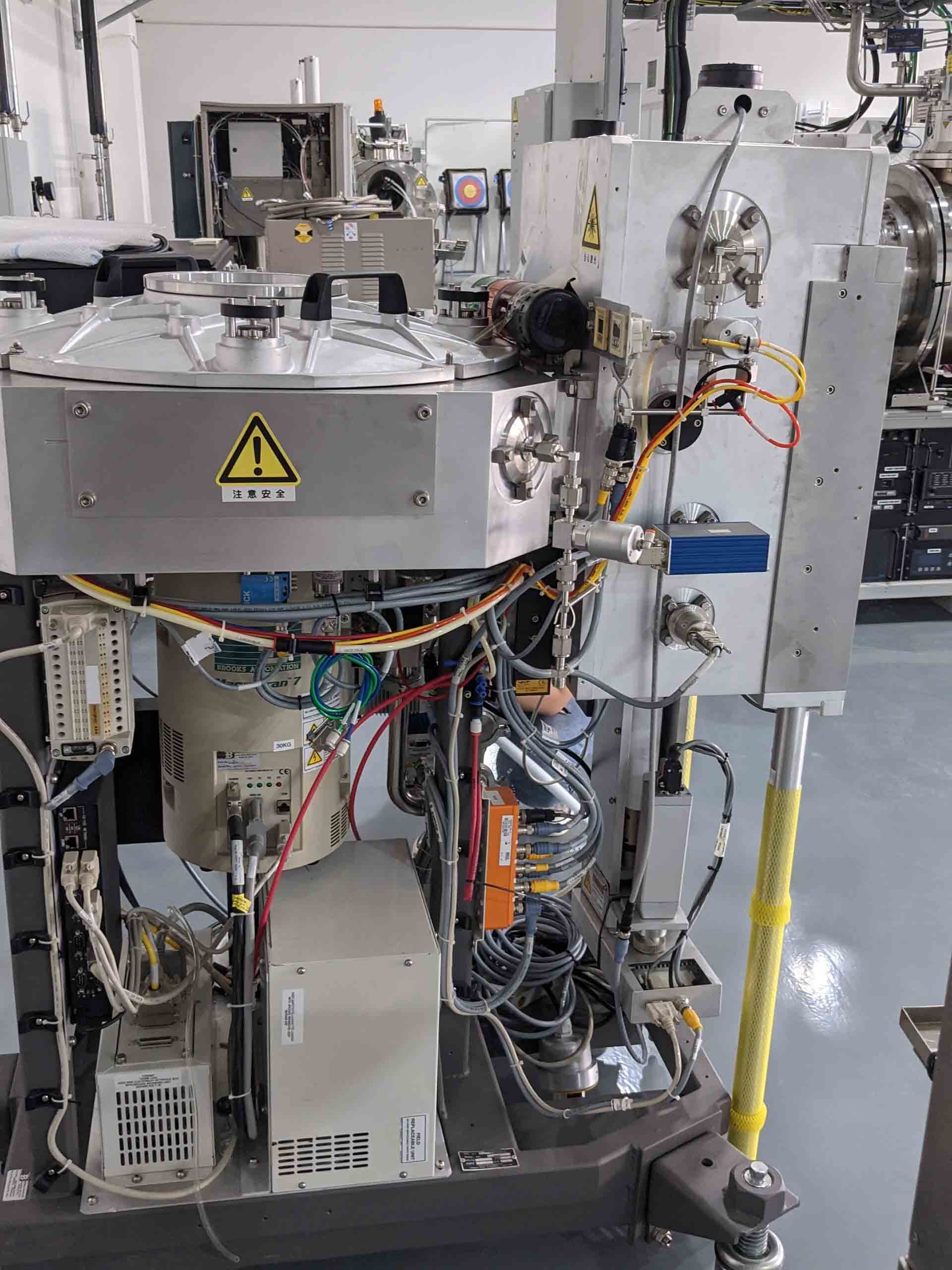

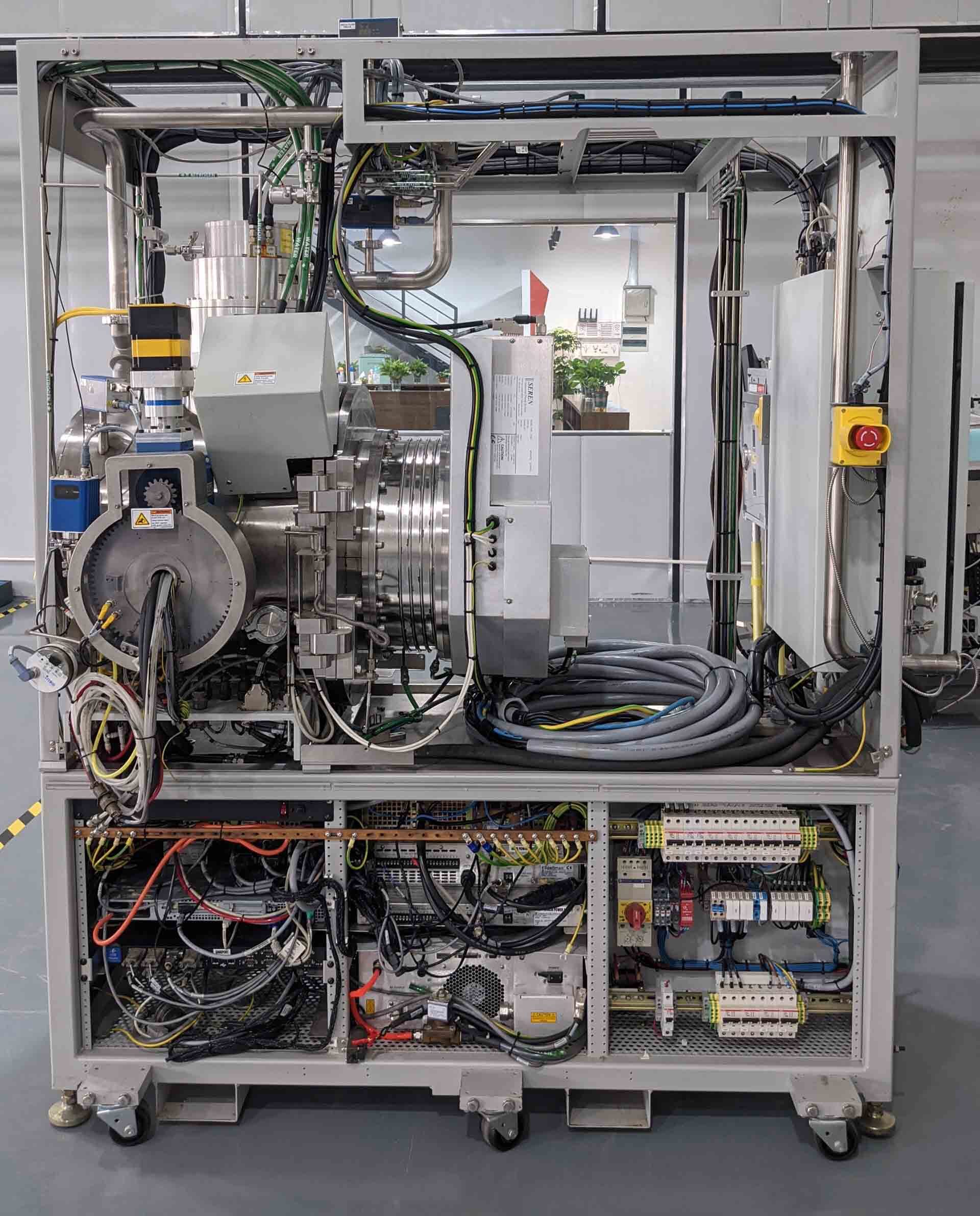

