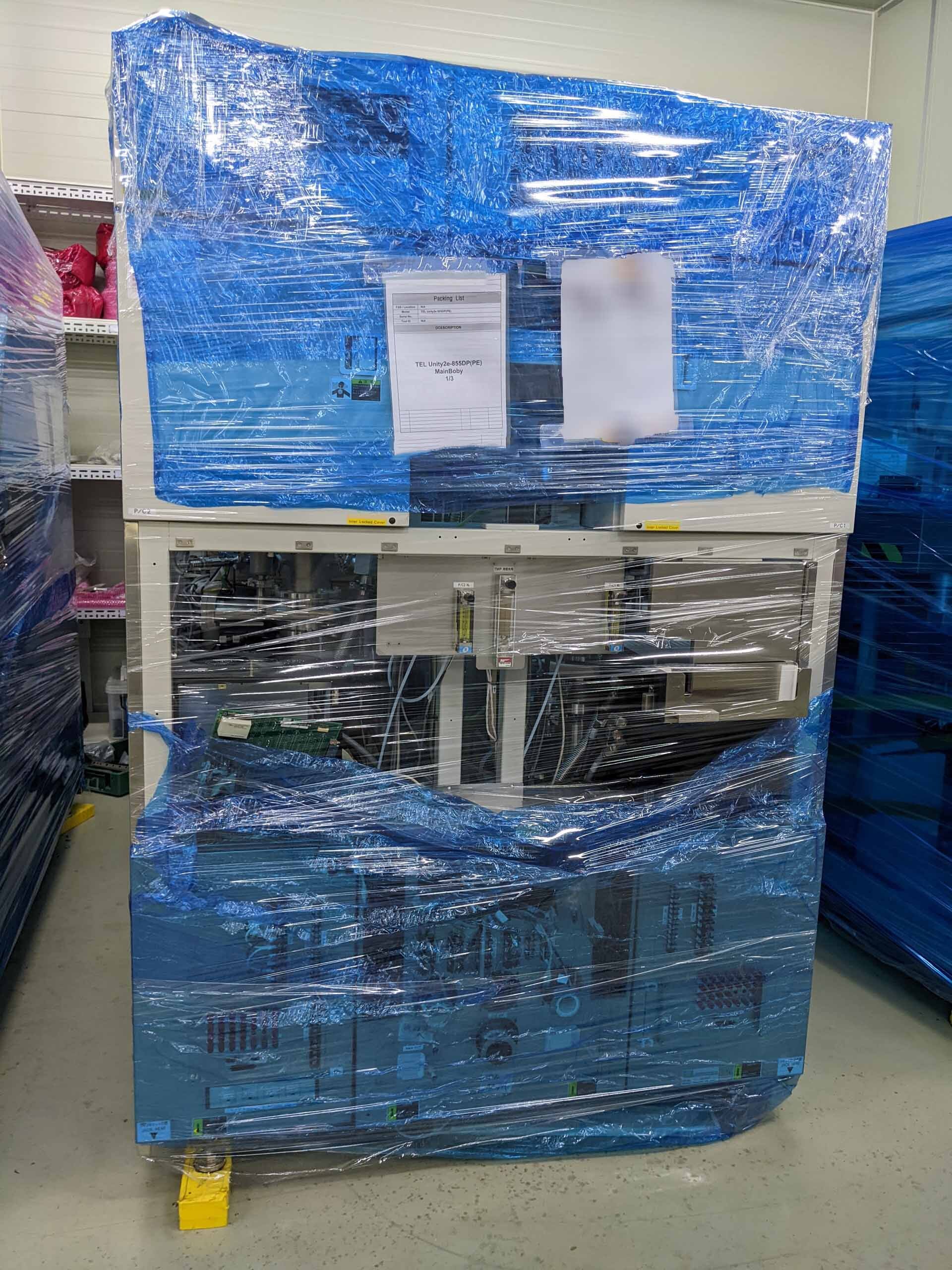

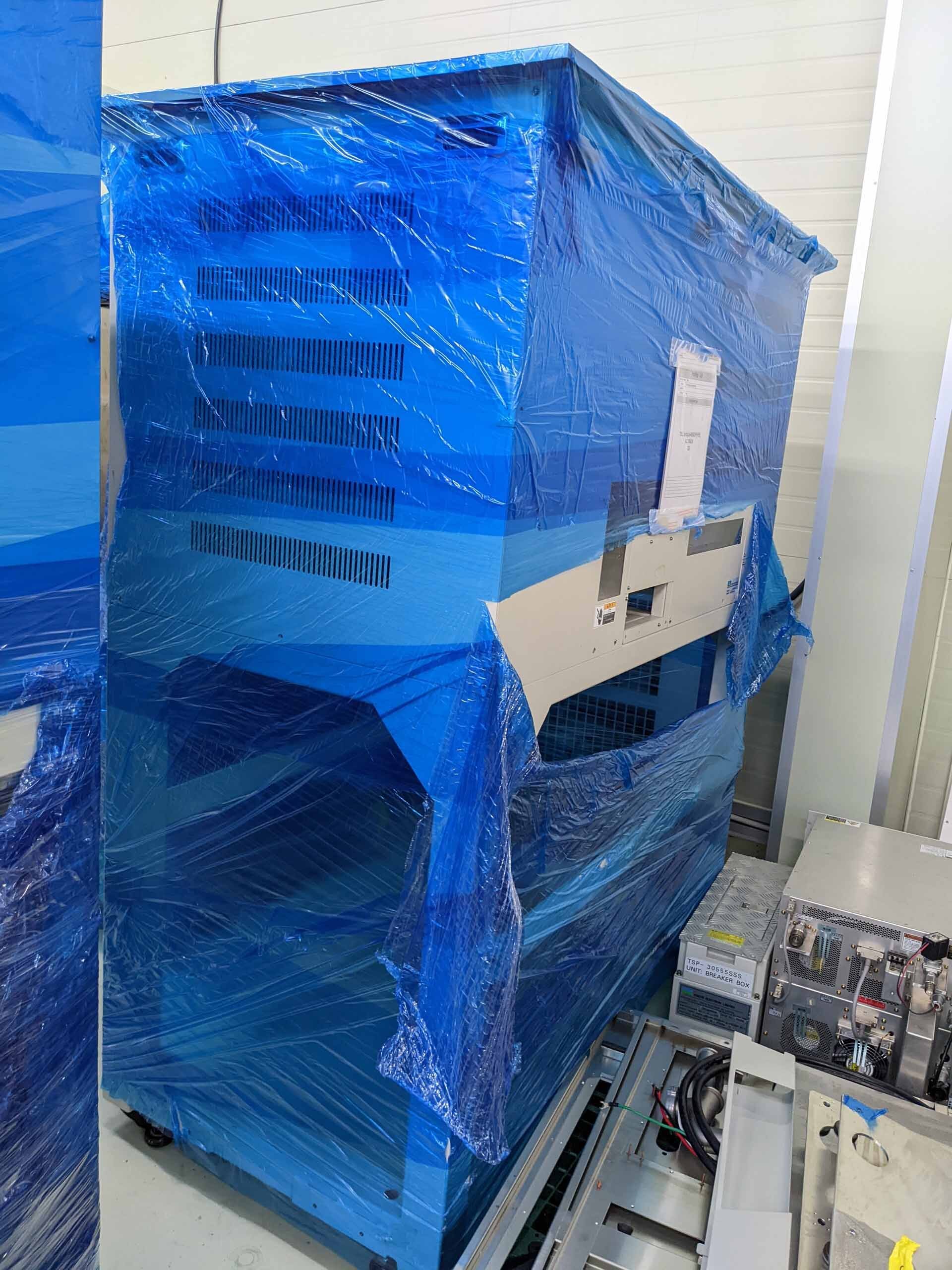

