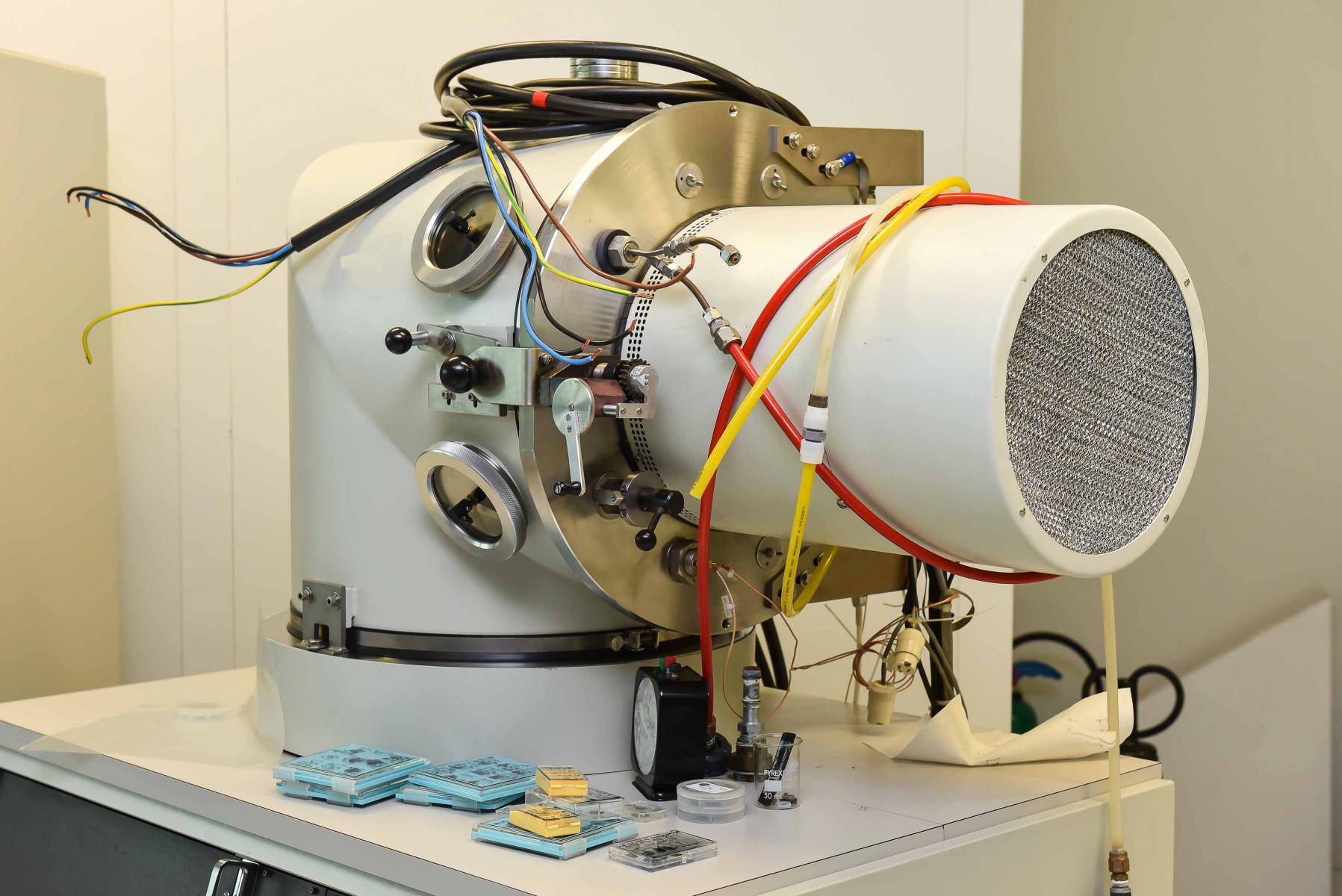

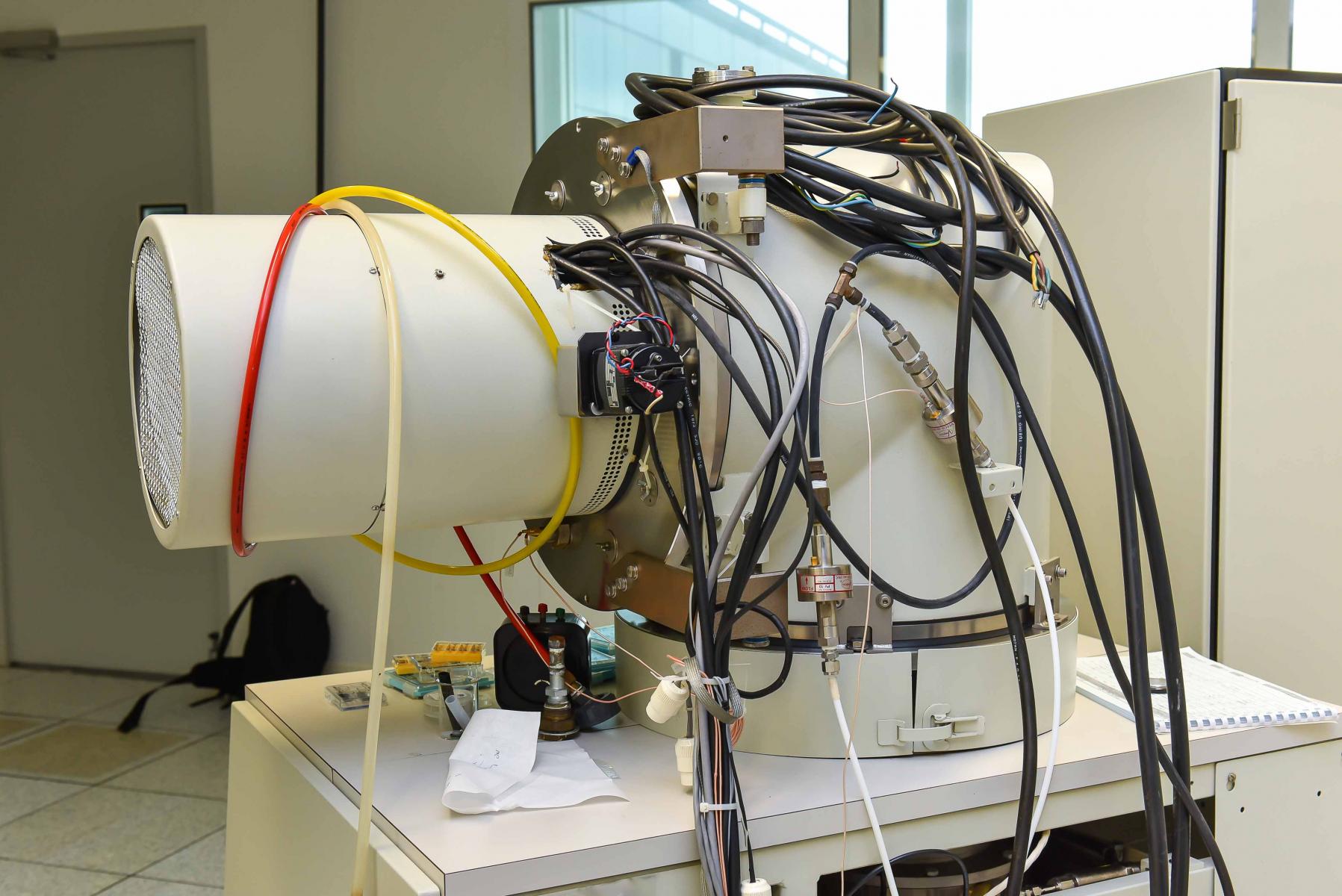