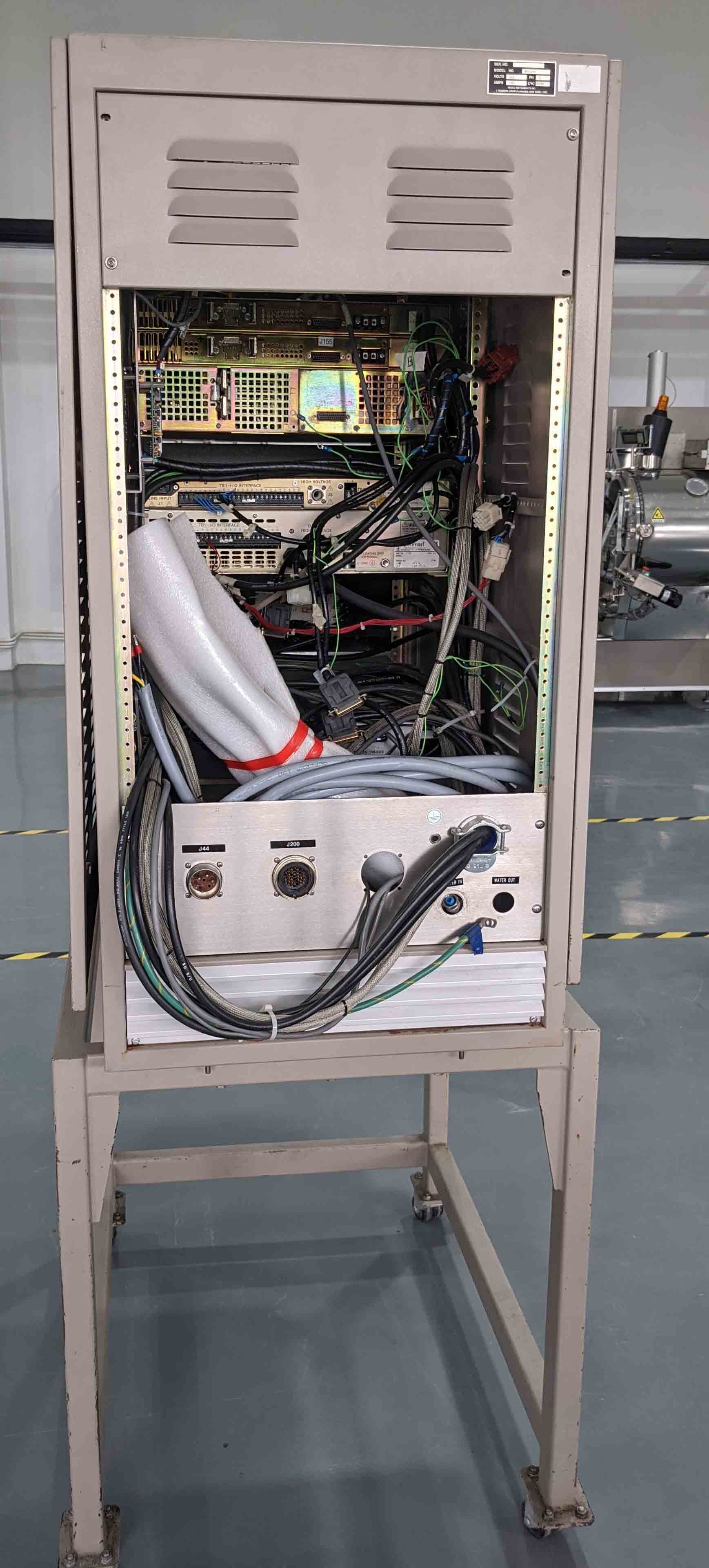

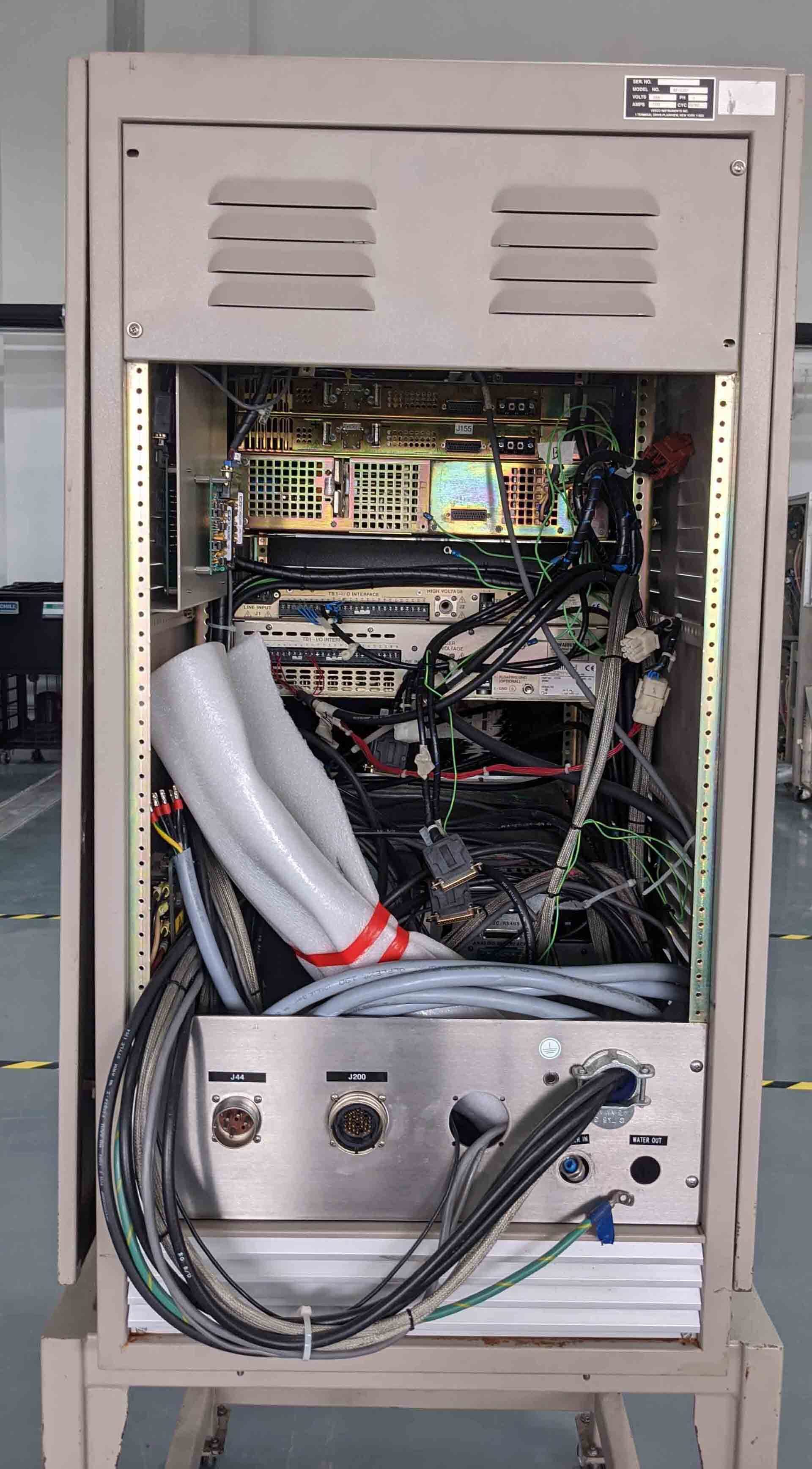

