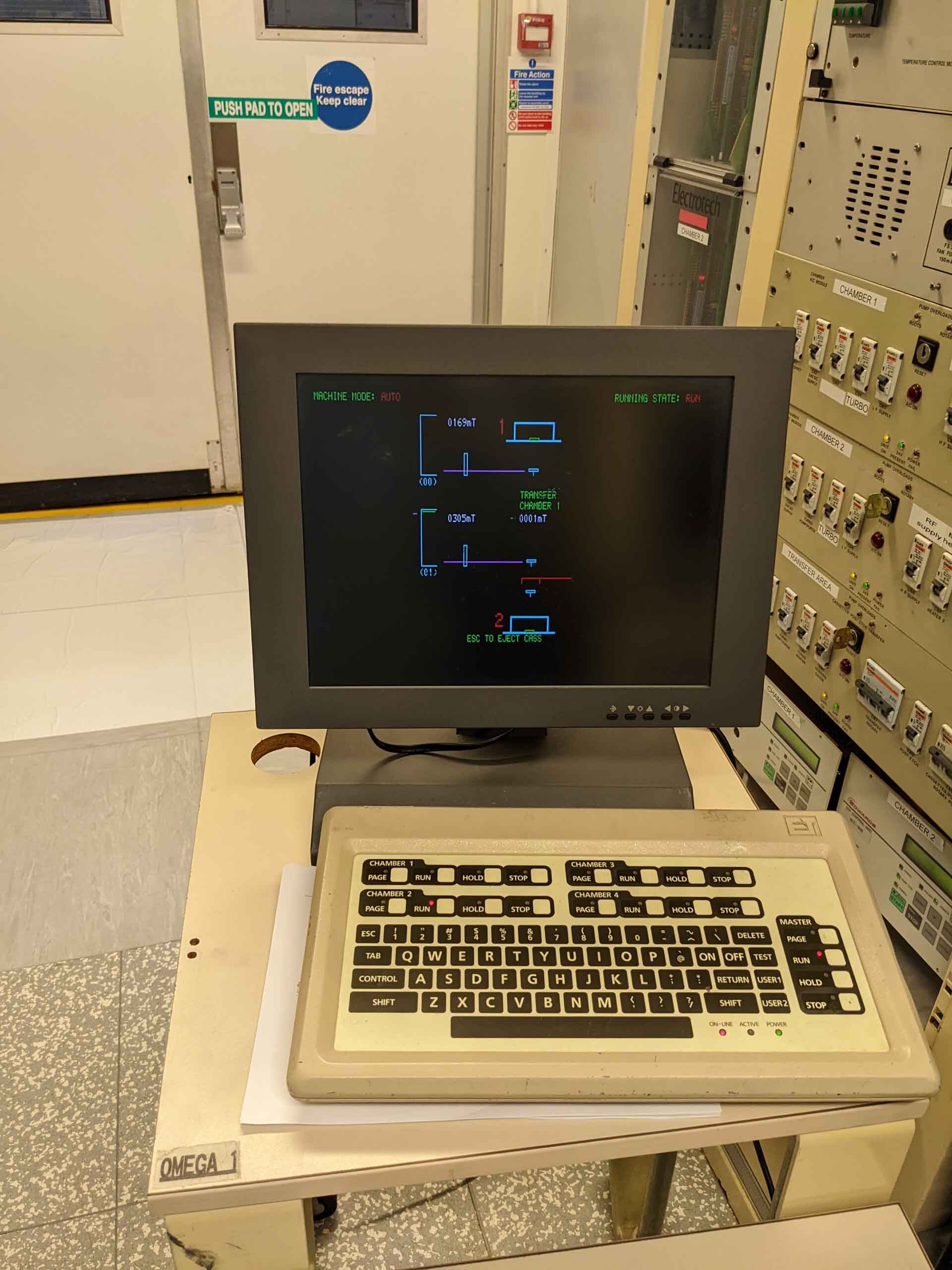

Used TRIKON / ELECTROTECH Omega II #293668338 for sale

URL successfully copied!

