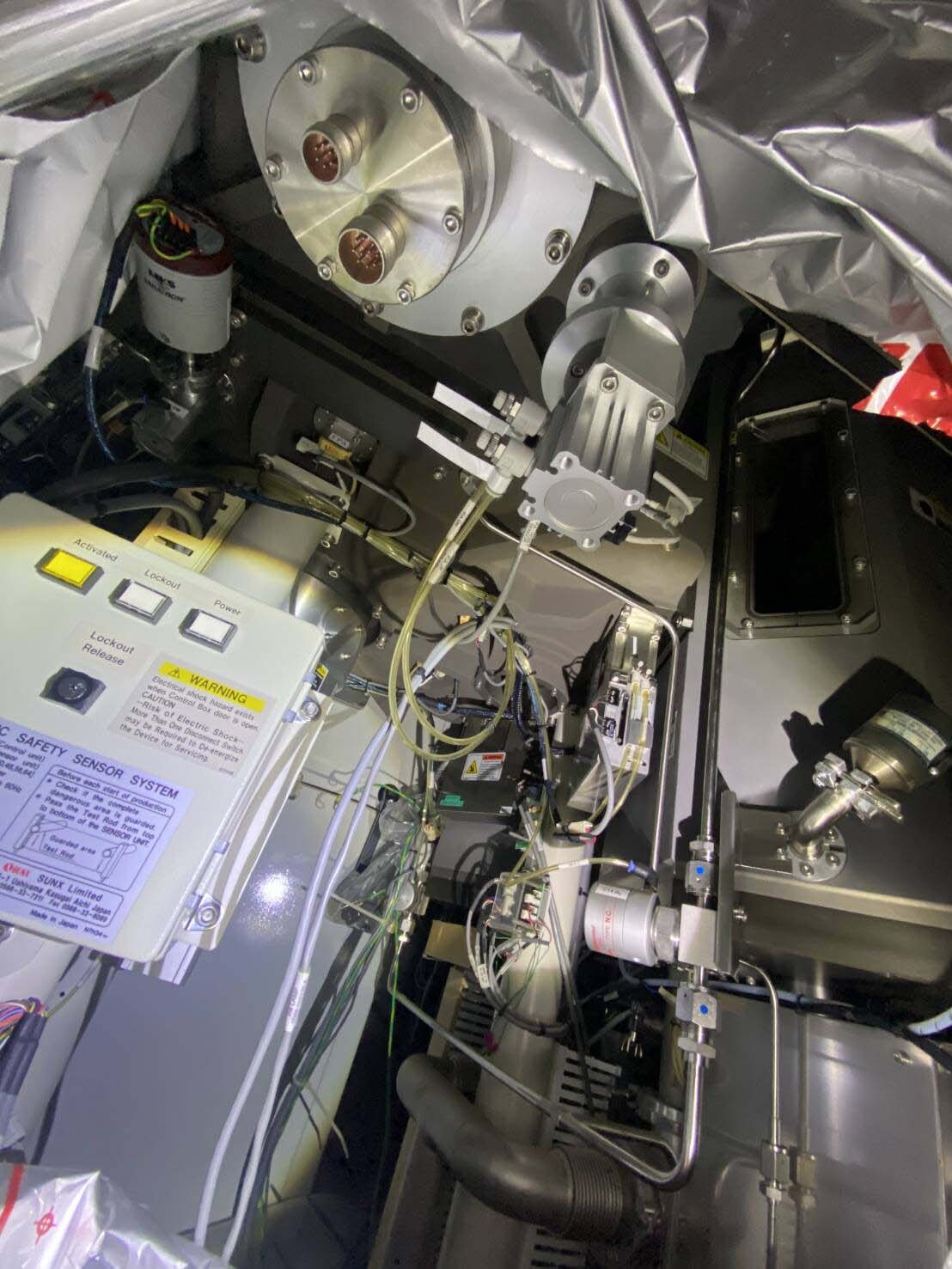

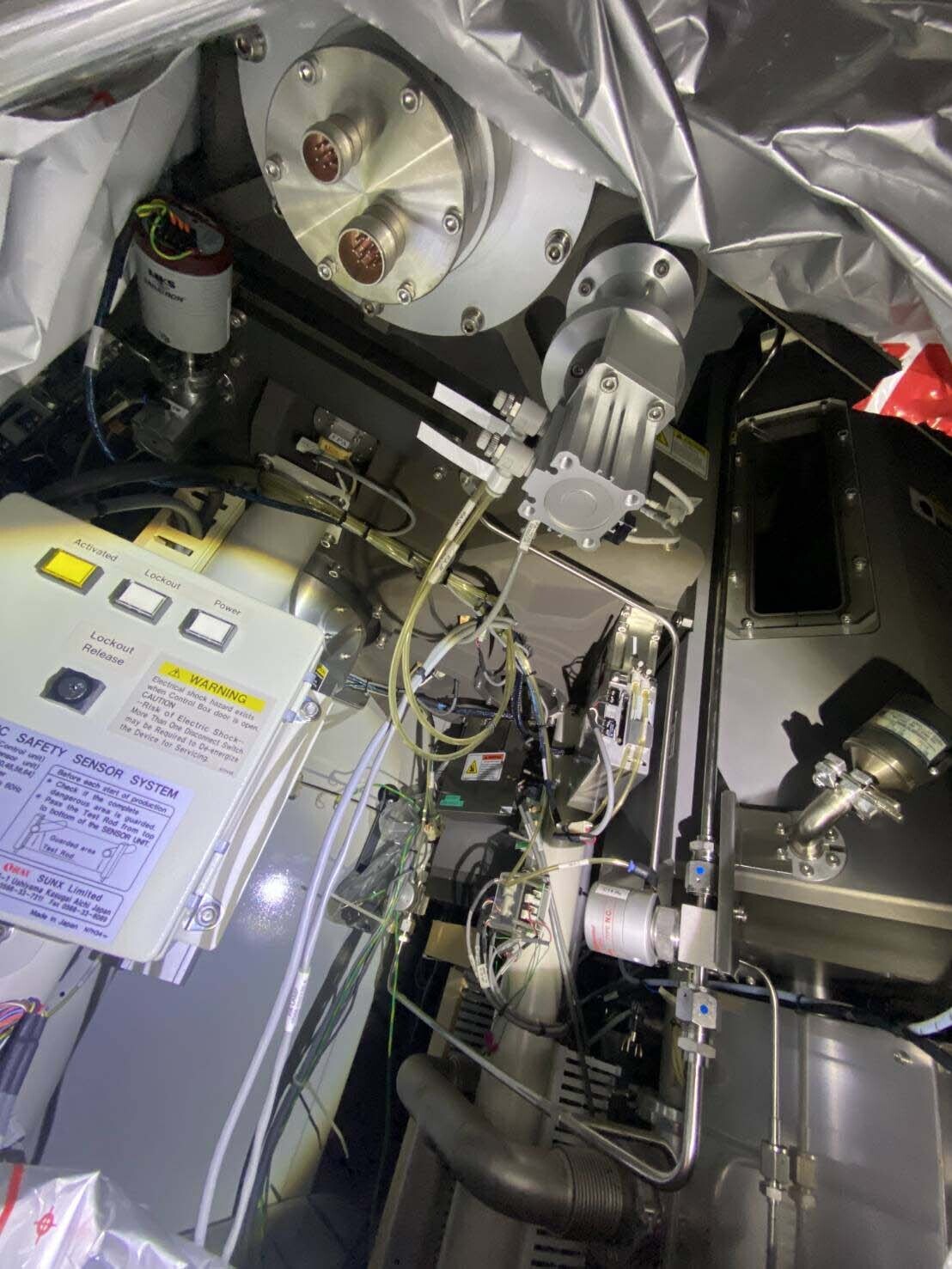

Used TEL / TOKYO ELECTRON Unity M #293654956 for sale

URL successfully copied!

Tap to zoom

ID: 293654956

Etcher, 8"

(3) DRM Chambers

V2 Rack

Transfer system:

Transfer chamber

Cassette chamber

Pre-alignment unit

Transfer robot

Chamber accessories:

Dipole ring magnet

Rotation speed

Pressure control system

He cooling system

Fixed gap cylinder

RF System:

