Used VEECO Microetch LL250 #120499 for sale

URL successfully copied!

Tap to zoom

ID: 120499

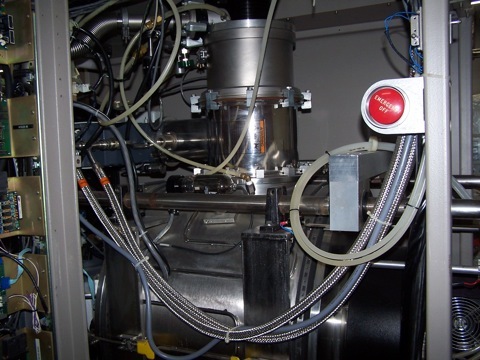

Automatic loadlock ion mill

Anisotropic, materials including: Au, Du, Ni, Cr, and TiW

Includes:

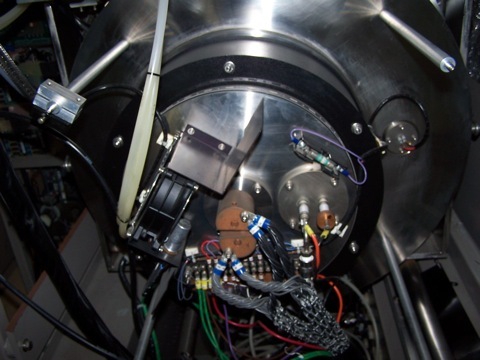

Ion gun

Vacuum robot

Vacuum cassette

Main Process Modules :

Sub-Process Module : Automatic Loadlock

Brooks Robot & Controller

Ion Beam Power Supply

Turbo Pump : Leybold NT20 Controller & Turbo Pump

Lebold Inficon IG3 Vacuum Measurement.

VEECO LL 250 is one of the most advanced ion milling systems on the market. It combines the power of lithography and milling to enable the detailed machining of complex structures. The system operates by utilizing a high-voltage ion beam to remove material from the surface of a specimen in a precise and controlled manner. The resulting patterns can be used to create micro-scale and nano-scale components with extremely high levels of accuracy. VEECO Microetch LL250 utilizes an ultra-high vacuum chamber for low-energy material redeposition, allowing for extremely versatile milling parameters such as ion sputter depths, sputter temperature, and target-to-cathode distance. An advanced beam control subsystem ensures that the ion beam remains extremely stable, allowing for extremely precise etch patterns. This makes even the most complex structures achievable with LL 250. Microetch LL250 utilizes a polymer-based substrate holder to provide low-energy substrate treatment and surface preparation that is ideal for sensitive materials. It is also equipped with a telescoping gun carriage for easy loading of specimens and a collapsible hood for a dust-free environment. VEECO LL 250 also has a number of accessories for further enhancements such as automated substrate loading and unloading systems, easy-to-use computer interfaces, and multiple ion milling tips for increased precision and increased flexibility. In short, VEECO Microetch LL250 is an ideal system for etching and machining extremely complex structures with high levels of accuracy and detail. Its powerful combination of control, stability, and versatility make it an excellent choice for any ion milling application.

There are no reviews yet