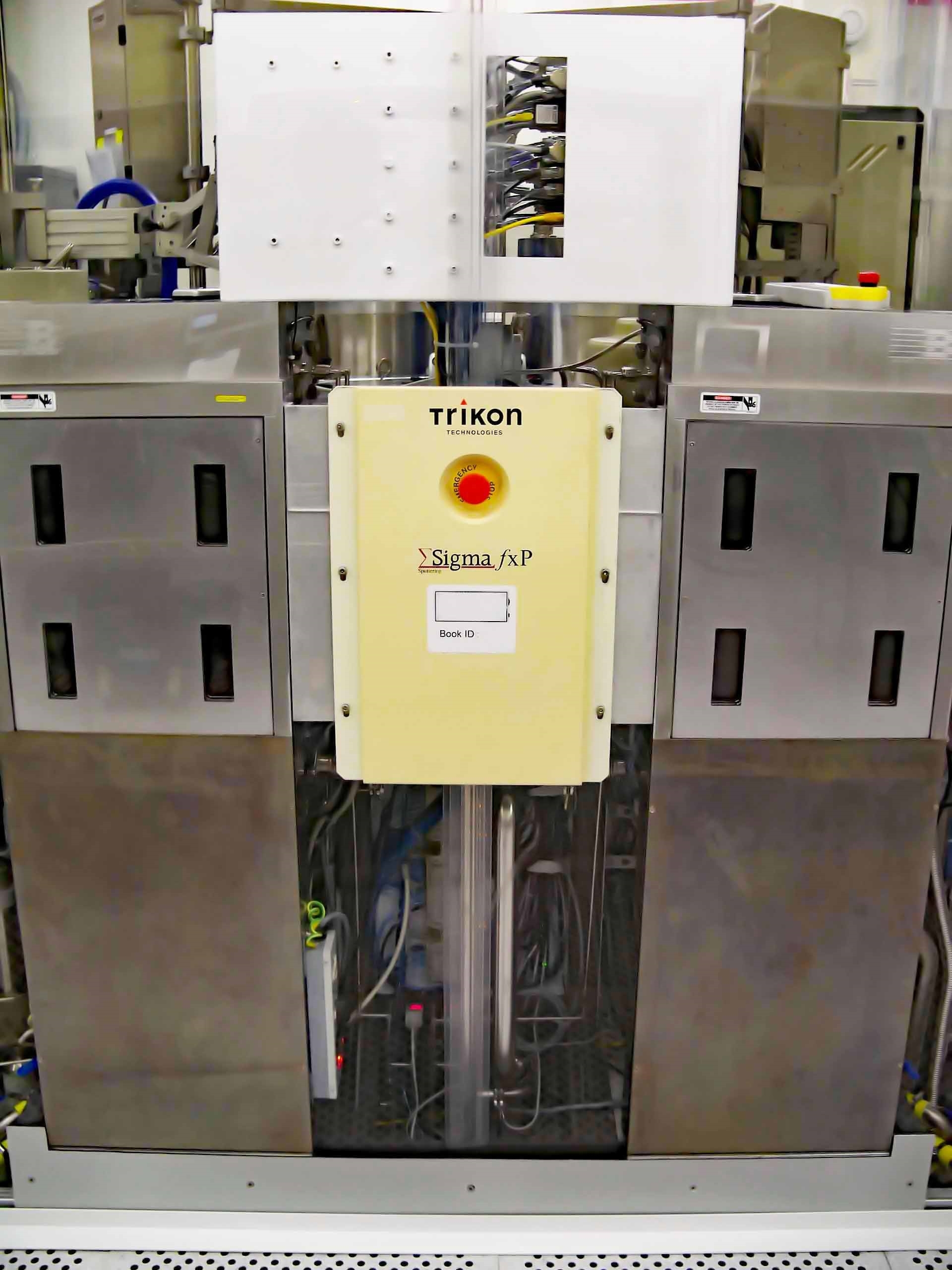

Used TRIKON Sigma FxP #9221542 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9221542

Wafer Size: 8"

Sputtering system, 8"

Includes robot

Hot sputter etch chamber: Station 2 (DepE-HSE)

Spares parts:

(1) Pack of 6 Lamp pack: 1000 W

(2) Generic dep platen caps, 8"

(2) Rev B extended anode rings

(2) Assembly solid chamber shields

(2) Extended shutter slot shields

(2) Platen shields, 8"

(2) Back sputter shields, 8"

Two load locks:

Station 1: VCEA

Station 8: VCEB

(3) Deposition chambers:

Station 3 (DepC- HU platen aluminium)

Station 4 (DepB - HiFill TTN)

Station 5 (DepA - HiFill TTN)

Pre heat chamber: Station 7

Orienter: Station 9 (In front of VCEA)

Top cooler for cooling wafers: Station 10 (In front of VCEB)

(2) Cryo compressors 9600

Transport chamber

MX800 Upgraded to GTM

CTC Upgraded to Win7

Process modules controller (PC104) upgraded

Process modules:

DepA

DepB

DepC and DepE

Pump down: Dry roughing pump and blower

DC Power supplies: Single and double rack

Turbo controller

Main computer

Main AC

RF / DC Power supplies

Chamber AC control

Heat exchanger

Temperature set point: 20°C

Resistivity set point: >50 k Ohm

Recirculating flow: 20 gpm

Recirculating pressure: 22 psi.

TRIKON Sigma FxP is a full range of precision process tools designed for ground-breaking etching, ashing, and curing of both polyimide and other substrates in ultra-clean environments. The equipment offers reliable and scalable results for fine-etching, etching, and ashing of any substrate including polyimide and silicon. The system is designed to provide reliable and repeatable etching, ashing, and curing through advanced automation and precise, on-board control and monitoring. Sigma FxP is designed with a modular platform that offers high flexibility and functional scalability. It features a high-end, fully automated platform that can be tailored to each specific application or substrate, allowing for precise fine-tuning of all etching and ashing parameters. This robust process tool provides in-situ process control, excellent etching and ashing rate, and ultra-low levels of residue. The etching and ashing process is enabled by a single- or multi-gas generator module, with a maximum flow-rate of 25 sccm and minimum gas pressure of 2 psig. This advanced unit is able to monitor accurate gas composition for greater etching and ashing control and reproducibility. In addition, the machine can be programmed with user-defined recipes that can be recalled at any time to repeat the process with utmost repeatability. The integrated Advanced Control module monitors process parameters and provides an intuitive user interface, including an intuitive graphical display and multiple views that can provide real-time process information. The tool also offers an on-board diagnostics asset that allows for monitoring of critical parameters for optimal process performance and maintenance as well as model alerts for prompt action. TRIKON Sigma FxP equipment also provides an Auto-Sensing mode, allowing the user to switch to a different etching or ashing gas if the etching or ashing conditions are not optimal. This mode makes the system highly versatile, allowing etching and ashing of complex substrates without any need for manual parameter tuning. The unit also provides integrated process improvement tools and options, such as electronic signature capture and audit trail capabilities, to help ensure optimum and detailed documentation of process conditions. These tools help to maximize the end-product quality.

There are no reviews yet