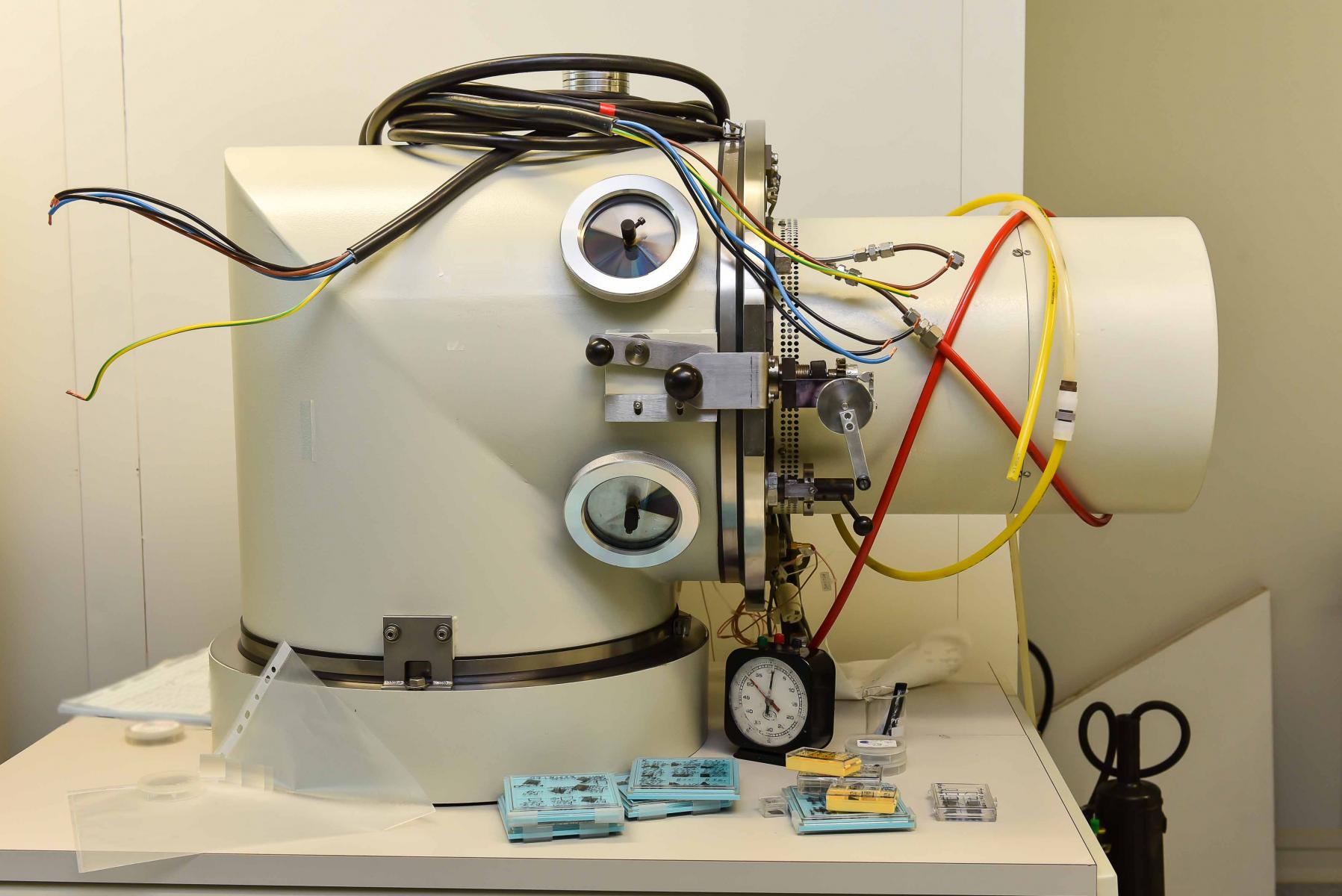

