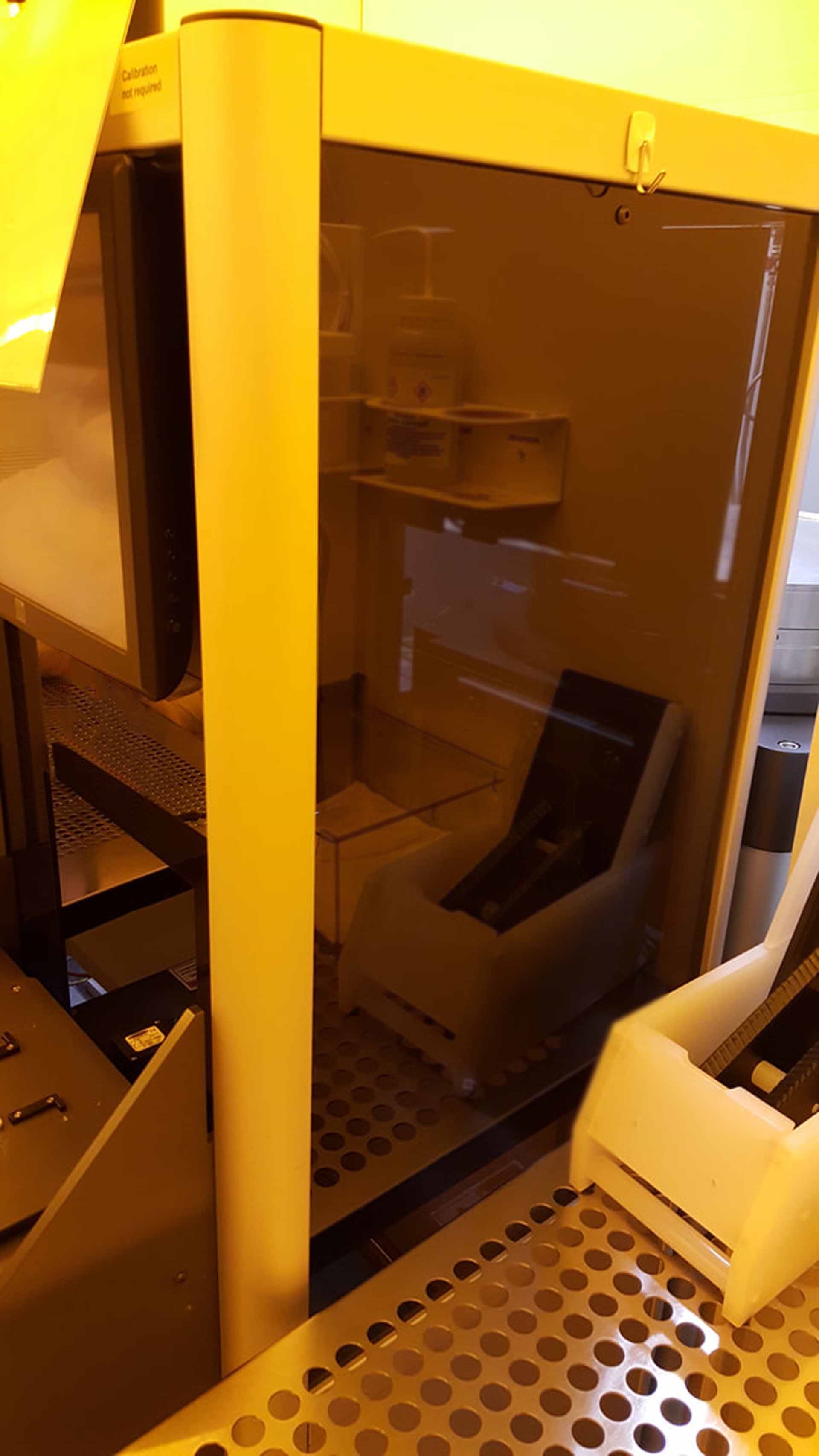

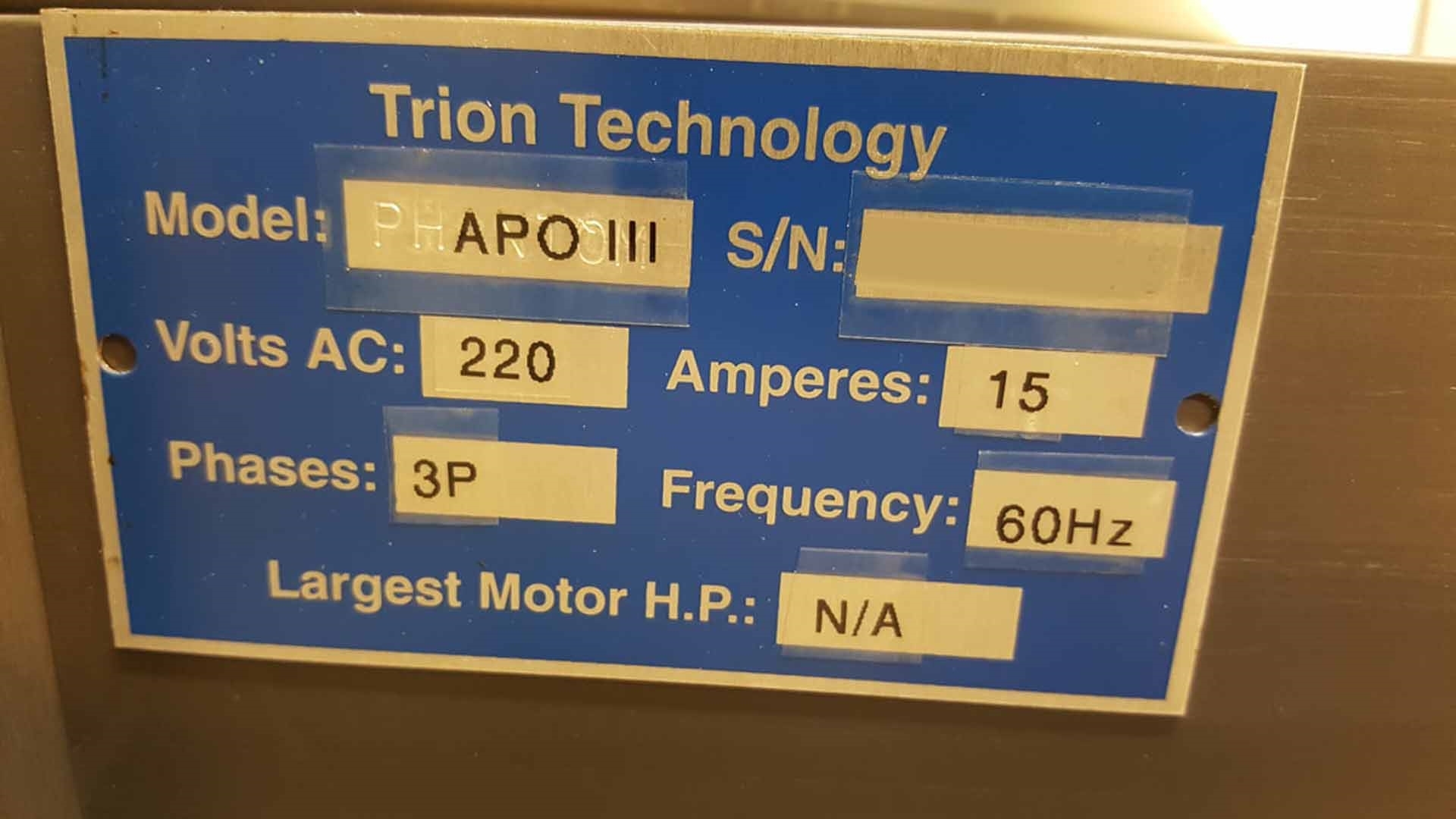

Used TRION APO III #9216394 for sale

URL successfully copied!

