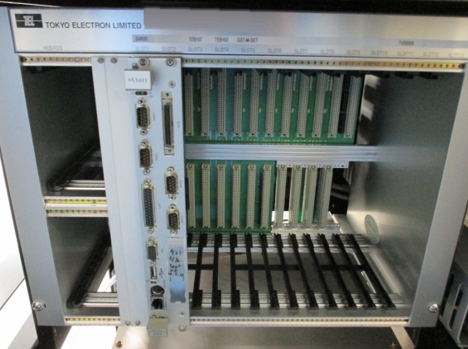

Used TEL / TOKYO ELECTRON Unity IIe 855SS #9033646 for sale

URL successfully copied!

Tap to zoom

ID: 9033646

Wafer Size: 8"

Vintage: 2004

Oxide etcher, 8"

Flat-zone wafer type

(2) Chambers

Mass flow controller

GAS #1 C5F8 20

GAS #2 C4F8 20

GAS #3 CF4 100

GAS #4 CHF3 50

GAS #5 CH2F2 50

GAS #6 AR 1,000

GAS #7 O2 50

GAS #8 P-N2 500

Pressure controller

ISO V/V (PC1) VAT 65048-JH52

ISO V/V (PC2) VAT 65048-JH52

Gauge

Baratron MKS 627B-15405

Baratron MKS 627B-15405

Robot YASKAWA VS2C

Robot controller YASKAWA SRC-Ⅱ016

TMP (PC1) EDWARDS STP-A2203W1

TMP Controller (PC1) EDWARDS STP-A2203W1

TMP (PC2) EDWARDS STP-A2203W1

TMP Controller (PC2) EDWARDS STP-A2203W1

Generator (PC1) DAIHEN WGA-30C

Generator (PC2) DAIHEN WGA-30C

Matcher (PC1) DAIHEN AMN-30C11

Matcher Controller (PC1)

Matcher (PC2) DAIHEN AMN-30C11

Matcher Controller (PC2)

EPD (PC1)

EPD (PC2)

T/C TMP Controller

AC RACK (PCB BOARD):

SVA031

Not included:

TEB107

TEB162

GST-M-SET

TVB0008

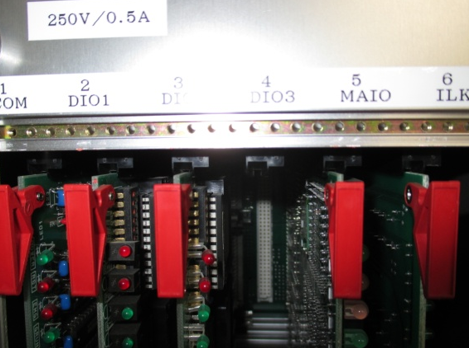

TC(PCB BOARD)

COM

DIO1

DIO2

DIO3: Not included

MAIO

ILK

PC1 (PCB BOARD):

APC

DIO

MAIO

EPD

COM

TEMP

PC2 (PCB BOARD):

APC: Not included

DIO

MAIO

EPD

COM

TEMP

2004 vintage.

TEL / TOKYO ELECTRON Unity IIe 855SS is a next-generation single wafer plasma etching tool that provides superior performance and improved process capability. It features an advanced plasma source that optimizes process uniformity and delivers precise gas control with no erosion of components. TEL UNITYIIE-855 SS has a patented low-temperature-diffusion plasma source that delivers excellent performance with maximum throughput, and excellent precision control of the reactive species. TOKYO ELECTRON UNITY IIE-855SS features a high-precision wafer stage capable of reaching temperatures as low as -60°C. This stage provides an enhanced deposition process that is ideal for creating surfaces with desired properties. The wafer stage is driven by a state-of-the-art motor and stepper coil equipment that ensures an accurate and uniform distribution of energy. The PC-controlled production system also includes a sophisticated diagnostics unit that provides real-time monitoring of the etching process and can alert the user if an issue arises. TEL / TOKYO ELECTRON UNITY IIE-855SS is also equipped with a fully integrated machine that eliminates mechanical transfere of particles and contaminants between wafers and the vacuum chamber. This comprehensive tool ensures the highest levels of cleanness and process repeatability. Additionally, TEL / TOKYO ELECTRON UNITY II E 855SS supports the use of a wide range of chambers configurations, including chemical vapor deposition (CVD) and reactive ion etching (RIE) chambers for etching processes. TEL UNITY IIE 855 SS also has an energy-efficient design and is capable of running at faster speeds while consuming less power than other etching tools. Its advanced control software allows for unattended operation and automated recipes that facilitate loading and unloading wafers, as well as an integrated online tracking asset that provides information on production data, calibration history, and performance. Overall, TEL UNITY IIE-855SS is a high-performance etching tool that provides superior process capabilities and improved cost savings. Its advanced technology, energy-efficient design, and comprehensive control model make it a reliable and efficient option for etching applications.

There are no reviews yet