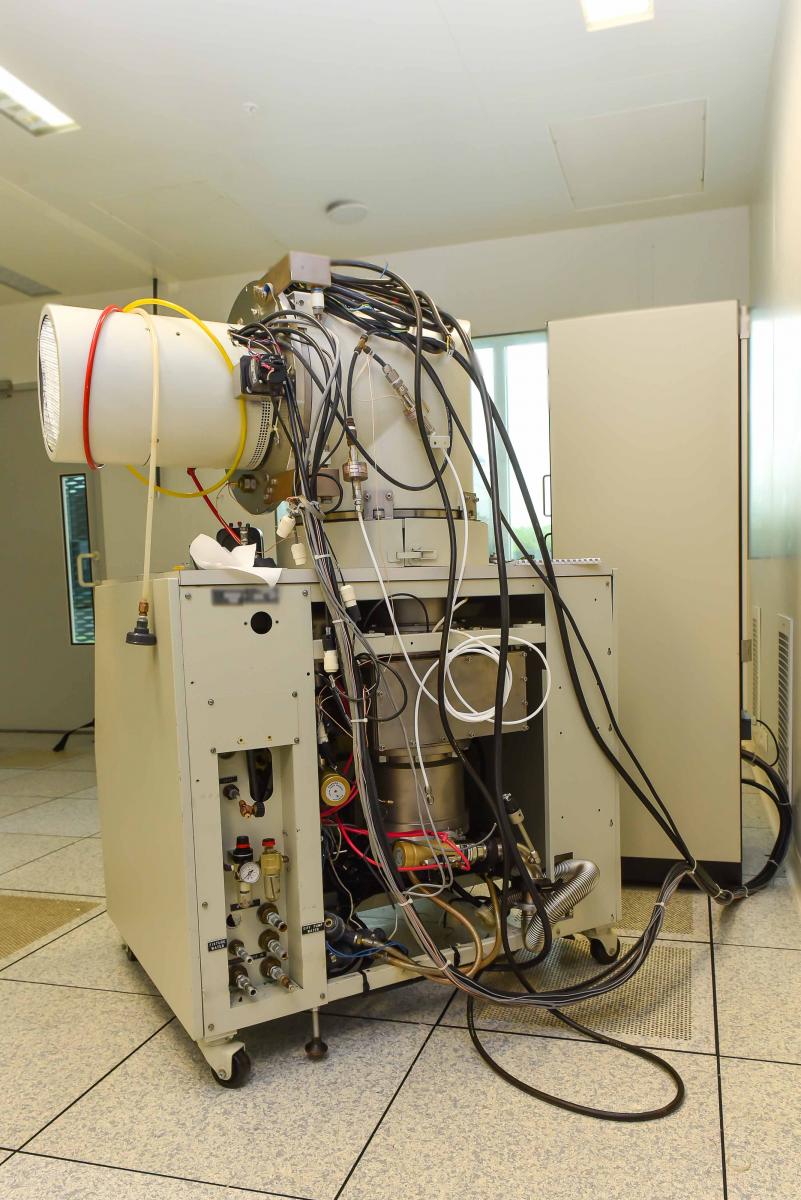

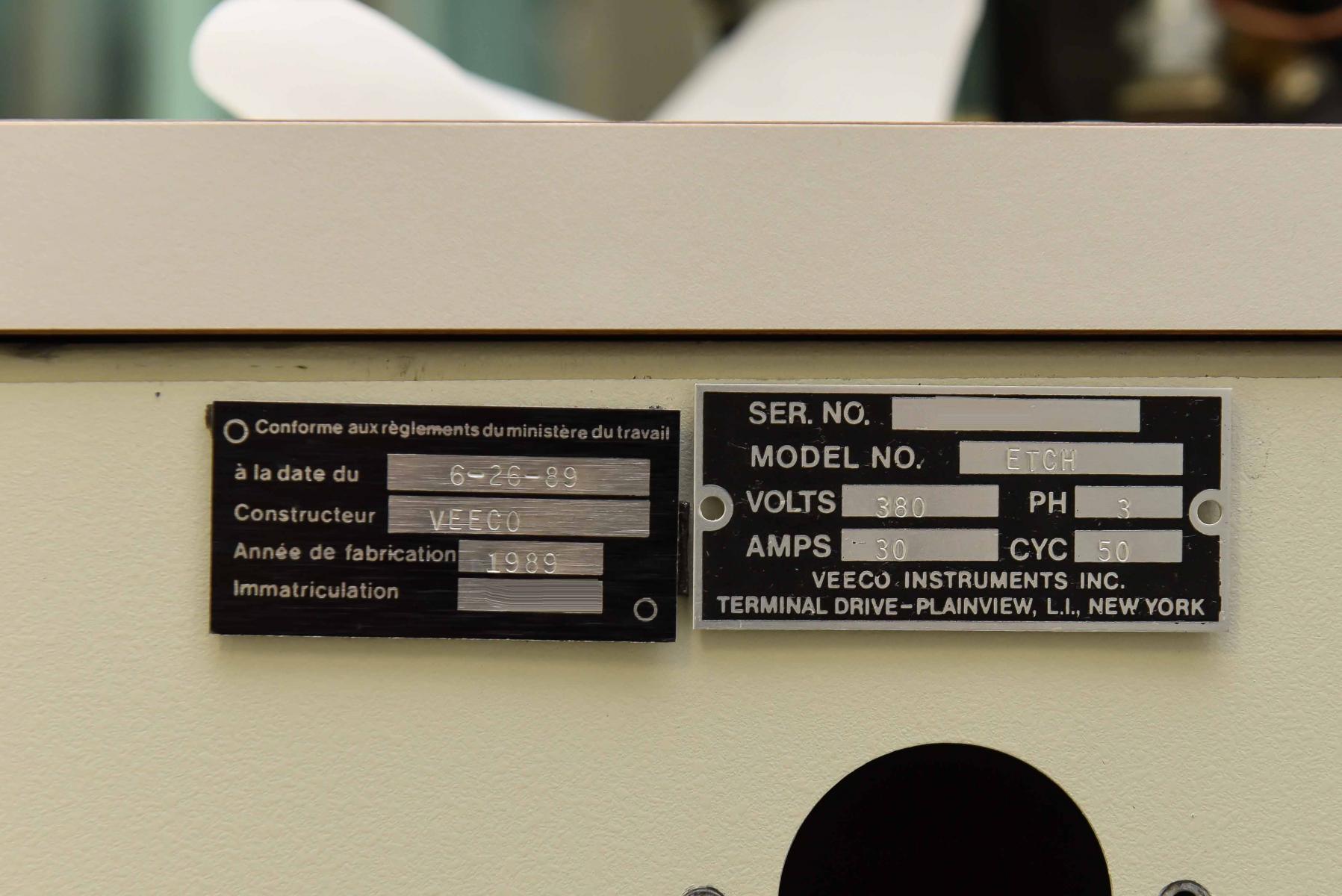