ENI GHW25A RF Generator

Oscillating frequency: 13.56 MHz

Maximum output: 2500 W

ENI MWD-25LD-06 RF Match

Oscillating frequency: 13.56 MHz

Maximum output: 2500 W

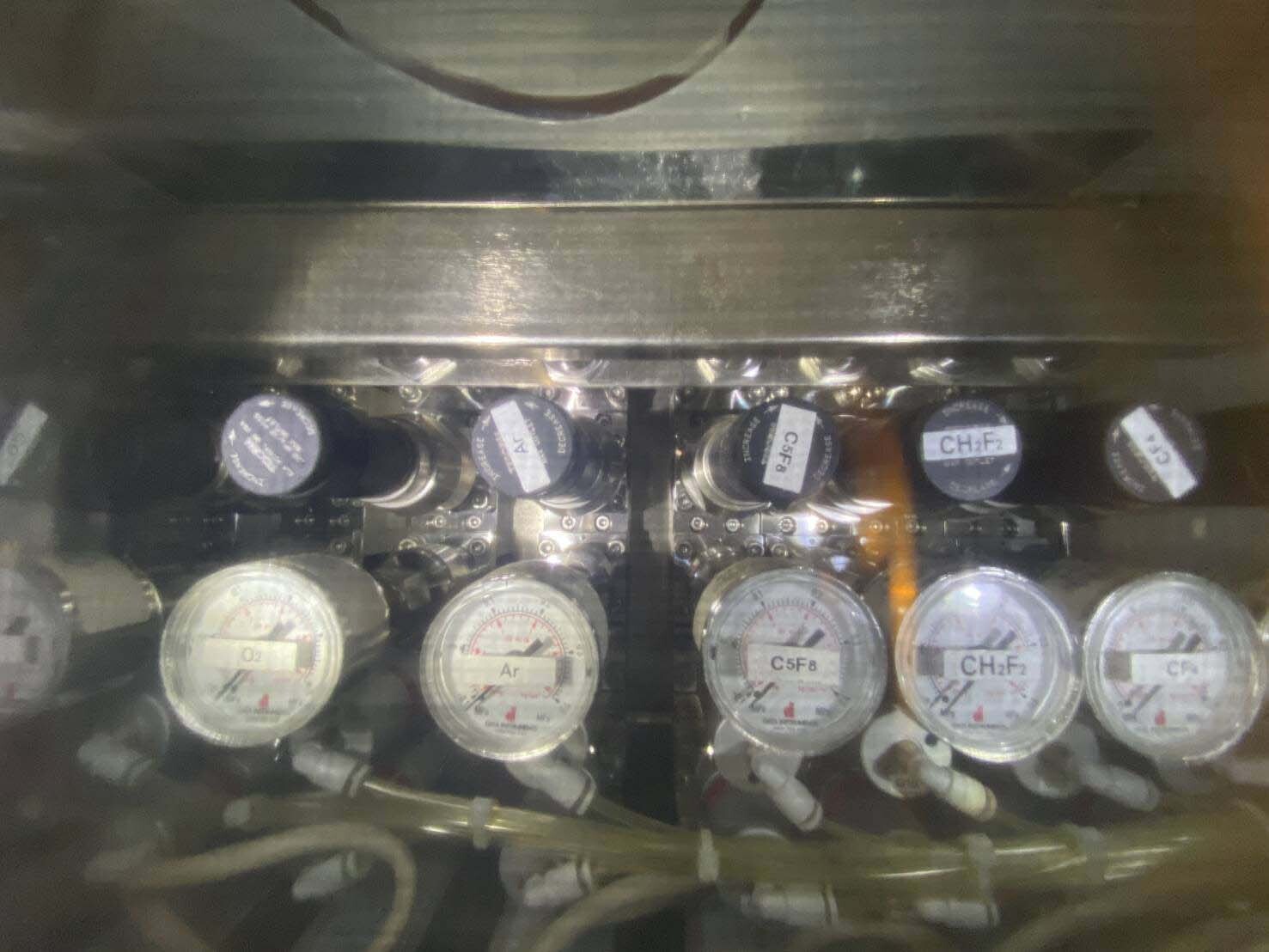

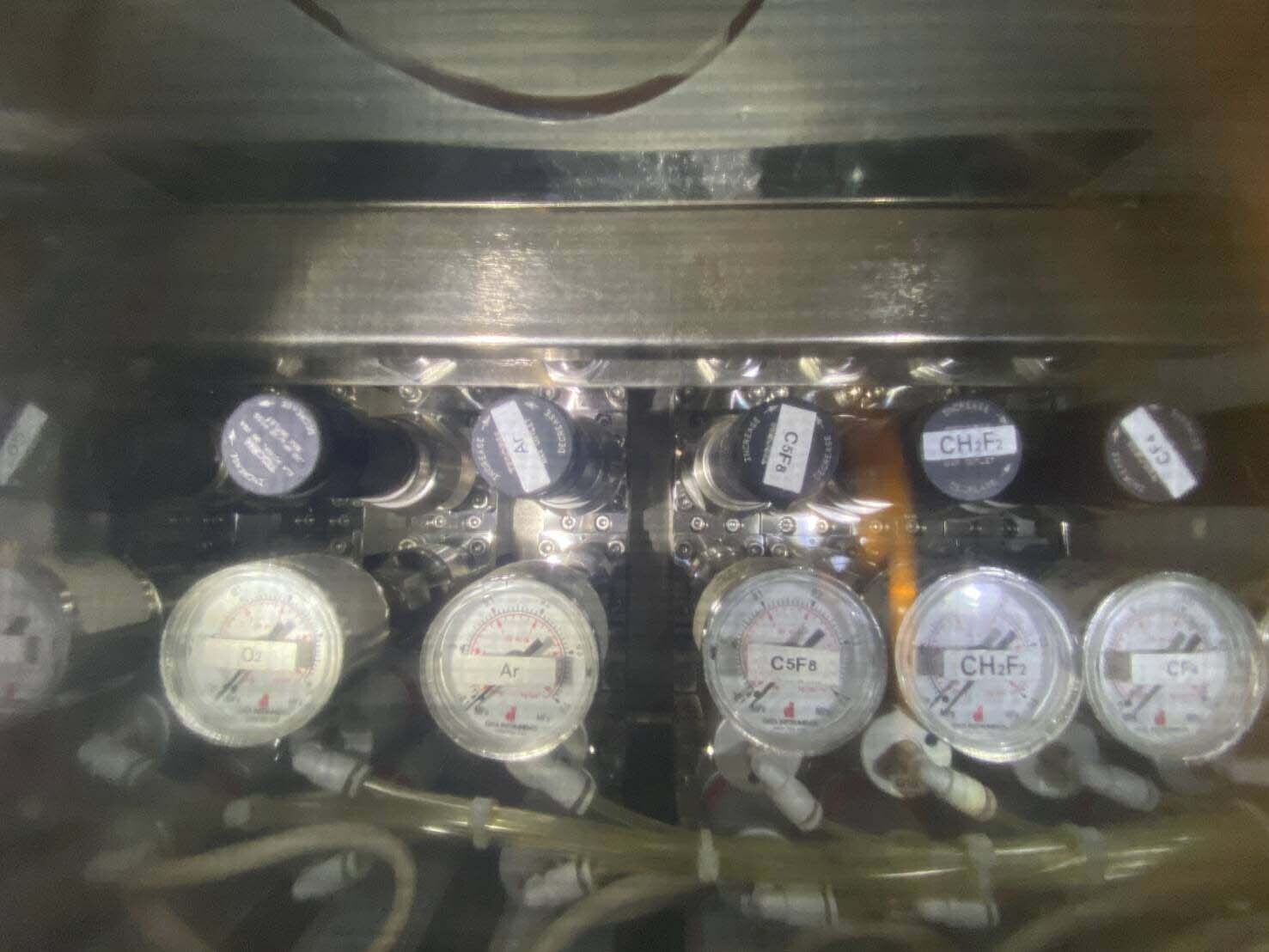

Gas delivery option:

SUS316L Piping

SUS Gasket

IGS Fitting

MEGA-MINI Valve

HORIBA SEC-Z512MGXC (IGS) Mass flow controller

End point system (302x):

Controller: 1x

Fibre: 1D80-005308-11

Lens: 1D80-004290-11

Remote:

10" Colour LCD display

Buzzer alarm

Lot end melody

AC Rack:

Machine on/off circuit

Interlock on/off circuit

EMG Off circuit

Hard disk: System HD, data HD

EDWARDS STP-A1303C Turbo pump for process chamber

EDWARDS STP-A1303C Turbo pump controller for process chamber

Power supply: 208 V ± 10%, 60 Hz.

TEL / TOKYO ELECTRON Unity M is a high-performance etching equipment ideal for use in a wide variety of industries. This system uses a microwave-based plasma etch to etch materials such as silicon wafers and other substrates with accuracy and speed. It is capable of handling multiple layers at once and can etch pieces up to a maximum of 200 mm in diameter. The unit can be used for batch processing, which allows for the rapid production of high-volume products. This etcher uses high-frequency radio signals generated inside the process chamber to create plasmas with a wide range of characteristics. This makes it possible to etch at high temperatures and with high throughput. The result is an etch that is clean and highly precise. In addition, the etcher includes a large substrate capacity for larger volume