Tap to zoom

ID: 9216394

Wafer Size: 4"

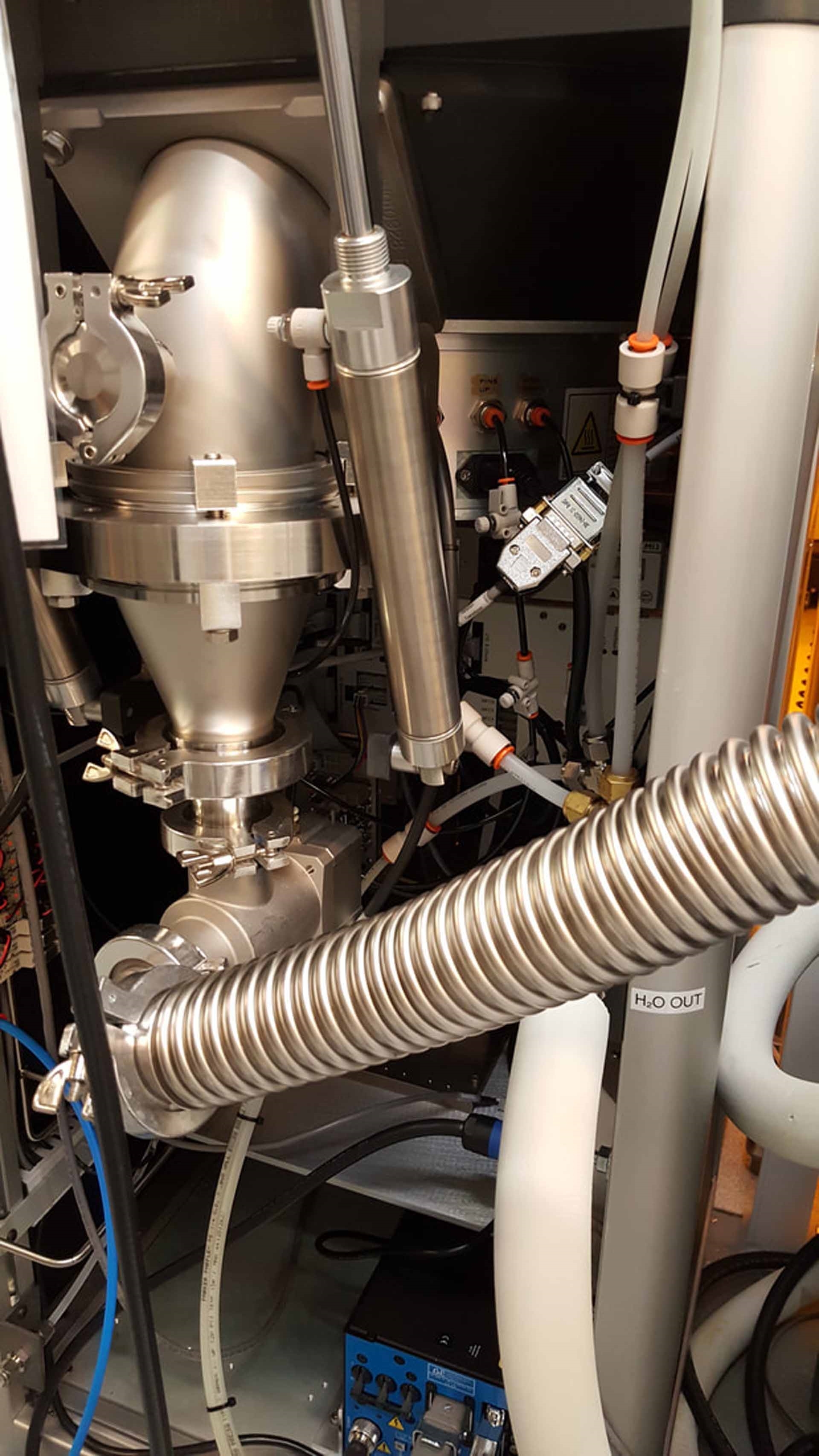

