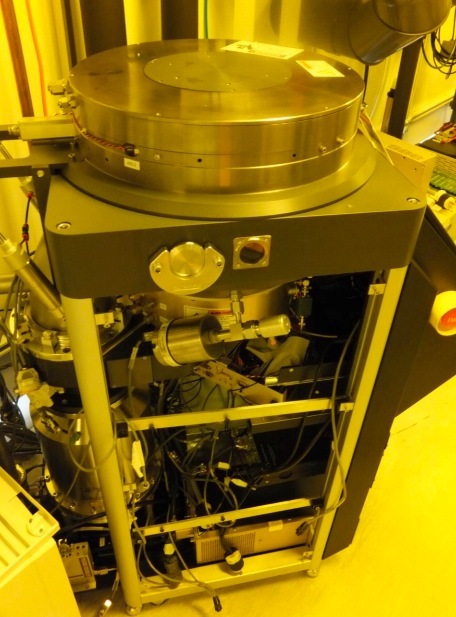

Used TRION Phantom III #9039842 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9039842

RIE / ICP System, parts machine

Bottom electrode: 8”

Vacuum port: 6"

System controller: Pentium computer, touch screen

(4) Mass flow controller gas channels

Automatic pressure control

Automatic RF tuning of bottom electrode, RF generator: 600 watt 13.56 MHz

Automatic RF tuning of ICP coil, RF generator: 600 watt 13.56 MHz RF generator

Cryogenic chuck: 100mm wafer, temperature control, -50ºC to 100ºC

Electrostatic chuck: 6", He backside cooling

Emergency on/off with AC power distribution box

Components:

High vacuum Pump: Osaka TG1003BW Osaka TC1003 controller

Backing mechanical pump: none

High vacuum valve: VAT 98801-R1 valve

Chamber pressure transducer: MKS 627

RF1 Generator: Comdel CX-600AS, RF1 automatch = Trion OEM

RF2 Generator: Comdel CX-600AS, RF2 automatch = Trion OEM

Heat exchanger: none

Chuck heat exchanger: Julabo LH85

Elecrostatic Chuck: Gripping Power EPS300

Gas Controls:

Separate exhausted cabinet for gas mixing

He backside MFC: MKS 649A, 10sccm Cal’ed for He, used with He

Gas 1 MFC: Unit 8100 250 sccm, Cal’ed for N2, used with CF4

Gas 2 MFC: Unit 8100 100 sccm, Cal’ed for N2, used with O2

Gas 3 MFC: Unit 8100 250 sccm, Cal’ed for N2, used with SF6

Gas 4 MFC: Unit 8100 100 sccm, Cal’ed for N2, used with N2

Gas 5 MFC: Unit 8100 250 sccm, Cal’ed for N2, used with CHF3

Parts missing:

PC board

Ion Gauge

Mechanical backing pump

Touch screen dead, replaced with standard PC monitor & keyboard.

TRION Phantom III is an etcher/asher specifically designed and developed for the production of high-precision microelectronic structures. It is a market leader in its class, providing high performance, accuracy, and reliability. The equipment is designed for high productivity, enabling users to fabricate complex microelectronic structures quickly and efficiently. The system is the perfect tool for etching and ashing materials such as polysilicon, silicon dioxide, tin oxide, GaAs, and other materials used in semiconductor production. Phantom III features a robust and durable design that is able to withstand harsh production environments. It features an automated loading chamber that is capable of processing up to 19 wafers at a time. TRION Phantom III is able to process 25μm structures with a precision of 5μm, and its uniformity is unmatched in the market. This is possible due to the advanced precision control unit that utilizes an integrated inter-position control machine to maintain precise alignment during etching and ashing processes. Phantom III also features advanced process control capabilities, allowing users to accurately monitor and adjust etch and ashing processes to ensure excellent precision. This includes a closed-loop feedback control for power, temperature, and time, allowing users to easily adjust parameters to achieve desired outcomes. The tool is also capable of analyzing on-wafer process data to facilitate further optimization and reliability. TRION Phantom III's advanced optical asset is able to efficiently and precisely detect and monitor the condition of wafers throughout the etching and ashing process. The model is integrated with a high-precision beam deflection equipment that is capable of focusing the beam on a single spot for precision etching/ashing at high-speed. Phantom III is a cost-effective etcher/asher that provides outstanding performance and accuracy. Its user-friendly design and robust hardware make it an essential tool for any microelectronic laboratory. With its powerful process control capabilities, it is able to ensure consistent etching and ashing processes that are incredibly precise and reliable.

There are no reviews yet