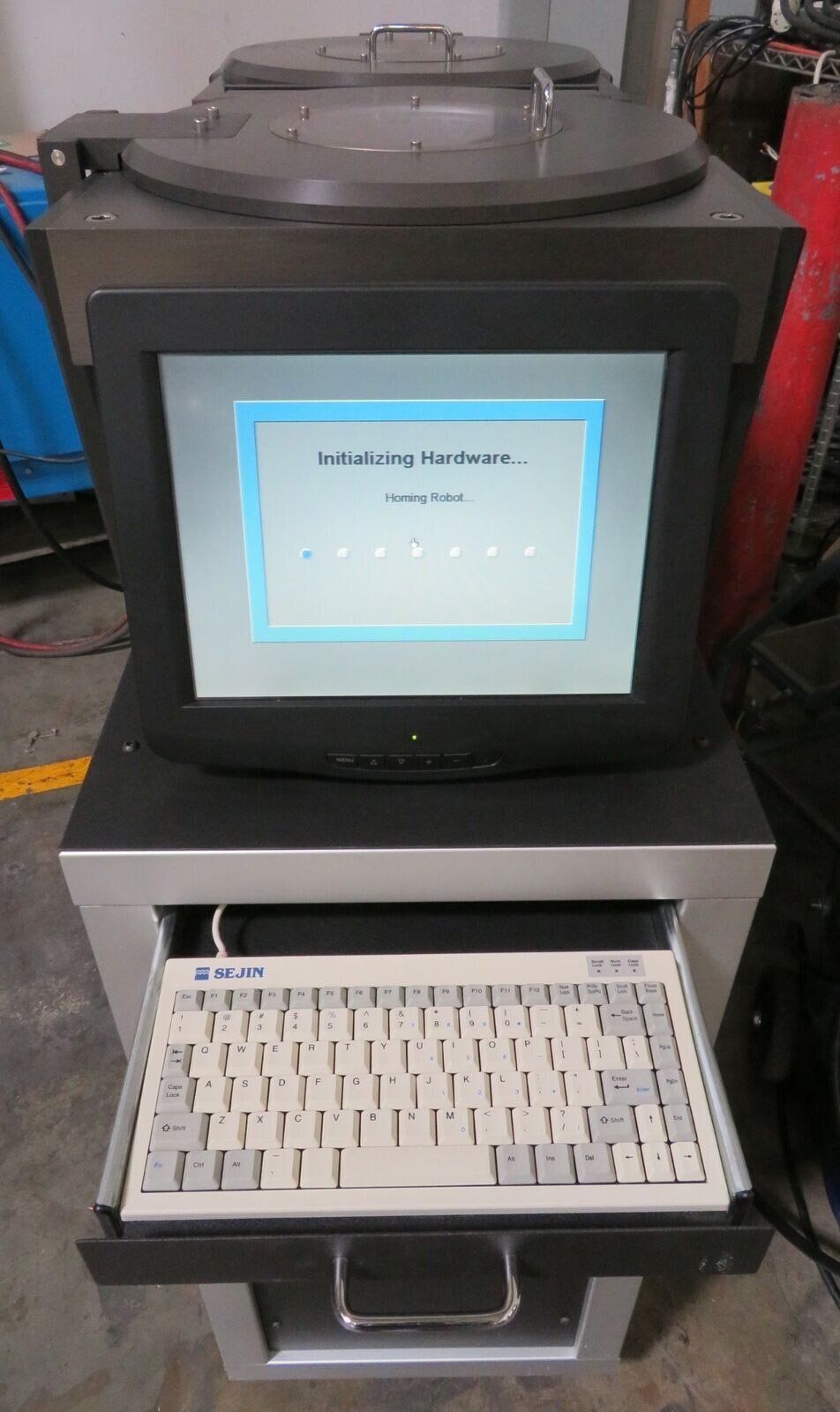

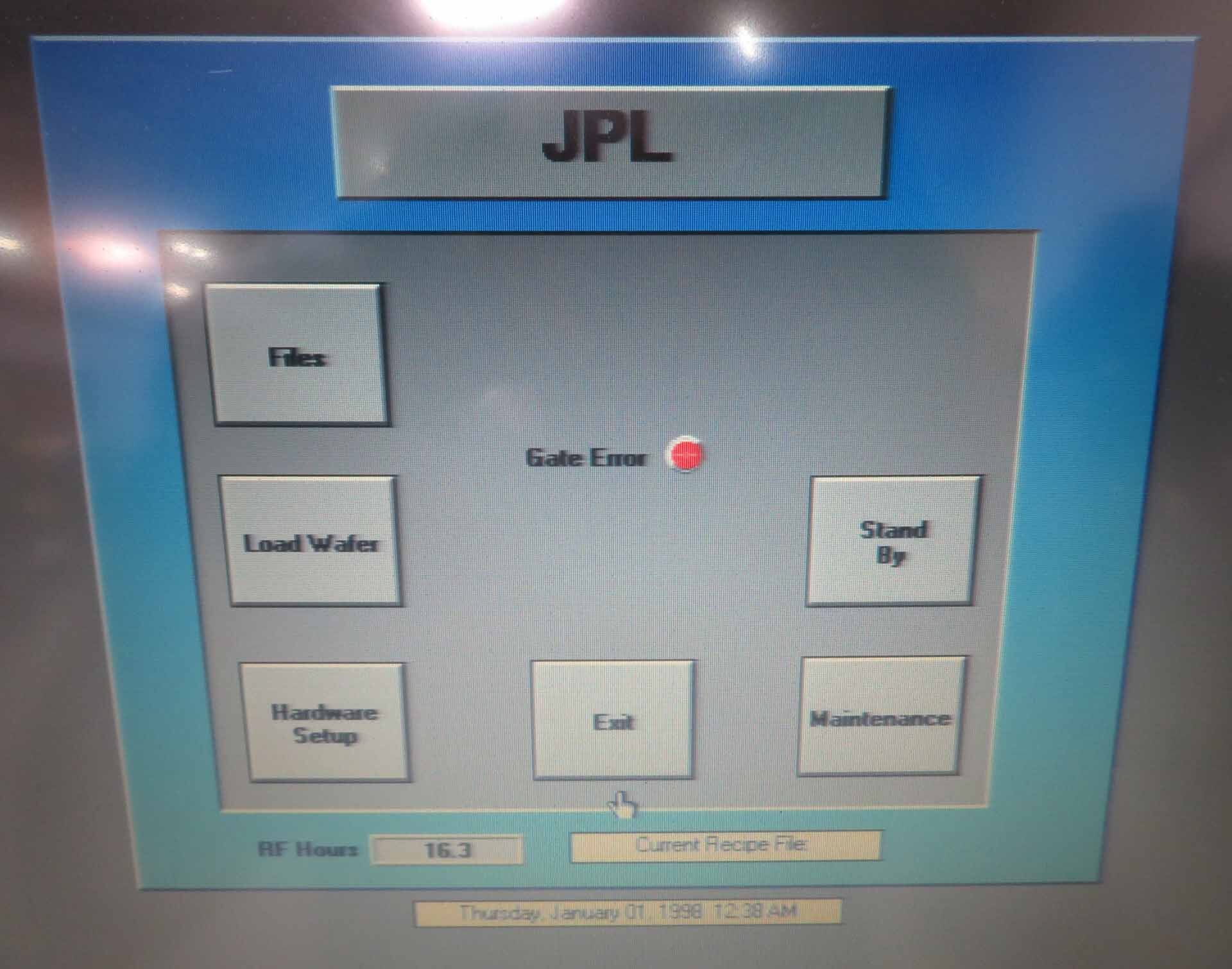

Used TRION Minilock II #9389392 for sale