Tap to zoom

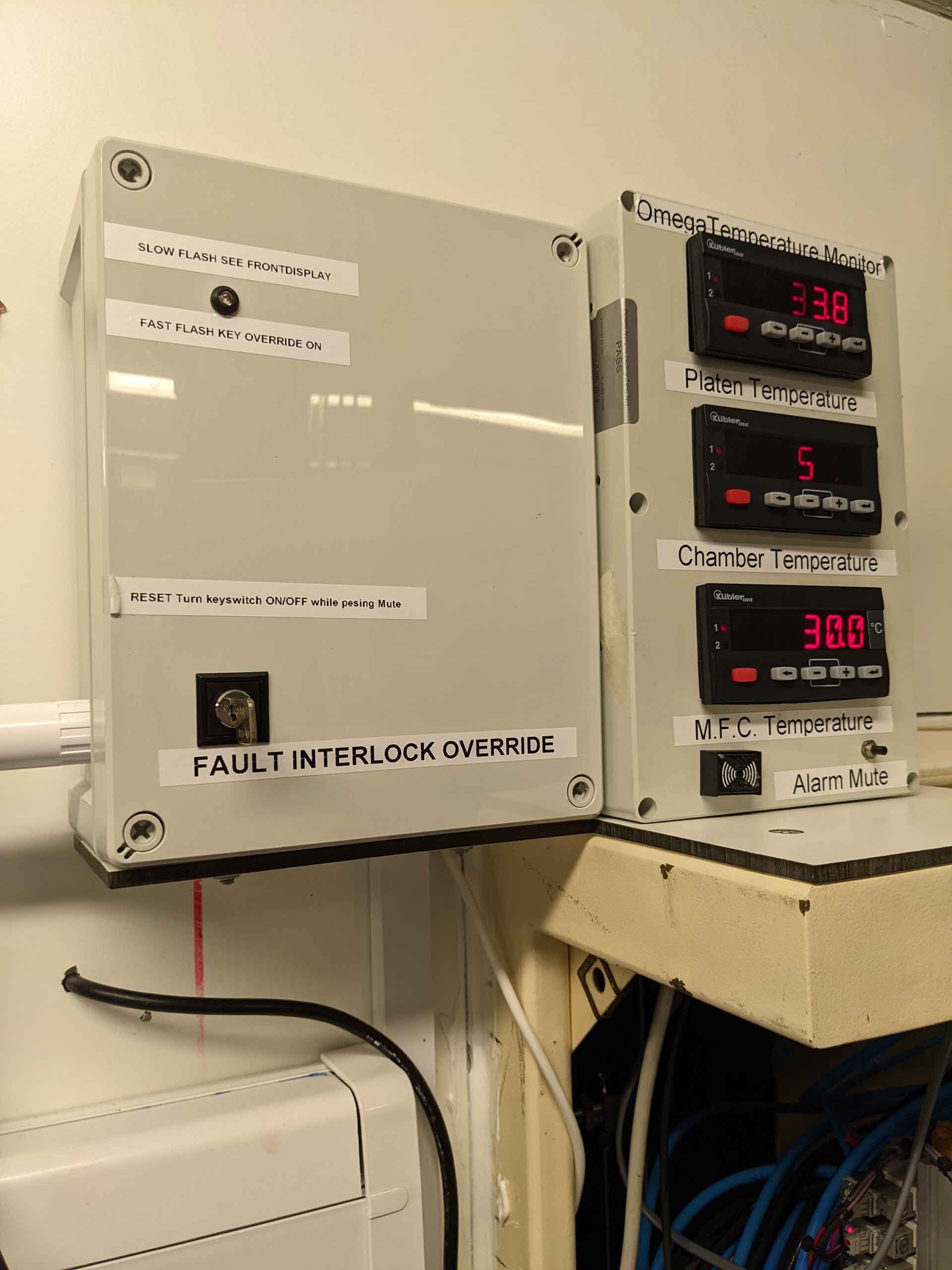

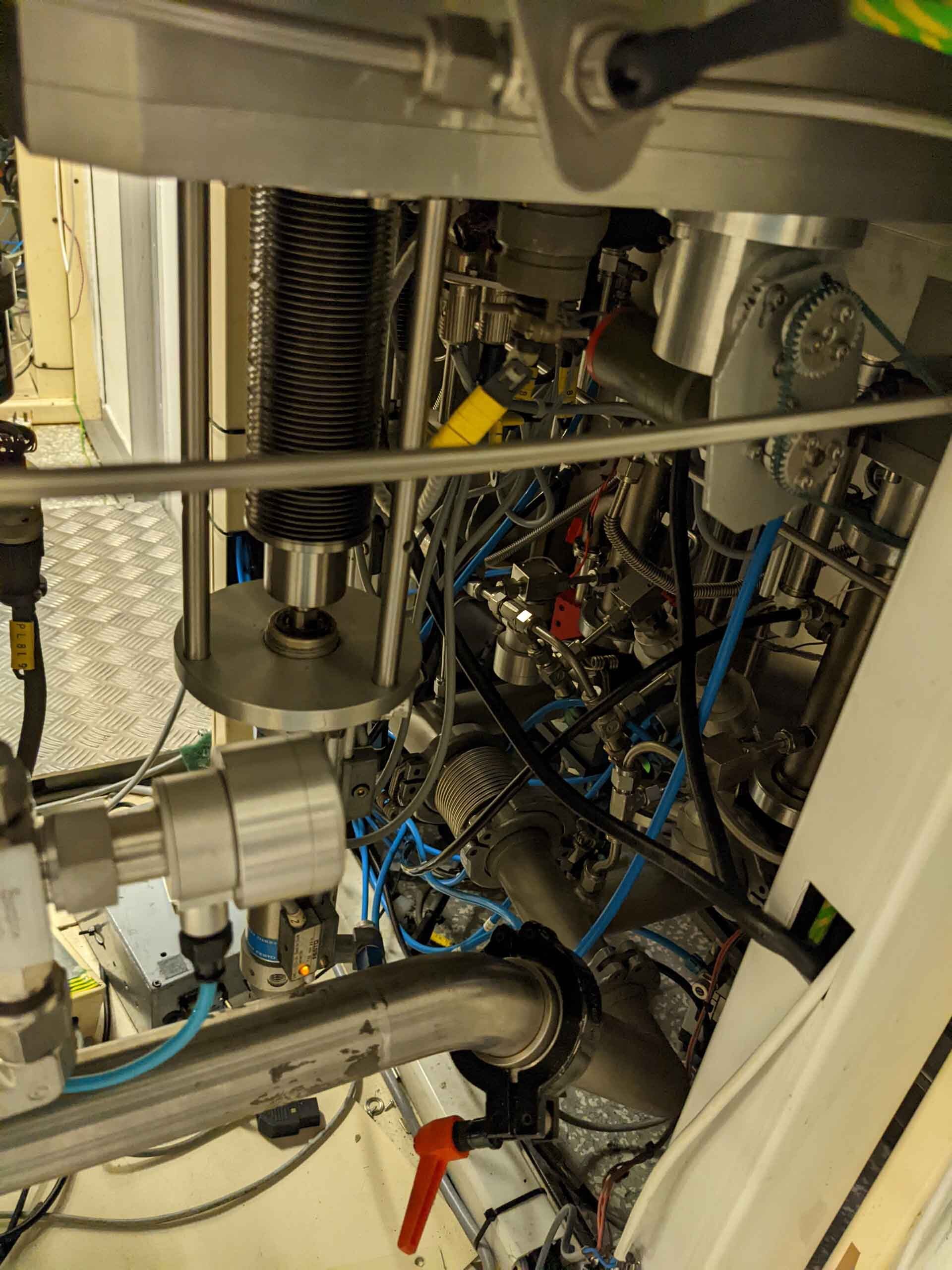

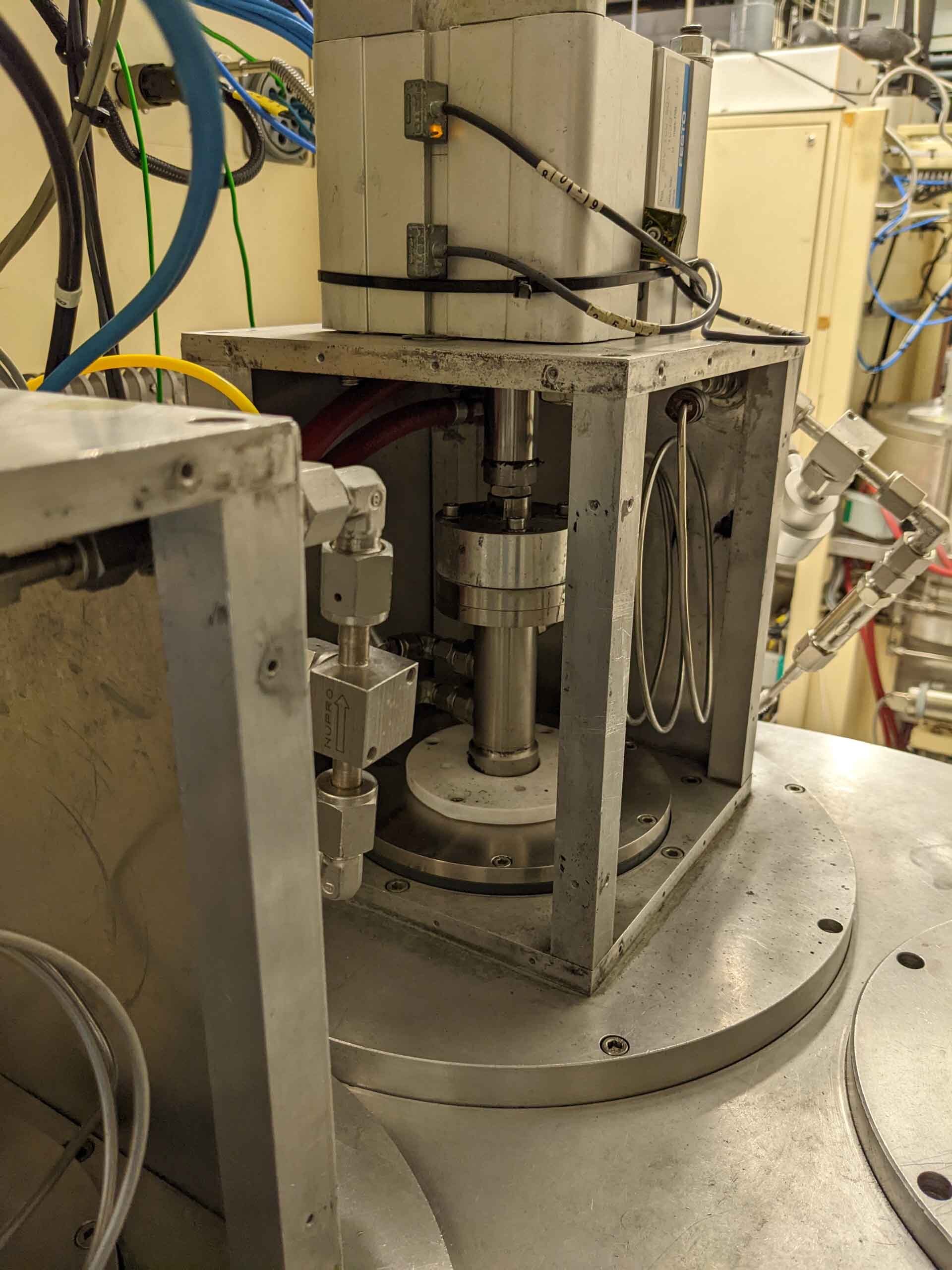

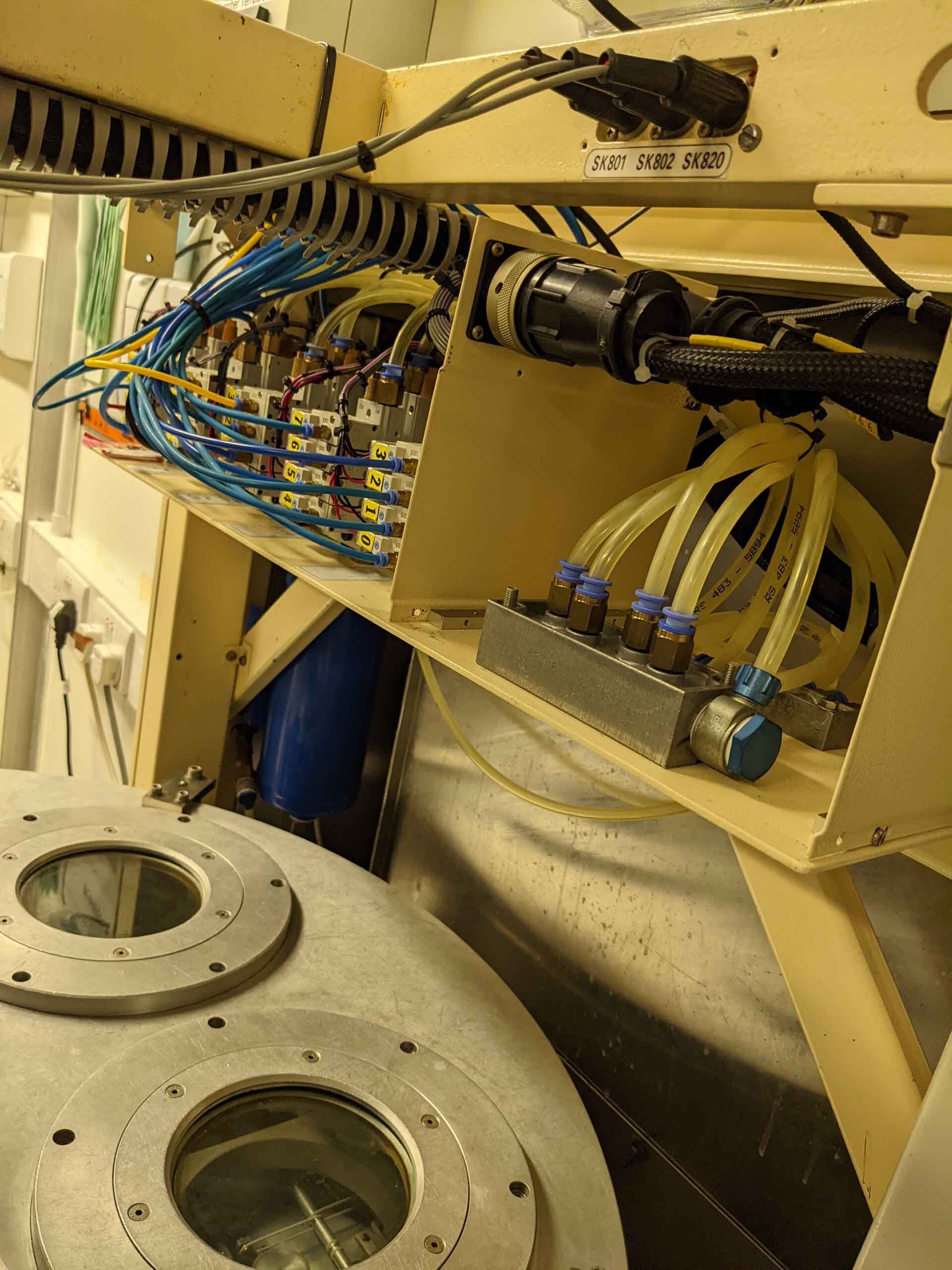

TRIKON / ELECTROTECH Omega II is an etching and ashing equipment designed for a variety of applications in the area of substrate preparation. The device features programmable controls that allow for automated options and sophisticated recipes for a range of etching and ashing processes required for high-end photolithography application. It has a maximum etching rate of 40 microns/min, a maximum ashing rate of 