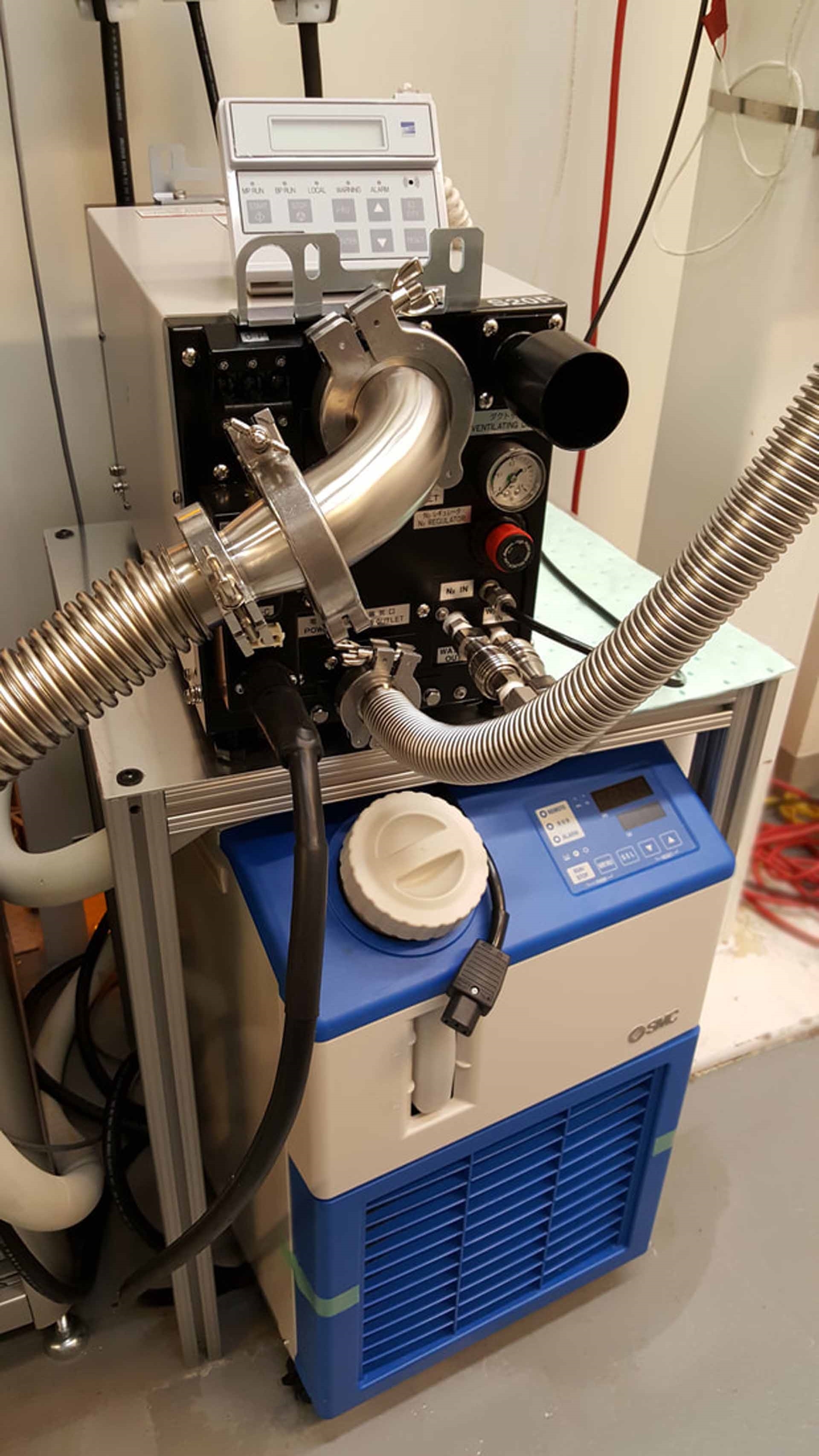