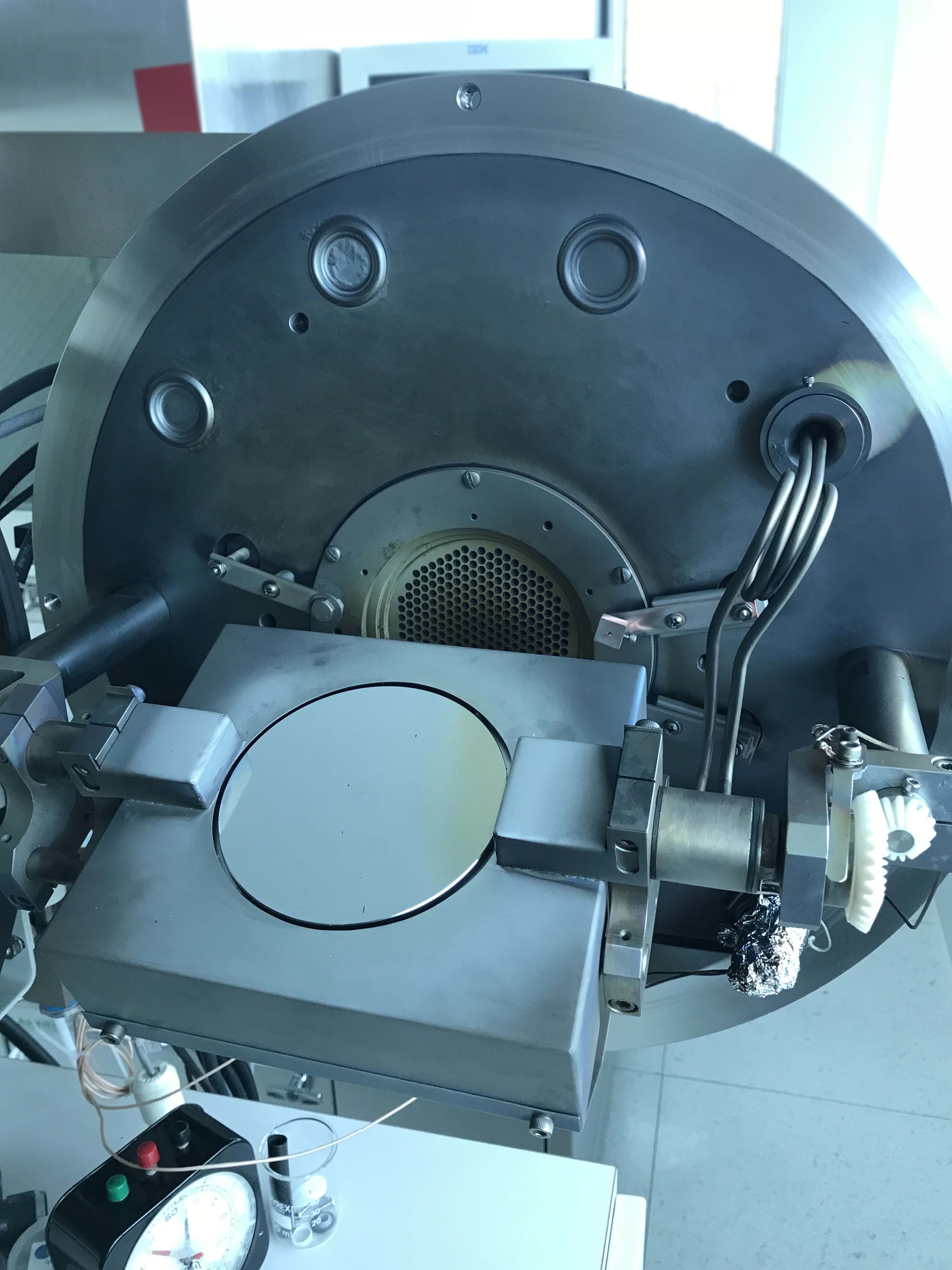

Used VEECO Microetch #9183385 for sale

URL successfully copied!

