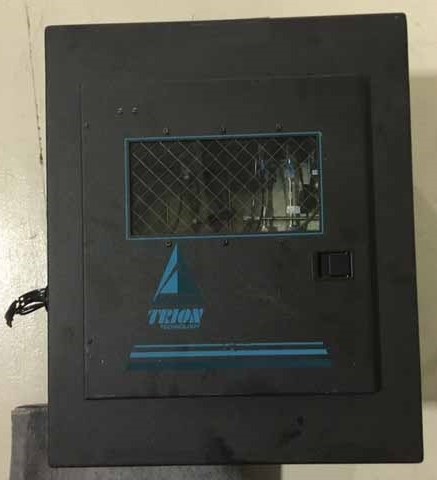

Used TRION Minilock Orion II #9195271 for sale

URL successfully copied!

Tap to zoom

ID: 9195271

Vintage: 2001

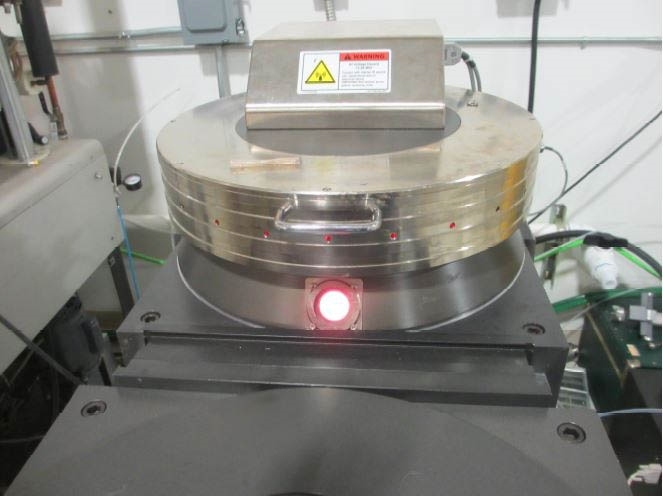

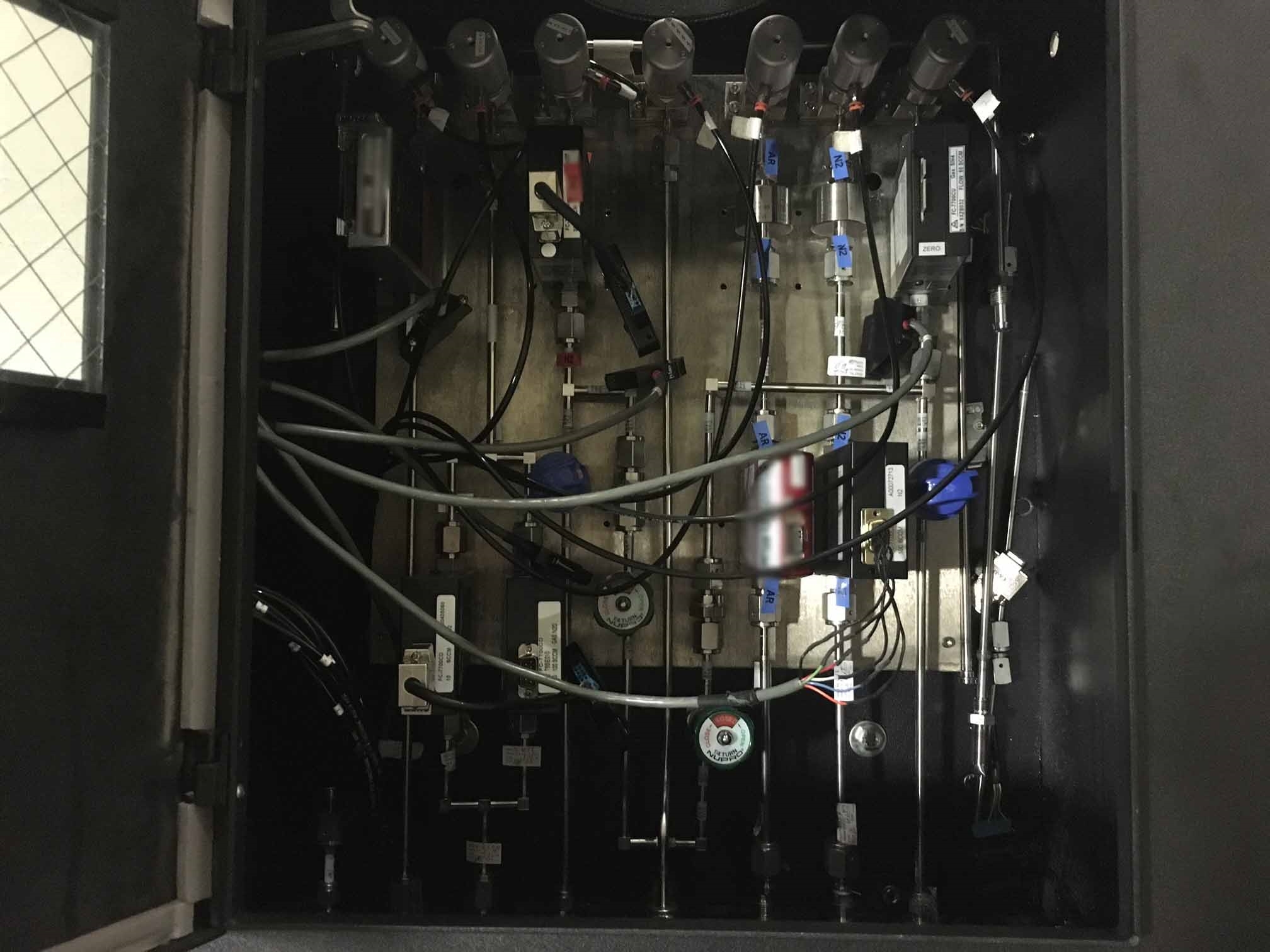

PECVD Load lock triode system

(6) MFC: CF4, O2, TEOS, DES, NH3 and N2 for purge

Automatic purge (Gas cabinet)