URL successfully copied!

Tap to zoom

ID: 9389392

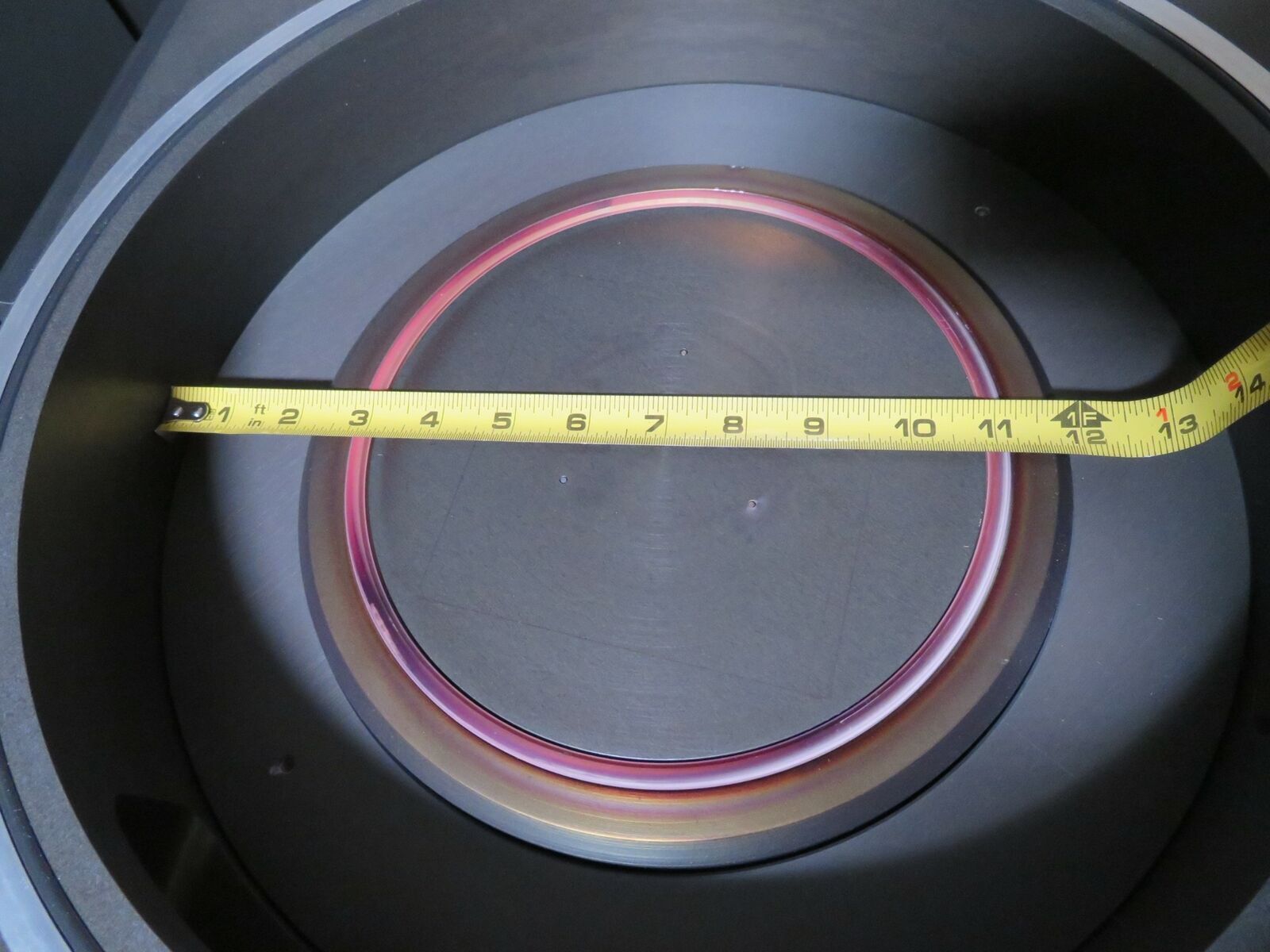

Reactive Ion Etcher (RIE)