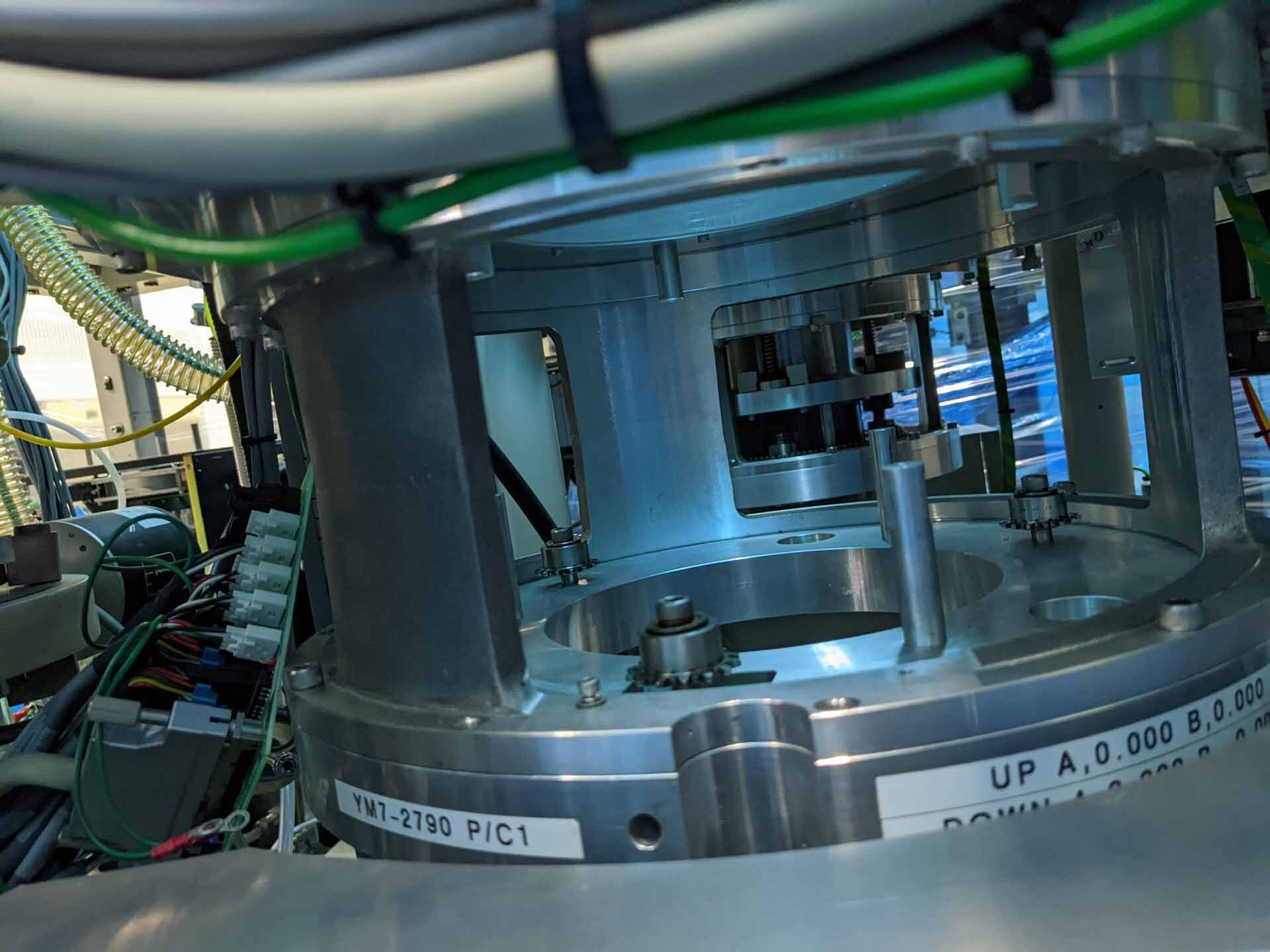