Ceramic ring focuses plasma

Optimizing power utilization

Bottom and top electrodes are water cooled

Chamber equipped with: (2) Circular quartz viewing windows

Primary chamber material: Anodized aluminum

Components: Ceramic / Quartz

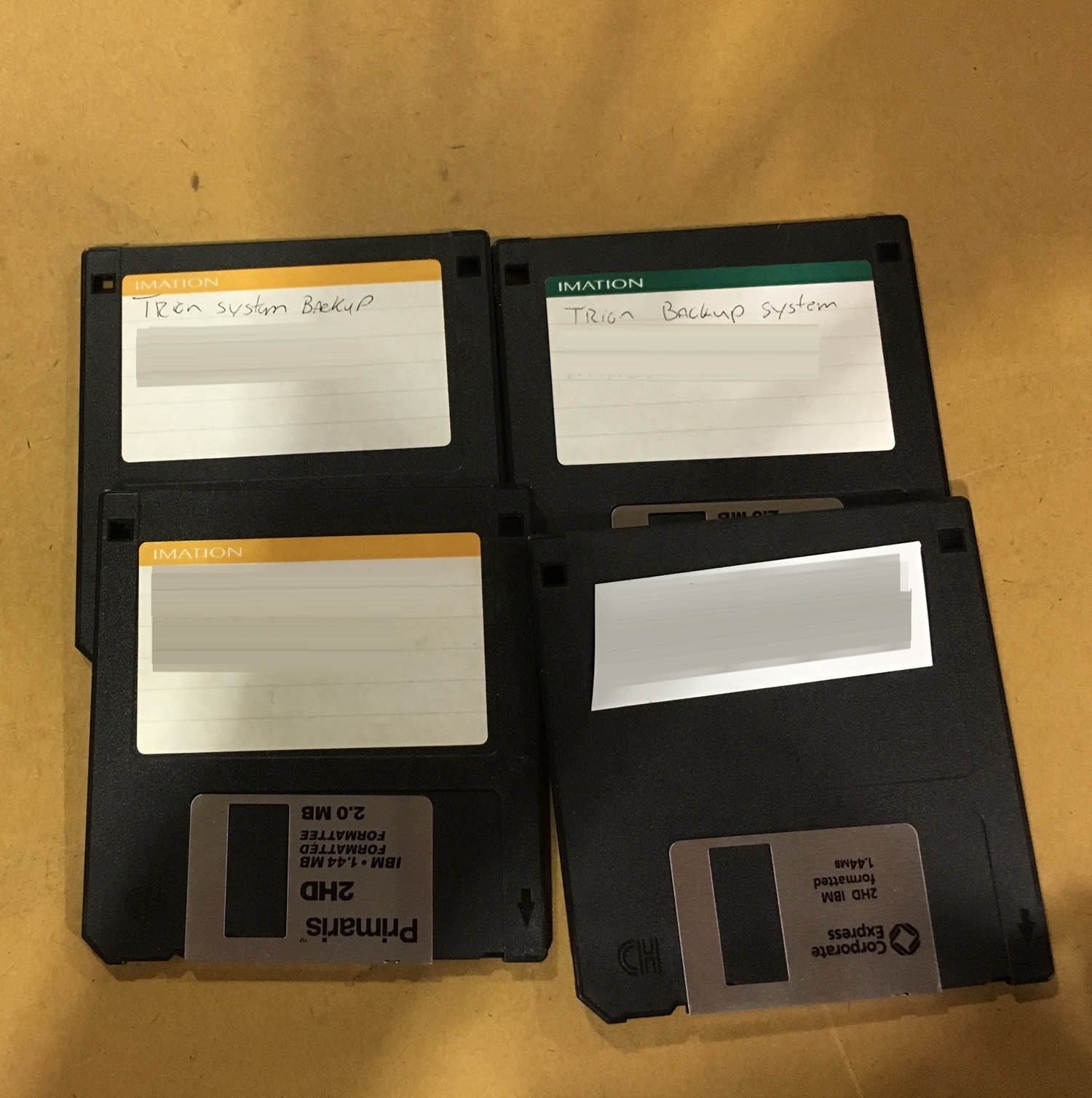

Computer has been replaced

Bottom electrode temperature: Resistive heater / IR Thermocouple

Upper electrode

Shower head gas distribution

Substrate loading system: Robotic / Manual

Ceramic upper chamber ring

Bottom chamber

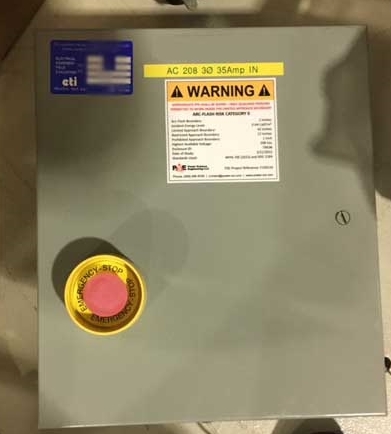

AC Distribution / EMO

Gas cabinet: Mass flow controllers

Bottom electrode:

ADVANCED ENERGY Variable: 300-500 Watts (350-460 kHz)

AE RFPP LF-5 RF Power supply (Low frequency: 50-460 KHz)

Top electrode:

Triode source

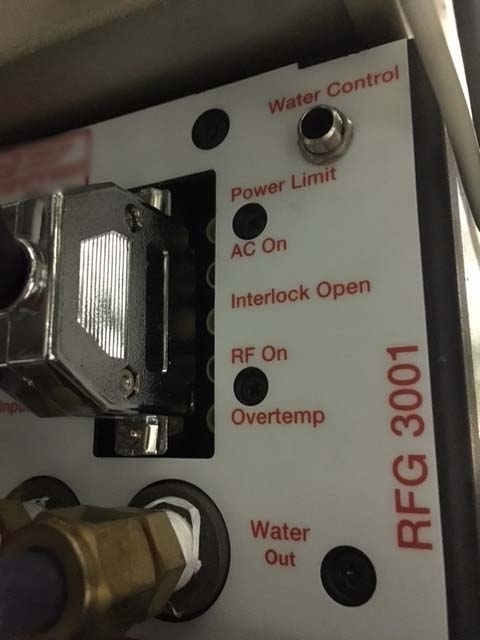

ADVANCED ENERGY AE RFG 600 Watts

For film stress control capability 3001: 13.56 MHz

Includes:

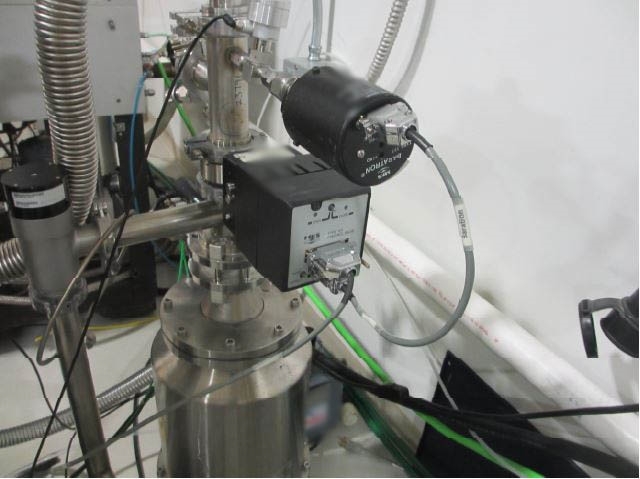

EDWARDS QDP40 Drystar dry backing vacuum pump 230 VAC, 3 Phase pump

OSAKA TS443 Helical grooved turbo pump & controller

MKS 153 Throttle valve & controller

2001 vintage.

TRION Minilock Orion II is a high-performance etcher/asher used to fabricate integrated circuits, chip packages, and other electronic components. Its compact design and versatile features provide efficient and precise material processing for a wide range of applications. Minilock Orion II can process up to five layers of material simultaneously at a maximum speed of 2,500 rpm for optimal throughput. TRION Minilock Orion II's features include a high-accuracy motion equipment, a comprehensive set of safety features, variable speed rates, and an all-metal chamber for faster etching. It also has built-in material recognition software to simplify programming and ensure precise and repeatable results. For added flexibility, Minilock Orion II can be customized with additional accessories such as an extended chamber, integrated containment ring, and automated material handling systems. TRION Minilock Orion II is powered by a low-maintenance direct drive motor supported by a dual-stage feed system. This allows for precise material positioning and greater accuracy while etching. It can be precisely adjusted to the exact position by using adjustable nozzles and a manual focus control unit. Its temperature range can be adjusted to temperatures as low as -40°C for fine etching, while a water-cooling machine ensures device reliability. Minilock Orion II is designed to offer unparalleled reliability and flexibility and is easy to integrate with other equipment. It is also equipped with extensive monitoring capabilities to provide users with accurate data during the etching process. The advanced safety features of this etcher/asher make it suitable for a wide range of uses in production and research settings.

There are no reviews yet