ADVANCE ENERGY RFX 600A RF Plasma generator

MKS 153 Control valve

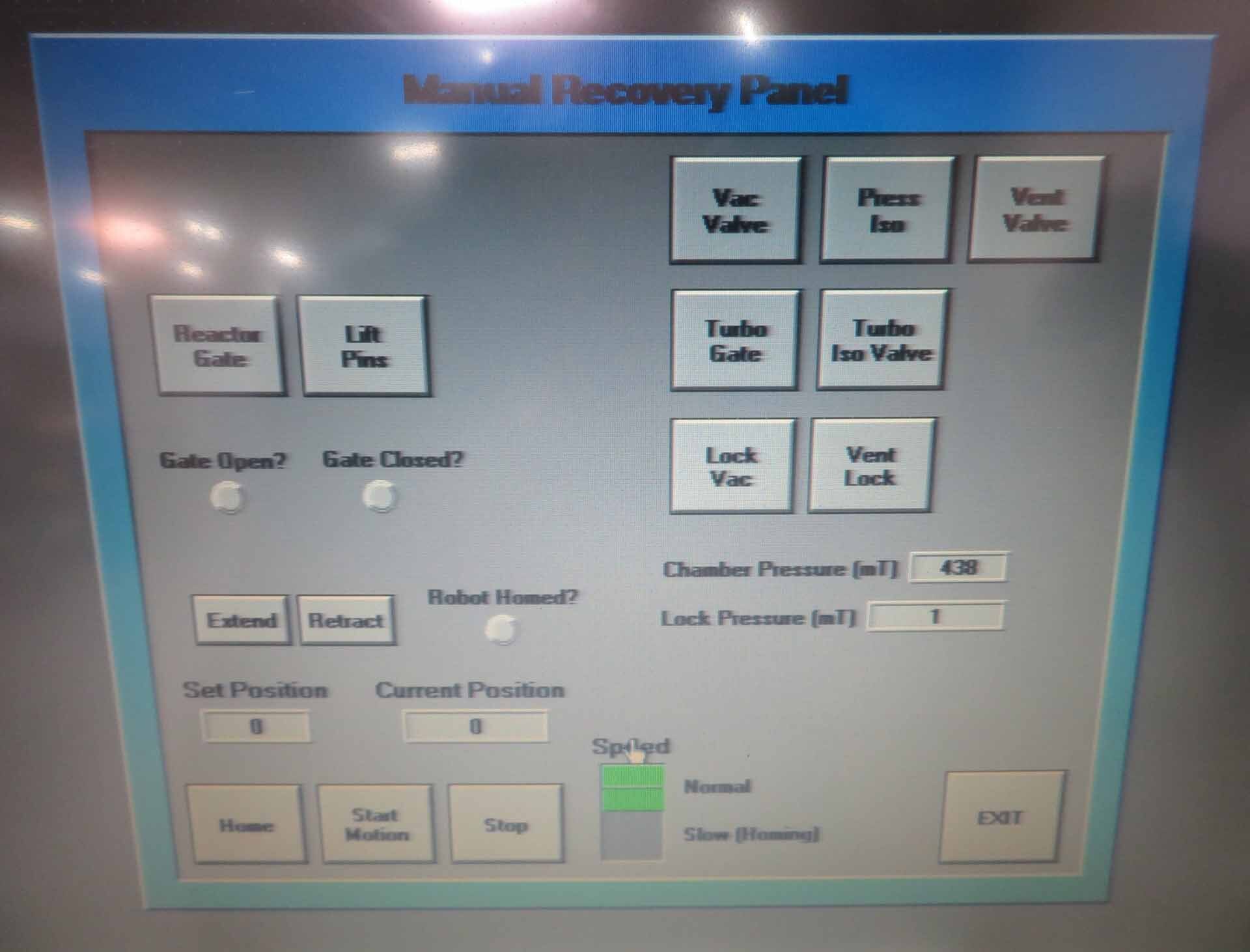

VAT 02110-BH24-0001/0039 Rectangular gate valve