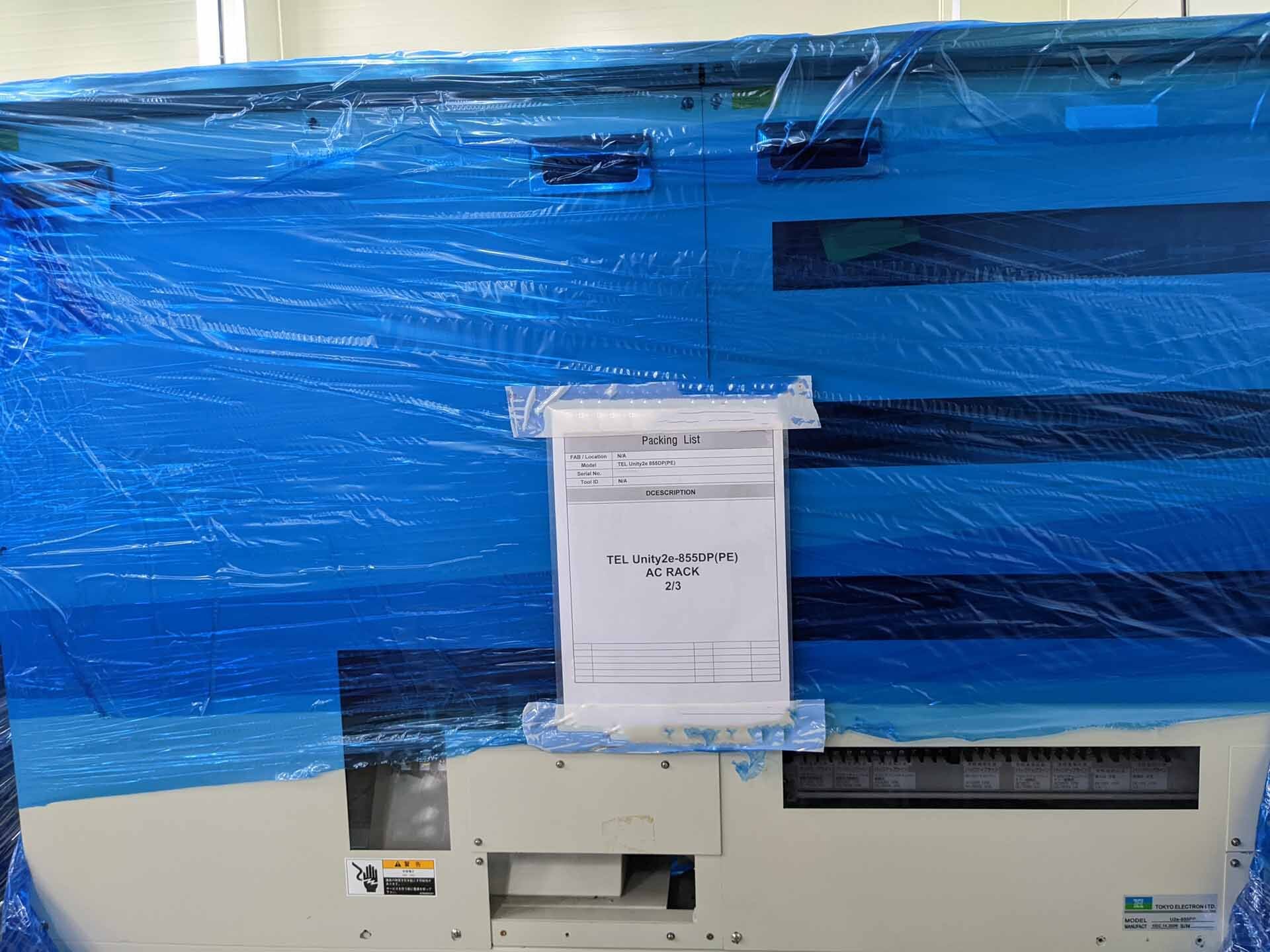

Used TEL / TOKYO ELECTRON Unity IIe 855DP #293646577 for sale

URL successfully copied!