projects. TEL Unity M features a multi-chamber architecture, which allows for multiple layers of etching to be completed in parallel. This provides a high-speed and high-quality etch process. Furthermore, the machine can handle materials ranging from 4 to 200 microns in thickness and can etch at temperatures up to 1000°C. The process is also designed to be dynamically consistent between multiple tool components. This ensures uniform etching results even when using wafers of different materials and thicknesses. Other features of TOKYO ELECTRON UNITY-M include an easy-to-use touchscreen interface and a dedicated edge-exclusion chamber. This allows the user to create etches without edge exclusion and other artifacts. Furthermore, the asset can be equipped with an automatic quality monitor that allows the user to monitor the etch quality in real-time. This provides an additional level of control and quality assurance. Additionally, TOKYO ELECTRON Unity M is compatible with a wide range of substrates and materials as well as a variety of deposition processes. Overall, TEL UNITY-M is a powerful etching model ideal for any industry. The equipment's multi-chamber architecture allows for multiple layers of etching in parallel while the microwave-based plasma etch and dynamic consistency ensure the highest precision etching results. In addition, the system is designed for ease of use and includes features such as an intuitive touchscreen interface and an automatic quality monitor. As a result, UNITY-M is capable of rapid and precise etching and deposition processes.

There are no reviews yet