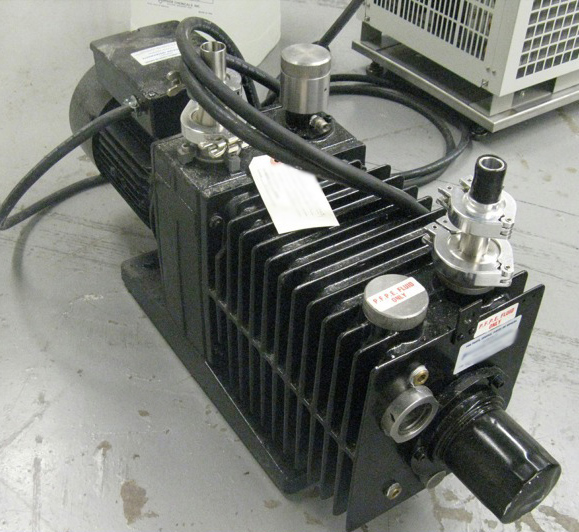

Used TRION Phantom III #189297 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 189297

Vintage: 2006

Plasma Etcher

Includes:

SMC HRG002-A-X047 Thermo cooler

PFEIFFER / BALZERS TCP 310 power supply

200/220V, 50/60Hz

2006 vintage.

TRION Phantom III is an etcher and asher that is designed to provide precise and efficient materials processing. It is suitable for applications in a variety of sectors, including the manufacture of semiconductor devices, the production of thin film structures, and the fabrication of precision components. The equipment has a maximum wafer size of 8 inches and is capable of etching with a variety of gases. Its built-in diagnostics allow for easy troubleshooting and maintenance, while the plant's advanced control system guarantees process stability and repeatability. Phantom III is constructed using a component-style architecture; this allows the user to install components for specific applications, such as single wafer processing or batch processing. Etching and ashing take place in either horizontal or vertical orientation, allowing for higher production rates and more precise results. The specific components used include corrosion-resistant alloys, quartz tubes and anodes, titanium-based material for anode deposition, and various insulators and capacitors. The unit is equipped with a remote touchscreen, allowing for real-time monitoring of the etching and ashing processes. This monitoring includes temperature, pressure, and etching time. It also allows one to adjust the power settings, plasma gas pressure, and process variables for higher precision. The etch rate of TRION Phantom III is approximately one etch per pass. The machine's other features include etch particle extraction systems, which help remove harmful particles from the etching chamber, and process time optimization, which reduces unwanted etching time. The plasma source can also be used to modify the etch kinetics, which improves the uniformity of the etched surface. Phantom III is designed to be relatively maintenance free, with most components replaceable or repairable in-house. It is also designed to be used in conjunction with other standard processing equipment, such as load locks, conveyors, and Vacuum Filtration Units. In conclusion, TRION Phantom III is a highly reliable and efficient etcher and asher, suitable for precise and difficult applications. It offers a range of advanced features, such as remote monitoring and process optimization, along with more conventional etch and ashing functions. This makes it ideal for use in a variety of sectors, including semiconductor manufacturing, thin film structures production, and precision component fabrication.

There are no reviews yet