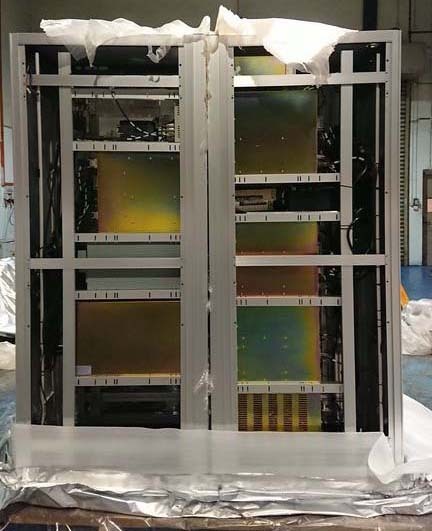

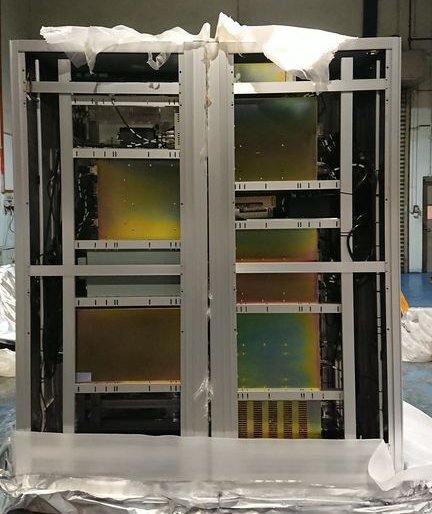

Used TEL / TOKYO ELECTRON Unity #9316187 for sale

URL successfully copied!

Tap to zoom

ID: 9316187

Metal CVD system, 8"

Process: TiN

Main body

Power supply

Power rack

EDWARDS TDV4 System

(2) Traps

Cable

Panel

Accessories.

TEL / TOKYO ELECTRON Unity is an etching/ development machine designed to produce fully-sealed wafers. This tool is used to pattern, etch, and deposit material for chemical-mechanical polishing. It is able to provide wafers with a flat surface that is suitable for creating advanced semiconductor devices. The machine is capable of producing high-resolution patterns, enabling the development of new devices. It supports both wet and dry etching, and its etching mechanism enables precise control of shape and thickness of the layers of material in the processed wafers. In addition, its large chamber enables highThrough-put. TEL Unity etcher is composed of a main etching chamber and a pre-etch chamber, which allow for multiple operations to be carried out in the same cycle. Inside the main chamber, ions are injected onto the substrate to etch it. The main chamber is also equipped with a movable robot arm, which is used to transfer substrate from one chamber to another, including the pre-etch chamber. The substrate is then loaded into the main chamber, where the etching process takes place. The etching process begins with the introduction of a gas mixture, such as CF4, into the etching chamber. The gas mixture is then ionized to break into ions, which are then directed onto the substrate. The ions react with the substrate to etch and shape it. The process can be controlled so that the etch depth and side-wall angle are precise. Once the etching is complete, the etching solution is flushed out of the main chamber. The wafer is then transferred to a post-etch chamber, which is used for downstream processes, such as chemical-mechanical polishing and resist strip. TOKYO ELECTRON Unity etcher is an ideal tool for semiconductor device development, as it provides precision etching capabilities and a highThrough-put. Its ability to produce precise and accurate patterns and types of layers make it an ideal choice for developing cutting-edge devices.

There are no reviews yet