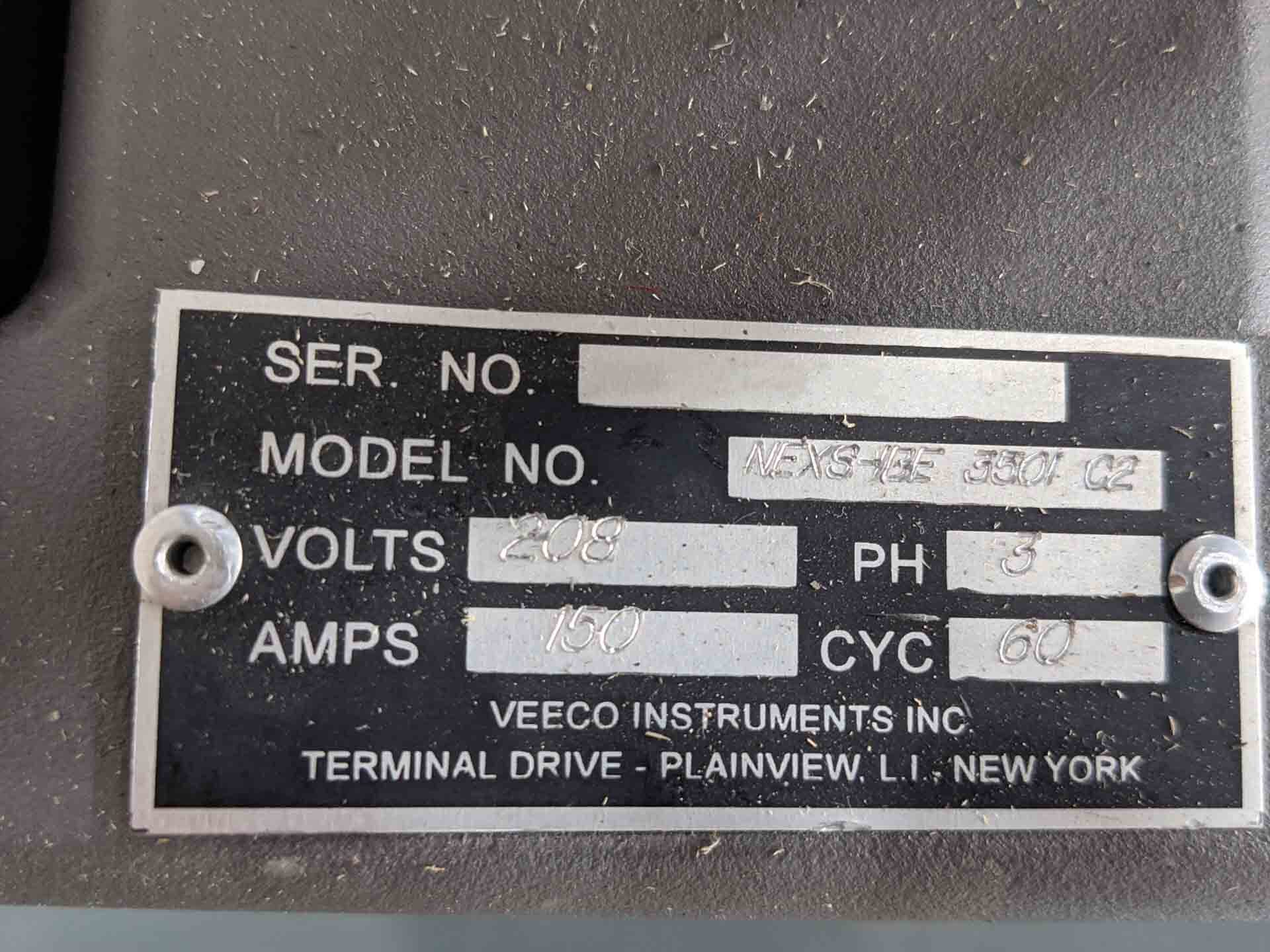

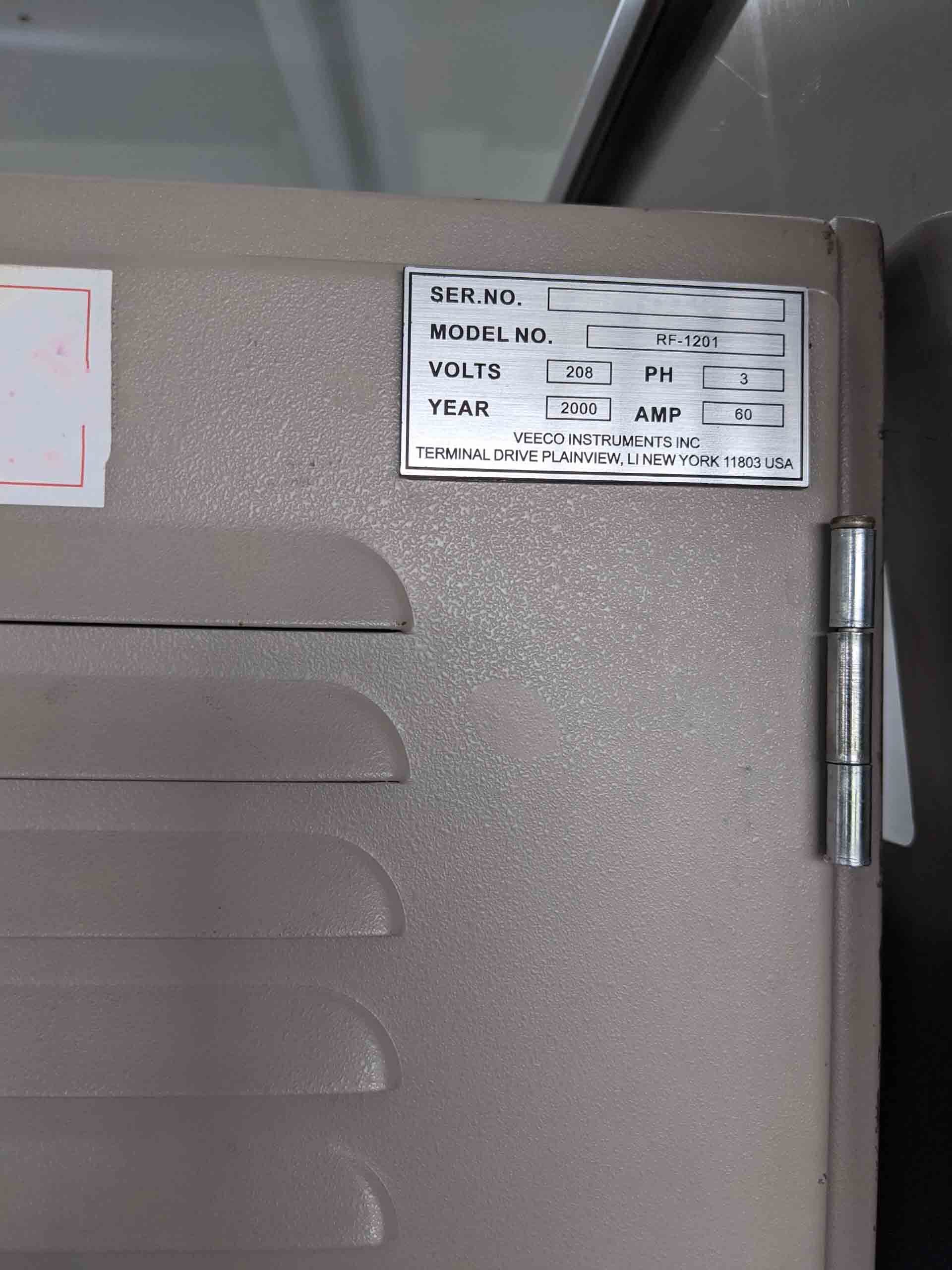