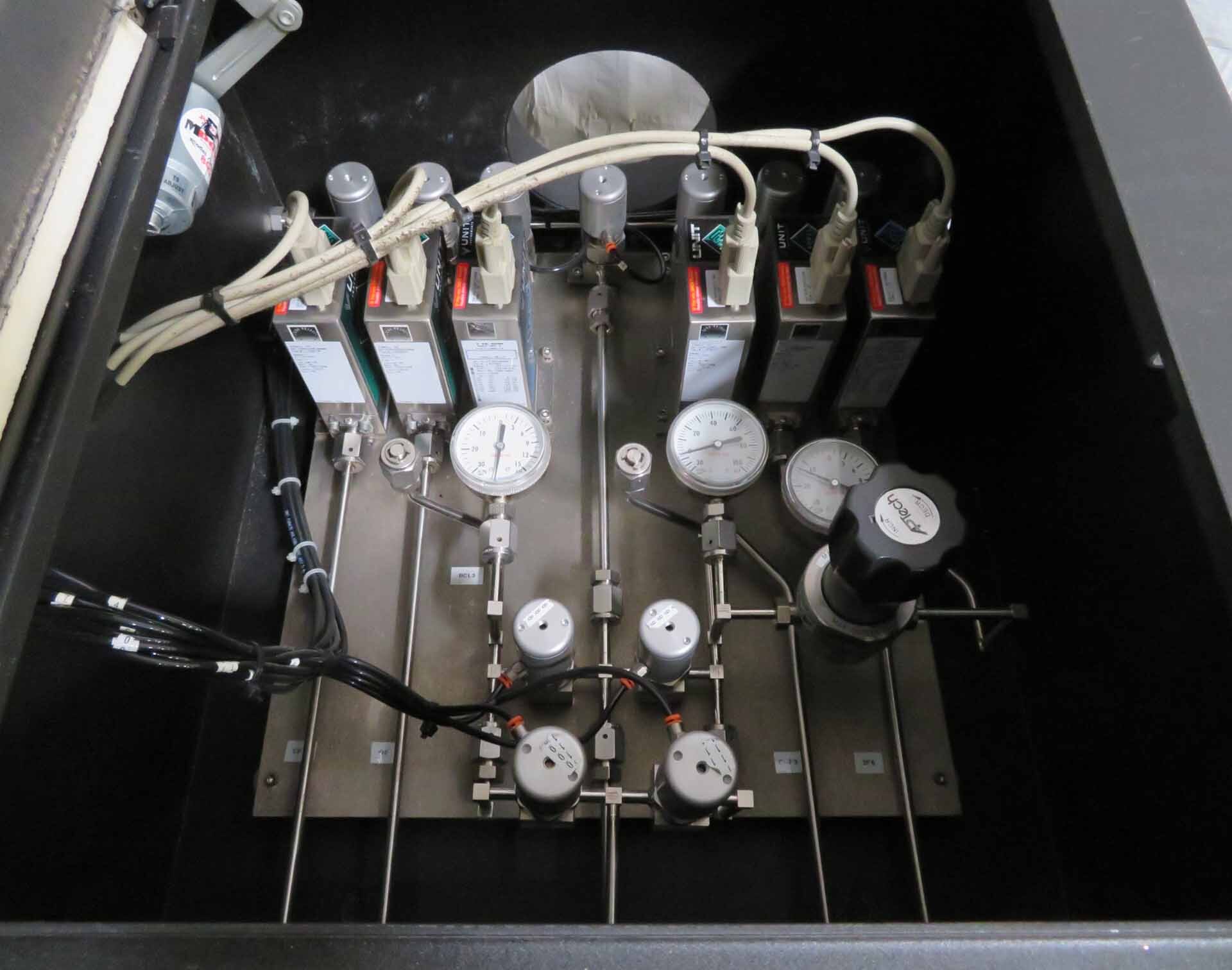

Gas cabinet

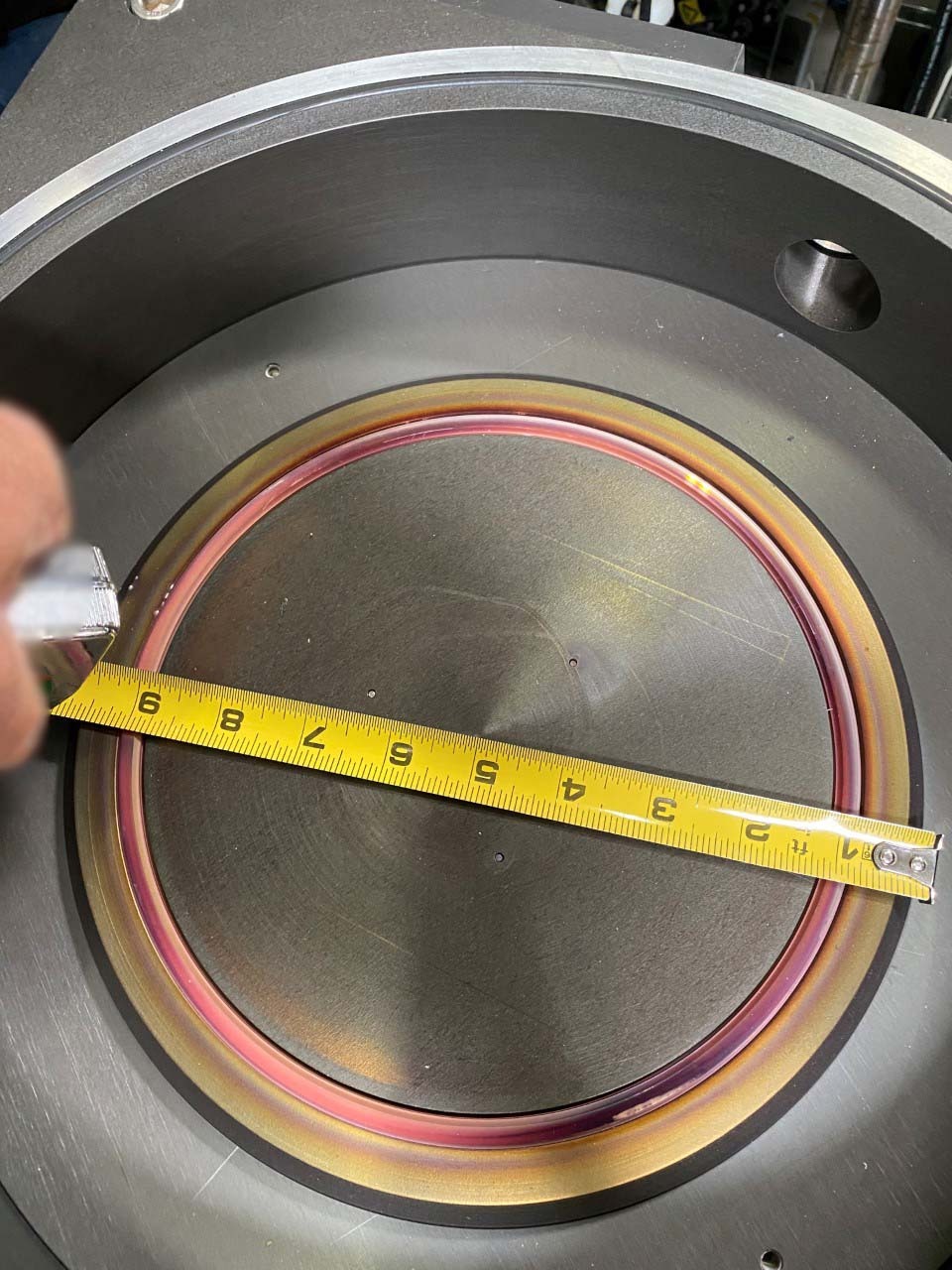

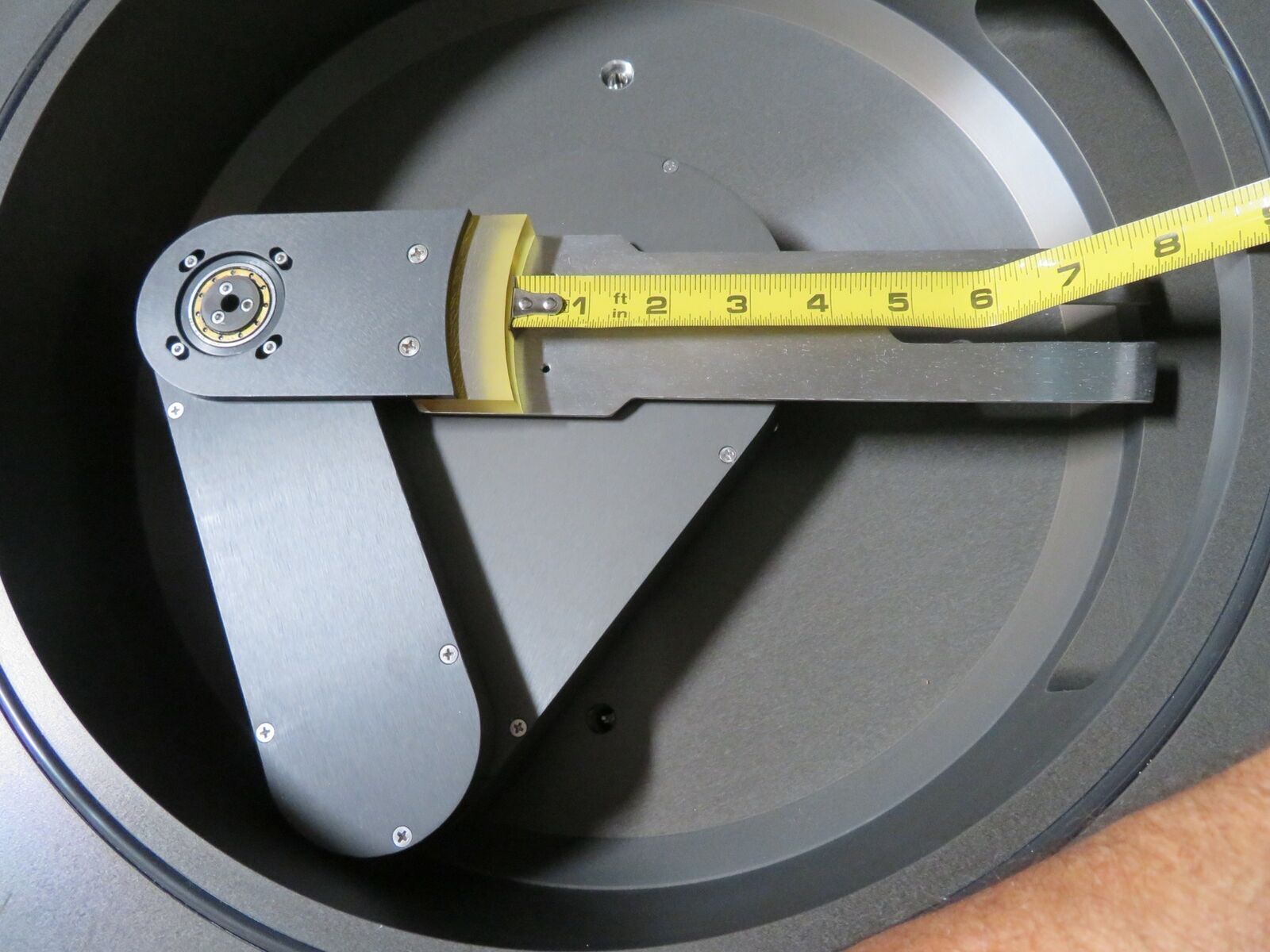

Load lock

(6) UNIT INSTRUMENTS Mass flow controller:

(4) UFC-1800 (Gases: N2, (2) 100cc, and (2) 250cc)

(2) UFC-1660 (100cc BCl3, and 100cc CL2).