Tap to zoom

ID: 9183385

Vintage: 1989

Ion beam etcher

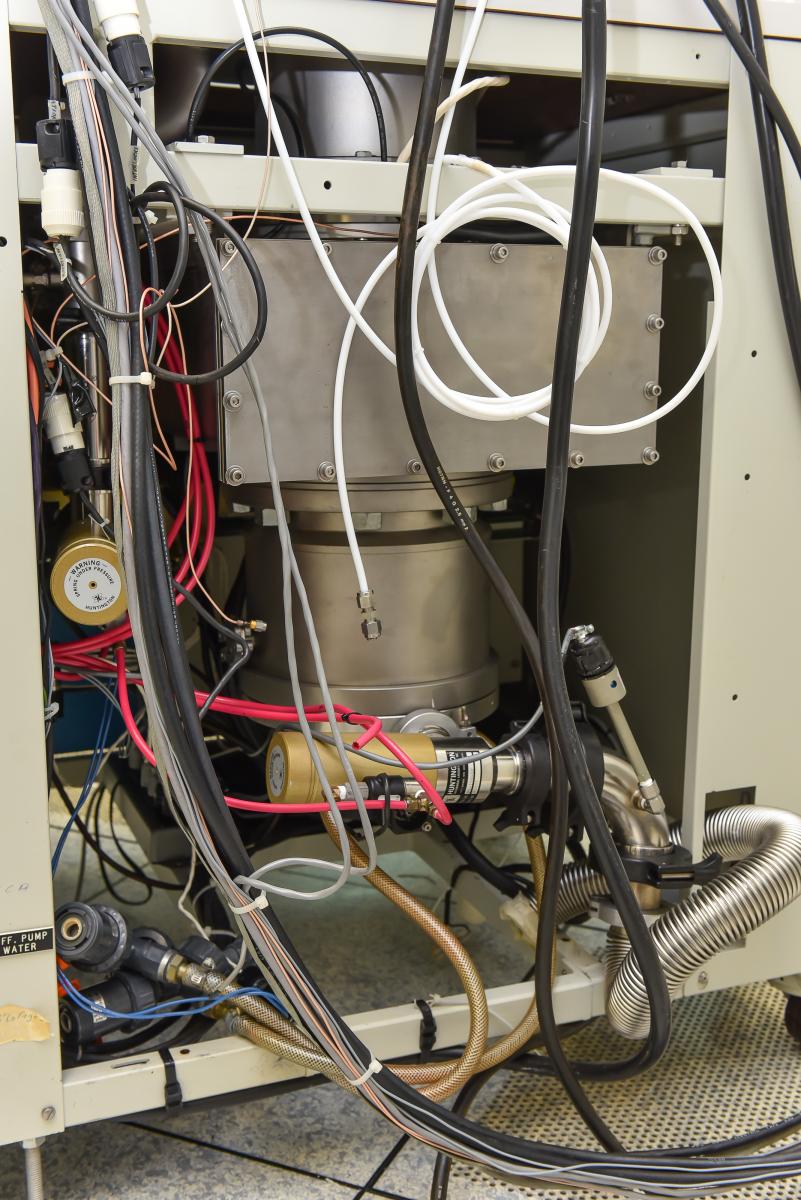

MICROTECH Controls

Automatic beam controller

LAMBDA Neutralizer

UNIVERSAL VOLTRONICS Accelerators

UNIVERSAL VOLTRONICS Suppressors

Process gases: Ar, Ar/O2

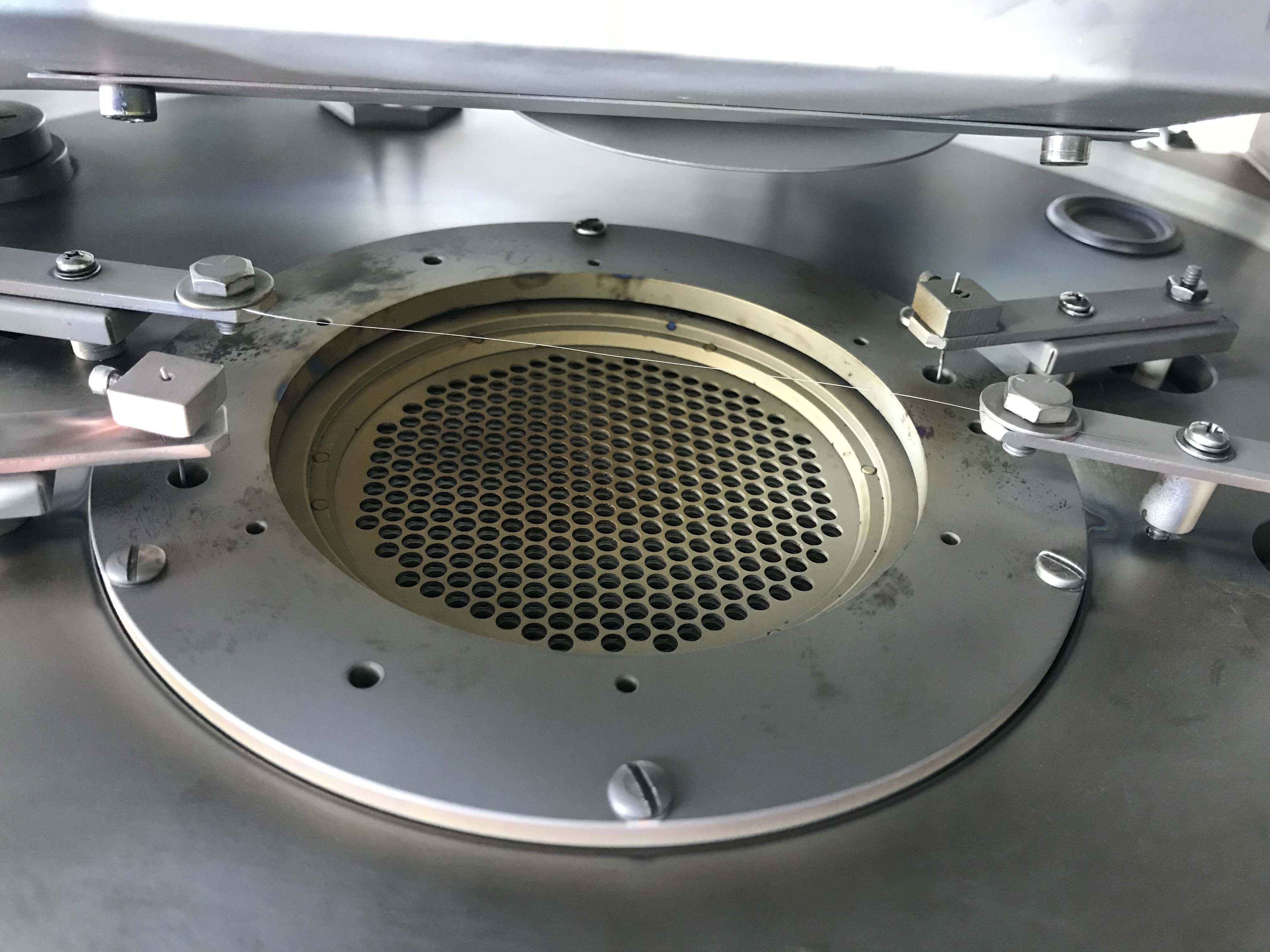

Gun, 6"