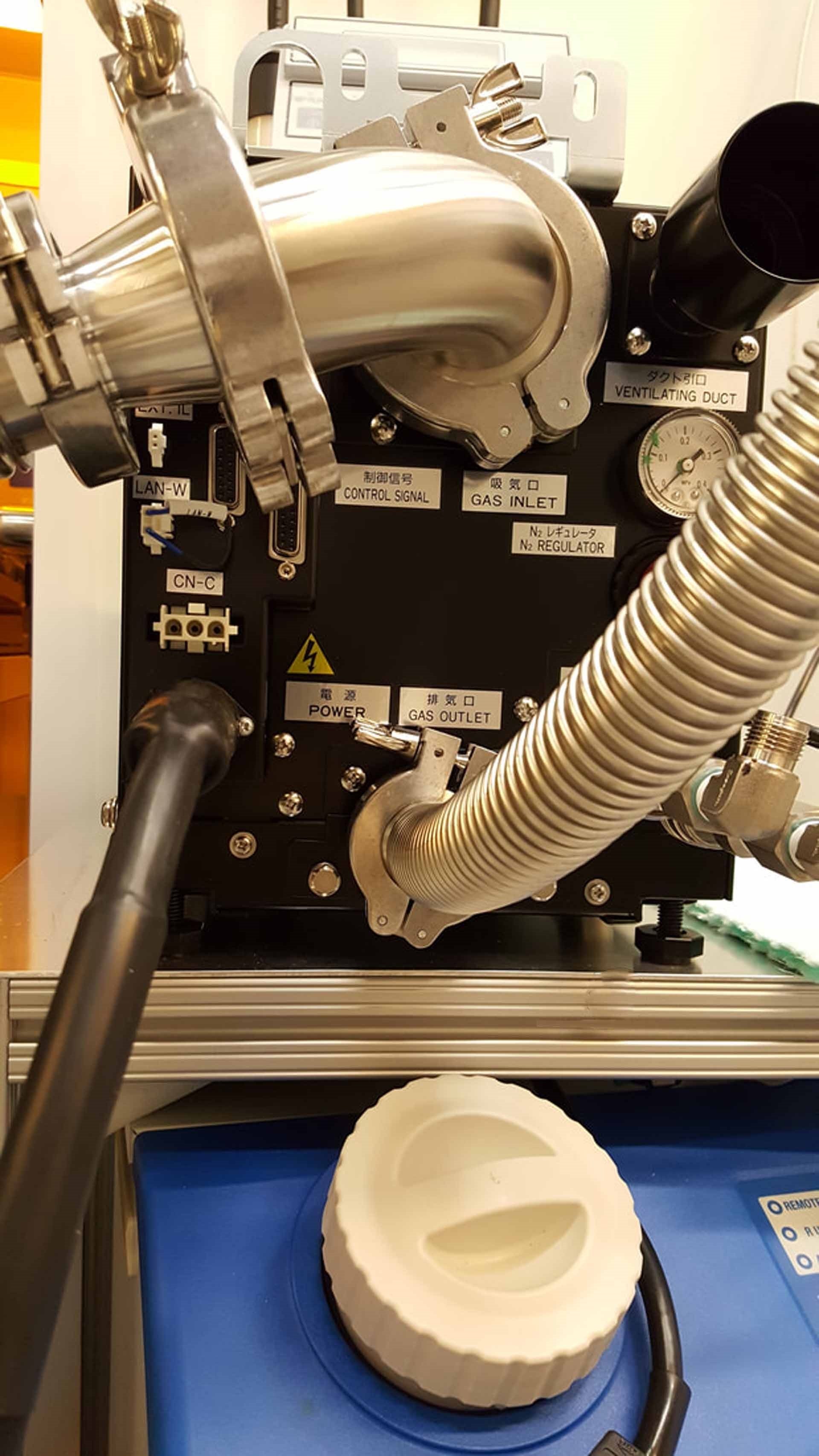

ICP Etcher, 4"

No RIE

Process:

Descum

Ashing with downstream O2 plasma

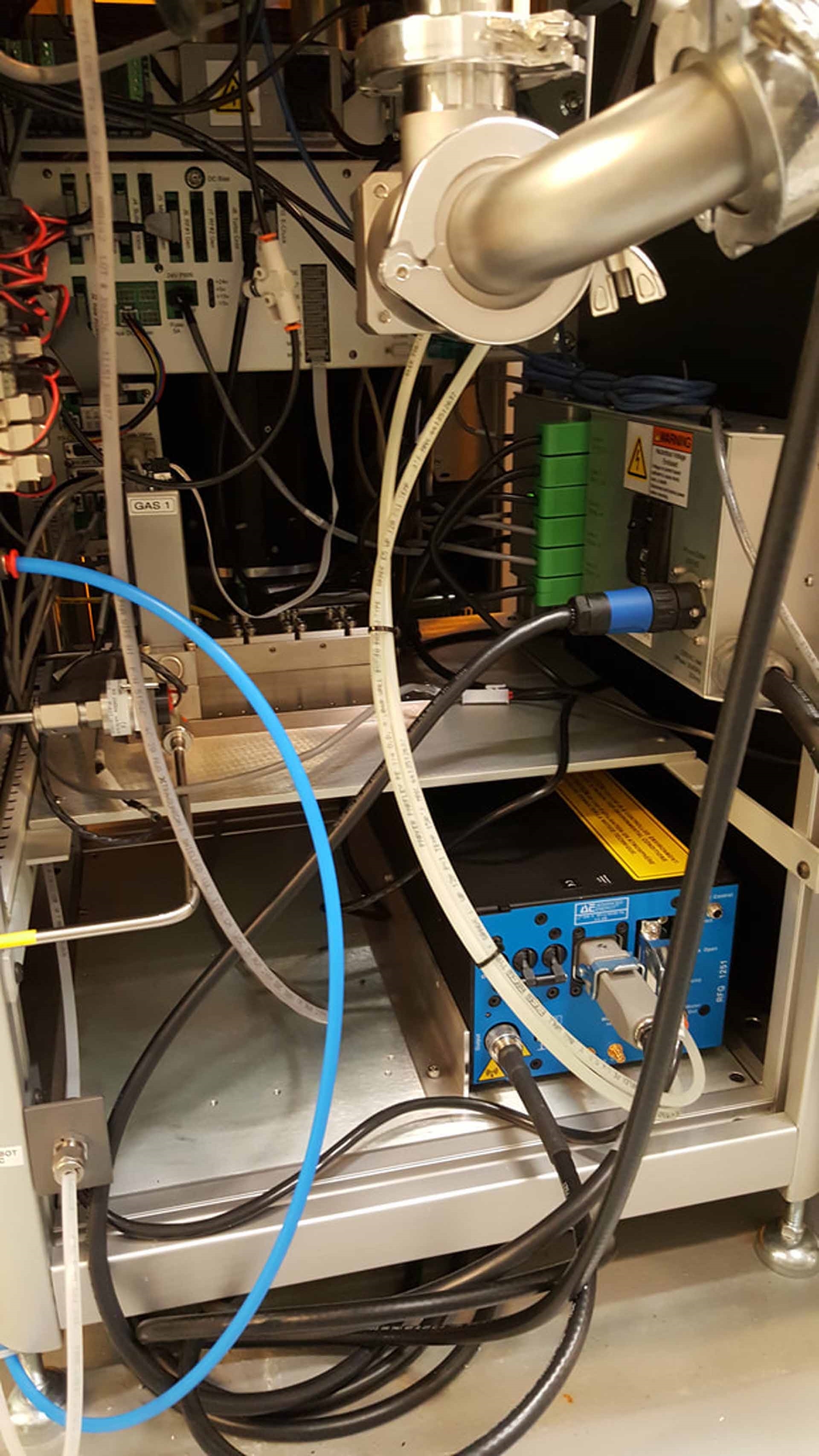

MFC: O2 2000 SCCM

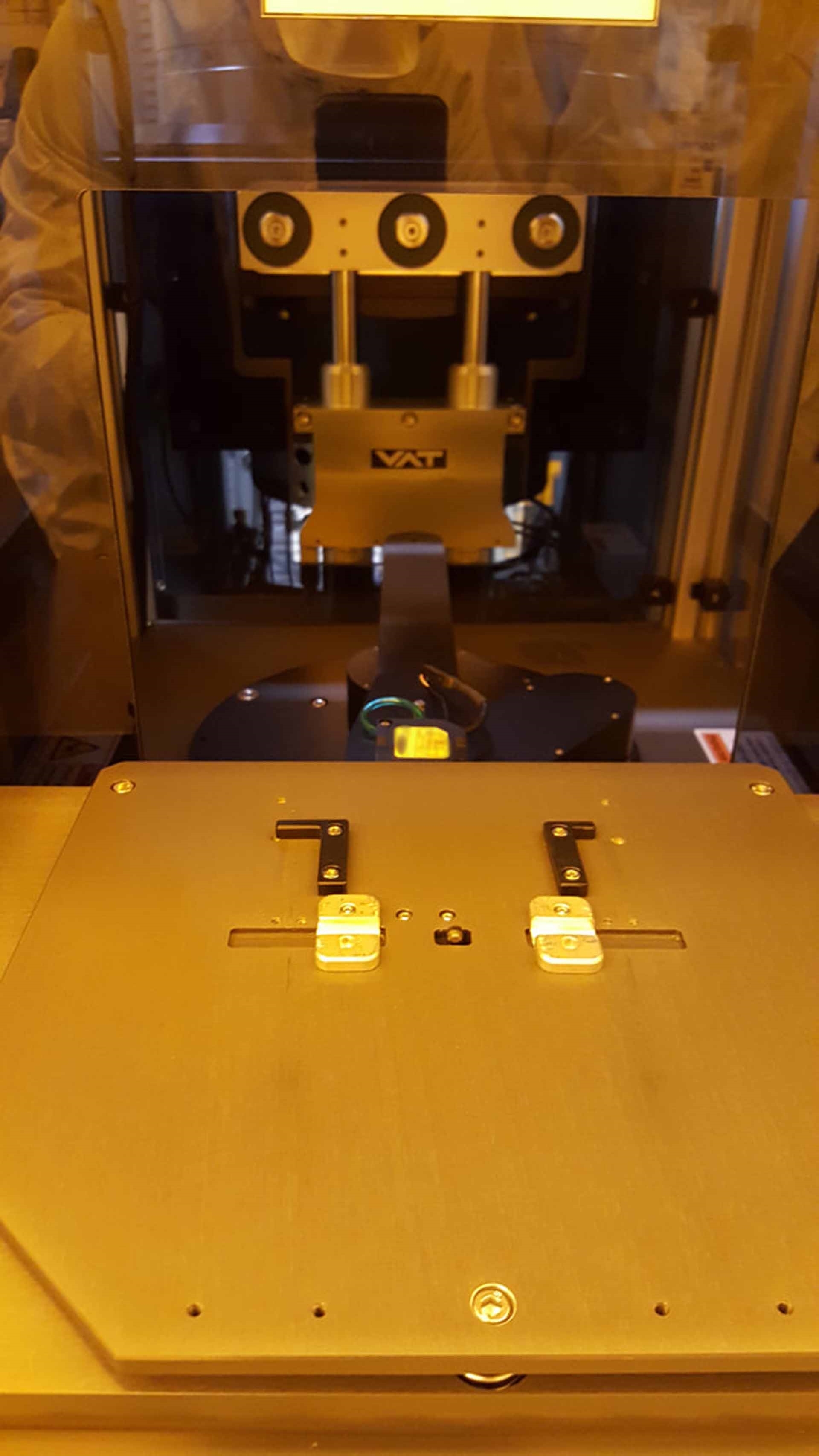

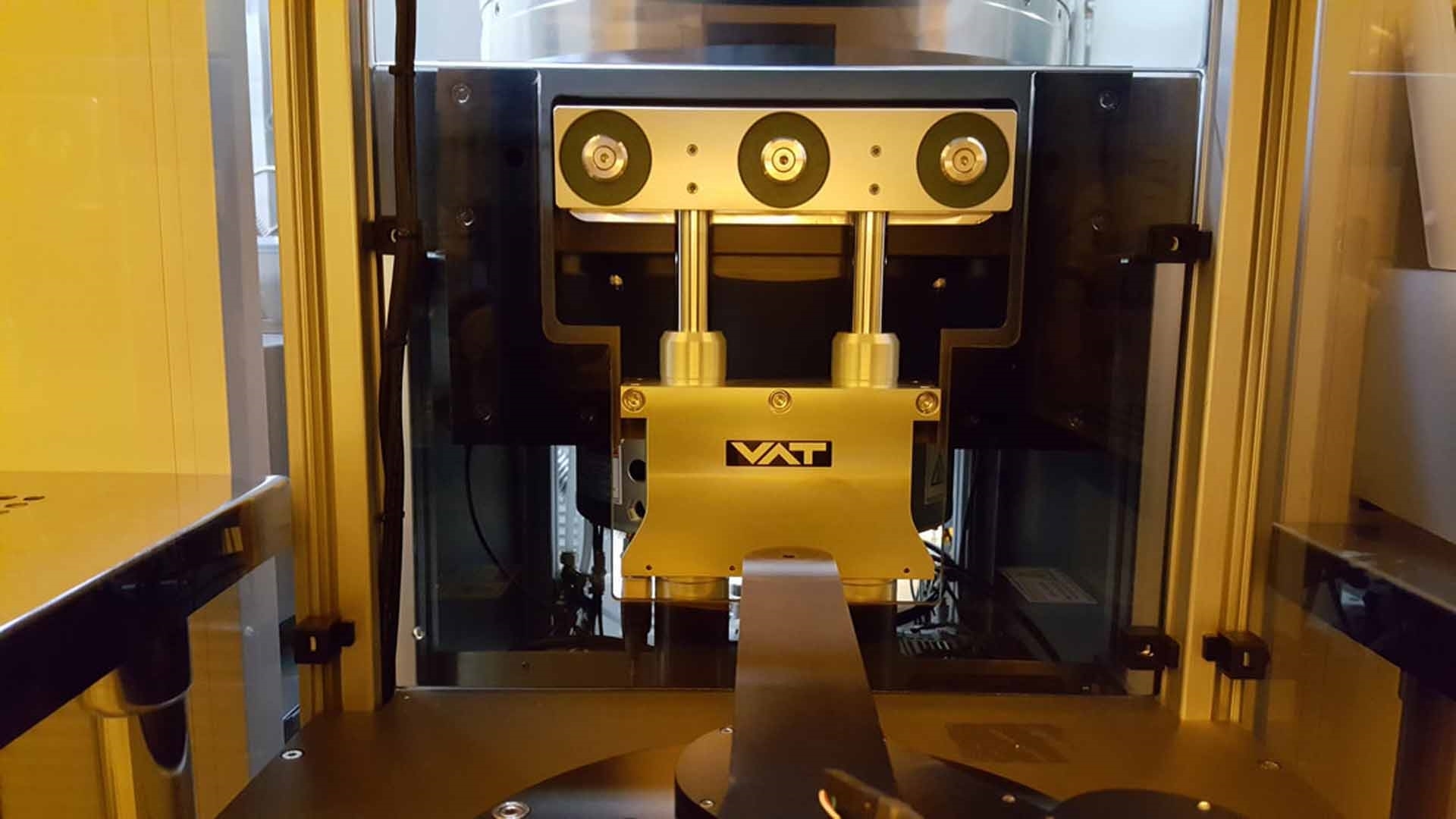

Heated platen

Heated end effector

Power: 220 V, 60 Hz, 15 A, 3 Phase, 1250 W.

TRION APO III is an high resolution etcher/asher designed specifically for production processes in the photomask industry. APO III achieves maximum resolution accuracy and uniformity while etching or ashing photomasks quickly and accurately. TRION APO III is designed for repeatably consistent performance and ease of operation. APO III is an integrated equipment comprised of a fully enclosed process chamber, mask handling module, and control and monitoring system. The process chamber is equipped with two precision regulated Ion sources and four processing chambers. The mask handling module has an automatic mask-to-substrate alignment unit for convenient loading and mask alignment. TRION APO III control and monitoring machine incorporates pressure control, RF tuning, recipe generation, monitoring and diagnostics. APO III has a maximum resolution of 0.010 micron with uniformity and repeatability of +/- 0.0005 micron. The first level etch process produces etch rates between 10-20 Angstroms/second, with an ability to bias etch up to 1000 Angstroms per mask. TRION APO III also performs wet/dry processing with HF and HCI to create hard-mask layers applied to photomasks for a variety of different applications. APO III offers flexibility through its multi-level etch process, which allows for greater throughput by etching multiple layers in one process cycle. TRION APO III also features a powerful high-capacity cooling tool to help maintain maximum process repeatability during long etching cycles. Additionally, APO III is designed for high-volume production, and can offer fully automated pattern/alignment test and repair capability. Finally, TRION APO III is designed to be user-friendly and operator safe. Through LCD display touch screen, the user can easily setup and monitor the etching process, and view various diagnostics during the process. The asset is also equipped with safety systems such as gas alarms, chamber dryers, and gas leakage/overpressure detection monitoring that promote safer operating environment.

There are no reviews yet