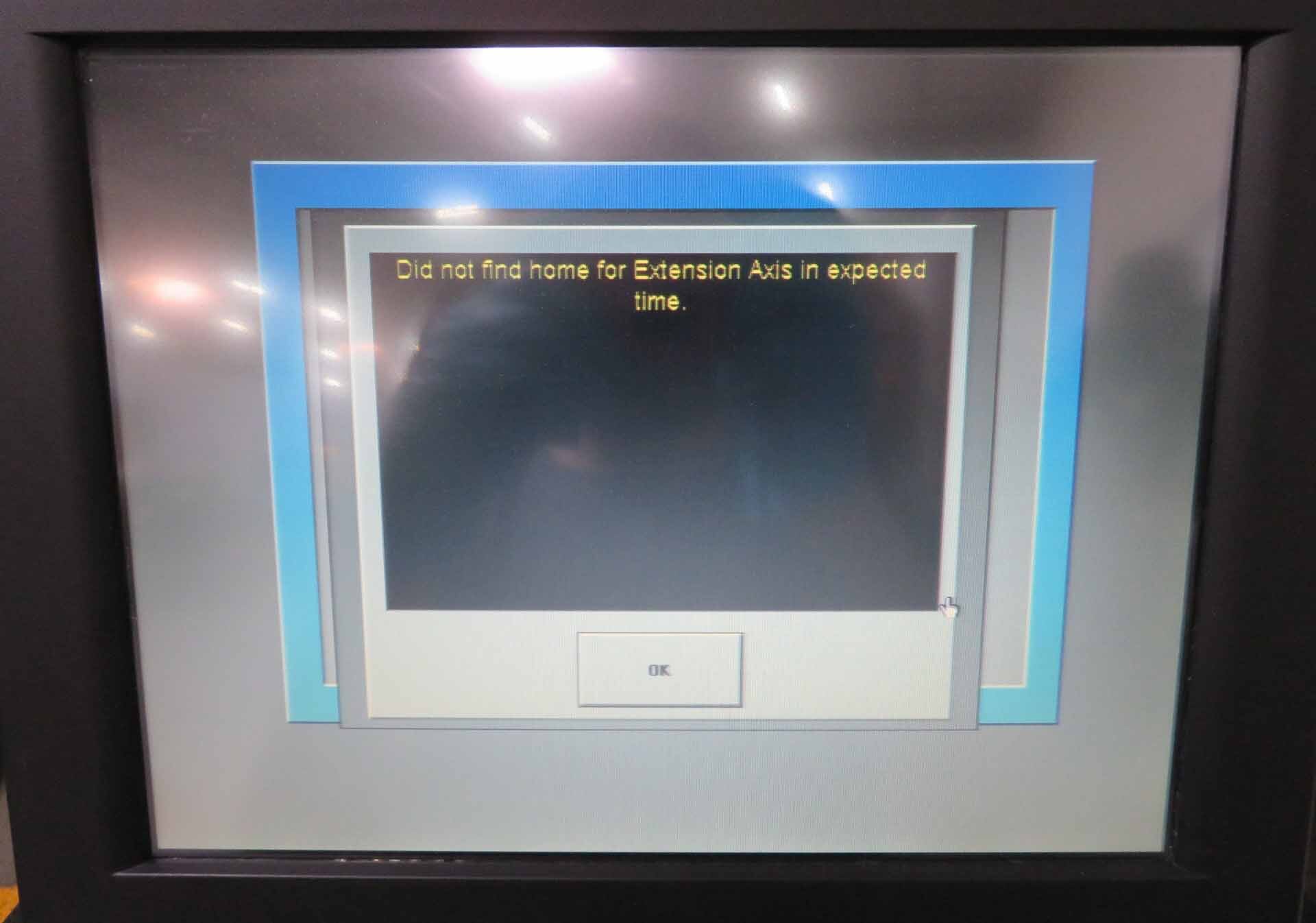

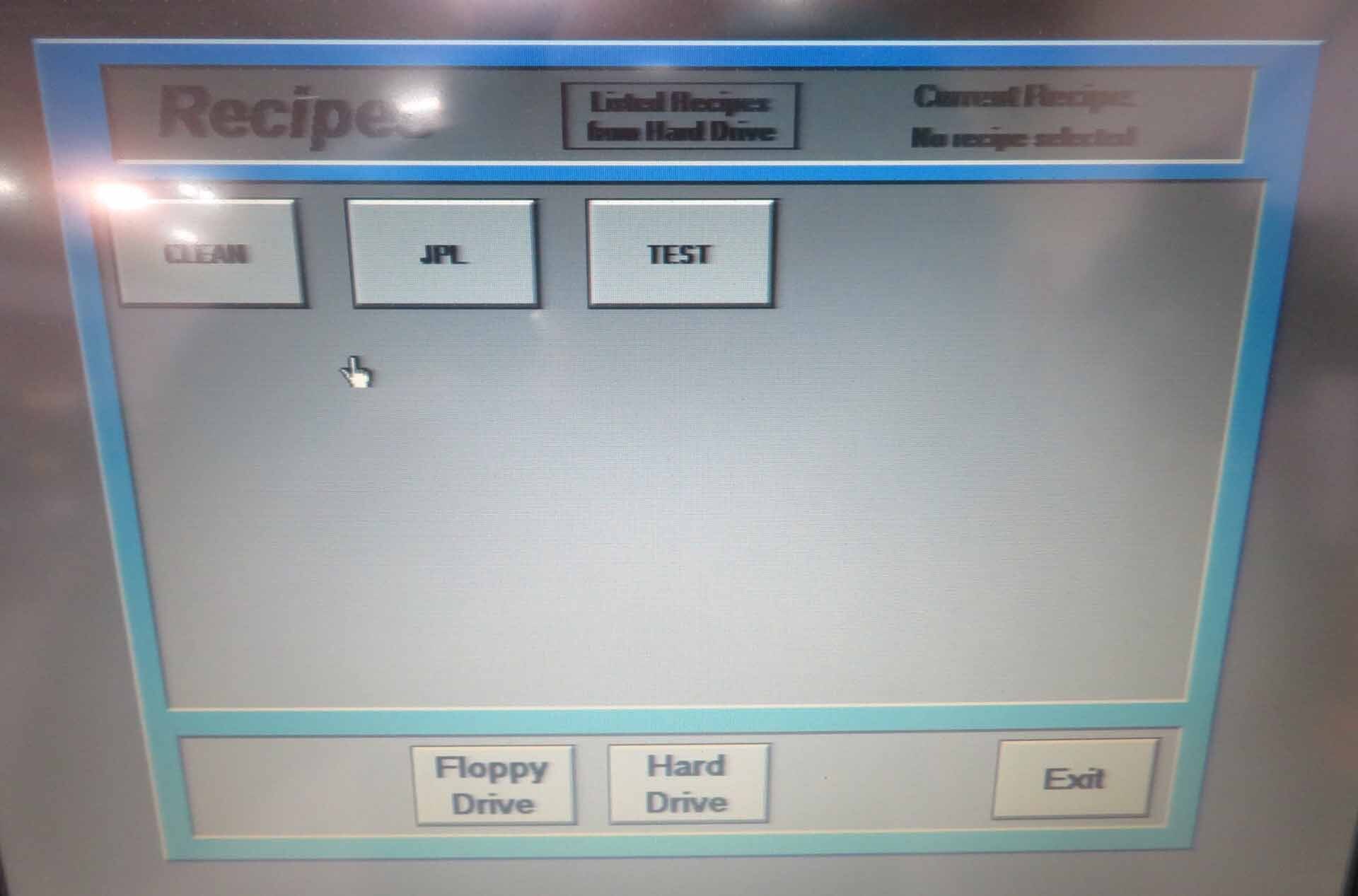

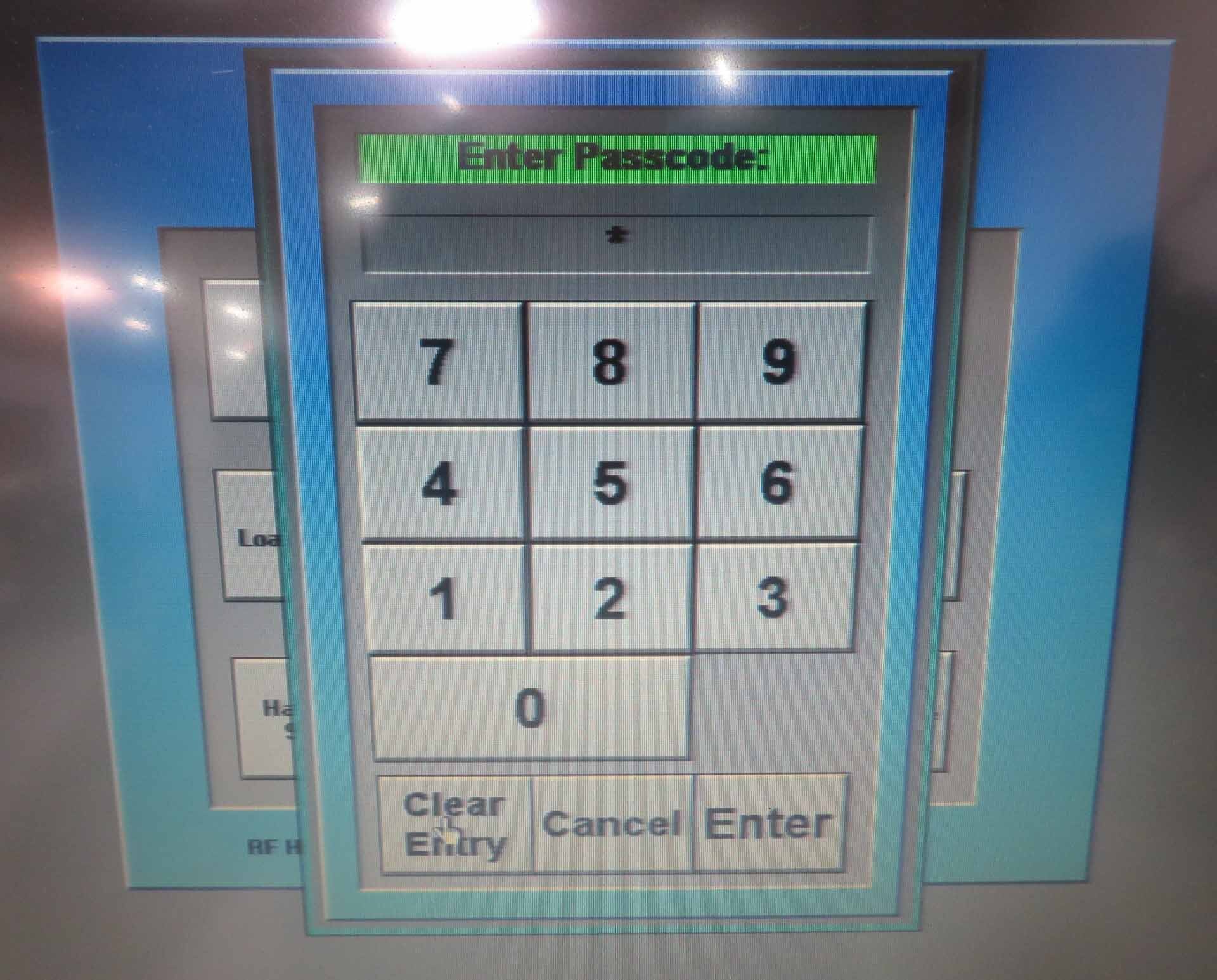

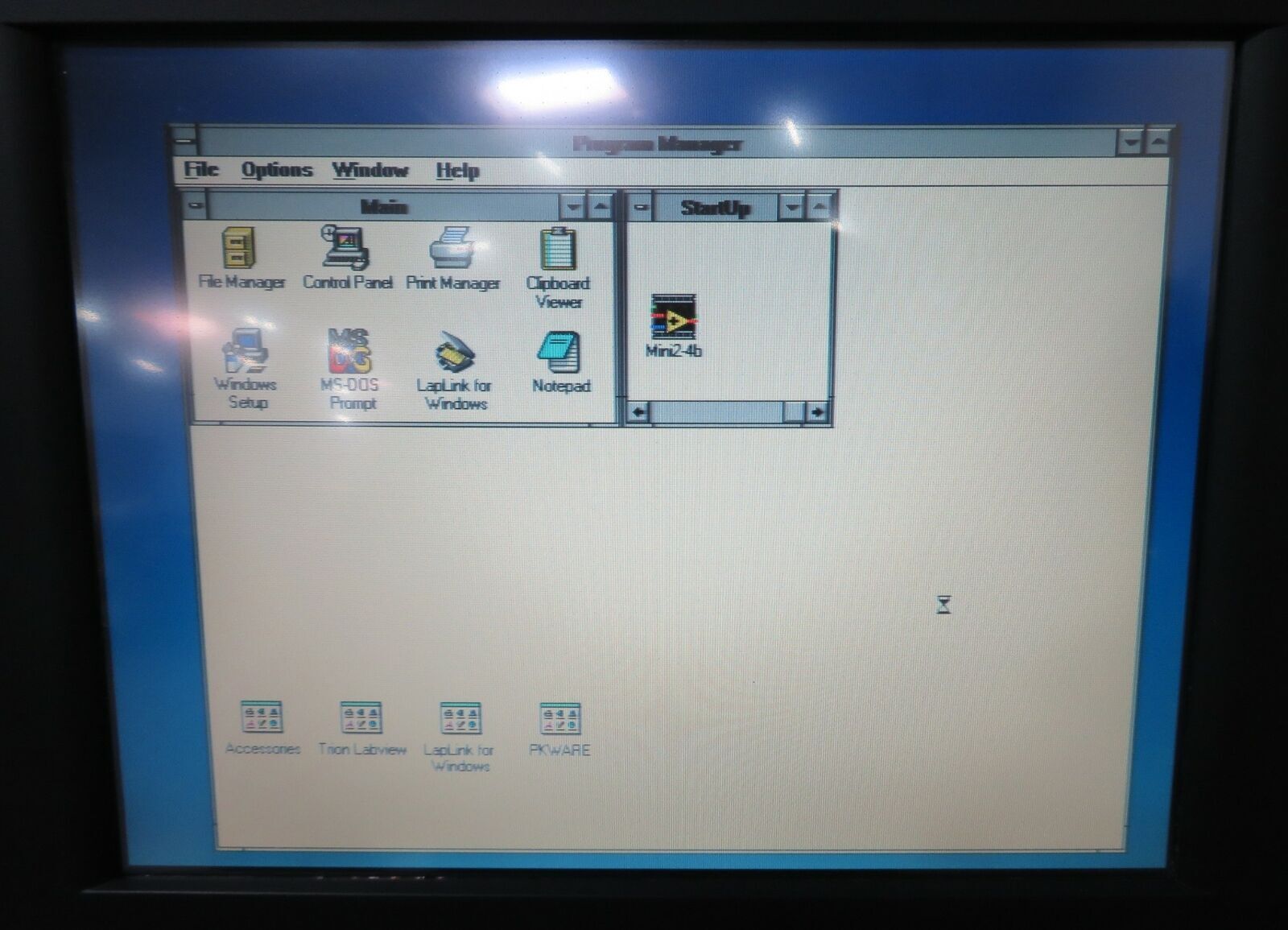

TRION Minilock II is an advanced etcher/asher ideal for high-precision etching and ashing applications in semiconductor, microelectronic, and electronic industries. It utilizes three-stage selectable forced-air etching technology to ensure accurate and repeatable etch/ash depth control. The etched and ashed surfaces are left with uniformized characteristics that provide a much higher degree of reproducibility. The equipment consists of a high-performance metal reinforced housing with an integrated fan unit to provide efficient heat dissipation and minimize thermal decomposition of the etched and ashed material. The etcher/asher can be equipped with several internal options, depending on the process being performed, such as a chill