Includes:

RG1000 Ionization gauge

AVC 1000 Automatic valve controller

APC 2000 Automatic pressure controller

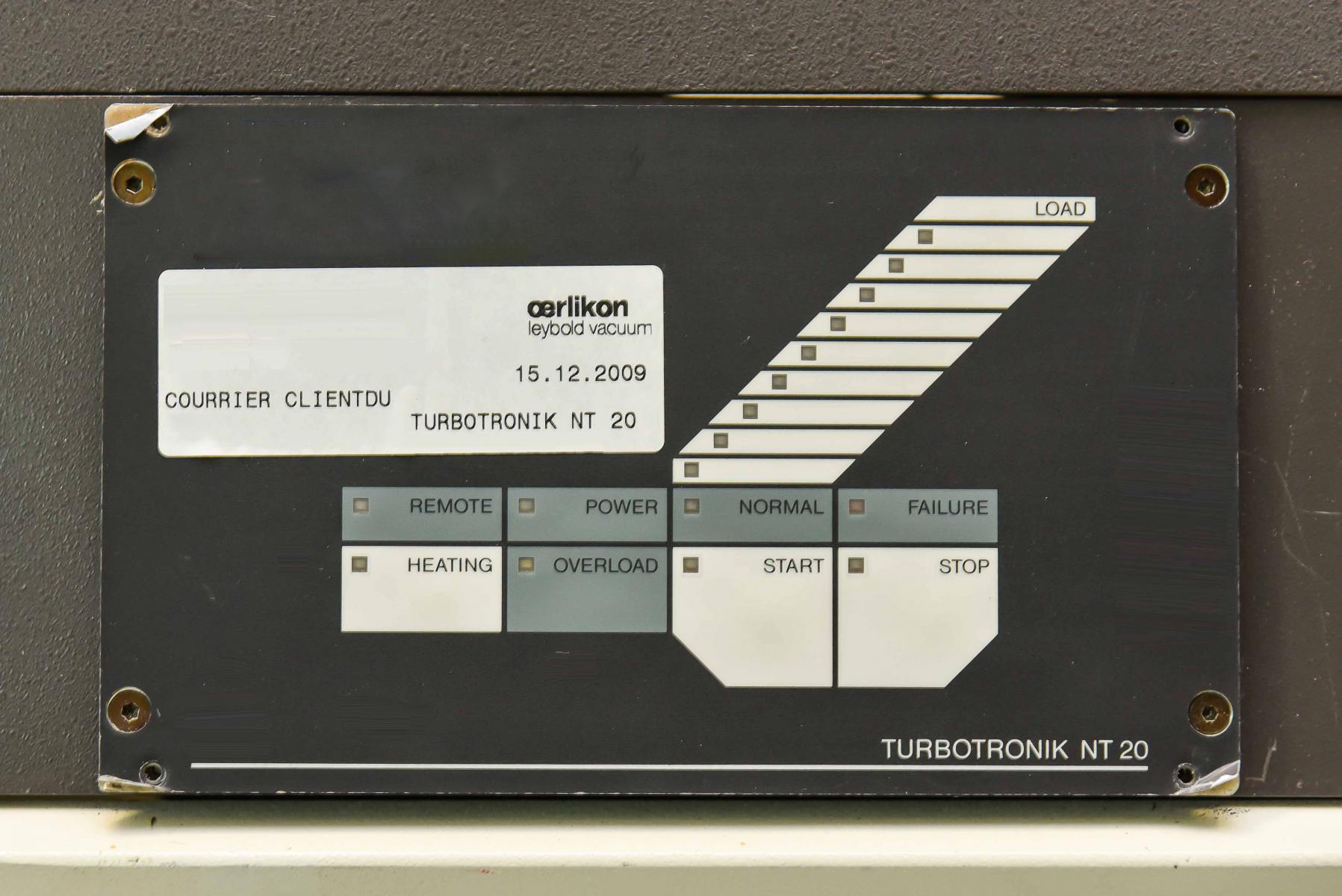

LEYBOLD Vacuum

TURBOTRONIK NT 20

1989 vintage.