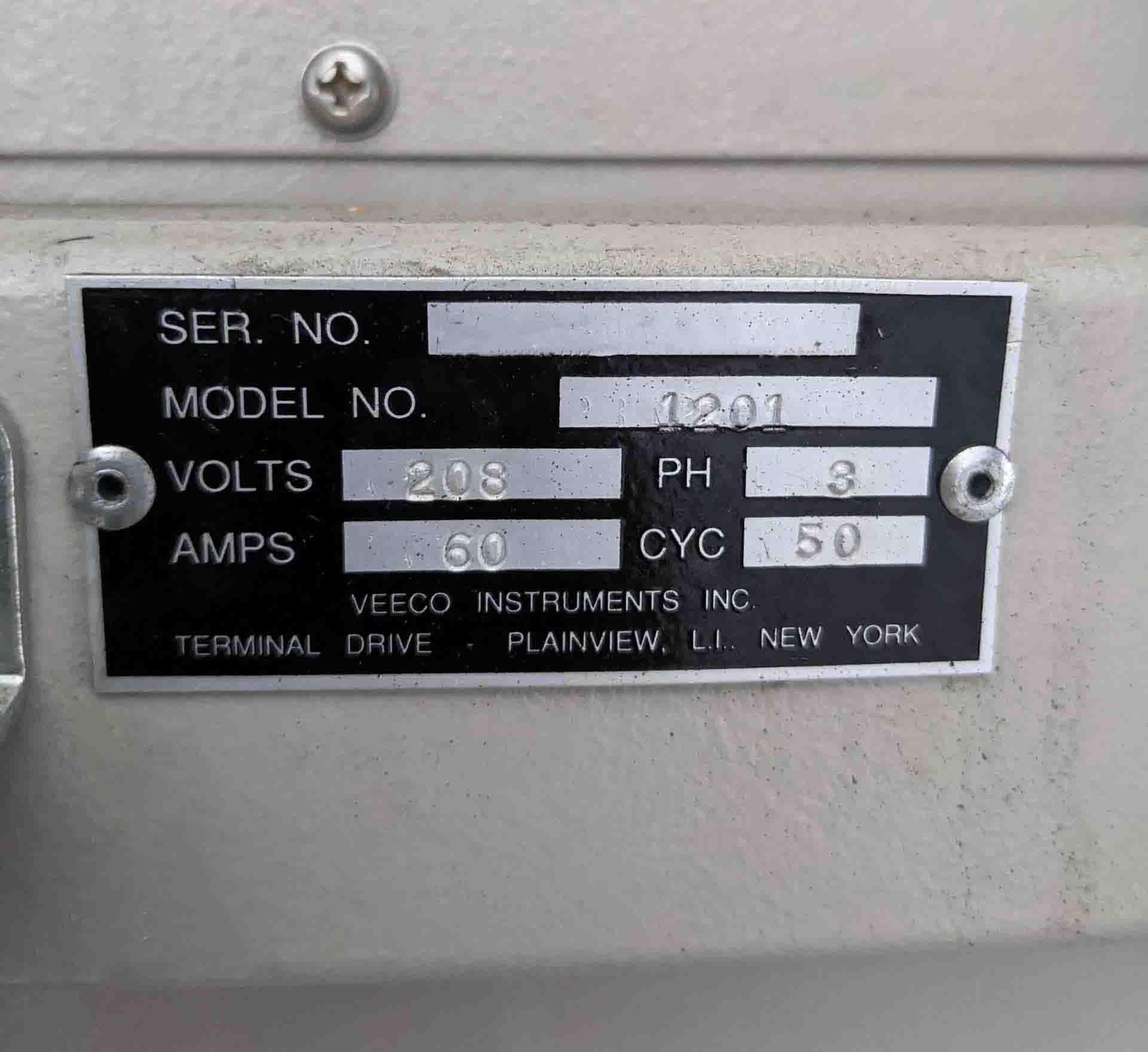

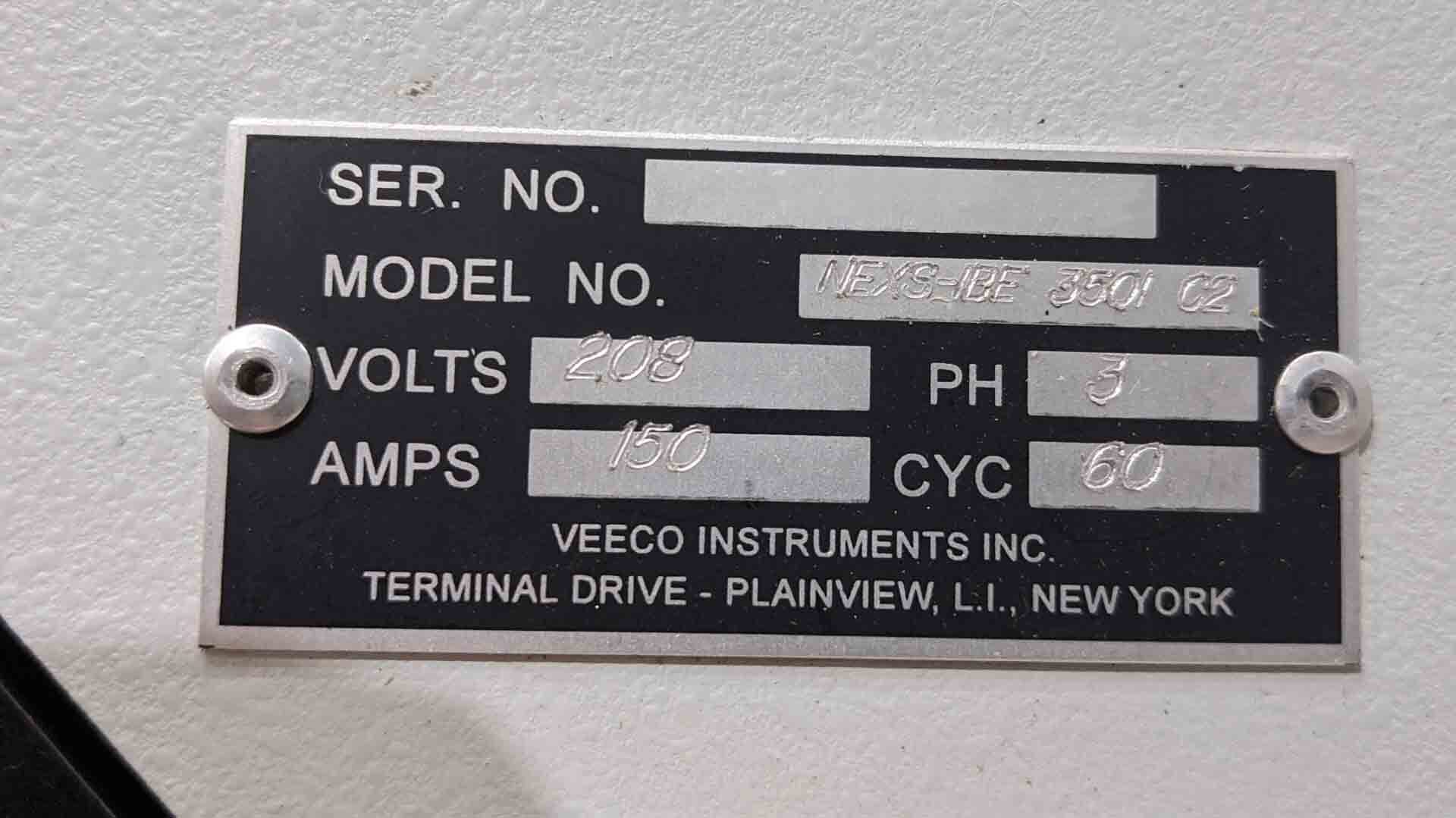

Used VEECO / MICROETCH 1201 #293628789 for sale

URL successfully copied!