plate, mesh filter, coolant tank, and purge covers. It also includes a microprocessor controller with a built-in temperature adjustment feature that allows the user to select from several pre-set temperature points for different types of etching and burning. A temperature sensor integrated into the etcher/asher also enables real-time monitoring of thermal processes. The system has an automatic temperature recovery feature which helps maintain uniform temperature during the entire etching/burning process. This feature can be used to reduce the tempering of the media, which results in a better result with no over-etching or over-burning. The unit also includes an integrated timer machine that can be used for various etching and ashing cycles and allows the user to set specific start and stop times for each cycle. This ensures precise control over the etching/burning process. The tool is also equipped with an in-situ gas-flow regulator which maintains optimal gas pressure for uniform etching/burning. This helps to reduce the damage which may be caused by over-pressurization of the gas. The asset can also be equipped with a remote control model that allows the user to start, stop, and control the etch/ash process from a remote location. It is designed with robust safety features such as an emergency power shutdown button, overheat sensors, latching-style solenoid valves, and all safety interlocks. Minilock II provides high accuracy and precision etching/burning, and is the perfect etcher/asher for commercial and industrial applications. Its metal reinforced housing, in-situ gas-flow regulator, thermal regulation, integrated timer, and robust safety features make it a reliable equipment that is ideal for applications that require uniform and precise surface etching/publication.

There are no reviews yet