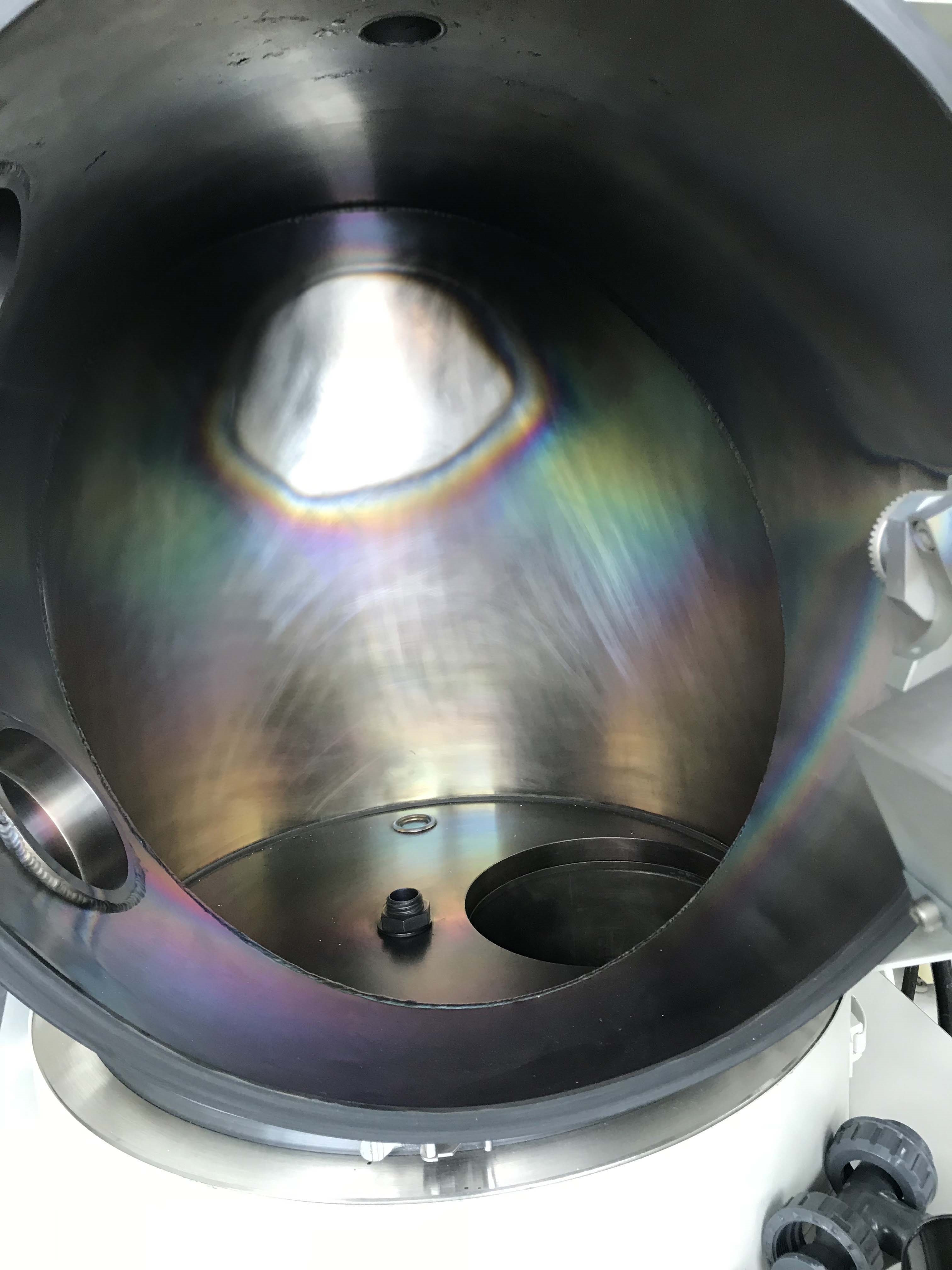

VEECO Microetch is an etching and ashing machine that provides precision etching, cleaning, and ashing for materials used in a wide range of industries. It is designed for both research and production applications and features a fully-enclosed chamber, allowing for repeatable and uniform etching and ashing operations. All of its components are housed in a durable aluminum construction for superior thermal control, and its internal chamber can be configured for both wet and dry etching/ashing processes. Microetch is powered by a high-powered, digitally controlled power source that allows for precise etching and ashing cycles. Its digital process controller and programmable logic controller (PLC) provide precision control over accuracy, repeatability, and cycle time. Additionally, the integrated graphical user interface (GUI) enables quick and easy parameter adjustments for etching/ashing process optimization. VEECO Microetch features a reaction vessel with an automated lift mechanism that allows for precise etching/ashing of up to 3 substrates in a single process. The ProClean Gas Management System delivers precise amounts of inert gas to minimize oxidation during etching/ashing. In addition, a variety of optional accessories are available to further customize the machine's capabilities. Microetch's features and capabilities make it an excellent choice for cost-effective and high-performance etching/ashing processes. Its precision process control makes it ideal for research applications, while its automated lift mechanism and optional accessories make it suitable for production processes. Its durable construction and accurate gas management system make it capable of producing repeatable and uniform results each and every cycle. Finally, its intuitive graphical user interface and programmable logic controller make it easy to use and configure for any etching/ashing process.

There are no reviews yet