80 microns/min and a temperature range of 35 to 70 C. TRIKON Omega II is designed to limit foreign contamination by providing enclosed chambers. This feature limits the release of hazardous residues created during the etching or ashing process. The device has a cool-down system that helps reduce the temperature of the etched or ashed product. Apart from the etching and ashing process, ELECTROTECH Omega II also features an integrated wafer handling unit. This enables the user to program a wafer motion that can be paused or accelerated based on the desired process. The wafer handling machine also facilitates automated wafer loading, saving time and labor. In addition, the device is equipped with a temperature stabilization tool, gas systems, overhead hood space, and a Class 1, Div 2 rated control panel. The temperature stabilization asset helps ensure that the temperature range remains within set limits throughout the etching and ashing process. The gas systems help reduce process variability and throughput. The Class 1, Div 2 rated control panel allows the user to monitor various parameters related to the etching and ashing process. Omega II is designed for ease of operation with PVC /FDA-approved process gases, including CF4, CF2, O2, CHF3, and others. Moreover, the device can be used for multiple applications, including chemical mechanical planarization, mask and wafer cleaning, and thermal oxide growth. Overall, TRIKON / ELECTROTECH Omega II is a versatile etching and ashing unit with precision controls and user-friendly features. Its enclosed chamber and other control options make it an ideal tool for various process applications. It offers a wide range of process options and is engineered for reliable, long-term performance.

There are no reviews yet