Tap to zoom

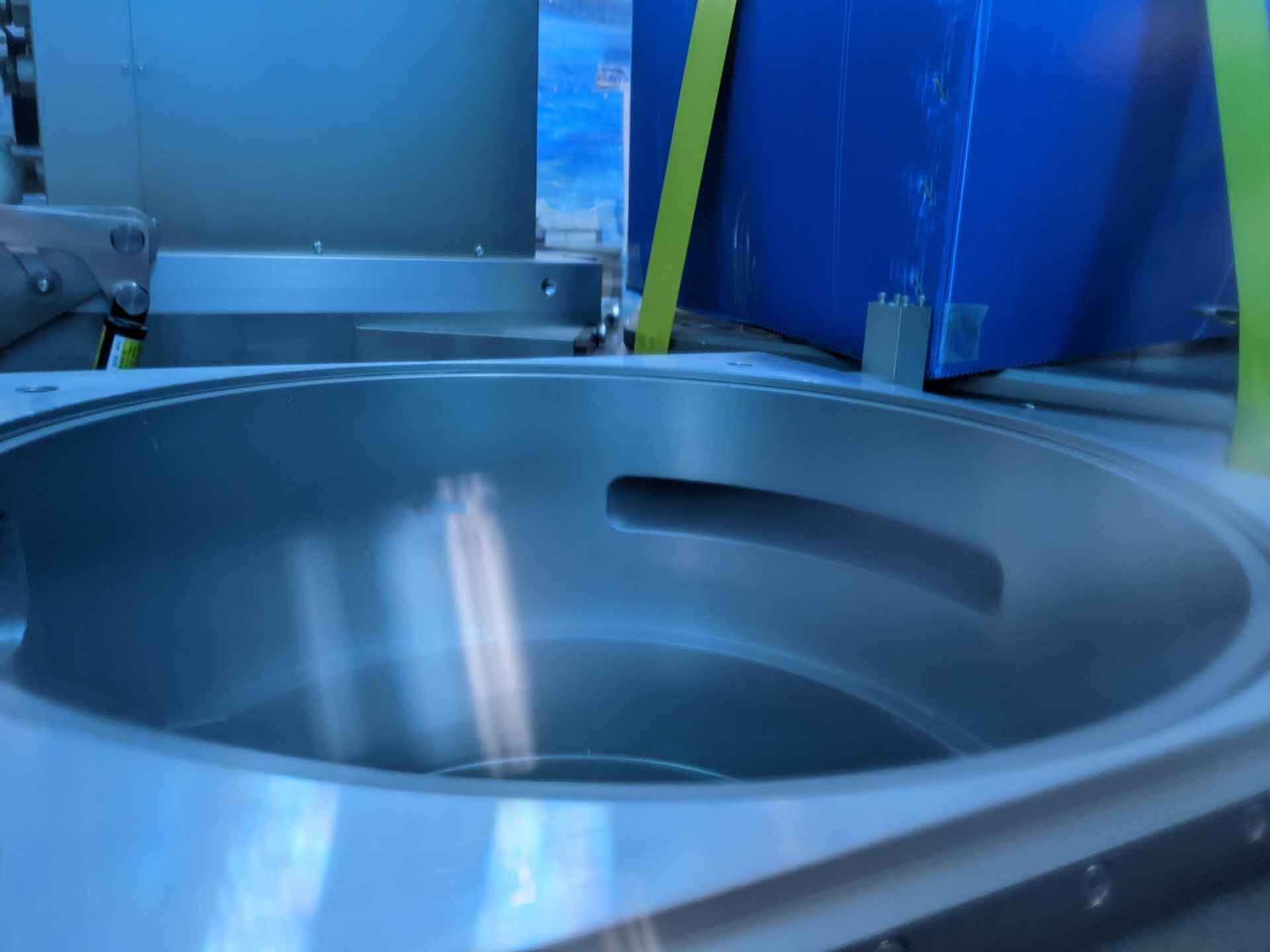

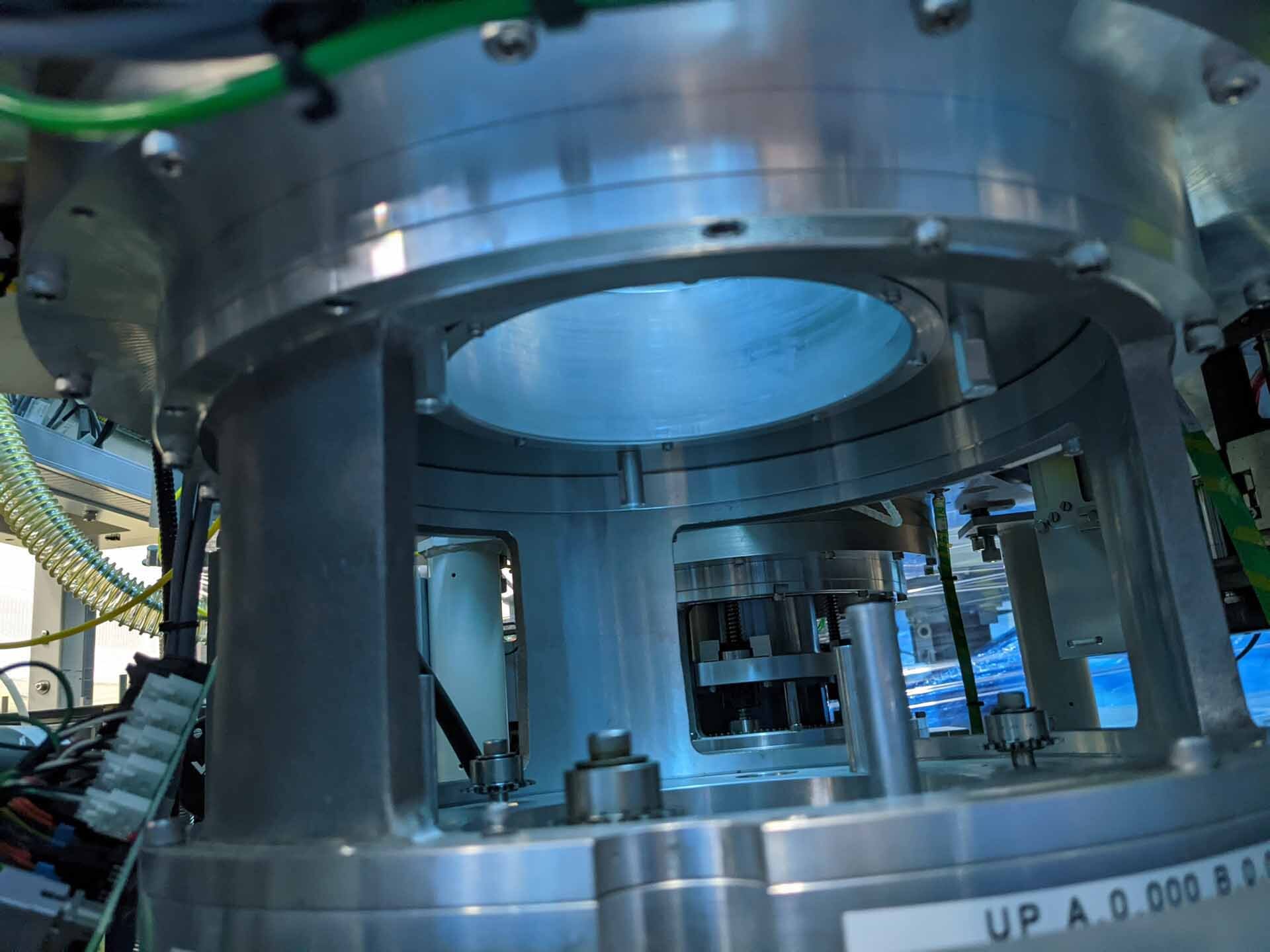

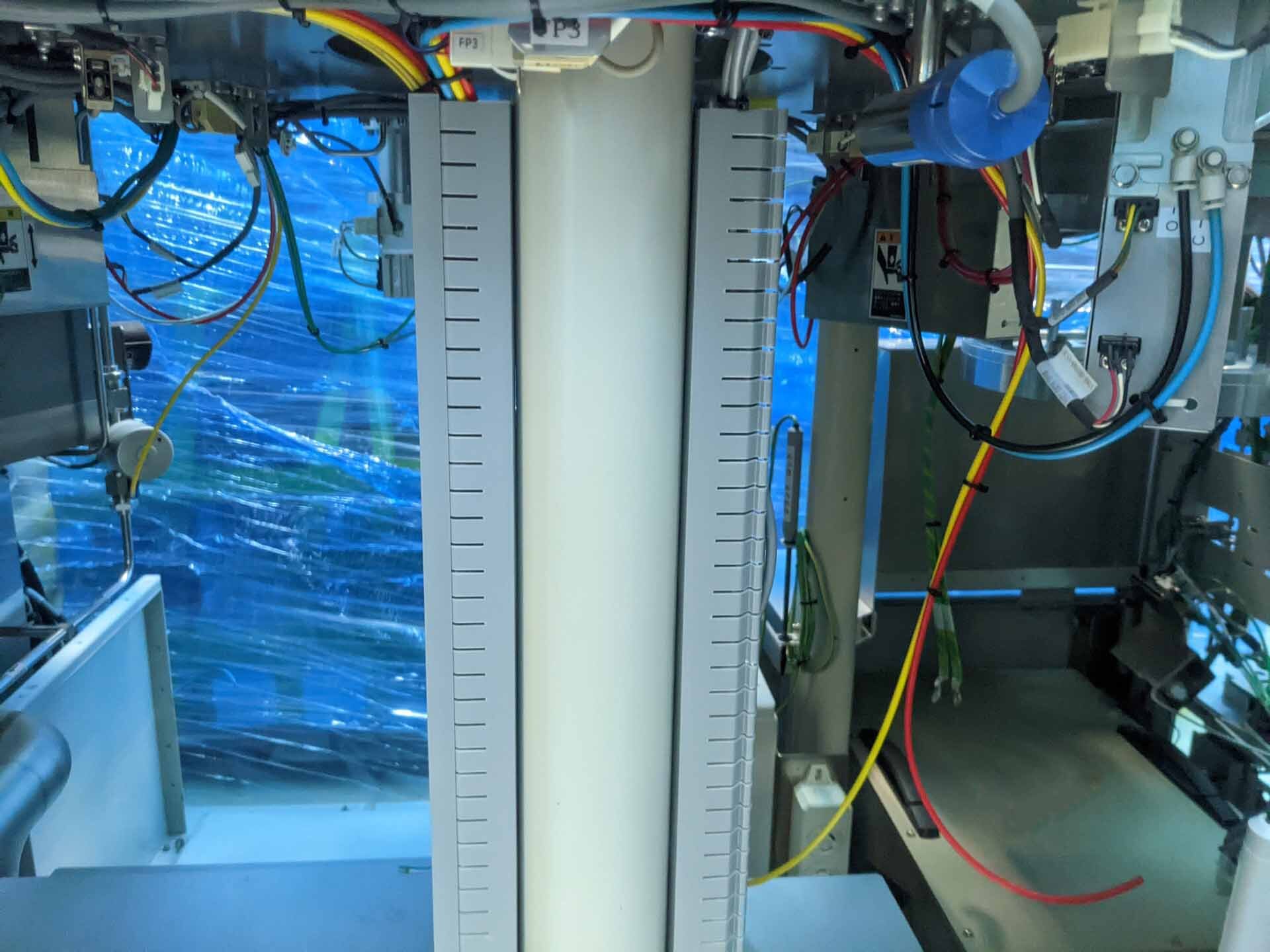

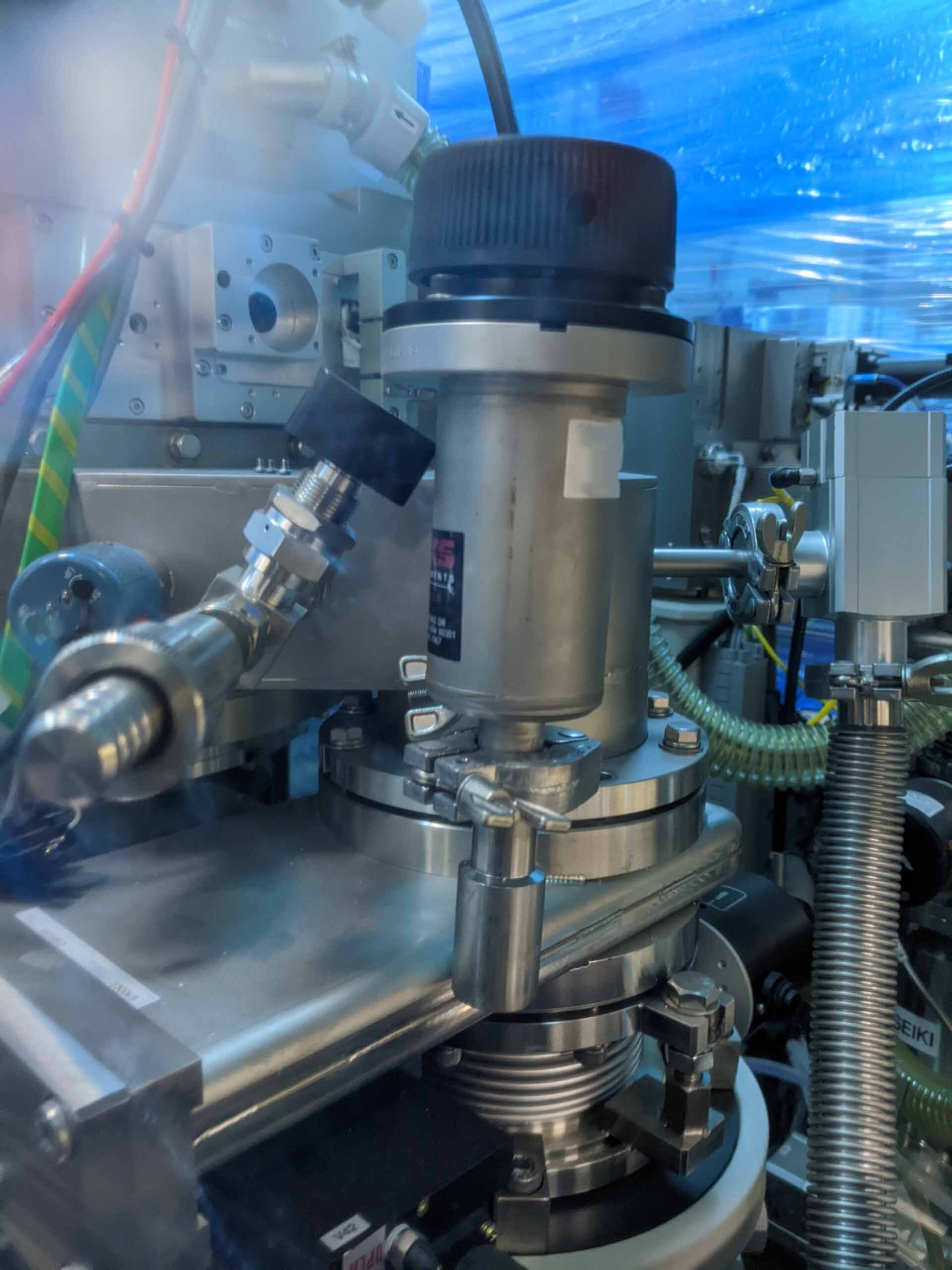

TEL / TOKYO ELECTRON Unity IIe 855DP is an etcher/asher. It is an advanced wet etcher/asher equipment designed for semiconductor process applications requiring high etch and clean capabilities. This system is used in the fabrication of microelectronic and photonic devices, like displays and chips, where precise etching of material is essential. The unit is equipped with an integrated