Tap to zoom

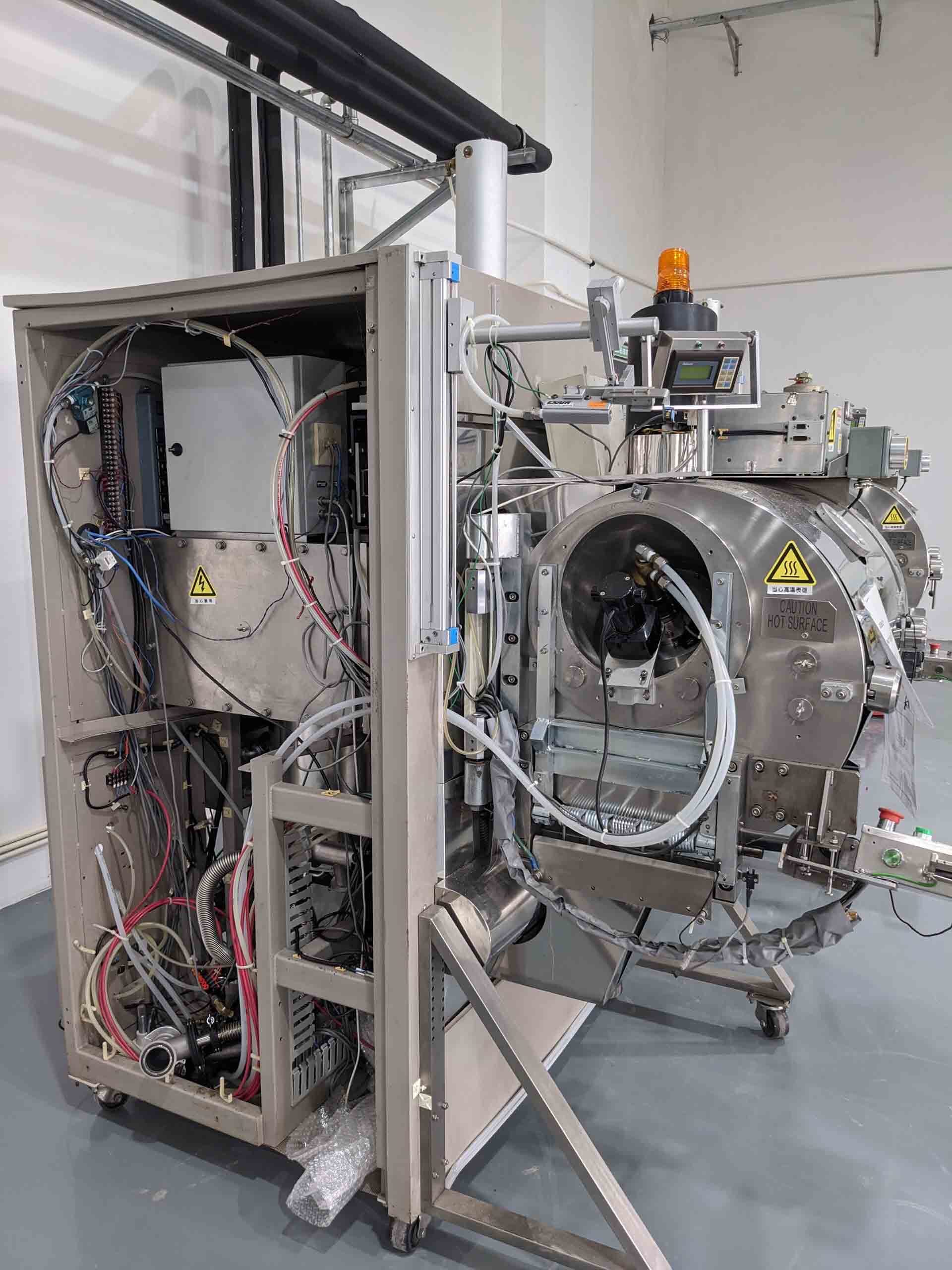

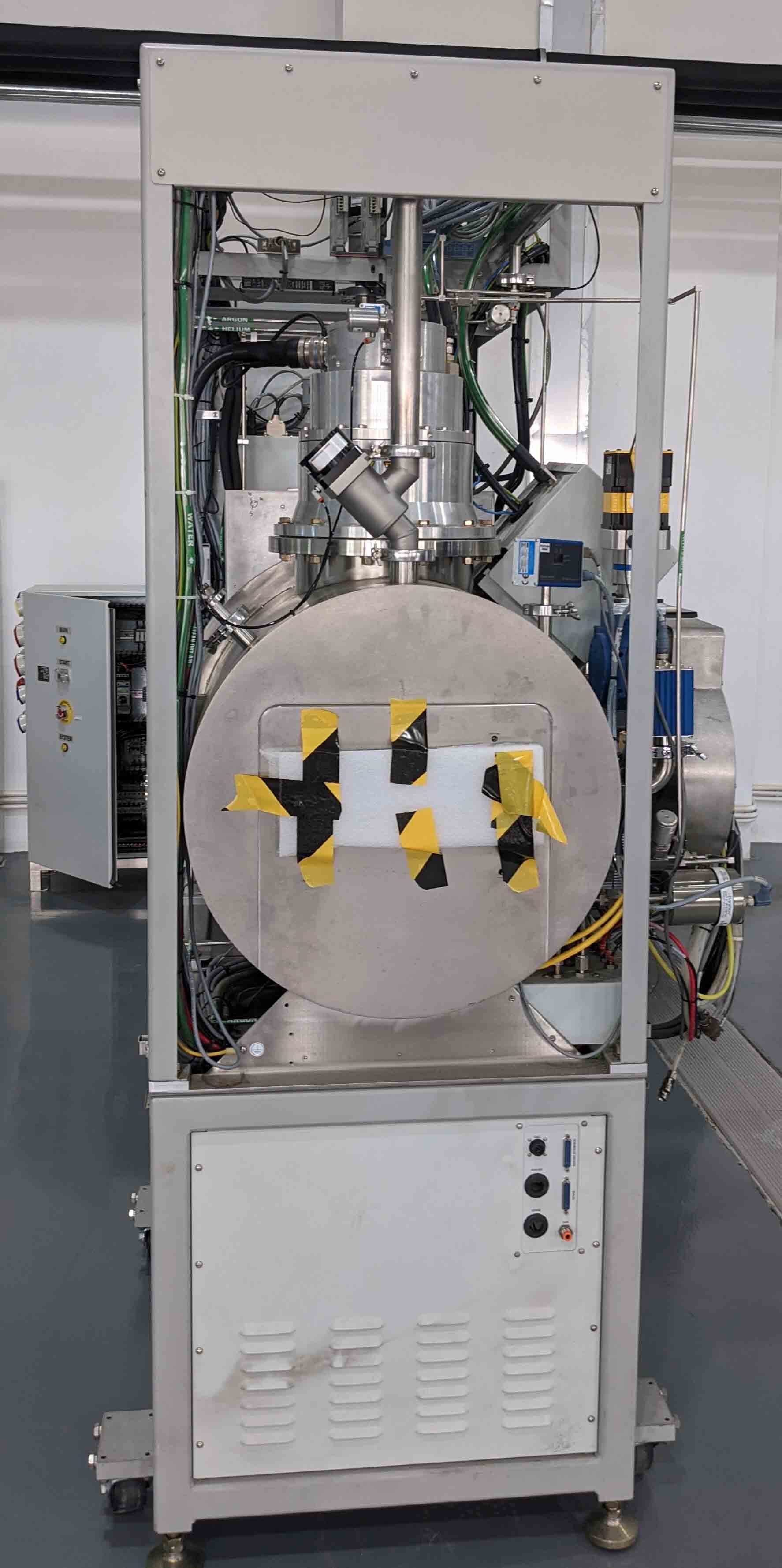

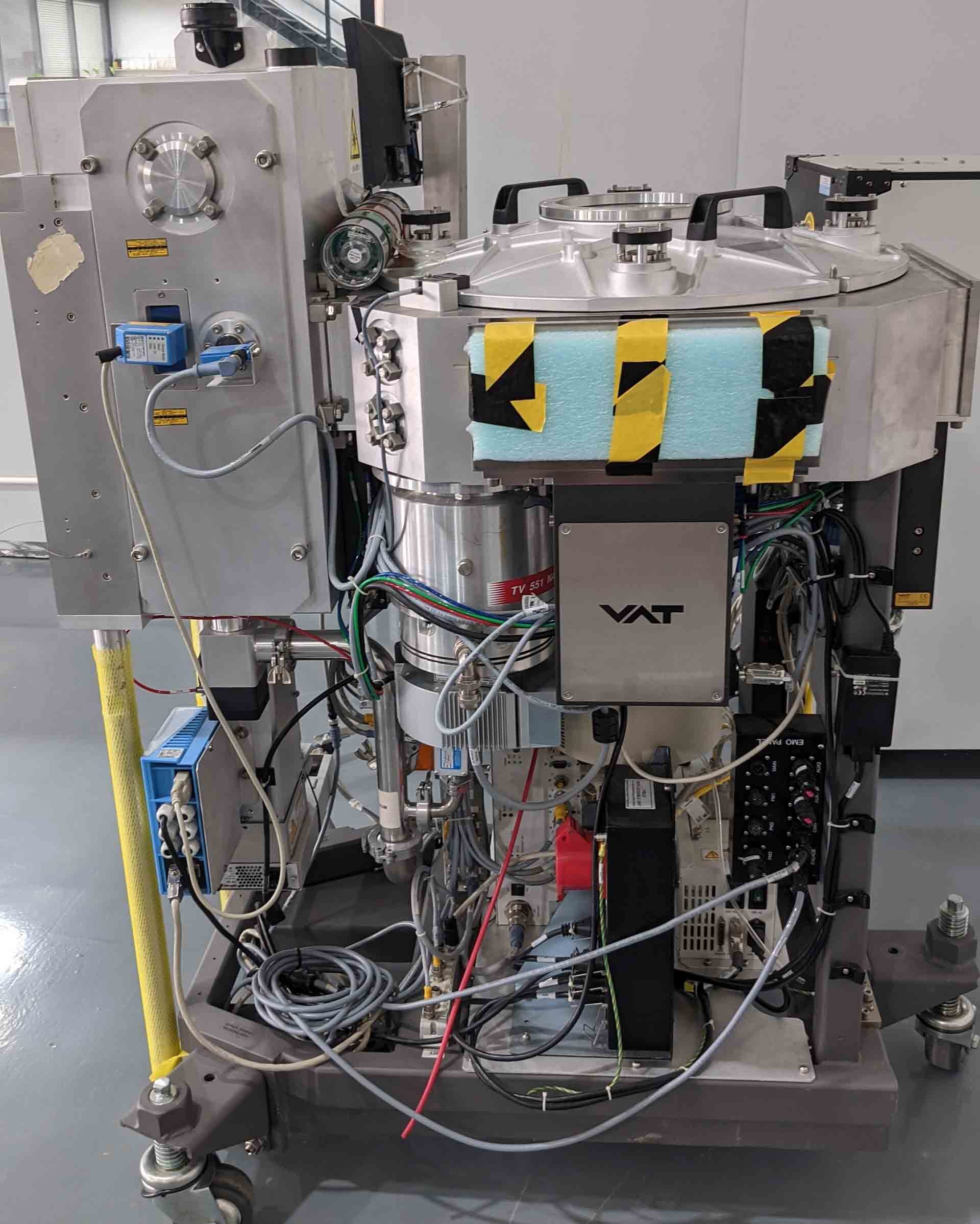

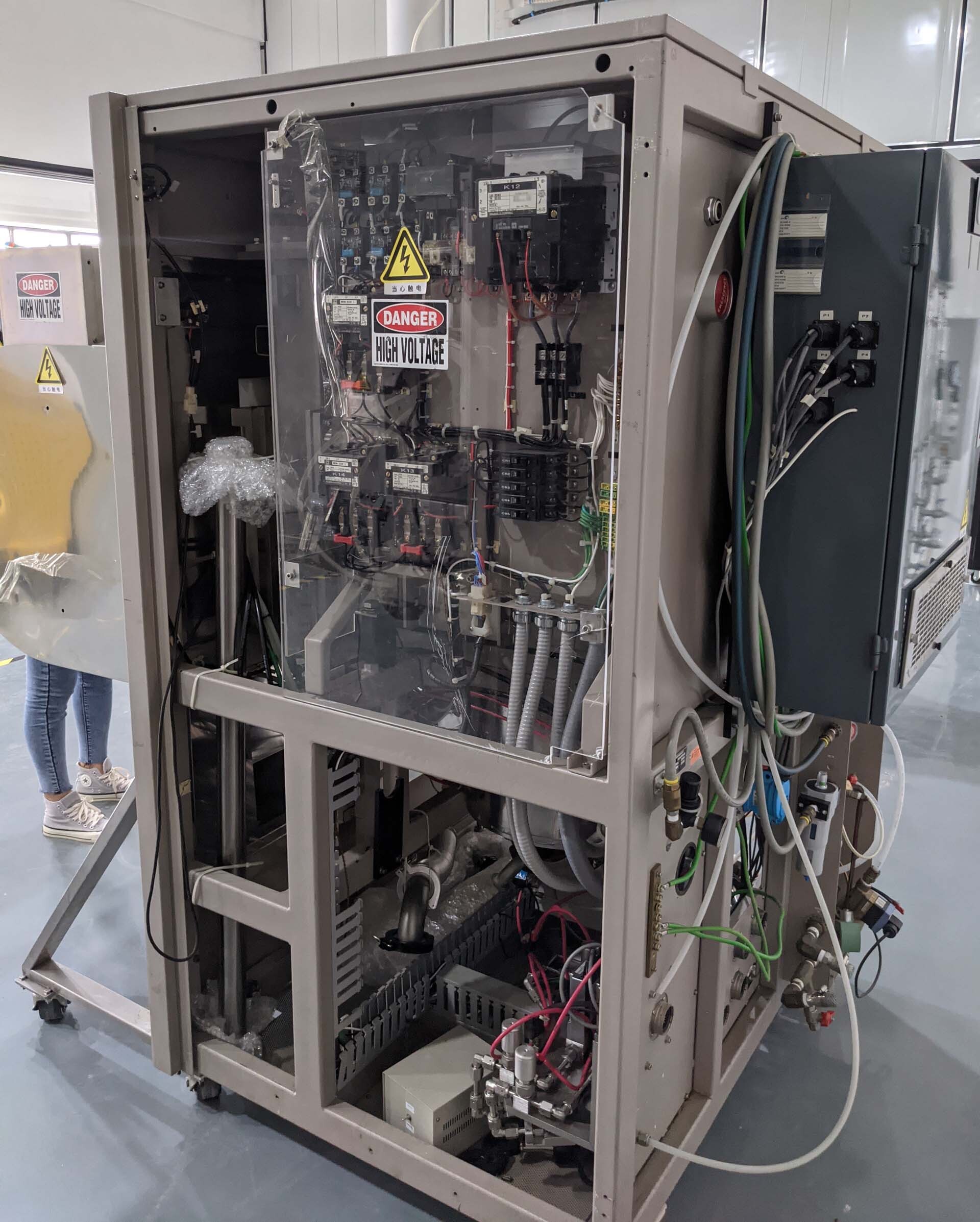

VEECO / MICROETCH 1201 is an advanced etcher/asher designed for precision applications in semiconductor device manufacturing. This sophisticated piece of equipment features a high-precision temperature and dielectric etch chamber that is capable of tolerancing tight process parameters while providing robust and consistent results. In addition, the integrated ion-gun technology provides both lateral and vertical etching control with precision accuracy, allowing for accurate and high-quality patterns to be developed. VEECO 1201 is designed for use with high substrate temperatures and low-temperature reactants for improved etching accuracy and repeatability. This allows for etching within tight process tolerance requirements without compromising process performance or quality. MICROETCH 1201 also features a high resolution imaging capability that can be used to monitor the etch process in real-time and detect local anomalies. The chamber is also outfitted with a variety of RF sources for generating various plasma densities, allowing for just the right process parameters for different etch applications. 1201 is highly versatile and can be used for a wide variety of etch and asher applications. It is capable of etching through thick films and through-silicon vias, while avoiding damage to sensitive substrates. Furthermore, VEECO / MICROETCH 1201 features integrated rapid thermal processing capabilities, which allow for rapid and efficient thermal processes such as nitriding and oxidation, as well as annealing of thin films and semiconductor substrates. This feature ensures highly uniform thermal processes regardless of substrate size and shape. This etcher/asher truly stands out due to its unique combination of functionality and performance. VEECO 1201 is a highly reliable and efficient equipment that offers unmatched precision, repeatability and accuracy for etching and asher applications. It is the perfect choice for semiconductor device and MEMS manufacturing, and can help to maximize yield and minimize costly process errors.

There are no reviews yet