Used TEL / TOKYO ELECTRON Unity IIe 855SS #9042813 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9042813

Wafer Size: 8"

Vintage: 2001

Oxide etcher, 8"

(2) Process chambers

Wafer type: flat

Signal tower: (3) lamps, (2) sides (front and back)

chamber type: Unity SCCM 2

Wafer handling type: vacuum load / unload station

Robot arm type: anodized aluminum

Wafer clamp type: ESC

ESC type: ceramic

EPD: both chambers

EPD type: EPD 30X

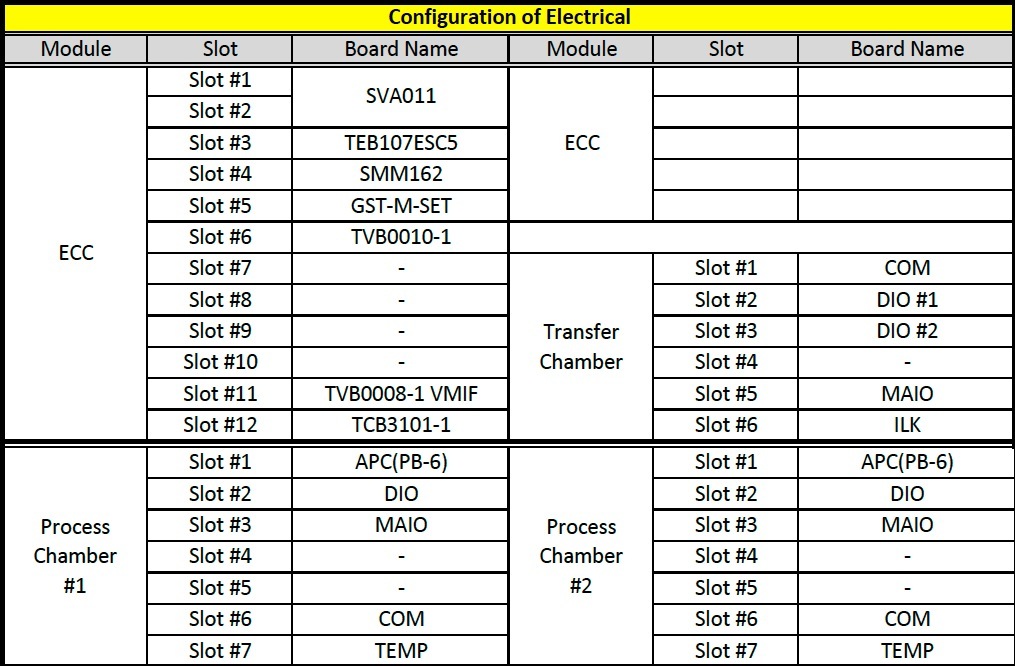

Transfer chamber configuration:

C/C1 Pressure switch: Leybold PS 113 16014

C/C2 Pressure switch: Leybold PS 113 16014

T/C Convactron: Phillips 275203

T/C CM: MKS 6220 A01 TDE, 1 Pa capacity

PCV Unit: STEC SV-P1000

DC power supply: SANKEN MLT-DCBOX5

Transfer robot: YASKAWA VS2C

RC/ELC1: YASKAWA SRC-II 015

RPA/ELC2: YAWKAWA SRC-II 016

Wafer alignment: YASKAWA VOSJ

2001 vintage.

TEL / TOKYO ELECTRON Unity IIe 855SS is an etcher/asher, designed for photolithography processes. It is semi-automated and offers advanced features in an easy-to-use design. TEL UNITYIIE-855 SS is constructed with a stainless steel tank with a built-in silicate bath, and a low dust collector to provide a clean work environment. It also has additional safety measures such as an emergency shut-off mechanism. The unit offers a chemical resistivity of up to 500 ohms, which helps angstrom-level processes remain stable throughout the etching process. TOKYO ELECTRON UNITY IIE-855SS has integrated diagnostics to make troubleshooting easier. The system is equipped with an intuitive graphical user interface (GUI) to facilitate the ease of use. The control system automatically monitors process parameters and can be easily adjusted to optimize recipes. The control system ensures repeatable, reliable results for each process. To ensure accuracy, TEL / TOKYO ELECTRON UNITYIIE-855 SS provides comprehensive process monitoring. The etcher/asher continuously monitors and provides feedback to the user during each of its processes. It can also provide data on each process, such as the temperature, pressure, and frequency of the process. The unit also offers advanced features such as the ability to save completed recipes, as well as the ability to program the unit's operations. TEL UNITY IIE-855SS offers a compact footprint and can process up to nine workstations. The etcher/asher is designed for both batch operation and single wafer operations. It has a wide range of fluids that can be used in an array of processes. It is highly programmable and can be used with a variety of etching and ashing equipment. UNITY IIE-855SS is a reliable, powerful etcher and asher unit. It offers advanced features to help ensure accuracy and repeatability while performing various processes. The etcher/asher is designed for ease of use and to provide customers with a clean work environment. It has comprehensive process monitoring capabilities and can provide detailed data on each of its processes. With its wide range of process capabilities, this product is well suited to those in need of a fast and efficient photolithography process.

There are no reviews yet