hydro-mechanical sweep pulse, which uses both sedimentation and drag forces to move the wafers on the platen surface. This allows for efficient material removal and substrate flatness over the entire etch cycle. Additionally, the integrated Cooled Gas Distribution Machine, CGD, keeps all of the process chamber components from reaching unsafe temperatures. This ensures that the tool can be operated in a safe and controlled manner at all times. TEL Unity IIe 855DP has advanced etch and clean capabilities. It is equipped with a pulsed etch process which uses both argon and chlorine to etch designs and patterns on the substrate, while an internal video monitor ensures the precise etching of these patterns. Additionally, the asset allows for the use of media such as plasma and RCA cleaners to remove any residues that are left on the substrate during the etching process. The model is designed to operate at high speeds, with a maximum throughput of up to 16 wafer synch/sec. It is also equipped with a number of temperature control, pulse and cycle time, as well as a vacuum cassette and cassette swap functions. This allows for reliable and repeatable results, even in the most challenging of etch and clean applications. Additionally, the equipment has a web-based control and monitoring software which allows for remote management and data collection. Overall, TOKYO ELECTRON UNITY IIE 855 DP is a versatile and precise etcher/asher. It is equipped with an array of features that allow it to attain high etch and clean capability, while providing precise control over the entire process. This makes it an essential tool in the fabrication of microelectronic and photonic devices.

There are no reviews yet