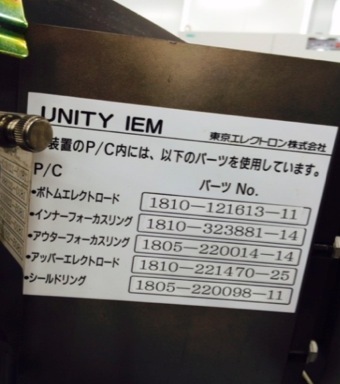

Used TEL / TOKYO ELECTRON Unity IIe 855II #9071931 for sale

URL successfully copied!

Tap to zoom

ID: 9071931

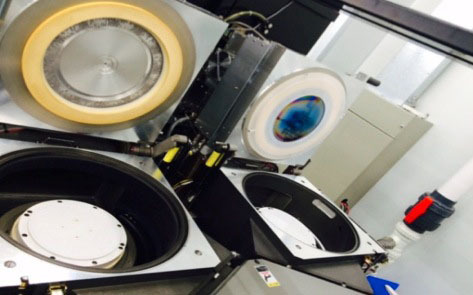

Wafer Size: 8"

Vintage: 1999

Oxide etcher, 8"

(2) Chambers

Wafer type: flat-zone

Rack type: V1 rack

Processing type: vacuum

Wafer loading type: normal

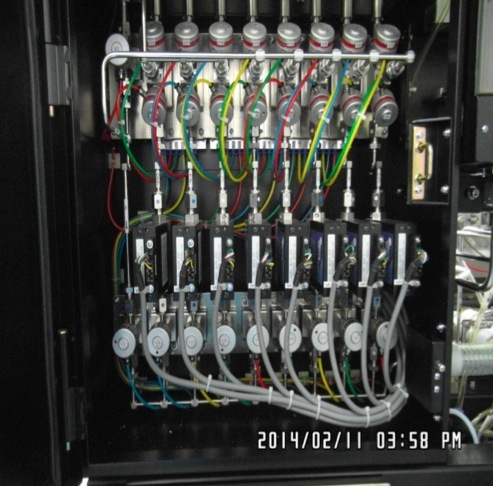

MFC:

GAS #1 C4F8 50

GAS #2 Ar 1000

GAS #3 SF6 100

GAS #4 CHF3 100

GAS #5 O2 20

GAS #6 CF4 200

GAS #7 PN2 100

GAS #8 CO 200

APC: VAT 61146-PH02-ABM1

Gauges:

Baratron CELERITY CDLD0112E 0~1TORR

Baratron TYRAN GENERAL CDL0112E 0~1TORR

Baratron MKS 622A01TDE 1PA

Convectron G/PHILLIPS 275203

TMP MITSUBISHI E-0776

TMP Controller MITSUBISHI FT-1200W

Robot YASKAWA VS2E

Robot Controller YASKAWA SRC-Ⅱ013

Generator PERAL LT-2000-800K; PERAL RP-3000-27M

6.Matcher PERAL M-30AW2VD-27M; PERAL M-20A2LS-V2

1999 vintage.

TEL / TOKYO ELECTRON Unity IIe 855II is an etching/ashing machine used in a wide variety of industries. It is a powerful, energy efficient tool designed to etch/ash a variety of substrates quickly and precisely. It features a robust design and advanced process technologies for etching/ashing processes. TEL UNITYIIE-855 II is capable of processing two-dimensional (2D) and three-dimensional (3D) structures in silicon (Si), indium phosphide (InP), gallium arsenide (GaAs), electrical substrates, and other precious materials. It is designed to create a uniform surface texture, and provide a high etching/ashing rate while maintaining end product the highest quality. TOKYO ELECTRON UNITY IIE 855 II boasts a wide range of process parameters, including pressure, time, temperature, and substrate thickness. It features a four-zones plasma source, flexible software control, and a quick start-up time. The easy to use and precise control offered by the machine allows for the reliable and repeatable etching/ashing of the substrates. TEL UNITY IIE 855 II is designed for maximum efficiency and integrates with a wide variety of tools and systems. The machine is capable of handling multiple wafers, and can be used with a number of specialty tools to support various etching/ashing process requirements. It is also compatible with other TEL/TOKYO equipment, such as wafer handlers, top-mount furnaces, and FOUP loaders, to create a complete and efficient system. TEL / TOKYO ELECTRON UNITY IIE 855 II is an industry leading etching/ashing machine designed to provide high quality results with a wide range of parameters and equipment. With its robust and varied capabilities, it is an ideal choice for the processing of a variety of materials with high precision, precision, and repeatability.

There are no reviews yet